Abstract

Stability of whey protein-pectin complexes is an essential criterion for their application in different food matrices. The impact of process parameters on micro- and macro-structural characteristics of thermally stabilised whey protein-pectin complexes was investigated using fluorescence spectroscopy, ζ-potential measurements, dynamic light scattering and phase separation. Complexes prepared from whey protein isolate (WPI) and pectins with different degrees of esterification (HMP, LMP) were generated at different biopolymer concentrations (WPI + pectin: 5.0 % + 1.0 %, c h i g h ; 2.75 % + 0.55 %, c m e d ; 0.5 % + 0.1 %, c l o w ), heating temperatures (80-90∘C) and pH levels (6.1-4.0). Micro- and macro-structural characteristics of the complexes depended on concentration level and degree of esterification, with complexes being more sensitive towards environmental changes at c l o w than at c m e d and c h i g h . WPI-LMP complexes exhibited sizes <1 μm suitable for micro-encapsulation, whereas WPI-HMP complexes at c m e d achieved sizes from 1-10 μm and at c h i g h from 10-200 μm underlining their potential as fat-replacers and structuring agents, respectively. Slopes and intercepts derived from intensity ratios of fluorescence spectra gave insights into the state of unfolding of β-lactoglobulin within the complexes and thus about the protective effect of pectin addition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the last years, a lot of work has been done on calorie reduced food [1, 2] due to an increasing incidence of overweight and obesity [3]. Special attention was drawn to the generation of new fat replacers as fat is very high in calories and plays a major role in sensory and textural properties [4, 5].

Fat replacer mimic or substitute the properties of fat in food systems. Based on their chemical composition, they can be subdivided into three categories: protein-based, carbohydrate-based and fat-based [6]. However, most research focused on protein-based fat replacers owing to their complementary nutritional benefits [7] such as found for microparticulated whey proteins [8–10]. In this context, special attention has been drawn to whey protein-pectin complexes due to their high nutritional [7, 11] and functional properties, e.g structuration, emulsification and hydration [12–16] and, as recently shown, as fat replacers [17]. The complexation of whey proteins with pectin limits the heat-induced aggregation of the proteins without suffering losses in structuring abilities [13, 17]. In order to add these complexes in different food systems, it is necessary to establish a manufacturing process for concentration or drying.

A common device for the generation of concentrated, thermally treated systems is a surface scraped heat exchanger (SSHE). The processing includes several processes, prominently heating and shearing [18, 19]. Typical parameters influencing thermally induced complex formation to a high extent are biopolymer concentration and heating temperature. However, very few information on higher concentration levels combined with low temperature-short time heating, is available as mainly low concentration levels and high temperature-long time heating conditions were studied [20–22]. In terms of modulating the interactions between the biopolymers, degree of esterification of pectins and post-heating acidification are important aspects [23–25] on which, especially in combination with varied concentration levels and heating conditions, very few information is available.

This work presents the study of whey protein-pectin complex structures as affected by degree of esterification of pectins, biopolymer concentrations, heating temperatures and post-heating pH levels. Resulting structures were studied using common methods such as ζ-potential and dynamic light scattering [20, 26–28] as well as fluorescence spectroscopy.

This method relies on the fluorescence of inherent aromatic residues or of fluorescent dyes and probes attached to the protein. It is applied in various fields to study inner structures and conformational changes of proteins. The main application regarding whey proteins is the investigation of binding of hydrophobic components such as nutraceuticals [21, 22, 29] and therapeutic drugs [30]. Fluorescence spectroscopy has already been applied on whey proteins in combination with pectin to study complex assembly at low pH [31] as well as the structural and thermal stability of complexes composed of separately heat-treated biopolymers [32, 33]. However, to our knowledge, the inner structure of co-heat-treated whey protein pectin complexes has not been investigated so far as multiple interactions between the biopolymers can occur during heat-treatment and subsequent acidification. First hints towards a disentanglement of these interactions might be displayed by fluorescence spectroscopy.

The application of a statistical design of experiments allows to identify critical parameters and parameter ranges within a limited amount of experiments by an appropriate choice of varied parameters. With respect to an aspired up-scaling, this experimental set-up can, if proved well, serve as basis for future research.

Thereby, the first objective was to get an idea of possible parameters derived from fluorescence spectroscopy that might help to make first approaches to describe inner structural properties of complexes. The second objective was to investigate application possibilities in food systems with special emphasis on fat replacers, based on the impacts of process parameters on thermally stabilised whey protein-pectin complexes.

