Abstract

The present study investigated the impact of edible coatings containing encapsulated antimicrobial and antibrowning agents on the quality and shelf life of fresh-cut potatoes. Polysaccharides extraction from potato peels using ultrasound/microwave-assisted extraction (UAE/MAE) was optimized via central composite design (CCD) and response surface methodology (RSM). Maximum starch recovery (216.55 ± 10.37 mg amylose/g potato peel) was achieved with UAE. Starch, pectin, and chitosan combination was the basis of the coatings. Rosemary essential oil (REO) and ascorbic acid (AA) were selected as antimicrobial and antioxidant agents, incorporated in free or encapsulated form via spray drying (SP) and electrospinning (EL). Over 14 days at 4 °C, coated potatoes exhibited improved appearance, reduced browning, enzyme activity, weight loss, hardness, and microbial load compared to controls. Notably, the potato starch-pectine coating with encapsulated REO/AA effectively inhibited browning and microbial growth, demonstrating the potential of edible coatings to enhance freshness and shelf life in fresh-cut potatoes.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fresh-cut fruit and vegetables have occupied an important market and have experienced an emerging trend in the last few decades when the modern lifestyle of consumers demands healthy, convenient, and fresh foods (Dite Hunjek et al. 2020; Liu et al. 2019b; Shen et al. 2019; Zhao et al. 2022). One of the most requested products in the category is potato (Solanumtuberosum) (Zhao et al. 2022). According to the latest data of FAOSTAT, potatoes represent one of the five major global crops and their consumption is constantly increasing due to their rich nutritional content in carbohydrates, proteins, minerals, vitamins, and other nutrients (FAOSTAT, World Crops 2021 2023; Liu et al. 2019b).

Nevertheless, as in the most fresh-cut fruits or vegetables, enzymatic browning, which is perceived as a dark colouring in the flesh, is a major problem of degrading the sensory quality and nutritional value of potatoes after the peeling and cutting processes (Liu et al. 2019b). This surface tanning is mainly brought by melanogenesis, the oxidation of phenolic substances of potato into dark-coloured compounds, melanins. This transformation is catalysed by the enzyme of polyphenol oxidase (PPO), which is found in the cytoplasm of plant cells. Therefore, the key step for the prevention of enzymatic browning of fresh-cut potatoes is the inhibition of the action of the enzyme at the initial stage of the reaction (Liu et al. 2019a; Zhao et al. 2022). For this purpose, various pre-treatment methods are currently applied as environmentally friendly methods, including, edible coatings, osmotic dehydration, and pre-drying (Su et al. 2021).

The technology of edible coatings has been used as a preservation method aiming to extend the shelf life and maintain the fresh-like properties of fresh-cut vegetables by preventing moisture and solute transfers and selectively allowing exchanges of gases that are involved in respiration processes (Rashid et al. 2021; Zhao et al. 2022). An edible coating is formed by a combination of biopolymers and various additives that are dispersed in aqueous media, is used to coat various foods, and can be consumed with the food with or without further removal (Díaz-Montes and Castro-Muñoz 2021; Huber and Embuscado 2009).

Polysaccharides, such as starch and pectin, constitute the most widely used components of edible coatings for fruits and vegetables since they are non-toxic, natural polymers that can be obtained from plant sources and agro-industrial wastes, such as potato peels (Vargas et al. 2009). The recovery of polysaccharides from potato byproducts is of particular significance, especially when using green extraction techniques like ultrasound/microwave-assisted extraction (UAE/MAE), as the recovered ingredients can be utilized for the improvement of the already produced potato products within the framework of the circular economy.

UAE/MAE represent well known eco-friendly, scalable, and low-cost extraction techniques that can reach high extraction yields within short time (Chronis et al. 2021). Τhe increased efficiency of UAE is attributed to cavitation forces that form bubbles in the liquid medium, which implode and rupture the cell walls of the solid matrix. Thus, the solvents penetrate into the matrix and recover easily the cellular content. On the other hand, the main reason of the improved yield of MAE is that the energy from electromagnetic waves is converted into thermal energy, raising the matrix’s temperature and causing cellular rupture, which in turn makes it easier for the compounds to diffuse in the solvents (Stramarkou et al. 2023). UAE/MAE are considered to be simpler and effective ways in starch extraction compared to conventional extraction methods, and they are applied in other previous studies (Calcio Gaudino et al. 2020; Krishnakumar and Sajeev 2017; Ying et al. 2011).

In general, polysaccharides, as a matrix, are effective barriers to oxygen, but poor barriers against water vapour, thus preventing water condensation that can be a source of microbial spoilage in agricultural products (CHA and CHINNAN 2004). Wu (2019) used cactus polysaccharide edible coatings to suppress the browning and microbial growth of fresh-cut potatoes (Wu 2019). Polysaccharides can be combined with proteins, such as whey protein, which are generally hydrophilic, but have good sensory and mechanical properties and can increase the nutritional value of the final product (McGrance et al. 1998).

The effect of edible coatings can be even more obvious when combined with natural preservatives including plant extracts or essential oils (Rashid et al. 2021). Plant essential oils, and specifically rosemary essential oil (REO), are excellent alternatives to chemical preservatives and are classified as “generally recognized as safe” (GRAS) (Yousuf et al. 2021). Due to their antimicrobial and antioxidant activity, they are able, thanks to their hydrophobic nature, to act synergistically with polysaccharides and proteins and improve the barrier capacity of edible coatings in water, thus reducing water loss phenomena in various foods. Although essential oils are not primarily used as anti-tanning agents, they still have an effect on enzymes that may be responsible for tanning, e.g., PPO (Yousuf et al. 2021). Last but not least, ascorbic acid (AA) represents a traditional antibrowning agent frequently used in edible coatings of various fruits and vegetables, like strawberries, apples, and potatoes (Baldwin et al. 1996; Najafi Marghmaleki et al. 2021; Saleem et al. 2021).

The antibrowning agents can be applied in the edible coating either in free or encapsulated form so that their controlled release can prolong their action and their beneficial effect. The encapsulation is an attractive technique to entrap and protect unstable active compounds (core material) within different wall polymers matrices (Castro Coelho et al. 2021) and can be performed using various methods, with spray drying and electrospinning representing two of the most widely known and efficient ones. Spray drying is a simple and continuous technique, able to produce particles with high stability, extended shelf life, and controlled release characteristics (Oikonomopoulou et al. 2022). On the other hand, electrospinning is a highly flexible and simple technique that can produce fibres with high porosity and high surface to volume ratio based on the use of electrostatic force (Castro Coelho et al. 2021; Stramarkou et al. 2024).

The objective of the present study is to enhance the shelf life and nutritional value of fresh-cut potato products by employing edible coating technology. For the development of the edible coatings, starch (amylose) was recovered from potato peels, which represents the industrial byproducts of potato, using microwave and/or ultrasound-assisted extraction. The process was optimized for maximising the yield of amylose extracts. The recovered amylose along with chitosan and pectin served as matrices in order to develop the edible coatings. Antimicrobial and antioxidant agents, such as rosemary essential oil (REO) and ascorbic acid (AA), were incorporated in the coatings in free or encapsulated form in order to inhibit the microbial spoilage and enzymatic browning. The study assessed the impact of various edible coatings on the quality and shelf life of potatoes over a 14-day storage period at 4 °C, considering parameters such as browning index, PPO activity, weight loss, texture, and microbiological stability.

Materials and Methods

Materials

Potato Tubers

Potatoes (Spunta variety) were kindly donated by Sklirakis Ioannis - Giakoumis Iakovos O.E., which is a potato processing company in Naxos, Greece.

Coating Materials

The coating materials that were used in this study were potato starch recovered by potato peels; pectin, chitosan, glycerol obtained from local market; acetic acid from Fisher-Scientific; Tween 80 and calcium chloride (CaCl2, 96%) from Acros Organics; whey protein isolate powder (WPI) from Agropur Ingredients Inc. (USA); and pullulan (PUL) from Hayashibara Biochemical Lab. Inc. (Japan). The active ingredients, including AA and REO, were obtained from Sigma-Aldrich and VIORYL, respectively.

Chemicals

Polyvinylpolypyrrolidone (PVPP), Triton X100, and 1,2-dihydroxybenzene (catechol), used for the determination of the PPO activity, were purchased from Sigma-Aldrich. The reagents of iodine (I2) and potassium iodide (KI), used for the determination of amylose content, as well as, Folin–Ciocalteau and sodium carbonate (Na2CO3) used for the evaluation of total phenolic content (TPC), were obtained from Sigma-Aldrich.

Recovery of Starch from Potato Peels and Determination of Starch Content

The first step of the recovery of starch was the washing and the peeling of the potatoes. Afterwards, the obtained potato peels were dehydrated through vacuum drying (Sanyo Gallenkamp PLC, Leicester, England, 220V, 1000 W) at 40 °C and 48 mbar for 48 h and then were ground to a fine powder (200–500 μm). The potato peel powder was stored in the refrigerator at 4 °C.

