Abstract

Lithium stannate (Li2SnO3) has been prepared by solution evaporation method. The precursor obtained is sintered at 800°C for 5, 6, and 7 h, respectively. X-ray diffractogram confirmed that the sample obtained after sintering is Li2SnO3. The pelletized Li2SnO3 after heating at 500 °C for 3 h is used for electrochemical impedance spectroscopy characterization. Impedance measurements have been carried out over frequency range from 50 Hz to 1 MHz and temperature range from 563 to 633 K. The conductivity–temperature relationship is Arrhenian. Several important parameters such as activation energy, ionic hopping frequency and its rate, carrier concentration term, mobile ion number density, ionic mobility, and diffusion coefficient have been determined. The characteristics of log conductivity and log ionic hopping rate against temperature for the system suggest that the conduction and ionic hopping processes are thermally activated. The values of activation energy for conduction and relaxation processes as well as activation enthalpy for ionic hopping are about the same.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Research on tin-based oxide compounds as electrode material for lithium-ion batteries have been intensified ever since Idota and co-workers employed amorphous tin composite oxide as anode material with its capacity higher than graphite [1]. Tin composite oxide is one promising material as anode for lithium-ion batteries since it can improve the electrochemical performance by reducing capacity fading compared to pure tin itself [2]. Lithium stannate or lithium tin oxide (Li2SnO3) is known to be a promising breeding material for nuclear fusion reactors [3, 4] and as one of the starting materials to synthesize zinc stannate (ZnSnO3) [5] other than being electrode materials for lithium-ion batteries [6–9]. From literature review, there have been several reports published on the Li2SnO3 structure [10–13] and also on the enthalpy and heat capacity of Li2SnO3 [14, 15]. Li2SnO3 has also been reported to exhibit good catalytic properties among other lithium-based oxides such as Li2MnO3, Li2CeO3, LiFeO2, LiZnO2, and LiAl5O8 [16].

Conductivity studies on various lithium-based oxides viz. Li2TiO3 [17], LiCeO2 [18], LiSmO2 [19], LiV2O5 [20], LiBiP2O7 [21], and others [17, 22] have been reported in the literature. However, to the best of our knowledge, there is no report on conductivity of Li2SnO3 that has been published in the literature except Zhang and co-authors who have prepared thick films of Li2SnO3 and examined its conductivity under vacuum condition and at different humidity atmospheres [23]. Studies on the conductivity of lithiated electrode materials are important in order to gain a better insight and understanding on the ionic conduction mechanism especially in its usage for lithium-ion batteries. Electrochemical impedance spectroscopy (EIS) is one simple and non-destructive way to investigate the ion transport of the material at the microscopic level. From conductivity data, various important parameters such as activation energy, hopping frequency, hopping rate of the ions, charge carrier concentration term, ionic mobility, diffusion coefficient, number density of mobile ions, activation enthalpy, and entropy for conduction can be determined. These parameters will add more information to the literature on Li2SnO3. The potential application of Li2SnO3 as an electrode material in lithium-ion batteries serve as a motivation for this study and the information gathered as stated above would be advantageous in the design of lithiated tin-based oxide for anode in lithium batteries.

In the present work, solution evaporation technique was employed for the synthesis of Li2SnO3. The Li2SnO3 was prepared by evaporating the solutions of lithium and tin acetates and sintering the product precursor. X-ray diffraction (XRD) was carried out to prove that the product obtained after sintering is Li2SnO3. EIS was performed on the pelletized Li2SnO3 at high temperatures ranging from 563 to 633 K. The dielectric and modulus studies of Li2SnO3 are also presented in this paper.

Experimental

Sample preparation

Tin (II) acetate (Sn(C2H3O2)2; 7.1034 g) (CAS: 638-39-1, Aldrich, Russia) was dissolved in 600 ml distilled water until the solution appeared muddy-like in color. Ethanol (10 ml) was then added to the solution to ensure complete dissolution before 6.1212 g lithium acetate dihydrate (C2H3O2Li·2H2O) (CAS: 6108-17-4, Sigma-Aldrich, USA) was added to the solution. At this point, 10 ml nitric acid was added until pH = 1 and a milky solution obtained. The mixture was continuously stirred and heated to ensure complete dissolution. Heating was continued until a white solid was obtained. The white solid was ground to powder and sintered at 1,073 K for 5, 6, and 7 h, separately. After sintering, the samples were once again ground into fine powder using pestle and mortar.