Materials and Methods

Materials

Native whey protein isolate (WPI895), obtained from sweet whey, was purchased by Fonterra co-operative Group Ltd. (Auckland, New Zealand). As stated by the manufacturer, the protein fractions were as follows: 69.2 % β-lactoglobulin, 14.2 % α-lactalbumin, 3.3 % bovine serum albumin, 2.1 % immunoglobulin G, 1.6 % glycomacropeptide and 1.2 % proteose peptone 5. The protein content of the samples was calculated according to the nitrogen content as determined by a nitrogen analyser (Dumatherm, C. Gerhardt GmbH & Co. KG, Königswinter, Germany) following the Dumas method (International Dairy Federation (IDF) 185:2002). The conversion factor 6.38 was used. The total protein content determined was 93.9 ± 0.2 %, which was used for further calculations.

Two unstandardised citrus pectins with different degree of esterification (DE) were kindly provided by Herbstreith & Fox (Neuenbürg, Germany) and used without further purification. According to the DE, pectins are subdivided into low-methoxyl (LMP, DE < 50 %) and high-methoxyl (HMP, DE > 50 %) classes. As stated by the manufacturer, the DE and the apparent molecular weight (MW, determined by capillary viscosimetry) of the citrus pectins were as follows: 36 % DE, 55 kDa (CU-L 057/11) and 71 % DE, 85 kDa (CU 201), respectively.

Preparation of Thermally Stabilised WPI-Pectin Complexes

Stock suspensions of WPI and pectins were prepared in percent weight per weight by suspending specified amounts of biopolymers in distilled water. WPI was suspended at room temperature and 450 rpm for 1 h, resulting in final protein concentrations of 10.0, 5.5 and 1.0 %, respectively. Pectin was suspended in distilled water at 70∘C and 550 rpm for at least 1.5 h. Pectin stock suspensions had concentrations of 2.0, 1.1 and 0.2 %, respectively. All stock suspensions were stored overnight at 10∘C to ensure complete hydration.

Stock suspensions of WPI and pectin were mixed by dropwise addition of pectin suspensions to WPI suspensions during stirring at 450 rpm. The ratio of protein to pectin was kept at a level of 5:1 [23]. Thereby, suspensions with protein and pectin concentrations of 5.0 % + 1.0 % (c h i g h ), 2.75 % + 0.55 % (c m e d ), 0.5 % + 0.1 %(c l o w ), respectively, and pH 6.10 ± 0.05 were obtained. 250 mL of unheated WPI-pectin suspensions were heated in a water bath at 80, 85 and 90∘C ± 1.5 K, respectively, for 250s (denaturation ≥ 90 %) [34, 35] while being unstirred. The resulting suspensions of thermally stabilised complexes were cooled to room temperature using running tap water.

In order to simulate application in different food matrices, complex suspensions were adjusted to pH values from pH 6.1 - 4.0, using lactic acid (analytical grade; Applichem GmbH, Darmstadt, Germany) and NaOH. The adjusted complex suspensions were stored over night at 10∘C and readjusted to the desired pH value, if necessary. Sodium azide was added to the complex suspensions as a preservative at a final concentration of 0.02 % [23]. NaOH and NaN3 were of analytical grade and purchased from Carl Roth GmbH & Co. KG (Karlsruhe, Germany).

Fluorescence Spectroscopy

Fluorescence measurements were performed using a LS 50B fluorescence spectrometer (Perkin Elmer Inc., Waltham, USA). Tryptophan (Trp) fluorescence determinations were performed at an excitation wavelength of 287nm since this resulted in maximum fluorescence emission intensities for the complexes (data not shown). Emission spectra were recorded at 300-500nm. Slit widths were set to 5nm, both for excitation and emission. Samples were diluted using distilled water to a final protein content of 0.025 % (w/w). All measurements were performed in triplicate at 24.4∘C.

The intensity ratio (IR) was calculated from the spectra by dividing the fluorescence intensity I 350 n m at λ 350 n m by the fluorescence intensity I 330 n m at λ 330 n m . Thereby, predictions on the degree of unfolding of β-lactoglobulin are possible [36]. The IR of samples at the same concentration level and heat treatment were plotted against the pH. Slope (m) and intercept (b) of the resulting lines were used for further evaluation.

