Abstract

Strawberries are highly perishable, leading to significant postharvest losses and reduced fruit quality during storage and distribution. Conventional preservation methods are often insufficient, necessitating the development of innovative and natural approaches to improve the longevity and quality of these fruits. This study investigates the use of sericin, chitosan, and Aloe vera blended formulation (SBF) coating to extend the shelf life and quality of strawberries. The coated strawberries were stored at 14 ± 1 °C and 40–45% humidity, with their properties monitored over 12 days. Scanning electron microscopy (SEM) and fourier transform infrared (FTIR) spectroscopy analyses of strawberries confirmed the uniform application and chemical interaction of the coating, while contact angle measurements demonstrated improved wettability (contact angle 50.73 ± 0.6 °). The SBF coating significantly reduced weight loss and maintained higher firmness i.e. with only 7 ± 1.14% weight loss resulted after 9 days compared to a 16.5 ± 0.7% weight loss in uncoated strawberries. It also preserved higher levels of total soluble solids and titratable acidity compared to uncoated strawberries. Additionally, the SBF coating effectively slowed moisture loss, prevented infection, and regulated pH and respiration rate, demonstrating its potential for postharvest preservation of strawberries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, significant research efforts have been devoted to the exploration of edible coatings and films to reduce crop losses and maintain the freshness of fruits over extended periods [1,2,3]. This is particularly important for both direct consumer sales and subsequent processing endeavors [2,3,4]. For non-climacteric fruits like strawberries, polysaccharide-based coatings have shown promise in extending shelf life by leveraging the selective permeability of these polymers to oxygen (O₂) and carbon dioxide (CO₂) [5,6,7]. Such coatings, either individually or blended with supplements like proteins and natural additives, have the potential to modulate the internal atmosphere of strawberries, thereby delaying senescence [8].

Despite the successful application of certain edible coatings to fresh produce, some instances have demonstrated adverse effects on quality [9]. Altering internal atmospheres through edible coatings may intensify disorders associated with heightened CO₂ or diminished O₂ concentrations [10]. Consequently, regulating gas permeability in film development is crucial [9]. Furthermore, the effectiveness of edible coatings in protecting fruits and vegetables largely depends on controlling the wettability of the coating solution, which directly affects film thickness [10, 11]. Optimal formulations must ensure uniform wetting and spreading across fruit surfaces, resulting in coatings with strong adhesion, cohesion, and durability [10, 11]. Additionally, edible coatings serve various functions, including acting as carriers for food additives such as antioxidants and antimicrobial agents [1,2,3].

Polysaccharides, proteins, resins, and lipids are common components of edible coatings, each with distinct properties [12,13,14,15]. Polysaccharides and proteins form films with good mechanical properties but poor permeability, while lipids and resins offer good permeability but form brittle films [12,13,14]. Composite coatings combining hydrocolloids (polysaccharides, proteins) and lipids with plasticizers (e.g., glycerol, polyethylene glycol (PEG)) produce non-greasy, low-caloric films [12,13,14]. Sericin, derived from silk waste, is a sustainable, cost-effective protein source for edible coatings [16]. It reduces fruit weight loss, enhances color and texture, and inhibits polyphenol oxidase activity [16]. Its film-forming ability improves when mixed with polysaccharides like glucomannan, offering tunable water vapor permeability [13]. Sericin-based films combined with other biomaterials can provide antioxidant, antibacterial and tunable water barrier properties [16]. Countries like China and Japan lead in silk sericin utilization [17]. The food and drug administration (FDA) has approved sericin and its derivatives as generally recognized as safe (GRAS), with applications in cosmetics, medical, and food industries in countries like Italy, USA, China, Austria, Japan, and Romania [18, 19]. However, in India, much sericin is wasted, increasing the biological oxygen demand (BOD) load in wastewater [20]. Utilizing sericin in food preservation and as a dietary additive can offer health benefits and secondary income for the silk industry.

