Abstract

Purpose

Fed aquaculture has long been based on fishmeal (FM) as the main protein source for carnivorous species, but when its demand and price began increasing, both researchers and the industry started to search for alternative protein sources to meet the challenge of securing aquafeed. Consequently, this study has recourse to life cycle assessment (LCA) methodology to identify any critical points and improvement strategies in the current production of four partial substitutes for FM namely dried microalgae biomass from Tetraselmis suecica (DMB_TETRA) and Tisochrysis lutea (DMB_TISO); insect meal (IM) from Hermetia illucens larvae; and poultry by-product meal (PBM).

Methods

System boundaries are from the cradle to the mill gate, thus including the production phase (and the related upstream activities) and the subsequent biomass processing into unpackaged dried meal. One tonne of protein content was chosen as functional unit. The inventory was based on foreground data provided by the industry and complemented by background data sourced from the Ecoinvent v 3.4 and Agribalyse® v 1.3 LCI databases. The environmental effects were assessed considering five impacts namely global warming (kg CO2 eq.), acidification (kg SO2 eq.) and eutrophication (kg PO43− eq.) estimated via the CML-IA method, plus cumulative energy use (MJ) and water use (m3 m−2 month−1). Two alternative scenarios per production chain were considered in order to increase the robustness of the results.

Results and discussion

The performance-based ranking indicated the PBM and IM scenarios as the most sustainable options. Both microalgal systems scored the worst performances in four impacts out of five, with eutrophication impact as the only exception. The nutrients provided to poultry and insects (i.e. the feed) as well as to microalgae (the carbon source and the fertilizers) were the main contributors to impacts, together with energy consumption. Despite being cultivated with identical technologies, the two microalgae showed different performances due to their different annual yields and to different consumable goods, water and energy consumptions.

Conclusions

The results provided a ranking of these four partial FM substitutes and allowed to make useful considerations on how to improve their environmental sustainability. To this regard, the impacts of IM and DMB production could be reduced by improving nutrient efficiency and reducing energy needs. On the other hand, PBM production is already optimized and is not expected to change substantially in the future years.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In large developed markets, including the European Union, high-value species such as salmonids, European seabass, gilthead seabream, shrimp and prawns are highly traded. Shrimp production grew at an average annual rate of 9.7% per year since 2000, reaching 5.5 million tonnes in 2017. Atlantic salmon and rainbow trout show a similar rise, with an average annual growth of 5.6% and 3.0%, respectively, and a production of 2.6 million tonnes and 0.81 million tonnes in 2017 (Tacon 2020). This trend may seem related exclusively to the more prosperous markets since, at a global scale, the top fed fish in 2017 were still represented by the Chinese fed carps (20% of world aquaculture production in terms of tonnes, live weight), while the four abovementioned carnivorous species accounted together for only 3.2% (FAO 2019). Still, the rising income levels and urbanization are changing the consumption habits in emerging markets, particularly in East and Southeast Asia, and the demand for more expensive seafood is growing (FAO 2018).

Over the years, the growing demand for these high-value species naturally led to a growing demand for fishmeal (FM), which is the optimal source of protein and, together with fish oil (FO), the most digestible and nutritious aquafeed ingredient (FAO 2018). In the 1990s, the production of many marine shrimp and carnivorous finfish required up to five times the fish biomass as inputs than the farmed fish produced (Naylor et al. 2000). Indeed, commercial feeds for the black tiger shrimp (Penaeus monodon) and the Indian white prawn (Penaeus indicus) included approximately 25% fishmeal (Kumaraguru vasagam et al. 2005; Venero et al. 2008), while the typical inclusion level for the giant river prawn (Macrobrachium rosenbergii) was even higher (30–50%) (Jain 2007). The percentage of FM inclusion in industrial feeds for carnivorous species was large as well (e.g. 35% in salmon and 30% in trout according to Mente et al. 2006).