Electrophoretic Mobility and ζ-Potential Determination

The electrophoretic mobility was measured as described in Krzeminski et al. [23]. WPI-pectin complex suspensions were placed into the measurement chamber of the particle electrophoresis instrument (Zetasizer Nanoseries Nano-ZS, Malvern Instruments, Worcestershire, UK). Samples with c m e d or c h i g h were diluted with distilled water 1:5 or 1:10, respectively, to reach an optimal attenuation of 7. Changes in pH-values due to dilution were considered in further evaluations. As a refractive index, 1.42 was used [23]. All measurements were performed in triplicate at 20∘C.

Particle Size Determination

Particle size distributions of WPI-pectin complexes were determined using a LS-230 laser scattering particle size analyzer (BeckmanCoulter, Brea, USA). The calculations are based on the Mie theory allowing a particle detection within a range of 0.01 - 3000 μm. Datasets were evaluated based on a logarithmic density distribution [37, 38]. A refractive index of 1.42 was used for the measurements [23]. All measurements were performed in triplicate at 23∘C.

Visual Observation

WPI-pectin complex suspensions (10 mL) were placed in test tubes and stored at room temperature (23∘C) for 30min. Digital images were taken and phase separation was recorded.

Statistical Analysis

The effects of the variables concentration level C, heating temperature 𝜗 and pH on the micro- and macro-structural properties of WPI-pectin complex suspensions were studied using a 3-factorial experimental design with two blocks. Experiments were performed in randomised order. The entire experimental design was used for suspensions of WPI-HMP and WPI-LMP complexes separately.

Results were analysed statistically using SAS software (version 9.4, SAS Institute Inc., Cary, USA). Significant differences in micro- and macro-structural properties (p < 0.05) and significant parameter interactions (p < 0.05) were evaluated.

Results and Discussion

Fluorescence Spectroscopy

β-Lg is a globular protein consisting of 162 amino acids. It has two Trp residues, Trp19 and Trp61. Whereas the first one is located at the bottom of a hydrophobic calyx formed by beta-sheets, the second one is located close to the exposed disulfide bond between Cys66 and Cys160 which is assumed to quench Trp61 fluorescence. Therefore mainly Trp19 contributes to fluorescence emission [39]. Trp19 is very susceptible towards changes in its local environment, so that conformational changes can be monitored by changes in fluorescence intensities and shifts in emission maxima. It was shown that the fluorescence intensity of β-Lg is greater than of α-lactalbumin [40] so that the following assumptions will focus on b-LG even though the WPI contained small amounts of α-lactalbumin.

Addition of pectin to WPI, exemplarily shown for HMP (Fig. 1), resulted in an increase in maximum fluorescence intensity, whereas just a small red shift in the emission maximum occurred. Increases in intensity are associated with unfolding of tertiary protein structure [41, 42]. Hence it can be assumed that pectin induces an opening of the β-Lg molecule. Complete unfolding of β-Lg is characterized by a large red shift [43], such as for pure heat treated WPI (Fig. 1). The small red shift due to pectin addition indicates that the local environment became slightly more hydrophilic, suggesting that β-Lg did not unfold completely.

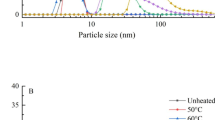

The impact of specific parameters on the inner complex structure can be studied by plotting the IR against the pH as shown exemplary in Fig. 2 for WPI-HMP complex suspensions heated at 90∘C at c l o w , c m e d and c h i g h . The slope can serve as a measure for the sensitivity of complexes towards changes in their environment such as post-heating acidification. A positive slope indicates a higher sensitivity, associated with unfolding of β-Lg, whereas a slope near zero indicates stability against environmental changes associated with very little conformational changes. The intercept can be used as a measure for tendencies of the whole complex suspension regarding unfolding of β-Lg. The equation parameters of all suspensions are summarised in Table 1 and were evaluated with respect to the impact of heating temperature, concentration level and DE.