Sericin’s complex formation ability allows it to polymerize with other proteins and polysaccharides readily without additional treatment steps [21]. Our group identified sericin’s ability to form a stable formulation with chitosan and A. vera, which was used to enhance the shelf life of tomatoes [22]. The addition of chitosan and A. vera to sericin offers unique advantages, including medicinal, antimicrobial, protective, and stable film-forming properties [22,23,24,25,26,27]. For instance, reports state that chitosan-based coatings enhanced strawberries preservation, reduced microbial load, maintained nutrients, and extended shelf life during cold storage [5, 6, 28]. However, there is currently no scientific literature available on the use of antioxidant and sustainable sericin protein alone or in combination with other natural protective agents like chitosan and A. vera for enhancing the postharvest quality of strawberries. Therefore, the present study intends to investigate the potential of a blended coating formulation containing sericin, chitosan, and A. vera to extend the shelf life and improve the quality of strawberries. Key parameters of elucidation include weight loss, pH, respiration rate, firmness, total soluble solids, and titratable acidity during storage. Furthermore, microscopy and spectroscopic analyses were followed to assess the coating’s structural integrity and its impact on the fruit’s preservation.

Materials and Methods

Chemicals and Plant Materials

Sericin was gifted by from Central Silk Technological Research Institute (CSTRI), Bengaluru, India and chitosan (10–150 mPa.s. deacetylated degree. Min. 90%), glycerol, glacial acetic acid and other chemicals used in the study are purchased from SRL, India. Garden fresh strawberries (Fragaria ananassa¸chandler) were purchased from local market, Chennai, India.

Preparation of Strawberries

Fruits with uniform size, shape, and ripeness with a bright red color and no visible defects, bruises, or signs of disease were used in this study. Only strawberries that were freshly harvested and stored under optimal conditions were used. Strawberries were immediately transferred to laboratory in a closed thermocol box and stored at 5 °C in a temperature controlled refrigerator until processing.

Prior to the study, fruits were sanitized using 5% sodium hypochlorite solution with 1:100 dilution for 5 min. Then the fruits were subjected to distilled water washing for 3 min, subjected to air drying for 2 h at room temperature with forced air.

Preparation of Individual Components

Primarily, sericin for coating formulation was prepared by enzymatic treatment as reported in our earlier study. [22]

Silk sericin was exposed to alkaline protease at pH 9 and incubated for 90 min at 60 °C. Then the enzyme was inactivated by heating step and separated from soluble sericin by a centrifugation step. The recovered sericin from the supernatant was collected in solid form using lyophilisation step (using CareBios Laboratory Freeze Dryer DFD-10) and stored for further investigation.

Chitosan solution was prepared by dissolving it in 0.6% glacial acetic acid through homogenization at 60 °C and 800 rpm. A. vera gel was prepared as per our earlier study [22]. Primarily, mature and healthy leaves from the lower part of the A. vera plant were selected and thoroughly cleaned with distilled water. To eliminate the yellow latex, the leaves were positioned vertically and allowed to drain from the cut end. Using a sterile knife, the outer rind was peeled away, and only the clear gel from the inner portion was retained and collected in a sterile container. The gel was then blended using a homogenizer until it reached a uniform consistency. Afterward, it was filtered through cheesecloth. The filtered gel was subjected to a heating step at 70 °C for 45 min, then cooled to room temperature (25 °C) and lyophilized to obtain powder. A. vera. Ultrapure water with 18.2 mΩ.cm resistivity was used throughout the study.

Coating Formulation Preparation and Dip Coating of Fruits

The coating formulation solution was prepared by sequentially mixing 40 mL of sericin (1.5%) and 40 mL of chitosan (1%), followed by the addition of 0.4 g of extracted A. vera powder and 0.6 g of glycerine.A. vera [22]. This SBF was thoroughly mixed using a hot plate magnetic stirrer (1500 rpm) at temperature of 70 °C with stirring at 800 rpm until the final volume reduced to half. The final strengths of ingredients in the SBF are sericin (1.5%), chitosan (1%), A. vera (1%) and glycerine (1.5%). After cooling of SBF to 25 °C, strawberries were dipped or submerged in the coating formulation for 1 min and then drained with the help of sieves. These fruits were dried at room temperature of 25 °C for 2 h, placed in plastic boxes and stored at 14 ± 1 °C in the environment where the relative humidity was 40–45%. With similar stated approach, strawberries dipped in distilled water served as control samples. The selected storage conditions (14 °C with 40–45% relative humidity) were specifically chosen to simulate real-world scenarios such as those encountered during transportation or storage in less controlled environments. Although lower temperatures (close to 0 °C) are typically recommended to prolong the shelf life of strawberries, this study sought to evaluate the efficiency of the SBF coating under conditions where the strawberries are more prone to spoilage. Both control and coated strawberries were monitored over a 12 day period to assess the effectiveness of the SBF coating in maintaining fruit quality and extending shelf life under these conditions.

