Abstract

This study focuses on the quantitative description of the evolution of creep coefficient (C αe) with both soil density and soil structure under 1D compression. Firstly, conventional consolidation test results on various reconstituted clays are selected in order to investigate the evolution of C αe with void ratio of soils, which can be described by a simple nonlinear creep formulation. Secondly, the contributions of the inter-particle bonding and debonding for soft structured clays to C αe are analyzed based on test results on intact and reconstituted samples of the same clay. A material constant ρ, function of the bonding ratio χ, is introduced in order to quantify the contribution of the soil structure to C αe, and a nonlinear creep formulation accounting for both soil density and soil structure is finally proposed. Furthermore, the parameters used in the formulation are correlated with Atterberg limits, allowing us to suggest a relationship between C αe, Atterberg limits and inter-particle bonding for a given soil. Finally, the validity of the proposed formulation is examined by comparing experimental and predicted C αe values for both reconstituted and intact samples of natural soft clays. The proposed formulation is also validated by comparing the computed and measured void ratio with time on two intact clays.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Natural soft clays exhibit significant creep under both laboratory and in situ conditions after primary consolidation [2, 3, 7, 9, 10, 15, 17, 19, 27, 29–32, 34]. In early days, this was often called “secondary consolidation.” The term “creep” is preferable because it is referred to the compression of soil skeleton under a constant loading, having nothing to do with consolidation [28]. The creep coefficient, defined as C αe = Δe/Δlogt based on one-dimensional creep testing, is a key parameter for engineering practice and viscoplastic modeling [1, 11, 12, 26, 29, 32, 33]. Thus, it is important to evaluate this coefficient with accuracy.

Many studies on the characteristics of the creep have been carried out through one-dimensional creep tests on both reconstituted and intact natural clay samples. For reconstituted clay, the value of C αe varies with the void ratio. For instance, Yin [27] and Yin et al. [30] formulated a nonlinear expression of C αe function of volumetric strain and time under applied stresses considering the density or void ratio of soils. More recently, Yin et al. [34] proposed in a more precise way a linear decrease in C αe with the void ratio in a double logarithm plane based on results on various reconstituted clays. For intact natural soft clays, the value of C αe depends highly on the destructuration, as demonstrated by Karstunen and Yin [10], Leroueil et al. [15], Mesri and Godlewski [17] and Yin et al. [33], etc. Therefore, C αe is generally not constant but dependent on both the void ratio and the soil structure (or inter-particle bonding and debonding) of soft soils. However, few studies have been devoted to a quantitative description of the nonlinear evolution of C αe due to changes of both soil density and soil structure in natural soft clays. Furthermore, for correlating C αe to clay physical properties (e.g., Atterberg limits), an average value or the value of C αe corresponding to a final high stress level in conventional oedometer tests has usually been adopted. Since C αe is not a constant, it is necessary to seek a reference value of C αe to re-establish the correlation.

In this study, therefore, we focus on the quantitative description of the evolution of C αe with both void ratio and soil structure under the condition of applied stresses exceeding the yield stress. For this purpose, available test results on intact and reconstituted samples of natural soft clays are selected for analyses. We also carry out conventional consolidation tests on reconstituted and intact samples of several clays for expanding our data base. The values of C αe corresponding to liquid and plastic limits (C αeL, C αeP) are then estimated as reference values, based on which C αe could be expressed as a function of one of the reference values C αef (=C αeL or C αeP), the water content (w) and the inter-particle bonding (χ). Furthermore, correlations could be established in order to estimate the value of C αe from Atterberg limits for a given natural soft clay. Then, the proposed function is validated by comparing the estimated and experimental C αe values.

2 Nonlinear creep related to soil density

2.1 Experimental evidence

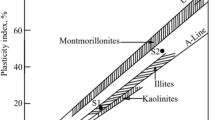

Conventional consolidation tests on various soft clays with different mineral contents and Atterberg limits were selected for this study. In this section, all the selected data are based on reconstituted samples to eliminate the influence of soil structure. Some physical properties of the selected clays are summarized in Table 1. According to the chart shown in Fig. 1, the selected soils consist of low plastic clays, high plastic inorganic clays and high plastic silty clays. Since the void ratio (e) is a physical state of soils representing the soil density and the deformation potential, the C αe values for all the selected clays are individually plotted against the void ratio in a double logarithmic plane, presented in Fig. 2. All the results show that log(C αe) is linearly related to log(e).

