Abstract

Various edible polymers [sodium alginate, carboxyl methylcellulose, sodium oleate, liquid paraffin, pectin, pullulan, polyvinyl acetate, and shellac (SHE)] as potato-coating materials and their effect on extending the shelf life of potatoes when combined with an edible coating and UV-C irradiation treatments were evaluated. As a result of the characterization of the edible polymers, SHE was selected as the optimal coating material because it had the best moisture and light barrier properties. SHE coating successfully prevented the greening, respiration, and sprouting of potatoes caused by exposure to light and oxygen. Additionally, it reduced weight loss by inhibiting transpiration on the potato surface. While the SHE coating did not exhibit antimicrobial effects, a significant effect was observed when combined with UV-C irradiation. This study suggests the potential of combined treatment of SHE coating and UV-C irradiation in extending the postharvest quality of potatoes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Potatoes are the largest non-cereal food crop globally and rank as the world's fourth most important food crop, following rice, wheat, and maize (Zhang et al., 2017). They are rich in high-quality starch, protein, dietary fiber, vitamins, and minerals but low in calories (Raigond et al., 2023). Therefore, potatoes are not only used in various cuisines worldwide but also extensively utilized in numerous processed food products. However, due to their high moisture content, potatoes are susceptible to considerable weight loss through transpiration and respiration. They are also prone to sprouting due to respiratory activities and can experience greening when exposed to light, making storage challenging (Emragi et al., 2022). Accordingly, there is a demand for potato storage techniques for preventing or delaying such phenomena. Furthermore, potatoes are reported to be vulnerable to soft rot disease caused by Pectobacterium carotovorum, a soil microorganism. Pectobacterium carotovorum can invade the inner flesh of potatoes and cause cell tissue maceration and black rot lesions, seriously reducing the economic value of the potatoes (Cho et al., 2022; Park et al., 2023).

One of the possible approaches to prevent such deterioration in potato quality is the use of edible coating technology. An edible coating is defined as a thin layer applied to the surface of food using edible polymers such as carbohydrates, proteins, lipids, and their combinations. Edible coatings play a barrier role for food against humidity, various gases, light, and other contaminants, thereby contributing to the extension of food shelf life (Singh and Packirisamy, 2022). The effectiveness and functionality of edible coatings heavily rely on the characteristics of the chosen polymer materials. Hence, the most essential point is to select the optimal material considering whether its physical, chemical, and structural properties suit the food in question. Nevertheless, there have only been a few studies on applying edible coatings to potato tubers, as reported by Emragi et al. (2022).

However, simply applying an edible coating made only from neat polymers cannot effectively control the microorganisms originally attached to food. Therefore, many researchers have been using various essential oils to impart antimicrobial effects on edible coatings, such as lemongrass (Erceg et al., 2023) and oregano (Yang et al., 2023b) essential oils. However, since essential oils have an intense aroma, even adding a tiny amount may negatively impact the sensory quality of the food. Therefore, this study used UV-C irradiation instead of essential oil as an alternative method to control microorganisms. In addition, since UV-C radiation has the advantage of being safe because it does not leave harmful chemical residues on the surface of the treated food, it is approved legally for surface treatment of food in many countries, including South Korea (Yun et al., 2022).

The objectives of this study were as follows: (1) to analyze the physicochemical characteristics of eight types of edible coating materials; (2) to select one of the most suitable edible coating materials for application on potatoes and apply it to potatoes; (3) to investigate the combined effects of edible coating and UV-C irradiation treatment on the postharvest quality of potatoes.

Materials and methods

Coating materials

A total of eight materials were used to formulate edible coating solutions. Five of them, liquid paraffin (PAR; Daejung Chemicals and Metals Co., Ltd, Siheung, Korea), sodium oleate (OLE; Junsei Chemical Co., Ltd., Tokyo, Japan), pullulan (PUL; Hayashibara Co., Ltd., Okayama, Japan), polyvinyl acetate (PVA; Shanghai Aladdin Bio-Chem Technology Co., Ltd., Shanghai, China), and shellac (SHE; Excelacs Co., Ltd., Bangkok, Thailand), were selected because they are officially recognized as food coating materials by the Ministry of Food and Drug Safety (MFDS; Cheongju, Korea) notified could be used as a coating material for food.

The remaining three materials, sodium alginate (ALG; Daejung Chemicals and Metals Co., Ltd, Siheung, Korea), carboxyl methylcellulose sodium salt (CMC; Daejung Chemicals and Metals Co., Ltd, Siheung, Korea), and pectin (PEC; Daejung Chemicals and Metals Co., Ltd, Siheung, Korea), while not officially designated as coating material by the MFDS, were chosen due to their widespread use as edible coatings in numerous studies worldwide.

Other chemicals and reagents

5% (v/v) sodium hypochlorite solution and 70% (v/v) ethanol were purchased from Daejung Chemicals and Metals Co., Ltd. (Siheung, Korea) for the washing treatment of potatoes. Ethanol [99.5% (w/w)] for preparing the SHE coating solution was also purchased from Daejung Chemicals and Metals Co., Ltd. (Siheung, Korea). Methylene blue and methyl red, used for dyeing the edible coating solutions, were purchased from Nacalai Tesque Inc. (Kyoto, Japan) and Sigma-Aldrich Inc. (St. Louis, MO, USA), respectively. For microbial analyses, plate count agar (PCA) and crystal violet pectate (CVP) agar were purchased from Kisan Bio Co. (Seoul, Korea). Phosphate buffered saline (PBS) was purchased from Sigma-Aldrich Inc. (St. Louis, MO, USA).

Microbial strain

The Pectobacterium carotovorum (ATCC 15390) strain used to inoculate potatoes was obtained from the American Type Culture Collection (Manassas, VA, USA). The P. carotovorum strain was inoculated in a Luria–Bertani liquid medium and incubated aerobically at 30 °C until the final concentration of the bacterial solution was approximately 108 CFU/mL.