X-ray diffractogram

The samples were characterized by XRD with Cu-Kα X-radiation of wavelength λ = 1.5406 Å using Siemens D5000 diffractometer to prove them to be Li2SnO3. XRD data in the range of 2θ = 15° to 80° were collected with a step size of 0.05°. Diffraction occurs based on Bragg's Law:

where d is the interplanar spacing, θ is the Bragg angle of the diffraction peak, n is the order of reflection, and λ is the wavelength of x-ray.

Electrochemical impedance spectroscopy

For impedance measurements, 1.0 g of each sample was pelletized to a thickness of about 0.1 cm and diameter of 1.5 cm. The applied pressure was 400 bar. The pellets were then heated at 500°C for 3 h to minimize the grain boundary effect [24]. The impedance of the pelletized samples was determined by complex impedance spectroscopy using the HIOKI 3531 Z Hi-tester bridge over the frequency range from 50 Hz to 1 MHz at temperatures ranging from 563 to 633 K. The pellets were sandwiched between stainless steel electrodes. From the complex impedance plot, the bulk resistance, R b can be determined. The ionic conductivity, σ was then calculated using the following equation:

where t is thickness of the pellet in centimeters and A is area of the pellet in square centimeter.

Results and discussion

X-ray diffractogram

Figure 1 shows the XRD patterns of Li2SnO3 using acetates of lithium and tin as starting materials and sintered at 1,073 K for several sintering times. The product obtained was identified as monoclinic Li2SnO3 following the JCPDS 31-0761 data. These results are found to be closely matched to the X-ray diffractogram of Li2SnO3 reported by Zhang et al. [8]. From the XRD, pattern of Li2SnO3 sintered for 8 h, four additional peaks with low intensity can be observed at 2θ = 20.45°, 22.75°, 26.65°, and 51.85°. This is in good agreement with the JCPDS file no. 76-1149 in which peaks at 2θ = 20.25°, 22.84°, 26.50°, and 52.50° have been assigned to (\( \overline 1 11 \)), (111), (022), and (223) crystal planes that are also assigned to monoclinic Li2SnO3. Hence, it can be concluded that no impurity peak can be observed in the XRD patterns indicating purity of the material. Also, it can be observed that sharper peaks appeared as sintering time increases. Table 1 compares the standard d interplanar spacing from JCPDS data with the calculated d spacing of the product obtained in this work using Eq. 1. It can be observed that the calculated values of d spacing are well-matched to the standard d interplanar spacing and thus indicate the formation of Li2SnO3.

Crystallite size (t) of the samples can be calculated using Scherrer's equation:

Here, β is the full width at half maximum height of the most intense diffraction peak representing the (002) plane in radians. Crystallite size of the Li2SnO3 sample at different sintering times was calculated and tabulated in Table 2. It is noted that crystallite size decreases as sintering time increases.

Conductivity studies

Figure 2 depicts the complex impedance plot at 573 K obtained for Li2SnO3 samples sintered at 800 °C for various sintering times. As can be seen from the figure, the Cole-Cole plot revealed semicircle shape which is due to bulk resistance, R b , and bulk capacitance, C b , of the sample. It arises because of the ion migration in the bulk of the material and is due to different relaxation times of the ions [25]. The fact that the center of the semicircle is located below the real axis reveals the non-Debye nature of the material [26]. The intercept of the semicircle with the real axis gives the bulk resistance, R b . The bulk capacitance at the maximum of the semicircle can be calculated using the equation below:

From the figure, C b in the range between 21 and 41 pF are obtained. According to literature [21], the bulk capacitance in the order of pF indicates that the conduction process occurs through the bulk or grain interior of the material. The shape of the impedance plot is due to the response of the surface of a material to an input signal that is equivalent to the response of an electrical circuit. Hence, the impedance data can be fitted to the response of an equivalent circuit when subjected to an ac signal as shown in the inset of Fig. 2. CPE represents the constant phase element and is used instead of a capacitor to account for the depressed semicircle. The impedance of CPE is given by [27]:

or

Here k −1 corresponds to the capacitance value of the CPE element, ω is angular frequency (ω = 2πf where f is frequency), and p is related to the deviation from the vertical axis in the Z″ versus Z′ plot. CPE behaves in an intermediate way between resistor and capacitor. The real and imaginary parts of the impedance associated to the equivalent circuit can be calculated using the expressions given below:

Table 3 lists the parameters involved in the circuit. It can be observed that k −1 capacitance values are in pF range which is comparable to C b obtained from Eq. 4. The good fit between the experimental data and calculated line indicates that the equivalent circuit recommended suited well.