2.2 Nonlinear creep formulation accounting for void ratio

The consideration of the density and void ratio has been addressed by Yin [27] based on Hong Kong marine clay. Based on the results in Fig. 2, the nonlinear creep formulation based on Finnish clays proposed by Yin et al. [34] can be adopted:

where C αef and e f are reference values of C αe and e, respectively (the initial in situ void ratio e 0 was used as e f by Yin et al. [34]) and m is a material constant representing the slope of the log(C αe)–log(e) curve which can be measured in a straightforward way (summarized in Table 1 for all clays). It is worth noting that C αe is conventionally defined as the slope of the secondary compression line with the logarithm of time, which is reasonable for design purpose in civil engineering, but resulting in a negative void ratio during creep under long periods of time, whereas Eq. (1) imposes a value of e converging toward zero but remaining always positive.

The reference point (C αef, e f) can be arbitrary selected. However, it could be of interest to select specific values of the reference void ratio. The void ratio at the liquid or plastic limit (e L or e P) is usually adopted to establish the equations for compressibility [20, 21]. These two values can be easily determined from the liquid or plastic limits w L and w P which are usually available physical properties of clayey soils. Along these lines, two representative points (corresponding to e L and e P) on the log(C αe)–log(e) curve can be alternatively used as reference points. Based on Fig. 2, both C αeL and C αeP corresponding to the void ratios e L and e P can be obtained and Eq. (1) can be rewritten as

3 Nonlinear creep related to soil structure

3.1 Experimental evidence

During conventional consolidation tests on intact samples of natural soft clays, the shape of the post-yield compression curve is significantly influenced by the debonding process during straining [10, 13, 23]. Figure 3 shows the schematic plot of the compression curves of intact and reconstituted clay samples. For a given inelastic strain level Δe p, the bond degradation results in the current stress \( \sigma_{\text{v}}^{\prime } \) reaching point A instead of point B (assuming no destructuring). Corresponding to stress \( \sigma_{\text{v}}^{\prime } \) at Δe P, we define an intrinsic stress \( \sigma_{\text{vi}}^{\prime } \), which is the stress for a reconstituted sample at the same inelastic strain increment (point C). Based on this plot, a bonding ratio can be defined by \( \chi = {{\sigma_{\text{v}}^{{\prime }} } \mathord{\left/ {\vphantom {{\sigma_{\text{v}}^{{\prime }} } {\sigma_{\text{vi}}^{{\prime }} - 1}}} \right. \kern-0pt} {\sigma_{\text{vi}}^{{\prime }} - 1}} \) with an initial bonding ratio of \( \chi_{0} = {{\sigma_{{{\text{p}}0}}^{{\prime }} } \mathord{\left/ {\vphantom {{\sigma_{{{\text{p}}0}}^{{\prime }} } {\sigma_{{{\text{pi}}0}}^{{\prime }} - 1}}} \right. \kern-0pt} {\sigma_{{{\text{pi}}0}}^{{\prime }} - 1}} \) (similar to Gens and Nova [8]; Yin et al. [33, 34]). When the strain increases, the inter-particle bonds are progressively broken and χ decreases from its initial value χ 0 toward zero, corresponding to a state where all the bonds are completely destroyed, as shown in Fig. 3.

Adopting this concept, we consider that the difference between the values of C αe at point A and point C is due to the effect of soil structure. Defining the creep coefficients C αe(I) and C αe(R) at points A and C (Fig. 3), the additional creep induced by destructuration (or inter-particle debonding) can be written as:

3.2 Nonlinear creep formulation accounting for soil structure

To investigate the contribution of soil structure on C αe, conventional consolidation tests on both intact and reconstituted clay samples of the same clay are necessary. Table 2 summarizes the available results of 1D creep tests on both intact and reconstituted samples of ten different clays (corresponding to the first ten clays in Table 2, including the tests on Shanghai clay performed in this study). The classification of these clays is shown in Fig. 1.