SEM and FTIR Analysis

The SEM and FTIR analyses were conducted on the coated peels of the strawberries (1 × 1 cm). The coated peel samples were carefully prepared by first applying the SBF composite coating to the strawberry surface. After the coating was applied, the strawberries were allowed to dry at room temperature. After 48 h, the peel was then gently separated from the fruit and cut into small sections suitable for SEM and FTIR analysis. For SEM, the samples were sputter-coated with a thin layer of gold to enhance conductivity before imaging and analysed using TESCAN VEGA3 model, Czech Republic. For FTIR, the peel sections were ground into a fine powder, and the spectra were recorded in the range of 4000–650 cm−1 to identify the functional groups present in the coating material using the Agilent Cary 600 FT-IR Spectrometer, which was equipped with an attenuated total reflectance (ATR) accessory.

Contact Angle Analysis

The contact angle (θ) was measured using a contact angle meter (Kyowa Contact Angle Meter - DMe-211 Plus). The contact angle of water at the strawberry surface (coated and uncoated) was measured by the sessile drop method [8], in which a droplet of water was placed on a horizontal surface of strawberry sample and observed with a contact angle meter. To avoid changes on the strawberry surface, measurements were taken within 60 s. This process repeated five times at different points on the surface, all at a temperature of 25 ± 2 °C.

For SEM, FTIR, and contact angle measurements, freshly cut peels from both the control and SBF-coated strawberry fruits were used.

Physico-Chemical Assessments

The physical, chemical and microbiological analyses were performed in triplicate during 12 days storage period of strawberry fruits.

Weight Loss and Total Soluble Solids (TSS)

The weights of coated and uncoated strawberries monitored using an analytical balance (accuracy: ± 0.01 mg) during the storage period. The difference between initial and final weight of the samples were considered as the total weight loss and weight loss in terms of percentage was calculated as per the standard method of Association of Official Analytical Collaboration (AOAC), 1994 using the following equation. [7]

TSS content was determined using benchtop refractrometer (Hanna, India). Sample extract was prepared by homogenizing the fruit using a blender followed by a quick mixing. A few drops of this juice was placed on the prism glass of the refractrometer and the °Brix reading was taken as reported by Gol et al. [7].

Decay Percent

The number of decayed strawberry fruits due to fungal or microbial infection was recorded at day 3, day 7 and day 12 and expressed as a percentage. For controls and SBF coated samples, 12 fruits were observed in three replicates. The decay percentage for both SBF coated and uncoated fruits was calculated by dividing the number of decayed fruits by the initial total number of fruits, then multiplying by 100 [7].

Titratable Acidity (TA)

TA of strawberry fruit was calculated by the method reported by AOAC (1994) [29] and was expressed as g of citric acid per 100 g of fruit.

Where V (NaOH) is the ml of NaOH spent for titration, 0.1 is the molarity of the NaOH solution, 0.064 is conversion factor for citric acid and maliquot is the mass of the aliquot sample taken for analysis [29].

pH

10 g of strawberry fruit was homogenized, and the juice was filtered for pH measurement. A digital pH meter was calibrated with standard buffers at pH 4.0 and 7.0 before use. The electrode was rinsed, dried, and immersed in the juice. Measurements were taken three times per sample to ensure accuracy, and the average pH was recorded as per the standard approach [30].

Firmness

The firmness of strawberry fruit was analyzed using fruit penetrometer (Genex, TechZone Enterprises, India) during storage period in each interval time. An 8 mm diameter stainless steel cylindrical probe with a flat end was used for this measurement. The probe was pushed to a depth of 3 mm into strawberries. The maximum penetration force (kg/cm2) was used as the firmness value of the strawberry. Three whole strawberries (two opposite locations in each strawberry) from each replication were used [31, 32].

Respiration Rate

The respiration rate of strawberries in terms of CO2 levels were monitored using a compact CO2 detector (Serplex 1 air quality meter, China), with readings expressed in parts per million (ppm). Strawberries, both coated and uncoated, were packed in a sealed container to measure the respiration rate accurately [33].

All the statistical analysis of the study was performed using OriginPro 8.5 software (OriginLab Corporation, Northampton, USA) and MINITAB@release 14.1 (Minitab, Inc., USA). analytical softwares.