Preparation of potatoes

Fresh potatoes harvested between late June and early July 2022 in Korea were purchased from a supermarket in Seoul, Korea, and used for experiments. To disinfect the surface of the potatoes, they were washed several times with running tap water, submerged in 1% (w/w) sodium hypochlorite solution for 2 min, immersed in 70% (w/w) ethanol for 1 min, and then washed twice with sterilized distilled water (DW). Afterward, they were air-dried at room temperature (RT; 23 ± 1 °C).

Selection of optimal edible coating material candidates

Preparation of edible coating solutions and measurement of their viscosity

The coating solutions were prepared using the composition described in Table 1. SH was dissolved in 99.5% (v/v) ethanol at 70 °C for 1 h, and the other materials were dissolved in DW at 70 °C for 1 h. The viscosity of the coating solution was measured using a viscometer (LVDV-II + P; Ametek Brookfield Inc., Middleborough, MA, USA) equipped with a spindle at RT.

Coating treatment of potatoes and measurement of adherence rate of coating solution on them

The potatoes were immersed in each coating solution for 1 min, then taken out and placed on a mesh to allow the excess coating solution to drain off. Afterward, they were dried on a clean bench for 30 min, flipped upside down, and dried for an additional 30 min. Then, the potatoes were immersed in the coating solution again for 1 min and dried for 2 h, flipping them upside down every 30 min. The adherence rate of each coating solution on potatoes was calculated using Eq. (1):

where Wi is the initial weight (mg) of the potato before coating treatment and Wf is the final weight (mg) of the potato after coating treatment. Three replicates were used for each sample (n = 3).

Surface morphology of the coating layer on potatoes

To enhance the visibility of the coating layer, a 0.05% (w/w) methylene blue dye was added to all coating solutions except for PAR. PAR was exceptionally dyed with methyl red due to its hydrophobicity. The dyed coating solutions were applied to the potatoes as described in ‘Coating treatment of potatoes and measurement of adherence rate of coating solution on them’ section. The surface morphology of the coating layer applied to the potatoes was used to image using an optical microscope (BX43, Olympus Co., Ltd., Tokyo, Japan) with a digital camera (DP22, Olympus Co., Ltd., Tokyo, Japan). Images were captured at 40 × magnification using the CellSens imaging software (Version 1.12, Olympus Co., Ltd., Tokyo, Japan).

Contact angle of optimal edible coating material candidates

To analyze the affinity of ALG, CMC, PUL, and SHE coating solutions with the potato surface (peel), the contact angle of the coating on the pure potato peel was measured using a contact angle meter [Pheonix-MT(T); SEO Co., Suwon, Korea]. The specimen was a pure potato peel area of at least 20 × 10 mm2, and the inner flesh was removed as much as possible to flatten the specimen on the stage of contact angle meter. A droplet of coating solutions (1 μL) was formed at the tip of a syringe needle and carefully deposited onto the top of the surface of the pure potato peel at RT. The change in the contact angle of coating solutions was measured for 3 min immediately after dropping the droplet of coating solution on the surface of the pure potato peel.

Characteristics of optimal edible coating material candidates in the dry film state

Preparation of films

The coating solutions of ALG, PEC, PUL, and SHE were prepared by the same method described in ‘Preparation of edible coating solutions and measurement of their viscosity’ section. Then, 50 g of the coating solutions were cast into a circular petri dish (inner diameter of 138.5 mm; area of 14,800 mm2) (10,150; SPL Life Science Co., Ltd., Pocheon, Korea) and dried for 48 h at 25 °C in the incubator. The characteristics of dried films were measured after conditioning for more than 48 h in a thermo-hygrostat (C-CTHM2; Changshin Science Co., Seoul, Korea).

Water vapor permeability (WVP)

The WVP of films was measured using the cup method described in ASTM E96 (standard test methods for the gravimetric determination of water vapor transmission rate of materials). The films were cut into round shapes and placed onto cups containing CaCl2. Subsequently, the cups were sealed with the lids having a circular hole (diameter of 45 mm; area of 0.00159 m2) at the center. The assembled cups were weighed and stored in the thermo-hygrostat (C-CTHM2; Changshin Science Co., Seoul, Korea) at 25 °C and 50% relative humidity (RH) for 24 h. Afterward, the final weight of the cups was measured, and the WVP of the films was calculated using Eq. (2):

where ∆W is the weight difference (g) of the cup before and after 24 h of storage in the thermo-hygrostat; X is the thickness of the film (mm); A is the testing area of the film (m2); T is the storage time (day); ∆P is the partial pressure difference across the film (atm). Tests were replicated thrice (n = 3).

Mechanical properties

The films were cut into 15 × 100 mm2 pieces. The tensile strength, elongation at break, and Young’s modulus of the films were evaluated using an Instron universal tester (Instron 3666; Instron Engineering Corp., Norwood, MA, USA) according to ASTM D882-02. The operating parameters were set as follows: grip distance, 50 mm; cross-head speed, 60 mm/min. Tests were replicated thrice (n = 3).

Light barrier properties

The light barrier properties of the film were evaluated by their transmittance using a UV–Vis spectrometer (Evolution 60, Thermo Fisher Scientific, Middlesex County, MA, USA) at wavelengths ranging from 200 to 700 nm with an interval of 1 nm.

