Abstract

In this paper, a novel Nafion polymer-coated stannum film-modified carbon paste electrode was developed for the analysis of trace cadmium by square wave anodic stripping voltammetry. The electronic conductive material—molecular wire (diphenylacetylene)—was employed as the binder instead of traditional mineral oil for fabricating this electrode. It was found that the prepared electrode possessed excellent electrochemical performance and increased electron transfer rate due to the introduction of molecular wire as a binder, and exhibited a better sensitivity and stability as well as high resistance to surfactants due to the synergistic effect of Nafion and stannum film. Under the optimal conditions, the stripping peak currents showed a good linear relationship with the Cd(II) concentration in the range from 1.0 to 80.0 μg L−1 with a detection limit of 0.13 μg L−1 (S/N = 3). The developed electrode was further applied to the determination of Cd(II) in soil extracts with satisfactory results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cadmium is regarded as one of the most toxic heavy metals in the environment. It can irreversibly accumulate in the kidney, liver, lung, and pancreas of the human body and cause neurological, gastrointestinal, and skeletal illnesses [1]. A major pathway of cadmium entering the body is by foods intake. This is to say, from plants grown in tainted agricultural land or meat from animals which have ingested plants grown in contaminated soil [2]. Therefore, it is necessary to establish a convenient, fast, and precise method for the detection trace level of cadmium in soil to assess the potential risk of environmental pollution.

Electrochemical stripping analysis (ESA) has been widely recognized as a powerful and versatile technique for the determination of trace metals in various samples. It possesses many intrinsic advantageous features such as rapid response, simple operation, low cost, and high sensitivity. Traditional working electrodes for ESA determination were generally based on hanging drop mercury electrode and mercury film electrode (MFE). However, the toxicity of mercury and the risks of it during disposal make the use of mercury electrodes undesirable. In search for alternative electrode materials, bismuth film electrodes (BiFE) have been shown to offer comparable performance to mercury electrode for stripping analysis. The notable advantages of BiFE include low toxicity, high sensitivity, large cathodic potential range, as well as its insensitivity to dissolved oxygen [3, 4]. Recently, a new electrode material—stannum—has been proposed [5–7]. Because the stannum and bismuth are in diagonal position in element periodic table, the stannum may possess many analogical characters of bismuth including the property of forming alloys with different metals. Moreover, stannum is also an “environmentally friendly” material that has less toxicity and lower price than bismuth. Therefore, the stannum holds great promise to be another electrode material for the “green analytical chemistry.”

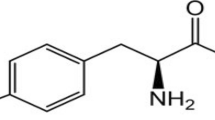

Carbon paste electrodes (CPE) have been widely used in biomedical, environmental, and industrial applications. However, CPE exhibit some disadvantages, such as low reproducibility and mechanical stability compared to the solid electrodes due to the poor adherence of liquid binders [8]. In addition, the use of non-conductive binders such as mineral oils or Nujol may weaken the electrochemical response of the sensor [9]. Many efforts have been made to promote the performance of CPE by alteration the binders. Recently, a kind of conducting binder—room temperature ionic liquid (IL)—was introduced to fabricate a new type of carbon composite electrode called carbon ionic liquid electrodes [10]. These electrodes exhibited many advantages over traditional CPE, such as high sensitivity, low impedance, and good ionic conductivity. However, those IL-based paste electrodes are found to suffer from large capacitive charging current. This high background current may obscure the analytical faradaic current of interest and reduce the detection performance, especially at low analyte concentration [11, 12]. Therefore, new binder materials are still highly desired. Molecular wire, a conductive organic molecule entity, has aroused great attention in recent years due to its outstanding electrical conductivity, good chemical and thermal stability, and wide electrochemical windows [13–15]. As one of the smallest conjugated oligomers, diphenylacetylene (DPA) possesses a rigid wire-like molecule structure and a good electron transport capability. Safavi’s group had successfully fabricated a DPA-based carbon paste electrode and investigated its electrochemical behavior, which exhibited better performances than the traditional GCE [16].