Results and Discussion

SEM Analysis

The SEM analysis provided valuable insights into the surface micromorphology of strawberry fruits, both with and without the SBF coating (Fig. 1a-f). The control samples exhibited a typical network of parenchyma cells with visible stomatal pores (Fig. 1a). The stomatal pores, critical for regulating gas exchange and water loss, were not occluded by the SBF coating, as seen in Fig. 1d,e. This is a significant observation since coatings that occlude stomatal pores can adversely affect fruit physiological processes, such as respiration rate and water loss, potentially accelerating senescence and reducing shelf life [34]. With noticeable changes in micromorphology, SBF coating resulted in a uniform coating layer on the fruit surface (Fig. 1f), exhibiting a more homogeneous appearance compared to the control fruit (Fig. 1c). This behaviour complements with previous studies that reported the formation of continuous and fissure-free layers with nanocomposite-based coatings [35]. And findings from this study suggest that the SBF coating, like chitosan and A. vera gel-based coatings, can provide a protective barrier without compromising the natural gas exchange through stomata [26].

Contact Angle and FTIR Analysis

Contact angle measurements (Fig. 2a) demonstrated a significant difference between the coated and uncoated strawberries, with values of 74.36 ± 1.3 for the control and 50.73 ± 0.6 for the SBF-coated samples. These lower contact angle values for the SBF-coated samples indicate better wettability and uniform spreading of the coating across the strawberry surface. Due to the inherent irregularity of strawberry surfaces, lower contact angles suggest enhanced coverage, which is desirable for maintaining the quality and prolonging the shelf life of the fruit [8]. Our results align with previous findings on coatings that achieve low surface tension, enhancing fruit protection without the need for additional surface tension-lowering agents [8]. Moreover, in some cases, fruits coatings such as Carrageenan which have high surface tension may not be ideal as it can lead to strong forces between molecules, resulting in high contact angles and improper barrier properties [8]. In such cases, surface tension-lowering agents like Tween 80 are often added to improve contact between the fruit and coating material [8]. However, with the developed SBF in this study, this challenge is minimized as the coating naturally achieves low contact angle values on strawberry fruits, which is desirable and reduces the need for procedural adjustments.

Furthermore, FTIR analysis provides direct evidence of the interaction between the strawberry fruit surface and SBF coating. The spectral data (Fig. 2b) reveal characteristic peaks that are summarized in Table 1, showing comparisons between SBF-coated and control strawberries. Most peaks originate from the strawberries themselves, predominantly reflecting the presence of sugars, pectin, pigments, and organic acids in both control and SBF-coated fruits [36]. However, variations are observed in the SBF-coated fruits, particularly in the region from 700 to 1500 cm−1 (Fig. 2b). These differences are attributed to the ingredients in the SBF coating, which forms a barrier on the strawberry peel, as observed in SEM images (Fig. 1d-f). The SBF coating includes sericin, chitosan, A. vera, and glycerine. Although identifying the specific groups involved in bonding is challenging, free bands from the SBF coating are detectable (Fig. 2b) and tabulated (Table 1). Key peaks corresponding to sericin (1625 cm−1), A. vera (1230, ~ 870 cm−1), and chitosan (1394 cm−1) confirm the presence of the SBF coating on the strawberries [22]. Additionally, shifts in wave numbers, such as from 3272 cm−1 to 3294 cm−1, suggest interactions between the organic components of the strawberries and the SBF coating, possibly due to hydrogen bonding or van der Waals interactions [36]. This evidence indicates that the SBF coating was evenly distributed on the surface of the strawberry fruits.

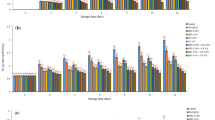

Weight Loss, Decay Percentage, Firmness

Digital images of coated and uncoated strawberry fruits are shown in Fig. 3a. The weight losses of SBF coated and uncoated fruits over time are depicted in Fig. 3b. Notably, all strawberries, regardless of coating, exhibited increased weight loss with storage duration (12 days). However, the application of SBF coating significantly alleviated weight loss compared to untreated strawberries when stored at 14 °C. After 5 days, uncoated strawberries reached a maximum weight loss of 9.75 ± 0.81%, whereas all coated strawberries maintained losses below 3.8 ± 0.67%. By the day 9, control strawberries experienced a substantial 16.45 ± 0.71% weight loss, indicative of significant deterioration, whereas coated strawberries exhibited only a 7 ± 1.14 20% loss, maintaining their freshness. These findings highlight the efficacy of SBF coating in delaying weight loss, with a net loss of 9.2 ± 1.2% by day 12. It is worth noting that moisture loss accounts for the predominant mechanism behind weight loss in strawberries. The observed results align with previous studies [7, 39,40,41] suggesting that fruit coatings establish a semi-permeable membrane on the fruit’s surface, thereby retarding moisture transfer from the fruit to the environment.