Course of intensity ratios, derived from fluorescence spectra, depending on the pH after heating for WPI-HMP complex suspensions after heating at 90∘C for 250 s at ∙ c l o w , ∘ c m e d and \( \blacktriangledown \) c h i g h . Dotted line: intensity ratio of native β-lactoglobulin. I 350 n m : Fluorescence intensity at 350 nm, I 330 n m : Fluorescence intensity at 330 nm, IR: Intensity ratio

Post-heating acidification of pure β-Lg suspensions under similar conditions leads to distinct changes in particle size and structure [23] implying conformational changes in β-Lg. All complex suspensions, however exhibited very small slopes and intercepts close to 1.00 indicating that post-heating acidification had a low impact on unfolding of b-LG in the complexes (s. Table 1). Thus, we deduced that pectin addition had a protective effect on β-Lg against environmental changes. This is in good accordance with literature, as a protective effect on complex components has already been shown for Trp in β-Lg [44] and polyunsaturated fatty acids [45] using pectins of other origins.

Systems with LMP exhibited an increase in slope with increasing concentration level indicating a higher sensitivity towards acidification. Two groups could thereby be defined: the magnitudes of slopes at c m e d and c h i g h were similar, whereas the slope at c l o w was always smaller. Complex structures formed at c l o w were possibly different from those formed at c m e d and c h i g h causing different responses to acidification. A decrease in unfolding with increasing concentration level, indicated by decreasing intercepts, implies different concentration related structuring behaviour as well. Thus, the degree of unfolding decreased with increasing concentration level, pointing towards a looser structure similar as found for pure WPI particles [46].

In contrast to LMP, complex suspensions with HMP exhibited no clear trends for slopes. However, the slope at c l o w was always higher than for suspensions with LMP, no classification according to concentration level was possible. Moreover, a positive correlation between intercept and concentration level was found for the same heating temperature. This implies a higher degree of unfolding with increasing concentration level, contrary as seen for complex suspensions with LMP. Thus we assumed that complexes with LMP possibly have a looser structure at c l o w and a more compact structure at c m e d and c h i g h . Complexes with HMP are assumed to exhibit different structures independent of concentration level.

ζ-Potential of Complexes in WPI-Pectin Suspensions

The influence of process parameter variation on the ζ-potential of WPI-pectin suspensions is shown in Fig. 3. All complex suspensions showed an increase in ζ-potential with decreasing pH which is characteristic for complexes between WPI and anionic polysaccharides [13]. The average ζ-potential for complex suspensions with LMP was approximately -20 mV lower than for suspensions with HMP, independent of concentration level and heating temperature. This is attributed to the differences in negative charge between LMP and HMP, as LMP has a lower DE than HMP and thus possesses more carboxylic groups [27].

Influence of pH on the ζ-potential of WPI-pectin complex suspensions at (a) c l o w (0.5 % WPI+0.1 % pectin) and (b) c h i g h (5.0 % WPI+1.0 % pectin), after heating at different temperatures (∘/ ∙ 80∘C, \(\square \)/\( \blacksquare \) 85∘C, \(\vartriangle \)/\( \blacktriangle \) 90∘C) for 250 s. Empty symbols: complexes with LMP, filled symbols: complexes with HMP

Complex suspensions at c l o w exhibited a gradual increase in ζ-potential, whereas suspensions at c m e d and c h i g h , exemplary shown for c h i g h in Fig. 3b, remained almost constant until pH 5.0. The critical range between ±15 mV favouring particle aggregation, was reached at higher pH values for WPI-HMP complex suspensions at c l o w than at the other two levels. This indicates that complex suspensions at c l o w were more sensitive against acidification than the other two suspensions. Complex suspensions with LMP showed the same pH-induced behaviour, however due to the overall more negative ζ-potential, these suspensions did not reach the critical range.

An increase in heating temperature from 80 to 90∘C caused a significant decrease in ζ-potential in all complex suspensions (p <0.01). Still, the impact of heating temperatures on the overall ζ-potential was minor, as the concentration level showed a higher significance (p <0.001) and the magnitude of its overall impact was more distinct. Based on our results, we concluded that the protective effect of pectin addition against acidification depended on the DE of pectin and on the concentration level.

Particle Size Distribution

As our experiments on ζ-potential measurements revealed a correlation of concentration levels, acidification and DE with favoured complex aggregation, we further investigated their impact on particle size distributions of complexes (s. Table 2).

Complex suspensions with LMP were characterised by complex sizes <1 μm, only the suspension at c m e d and pH 4.0 revealed a d90,3 >1 μm. Complex suspensions with HMP exhibited complex sizes ranging from 0.25 - 197 μm. These results are in good accordance with the ζ-potential measurements (s. Fig. 3), implying that the DE determines the overall dimension of complex sizes. Differences in complex sizes due to different DE have been reported in similar contexts and are attributed to the amount of esterified groups, enabling a more compact structure at low concentrations and a more loose structure at high concentrations of esterified groups [23, 47, 48].