Application of edible coating and UV-C irradiation treatment on potatoes

Preparation of potatoes treated with an edible coating or a combination of edible coating and UV-C irradiation

The potatoes were prepared using the method described in ‘Preparation of potatoes’ section. Next, to prepare potatoes treated with a combination of edible coating and UV-C irradiation, the inoculated potatoes were placed inside the biosafety cabinet equipped with two UV-C lamps (G40T10, Sankyo denki, Hiratsuka, Japan) at a distance of approximately 50 cm from the samples. The wavelength of the UV-C lamp was 254 nm and the power was 40 W per piece. After UV-C irradiation treatment, the samples were coated with ALG and SHE, according to the method described in ‘Coating treatment of potatoes and measurement of adherence rate of coating solution on them’ section. Potatoes that were only inoculated without any edible coating or combined edible coating and UV-C irradiation treatment were considered control samples. Samples were packaged in six per perforated plastic bag (150 × 360 mm2) and the ends of the bags were sealed with the twist tie, following the packaging method commonly used for small-packaged potatoes in Korea. To simulate the environment of a vegetable display stand in a supermarket, the bags were stored in a space with incandescent lights installed, maintaining the temperature at RT with a 40% RH.

Visual appearance

Potatoes were photographed using a digital camera (IXUS 285 HS; Canon Inc., Tokyo, Japan). All pictures were taken against a black background in a photo box (Daehan Co., Osan, Korea) with a light source.

Instrumental color

The surface color of the potatoes after the storage period of 0, 3, 7, and 11 days was measured using a colorimeter (CR-400; Konica Minolta Sensing, Inc., Osaka, Japan) according to the CIELAB color space. Calibration was performed with a standard white plate (L* = 97.55, a* = 5.22, and b* = − 3.86) and the color of each sample was calculated as the average of the measured values at three points.

The total color difference (\(\Delta\)E*) between the potatoes on day 0 and potatoes on other storage day x (3, 7, or 11) within the same treatment group was calculated using Eq. (3).

where \({\Delta L}^{*}={{L}^{*}}_{day x}-{{L}^{*}}_{day 0}\), \({\Delta a}^{*}={{a}^{*}}_{day x}-{{a}^{*}}_{day 0}\), and \({\Delta b}^{*}={{b}^{*}}_{day x}-{{b}^{*}}_{day 0}\).

Respiratory quotient

The respiratory quotient of the potatoes after the storage period of 0, 3, 7, and 11 days was measured. Each potato sample was placed in a glass jar (900 mL) and the upper part was closed with a lid with a rubber septum for penetration with a needle for the gas analyzer. The jars were then stored in an incubator at 25 °C for 48 h. Then, the CO2 concentrations of the headspace in the jar were measured using a gas analyzer (GS6600; Systech Illinois, Johnsburg, IL, USA). The respiratory quotient was calculated with Eq. (4):

where \({V}_{{CO}_{2}}\) is the volume (mL) of generated CO2; T is the storage time (h); W is the sample weight (kg). All tests were replicated thrice.

Weight loss

The weight loss of potatoes after the storage periods of 0, 3, 7, and 11 days was assessed based on the comparison of the weight of treated samples in their initial condition and final condition. The percentage of weight loss was calculated by the following Eq. (5):

where Wi is the initial weight (g) of potatoes and Wf is the final weight (g) of potatoes.

Inoculation of P. carotovorum in potatoes and analysis of their microbial counts

Potatoes inoculated with microorganisms were analyzed for a maximum of 3 days because they could not be stored for 11 days due to rapid decay, and samples were prepared separately as follows: The Potatoes pretreated using the method described in ‘Preparation of potatoes’ section. were punctured with a sterilized steel rod to create a wound (3 mm in diameter; 5 mm deep). Next, 10 μL of P. carotovorum solution was dropped into the wound, resulting in a final population of 106 CFU/sample. Then, the inoculated samples were dried in a laminar flow biosafety cabinet for 1 h to facilitate the attachment of P. carotovorum to the wound of the potatoes. Then, inoculated potatoes were treated with an edible coating or a combination of edible coating and UV-C irradiation according to the method described in ‘Preparation of potatoes treated with an edible coating or a combination of edible coating and UV-C irradiation’ section. The packaging and storage methods of potatoes also followed the procedure described in this section.

The microbial counts of the potatoes after the storage period of 0, 12, 24, 48, and 72 h were evaluated. Each whole potato was placed into the sterilized stomacher bag with a filter containing 80 mL of 0.2% (w/v) peptone water and homogenized for 3 min using a stomacher (HG400V, Mayo International Srl., Novate Milanese, Italy). The filtrate was serially diluted with PBS solution and spread on the PCA and CVP plates for the counting of total aerobic bacteria and P. carotovorum populations, respectively. The plates were incubated at 30 °C for 24 h and microbial counts were determined as the log of colony-forming units (CFU) per gram of potato.

Statistical analysis

Statistical analyses were performed using the Statistical Package for the Social Sciences (SPSS) software (version 26.0; SPSS Inc., Chicago, IL, USA). Significant differences (P ≤ 0.05) among the samples were determined based on a one-way analysis of variance, followed by Duncan’s multiple range test.

Results and discussion

Selection of optimal edible coating material candidates

Viscosity of edible coating solutions and their adherence rate on potatoes

As shown in Table 1, the viscosity of edible coatings varied according to materials and concentrations. The ALG, CMC, and PEC coating solutions tended to increase the adhesion rate as the viscosity of the coating solution increased. These results indicate a positive correlation between viscosity and adherence rate in the coating solution prepared from the same materials. Therefore, one of the methods for controlling the coating layer thickness of materials used in this study through the dip-coating treatment was to adjust the viscosity of the coating solution (Wigati et al., 2023). The viscosity of OLE and SHE was 0 cP. Due to its extremely low viscosity, the OLE coating solution quickly flowed off the surface of the potatoes during the dip-coating treatment, preventing effective adhesion. Therefore, the adherence rate of the OLE coating solution was relatively lower than those of other solutions of the same concentration (10%, w/v).