In addition to weight loss, the decay percentages and firmness of the strawberries were assessed. Figure 4a shows that strawberries are highly perishable due to significant postharvest physiological activity. Our results indicate that uncoated strawberries had decay percentages of 13 ± 1.8%, 90 ± 2.2%, and 100% on days 3, 7, and 12, respectively, with most fruits becoming infected and unusable after seven days. In contrast, SBF-coated strawberries exhibited significantly lower decay percentages of 4 ± 1.1%, 6 ± 0.8%, and 10 ± 1.2% over the same periods. The SBF coating effectively protected the fruits from microbial infection, extending their shelf life to 12 days. This antimicrobial protection might be attributed to chitosan in the SBF formulation, which enhances fruit resistance by inducing chitinase, a defense enzyme that breaks down chitin in fungal cell walls [7, 42].

The firmness of the strawberries depicted in Fig. 4a was initially recorded to be 0.84 ± 0.03 kg/cm2 and decreased progressively with storage. Uncoated strawberries showed shaper decline in firmness compared to SBF-coated ones i.e.11% loss in firmness for coated strawberries whereas it was 47% loss for uncoated ones after 9 days. This reduction in firmness correlates with the weight loss behavior, as softening results from cell wall degradation and/or microbial infection [43]. While fruit coatings can mitigate softening [8], cold storage can also induce softening due to increased respiration and membrane damage [35]. The SBF coating, enriched with sericin, provides weight reduction and antioxidant benefits, while chitosan and A vera help inhibit microbial spoilage and delay softening [22].

Changes in TSS, Fruit Respiration Rate, pH and TA Levels

The TSS levels of both control and coated strawberry samples during storage are depicted in Fig. 4b. Initially, the TSS content was 7.3% and increased significantly over the storage period for uncoated strawberries. Within the first 2 days of storage, the uncoated control samples exhibited significantly higher TSS levels (8.2%) compared to the coated samples. Over the 12 day storage period, the TSS content in the control fruit decreased from 8.2% to 6.6%, while strawberries coated with SBF showed a slight increase in TSS up to 9 days of storage (from 7.3 to 8%) and slightly decreased (7.8%) at the end of storage (day 12). By the end of the 12 day storage period, SBF coated fruits exhibited a TSS content of 7.8%. Coatings typically assist in maintaining TSS levels during storage, as uncoated fruits experience rapid TSS loss due to uncontrolled respiration [35]. The SBF coating notably contributed to maintaining higher TSS levels in the fruits by the end of 12 day storage. These results are in alignment with those of Gol et al., [7] who observed chitosan enriched edible coatings with carboxymethyl cellulose (CMC) and hydroxylpropyl methylcellulose (HPMC) significantly reduced the TSS content with respect to the control for strawberries preservation. Regulation of TSS in coated fruits may be attributed to SBF’s ability to slow respiration and metabolic activity, thereby delaying fruit ripening.

In addition to TSS monitoring, fruit respiration rate in terms of CO₂ levels were measured in both SBF-coated and uncoated strawberries at different intervals (Fig. 4c). A significant difference in CO₂ levels was observed between the control and SBF coated fruits. The SBF-coated fruits exhibited a gradual increase in CO₂ levels, while the control fruits showed a gradual increase until the second day, followed by a steep decline from day 4 to day 12. Typically, during aging and senescence, the respiration rate increases, leading to higher CO₂ production [8]. The elevated CO₂ levels in the control fruits indicate the aging process [8], as they lack the protective SBF coating. Although not directly indicative, the elevated CO₂ levels correlate with the decrease in TSS observed in the control fruits (Fig. 4c), which is usually due to high respiration and metabolic activity [7]. In contrast, the SBF coating regulated the levels of CO₂ and TSS, keeping them low compared to the control fruits. Furthermore, the one-way ANOVA and Fisher’s LSD test (detailed in SI) revealed that SBF-coated strawberries had significantly lower CO2 levels (Fig. 4c) compared to the control group with higher F (13.35) and lower p (0.004) values. This suggests that the SBF coating effectively reduces CO2 levels, improving the postharvest quality of strawberries.