Despite the different size ranges, both suspension types exhibited an increase in complex size due to post-heating acidification, indicating a secondary aggregation. This phenomenon is attributed to reduced electrostatic repulsion between complexes, typically found for negatively charged biopolymer complexes [13]. Complex suspensions with LMP showed secondary aggregation at pH < 4.5, whereas suspensions with HMP exhibited this behaviour already below pH 5.0 (except the suspension at c h i g h ) (s. Table 2). This indicates that LMP had a more distinct protective effect against acid-induced aggregation than HMP. The differences in pH stability can be ascribed to the more negative ζ-potential of WPI-LMP complexes [27]. The protective effect of pectin addition seems to be related to the specific conditions of complex formation, as a more rigid thermal treatment combined with an initial pH of 4.75 showed little impact of the DE on secondary aggregation [49]. Complex formation under conditions similar to ours resulted in a higher stability of complexes with LMP than with HMP [23].

Complex suspensions with HMP exhibited an increase in complex size with increasing concentration level. Similar results have been found for pure WPI and WPI and other polysaccharides [50, 51] indicating that WPI-HMP complexes are subjected to the same concentration-size correlation as the other polymers. The increase in complex size went along with an increase in standard deviations. Shear forces, here occurring during measurements of static light scattering, are suspected to disrupt large, loose aggregates causing an increase in standard deviation. Thus, we deduced that the structure of WPI-HMP secondary aggregates was more loose than of WPI-LMP aggregates as no increase was observed for complexes with LMP. A more loose structure in secondary aggregates with HMP has been found in other contexts and is ascribed to the higher amount of esterified groups causing steric hindrance [23, 47, 48].

With respect to an application as fat replacer, WPI-pectin complexes should be sensorial active, possessing complex sizes in the target range of 1-10 μm [24, 25, 52]. Complex suspensions at c m e d were able to meet this requirement, in fact three suspensions based on WPI and HMP at pH 6.1 - 5.0 and one with LMP at pH 4.0. It seems as if a minimum concentration of biopolymers is necessary to receive complex sizes >1 μm, whereas the biopolymer concentration at c h i g h is too high to obtain complex sizes <10 μm. The other prerequisite appears to be a ζ-potential in the range between -55 and -30 mV, which corresponds to the pH-values at pH 6.1 - 5.0 for WPI-HMP complex suspensions and pH 4.0 for WPI-LMP, respectively. Other than for complexes between β-Lg and acacia gum which showed a superposition of the impact of acidification on complex size by the concentration level [53], here both prerequisites have to be fulfilled to receive complexes within the target range. However, even though the system at c h i g h and pH 4.0 fulfils both requirements, the resulting d90,3 was <1 μm. As the standard deviation of the d90,3 from three independent experiments is low, it might be possible that there are other superposing effects preventing the particles from aggregation.

The complexes with sizes >10 μm, such as in WPI-HMP suspensions at c h i g h , might be utilised as structuring agents or fat replacers, if subjected e. g. to a post-heating shear treatment.

Visual Observation of Phase Separation

The particle-size distributions of WPI-pectin complex suspensions revealed that certain suspensions were more suitable for the application as fat replacers than others. With respect to an application in complex food systems, the phase separation behaviour provides further information on the interactions in multi-component food systems and gives a broader impression of WPI-pectin complex characteristics.

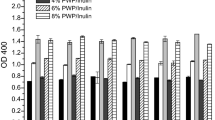

At any parameter combination (data exemplary shown for heating at 90∘C), all suspensions containing WPI-LMP complexes showed no tendency towards phase separation (Fig. 4a). This indicates a distinct stability against post-heating acidification which is in good accordance with ζ-potentials, particle size distributions and other studies [28, 54]. Even though WPI-LMP complexes did not meet the size-requirements for fat replacers, the high stability against post-heating acidification points to a potential application as nano-delivery systems, for micro-encapsulation and in emulsions [55–57].