Meanwhile, despite having the same viscosity of 0 cP as the OLE coating solution, the SHE coating solution exhibited an adherence rate approximately 3.3 times higher than that of the OLE coating solution. This was because the solvent used in the SHE coating solution was ethanol with high volatility, which led to the instantaneous drying and adhesion of the SHE coating solution as soon as it came into contact with the surface of the potatoes. Meanwhile, the viscosity of the 5% ALG, 3% CMC, and PVA coating solutions could not be assessed due to their viscosities exceeding the measuring range of the used viscometer.

Surface morphology of the coating layer on potatoes

The surface morphology of the coating layer on potatoes to evaluate the wettability of the coating layer was analyzed (Fig. 1A). Wettability is defined as the ability of liquid materials to spread on a solid surface (Tavassoli-Kafrani et al., 2022). When the concentration of the ALG coating solution was 1% (w/v), it was not adequately applied to the potato surface, leaving parts of the exposed skin. At a concentration of 3% (w/v), the ALG coating solution adhered uniformly to the potato surface. However, at a concentration of 5% (w/v), an excessive amount of thick coating solution was attached and took a long time to dry. For the same reason, 2% (w/v) for CMC and 5% (w/v) for PEC coating solutions were evaluated as the optimal concentrations. OLE was deemed unsuitable as a coating material because a small amount adhered to the potato surface due to its low viscosity. PAR is a lipid that is liquid at RT because it has a very low melting temperature below RT. Therefore, the PAR coating solution did not solidify or dry after the dip-coating treatment. This property can contaminate the potato packaging and cause problems when the coating solution is stained with the consumer’s hands. Accordingly, PAR was also considered unsuitable as a coating material. The PUL and SHE coating solutions formed an even and moderately thick coating layer on the surface of the potatoes. Meanwhile, PVA non-uniformly aggregated on the potato surface, making it unsuitable for coating. As a result, four materials—ALG (3%, w/v), CMC (2%, w/v), PUL (10%, w/v), and SHE (10%, w/v)—were selected as candidate materials for optimal edible coating material selection [Hereafter, they are mentioned only by their material name (ALG, CMC, PUL, and SHE) without their concentrations].

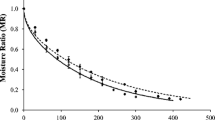

A Surface morphology of the ALG, CMC, OLE, PAR, PEC, PUL, PVA, and SHE coating layers on potatoes, B changes in the contact angle of the ALG, CMC, and PUL coating solutions on the surface of potatoes over time, and C light transmittance of the ALG, CMC, PUL, and SHE films at the 200–700 nm wavelengths. ALG sodium alginate, CMC carboxyl methylcellulose, OLE sodium oleate, PAR liquid paraffin, PEC pectin, PUL pullulan, PVA polyvinyl acetate, SHE shellac

Contact angle of optimal edible coating material candidates

The contact angle of the four coating solutions (ALG, CMC, PUL, and SHE) on the pure potato peel was measured to analyze the affinity of the coating solutions to the potato surface (Fig. 1B). The potato peel is formed of rough cork-like structure (Vulavala et al., 2019). Therefore, it is easier to apply the coating solution than fruits and vegetables having a smooth wax layer, such as paprika, zucchini, eggplant, apple, and plum. As the contact angle value of the coating solutions on the potato surface decreased, the affinity between the coating solutions and the potato surface increased. In the case of the SHE solution, the contact angle could not be measured because the droplet on the pure potato peel did not maintain a liquid state. This was due to the ethanol used as the solvent in the SHE solution, which evaporated and dried immediately after the droplet was attached to the pure potato peel.

The contact angle values of the ALG, CMC, and PUL coating solutions gradually decreased over time. These values sharply decreased during the first 60 s, since the coating solutions were absorbed or diffused on the surface (Farris et al., 2011). The increment order in the contact angle was CMC > ALG > PUL. This suggests that PUL exhibits the highest affinity for the potato surface among the coating solutions, while CMC shows the lowest affinity. However, all materials were found suitable as coating materials for potatoes because they did not exhibit dewetting on the potato surface or shrinkage and cracking of the coating upon drying.

Characteristics of optimal edible coating material candidates in the dry film state

Water vapor permeability (WVP)

One of the purposes of edible coatings is to extend the shelf life of food by forming a membrane on the food surface to prevent moisture evaporation. Therefore, edible coatings require low water vapor permeability (Lee et al., 2020). WVP was lowest in the order of SHE < PUL < CMC < ALG (Table 2). SHE is a purified hard resin having high hydrophobicity secreted by insects. It has superior water vapor barrier properties compared to films composed of polysaccharides or proteins (Song et al., 2022). Accordingly, SHE showed the best water vapor barrier properties among all coating solutions. PUL is a water-soluble exopolysaccharide obtained from the fungi, Aureobasidium pullulans (Wani et al., 2021). CMC is also a hydrophilic substance obtained by chemically modifying natural cellulose to enhance its solubility and has a very high water affinity (Yang et al., 2023a). ALG is one of the most plentiful marine polysaccharides extracted from brown seaweed (Qiang et al., 2022). ALG has excellent film-forming capacity. However, being a hydrophilic biopolymer, its susceptibility to water has restricted its widespread application.

The weight loss of potatoes leads to major losses in quality and commercial value. Therefore, weight loss must be prevented during potato storage and distribution. The most desirable material in terms of moisture barrier properties is SHE. Hence, coating potatoes with SHE is likely to suppress weight loss due to evaporation and sweating compared to coating with other materials.

Mechanical properties

ALG, CMC, and PUL films showed relatively higher TS and YM compared to SHE films (Table 2). These findings suggest that they possess excellent structural durability and integrity, making them suitable not only as coating materials but also as film materials offering resistance to external impacts. However, their EAB value was remarkably and significantly lower (P < 0.5) than that of the SHE film, which exhibited characteristics opposite those of the other three films. It had the lowest TS and YM of all films, but the highest EAB.