Figure 4 presents the plots of C αe(I) with the bonding ratio χ, where C αe(I) in these graphs was directly measured from tests on intact clays. Note that C αe(R) was estimated by Eq. (1) from experimental data on reconstituted clays at the corresponding void ratio (point C in Fig. 3) and served as the reference for the effect of destructuration. It can be seen that C αe(I) decreases linearly with the decreasing of χ in a logarithmic scale. Based on the concept used to define χ (Fig. 3), we can express the contribution of the soil structure to the creep coefficient by the index ρ:

where ρ is always positive. In order to investigate the relation between ρ and χ, values of ρ for all the selected clays were estimated by Eq. (4) and plotted versus χ in Fig. 5. It can be observed that ρ presents a linear relationship with log(χ), which can be expressed as:

where n is a material constant representing the slope of the ρ–log(χ) curve, ρ 0 is the initial value of ρ corresponding to χ = χ 0 and ρ decreases from ρ 0 toward zero when all the bonds are completely destroyed.

Substituting Eqs. (1) and (5) into Eq. (4), the creep coefficient for intact natural soft clays can be written as:

Equation (6) indicates that C αe depends on the material constants C αef, e f, m, χ 0, ρ 0, n and the current state variables χ and e. As described earlier, e L or e P can be used as e f, and the corresponding values C αeL or C αeP obtained from Fig. 2 can be used as C αef. The material constants C αef, e f, m can be determined from tests on reconstituted clay and χ 0, ρ 0, n from tests on both reconstituted and intact clays. Note that all material constants can be determined from conventional oedometer tests in a straightforward way.

The creep behavior is closely connected to the micro-properties of clay, such as the shape of particle, the inter-/intra-aggregate pore size distribution and the double layer, which can be characterized by Atterberg limits [18]. Thus, the correlations between material constants relating to creep (Eq. 6) and Atterberg limits were investigated based on available results, considering that such correlations would be useful for engineering practice.

4 Correlations of nonlinear creep properties with Atterberg Limits

4.1 Correlations of CαeL and CαeP with Atterberg Limits

For correlating C αeL and C αeP with Atterberg limits, the available test results on 15 reconstituted clays (with tests on three clays performed in this study) listed in Table 1 were selected. Figure 6a, b presents the plots of C αeL with Atterberg limits, from which the following relation could be obtained with a correlation coefficient R 2 = 0.9336:

Similarly, Fig. 6c, d shows the correlations for C αeP indicating that the optimized correlation is obtained by using both the liquid limit and the plasticity index with a correlation coefficient R 2 = 0.6913:

From these correlations, it appears that the choice of C αeL as the reference value for C αe in Eqs. (2) and (6) is preferable given the higher correlation coefficient. Thus, the C αeL with w L can be used as reference in Eq. (6), and the Eq. (6) is rewritten as,

4.2 Correlation of m with Atterberg Limits

Based on all the estimated values of m shown in Eq. (6) for 15 reconstituted clays, the correlations between m and Atterberg limits were fitted. Figure 7 shows that the optimized correlation is obtained by using both liquid limit and plasticity index with a correlation coefficient R 2 = 0.5217:

4.3 Correlation of n with Atterberg Limits

Figure 8 presents the correlations between the material constant n shown in Eq. (6) and Atterberg limits based on test results on both intact and reconstituted samples of ten clays. It can be observed that the magnitude of n decreases with the increase in the liquid limit or plasticity index. Furthermore, the values of n are shown to relate better with the liquid limit and plasticity index with a correlation coefficient R 2 = 0.6300:

4.4 Correlation of ρ 0 with Atterberg Limits

As mentioned above, ρ 0 is the initial value of ρ corresponding to χ = χ 0 and it represents the secondary compression potential induced by debonding. Consequently, a certain relation between ρ 0 and χ 0 can be observed. Hence, the link between the ratio ρ 0/χ 0 and Atterberg limits was analyzed from the test results on both intact and reconstituted samples of ten clays. Based on the findings, ρ 0/χ 0 can be expressed either by the liquid limit (Fig. 9a), or the plasticity index (Fig. 9b), or also by a unified expression with the liquid limit and the plasticity index (Fig. 9c). We adopted the latter expression with a correlation coefficient R 2 = 0.7641:

5 Discussions

5.1 Correlation between I P with w L

A certain relationship between I P and w L is apparent. In the past, several expressions have been proposed such as the ones by Burland [4] with I P = 0.73(w L − 20) and Biarez and Hicher [5] with I P = 0.73(w L − 13). Figure 10 presents the plots of these two parameters for the clays selected in this study together with the two lines representing the above correlations. The differences between these two lines and the experimental points are rather small, and we could consider one or the other correlation for our own materials. In order to remain as close as possible to our set of data, we chose to adopt the following best correlation represented in Fig. 10 by the bold line with a correlation coefficient R 2 = 0.9587:

Using Eq. (12), the above correlations of parameters with Atterberg limits can be simplified.

5.2 How to determine nonlinear creep

Over all, if the current water content (w), the bonding ratio (χ) and the liquid limit (w L) of the clayey soil are known, the current C αe can be obtained with the following process:

-

1.

Substituting w L into Eqs. (7), (12) and (13), C αeL, ρ 0/χ 0 and I p are obtained, respectively.

-

2.

With w L and I p, m and n can be obtained by Eqs. (10) and (11), respectively.

-

3.

The initial bonding ratio χ 0 can be taken equal to (S t − 1) according to Karstunen and Yin [10] and Yin et al. [32] with S t the soil sensitivity, and then ρ 0 can be obtained since ρ 0/χ 0 is known from the first step of process.

-

4.

Substituted all above correlated parameters into Eq. (9), C αe is obtained.

Note that w and χ are two state variables representing current soil density and current soil structure, respectively. Thus, Eq. (9) accounts for the soil density and the soil structure during straining with clear physical meaning, and can be of practical use for determining simply the creep potential of a given natural soft clay.

5.3 Validation for reconstituted clays

For reconstituted clays, the structure between particles is eliminated; therefore, χ 0 can be regarded null. Consequently, a reduced form of Eq. (9) for reconstituted clays can be written as:

Figure 11 shows the comparison between experimental and predicted results estimated by Eq. (14) for all the selected clays. Despite there are some discrepancies between measured and estimated values, Eq. (14) generally describes the evolution of C αe for reconstituted clays fairly well. We illustrated the influence of w L on C αe in Fig. 12. Because the maximum and minimum values of w L in Table 1 are 90 and 40 %, we plotted the evolution of C αe with water content for two clays having these liquid limits. It can be seen that the clay with a higher w L presents a higher increasing rate and that C αe decreases with the decreasing water content (i.e., decreasing void ratio) for each clay.

5.4 Validation for intact clays

For the ten intact clays shown in Fig. 4, the predicted values of C αe were estimated by Eq. (9) with the liquid limit w L and the structural parameter χ 0 listed in Table 2. Figure 13 compares experimental and predicted results in a 3D form (C αe–w–χ). It can be concluded that Eq. (9) is able to estimate with good accuracy the evolution of C αe for the majority of the studied clays. For the others, even if differences between measured and estimated values still remain (e.g., Lianyungang clay), the trend is well captured.

Furthermore, the proposed formulation (Eq. 9) was examined on predicting the evolution of void ratio with time during creep. For this, long-term oedometer tests on Vanttila and Wenzhou intact clays, with strong and moderate level of soil structure, were selected. Only parts of curves apparently after consolidation or dissipation of excess pore pressure were plotted for both computed and measured results in Fig. 14. Curves by using constant C αeL were also computed shown by dash lines for comparison. The computed void ratio by Eq. (9) decreases nonlinearly with time in logarithm scale for each loading shown by solid lines, which demonstrates that the proposed formulation can well capture the nonlinear creep degradation.

6 Conclusions

The one-dimensional creep characteristics of soft clays have been investigated based on experimental results from oedometer testing. The evolution of C αe for reconstituted and intact clays was studied.

For reconstituted clays, the influence of the soil structure could be eliminated. A nonlinear creep behavior has been observed with C αe decreasing when the soil density increases. Based on these results, a simple nonlinear creep formulation was adopted with an additional parameter of nonlinearity m. For simplification and practical use, C αeL (corresponding to the liquid limit) and C αeP (corresponding to the plastic limit) were suggested as the reference C αe.