The growing pressure on small pelagic fish species used for reduction to FM contributed to a progressive decrease in these fish stocks (Rana et al. 2009; FAO 2018), thus increasing FM market price. In order to reduce the reliance on this traditional marine resource, both the scientific community and the aquafeed industry began to move towards FM partial substitution with plant and terrestrial animal proteins (Tacon and Metian 2008; Naylor et al. 2009). Besides fulfilling fish nutritional requirements (which differ from species to species), these substitutes should also be economically affordable and environmentally sustainable. Thus, research focused on resources believed to meet these requirements: ingredients obtained from by-product valorisation (such as fish protein hydrolysates, fish oil from trimmings, processed animal proteins, meal and fat from insects fed on by-products) and from plant sources (e.g. macro- and micro- algae, vegetable oils). Despite much progress has been made in reducing the FM level in the feeds since the 1990s (FAO 2018), further research is still needed.

This paper forms part of the SUSHIN project (SUstainable fiSH feeds INnovative ingredients) born to design new feed formulations having high nutritional performance and low environmental impacts. The project focused on a set of protein sources suitable as FM substitutes: dried microalgae biomass from Tetraselmis suecica (DMB_TETRA) and Tisochrysis lutea (DMB_TISO), insect meal (IM) and poultry by-product meal (PBM). Tetraselmis suecica and Tisochrysis lutea are two marine microalgal species farmed in outdoor photobioreactors, which are closed cultivation systems that allow reducing the use of chemicals while optimizing the use of fertilizers. According to European Union legislation, both microalgal species are considered as safe ingredients for food and feed purposes (Enzing et al. 2014) and are included in the European catalogue of feed materials (Commission Regulation (EU) No 68/2013). IM, which is obtained from the processing of black soldier fly (Hermetia illucens) larvae, and PBM, a processed animal protein obtained from category 3 poultry by-products, can be fed to fish according to Commission Regulation (EU) No 893/2017 and Commission Regulation (EU) No 56/2013. According to the literature, all candidate protein sources are suitable as partial FM substitute within aquafeed formulations (Bruni et al. 2018; Zarantoniello et al. 2018; Hekmatpour et al. 2018; Henry et al. 2018a, b; Cardinaletti et al. 2018; Wu et al. 2018; Secci et al. 2019; Gong et al. 2019; Messina et al. 2019; Davies et al. 2019; Karapanagiotidis et al. 2019; dos Santos et al. 2019).

With regard to the current systems technology readiness levels, PBM is already one of the main animal protein sources used in livestock and fish feed formulations (Meeker and Hamilton 2006), while IM and the two DMB have only recently emerged as valuable aquafeed ingredients and their production processes surely have margin for technological improvements. With regard to insect farming, there is still little knowledge about how to improve production efficiency in terms of management and mechanization (Dossey et al. 2016). A major problem specifically related to fly farming is that the larvae do not burrow deeper than 10 cm into the substrate (Čičková et al. 2015). Thus, an increase in the production scale would require an increase in the number of the shallow rearing boxes, which in turn would increase the number of workers required to carry out on-farm activities. In parallel to techno-economic aspects, the social consequences of future large-scale production should also not be ignored (Macombe et al. 2019). Microalgae, besides being important protein sources, contain other valuable nutritional elements (e.g. the eicosapentaenoic acid—EPA and the docosahexaenoic acid—DHA). As such, they have been used in aquaculture for a long time as feed supplements (since they meet the specific nutritional needs of molluscs and shrimp larvae) and as growth performance enhancers (i.e. through green water techniques). Still, their potential use as a bulk feedstuff for aquafeeds has been stressed only in the recent years (Yaakob et al. 2014). And, despite several species showing potential for large-scale cultivation (Khan et al. 2018), currently, the largest microalgae facilities are still based on open systems, which are penalized by frequent grazers, pests and pathogens contaminations (Hannon et al. 2010). Nevertheless, microalgae technology is rapidly improving, and it is foreseeable a larger number of industrial scale closed system in the near future (Shah et al. 2018).