SHE is a hard resin with crystalline characteristics that is formed by chain-to-chain ester linkages. Therefore, the SHE film has brittleness, which induces a lack of durability and integrity (The et al., 2008). However, the SHE film had a significantly higher (P < 0.5) EAB than the other films. EAB indicates the level of flexibility. Based on the fact that edible coating should possess enough flexibility to accommodate particular morphological changes, such as physical damage caused by the collision between co-packaged fruits or vegetables and shrinkage due to moisture evaporation, the high EAB of SHE film could play a positive role when applying the coating to potatoes (Pham et al., 2023).

Light barrier properties

When potatoes are exposed to light during storage, chlorophyll and α-solanine are generated through photosynthesis (Xiong et al., 2022). If the edible coating layer on the potatoes has light barrier properties, the greening of coated potatoes can be inhibited. Chlorophyll causes the surface greening of the potatoes, and there is a positive correlation between the amount of chlorophyll and α-solanine production. Therefore, the degree of greening is also considered proportional to the amount of α-solanine generated (Shen et al., 2022). α-Solanine is a glycoalkaloid that acts as a protective metabolite, shielding potatoes from insects, viruses, and bacteria. However, α-solanine is poisonous to humans and negatively impacts the taste of the potato. In addition to the green parts of potatoes, α-solanine is also contained in considerable amounts in the sprouts (Okada and Matsuo, 2023). Therefore, the green or sprouted parts must be removed during potato processing; this leads to the wastage of raw materials.

Since all four (ALG, CMC, PUL, and SHE) coating layers were transparent, expecting effective light barrier properties was challenging. However, it was determined that they would possess a certain level of light barrier properties due to their physical thickness. Therefore, their light barrier properties were analyzed based on the range of light wavelengths (Fig. 1C). Chlorophylls a and b, used for photosynthesis, have been reported to absorb light at the 450–475 nm and 630–675 nm wavelengths, respectively (Kim et al., 2013). The light transmittance of the films in the wavelengths of 450–475 nm was in the following order: PUL > CMC > ALG > SHE. The light transmittance of SHE film, which showed the lowest in this range, was 80 to 84%, and the remaining materials were 85 to 90%. Meanwhile, the light transmittance in 630–675 nm wavelengths was about 90% in all films. As expected, these values were not exceptionally low. However, considering that the transmittance of uncoated (control) potatoes was 100%, it was concluded that coated potatoes could be expected to exhibit at least 10% or higher light barrier properties compared to the control potatoes. Accordingly, it was possible to predict that the photosynthesis of coated potatoes would also be inhibited compared to control potatoes.

Consequently, among the four optimal edible coating material candidates (ALG, CMC, PUL, and SHE), SHE, which had the best water vapor and light barrier properties, was selected as the optimal edible coating material and applied in potatoes. Of the four candidates of optimal edible coating material, ALG, which exhibited the lowest water vapor property, was chosen as the negative control for the potato application experiment.

Application of edible coating and UV-C irradiation treatment on potatoes

Visual appearance

Figure 2 shows the appearance of coated potatoes during a storage time of 11 days. The coated potatoes were glossy, while the control potatoes were matte. The potatoes treated with an edible coating and a combination of UV-C irradiation and the edible coating did not show a greening phenomenon during storage. However, control potatoes began to exhibit greening from day 3 of storage. These results indicate that the reduced light transmission into the potatoes by the ALG and SHE coating layers downregulated photosynthesis. As a result, a greening of coated potatoes was prevented during the storage period compared to control potatoes. In addition, potatoes treated with an edible coating and a combination of UV-C irradiation and edible coating did not sprout during the storage period.

Changes in the visual appearance of potatoes according to storage time. Control potatoes without both UV-C irradiation and coating treatments, SHE shellac-coated potatoes, UV-C/SHE potatoes coated with shellac after UV-C irradiation, ALG alginate-coated potatoes, UV-C/ALG potatoes coated with alginate after UV-C irradiation

In contrast, control potatoes showed sprouting from day 7; it was confirmed that the edible coating treatment reduced greening and sprouting. Emragi et al. (2022) also reported that a zein-based edible coating retarded sprouting in potatoes compared to the control over eight weeks. However, no visual differences were observed between the potatoes treated with an edible coating alone and those treated with a combination of UV-C irradiation and edible coating.

The SHE and UV-C/SHE potatoes maintained excellent appearance quality without decay during the whole storage period. However, the ALG and UV-C/ALG potatoes showed decay and black discoloration with an unacceptable odor from day 7. The cause of decay in ALG and UV-C/ALG potatoes may be an insufficient O2 supply to potatoes coated with alginate, a material with high O2 barrier properties. When fruits and vegetables are coated with a material having excessively high O2 barrier properties, gas exchange is suppressed, restricting the influx of O2 into the fruits and vegetables. Through this, the fruits and vegetables may suffocate and decay (Banks et al., 1997). In addition, the depletion of endogenous O2 and increased CO2 caused by excessive gas exchange restrictions result in anaerobic and off-flavor production. Therefore, the O2 concentration in the potato storage environment is one of the critical factors determining potato quality.

Maintaining a minimum of 1–3% O2 around a commodity is essential to prevent a transition from aerobic to anaerobic respiration. This ensures no depletion of O2 or excessive buildup of CO2 (Dhall, 2013). O2 permeability of the ALG and SHE films was reported as 0.507 (Jost et al., 2014) and 230 cm3·mm/m2·day·atm (Hagenmaier and Shaw, 1991), respectively. As such, the O2 barrier properties of ALG are too high for it to be used as an edible coating material for fruits and vegetables. Therefore, when ALG was applied to potatoes as a coating material, it blocked the contact between potatoes and O2, inhibiting sprouting but promoting decay.