In this paper, a molecular wire carbon paste (MWCPE) was fabricated by using DPA as binder and further in situ deposited stannum film for the measurement of Cd(II) ions in soil extracts. In the analysis of the real natural samples, one of the most serious problems may arise from various surface active compounds that may adsorb on the electrode surface and cause the electrode performance deterioration. A kind of effective methods to alleviate this electrode fouling by surfactants is coating the electrode with a layer of a semipermeable membrane [17]. Nafion (perfluorosulfonate cation-exchange polymer) has been proven to have the ability of preconcentrating metal ions, offers higher resistance to surface active compounds, as well as improves the mechanical stabilization of the deposited metal layer [18]. It has been successfully applied in the combination with mercury and bismuth film-modified electrode [19, 20]. However, to the best our knowledge, the electrochemical characteristics of Nafion-modified stannum film electrode have not been explored by now. In our work, a Nafion layer was coated on the surface of prepared electrodes and applied to the determination of cadmium in real sample. The experimental results show that the developed electrode possesses good sensitivity, repeatability, and mechanical stability along with the low background current and excellent resistance to surfactant interference.

Experimental

Reagents

DPA (98 %) and Nafion (5 wt% solution in lower aliphatic alcohols) were obtained from Aldrich (Sigma-Aldrich, USA). Nafion was then diluted to 1 wt% with pure ethanol. Graphite powder (spectrum pure, size <30 μm) and paraffin oil were obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). SnCl2 was purchased from Jinlong Chemical Reagent Co. (Beijing, China) and dissolved to 100 mg L−1. Stock solution of Cd(II) (1,000 mg L−1) was obtained from national standard reference materials center of China and diluted as required. Acetate buffer (0.11 M) was used as supporting electrolyte. Millipore-Q (18.2 MΩ cm) water was used for all experiments.

Apparatus

Cyclic voltammetry (CV), square wave anodic stripping voltammetry (SWASV), and electrochemical impedance spectroscopy (EIS) were carried out on a CHI660D electrochemical workstation (Shanghai CH Instruments, China). The electrochemical cell was assembled with a conventional three-electrode system: the prepared carbon paste working electrodes, an Ag/AgCl (3 M KCl) reference electrode, and a platinum wire auxiliary electrode. A magnetic stirrer was used to stir the test solutions during the deposition steps.

Soil samples preparation

Soil samples were collected from a cultivated land in China. The extraction process was performed according to the published literatures [21, 22]. Briefly, soil sample was dried in an oven for about 2 h. Then, the sample was grinded by a mortar and sieved by a 200-μm sieve. A portion (1 g) of soil was transferred to an extraction bottle in which 40 mL of 0.11 M acetic acid was added. The mixed sample was shaken on an end-over-end shaker for 16 h at room temperature. Then, the mixture was centrifuged for phase separation and the aqueous phase was filtered through a membrane of 0.2 μm pore size. Before the measurement, the pH of the extract solutions was adjusted to 4.0 by addition of NaOH solution (0.11 M).

Preparation of electrodes

MWCPE was prepared by hand-mixing graphite powder with DPA at a mass ratio of 70/30 [16] to produce a homogeneous paste. Then, a portion of the resulting paste was firmly packed into one end of a glass tube (Φ = 3 mm). The electrical contact was provided by inserting a copper wire to the paste through the opposite end of the tube. The electrode was further heated to a temperature of higher than the melting point of DPA (62.5 °C) for 2 min. After cooled at the room temperature, the electrode was well polished by a weighting paper into a mirror surface. The Nafion coating was made by applying 5.0 μL Nafion solution, followed by 5.0 μL of N,N′-dimethylformamide (DMF), directly on top of the electrode. After evaporation of the solvents, the membrane of Nafion was cured by a warm air stream, and the resulted electrode was denoted as NA/MWCPE. For comparison purposes, the traditional CPE was prepared by hand-mixing 0.7 g graphite powder and 0.3 g paraffin oil in a similar way, and was then coated with a Nafion film which denoted as NA/CPE.

Measurement procedures

The analysis of Cd(II) by SWASV was performed in 0.11 M acetate buffer solutions in the presence of 3.5 mg L−1 Sn(II). Under the stirring conditions, the deposition potential of −1.2 V was applied to the working electrode for 120 s. Then, the stirring was stopped, and after a 10-s equilibration period, the SWASV potential scan was carried out from −1.2 V to 0 V (square wave amplitude, 25 mV; potential step, 5 mV; frequency, 25 Hz). Prior to the next measurement, a 30-s clean step at 0.3 V under stirring condition was used to remove the residual metals and the stannum film. All experiments procedures were carried out in the presence of dissolved oxygen in the test solutions.