2 Methods

The life cycle assessment (LCA) was performed according to the four main steps recommended by the International Standard Organisation (ISO 2006a, b): (1) Goal and scope definition; (2) Life cycle inventory; (3) Life cycle impact assessment; and (4) Results interpretation. Calculations were made using SimaPro 8.5.2.0 (PRé 2012) software. A problem-oriented approach (attributional LCA) was adopted in order to focus on the extent of existing impacts (Tillman 2000).

2.1 Goal and scope definition

The goal of the study was to compare a set of protein sources suitable as FM substitutes via LCA methodology, with the aim of identifying the most environmentally sustainable one and of indicating the potential improvements to their present production processes.

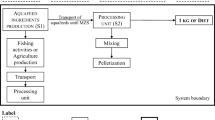

The main characteristics of the selected protein sources are presented in Table 1. A “cradle to plant gate” LCA was performed thus including the production of poultry by-products, fly larvae, fresh microalgae and their processing into unpackaged dried meal within the system boundaries (Fig. 1). One tonne of protein (i.e. the percentage of crude protein contained in the dried meal) was used as the functional unit, since it is the nutritional property on which partial FM substitution is based, in the formulation of new aquafeeds. The set timespan considered is that needed to manage the plants for a whole year, so as to include production seasonal fluctuations in each model. This choice is particularly important for microalgae production since their growth is highly affected by outdoor environmental conditions (available sunlight and air temperature).

System boundaries set for each novel FM substitute modelled. They include the production of the raw material (i.e. chicken by-products, fly larvae, whole microalgal organisms) and its processing into meal. In each model, a star (☆) highlights the point where most of the uncertainty lies and for which 2 different scenarios were considered

Two alternative scenarios per meal were considered in order to provide a range of impact magnitude and to increase the robustness of the research. Furthermore, as shown in Fig. 1, the production of IM and PBM includes multifunctional processes. To enable a fair comparison among these meals, the mono-functional process leading to their production should be isolated from the ones related to additional system outputs (co-products). However, a subdivision into mono-functional processes cannot be performed, since in both cases the meal and the co-product(s) are obtained from a single input source (raw material) entering the process. Thus, according to ISO standard 14044 (ISO 2006a), the first solution to solve multifunctionality is the expansion of the system boundaries in order to ensure that all environmental burdens are taken into account. This means a change in the functional unit which, in this case, would include 1 t of meal plus 0.3 t of insect oil (in IM production process) and 1 t of meal plus 2.8 t of other feed ingredients (in PBM production process). As these functional units can neither be compared with each other, nor to 1 t of DMB, partitioning remained as the only solution. In fact, the last option (the substitution method) is not perceived as correct: as having taken place over time, it is not in line with the scope of the study which is, according to the attributional retrospective, to portray current production scenarios (Schrijvers et al. 2016). Details of the partitioning approach used, and the alternative scenarios considered are better discussed in the Section 2.2.2.

2.2 Life cycle inventory

2.2.1 Data sources

Inventories are provided in Tables 2, 3 and 4. Data concerning the production of PBM and IM were provided by two industrial scale companies: AIA—Agricola Italiana Alimentare S.p.A.—Unipersonale (San Martino Buon Albergo, Veneto region, Italy) and Innovafeed (Gouzeaucourt, Hauts-de-France region, France), respectively. Data concerning the production of both microalgal meals (DMB_TETRA and DMB_TISO) were based on the model of a 1 ha plant using Green Wall Panel technology. The model is grounded on the technologies and operations of both the Green Wall Panel pilot installation at the Fotosintetica & Microbiologica S.r.l. research area (a University of Florence spin-off, Florence, Italy) and the industrial scale plant at Archimede Ricerche S.r.l. (Camporosso, Imperia, Italy) and was previously used for a techno-economic analysis of microalgae biomass production (Tredici et al. 2016). Despite having a different production scale (Table 1), the four systems can be compared with each other since they represent the state-of-the-art practices and technologies in their respective production field.