The bond degradation process during straining exerts a significant influence on the values of C αe. The significant difference of C αe between intact and reconstituted clays was analyzed. The ratio of C αe between intact clay and the corresponding value for reconstituted clay was related to the bonding ratio with an additional parameter n, leading to a nonlinear creep formulation accounting for soil structure.

The proposed formulation of C αe for intact clays contains five material constants C αeL, C αeP, m, n and ρ 0, which can be determined in a straightforward way from conventional oedometer testing. Furthermore, correlations between these material parameters and Atterberg limits were proposed based on available data. By expressing the material constants as functions of the liquid limit and the plasticity index, we are able to suggest a practical expression of C αe as a function of the current water content w, the bonding ratio and the physical properties of the clay. These correlations allow the determination of the material constants from the sole knowledge of the liquid limit of a given clayey soil. Its capacity of estimating the C αe values of various clays has been demonstrated, and accurate estimations of the one-dimensional creep characteristics of both reconstituted and natural soft clays were obtained. Furthermore, the proposed formulation is also validated by comparing the computed and measured void ratio with time on two intact clays.

This study provides a simple way of estimating the creep coefficient of natural clays, which can be of practical use in geotechnical engineering. Since it is a key parameter for many creep modeling approaches, the creep coefficient can be used as a state variable based on this study and applied to a framework of modern and full-edged constitutive description in future studies, along with the modeling of the consolidation phase.

References

Adachi T, Oka F (1982) Constitutive equations for normally consolidated clay based on elasto-viscoplasticity. Soils Found 22(4):57–70

Augustesen A, Liingaard M, Lade PV (2004) Evaluation of time-dependent behavior of soils. Int J Geomech 4(3):137–156

Bjerrum L (1967) Engineering geology of Norwegian normally-consolidated marine clays as related to settlements of building. Géotechnique 17(2):81–118

Burland JB (1990) On the compressibility and shear strength of natural clays. Géotechnique 40(3):329–378

Biarez J, Hicher PY (1994) Elementary mechanics of soil behaviour. Balkema, Boca Raton

Chen XP, Zeng LL, Lü J, Qian H, Kuang LW (2008) Experimental study of mechanical behavior of structured clay. Rock Soil Mech 29(12):3223–3228

Desai DS, Sane S, Jenson J (2011) Constitutive modeling including creep- and rate-dependent behavior and testing of glacial tills for prediction of motion of glaciers. Int J Geomech 11(6):465–476

Gens A, Nova R (1993) Conceptual bases for a constitutive model for bonded soils and weak rocks. In: Proceedings of international symposium on hard soils–soft rocks, Athens, pp 485–494

Graham J, Crooks JHA, Bell AL (1983) Time effects on the stress-strain behaviour of natural soft clays. Géotechnique 33(3):327–340

Karstunen M, Yin Z-Y (2010) Modelling time-dependent behaviour of Murro test embankment. Géotechnique 60(10):735–749

Kutter BL, Sathialingam N (1992) Elastic-viscoplastic modelling of the rate-dependent behaviour of clays. Géotechnique 42(3):427–441

Leoni M, Karstunen M, Vermeer PA (2008) Anisotropic creep model for soft soils. Géotechnique 58(3):215–226

Leroueil S, Kabbaj M (1987) Discussion on ‘Composition and compressibility of typical samples of Mexico City clay’ by Mesri et al. J Geotech Eng Div 113(9):1067–1070

Leroueil S, Kabbaj M, Tavenas F (1988) Study of the validity of a \( \sigma_{\text{v}}^{\prime } - \varepsilon_{\text{v}} - \dot{\varepsilon }_{\text{v}} \) model in in situ conditions. Soils Found 28(3):13–25

Leroueil S, Kabbaj M, Tavenas F, Bouchard R (1985) Stress–strain–strain rate relation for the compressibility of sensitive natural clays. Géotechnique 35(2):159–180

Li Q, Ng CWW, Liu G (2012) Low secondary compressibility and shear strength of Shanghai clay. J Cent South Univ 19(8):2323–2332