Result and discussion

Electrochemical characteristics of prepared electrodes

Figure 1a compares the CV responses of CPE, MWCPE, and NA/MWCPE electrodes in [Fe(CN)6]3−/4− solution, respectively. A pair of poor redox peaks was observed at the CPE with a peak potential separation of 205 mV (Fig. 1a(b)), suggesting the sluggish electron transfer at the interface due to the poor conductivity of the paraffin oil. While at the MWCPE (Fig. 1a(a)), a well-defined and enhanced redox peaks with a small peak potential separation of 85 mV was observed, indicating that the electron transfer at the interface was dramatically improved. This change may be attributed to the effect of conjugated system of DPA and its π–π interaction with graphite atoms [16]. Figure 1a(c) shows the CV response of NA/MWCPE under the same conditions. The redox peaks became much smaller than that of MWCPE. Two mechanisms can be employed to explain the results. First, the Nafion film is non-conductive, and the insulated surface of Nafion can block the electron transfer of the electrode. Second, the negatively charged skeleton of Nafion layer repelled the [Fe(CN)6]3−/4− anion and made the diffusion of ferricyanide more difficult to the surface of the electrode [23]. On the other hand, this negatively charged characteristic of Nafion can facilitate the preconcentration of cationic target analytes and, under a certain circumstances, improve the detection sensitivity.

The interface properties of prepared electrodes were studied by the EIS and the results were shown in Fig. 1b. After fitting suitable circuit and calculation, the value of electron transfer resistances (Rct) were 159 Ω, 746 Ω, and 1.3 MΩ for MWCPE, CPE, and NA/MWCPE, respectively, which was in agreement with the conclusion obtained from the CV.

The hydrogen evolution process and the background current have a profound effect on the performance of the electrode. Figure 2 shows the cyclic voltammograms of MWCPE, stannum film-modified MWCPE (Sn/MWCPE), and stannum film-modified NA/MWCPE (Sn/NA/MWCPE) in bare acetate buffer solution, respectively. A low background current between −0.7 and −1.1 V was observed on the MWCPE (Fig. 2(a)). Moreover, this background current was very stable during the repetitive scans which suggested a higher mechanical strength of solid binder over the liquid binder. In comparison, the Sn/MWCPE (Fig. 2(b)) exhibited a more negative hydrogen evolution potential than the MWCPE due to the formation of a stannum film. While at Sn/NA/MWCPE (Fig. 2(c)), a more negative hydrogen overvoltage (about −1.4 V) than that of Sn/MWCPE was observed. This change can be attributed to the synergistic effect of Nafion and stannum film, which the Nafion can efficiently facilitate the deposition of the Sn(II) and improve physical stability of the Sn film. Similar effect of Nafion on BiFE and MFE electrodes were also been reported [24, 25]. These results demonstrated that the Sn/NA/MWCPE electrodes possess a sufficient reduction potential and small background current that can be used to stripping analysis.

Stripping response of Sn/NA/MWCPE

Figure 3 compares the square wave stripping responses of 20 μg L−1 Cd(II) at the MWCPE, Sn/MWCPE, Sn/NA/MWCPE, and Sn/NA/CPE, respectively. A weak and unobvious stripping peak of Cd(II) was observed on the bare MWCPE (Fig. 3(a)). However, after adding 3.5 mg L−1 Sn(II) into the deposition solution, the response at the Sn/MWCPE was remarkably enhanced (Fig. 3(b)). This enhancement can be attributed to the fact that stannum can form “fused” or “low-temperature” alloys with heavy metals that makes metal ions reduced more easily [5]. While at Sn/NA/MWCPE, a higher sensitivity toward Cd(II) detection (Fig. 3(c)) was observed. Such improvement can be attributed to two factors: one is that the sulfonate groups in the Nafion were negatively charged and, as a result, the polymeric membrane acted as a cation-exchanger facilitating the non-faradaic preconcentration of metal cations [20]. The other is as previously mentioned that the presence of Nafion film efficiently helped the electrodeposition of the stannum. Figure 3(d) also showed the stripping response of Cd(II) at the Sn/NA/CPE. However, the peak current was relatively weaker than that of Sn/NA/MWCPE. In Fig. 3, we also noted that the peak potential of Cd(II) was shifted about 21 mV to the cathodic direction on the Sn/NA/MWCPE than that of Sn/MWCPE. This shift can be attributed to the coulombic interactions between the cation-exchanging Nafion film and the accumulated metals. The similar phenomenon was also observed in the Nafion-modified MFE and BiFE [20, 25].