From Eq. 2 and the Cole-Cole plot, it can be noted that the highest conducting sample is sintered at 8 h with conductivity value of 3.57 × 10−8 S cm−1 at 573 K. At the same temperature, Li2TiO3 has been reported to exhibit conductivity of ∼6.00 × 10−8 S cm−1 [17]. Vītiņš et al. [17] strongly agreed that lithium ions are the main contribution for Li2TiO3 conductivity due to its insignificant electronic conductivity and the immobile oxygen ions in cubic close pack arrangement. Lithium-ion conduction is thought to occur by interstitial diffusion. Therefore, it conforms that Li+ ions are responsible for Li2SnO3 conductivity since both Li2SnO3 and Li2TiO3 have the same structure.

Figure 3 presents the Cole-Cole plot for Li2SnO3 sample sintered for 7 h at various temperatures. It can be observed that R b decreases as temperature increases leading to increment in conductivity. From Eq. 2, it can be concluded that the lower value of R b gives the higher conductivity. Hence, highest conductivity of 1.42 × 10−7 S cm−1 is obtained at 633 K. Impedance plot for Li2SnO3 sample at temperatures of 563, 573, and 583 K depicted in Fig. 3a can be best represented by the equivalent circuit comprising a parallel combination of resistance, R b , and CPE as shown in the inset figure. For temperatures higher than 583 K, the Cole-Cole plot in Fig. 3b shows a few data points after the semicircle which implies the beginning of formation of a spike. Hence, the equivalent circuit becomes a parallel combination of resistance, R b , and CPE with another CPE in series as depicted in the inset Fig. 3b. CPE can also be used to represent the spike [27]. The expressions for the real and imaginary parts of the impedance related to this new equivalent circuit are given below:

All the parameters for the circuit elements are summarized in Table 4.

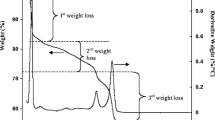

Temperature dependence of conductivity for Li2SnO3 systems with different sintering times is displayed in Fig. 4. From the plot of log σ versus 1,000/T for Li2SnO3 pellets, the temperature dependence of ionic conductivity obeys Arrhenius rule:

Here σ 0 is a pre-exponential factor, E A is the activation energy of conduction, k is Boltzmann constant, and T is temperature in Kelvin. The activation energy can be obtained from the slope of the graph. From the graph, it can be observed that the conductivity increases linearly with temperature implying that conduction is a thermally activated process. The regression value, R 2 is found to be 0.99 for all samples.

The conductivity at 563 K and activation energy values for all samples studied is listed in Table 5. The low conductivity obtained in this work may be due to the strong octahedral coordination between Li+ and O2− ions that provides difficulty for the Li+ ions to detach itself from the oxygen ions to jump to neighboring sites. This could possibly account for the high activation energy obtained.

Figure 5 depicts the graph of log σ(ω) versus log ω for Li2SnO3 sample sintered for 7 h. Here, σ(ω) is the total direct current (d.c.) and alternate current (a.c.) conductivity. From the figure, it can be seen that there is plateau at the low-frequency region and extrapolating it on the y-axis gives the value of d.c. conductivity. These σ dc values are found to be in good agreement with the values depicted in Fig. 4. On the other hand, the sample exhibits strong frequency dispersion of conductivity in the high frequency region as temperature increases. Hence, it can be inferred that a.c. conductivity is dominant in the high-frequency region. It is also clear from the figure that the σ(ω) spectra in the high-frequency region converge at different temperatures which implies that a.c. conductivity is temperature independent at high frequencies. Such behavior has also been observed in the LiDyO2 [22] and LiNiVO4 [28] systems.