Influence of concentration and pH on the phase separation behaviour of WPI-pectin complex suspensions after heat treatment (90∘C, 250 s); a WPI-LMP complexes, b WPI-HMP complexes; c h i g h : 5.0 % WPI + 1.0 % pectin, c m e d : 2.75 % WPI + 0.55 % pectin, c l o w : 0.5 % + 0.1 % pectin; \( \square \) no separation ■ phase separation

All suspensions with WPI-HMP complexes showed phase separation for pH-values < 4.5 (Fig. 4b). The reduced electrostatic interactions seem to be independent of heating temperature and concentration level, enabling a separation of WPI-HMP complexes. This is in good accordance with studies on phase separation of mixed protein-polymer suspensions, showing precipitation at pH-values below the isoelectric point of the protein [29, 51]. Apart from complex suspensions at pH 4.0, only the suspension at c l o w and pH 4.5 exhibited phase separation. As the pH-value is a main factor determining the phase separation behaviour [58], also complex suspensions at c m e d and c h i g h could have exhibited phase separation. A possible explanation might be that phase-separation via segregative depletion-flocculation took place. This phenomenon occurs for suspensions with particle like proteins such as large aggregates of heat-treated proteins and total biopolymer concentrations <1 % [29, 59] as given in this case. We concluded that the separation behaviour of WPI-HMP complexes was mainly influenced by the pH value and to a lesser extend by the concentration level. Chun et al. [29] found that the separation behaviour of complexes between β-Lg and HMP was strongly influenced by total biopolymer ratio and concentration and to a lesser extend by the pH value. However, the complexes studied by Chun et al. consisted of β-Lg which was heated at 80∘C for 30min, resulting in a completely different response to environmental impacts. This underlines the strong impact of different heating conditions on complex characteristics.

Evaluation of Parameter Interactions

By using a statistical design of experiments, we were able to give a detailed overview on the effects of varied parameters on micro- (IR) and macro-structural (ζ-potential, d90,3, phase separation) characteristics of WPI-pectin complexes (Table 3).

We found that the concentration level had a positive influence on intensity ratio and ζ-potential of the WPI-LMP complexes, resulting in a stronger unfolding of β-Lg and a higher stability against post-heating acidification, respectively. However, the concentration level had no significant impact on the macro-structural characteristics of the complexes. The impact of the heating-temperature was limited on the ζ-potential, but can be considered as minor (p < 0.01) compared with the impact of concentration level and DE (p < 0.001). The pH-value, however had a strong impact on ζ-potential (p < 0.001) and also on the macro-structural parameter ln(d90,3) (p < 0.001) which is in good accordance with literature [23, 47]. Any of the parameters caused phase separation. With respect to an application in food formulations, it appears that all parameters influence the ζ-potential of the complexes, but only the post-heating acidification significantly affects the particle size distribution. As no parameter interactions were found, tailoring of WPI-LMP complexes using the examined set of parameters seems to be possible.

In contrast to WPI-LMP complexes, the impact of the concentration level on suspensions with WPI-HMP complexes comprised micro- and macro-structural characteristics, indicating a higher sensitivity against environmental influences. Similarly as found for LMP-complexes, the impact of heating-temperatures on WPI-HMP complexes was limited to micro-structural characteristics. The acidification, however affected all levels of complex characteristics. This finding indicates the importance of control of post-heating pH, especially for pH ≤ 4.5, as distinct changes in complex characteristics were observed below this value. On tailoring WPI-HMP complexes, interactions of process parameters have to be considered, as significant synergisms were found affecting micro- and macro-structural characteristics.

Conclusion

The impact of intrinsic (concentration level, DE) and extrinsic (𝜗, pH) parameters on stability of thermally stabilised whey protein-pectin complexes was investigated on micro- and macro-structural levels using fluorescence spectroscopy, ζ-potential measurements, dynamic light scattering and phase separation behaviour. We established a set of parameters by which whey protein-pectin complexes with tailored properties can be generated. Complex suspensions with LMP possessed high pH-stability and complex sizes <1 μm, predestining them for nano-scale applications such as micro-encapsulation. Stable complexes with sizes ranging from 1-10 μm were achieved by heating WPI-HMP suspensions at a medium biopolymer concentration level at 90∘C for 250s, demonstrating their potential as fat-replacers in neutral and slightly acidic food systems. At c h i g h , WPI-HMP complex aggregates exhibited sizes from 20-200 μm suggesting an application as structuring elements in neutral and acidic food systems. By using fluorescence spectroscopy, we got additional information on the protective effect of pectin addition against unfolding of β-Lg. Its magnitude depended on the DE, being more pronounced for complex suspensions with LMP than with HMP.