Foreground data were gathered by interviewing PBM and IM company staff and DMB experts. Background data, such as consumable goods, production, transportation modes and energy generation (electricity, diesel fuel, etc.), were mainly derived from Ecoinvent v 3.4 database (Ecoinvent 2017). However, data on crop production is poor within Ecoinvent, thus it was sourced from the Agribalyse® v 1.3 database (Koch and Salou 2016). Poultry by-product production was also sourced from the Agribalyse since previous LCA publications on the Italian poultry production chain do not provide an exhaustive inventory. The electricity mix and water consumption in background inventory data were adapted to the Italian context for PBM and the two microalgal meals and French context for the IM.

2.2.2 Brief description of the production systems and of their related scenarios

DMB production

Meal is obtained through the cultivation, harvesting and processing of two unicellular marine microalgae (Tisochrysis lutea and Tetraselmis suecica) produced in a 1 ha Green Wall Panel plant close to the sea (Fig. 1). The production of the two meals (DMB_TETRA and DMB_TISO) requires the same infrastructures and machinery but differs in terms of consumable goods, water and energy consumption. The production at full plant size (i.e. in the Green Wall Panel photobioreactors) is carried out in a semi-continuous mode. Part of the microalgae culture is harvested and substituted daily with fresh culture medium. The saltwater filling the system is taken and discharged into the sea. At harvesting, microalgae cells are separated from the exhausted culture medium by centrifugation. The paste thus obtained, which still contains 75–85% water, is dried in order to get the feed ingredient. Carbon dioxide can be injected into the photobioreactors either as flue gas, which is a recycled waste-product obtained from the burning of used vegetable oils, or as pure carbon dioxide from cylinders. These two alternatives were investigated as two scenarios, S1 and S2 (Table 5). In the former case, the flue gas was assumed to be a burden-free input as we entirely assigned the credits related to its production to the producer. Both scenarios were modelled in accordance with Collotta et al. (2018).

IM production

Insect farming, slaughtering and processing are carried out in the same facility. At the end of the larval stage, most of the pre-pupae is processed while the rest develop into the adult colony that will provide the supply of new eggs. Due to IPR protection, the exact composition of the growing substrate (i.e. the insect feed) was not provided by the company which, however, communicated that the diet formulation is based on cereal by-products. Based on this information, two production scenarios were investigated assuming two alternative diets (Barry 2004; Smetana et al. 2016) (Table 5). With regard to mass balance (Fig. 1), the use of 9.3 t of growing substrate leads to the production of 1.3 t of larvae (live weight) and 8 t of uneaten substrate. The larvae are then converted into 1 t of IM and 0.3 t of insect oil. According to information provided by the producer, the uneaten growing substrate is sold on the market as fertilizer. However, if compared with the economic value of the other two products (IM and insect oil), the uneaten substrate accounts for less than 3% of the total net sales. Accordingly, total environmental burdens were allocated to the production of grown-out larvae leaving the uneaten substrate completely burden-free. The two co-products (insect meal and oil) have the same sales price (as communicated by the company), thus the partitioning of impacts was based on biomass ratio only. In summary, multifunctionality was handled here by cutting off the uneaten substrate and by applying mass partitioning between IM and insect oil.