The recovery of polysaccharides from potatoes’ peels was performed through agitation using magnetic stirrer at 600 rpm (Multimatic 5-N, JP SELECTA, Barcelona, Spain), ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), and ultrasound and microwave-assisted extraction (UMAE) with the XO-SM50 Ultrasonic Microwave Reaction System (Nanjing Xianou Instruments Manufacture co., Ltd., Nanjing City, China). The extraction experiments were carried out using water as solvent under the following operating conditions: ultrasonic frequency at 25 kHz, extraction temperature up to 40 °C and ultrasound emission time/pause time at 6 s/1 s. Response surface methodology (RMS) was applied to optimize the extraction factors for the recovery of starch from potato peels. Central composite design (CCD) was used to investigate the effects of three independent variables. Two replications were performed for each independent experiment. The independent variables used were MAE power (X1), UAE power (X2), solid:liquid ratio (X3), and extraction time (X4) which were coded at three levels, −1, 0, and 1 (Table 1). The amylose content of the potato peel extracts (mg amylose/g potato peel), was quantified through the starch–iodine method at 600 nm according to McGrance et al. (1998). Recovery of starch (mg amylose/g potato peel) was selected as the response variable (Y) was clarified for the various combinations of the specified independent variables. The generalized mathematical model describing the CCD is as follows:

where Y is the dependent variable (amylose recovery), b0, bi, bii, and bij are the regression coefficients of the intercept, linear, quadratic, and interaction terms, respectively, n is the number of independent variables and Xi and Xj are the independent variables.

The regression analysis of the experimental data was performed using the Statistica™ software (Statsoft version 12.0, USA). The adequacy of each model to fit the data was assessed by evaluating the coefficient of determination (R2). The significance of each coefficient was determined by using the F test derived from the analysis of variance (ANOVA), whereas the test of statistical significance was based on the total error criteria with a confidence level of 95%. Extraction experiments were carried out twice for each independent experiment.

Encapsulation of Active Ingredients

Development of Encapsulation Structures through Spray Drying

Aqueous solutions of WPI and PUL (pH = 3.0) were prepared at a weight proportion of 80:20 w/w and concentration of 20% w/v by mixing them with a magnetic stirrer (M 6.1, Ingenieurbüro CAT, M. Zipperer GmbH, Ballrechten-Dottingen, Germany) for at least 4 h and 500 min−1 at room temperature to ensure complete solubilization of the polymers. AA was subsequently dissolved in the prepared solution at 3.5% w/w. An oil-in-water emulsion was then prepared by mixing 1.5% w/w aqueous solution of WPI (pH= 3), REO (0.15 g/mL) using a high-speed homogenizer (T 25 digital ULTRA-TURRAX, IKA, Germany) equipped with a dispersing tool S25N-18G operating at 10,500 rpm for 5 min. The resulting emulsion was passed through an ultrasonic system (Nanjing Xianou Instruments Manufacture co., Ltd., China) operating at 720 W for 5 min in order to reduce the droplet size of the emulsion and the degree of dispersion. The final emulsions, which were used as feed solutions in spray drying, were prepared by mixing the aqueous solution of the biopolymers (WPI and PUL) enriched with the AA with the oil emulsion in the ratio of 67:33 v/v in a magnetic stirrer for about 30 min. In the final emulsions, the concentration of the dispersed oil phase was adjusted to 5% w/w.

The development of the encapsulated structures was performed by feeding the produced emulsions in a spray dryer (Model YC-015, Shanghai Pilotech Instrument & Equipment Co. Ltd, China), operating in parallel flow. The nebulizer used was a dual fluid nozzle type, possessing an internal diameter of 0.7 mm and using compressed air at a flow rate regulated by a variable area flow meter. During spray drying, the emulsions were stirred continuously on a magnetic stirrer at 40 °C. The feed solution was introduced into the dryer via a peristaltic pump. The drying medium used was air, which after passing through an electric heater, was coming into contact with the sprayed feed solution in the main drying chamber. A cyclone separator was used to recover the dried powders. The collected powder was packaged in multilayer packages and kept refrigerated until further examination. After preliminary experiments, the emulsion flow rate was adjusted at 200 mL/h and the air inlet temperature at 180 °C. The outlet air temperature depended on the combination of the inlet air temperature, the feed solution flow rate, the concentration of the liquid dispersion, and other factors.

Development of Encapsulation Structures through Electrospinning

In order to produce encapsulation structures of REO/AA via EL, an aqueous solution of WPI:PUL mixture in a ratio of 30:70 w/w was prepared. The total concentration of polymers in the solution was equal to 20% w/v. The solution was mixed using a magnetic stirrer until the complete dissolution of the polymers in the solution was ensured. AA was subsequently dissolved in the prepared solution at a concentration of 6% w/w.

The encapsulation of REO/AA was carried out using the lab-scale FluidNatek L-10, Βioinicia (Valencia, Spain) electrospinning equipment through the coaxial electrospinning method. In the coaxial methodology, two stainless steel concentric needles were used; the inner was used for the core material REO, and the outer was used for the matrix solution (WPI:PUL solution) enriched with AA. The structures were collected on aluminium foil, which was placed on a copper plate (collector). After preliminary experiments, the collector was set at a distance of 17 cm from the tip of the needle, the applied voltage at 24 kV, the polymer solution flow at 1.0 mL/h, and the REO solution flow at 0.1 mL/h.

Characterization of Encapsulated Structures

Scanning Electron Microscopy

The characterization of the morphology and microstructure of the encapsulated structures was performed by scanning electron microscopy (SEM) (Quanta 200 FE, 2004, OR, USA), using a large field detector (LFD) operating at a voltage of 12.5 kV. Prior to SEM, the samples were gold plated on the SC7620 Mini Sputter Coater (Quorum Technologies, West Sussex, UK) for 120 s, creating a thin layer of gold of 15 nm thickness.

Attenuated Total Reflectance, Fourier Transform Infrared Spectroscopy

The quantitative and chemical characteristics of pure REO, pure AA, dry matter of WPI:PUL (30:70) fibres, dry matter of WPI:PUL (80:20) powder and dry matter of REO/AA-loaded structures were monitored by attenuated total reflection (ATR) (ATR PRO-410 -S, JASCO International Co., Ltd.) and infrared spectroscopy (FT-IR) (FT/IR-4200, JASCO International Co., Ltd. Japan). The spectra of the samples were collected at wavelengths between 700 and 4000 cm−1 by averaging 32 scans at a resolution of 4 cm−1.

Determination of Encapsulation Efficiency

The encapsulation efficiency (EE, %) of REO/AA-loaded structures was determined using different protocols tailored to the specific active ingredient. Notably, the EE of REO/AA-loaded structures was calculated by dividing the amount of REO/AA content encapsulated within the carrier material by the total amount of REO/AA used in the formulation, according to Eq. (2):

REO content was evaluated by determining the TPC of the encapsulated products through the Folin–Ciocalteu method (Ainsworth and Gillespie 2007). The TPC was calculated and expressed as mg of gallic acid equivalents (GAE)/g of the initial sample. The amount of REO entrapped in the structures was determined using a solvent extraction process as described by Drosou et al. (2022).

AA content was evaluated by dissolving 10 mg of the encapsulated products in 10 mL of phosphate-buffered saline (PBS) and measuring their concentration at 265 nm using UV-vis spectrophotometer (Bel Photonics UV-M51 spectrophotometer, Piracicaba, Brazil), as described by Janmohammadi et al. (2021).

Formation of Edible Coatings

Preparation of Coating Solutions

All the coating solutions that were applied to the fresh-cut potatoes were starch-based. Table 2 shows a summary of the composition of all formulas used: potato-control (P-C), potato starch-pectin coating (P-S-PE), potato starch-chitosan coating (P-S-CH), potato starch-pectin coating enriched with non-encapsulated REO and AA (P-S-PE-F), and potato starch-pectin coating enriched with SP and EL encapsulated REO/AA structures (P-S-PE-SP, P-S-PE-EL).

Potato Starch-Pectin Coating

Potato starch and pectin solutions were prepared separately at first. The potato starch solution was prepared by heating an aqueous potato starch powder solution (2% w/v) at 90 °C for 3 h, in order to gelatinize the starch and obtain a clear solution. The pectin solution was prepared by heating an aqueous pectin solution (4% w/v) at 50 °C until complete solubilization of pectin. Glycerol was added at 1.5% w/v as a plasticizer. The prepared solutions were mixed at a ratio of 1:2, forming potato starch (1% w/v), and pectin (2% w/v) solution.

Potato Starch-Chitosan Coating

Potato starch and chitosan solutions were prepared separately, too. Potato starch solution was prepared as described in the “Potato starch-pectin coating” section. The chitosan solution was prepared by dissolving 2% w/v chitosan dry powder in 1% v/v acetic acid aqueous solution, stirred at room temperature. Glycerol (50% w/chitosan dry weight) and Tween 80 (0.2% w/v) were added as plasticizer and as an emulsifier agent, respectively. The prepared solutions were mixed at a ratio of 1:1, forming potato starch (1% w/v) and pectin (1% w/v) solution.