We were able to show that specific thermally stabilised whey protein-pectin complexes have the potential to be applied as a fat-replacers similar to microparticulated whey proteins but with an additional carbohydrate component bringing further nutritional benefits.

With respect to stability during processing, future research will focus on the impact of shear stress and calcium ions on micro- and macro-structural levels. In order to elucidate the improved stability due to heat-treatment, additional studies on stabilising bonds are necessary.

Abbreviations

- b-Lg:

-

β-lactoglobulin

- DE:

-

Degree of esterification

- HMP:

-

High methoxyl pectin

- IR:

-

Intensity Ratio

- LMP:

-

Low methoxyl pectin

- Trp:

-

Tryptophan

- WPI:

-

Whey protein isolate

References

B. Rolls, K. Leahy. Obesity prevention (Academic Press, San Diego, 2010), pp. 543–554.

J. Buttriss, Proc. Nutr. Soc. 75, 61–69 (2013).

V. Malik, W. Willett, F. Hu, Nat. Rev. Endocrinol. 9, 13–27 (2013).

D. Sandrou, I. Arvanitoyannis, Crit. Rev. Food Sci. Nut. 40, 427–447 (2010).

M. Frost, T. Janhoj, Int. Dairy J. 17, 1298–1311 (2010).

P. Lucca, B. Tepper, Trends Food Sci. Tech. 5, 12–19 (1994).

S. Patel, J Food Sci Tech 1–12, 2015.

H. Liu, M. Xu, S. Guo, Food Sci. Tech. 40, 946–954 (2007).

P. Schenkel, R. Samudrala, J. Hinrichs, Int. J. Dairy Tech. 66, 220–230 (2013).

M. Tomaschunas, J. Hinrichs, E. Kühn, M. Busch-Stockfisch, Int. Dairy J. 26, 31–35 (2014).

B. Hamaker, Y. Tuncil, J. Mol. Biol. 426, 3838–3850 (2014).

V. Tolstoguzov. (Marcel Dekker Inc., New York, 1997), ed. by S. Damodaran. Food proteins and their applications, pp. 171– 198.

O. Jones, D. McClements, Compr. Rev. Food Sci. F. 9, 374–397 (2010).

E. Dickinson, J. Sci. Food Agr. 93, 710–721 (2013).

C. Schmitt, S. Turgeon, Adv. Colloid Interfac. 167, 63–70 (2011).

U. Schmidt, V. Pietsch, C. Rentschler, T. Kurz, H. Endress, H. Schuchmann, Food Hydrocoll. 56, 1–8 (2016).

A. Krzeminski, K. Prell, M. Busch-Stockfisch, J. Weiss, J. Hinrichs, Int. Dairy J. 36, 118–127 (2014).

M. Dissanayake, S. Liyanaarachchi, T. Vasiljevic, J. Dairy Sci. 95, 1667–1679 (2012).

M. Dissanayake, T. Vasiljevic, J. Dairy Sci. 92, 1387–1397 (2009).

O. Jones, D. McClements, Food Biophys. 3, 191–197 (2008).

S. Hirt, O. Jones, J. Food Sci. Tech. 49, 2391–2398 (2014).

A. Perez, R. Andermatten, A. Rubiolo, L. Santiago, Food Chem. 158, 66–72 (2014).

A. Krzeminski, K. Prell, J. Weiss, J. Hinrichs, Food Hydrocoll. 35, 332–340 (2014).

L. Engelen, R. de Wijk, A. van der Bilt, J. Prinz, A. Janssen, F. Bosman, Physiol. Behav. 86, 111–117 (2005).

L. Engelen, A. van der Bilt, J. Texture Stud. 39, 83–113 (2008).

Q. Wang, K. Qvist, Food Res. Int. 33, 683–690 (2000).

B. Sperber, M. Cohen Stuart, H. Schols, A. Voragen, W. Norde, Biomacromolecules. 10, 3246–3252 (2009).

M.-C. Gentés, D. St-Gelais, S. Turgeon, J. Agric. Food Chem. 58, 7051–7058 (2010).