It is well-known that Almond and West have proposed that the σ(ω) data can be used to estimate the ionic hopping rate, ω p [29]. Extrapolating at twice the value of d.c. conductivity from the vertical axis horizontally towards the graph and then extrapolating downwards vertically to the horizontal axis will give ω p in logarithmic scale as shown in Fig. 5. The hopping rate of ions, ω p can also be given by the relation below [30]:

where

Here, K is charge carrier concentration term, e is electron charge, γ is correlation factor which is set equal to 1, and a is the jump distance, i.e., the distance between two adjacent sites for the ions to hop. From literature [30, 31], a is taken as 3 Å for all materials. n is the number density of mobile ions or charge carriers. n can be determined using Eq. 13. The ionic mobility, μ, and diffusion coefficient, D, can then be calculated using equations as given below:

The values of σ, ω p , K, n, μ, and D at all temperatures studied for Li2SnO3 sample sintered for 7 h are tabulated in Table 6. As can be seen from the table, it can be concluded that no significant change in K and n within the temperature range studied. This implies that the concentration of charge carriers is temperature independent. Savitha and co-workers [32] deduced that if K is independent of temperature, then all the ions in the system are mobile and thus can be best represented by the strong electrolyte model. Therefore, it can be concluded that the conduction mechanism in Li2SnO3 is attributed to the hopping of charge carriers. From the table, it can be observed that the mobility of ions, μ increases with increasing temperature. This suggests that the conductivity of the samples can be attributed to the increase in ionic mobility since number density of the mobile ions is considered to be constant over temperature range studied. Also, it is noted that the diffusion coefficient, D increases with temperature. The diffusion coefficient, D of Li2SnO3 is comparable to the diffusion constant of Li4Ti5O12 which is of the same magnitude order of 10−12 cm2 s−1, but lower than that of Li0.8Mn2O4 (10−9 cm2 s−1) [17] and even lower than that of LiV2O5 (10−4 cm2 s−1) [24]. The low value of diffusion coefficient of Li+ ions in Li2SnO3 may also be due to strong Li+-O2− octahedral coordination that imposes difficulty for the ions to diffuse.

The hopping rate of ions in a material is a valuable piece of information to elucidate the ionic conduction. The ionic hopping rate, ω p can also be represented by the following equation:

Here, ω e is the effective attempt frequency and H m is activation enthalpy for hopping or migration of ions [29]. Figure 6 depicts the plot of log ω p against 103/T for Li2SnO3 samples sintered for 5, 6, 7, and 8 h, respectively. From the graphs plotted, H m and ω e can be obtained from the slope and intercept at the vertical axis of the graph, respectively. The linear variation of log σ with temperature for all the samples suggests that the ionic hopping process for Li2SnO3 is thermally activated. The effective attempt frequency, ω e can also be expressed as:

where ω 0 is the true attempt frequency and S m is activation entropy for hopping or migration of ions [29]. The true attempt frequency, ω 0 , can be estimated using harmonic potential expression given by [29]:

Here, m is the mass of the mobile ion (Li+). Substituting both the obtained values of ω e and ω 0 (see Eqs. 16 and 18) into Eq. 17 gives the value of S m /k. According to Almond and West [29], the hopping rate of ions is strongly dependent on the entropic term, S m /k. Table 7 lists the transport properties for all Li2SnO3 samples. For all samples, the values of ω p , n, and μ are taken at 593 K.

From Table 7, it can be noted clearly that H m value is in good agreement with E A value for all samples studied. According to literature, if H m and E A are closely matched, it is said that the concentration of carriers is temperature independent and thus the enthalpy of carrier formation can be neglected [19, 33]. If H m and E A values are different, this implies that certain amount of energy has been used in the formation of a free charge carrier [21]. The negative value of the entropic term is also observed in LiGaO2 system [29]. The trend of n follows the conductivity trend with sintering time.

Dielectric studies

The conductivity of ionic conductors can also be understood from dielectric studies. The dielectric property of a material is attributed to the formation of dipoles which arises due to the migration of ions along the sites. The complex permittivity of a system is defined by

where ε′ is dielectric constant (the real part of complex permittivity) and ε″ is dielectric loss (the imaginary part of complex permittivity). Using the measured impedance values, the dielectric constant and dielectric loss can be calculated from the equations:

Here Z″ and Z′ is the imaginary and real parts of the complex impedance. C 0 = ε 0 A/t and ε 0 is permittivity of free space.