Potato Starch-Pectin Coating Enriched with REO/AA

For the potato starch-pectin coating enriched with AA and REO, two solutions were prepared to form a final emulsion: the matrix and the pre-emulsion. The matrix was prepared as described in the “Potato starch-pectin coating” section to form potato starch (1% w/v) and pectin (2% w/v) solution and subsequently, AA was dissolved at 0.5% w/v. For the pre-emulsion, 2.5% w/v aqueous solution of WPI (pH= 3) was prepared and afterwards, mixed with REO using a high-speed homogenizer (T 25 digital ULTRA-TURRAX, IKA, Germany) equipped with a dispersing tool S25N-18G operating at 10,500 rpm for 5 min. The matrix and the pre-emulsion were mixed at a ratio of 95:5 v/v, forming the final emulsion. In the final emulsion, the concentration of REO was adjusted to 5% w/w.

Potato Starch-Pectin Coating Enriched with SP and EL Encapsulated REO/AA Structures

The P-S-PE-SP and P-S-PE-EL were prepared by adding to the P-S-PE solution the SP and EL encapsulated REO/AA structures at a concentration equal with 1.3% w/v and 1.8% w/v, respectively. Each solution was stirred at room temperature.

Coating of the Samples

Potato tubers were washed, peeled, and sliced in rectangular pieces of specific size (40 mm length × 12 mm width × 12mm height). The fresh-cut potatoes were immersed at each coating solution for 2 min. The P-S-PE samples were also dipped in an aqueous 2% w/v calcium chloride solution for 2 min. The coated potatoes were placed in a rack for approximately 15 min in order to dry the coating films on the surface of them. All the samples (coated and control) were packaged at plastic bags and were stored at 4 °C for 14 days.

Evaluation of Edible Coated Fresh-Cut Potatoes during Storage

Control samples as well as the edible coated fresh-cut potatoes were packed in the air-tight food grade PET containers and were stored at 4 °C for 14 days. Day 0 was recorded as the day the potatoes were coated. The products were characterised in terms of colour, weight loss, enzymatic activity, hardness, and microbial load at fixed time intervals.

Colour Analysis and Browning Index

For the colour determination of the samples, a colorimeter (MiniScan XE, Hunter Associates Laboratory Inc., Reston Virginia) equipped with a 4-mm measuring head, in the reflectance mode and in the CIE L* a* b* colour scale was used. The colour parameters (L* a* and b*) were measured on three different points on the cut surface. The colour parameters were used to calculate the browning index (BI) using Eq. (3):

where \({a}_0^{\ast }\) is the colour measurement at 0 day and \({L}_t^{\ast }\), \({a}_t^{\ast }\), and \({b}_t^{\ast }\) are the colour measurements at fixed times intervals. Colour measurements were conducted in triplicates.

Enzymatic Activity

The enzymatic activity (PPO) was measured according to the method described by Fang et al. (2007) with slight modifications (Fang et al. 2007). In order to extract PPO, 6 g of potatoes were mixed with 6 mL of 0.2 M sodium phosphate (Na2HPO4/NaH2PO4) buffer (pH 6.5) containing 4% (w/v) PVPP, and 1% (v/v) Triton X100 and stirred at 25 °C for 25 min and then centrifuged at 3500 rpm for 15 min. The PPO was detected in the supernatant, which was filtered through 0.45-μm filters (Chromafil PVDF-45/25, Macherey-Nagel, Germany), and kept at 0 °C until the enzymatic activity measurements. For the determination of PPO activity, 100 μL of PPO extracts was diluted in 3 mL of 0.05 M sodium phosphate buffer (pH 6.5) containing catechol at a concentration of 0.07 M. The variation in absorbance in the final solution was measured at 420 nm for 2 min. The absorbance graph (A420 nm) in the first 60 s was plotted against the reaction time to simulate the enzymatic inactivation kinetics. It is noted that the absorbance values after 60 s and until the end of 2 min were not taken into account as they remained almost constant with time. The enzymatic activity corresponding to one unit of PPO activity was defined as the change in absorbance of 0.001 units per minute at 420 nm. Therefore, based on the least squares method, a linear equation for the curve was found, and the slope of the curve was thus calculated. The slope for the curve of each sample was divided by 0.001 to obtain the result in units and then expressed in units/g of potato, by dividing by the weight of the potato sample.

Weight Loss

Samples were weighed at 0 day and stored at 4 °C. Samples were weighed again at fixed time intervals and weight loss was calculated using Eq. (4):

where Wi is the initial weight at 0 day (g) and Wt is the weight at fixed time intervals (g).

Hardness

The hardness of potatoes was measured using a universal testing machine (model Z2.5/TN1S, Zwick, Ulm, Germany). Parallel plates were inserted in the instrument for uniaxial compression using a 100 N load cell, and compression of potatoes was performed with a constant deformation rate of 5 mm/min. Before each test, the dimensions of the cubes were measured using a digital Vernier caliper. All compression tests were performed at room temperature (25 °C) and in four replications. Force and deformation were recorded electronically and the resulting stress–strain compression curves were constructed according to the Eqs. (5) and (6):

where, σ is the stress (Pa), εn is the strain (mm/mm), A is the cross-section area (m2), Lo is the initial thickness of the samples (m), F is the force (N), and DL is the deformation (m).

Microbial Load

The quantitative assay of the microbial count on coated and uncoated samples was carried out by a serial dilution technique as reported by Kumari and Nikhanj (2022) with some modifications. The fresh-cut potato samples were subjected to microbial enumeration using nutrient agar, yeast, mould agar, and EMB agar. After the samples were weighed and divided into smaller pieces, they were put in sterile filter bags with a 1:9 ratio of Ringer serum added. A Ringer tablet (Merck code 1.15525, Darmstadt, Germany) was dissolved in 500 mL of deionized water to create Ringer serum. After that, the solutions were appropriately diluted and prepared using a Stomacher extraction for around 1.5 min.

Sterile pestle and mortar were used to homogenize 10 g of representative samples of coated and uncoated (control) fresh-cut potatoes. The homogenates were then diluted with 90 mL of sterile distilled water to produce a 10−1 dilution. Tenfold dilutions of the homogenates were then created up to 107 by plating 1 ml of the diluents on sterile petri plates and 9 mL of sterile blanks (Rahimi and Hanumaiah 2019). The nutrient agar medium was sterilized following the manufacturer's instructions, for 15 min at 121 °C and 15 psi. A sterile petri plate was aseptically plated with 1-mL aliquot of the serially diluted samples (one dilution per plate). Next, 15 to 20 mL of sterile nutrient agar were added and spun to guarantee even mixing in accordance with the pour plate method (Samuel et al. 2016). Accordingly, the same process was used to determine the presence of yeasts and moulds. A millilitre of the sample was extracted from the intended dilution (based on the storage days and beginning count) and placed in a petri dish, followed by the addition of the necessary media.

Microbial count was taken after 24–48 h of incubation period at respective incubation temperature (37 ± 2 °C for total plate count [TPC] and 28 ± 2 °C for yeasts and moulds [YM]) of each media plate. Microbial colonies were counted on the plate to calculate cfu/g according to Eq. (7):

Results were expressed as log (cfu/g) on a fresh weight basis.

Statistical Analysis

One-way and factorial analysis of variance (ANOVA) was applied in order to analyse the differences. Tukey’s range test (a=0.05) was applied, and all the statistical tests were performed with SPSS 23.0 (IBM SPSS Statistics, Chicago, IL, USA).

Results and Discussion

Recovery of Starch from Potato Peels

Table 3 presents the results of the recovery of the starch from potato peels for the extraction procedures applied in this study. Based on these results, the best performing extraction technique was UAE and the optimized conditions were the following: ultrasound power 700 W, solid/liquid ratio 0.03 g/mL, and extraction time 5 min.

The effects of microwave power (X1, W), ultrasound power (X2, W), solid/liquid ratio (X3, g/mL), and extraction time (X4, min) on the recovery of starch from potato peels were also explored by the mathematical modelling of the recovery of starch through the response surface methodology (RSM) and are clearly depicted in Fig. 1.

Response surface and contour plots showing the effects of ultrasound power, solid/liquid ratio, extraction time on the recovery of starch from potato peels (mg amylose/g potato peel). Solid/liquid ratio vs. ultrasound power (microwave power: 200 W, extraction time: 10 min) (a); extraction time vs. ultrasound power (microwave power: 200 W, solid/liquid ratio: 0.05 g/mL) (b)

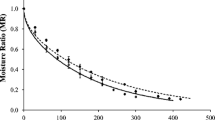

RSM was used for the evaluation of the effect of the four processing parameters and their interaction on the recovery of starch from the potato peels. Table 4 presents the results of fitting the experimental data to the mathematical model, and Fig. 2 shows the regression analysis between the predicted and the observed values. The accuracy of the developed model was determined based on the value of the coefficient of multiple correlation (R2), which is 0.88 indicating that the model satisfactorily represents the relation between the selected parameters. The significance of the different terms for each coefficient was determined using the F value and p value. A large F value or low p value implies a significant effect on the corresponding response variable (Chanioti and Tzia 2017). Furthermore, based on Fig. 2, a large concentration and constant deviation of the points around the diagonal (small errors) throughout the range of the values examined for the efficiency of the extraction. Therefore, the used model predicts with consistent accuracy the extraction yield. The correlation between the recovery of starch and the extraction processing parameters is described using the polynomial Eq. (8):

The regression analysis of the experimental data was then performed again ignoring the variables with no significant effect on recovery of starch and the fitted ‘surface model’ is described by Eq. (9). The model F value of 534.94173 and the low p value (p<0.0001) indicate that the revised model is significant; these values imply a good fit of the experimental data to Eq. (9).