Instrumental color

The changes in instrumental color parameters L*, a*, b*, and ΔE* of potatoes according to storage period were presented in Table 3. Control potatoes showed a tendency of decreased L*, a*, and b* values during the storage period. These results indicate that the control potatoes became darker, greener, and bluer over time. Especially, the a* value of the control potatoes steadily decreased throughout the storage period, and after 11 days, it decreased to more than half of the initial value at day 0. This meant that a severe greening phenomenon occurred in the control potatoes without an outer barrier layer, as described in ‘Visual appearance’ section.

Meanwhile, there were few or no fluctuations in the a* values of SHE, UV-C/SHE, ALG, and UV-C/ALG throughout the storage period. This indicated that the edible coating treatment effectively prevented light from penetrating the potatoes. Greening negatively impacts consumers' willingness to buy potatoes in retail stores (Tanios et al., 2018). Accordingly, the anti-greening effect of the edible coating treatment is an encouraging result in the potato industry. Like this, the coated potatoes showed apparent differences from the control potatoes in instrumental color parameters. However, no distinct difference was observed between the coated potatoes and the potatoes treated with a combination of UV-C irradiation and edible coating.

The L* value of the ALG and UV-C/ALG significantly decreased (P < 0.5) within the storage period, and from day 7, they began to exhibit significantly lower (P < 0.5) values compared to other samples. These results support the statement in ‘Visual appearance’ section that the ALG and UV-C/ALG potatoes started to decay and turned black from day 7.

The rate of increase in ΔE* during the entire storage period was in the following order: ALG > UV-C/ALG > control > SHE > UV-C/ALG. Considering that ΔE* is one of the quality indicators for crops, and lower values are preferable, these results suggested that UV-C/ALG potatoes had the best quality stability among all samples.

Respiratory quotient

The respiratory quotient of all samples increased with storage time (Fig. 3A). In addition, except for UV-C/ALG potatoes on day 11, all other samples showed a significantly lower (P < 0.5) respiratory quotient than control potatoes throughout the entire period. The lower respiratory quotient of SHE and UV-C/SHE potatoes indicated the inhibitory effect of SHE coating on potato respiration. The differences in respiratory quotient between SHE and UV-C/SHE, as well as between ALG and UV-C/ALG, indicated that UV-C irradiation increases the respiratory quotient of potatoes. Fruits and vegetables can increase respiration quotient after exposure to abiotic stresses, including UV stress (Duarte-Sierra et al., 2020). Allende and Artés (2003), Duarte-Sierra et al. (2020), and Li et al. (2022) also reported an increase in the respiratory quotient compared to the control group (non-UV irradiated samples) when UV irradiation was applied to lettuce, broccoli, and peaches, respectively.

A Changes in the weight loss of potatoes according to storage time. Data are expressed as mean ± standard deviation of three replicates (n = 3). Different uppercase letters (A–D) indicate significant differences (P < 0.05) among the samples at the same storage time analyzed by Duncan's multiple range tests. Different lowercase letters (a–d) indicate significant differences (P < 0.05) among the same samples with different storage times analyzed by Duncan's multiple range tests, B changes in the respiratory quotient of potatoes according to storage time. Data are expressed as mean ± standard deviation of three replicates (n = 3). Different uppercase letters (A–C) indicate significant differences (P < 0.05) among the samples at the same storage time analyzed by Duncan's multiple range tests. Different lowercase letters (a–c) indicate significant differences (P < 0.05) among the same samples with different storage times analyzed by Duncan's multiple range tests, changes in C total aerobic bacterial and D Pectobacterium carotovorum counts of potatoes according to storage time. Data are expressed as mean ± standard deviation of three replicates (n = 3). Different lowercase letters (a–e) indicate significant differences (P < 0.05) among the samples at the same storage time analyzed by Duncan's multiple range tests. The data grouped in the yellow box indicate that they belong to the same statistical group. Control potatoes without both UV-C irradiation and coating treatments, SHE shellac-coated potatoes, UV-C/SHE potatoes coated with shellac after UV-C irradiation, ALG alginate-coated potatoes, UV-C/ALG potatoes coated with alginate after UV-C irradiation

Meanwhile, as described in ‘Visual appearance’ section, ALG possesses higher oxygen barrier properties than SHE. Nevertheless, on day 11, the ALG and UV-C/ALG potatoes showed a significantly higher (P < 0.5) respiration quotient than the SHE and UV-C/SHE potatoes. This phenomenon was caused by the suffocation of ALG and UV-C/ALG potatoes due to the excessively excellent oxygen barrier properties of the ALG coating layer (Banks et al., 1997; Sáenz-Baños et al., 2022). As a result, anaerobic respiration and the decay of potatoes were accelerated, resulting in increased CO2 generation (Pinhero et al., 2009).

Potatoes must be supplied with an appropriate amount of O2, and the excessive accumulation of CO2 should be prevented during storage. Accordingly, warehouses that store potatoes in large quantities are periodically ventilated to avoid O2 depletion and potato packaging materials are perforated to induce ventilation. In summary, SHE coating treatment was effective in reducing the respiration quotient of potatoes, whereas UV-C irradiation treatment and ALG coating treatment had a negative impact.