Optimization of experimental conditions

Thickness of Nafion layer

The actual polymer loaded on the electrode surface was changed by applying a 5.0-μL drop of the Nafion solution containing 0.25, 0.5, 1, 1.5, and 2 wt% of Nafion, respectively. It was found that the peak current of Cd(II) reaching its maximum when the concentration of Nafion was 1 %. The reason would be that at too thin or too thick polymer film, the oxidized species could diffuse away from the surface of electrode due to incomplete coating or cracks, respectively [26]. Therefore, a 1 wt % Nafion solution was employed to construct Nafion film. Under the assumption of Nafion completely covered on the surface of electrode, the average thickness of the Nafion layer, L NA, can be calculated by the formula [27]:

Calculations showed that the optimized average thickness of membrane was about 3.9 μm.

pH of supporting electrolyte

The effect of pH on the peak current of Cd(II) that was investigated in the pH range of 3.0–6.0 is shown in Fig. S1(a) (Supporting Information). It can be seen that the optimum pH was 4.0. The reason of lower responses at relative acid electrolyte was probably due to the hydrogen evolution that could interfere with the deposition process. Furthermore, under the excessively acidic circumstances, the sulfonic groups of Nafion will not effectively deprotonate and lead to fewer ion-exchange sites. Nevertheless, at higher pH values, Sn(II) is very susceptible to hydrolysis [28]. Therefore, a pH of 4.0 was chosen for further study.

Concentration of Sn(II)

The effect of the Sn(II) concentration on the stripping peak current is displayed in Fig. S1(b) (Supporting Information). The peak heights of Cd(II) increased with the raising of Sn(II) concentration from 0.5 to 3.5 mg L−1 due to the formation of adequate binary “fusing” alloy. However, with subsequent additions of stannum ions into the solution, the stripping signals were decreased gradually. This phenomenon could be explained by the formation of thick stannum layer on the electrode surface which hampered the target metal ions diffusing out of the stannum film. As a result, 3.5 mg L−1 was selected as the optimal Sn(II) concentration.

Deposition potential and deposition time

Figure S1(c) (Supporting Information) demonstrates the effect of deposition potential upon the stripping responses. When the deposition potential shifted from −0.8 to −1.2 V, the stripping peak currents of Cd(II) increased remarkably. But when the deposition potential became more negative, the peak currents reduced gradually, which probably due to hydrogen evolution was occurred at such potentials. Therefore, the deposition potential performed at −1.2 V. The effects of the deposition time on the stripping response of Cd(II) is show in Fig. S1(d) (Supporting Information). The peak currents increased linearly from 30 to 210 s. However, when the deposition time exceeded 210 s, the peak currents started to level off, which was probably due to the saturation effect of the stannum film on the electrode surface. In view both of sensitivity and determination time, 120 s was selected for deposition.

Analytical performance of Sn/NA/MWCPE

To investigate the dynamic range and sensitivity of the developed electrode, the SWASV measurement under the optimal conditions were performed. A series of stripping responses for successive additions of Cd(II) are illustrated in Fig. 4. It can be seen that the peak currents displayed a good linear relationship with the concentration of Cd(II) in the range from 1.0 to 80.0 μg L−1. The linear regression equation was calculated as: \( {i_{\mathrm{p}}}=0.3621c-0.2065\left( {{i_{\mathrm{p}}}:\upmu \mathrm{A},\,c:\upmu \mathrm{g}\ {{\mathrm{L}}^{-1 }}} \right) \), with the correlation coefficient of 0.9978. Based on three times the standard deviation of the blank signals (S/N = 3), the limit of detection (LOD) was 0.13 μg L−1. The comparison of the Sn/NA/MWCPE with other electrodes for the determination of Cd(II) was listed in Table 1. From Table 1, one can see that prepared electrode exhibited a comparable linear range and a lower LOD than other electrodes.