The frequency dependence of the dielectric constant, ε′, at various temperatures for Li2SnO3 sample at sintering time of 7 h is shown in Fig. 7a. It can be noted that the ε′ shows frequency dependence in the frequency region investigated for all temperatures. This is attributed to the occurrence of electrode polarization and space charge [34]. Also, it can be seen clearly from the figure that the dielectric constant increases with increasing temperature which is the result of lithium-ion migration [35]. Figure 7b displays the variation of dielectric loss, ε″, with frequency for Li2SnO3 sample (sintering time 7 h) at different temperatures. Similar to Fig. 7a, it can be seen that ε″ decreases with the increase in frequency but increases with the increase in temperature. When the frequency is increased, there is no time for charge carriers to accumulate at the electrode–pellet interface due to the increasing rate of reversal of the electric field and the ions are mainly confined in the bulk of the material resulting in the decrease of ε″ [36]. However, both dielectric constant and dielectric loss exhibit a small increase in the high frequency region (inset Fig. 7a and b). Dielectric loss occurs as a result of collisions among the mobile charge carriers [37]. The large value of ε″ can be attributed to the motion of free charge carriers within the material [38].

Other than permittivity, the dielectric relaxation can also be studied in terms of electrical modulus. The electrical modulus of a system can be expressed as below:

where M′ and M″ are real and imaginary parts of the modulus. From Eqs. 20 and 21, the imaginary and real parts of modulus can be obtained using the relations below:

Figure 8 depicts the graph of imaginary part of the modulus, M″ versus log ω for Li2SnO3 sample (sintering time 7 h) at various temperatures. The imaginary component of the electrical modulus, M″ is associated to energy loss that occurs in the conduction process [39]. It can be seen clearly that the peaks shift towards higher frequency with increasing temperatures. This indicates that the dielectric relaxation process is thermally activated in which the ionic transport is by hopping [28]. Also, it can be noted that the height of the peak increases slightly as temperature increases. The region on the left of the M″ peak, i.e., the low-frequency region determines the frequency range in which the mobile ions are able to hop from one site to an adjacent site [39]. On the contrary, the high-frequency region represents the charge carriers being confined in potential wells that they can only move in short distance [39]. The appearance of peaks indicates the presence of relaxation time for the sample at selected temperatures. The relaxation time is defined as the time of the transition for the mobile ions to move from long distance to short distance. The occurrence of relaxation time, τ can be obtained from the peak of M″ using the relation τ = 1/ω peak . The existence of the peak also confirms that the material is an ionic conductor [40].

Figure 9 shows the plot ln τ versus 1,000/T for Li2SnO3 sample with sintering time of 7 h. The regression value R 2 is 0.98. It can be observed that the value of τ decreases with increasing temperature. The plot can be represented as

where the activation energy for relaxation process is 0.86 eV. This value is comparable to the activation energy of conductivity which is 0.80 eV. It is understood that if the activation energy value for the conductivity is similar to that of relaxation process, the mobile ion has to overcome the same barrier while conducting as well as relaxing [41]. The small difference may be due to the fact that the relaxation process involved only the hopping energy of the carriers between localized states.

Conclusions

The impedance of the pelletized lithium stannate (Li2SnO3) heated at 500 °C for 3 h is measured. The plot of log conductivity against reciprocal temperature obeys the Arrhenius rule. Transport parameters for conduction mechanism such as activation energy, ionic hopping frequency and its rate, carrier concentration term, mobile ion number density, ionic mobility, and diffusion coefficient have been determined. The ionic transport of Li2SnO3 is by hopping. Both the conductivity and ionic hopping are thermally activated processes. Variation of imaginary part of modulus, M″ as a function of frequency shows the shifting of peaks towards high frequency as temperature increases which implies that there is a distribution of ionic relaxation time. The nearly same value of activation energies for conduction and relaxation processes indicates that the energy required for the lithium ion to jump to adjacent sites in both processes are the same.

References

Idota Y, Kubota T, Matsufuji A, Maekawa Y, Miyasaka T (1997) Science 276:1395–1397

Zhang R, Lee JY, Liu ZL (2002) J Power Sources 112:596–605

Inagaki M, Nakai S, Ikeda T (1988) J Nucl Mater 160:224–228

Moritani K, Moriyama H (1997) J Nucl Mater 248:132–139

Kovacheva D, Petrov K (1998) Solid State Ionics 109:327–332

Courtney IA, Dahn JR (1997) J Electrochem Soc 144:2045–2052

Belliard F, Irvine JTS (2001) Ionics 7:16–21

Zhang DW, Zhang SQ, Jin Y, Yi TH, Xie S, Chen CH (2006) J Alloys Compd 415:229–233

Vaughey JT, Geyer AM, Fackler N, Johnson CS, Edstrom K, Bryngelsson H, Benedek R, Thackeray MM (2007) J Power Sources 174:1052–1056