Figure 4d illustrates the impact of different SBF coatings on the pH of strawberries compared to control samples throughout the storage period. The results demonstrate a consistent increase in pH levels in strawberry fruit over time, with significant (P < 0.05) differences observed between coated and uncoated samples. Specifically, strawberries coated with SBF exhibited the least increase in pH, measuring from 3.74 (initial day) to 4.3 (12 days) of storage, while the pH of uncoated fruits reached to 4.7 after 12 days. The observed results are in agreement with those of Maftoonazad et al. [44], who reported that a higher increase of pH was found in the control samples compared to CMC coated fruits like peaches. Furthermore, Gol et al. [7] also showed coating with CMC with HPMC with chitosan displayed retention of pH in coated strawberries. Edible coatings act by forming a barrier that controls the exchange of moisture and gases between the fruit and its surroundings [45, 46]. This barrier helps reduce the rates of respiration and ethylene production processes that can contribute to pH level increase over time [7, 35]. For instance, a study reported that 1-(3-phenyl-propyl) cyclopropene (1-PCP) acts as an ethylene inhibitor, effectively slowing down the ripening and decay of apricots [47]. Similarly, another study demonstrated that melatonin, a potent antioxidant, can inhibit ethylene biosynthesis, thereby slowing the ripening process and reducing the rate of deterioration when combined with tragacanth gum [48]. In this study, the SBF coating composite also effectively regulated the increase in pH and decelerated the respiration rate of the fruit (Fig. 4d).

The impact of coatings on the TA of strawberries is depicted in Fig. 4e. Over the storage period, both SBF-coated and control samples showed a decrease in TA, albeit at a slower rate for coated fruit. As shown in Fig. 4e, TA from the SBF coated fruits declined intensely for after 2 days of storage (from 0.96 to 0.7%), then it was gradual till 12 days and reached 0.54%. But TA for the SBF coated fruits steadily decreased and reached 0.69% after 12 days. TA levels are directly linked to the organic acid content in fruit, and reductions in acidity may occur due to metabolic changes or the utilization of organic acids in respiration [7, 35]. Past studies suggest that coatings can reduce respiration rates, thereby delaying the depletion of organic acids [22, 23, 49]. Previous research has also shown that starch-based coatings and more recently, chitosan-beeswax coatings, can help retain TA in strawberry fruit [5, 50, 51].

In summary, this study demonstrates that the SBF coating significantly enhances the postharvest quality and shelf life of strawberries by providing a uniform, smooth coating that effectively reduces weight loss, enhances firmness, and maintains higher levels of TSS and TA compared to uncoated strawberries. The SBF coated strawberries also exhibit significantly lower decay rates, indicating superior protective properties likely due to the synergistic effects of sericin, chitosan, and A. vera, which together create a more effective barrier against spoilage organisms. Additionally, this work shows that the developed SBF coating offers an optimal balance between hydrophilicity and hydrophobicity (as evidenced by contact angle measurements). This balance is critical for preserving fruit quality during storage by preventing excessive moisture loss while still allowing for adequate gas exchange. Furthermore, SEM and FTIR analyses provide evidence of the coating’s uniform distribution and its strong chemical interaction with the fruit surface, underscoring the enhanced functional properties of this novel formulation compared to traditional coatings. Overall, SBF coating’s potential as a promising solution for the preservation of perishable fruits like strawberries offers dual benefits of improved performance and sustainability benefits.

Conclusion

This study illustrates the application of a SBF composite coating in significantly extending the postharvest shelf life and maintaining the quality of strawberries under refrigerated conditions till 12 days. The findings from SEM, contact angle, and FTIR analyses confirmed the uniform and effective application of the coating. The SBF coating reduced weight loss and decay while maintaining higher firmness. Moreover, coated strawberries retained higher TSS levels, experienced a more gradual increase in CO₂, and showed a slower rise in pH. Additionally, the coated strawberries preserved more TA, indicating effective regulation of respiration and metabolic activity, which helped maintain their organic acid content over the 12 day storage period. These findings emphasize the potential of the SBF coating to effectively preserve strawberries and indicate its possible advantages for other fruits as well. Moreover, this research paves the way for future investigations into sericin-based coatings combined with other natural biopolymers, potentially leading to the creation of a new class of edible coatings with superior preservation properties.

Data Availability

No datasets were generated or analysed during the current study.