The variables with the greatest effect on the starch recovery were the linear terms of microwave power (X1), ultrasound power (X2), solid/liquid ratio (X3), and extraction time (X4) and the square term of microwave power (X12). The interaction term of ultrasound power and solid/liquid ratio (X2 X3) was also significant (p<0.01), as well as the square term of extraction time (X42) and the interaction term of ultrasound power and extraction time (X2 X4). The other variables did not significantly contribute to the extraction efficiency.

The interplay between the independent and dependent variables is visualized using 3D representations of response surfaces, as well as the corresponding 2D contour plots, which have been generated using the final model for starch recovery (Eq. 9). To enhance clarity, the interaction effects of factors with the most substantial impact on starch recovery are showcased.

Figure 1a shows the impact of varying solid/liquid ratio and ultrasound power at fixed microwave power of 200 W and extraction time of 10 min. As it can be seen, for each ultrasound power value, the increase in the solid/liquid ratio had a negative effect on the recovery of starch from potato peels. This can be attributed to the insufficient amount of solvent to perform effectively under higher solid loading. Furthermore, higher solid/liquid ratios cause a higher concentration gradient, which is also the driving in solvent extraction. Thus, a decreasing concentration gradient between the internal starch and the external solvent reduces the rate of the mass transfer from the solid matrix to the solvent having a negative impact on the extraction efficiency (Tan et al. 2021).

Additionally, Fig. 1b shows the effect of varying extraction time and ultrasound power at fixed microwave power of 200 W and solid/liquid ratio of 0.05 g/mL. According to this figure, prolonging the extraction time resulted in an increase in starch recovery up to a specific threshold (10 min), after which a decline in extraction yield is noticed. This result aligns with another study, where the starch extraction efficiency obtained by sonication at 70% for 15 min was found to be lower than that obtained by sonication at 50% and 60% (Tan et al. 2021). In the initial minutes of extraction, there was intense mass transfer from the potato peels to the solvent, resulting in fast extraction rates. However, the extension of the duration of sonication may lead to excessive mechanical bond breaking and destruction of molecular covalent bonds, reducing, thus, the yield, possibly due to free radicals generated in the solution from the breakdown of the bubbles and their subsequent interaction with water molecules (H- and OH- radicals) (Stramarkou et al. 2023; Wang et al. 2022; Laina et al. 2021).

Finally, the influence of the ultrasound power in Fig. 1a was not obvious, whereas in Fig. 1b, the increase in ultrasound power resulted in higher yield during extraction for short durations lower than 10 min. Similar results were noted after the extraction of high-amylose starch from Radix Puerarie root using UAE, where the amylose content of the extracts increased by increasing intensity. This phenomenon is attributed to partial depolymerization of amylose and amylopectin molecules during sonication, which in turn increases the number of linear chains and the amylose content of starch (Li et al. 2019). Furthermore, in another study of starch extraction, it has been found that excessive ultrasonic power for a long time reduces the yield as it may degrade the structure of starch (Tan et al. 2021).

Encapsulation of Rosemary Essential Oil /Ascorbic Acid

Encapsulation Efficiency

Table 5 presents the EE of the SP-REO/AA and EL-REO/AA structures for their respective active ingredients. The TPC content of these structures is also presented, with the TPC content of the non-encapsulated REO being 97.74 ± 1.23 mg GAE/g. Based on the results for both of the active ingredients, it is evident that EE is notably high for both encapsulation techniques confirming the efficacy of the selected matrices and the operational parameters. For REO, when comparing the effectiveness of the encapsulation methods, it is apparent that SP tended to result in REO structures with a slightly higher EE compared to EL. This difference can be attributed to the varying ratios of WPI in the formulations of each encapsulation method. The increased ratio of WPI used in the SP process (80% wt.) contributed to the higher EE of REO. This can be explained by the fact that the incorporation of surface-active ingredients, including milk proteins, enhances the encapsulating capacity of lipophilic compounds. These ingredients have the ability to interact with lipophilic compounds through hydrogen bonds or van der Waals forces reducing the amount of REO deposited on the surface of the structures (Barbosa et al. 2005; Soukoulis and Bohn 2018). In contrast, for AA, the trend was observed to be opposite, with the EE of EL being slightly higher than that of SP. The difference in EE can also be attributed to the variation in the matrices’ properties. AA is a hydrophilic compound resulting in higher EE when it was incorporated in the formulation used in EL with increased PUL ratio.

Morphological Characterization

The obtained micrographs of the SP and EL products are presented in Fig. 3. It was observed that the encapsulated products obtained by SP consisted of structures in the shape of microspheres of various sizes with good dispersion, while visible cracks and breaks were absent in the particles. This morphology is desirable as the absence of cracks indicates successful encapsulation of the target compounds since the component cannot diffuse from the interior of the encapsulated structure to its surface and be released from the encapsulation matrix. Regarding the EL products, the results of encapsulating REO/AA in the aqueous WPI:PUL (30:70 % w/w matrix) through EL were satisfactory (Laina et al. 2022). In particular, the produced nanofibres were characterized by random orientation, uniformity, good dispersion of the component, and minimal spherical formations-failures (beads) and aggregates.

Chemical Structure

The new encapsulated complexes formed by SP and EL and the interactions between the matrix and the active ingredient can be studied through attenuated total reflectance, Fourier transform infrared spectroscopy (ATR-FTIR), which allows the control and identification of the presence of REO and AA in the encapsulation system by providing information on the chemical bonds and functional groups (Stramarkou et al. 2020). The infrared spectra obtained for the, pure REO, pure AA, used matrix and the encapsulated structures for SP and EL are shown in Fig. 4a and b, respectively.

It is observed that the ATR-FTIR spectra of the encapsulated products for both techniques present the characteristic peaks of both the encapsulation carrier and the active ingredients. Specifically, the characteristic WPI peaks at 1643 cm−1 corresponding to the amide type I or for the C=O stretching vibration and at 1528 cm−1 due to the amide type II or for the C=O stretching vibration of N-H stretching and bending occur in both used matrices. Furthermore, the characteristic peaks of PUL at the wavelengths between 1200 and 1030 cm−1 corresponding to the C-O bond, at 1147 cm−1 due to the stretching vibration of the (1→4) glycosidic bond, and at 844 cm−1 and 930 cm−1 derived from the α-glucopyranoside units and α-(1→6) glycosidic linkages, respectively, are present in the encapsulation structures (Drosou et al. 2017). As it can be seen from the above figures, these peaks are found in both encapsulation products, confirming the presence of the matrix.

Regarding REO, the majority of its components are classified as terpenes, while 1,8-cineole and camphor represent more than 50% of its total content, followed by pinene isomers. All the above-mentioned components contribute to C–H stretching bands from 2967 to 2873 cm−1 as seen in the spectrum of the plain REO (Stramarkou et al. 2020). The fact that both encapsulated products show higher absorptions at the wavenumbers between 3000 and 2800 cm−`1 than the plain WPI:PUL structures reveals its presence. The existence of REO in the final products can also be perceived by the presence of the characteristic peak at 1745 cm−1, which is attributed to the keto group of camphor (Stramarkou et al. 2020).

Finally, regarding the encapsulation component of AA, the low peaks in the range between 3900 and 3200 cm−1 approximately are associated with the different hydroxyl groups of AA (Sreeja et al. 2015), whereas the highest peak at 1670 cm−1 in the IR spectra is attributed to the C = C stretching (Janmohammadi et al. 2021). The encapsulation of AA in the matrices by both methods is confirmed by the presence of the small characteristic peaks of AA in the band of 3900–3200 cm−1 in the spectra (iv) of Fig. 4a and b. On the other hand, the absorption peak at 1670 cm−1 is overlapped with the WPI peaks at 1643 cm−1, so the success of the incorporation of AA can only be based in the higher wavelength peaks of the IR spectra, and not on the beforementioned peak.

Characterization of Edible-Coated Fresh-Cut Potatoes

Optical Observation

Table 6 involves characteristic images of the control and edible coated samples at 0, 7, and 14 days of storage. Comparing the effectiveness of appearance maintenance of pectin and chitosan based coatings, it was observed that P-S-PE demonstrated a higher degree of appearance retention in the samples until the 7th day of storage. In contrast, P-S-CH exhibited the development of dark brown spots on the potato surface during the same period. Notably, the appearance of the P-S-CH samples deteriorated even more rapidly than that of P-C. Therefore, the active ingredients were incorporated only in the P-S-PE as this coating effectively contributed to preserving the overall appearance of the potatoes until the 7th day of storage. In contrast, the appearance of P-C samples became unacceptable from the very early days of storage.

Comparing the effectiveness of P-S-PE coating enriched with REO/AA in encapsulated or free form, it was observed that the samples maintained their appearance up to the 7th day suggesting that the addition of active ingredients had a positive effect on the appearance of the sliced potatoes. Notably, both P-S-PE-SP and P-S-PE-EL demonstrated a higher retention of potatoes’ appearance compared to P-S-PE-F with almost no change in their appearance up to the 14th day of storage. This observation suggests that the encapsulation of active ingredients contributed to the sustained activity of these ingredients during storage. When comparing P-S-PE-SP and P-S-PE-EL, it was observed that P-S-PE-EL samples exhibited more white shades on the 14th day, whereas P-S-PE-SP displayed a yellowish colour. All the above observations are analytically explained in the next sections, where the modifications of the crucial parameters of browning index, enzymatic activity, weight loss, and hardness are presented.