Mesri G, Godlewski P (1977) Time and stress-compressibility interrelationship. J Geotech Eng Div 103(5):417–430

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. Wiley, New York

Niemunis A, Grandas-Tavera CE, Prada-Sarmiento LF (2009) Anisotropic visco-hypoplasticity. Acta Geotech 4:293–314

Nagaraj TS, Srinivasa Murthy BR (1983) Rationalization of Skempton’s compressibility equation. Géotechnique 33(40):433–443

Nagaraj TS, Pandian NS, Narasimha Raju PSR, Vishnu Bhushan T (1995) Stress-state-time permeability relationships for saturated soils. In: Proceedings of the International symposium on compression and consolidation of clayey soils is–Hiroshima, Japan, pp 537–542

Nash DFT, Sills GC, Davison LR (1992) One-dimensional consolidation testing of soft clay from Bothkennar. Géotechnique 42(2):241–256

Smith PR, Jardine RJ, Hight DW (1992) On the yielding of Bothkennar clay. Géotechnique 42(2):257–274

Stapelfeldt T, Lojander M, Vepsäläinen P (2007) Determination of horizontal permeability of soft clay. In: Proceeding of the 17th international conference of soil mechanics and foundations, vol 3, Madrid, pp 1385–1389

Suneel M, Park LK, Im JC (2008) Compressibility characteristics of Korean marine clay. Mar Georesour Geotechnol 26:111–127

Vermeer PA, Neher HP (1999) A soft soil model that accounts for creep. In: Proceedings Plaxis symposium “beyond 2000 in computational geotechnics”, Amsterdam, pp 249–262

Yin JH (1999) Non-linear creep of soils in oedometer tests. Géotechnique 49(5):699–707

Yin J (2015) Fundamental issues of elastic viscoplastic modelling of the time-dependent stress–strain behavior of geomaterials. Int J Geomech. doi:10.1061/(ASCE)GM.1943-5622.0000485

Yin JH, Graham J (1989) Viscous elastic plastic modelling of one-dimensional time dependent behavior of clays. Can Geotech J 26:199–209

Yin JH, Zhu JG, Graham J (2002) A new elastic viscoplastic model for time-dependent behaviour of normally and overconsolidated clays: theory and verification. Can Geotech J 39:157–173

Yin ZY, Hicher PY (2008) Identifying parameters controlling soil delayed behaviour from laboratory and in situ pressuremeter testing. Int J Numer Anal Methods Geomech 32(12):1515–1535

Yin ZY, Chang CS, Karstunen M, Hicher PY (2010) An anisotropic elastic viscoplastic model for soft soils. Int J Solids Struct 47(5):665–677

Yin ZY, Karstunen M, Chang CS, Koskinen M, Lojander M (2011) Modeling time-dependent behavior of soft sensitive clay. J Geotech Geoenviron Eng 137(11):1103–1113

Yin ZY, Xu Q, Yu C (2012) Elastic viscoplastic modeling for natural soft clays considering nonlinear creep. Int J Geomech. doi:10.1061/(ASCE)GM.1943-5622.0000284

Yu XJ, Yin ZZ, Dong WJ (2007) Influence of load on secondary consolidation deformation of soft soils. Chin J Geotech Eng 29(6):913–916

Zeng LL, Hong ZS, Liu SY, Chen FQ (2012) Variation law and quantitative evaluation of secondary consolidation behavior for remolded clays. Chin J Geotech Eng 34(8):1496–1500

Zhang XW, Wang CM (2012) Effect of soft clay structure on secondary consolidation coefficient. Rock Soil Mech 33(2):476–482

Acknowledgments

We acknowledge with gratitude the financial support provided by the National Natural Science Foundation of China (Grant No. 41372285), the Fundamental Research Funds for the Central Universities in China (2015QNA64) and the European project CREEP (PIAPP-GA-2011-286397).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, QY., Yin, ZY., Hicher, PY. et al. Nonlinearity of one-dimensional creep characteristics of soft clays. Acta Geotech. 11, 887–900 (2016). https://doi.org/10.1007/s11440-015-0411-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-015-0411-y