J. -Y. Chun, G. -P. Hong, S. Surassmo, J. Weiss, S.-G. Min, M.-J. Choi, Polymer. 55, 4379–4384 (2014).

A. -M. Ciuciu, I. Aprodu, L. Dumitrascu, G. Bahrim, P. Alexe, N. Stanciuc, J. Mol. Struct. 1095, 26–33 (2015).

A. Shpigelman, Y. Shoham, G. Israeli-Lev, Y. Livney, Food Hydrocoll. 40, 214–224 (2014).

A. Xu, L. Melton, G. Jameson, M. Williams, D. McGillivray, Soft Matter. 11, 6790–6799 (2015).

P. Qi, E. Wickham, R. Garcia, J. Agr. Food Chem. 62, 7567–7576 (2014).

P. Qi, H. Chau, M. Fishman, E. Wickham, A. Hotchkiss, Carbohyd. Polym. 107, 198–208 (2014).

F. Dannenberg, H. Kessler, J. Food Sci. 53, 258–263 (1988).

H. Kessler, H. Beyer, Int. J. Biol. Macromol. 13, 165–173 (1991).

C. Bhattacharjee, K. Das, Eur. J. Biochem. 267, 3957–3964 (2000).

A. Post, J. Weiss, J. Hinrichs, Milchwissenschaft. 67, 119–123 (2012).

K. Sommer, J. Hinrichs, Part Part Syst. Char. 18, 22–25 (2001).

T. Croguennec, D. Molle, R. Mehra, S. Bouhallab, Protein Sci. 13, 1340–1346 (2004).

L. Liang, J. Zhang, P. Zhou, M. Subirade, Food Chem. 141, 754–761 (2013).

J. Lakowicz, Principles of fluorescence spectroscopy (Spriger Inc., New York, 2006).

E. Ruffin, T. Schmit, G. Lafitte, J. -M. Dollat, O. Chambin, Food Chem. 151, 324–332 (2014).

P. Qi, D. Ren, Y. Xiao, P.M. Tomasula, J. Dairy Sci. 98, 2884–2897 (2015).

A. Perez, O. Sponton, R. Andermatten, A. Rubiolo, L. Santiago, Food Chem. 188, 543–550 (2015).

Y. Ni, L. Wen, L. Wang, Y. Dang, P. Zhou, L. Liang, Int. Dairy J. 51, 8–15 (2015).

H. Salminen, J. Weiss, Food Biophys. 35, 410–419 (2014).

M. Kazmierski, L. Wicker, M. Corredig, J. Food Sci. 68, 1673–1679 (2003).

O. Jones, U. Lesmes, P. Dubin, D.J. McClements, Food Hydrocoll. 24, 374–383 (2010).

S. Mehalebi, T. Nicolai, D. Durand, Int. J. Biol. Macromol. 43, 129–135 (2008).

G. Zhang, E. Foegeding, Food Hydrocoll. 17, 785–792 (2003).

P. Cayot, F. Schenker, G. Houze, C. Sulmont-Rosse, B. Colas, Int. Dairy J. 18, 303–311 (2008).

C. Schmitt, C. Sanchez, F. Thomas, J. Hardy, Food Hydrocoll. 13, 483–496 (1999).

O. Jones, E. Decker, D. McClements, Food Hydrocoll. 24, 239–248 (2010).

I. Arroyo-Maya, D. McClements, Food Res. Int. 69, 1–8 (2015).

D. Xu, F. Yuan, Y. Gao, D. McClements, E. Decker, Food Chem. 139, 1098–1104 (2013).

Z. Xiao, W. Liu, G. Zhu, R. Zhou, Y. Niu, J. Sci. Food Agr. 94, 1482–1494 (2014).

V. Tolstoguzov. (Woodhead Publishing Limited, Cambridge, 2007), ed. by D. McClements. Understanding and controlling the microstructure of complex foods, pp. 185–203.

J. -L. Doublier, C. Garnier, D. Renard, C. Sanchez, Curr. Opin. in Colloid. 5, 202–214 (2000).

Acknowledgments

This research project was supported by the German Ministry of Economics and Technology (via AiF) and the FEI (Forschungskreis der Ernährungsindustrie e. V.). Project AiF 17876 N. The authors thank Xiaohe He for performing the measurements on WPI-HMP complexes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Protte, K., Bollow, C., Sonne, A. et al. Impacts on Micro- and Macro-Structure of Thermally Stabilised Whey Protein-Pectin Complexes: A Fluorescence Approach. Food Biophysics 11, 226–234 (2016). https://doi.org/10.1007/s11483-016-9433-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-016-9433-8