Browning Index

Figure 5 presents the browning (BI) of the samples, a critical factor that significantly influences post-cutting handling and processing of potatoes during storage. According to the findings, P-C samples exhibited higher BI values throughout the storage period compared to the coated ones. This suggests that the application of the edible coating effectively hinders the formation of browning spots on the surface of the potatoes. Notably, the presence of the coating acts as a barrier to oxygen, inhibiting the activity of PPO and, consequently, preventing the formation of dark spots on the sample surfaces (Sahraee et al. 2019). Comparing the effectiveness of edible coated samples, P-S-PE coating enriched with active ingredients consistently exhibited lower BI values throughout the entire storage period than P-S-PE. This indicates the effectiveness of REO/AA as antioxidant agents in delaying enzymatic browning in potatoes. Similar findings were noticed by Saleem et al. (2021), reporting that edible coating enriched with AA delayed senescence of strawberry fruits. Furthermore, both P-S-PE-F, P-S-PE-SP, and P-S-PE-EL consistently displayed lower BI values with minor variations among the samples. Particularly noteworthy is that P-S-PE-SP exhibited slightly lower BI values, indicating the efficacy of SP in preserving the activity of active ingredients during storage. Further analysis and comparison of the encapsulated and non-encapsulated samples was carried out subsequently based on the values of the activity of the enzyme responsible for the enzymatic browning, namely PPO.

Browning index (BI) of edible coated fresh-cut potato samples including potato-control (P-C/▲), potato starch-pectin coating (P-S-PE/●), potato starch-chitosan coating (P-S-CH/■), potato starch-pectin coating enriched with non-encapsulated REO and AA (P-S-PE-F/x), potato starch-pectin coating enriched with SP encapsulated REO/AA structures (P-S-PE-SP/Δ) and potato starch-pectin coating enriched with EL encapsulated REO/AA structures (P-S-PE-EL/○) at different time intervals

Enzymatic Activity

PPO is the enzyme responsible for the enzymatic browning of potatoes, as it catalyses the reactions that trigger this process. Τhe intensity of enzymatic browning increases by increasing the enzymatic activity, which is initiated by its contact with oxygen. This enzymatic activity increases over time as the enzyme constantly interacts with oxygen in the absence of an inhibitor, prolonging thus, the enzymatic browning and resulting in further deterioration of potatoes. The enzymatic activity of the control and the edible coated potato samples is presented in Fig. 6.

Enzymatic activity (unit PPO/g) of edible coated fresh-cut potato samples including potato-control (P-C/▲), potato starch-pectin coating (P-S-PE/●), potato starch-chitosan coating (P-S-CH/■), potato starch-pectin coating enriched with non-encapsulated REO and AA (P-S-PE-F/x), potato starch-pectin coating enriched with SP encapsulated REO/AA structures (P-S-PE-SP/Δ) and potato starch-pectin coating enriched with EL encapsulated REO/AA structures (P-S-PE-EL/○) at different time intervals

At 14 days of storage the following general trend of the enzymatic activity was observed: P-C> P-S-PE> P-S-PE-F> P-S-CH> P-S-PE-SP> P-S-PE-EL. In general, one of the main objectives of the application of edible films is their function as a protective barrier against gases, including oxygen. The plain starch-pectin coating was effective in retarding and reducing enzymatic browning, as P-S-PE samples demonstrated not only lower PPO activity values but also a lower rate of increase of enzymatic activity compared to the control sample. This is due to the fact that both starch and especially amylose, and pectin form films with almost zero permeability to oxygen, which plays an important role in enzymatic browning (Huber and Embuscado 2009). The result was consistent with the appearance and values of the colour parameters of the samples. Comparing the two neat coatings, P-S-CH samples showed the lowest PPO activity values since chitosan coatings exhibit moderate oxygen permeability.

The incorporation of AA and REO into the starch-pectin coating inhibited the action of PPO since AA is widely used as an antibrowning agent. Despite the fact that it may not directly interact with the enzyme, it has the ability to inhibit enzymatic browning by reducing oxidized substrates. Specifically, in the first stage, it may inhibit the hydroxylation reaction of monophenols to o-diphenols, which requires the presence of oxygen, or secondly it may reduce the formed o-quinones to their diphenol precursors (Arias et al. 2007; Moon et al. 2020). REO had a similar effect, enhancing the action of AA. The antioxidant compounds of essential oils can initially react with oxygen and then with all the other enzymatic browning mentioned intermediates. Also, antioxidants are able to limit the loss of AA, which is susceptible to degradation by oxygen (Yousuf et al. 2021).

Among P-S-PE-F, P-S-PE-EL, and P-S-PE-SP samples, the first-mentioned had higher enzymatic activity, which displayed a more significant increase from day 8 until the end of storage. This can be attributed to the controlled release of encapsulated antioxidants, achieved through both encapsulation methods, which extends their action during storage. Finally, the comparison of the encapsulation methods demonstrated that EL resulted in the lowest enzymatic activity, which remained approximately the same until the end of storage, while SP was also effective, but led to a slightly greater increase in PPO values in the last 4 days. Therefore, encapsulation by EL achieved a more controlled release over the total storage period.

Weight Loss

In food products, weight loss is the result of gas diffusion, driven by water vapour pressure (Maftoonazad and Ramaswamy 2019). It is worth to mention that weight loss is assumed to correspond exclusively to water loss, since other components that may be lost, such as aromas or flavours, and gaseous products of breath are practically undetectable in terms of weight (Olivas and Barbosa-Cánovas 2005). Water loss is determined by several factors with the most important being the resistance of the outer skin to the respiratory movement of water vapour. The removal of the protective skin and the reduction of the tissue volume (i.e., the increase in the surface-to-volume ratio) due to peeling and cutting, cause an increase in water loss in the product (Rocculi et al. 2009). Water loss is a major cause of structural changes in fresh-cut vegetables as it affects their texture. In Fig. 7, the weight loss of the processed fresh-cut potatoes compared to the control sample is presented.

Weight loss of edible coated fresh-cut potato samples including potato-control (P-C/▲), potato starch-pectin coating (P-S-PE/●), potato starch-chitosan coating (P-S-CH/■), potato starch-pectin coating enriched with non-encapsulated REO and AA (P-S-PE-F/x), potato starch-pectin coating enriched with SP encapsulated REO/AA structures (P-S-PE-SP/Δ) and potato starch-pectin coating enriched with EL encapsulated REO/AA structures (P-S-PE-EL/○) at different time intervals

As it can be seen, the rate of weight loss showed an increasing trend over time in all samples with the sequence of weight loss on the last day of storage being P-C> P-S-CH> P-S-PE-SP> P-S-PE> P-S-PE-EL> P-S-PE-F. Despite the fact that polysaccharides are a poor barrier against water vapour due to their hydrophilicity, it is observed that the application of both neat matrices led to smaller weight losses, compared to the control sample, which on the last day of storage had lost 5.10% of its original weight. This behaviour is justified by the fact that the application of a coating modifies the internal atmosphere of the food and determines its respiration rate, making the passage of gases and water vapour difficult, and thus slowing down the weight loss (Maftoonazad and Ramaswamy 2019). P-S-CH samples showed a higher final percentage of weight loss than P-S-PE due to the fact that chitosan-based membranes exhibit high water vapour permeability (Dhall 2013).

The samples with bioactive components exhibited smaller changes in their weight loss compared to P-C, P-S-PE, and P-S-CH. This is also observed in many similar studies of coated fresh-cut fruits and vegetables, where the samples with coatings that included essential oil, such as REO, showed lower weight loss. This fact is due to the hydrophobic character of essential oils, the presence of which in the form of an emulsion in coatings, mainly, strengthens their hydrophobic character leading to improved barrier characteristics of water vapours. Protection against moisture loss is very important in this case, as the coatings made of polysaccharides, starch and pectin, are poor barriers to water vapour. However, it is important to emphasize that the presence of REO simply slows down the weight loss and does not prevent it completely, since the loss of water vapour from the food product takes place in the hydrophilic part of the membrane. Therefore, the ratio of hydrophilic to hydrophobic or simply the concentration of the essential oil in the coating is of critical importance as it plays an important role in water vapour permeability (Yousuf et al. 2021).

Comparing the samples with free and encapsulated agents, namely P-S-PE-F, P-S-PE-EL, and P-S-PE-SP, the last mentioned showed higher moisture losses. This is explained by the fact that in P-S-PE-SP, the ratio of WPI:PUL matrices was 80:20, while P-S-PE-EL coating contained less WPI with the WPI:PUL ratio being equal to 30:70. Despite their excellent sensory, mechanical and oxygen barrier properties, WPI films are, in general, hydrophilic and sensitive to moisture adsorption, and, thus, represent poor vapour barrier to moisture (Dhall 2013).