Weight loss

The effect of reducing weight loss in potatoes compared to control potatoes was observed in the SHE and UV-C/SHE potatoes, but not in the ALG and UV-C/ALG potatoes (Fig. 3B). As previously described in Section ‘Water vapor permeability (WVP)’, SHE has higher water vapor barrier properties than ALG. Therefore, SHE potatoes showed less weight loss compared to control potatoes by effectively suppressing transpiration on the potato surface. In contrast, ALG coating has poor moisture barrier properties, and much weight loss occurs in ALG potatoes due to water vapor evaporation. Even the ALG and UV-C/ALG potatoes had a significantly higher (P < 0.5) weight loss than the control potatoes. As described in ‘Respiratory quotient’ section, this can be interpreted as the result of increased moisture evaporation due to the acceleration of anaerobic respiration and decay of potatoes due to the excessively high O2 barrier properties of ALG. The control potatoes exhibited lower weight loss than ALG and UV-C/ALG potatoes but higher weight loss than SHE and UV-C/SHE potatoes. As shown in Fig. 2 of ‘Visual appearance’ section, the control potatoes germinated on the seventh day of storage. Since sprouts have 100 times higher moisture permeability than the rest of the potato surface, germination would have influenced weight loss (Jaiswal et al., 2023). Meanwhile, there is no significant difference (P < 0.5) between SHE and UV-C/SHE potatoes and ALG and UV-C/ALG potatoes. These results indicate that UV-C irradiation does not affect the weight loss of potatoes.

Microbial population

Both populations of total aerobic bacteria (Fig. 3C) and P. carotovorum (Fig. 3D) showed the following order pattern during the 72 h storage period: Control > ALG > SHE > UV-C/ALG > UV-C/SHE. UV-C/SHE and UV-C/ALG irradiated with UV-C showed significantly lower (P < 0.5) numbers of microbial counts than other samples due to the antimicrobial effect of UV-C irradiation (Kim et al., 2022). The microbial counts of UV-C/SHE were significantly lower (P < 0.5) than those of UV-C/ALG throughout the entire storage period. As mentioned in ‘Respiratory quotient’ section, this phenomenon can be interpreted as the result of promoting anaerobic respiration and decaying in potatoes coated with ALG because contact with O2 is blocked.

SHE and ALG potatoes showed significantly lower counts of P. carotovorum than the control throughout all storage days. However, at 72 h of storage, the total aerobic bacterial count of SHE was not significantly different (P ≥ 0.5) from, and that of ALG was significantly higher (P < 0.5) than, that of the control. These results suggest that the antibacterial effect cannot be expected only by coating treatment with a neat polymer. As a result, it was confirmed that the combination of edible coating and UV-C irradiation on potatoes could delay both microbiological and physicochemical deterioration.

This study demonstrates that SHE coating treatment can prolong the postharvest quality of potatoes and, when combined with UV-C irradiation treatment, effectively reduces microbial counts in potatoes. Potatoes treated with SHE coating and a combination of UV-C irradiation and SHE coating did not experience greening and sprouting during storage. In contrast, control potatoes (without UV-C irradiation and coating treatments) showed greening and sprouting starting on days 3 and 7, respectively. Changes in the color parameter values of potatoes with storage period were also restrained by SHE coating, which positively affected the postharvest quality of potatoes. In addition, SHE-coated potatoes showed a lower respiratory quotient than the control potatoes during the entire storage period. SHE-coated potatoes demonstrated reduced weight loss compared to the control potatoes through the effective inhibition of transpiration on the potato surface by the SHE coating layer. Although the SHE coating itself did not show notable antimicrobial properties, a superior effect was observed when combined with UV-C irradiation. Therefore, it was concluded that the combined treatment of SHE coating and UV-C irradiation could contribute to extending the postharvest shelf-life of potatoes by preventing physical, chemical, and biological changes and deterioration.

References

Banks NH, Cutting JGM, Nicholson SE. Approaches to optimising surface coatings for fruits. New Zealand Journal of Crop and Horticultural Science. 25: 261-272 (1997)

Cho E-R, Kim J-Y, Oh S-W, Kang D-H. Inactivation of Pectobacterium carotovorum subsp. Carotovorum and Dickeya chrysanthemi on the surface of fresh produce using a 222 nm krypton–chlorine excimer lamp and 280 nm UVC light-emitting diodes. LWT. 165: 113710 (2022)

Dhall RK. Advances in edible coatings for fresh fruits and vegetables: a review. Critical Reviews in Food Science and Nutrition. 53: 435-450 (2013)

Duarte-Sierra A, Hasan SMM, Angers P, Arul J. UV-B radiation hormesis in broccoli florets: glucosinolates and hydroxy-cinnamates are enhanced by UV-B in florets during storage. Postharvest Biology and Technology. 168: 111278 (2020)

Emragi E, Kalita D, Jayanty SS. Effect of edible coating on physical and chemical properties of potato tubers under different storage conditions. LWT. 153: 112580 (2022)

Erceg T, Šovljanski O, Stupar A, Ugarković J, Aćimović M, Pezo L, Tomić A, Todosijević M. A comprehensive approach to chitosan-gelatin edible coating with β-cyclodextrin/lemongrass essential oil inclusion complex—characterization and food application. International Journal of Biological Macromolecules. 228: 400-410 (2023)

Hagenmaier RD, Shaw PE. Permeability of shellac coatings to gases and water vapor. Journal of Agricultural and Food Chemistry. 39: 825-829 (1991)

Jaiswal AK, Singh B, Mehta A, Lal M. Post-harvest losses in potatoes from farm to fork. Potato Research. 66: 51-66 (2023)

Jost V, Kobsik K, Schmid M, Noller K. Influence of plasticiser on the barrier, mechanical and grease resistance properties of alginate cast films. Carbohydrate Polymers. 110: 309-319 (2014)

Kim T-H, Lee Y, Han S-H, Hwang S-J. The effects of wavelength and wavelength mixing ratios on microalgae growth and nitrogen, phosphorus removal using Scenedesmus sp. for wastewater treatment. Bioresource Technology. 130: 75-80 (2013)

Kim H-J, Lee C-L, Yoon K-S, Rhim J-W. Synergistic effect of UV-C LED irradiation and PLA/PBAT-based antimicrobial packaging film on fresh-cut vegetables. Food Control. 138: 109027 (2022)

Lee J-S., Lee, E-S, Han J. Enhancement of the water-resistance properties of an edible film prepared from mung bean starch via the incorporation of sunflower seed oil. Scientific Reports. 10: 13622 (2020)