Abbreviations

- BOD:

-

Biological Oxygen Demand

- SEM:

-

Scanning Electron Microscopy

- FTIR:

-

Fourier-Transform Infrared Spectroscopy

- TSS:

-

Total Soluble Solids

- TA:

-

Titratable Acidity

- FDA:

-

Food and Drug Administration

- GRAS:

-

Generally Recognized As Safe

- AOAC:

-

Association of Official Analytical Collaboration

- PEG:

-

Polyethylene Glycol

- CMC:

-

Carboxymethyl Cellulose

- HPMC:

-

Hydroxypropyl Methylcellulose

- SBF:

-

Sericin, Chitosan, and Aloe vera Blended Formulation

- ppm:

-

Parts Per Million

- ATR:

-

Attenuated Total Reflectance

- RH:

-

Relative Humidity

- mAliquot:

-

Mass of Aliquot (used in TA calculations)

- CSTRI:

-

Central Silk Technological Research Institute

References

R. Tabing, D. Senapoty, T. Jamja, J. Eco-Friendly Agric. 19, 201 (2024)

C. Ungureanu, G. Tihan, R. Zgârian, G. Pandelea (Voicu), Coatings 13, 1420 (2023)

T.T. Pham, L.L.P. Nguyen, M.S. Dam, L. Baranyai, AgriEngineering 5, 520 (2023)

K. Dybka-Stępień, H. Antolak, M. Kmiotek, D. Piechota, A. Koziróg, Polymers 13, 3606 (2021)

M.I. Pinzon, L.T. Sanchez, O.R. Garcia, R. Gutierrez, J.C. Luna, C.C. Villa, Int. J. Food Sci. Technol. 55, 92 (2020)

J. Qamar, S. Ejaz, M.A. Anjum, A. Nawaz, S. Hussain, S. Ali, S. Saleem, J. Hortic. Sci. Technol. 8 (2018)

N.B. Gol, P.R. Patel, T.V.R. Rao, Postharvest Biol. Technol. 85, 185 (2013)

C. Ribeiro, A.A. Vicente, J.A. Teixeira, C. Miranda, Postharvest Biol. Technol. 44, 63 (2007)

B. Maringgal, N. Hashim, I.S.M.A. Tawakkal, M.T.M. Mohamed, Trends in Food Science & Technology 96, 253 (2020)

L. Cisneros-Zevallos, J.m. Krochta, J. Food Sci. 68, 176 (2003)

D.C. Moncayo Martinez, G. Buitrago Hurtado, N.A. Algecira Enciso, Ing. Inv. 33, 11 (2013)

A.R.V. Ferreira, V.D. Alves, I.M. Coelhoso, Membranes 6, 22 (2016)

R. Sothornvit, R. Chollakup, Int. J. Food Sci. Technol. 44, 1395 (2009)

P.K. Raghav, N. Agarwal, M. Saini, Int. J. Sci. Res. Mod. Educ. 1, 188 (2016)

Y. Wu, H. Wu, L. Hu, Food Biophys. 19, 29 (2024)

T. Thongsook, W. Tiyaboonchai, Int. J. Food Sci. Technol. 46, 2052 (2011)

S. Takeda, in Encyclopedia of Insects (Second Edition), ed. by V. H. Resh, R. T. Cardé. (Academic Press, San Diego, 2009), pp. 117–119

S. Ghosh, R. Rao, K. Nambiar, V. Haragannavar, D. Augustine Mds, S. Sv, J. Med. Radiol. Pathol. Surg. 4, 13 (2017)

J.A. Barajas-Gamboa, A.M. Serpa-Guerra, A. Restrepo-Osorio, C. Ãlvarez-López, Ing. Compet. 18, 193 (2016)

S.K. Rajput, IOSR Journal of Polymer and Textile Engineering 2, 29 (2015)

C. Yang, L. Yao, L. Zhang, Smart Mater. Med. 4, 447 (2023)

K. Tarangini, P. Kavi, K. Jagajjanani Rao, eFood 3, e36 (2022)

A. Riaz, R.M. Aadil, A.M.O. Amoussa, M. Bashari, M. Abid, M.M. Hashim, J. Food Process. Preserv. 45, e15018 (2021)

M.Z. Elsabee, E.S. Abdou, Mater. Sci. Eng. C 33, 1819 (2013)

J. Ali, S. Pandey, V. Singh, P. Joshi, Curr. Res Nutr. Food Sci. J. 4, 58 (2016)

L. Mohammadi, A. Ramezanian, F. Tanaka, F. Tanaka, Food Meas. 15, 353 (2021)

D. Khatri, J. Panigrahi, A. Prajapati, H. Bariya, Sci. Hortic. 259, 108837 (2020)

P.-A. Popescu, L.M. Palade, I.-C. Nicolae, E.E. Popa, A.C. Miteluț, M.C. Drăghici, F. Matei, M.E. Popa, Foods 11, 3317 (2022)