Hardness

Figure 8 illustrates the modulus of elasticity of the samples during storage at 4 °C. Generally, a higher modulus of elasticity corresponds to increased hardness in the samples. According to the results, there was a decreasing trend in hardness during storage. This is primarily attributed to the mechanical cutting of potatoes, which disrupts the structure of their epidermal cell wall. This disruption leads to changes in the interlayer structure of the cells and degradation of cell wall material, resulting in tissue softening and water loss (Zhao et al. 2021). Specifically, alterations in the cell wall trigger the release of enzymes, such as pectinesterase, polygalactonourase, and β-galactosidase that react with substrates and accelerate the softening of the tissue. According to Fig. 8 and comparing the hardness among the various samples on the last day of storage, the hardness exhibited the following order: P-C > P-S-PE-SP > P-S-PE > P-S-CH > P-S-PE-EL > P-S-PE-F. Notably, P-C presented the higher hardness values possible due to the higher weight loss rate compared to the edible coated samples.

Hardness (E, N/mm2) of edible coated fresh-cut potato samples including potato-control (P-C/▲), potato starch-pectin coating (P-S-PE/●), potato starch-chitosan coating (P-S-CH/■), potato starch-pectin coating enriched with non-encapsulated REO and AA (P-S-PE-F/x), potato starch-pectin coating enriched with SP encapsulated REO/AA structures (P-S-PE-SP/Δ), and potato starch-pectin coating enriched with EL encapsulated REO/AA structures (P-S-PE-EL/○) at different time intervals

Comparing P-S-PE and P-S-CH, it appeared that pectin coating resulted in higher hardness values, closer to those of the control than chitosan. One possible justification for this observation is the immersion of P-S-PE in CaCl2 solution immediately after its immersion in the starch-pectin solution. Specifically, calcium ions interact with pectin polymers of the cell wall and bind them together to strengthen the cohesion among cells, creating a network that enhances the mechanical strength of the wall (Dhall 2013; Olivas and Barbosa-Cánovas 2005). The low hardness values of P-S-CH may be attributed to potential acid hydrolysis of cell walls during the preparation of the edible coating solution in the presence of acetic acid, leading to the degradation of the potato structure (Yousuf et al. 2021).

The incorporation of REO and AA in free or encapsulated form in the coatings did not increase hardness values; in fact, it had the opposite effect. The incorporation of essential oils or their components in edible coatings often leads to a decrease in hardness values, since the essential oils can reduce the mechanical tear strength due to structural discontinuities caused by the phase dispersed in the oil (Antunes et al. 2012). Similar results were noticed in the study of Raybaudi-Massilia et al. (2008) where the alginate coating containing essential oil had a negative effect on the hardness of fresh-cut melon, especially as the concentration of essential oil increased (Raybaudi-Massilia et al. 2008). The same finding was also in the work of Yousuf et al. (2021) where apple cubes coated with gellan gum with incorporated geraniol exhibited lower hardness values than other coating formulations without geraniol possibly due to the penetration of the oil into the cellular tissue and the creation of alterations in their structure (Yousuf et al. 2021).

Furthermore, P-S-PE-EL samples demonstrated a lower decrease rate of their initial hardness (0.35 N/mm2) compared to the other samples. Additionally, the hardness of P-S-PE-SP samples decreased at a slower rate than P-C, namely from 2.99 to 2.35 N/mm2, approaching the hardness values of P-C and P-S-PE. Thus, it can be concluded that although P-S-PE-SP and P-S-PE-EL coatings soften the tissues, they contribute to a more effective preservation of the initial hardness of the samples, likely attributed to their more effective retardation of ripening.

Microbiological Evaluation

The total microbial load, as well as the YM content of both coated and uncoated (control) fresh-cut potato samples, were tested at the middle (day 7) and at the end (day 14) of their storage. The calculated number of colonies in each plate (cfu) was divided with the weight of the potato sample and the final result is expressed in log (cfu/g potato), as shown in Table 7.

The samples were evaluated based on acceptable limits found in literature. Specifically, for food products with an extended shelf life that require refrigeration, the total microbial load is satisfactory below 106 cfu/g and marginally acceptable between 106 and 108 cfu/g, while higher values are rejected. Regarding YM content, their load should not exceed 105 cfu/g (Ali et al. 2021; Centre for Food Safety 2014; Levaj et al. 2023; Li et al. 2022). As anticipated, the microbial load for all tested microorganisms in the samples increased during storage. This phenomenon is particularly pronounced in minimally processed vegetables, such as fresh-cut potatoes, owing to the ample moisture and nutrients on their surface, creating an optimal environment for microbial growth (Rashid et al. 2021). The application of edible coatings exhibited a beneficial effect in inhibiting microbial growth compared to the control sample. This can be attributed to the creation of a modified atmosphere that influences the growth rate of both spoilage and pathogenic bacteria. Notably, the use of polysaccharide-based edible coatings has been selected due to their ability to control the release of food additives and protect sensitive compounds in coated foods (Cruz-Monterrosa et al. 2023; Kocira et al. 2021). Comparing P-S-PE and P-S-CH, it is evident that small yet significant differences were observed in the microbial load of the samples, with P-S-CH demonstrating enhanced microbial stability until the 7th day of storage. This fact can be attributed to the antimicrobial activity of chitosan. Notably, positively charged chitosan molecules interact with negatively charged microbial cell membranes causing a change in the microbial cell permeability and leading to leakage of cellular components (Huber and Embuscado 2009). The incorporation of AA/REO in both free and encapsulated form significantly enhanced the antimicrobial efficacy of the coatings. This enhancement can be attributed to the well-established antimicrobial properties of REO, as documented in various studies (Bashir et al. 2023; Choulitoudi et al. 2017). Additionally, AA, which is as an organic acid, exerts antimicrobial effects by lowering environmental pH, disrupting membrane transport, accumulating anions, or reducing intracellular pH through hydrogen ion breakdown (Ali et al. 2021).

Regarding the impact of encapsulation on the total microbial load, a heightened inhibition of the microorganisms’ growth was observed in the developed bioactive coatings. More specifically, P-S-PE-EL followed by P-S-PE-SP, emerged as the most effective in reducing initial microbial growth, with considerably enhanced performance in comparison to P-S-PE-F and untreated samples. Therefore, the controlled release of the encapsulated antimicrobial agents during storage, contributed significantly in lowering the total microbial content and prolonging the shelf life of fresh-cut potatoes.

The YM content emerged as a critical parameter, since fresh-cut potatoes are highly susceptible to fungal infection, resulting in a limited shelf life. The YM count significantly increased (p< 0.05) in all tested samples, with control samples displaying higher growth (1.85 to 4.27 log cfu/g). Coated samples exhibited lower YM content, attributed to the coating interacting with negatively charged phospholipid materials of fungal membranes. Comparative analysis between non-encapsulated and encapsulated bioactive coatings indicated that encapsulation resulted in lower YM growth, particularly pronounced on the 14th day of storage, confirming controlled and gradual release of the encapsulated component. Notably, P-S-PE-EL samples exhibited slightly lower YM content than P-S-PE-SP samples, likely due to the higher concentration of pullulan in the electrospun sample, known to be less assimilable as a carbon source by spoilage-causing bacteria, moulds, and fungi (Farris et al. 2014).

Conclusions

In summary, this study delved into the application of edible coatings with encapsulated antimicrobial and antibrowning agents to enhance the quality and shelf life of fresh-cut potatoes. The recovered polysaccharides from potato peels were used for the development of edible coatings, with pectin and chitosan as composite components. P-S-PE coating showed increased retention of all the quality characteristics studied compared to P-S-CH one. P-S-PE coating enriched with active ingredients consistently exhibited improved quality characteristics compared to P-S-PE and control samples. This indicates the effectiveness of REO/AA as antimicrobial/antioxidant agents in delaying potatoes’ deterioration during storage. The incorporation of encapsulated SP and EL REO/AA in the P-S-PE, especially when using EL as encapsulation technique, demonstrated a notable ability to effectively prevent enzymatic browning throughout the entire storage period, even up to the final day. Furthermore, the application of edible coating had a positive effect on inhibiting microbial growth compared to the control sample. The synergistic combination of edible coatings with bioactive ingredients successfully controlled spoilage microorganisms, consequently extending the shelf life of fresh-cut potatoes. The incorporation of REO/AA in both free and encapsulated form significantly boosted the antimicrobial efficacy of the coatings, with P-S-PE-EL demonstrating slightly better microbiological stability compared to P-S-PE-SP during storage. Ultimately, this comprehensive approach highlights the potential of edible coatings as an effective strategy for delaying deterioration and ensuring prolonged freshness in fresh-cut potatoes. This holistic strategy underscores the promise of edible coatings as a robust solution for retarding deterioration and ensuring extended shelf life in fresh-cut potatoes. Beyond enhancing product quality, the added value to the food industry lies in the potential to minimize food waste, meet consumer demand for premium-quality produce, and contribute to sustainable practices through the utilization of recovered polysaccharides and encapsulated active ingredients.