Hodeau JL, Marezio M, Santoro A, Roth RS (1982) J Solid State Chem 45:170–179

Kreuzburg G, Stewner F, Hoppe R (1970) Z Anorg Allg Chem 379:242–254

Mather GC (2000) J Mater Chem 10:2219–2230

Tarakina NV, Denisova TA, Maksimova LG, Baklanova YV, Tyutyunnik AP, Berger IF, Zubkov VG, Tendeloo G (2009) Z Kristallogr Suppl 30:375–380

Asou M, Terai T, Takahashi Y (1990) J Nucl Mater 175:42–46

Asano M, Kato Y, Harada T, Mizutani Y, Yamawaki M (1993) J Nucl Mater 201:156–161

Huang Y, Wang G-J, Wu T-H, Peng S-Y (1998) J Nat Gas Chem 7:102–107

Vītiņš Ģ, Ķizāne G, Lūsis A, Tīliks J (2002) J Solid State Electrochem 6:311–319

Prabu M, Selvasekarapandian S, Kulkarni AR, Hirankumar G, Sanjeeviraja C (2010) J Rare Earths 28:435–438

Prabu M, Selvasekarapandian S, Kulkarni AR, Hirankumar G, Sakunthala A (2010) Ionics 16:317–321

Selvasekarapandian S, Vijayakumar M (2002) Solid State Ionics 148:329–334

Bhuvaneswari MS, Selvasekarapandian S, Kamishima O, Kawamura J, Hattori T (2006) J Solid State Electrochem 10:434–438

Selvasekarapandian S, Vijayakumar M (2003) Mater Chem Phys 80:29–33

Zhang JL, Lu YD, Li BR (1993) Proceedings of 43rd Electronic Components & Technology Conference, 1–4 June 1993, Orlando, USA, pp 1095–1198

Vijayakumar M, Selvasekarapandian S (2003) Mater Res Bull 38:1735–1743

Govindaraj G, Baskaran N, Shahi K, Monoravi P (1995) Solid State Ionics 76:47–55

Prabu M, Selvasekarapandian S, Kulkarni AR, Karthikeyan S, Hirankumar G, Sanjeeviraja (2011) Ionics 17:201–207

Linford RG (1988) Experimental techniques for studying polymer electrolytes. In: Chowdari BVR, Radhakrishna S (eds) Solid state ionics devices. World Scientific, Singapore, pp 551–571

Selvasekarapandian S, Bhuvaneswari MS, Fujihara S, Koji S (2006) Acta Materialia 54:1767–1776

Almond DP, West AR (1983) Solid State Ionics 9–10:277–282

Almond DP, West AR (1987) Solid State Ionics 23:27–35

Vijayakumar M, Hirankumar G, Bhuvaneswari MS, Selvasekarapandian S (2003) J Power Sources 117:143–147

Savitha T, Selvasekarapandian S, Ramya CS, Bhuvaneswari MS, Hirankumar G, Baskaran R, Angelo PC (2006) J Power Sources 157:533–536

Almond DP (1989) Mater Chem Phys 23:211–223

Akgul U, Ergin Z, Sekerci M, Atici Y (2008) Vacuum 82:340–345

Orliukas A, Dindune A, Kanepe Z, Ronis J, Kazakevicius E, Kežionis A (2003) Solid State Ionics 157:177–181

Mariappan CR, Govindaraj G (2002) Mater Sci Eng B94:82–88

El-Nahass MM, Farid AM, El-Rahman KFA, Ali HAM (2008) Physica B 403:2331–2337

Dutta P, Biswas S, De SK (2002) Mater Res Bull 37:193–200

Baskaran N, Govindaraj G, Narayanasamy A (1997) Solid State Ionics 98:217–227

Mellander B-E, Albinsson I (1996) Electric and dielectric properties of polymer electrolytes. In: Chowdari BVR, Dissanayake MAKL, Careem MA (eds) Solid state ionics: new developments. World Scientific, Singapore, pp 83–95

Ahmad MM, Yamada K, Okuda T (2003) Physica B 339:94–100

Acknowledgment

We would like to thank the University of Malaya for financial support (PS326/2009B and RG087/09AFR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teo, L.P., Buraidah, M.H., Nor, A.F.M. et al. Conductivity and dielectric studies of Li2SnO3 . Ionics 18, 655–665 (2012). https://doi.org/10.1007/s11581-012-0667-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-012-0667-2