Voltammograms for additions of 0, 1, 5, 10, 20, 30, 40, 50, 60, 70, and 80 μg L−1 Cd(II) at Sn/NA/MWCPE (left part of figure). The right part of the figure shows the corresponding correlation plot. Other conditions were as in Fig. 3

The reproducibility of the developed electrode was evaluated by measuring a buffer solution containing 20 μg L−1 Cd(II). For a single electrode, the relative standard deviation (RSD) was 1.4 % in five times repetitive measurements. For the six different electrodes prepared by the same way, the RSD was 3.7 %. The long-term stability was also estimated by recording stripping voltammograms of Cd(II) at a same electrode every day over a week, the maximum deviation obtained was 6.3 %, indicating good stability of prepared electrode. It is worth to note that the use of DMF as casting solvent and heat curing process during Nafion film formation is the crucial steps for the production of electrode, which has a profound effect on the stability of Nafion film [27].

Interference study

The interferences from coexisting ions were investigated by adding various foreign substances (max: 1,000-fold) into buffer solution containing 20.0 μg L−1 Cd(II). Under the ±5.0 % tolerated ratios, it was found that 1,000-fold NO3−, SO4 2−, and Cl−; 1,000-fold K+, Na+, and Ag2+; 400-fold Mg2+, Mn2+, and Al3+; 80-fold Zn2+; and 50-fold Pb2+ have no evident influences on the signal of Cd(II). Cu2+ was found to have an obvious suppressing effect on the determination of Cd(II) in low mass ratio (0.7-fold). This interference is probably due to the competition between electrodeposited Sn(II) and Cu(II) for surface active sites on the electrode as well as the formation of an intermetallic compound between Cu(II) and Cd(II) [7]. However, it can be efficiently alleviated by the addition of ferrocyanide ions in the test solution [32].

The effects that came from the surfactants had also been investigated. Three types of surfactants, including cetyltrimethylammonium bromide (CTAB, cationic), Triton X-100 (nonionic), and sodium dodecyl sulfate (SDS, anionic), were selected as “model” to study the antifouling ability of the developed electrode. The normalized peak currents (calculated as I p/I pmax, where I p and I pmax were the stripping peak currents in the presence and the absence of surfactant, respectively) of Sn/MWCPE and Sn/NA/MWCPE were recorded. As shown in Fig. 5, the Sn/NA/MWCPE exhibited a more tolerance to the presence of different surfactants than Sn/MWCPE. This resistance can be attributed to the microstructure of Nafion that looks like a segregated area of fluorocarbon and clusters of hydrated sulfonate sites. The bulkier surfactant molecules are mechanically prevented by the membrane, while the smaller metal cations can pass through smoothly.

Soil sample extracts analysis

To evaluate the feasibility of the developed electrode for routine analysis, the Sn/NA/MWCPE was applied to the detection of cadmium in soil samples. The measurement was performed by standard addition method. A typical analysis from these tests is shown in Fig. S2 (Supporting Information). The obtained results were further validated by the analysis of atomic absorption spectroscopy and recovery tests. The result (summarized in Table 2) showed a good agreement between two analytical methods and satisfactory recovery results with an average recovery of 97.1 %, confirming the availability of the developed method.

Conclusion

In this work, a novel carbon paste electrode based on the molecular wire (DPA) as binder was fabricated, and further modified with Nafion and stannum film to the determination of cadmium by SWASV. Compared with conventional electrodes using mineral oil as binder, the electrochemical performance of prepared electrode was dramatically improved by the high conductivity of DPA. Combining the co-deposits ability with heavy metals of stannum film and ion-exchange property of Nafion film, the developed electrode exhibited a very high sensitivity toward the determination of Cd(II). Several fabrication and operational parameters were optimized and the influence caused by different ions and surfactants was investigated. The proposed electrode was further applied to detect trace cadmium in soil samples with satisfactory results. This work proposed a low cost, high sensitive, reproducible, and stable sensor, which holds great promise for its wide applications in environmental and food analysis.