Li Y-I, Liu S, Chen S-Q, Rashid A, Wang L, Wang K. Physicochemical changes in fresh-cut peaches with the combined treatment of UV-B irradiation and 1-MCP. Postharvest Biology and Technology. 184: 111755 (2022)

Okada K, Matsuo K. Development of new antibodies and an ELISA system to detect the potato alkaloids α-solanine and α-chaconine. Foods. 12: 1621 (2023)

Park J-H, Kim S, Chang Y, Imm J-Y. Synergistic antimicrobial effect and mode of action of palmarosa oil-loaded nanoemulsion and citric acid against Pectobacterium carotovorum. Food Science and Biotechnology. 32: 823-831 (2023)

Pham, TT, Nguyen, LLP, Dam MS, Baranyai L. Application of edible coating in extension of fruit shelf life. AgriEngineering, 5: 520-536 (2023).

Pinhero RG, Coffin R, Yada RY. Post-harvest storage of potatoes. pp. 339-370. In: Advances in Potato Chemistry and Technology. Singh J, Kaur L (eds). Academic, San Diego. (2009)

Qiang T, Wang J, Jiang L, Xiong K. Modulation of hyperglycemia by sodium alginate is associated with changes of serum metabolite and gut microbiota in mice. Carbohydrate Polymers. 291: 119359 (2022)

Raigond P, Jayanty SS, Parmar V, Dutt S, Changan SS, Luthra SK, Singh B. Health-promoting compounds in potatoes: tuber exhibiting great potential for human health. Food Chemistry. 424: 136368 (2023)

Sáenz-Baños M, Latorre-Biel JI, Martínez-Cámara E, Jiménez-Macías E, Longo F, Blanco-Fernández J. Methodology for energy demand reduction of potato cold storage process. Journal of Food Process Engineering. 45: e14127 (2022)

Shen D-D, Hua Y-P, Huang J-Y, Yu S-T, Wu T-B, Zhang Y, Chen H-L, Yue C-P. Multiomic analysis reveals core regulatory mechanisms underlying steroidal glycoalkaloid metabolism in potato tubers. Journal of Agricultural and Food Chemistry. 70: 415-426 (2022)

Singh DP, Packirisamy G. Biopolymer based edible coating for enhancing the shelf life of horticulture products. Food Chemistry: Molecular Sciences. 4: 100085 (2022)

Song G, Sun R, Li H, Zhang H, Xia N, Guo P, Jiang LW, Zhang X, Rayan AM. Effects of pine needle essential oil combined with chitosan shellac on physical and antibacterial properties of emulsions for egg preservation. Food Biophysics. 17: 260-272 (2022)

Tanios S, Eyles A, Tegg R, Wilson C. Potato tuber greening: a review of predisposing factors, management and future challenges. American Journal of Potato Research. 95: 248-257 (2018)

Tavassoli-Kafrani E., Gamage MV, Dumée LF, Kong L, Zhao S. Edible films and coatings for shelf life extension of mango: a review. Critical Reviews in Food Science and Nutrition. 62: 2432-2459 (2022)

The DP, Debeaufort F, Luu D, Voilley A. Moisture barrier, wetting and mechanical properties of shellac/agar or shellac/cassava starch bilayer bio-membrane for food applications. Journal of Membrane Science. 325: 277-283 (2008)

Vulavala VKR, Fogelman E, Faigenboim A, Shoseyov O, Ginzberg I. The transcriptome of potato tuber phellogen reveals cellular functions of cork cambium and genes involved in periderm formation and maturation. Scientific Reports. 9: 10216 (2019)

Wani SM, Mir SA, Khanday FA, Masoodi FA. Advances in pullulan production from agro-based wastes by Aureobasidium pullulans and its applications. Innovative Food Science and Emerging Technologies. 74: 102846 (2021)

Wigati LP, Wardana AA, Tanaka F, Tanaka F. Application of pregelatinized corn starch and basil essential oil edible coating with cellulose nanofiber as Pickering emulsion agent to prevent quality-quantity loss of mandarin orange. Food Packaging and Shelf Life. 35: 101010 (2023)

Xiong Y, Liu X, You Q, Han L, Shi J, Yang J, Cui W, Zhang H, Chao Q, Zhu Y, Duan Y, Xue T, Xue J. Analysis of DNA methylation in potato tuber in response to light exposure during storage. Plant Physiology and Biochemistry. 170: 218-224 (2022)

Yang X, Guo Y, Kong L, Lu J, Lin B, Xu C. Biobased epoxidized natural rubber/sodium carboxymethyl cellulose composites with enhanced strength and healing ability. International Journal of Biological Macromolecules. 242: 124681 (2023a)

Yang X, Zhao D, Ge S, Bian P, Xue H, Lang Y. Alginate-based edible coating with oregano essential oil/β-cyclodextrin inclusion complex for chicken breast preservation. International Journal of Biological Macromolecules. 251: 126126 (2023b)

Yun Y-S, Bae S-J, Park S-H. Inactivation of foodborne pathogens on inshell walnuts by UV-C radiation. Journal of Food Protection. 85: 1172-1176 (2022)

Zhang H, Xu F, Wu Y, Hu H-H, Dai X-F. Progress of potato staple food research and industry development in China. Journal of Integrative Agriculture. 16: 2924-2932 (2017)

Acknowledgements

This work was carried out with the support of “Cooperative Research Program for Agriculture Science and Technology Development (Project No. PJ016082052023)” of the Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, JS., Ahn, J. & Han, J. Enhancing effect on postharvest quality of potatoes through combined treatment of edible coating with UV-C irradiation. Food Sci Biotechnol 33, 1393–1405 (2024). https://doi.org/10.1007/s10068-023-01449-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-023-01449-0