Abbreviations

- AA:

-

Ascorbic acid

- CCD:

-

Central composite design

- EL:

-

Electrospinning

- EE:

-

Encapsulation efficiency

- MAE:

-

Microwave-assisted extraction

- PPO:

-

Polyphenol oxidase

- P-C:

-

Potato control

- P-S-CH:

-

Potato starch-chitosan coating

- P-S-PE:

-

Potato starch-pectin coating

- P-S-PE-EL:

-

Potato starch-pectin coating enriched with EL encapsulated REO/AA structures

- P-S-PE-F:

-

Potato starch-pectin coating enriched with non-encapsulated REO and AA

- P-S-PE-SP:

-

Potato starch-pectin coating enriched with SP encapsulated REO/AA structures

- PUL:

-

Pullulan

- RSM:

-

Response surface methodology

- REO:

-

Rosemary essential oil

- SP:

-

Spray drying

- TPC:

-

Total plate count

- UMAE:

-

Ultrasound and microwave-assisted extraction

- UAE:

-

Ultrasound-assisted extraction

- WPI:

-

Whey protein powder

- YM:

-

Yeasts and moulds

References

Ainsworth EA, Gillespie KM (2007) Estimation of total phenolic content and other oxidation substrates in plant tissues using Folin-Ciocalteu reagent. Nat Protoc. https://doi.org/10.1038/nprot.2007.102

Ali MR, Parmar A, Niedbała G, Wojciechowski T, Abou El-Yazied A, El-Gawad HGA, Nahhas NE, Ibrahim MFM, El-Mogy MM (2021) Improved shelf-life and consumer acceptance of fresh-cut and fried potato strips by an edible coating of garden cress seed mucilage. Foods 10(7):1536. https://doi.org/10.3390/foods10071536

Arias E, González J, Oria R, Lopez-Buesa P (2007) Ascorbic acid and 4-hexylresorcinol effects on pear PPO and PPO catalyzed browning reaction. J Food Sci 72(8):C422–C429. https://doi.org/10.1111/j.1750-3841.2007.00484.x

Baldwin EA, Nisperos MO, Chen X, Hagenmaier RD (1996) Improving storage life of cut apple and potato with edible coating. Postharvest Biol Technol 9(2):151–163. https://doi.org/10.1016/S0925-5214(96)00044-0

Barbosa MIMJ, Borsarelli CD, Mercadante AZ (2005) Light stability of spray-dried bixin encapsulated with different edible polysaccharide preparations. Food Res Int 38(8–9):989–994. https://doi.org/10.1016/j.foodres.2005.02.018

Bashir O, Amin T, Hussain SZ, Naik HR, Goksen G, Wani AW, Manzoor S, Malik AR, Wani FJ, Proestos C (2023) Development, characterization and use of rosemary essential oil loaded water-chestnut starch based nanoemulsion coatings for enhancing post-harvest quality of apples var. Golden delicious. Curr Res Food Sci 7:100570. https://doi.org/10.1016/j.crfs.2023.100570

Calcio Gaudino E, Colletti A, Grillo G, Tabasso S, Cravotto G (2020) Emerging processing technologies for the recovery of valuable bioactive compounds from potato peels. Foods 9(11):1598. https://doi.org/10.3390/foods9111598

Castro Coelho S, Nogueiro Estevinho B, Rocha F (2021) Encapsulation in food industry with emerging electrohydrodynamic techniques: electrospinning and electrospraying – a review. In Food Chem. https://doi.org/10.1016/j.foodchem.2020.127850

Centre for Food Safety (2014) Microbiological guidelines for food (for ready-to-eat food in general and specific food items). Food and Environmental Hygiene Department, Hong Kong

CHA DS, CHINNAN MS (2004) Biopolymer-based antimicrobial packaging: a review. Crit Rev Food Sci Nutr 44(4):223–237. https://doi.org/10.1080/10408690490464276

Chanioti S, Tzia C (2017) Optimization of ultrasound-assisted extraction of oil from olive pomace using response surface technology: oil recovery, unsaponifiable matter, total phenol content and antioxidant activity. LWT Food Sci Technol 79:178–189. https://doi.org/10.1016/j.lwt.2017.01.029

Choulitoudi E, Ganiari S, Tsironi T, Ntzimani A, Tsimogiannis D, Taoukis P, Oreopoulou V (2017) Edible coating enriched with rosemary extracts to enhance oxidative and microbial stability of smoked eel fillets. Food Packag Shelf Life 12:107–113. https://doi.org/10.1016/j.fpsl.2017.04.009

Chronis M, Christopoulou VM, Papadaki S, Stramarkou M, Krokida M (2021) Optimization of mild extraction methods for the efficient recovery of astaxanthin, a strong food antioxidant carotenoid from microalgae. Chem Eng Trans 87:151–156. https://doi.org/10.3303/CET2187026

Cruz-Monterrosa RG, Rayas-Amor AA, González-Reza RM, Zambrano-Zaragoza ML, Aguilar-Toalá JE, Liceaga AM (2023) Application of polysaccharide-based edible coatings on fruits and vegetables: improvement of food quality and bioactivities. Polysaccharides 4(2):99–115. https://doi.org/10.3390/polysaccharides4020008

Antunes D, Gago CM, Cavaco AM, Miguel MG (2012) Edible coatings enriched with essential oils and their compounds for fresh and fresh-cut fruit. Recent Pat Food Nutr Agric 4(2):114–122. https://doi.org/10.2174/2212798411204020114

Dhall RK (2013) Advances in edible coatings for fresh fruits and vegetables: a review. Crit Rev Food Sci Nutr 53(5):435–450. https://doi.org/10.1080/10408398.2010.541568

Díaz-Montes E, Castro-Muñoz R (2021) Edible films and coatings as food-quality preservers: an overview. Foods 10(2):249. https://doi.org/10.3390/foods10020249

Dite Hunjek D, Pranjić T, Repajić M, Levaj B (2020) Fresh-cut potato quality and sensory: effect of cultivar, age, processing, and cooking during storage. J Food Sci 85(8):2296–2309. https://doi.org/10.1111/1750-3841.15353

Drosou CG, Krokida MK, Biliaderis CG (2017) Encapsulation of bioactive compounds through electrospinning/electrospraying and spray drying: a comparative assessment of food-related applications. In Drying Technology. https://doi.org/10.1080/07373937.2016.1162797

Drosou C, Krokida M, Biliaderis CG (2022) Encapsulation of β-carotene into food-grade nanofibers via coaxial electrospinning of hydrocolloids: enhancement of oxidative stability and photoprotection. Food Hydrocoll 133:107949. https://doi.org/10.1016/j.foodhyd.2022.107949

Fang C, Wang C, Xiong YL, Pomper KW (2007) Extraction and characterization of polyphenol oxidase in pawpaw (Asimina triloba) fruit. J Food Biochem 31(5):603–620. https://doi.org/10.1111/j.1745-4514.2007.00133.x

FAOSTAT, World Crops 2021. (2023). https://www.fao.org/statistics/en/

Farris S, Unalan IU, Introzzi L, Fuentes-Alventosa JM, Cozzolino CA (2014) Pullulan-based films and coatings for food packaging: present applications, emerging opportunities, and future challenges. J Appl Polym Sci 131(13). https://doi.org/10.1002/app.40539

Huber, K. C., & Embuscado, M. E. (Eds.). (2009). Edible films and coatings for food applications. Springer New York https://doi.org/10.1007/978-0-387-92824-1

Janmohammadi M, Nourbakhsh MS, Bonakdar S (2021) Electrospun skin tissue engineering scaffolds based on polycaprolactone/hyaluronic acid/L-ascorbic acid. Fibers Polym 22(1):19–29. https://doi.org/10.1007/s12221-021-0036-8

Kocira A, Kozłowicz K, Panasiewicz K, Staniak M, Szpunar-Krok E, Hortyńska P (2021) Polysaccharides as edible films and coatings: characteristics and influence on fruit and vegetable quality—a review. Agronomy 11(5):813. https://doi.org/10.3390/agronomy11050813

Krishnakumar T, Sajeev M (2017) Response surface optimization of bath type ultrasound-assisted extraction (UAE) of native starch from fresh cassava tubers. Adv Res 12(3):1–13. https://doi.org/10.9734/AIR/2017/37317

Kumari J, Nikhanj P (2022) Evaluation of edible coatings for microbiological and physicochemical quality maintenance of fresh cut papaya. J Food Process Preserv 46(10). https://doi.org/10.1111/jfpp.16790

Laina KM, Eleni PN, Krokida M (2022) Encapsulation of oregano essential oil for innovative feed applications, using electrohydrodynamic processing. Chem Eng Trans 93:103–108. https://doi.org/10.3303/CET2293018

Laina KM, Eleni PN, Tsitseli KG, Krokida MK (2021) Process design for the extraction of bioactive compounds from several Mediterranean medicinal plants. Chem Eng Trans 86:1327–1332. https://doi.org/10.3303/CET2186222

Levaj B, Pelaić Z, Galić K, Kurek M, Ščetar M, Poljak M, Dite Hunjek D, Pedisić S, Balbino S, Čošić Z, Dujmić F, Repajić M (2023) Maintaining the quality and safety of fresh-cut potatoes (Solanum tuberosum): overview of recent findings and approaches. Agronomy 13(8):2002. https://doi.org/10.3390/agronomy13082002