References

Nawrot TS, Staessen JA, Roels HA, Munters E, Cuypers A, Richart T, Ruttens A, Smeets K, Clijsters H, Vangronsveld J (2010) BioMetals 23:769–782

Salazar MJ, Rodriguez JH, Nieto GL, Pignata ML (2012) J Hazard Mater 233:244–253

Švancara I, Prior C, Hočevar SB, Wang J (2010) Electroanalysis 22:1405–1420

Wang J (2005) Electroanalysis 17:1341–1346

Li B, Wu ZL, Xiong CH, Luo HQ, Li NB (2012) Talanta 88:707–710

Czop E, Economou A, Bobrowski A (2011) Electrochim Acta 56:2206–2212

Zhu WW, Li NB, Luo HQ (2007) Talanta 72:1733–1737

Maleki N, Safavi A, Tajabadi F (2006) Anal Chem 78:3820–3826

Ping JF, Wu J, Ru SP, Ying YB (2011) Microchim Acta 172:241–245

Liu HT, He P, Li ZY, Sun CY, Shi LH, Liu Y, Zhu GY, Li JH (2005) Electrochem Comm 7:1357–1363

Kachoosangi RT, Musameh MM, Abu-Yousef I, Yousef JM, Kanan SM, Xiao L, Davies SG, Russell A, Compton RG (2009) Anal Chem 81:435–442

Kachoosangi RT, Wildgoose GG, Compton RG (2007) Electroanalysis 19:1483–1489

Mohajeri A, Zare A (2009) Comp Mater Sci 45:935–940

Marwitz AJV, Lamm AN, Zakharov LN, Vasiliu M, Dixon DA, Liu SY (2012) Chem Sci 3:825–829

Liu GZ, Paddon-Row MN, Gooding JJ (2007) Electrochem Comm 9:2218–2223

Safavi A, Maleki N, Honarasa F, Tajabadi F (2009) Electrochem Comm 11:1113–1115

Torma F, Kádár M, Tóth K, Tatár E (2008) Anal Chim Acta 619:173–182

Legeai S, Vittori O (2006) Anal Chim Acta 560:184–190

Murimboh J, Lam MT, Hassan NM, Chakrabarti CL (2000) Anal Chim Acta 423:115–126

Xu H, Zeng LP, Huang DK, Xian YZ, Jin LT (2008) Food Chem 109:834–839

Kadara RO, Tothill IE (2008) Anal Chim Acta 623:76–81

Cooper J, Bolbot JA, Saini S, Setford SJ (2007) Water Air Soil Pollut 179:183–195

Li DY, Jia JB, Wang JG (2010) Talanta 83:332–336

Gouveia-Caridade C, Pauliukaite R, Brett CMA (2006) Electroanalysis 18:854–861

Hoyer B, Florence TM (1987) Anal Chem 59:1608–1614

Liu BZ, Lu LY, Wang M, Zi YQ (2008) Electroanalysis 20:2363–2369

Kefala G, Economou A, Voulgaropoulos A (2004) Analyst 129:1082–1090

Hutton EA, Hčcevar SB, Mauko L, Ogorevc B (2006) Anal Chim Acta 580:244–250

Hočevara SB, Švancaraa I, Vytřasa K, Ogorevc B (2005) Electrochim Acta 51:706–710

Tesarovaa E, Baldrianovaa L, Hocevara SB, Svancarab I, Vytrasb K, Ogorevca B (2009) Electrochim Acta 54:1506–1510

Hocevar SB, Svancara I, Ogorevc B, Vytras K (2007) Anal Chem 79:8639–8643

Crowley K, Cassidy J (2002) Electroanalysis 14:1077–1082

Acknowledgments

This work was supported by the National High Technology Research and Development Program of China (no. 2011AA100704) and Research Fund for the Doctoral Program of Higher Education of China (no. 20120008110033).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 276 kb)

Rights and permissions

About this article

Cite this article

Wang, Z., Liu, G., Zhang, L. et al. Electrochemical detection of trace cadmium in soil using a Nafion/stannum film-modified molecular wire carbon paste electrodes. Ionics 19, 1687–1693 (2013). https://doi.org/10.1007/s11581-013-0891-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-013-0891-4