E. Velickova, E. Winkelhausen, S. Kuzmanova, V.D. Alves, M. Moldão-Martins, LWT Food Sci. Technol. 52, 80 (2013)

D. Khodaei, Z. Hamidi-Esfahani, Postharvest Biol. Technol. 156, 110944 (2019)

S. H. Atress, M. M. El-Mogy, H. E. Aboul-Anean, and B. W. Alsanius, 10 (2010)

M.F. Vargas-Torrico, E. von Borries-Medrano, S. Valle-Guadarrama, M.A. Aguilar-Méndez, CyTA J. Food 20, 27 (2022)

A. Ghaouth, J. Arul, R. Ponnampalam, M. Boulet, J. Food Sci. 56, 1618 (1991)

F. Khorram, A. Ramezanian, S.M.H. Hosseini, Sci. Hortic. 225, 22 (2017)

A. Emamifar, S. Bavaisi, Food Meas. 14, 1012 (2020)

M. Sachadyn-Król, I. Budziak-Wieczorek, I. Jackowska, Antioxidants 12, 1719 (2023)

A. Drabczyk, S. Kudłacik-Kramarczyk, M. Głąb, M. Kędzierska, A. Jaromin, D. Mierzwiński, B. Tyliszczak, Materials 13, 3073 (2020)

Z.X. Lim, K.Y. Cheong, Phys. Chem. Chem. Phys. 17, 26833 (2015)

Y. Fan, Y. Xu, D. Wang, L. Zhang, J. Sun, L. Sun, B. Zhang, Postharvest Biol. Technol. 53, 84 (2009)

A.C. Guerreiro, C.M.L. Gago, M.L. Faleiro, M.G.C. Miguel, M.D.C. Antunes, Sci. Hortic. 194, 138 (2015)

K.D. Vu, R.G. Hollingsworth, E. Leroux, S. Salmieri, M. Lacroix, Food Res. Int. 44, 198 (2011)

J. Stanley, A. John, K. Pušnik Črešnar, L. Fras Zemljič, D.A. Lambropoulou, D.N. Bikiaris, Macromol 3, 1 (2023)

C. Xu, X. Zhang, J. Liang, Y. Fu, J. Wang, M. Jiang, L. Pan, Postharvest Biol. Technol. 192, 112017 (2022)

N. Maftoonazad, H.S. Ramaswamy, M. Marcotte, Int. J. Food Sci. Technol. 43, 951 (2008)

S.L. Nayak, S. Sethi, R.R. Sharma, in Polymers for Agri-Food Applications, ed. by T. J. Gutiérrez. and U. Prajapati (Springer International Publishing, Cham, 2019), pp. 417–432

F. Nazoori, S. Poraziz, S.H. Mirdehghan, M. Esmailizadeh, E. ZamaniBahramabadi, Int. J. Hortic. Sci. Technol. 7, 279 (2020)

J.M. Al-Khayri, E.H. Khedr, J. Hortic. Sci. Biotechnol., 1 (2024)

E.H. Khedr, J.M. Al-Khayri, Plants 12, 1887 (2023)

N. Kumar, Neeraj, Pratibha, A. Trajkovska Petkoska, ACS Food Sci. Technol. 1(500) (2021)

A. Bhardwaj, N. Sharma, T. Alam, V. Sharma, J.K. Sahu, H. Hamid, V. Bansal, M.S. Alam, Waste Biomass Valor. 14, 1625 (2023)

T.A.A. Nasrin, M.A. Rahman, M.A. Hossain, M.N. Islam, M.S. Arfin, J. Hortic. Sci. Biotechnol. 92, 598 (2017)

Acknowledgments

This research was financially supported by the Department of Biotechnology, India (grant no: BT/PR35666/TDS/121/52/2020), and by the Research and Development office, Vel Tech, through their Seed Grant.

Author information

Authors and Affiliations

Contributions

Kavi Palepu: original draft, experimentation and analysis. Dr. Tarangini Korumilli: conceptualization, supervision, administration, original draft and project. Dr K Jagajjanani Rao: data curation, analysis and supervision.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 12 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kavi, P., Korumilli, T. & Rao, K.J. Sericin-Chitosan-Aloe vera Composite Coating for the Postharvest Shelf-Life Improvement of Strawberries. Food Biophysics (2024). https://doi.org/10.1007/s11483-024-09889-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11483-024-09889-9