Li Y, Wu Z, Wan N, Wang X, Yang M (2019) Extraction of high-amylose starch from Radix Puerariae using high-intensity low-frequency ultrasound. Ultrason Sonochem 59:104710. https://doi.org/10.1016/j.ultsonch.2019.104710

Li Z, Zhao W, Ma Y, Liang H, Wang D, Zhao X (2022) Shifts in the bacterial community related to quality properties of vacuum-packaged peeled potatoes during storage. Foods 11(8):1147. https://doi.org/10.3390/foods11081147

Liu X, Wang T, Lu Y, Yang Q, Li Y, Deng X, Liu Y, Du X, Qiao L, Zheng J (2019a) Effect of high oxygen pretreatment of whole tuber on anti-browning of fresh-cut potato slices during storage. Food Chem 301:125287. https://doi.org/10.1016/j.foodchem.2019.125287

Liu X, Yang Q, Lu Y, Li Y, Li T, Zhou B, Qiao L (2019b) Effect of purslane (Portulaca oleracea L.) extract on anti-browning of fresh-cut potato slices during storage. Food Chem 283:445–453. https://doi.org/10.1016/j.foodchem.2019.01.058

Maftoonazad N, Ramaswamy HS (2019) Application and evaluation of a pectin-based edible coating process for quality change kinetics and shelf-life extension of lime fruit (Citrus aurantifolium). Coatings 9(5):285. https://doi.org/10.3390/coatings9050285

McGrance SJ, Cornell HJ, Rix CJ (1998) A simple and rapid colorimetric method for the determination of amylose in starch products. Starch - Stärke 50(4):158–163. https://doi.org/10.1002/(SICI)1521-379X(199804)50:4<158::AID-STAR158>3.0.CO;2-7

Moon KM, Kwon E-B, Lee B, Kim CY (2020) Recent trends in controlling the enzymatic browning of fruit and vegetable products. Molecules 25(12):2754. https://doi.org/10.3390/molecules25122754

Najafi Marghmaleki S, Mortazavi SMH, Saei H, Mostaan A (2021) The effect of alginate-based edible coating enriched with citric acid and ascorbic acid on texture, appearance and eating quality of apple fresh-cut. Int J Fruit Sci 21(1):40–51. https://doi.org/10.1080/15538362.2020.1856018

Oikonomopoulou V, Stramarkou M, Plakida A, Krokida M (2022) Optimization of encapsulation of stevia glycosides through electrospraying and spray drying. Food Hydrocoll 131. https://doi.org/10.1016/j.foodhyd.2022.107854

Olivas GI, Barbosa-Cánovas GV (2005) Edible coatings for fresh-cut fruits. Crit Rev Food Sci Nutr 45(7–8):657–670. https://doi.org/10.1080/10408690490911837

Rahimi BA, Hanumaiah S (2019) Effective edible coatings on control of microbial growth in strawberry fruits. Indian J Ecol 46(7):91–956. https://www.researchgate.net/publication/334130567

Rashid MH, Khan MR, Roobab U, Rajoka MSR, Inam-ur-Raheem M, Anwar R, Ahmed W, Jahan M, Ijaz MRA, Asghar MM, Shabbir MA, Aadil RM (2021) Enhancing the shelf stability of fresh-cut potatoes via chemical and nonthermal treatments. J Food Process Preserv 45(6). https://doi.org/10.1111/jfpp.15582

Raybaudi-Massilia RM, Mosqueda-Melgar J, Martín-Belloso O (2008) Edible alginate-based coating as carrier of antimicrobials to improve shelf-life and safety of fresh-cut melon. Int J Food Microbiol 121(3):313–327. https://doi.org/10.1016/j.ijfoodmicro.2007.11.010

Rocculi P, Romani S, Gomez F, Dalla Rosa M (2009) Effect of minimal processing on physiology and quality of fresh-cut potatoes, a review. Food 3:18–30

Sahraee S, Milani JM, Regenstein JM, Kafil HS (2019) Protection of foods against oxidative deterioration using edible films and coatings: a review. Food Biosci 32:100451. https://doi.org/10.1016/j.fbio.2019.100451

Saleem MS, Anjum MA, Naz S, Ali S, Hussain S, Azam M, Sardar H, Khaliq G, Canan İ, Ejaz S (2021) Incorporation of ascorbic acid in chitosan-based edible coating improves postharvest quality and storability of strawberry fruits. Int J Biol Macromol 189:160–169. https://doi.org/10.1016/j.ijbiomac.2021.08.051

Samuel O, Ogonna N, Ifeanyi O (2016) Isolation, characterization and identification of microorganisms from spoilt carrots obtained from Ose Market Onitsha, Nigeria. Univ J Biomed Eng 4(1):6–9. https://doi.org/10.13189/ujbe.2016.040102

Shen X, Zhang M, Devahastin S, Guo Z (2019) Effects of pressurized argon and nitrogen treatments in combination with modified atmosphere on quality characteristics of fresh-cut potatoes. Postharvest Biol Technol 149:159–165. https://doi.org/10.1016/j.postharvbio.2018.11.023

Soukoulis C, Bohn T (2018) A comprehensive overview on the micro- and nano-technological encapsulation advances for enhancing the chemical stability and bioavailability of carotenoids. Crit Rev Food Sci Nutr 58(1):1–36. https://doi.org/10.1080/10408398.2014.971353

Sreeja V, Jayaprabha KN, Joy PA (2015) Water-dispersible ascorbic-acid-coated magnetite nanoparticles for contrast enhancement in MRI. Appl Nanosci 5(4):435–441. https://doi.org/10.1007/s13204-014-0335-0

Stramarkou M, Oikonomopoulou V, Missirli T, Thanassoulia I, Krokida M (2020) Encapsulation of rosemary essential oil into biodegradable polymers for application in crop management. J Polym Environ. https://doi.org/10.1007/s10924-020-01760-5

Stramarkou M, Oikonomopoulou V, Panagiotopoulou M, Papadaki S, Krokida M (2023) Sustainable valorisation of peach and apricot waste using green extraction technique with conventional and deep eutectic solvents. Resources 12(6):72. https://doi.org/10.3390/resources12060072

Stramarkou M, Tzegiannakis I, Christoforidi E, Krokida M (2024) Use of electrospinning for sustainable production of nanofibers: a comparative assessment of smart textiles-related applications. Polymers 16(4):514. https://doi.org/10.3390/polym16040514

Su Y, Zhang M, Chitrakar B, Zhang W (2021) Reduction of oil uptake with osmotic dehydration and coating pre-treatment in microwave-assisted vacuum fried potato chips. Food Biosci 39:100825. https://doi.org/10.1016/j.fbio.2020.100825

Tan SX, Andriyana A, Lim S, Ong HC, Pang YL, Ngoh GC (2021) Rapid ultrasound-assisted starch extraction from sago pith waste (SPW) for the fabrication of sustainable bioplastic film. Polymers 13(24):4398. https://doi.org/10.3390/polym13244398

Vargas, M., Pastor, C., Albors, A., Chiralt, A., & Gonzalez-Martinez, C. (2009). Development of edible coatings for fresh fruits and vegetables : possibilities and limitations.

Wang N, Shi N, Fei H, Liu Y, Zhang Y, Li Z, Ruan C, Zhang D (2022) Physicochemical, structural, and digestive properties of pea starch obtained via ultrasonic-assisted alkali extraction. Ultrason Sonochem 89:106136. https://doi.org/10.1016/j.ultsonch.2022.106136

Wu S (2019) Extending shelf-life of fresh-cut potato with cactus Opuntia dillenii polysaccharide-based edible coatings. Int J Biol Macromol 130:640–644. https://doi.org/10.1016/j.ijbiomac.2019.03.022

Ying Z, Han X, Li J (2011) Ultrasound-assisted extraction of polysaccharides from mulberry leaves. Food Chem 127(3):1273–1279. https://doi.org/10.1016/j.foodchem.2011.01.083

Yousuf B, Wu S, Siddiqui MW (2021) Incorporating essential oils or compounds derived thereof into edible coatings: effect on quality and shelf life of fresh/fresh-cut produce. Trends Food Sci Technol 108:245–257. https://doi.org/10.1016/j.tifs.2021.01.016

Zhao S, Han X, Liu B, Wang S, Guan W, Wu Z, Theodorakis PE (2022) Shelf-life prediction model of fresh-cut potato at different storage temperatures. J Food Eng 317:110867. https://doi.org/10.1016/j.jfoodeng.2021.110867

Zhao Y, Bilbao-Sainz C, Wood D, Chiou B-S, Powell-Palm MJ, Chen L, McHugh T, Rubinsky B (2021) Effects of isochoric freezing conditions on cut potato quality. Foods 10(5):974. https://doi.org/10.3390/foods10050974

Acknowledgements

This research has been financed by the European Union – Next Generation EU in the context of the National Recovery and Resilience Plan (Greece 2.0) under the call 16971: RESEARCH - CREATE - INNOVATE (project code: TΑEDK-06186).

Funding

This study was funded by the European Union-Next Generation EU in the framework of the National Recovery and Resilience Plan (Greece 2.0) under the call ID 16971 “RESEARCH - CREATE – INNOVATE” [project code Τ2ΕΔΚ-03121 – project acronym: Fresh4ever].

Author information

Authors and Affiliations

Contributions