PBM production

The slaughter of broilers leads to the parallel production of the main product (i.e. broiler meat for human consumption) and of three types of by-products: meat and bone leftovers (heads, feet, skin and inedible offal), blood and feathers. Poultry by-product production was modelled starting from an Agribalyse life cycle inventory (LCI) record describing broiler farming and slaughter in France. This record was then modified by substituting the nested records on poultry feed with a formulation provided by the company contact person. Blood and feathers are directly processed into blood and feather meals, while the mix of meat and bone leftovers undergoes a special treatment (rendering) which separates the three animal tissue components: PBM, fat and water. For the sake of simplicity, all the products other than PBM are grouped together and named “other feed ingredients” (Fig. 1). The LCA model for poultry by-product processing includes fine chopping, heating with added steam, press separation and is modelled using primary data. The main assumption in the LCA model is represented by the partitioning approach, based on both mass and economic value (Table 5), as PBM and the other feed ingredients (feather meal, blood meal and fat) differ significantly in terms of both production yield and economic value. In the system chosen as the case study, 18.6 t of broiler (live weight) give 13.0 t of broiler meat and 5.6 t of poultry by-products. The latter yields 1.0 t of PBM, 2.8 t of other feed ingredients and 1.7 t of wastewater (removed from animal tissues). Thus, according to the mass balance, the by-products (obtained from poultry slaughtering) and the PBM (obtained from by-products rendering) are burdened by 30.1% and 26.3% of the background process impacts respectively (mass partitioning, in the PBM S1 scenario). Alternatively, the poultry by-products and PBM are burdened by 1.4% and 31.5% of the impacts, respectively, in line with their economic value (economic partitioning, in the PBM S2 scenario, according to the commodity price in November 2019). A partitioning approach based on nutritional characteristics (e.g. energy content) was not considered meaningful as the outputs of both the multifunctional steps (broiler slaughter and by-product processing) are meant for very different uses and have different nutritional functions.

2.2.3 Data aggregation and other assumptions

The inventory data were aggregated into 6 sub-categories. The sub-category “Main consumables” includes either feed for insect and poultry farming, or fertilizer for microalgae. Detergents and disinfectants were included in the “Other consumables” sub-category. All systems include the “Transportation” of consumable goods on road where distance is calculated in terms of kilometres between the retailer of each consumable good and the facility where it is used. The lifespan of machinery and equipment, i.e. “Capital goods”, was estimated by only assuming ordinary maintenance on them. Storage infrastructures and logistics, administration offices, laboratories, etc. were not included in the system boundaries since they are not representative of the production processes. The sub-categories “Energy consumption” and “Water consumption and emission” track the consumption of these resources within the foreground system. Wastewater emissions from the plants producing PBM and IM are treated in accordance with current legislation. Direct nutrient discharge from the cultivation of the two microalgal species was not taken into account under the assumption that nutrient inputs are entirely taken up by microalgae. As a consequence, no water treatments are needed here. Green-house gas emissions produced directly by poultry and insect metabolism and from insect substrate were not considered. Besides being lower than those of other livestock (Gerber et al. 2013; Van Huis et al. 2013; Smetana et al. 2015), their metabolic carbon dioxide releases were considered as part of a rapid biological system in which the amount of CO2 emitted by the animals can be considered roughly equivalent to that sequestered via photosynthesis by the plant material they are fed (Herrero et al. 2011). With regard to the organic matter provided to black soldier fly larvae as feed, it is consumed so quickly that it does not have the time to decompose, as already observed in housefly larvae (van Zanten et al. 2015). Similar considerations were made in an in-depth study on mealworm farming (Thévenot et al. 2018).

2.3 Life cycle impact assessment (LCIA)

Three impacts i.e. global warming (GWP, kg CO2 eq.), acidification (AP, kg SO2 eq.) and eutrophication (EP, kg PO43− eq.) were assessed using the CML-IA baseline V3.05 method (Guinée et al. 2002). The cumulative energy demand (CED, MJ) (Frischknecht et al. 2007) and water use (AWARE, m3 m−2 month−1) (Boulay et al. 2018) impacts were selected in order to quantify cumulative impact along the production chain. The first four impacts are indicated as the best proxies of aquaculture impacts in several studies, (such as Aubin 2013; Cao et al. 2013; Henriksson et al. 2012). AWARE, a water scarcity midpoint method, was selected among the other water footprint indicators as it is recommended by WULCA (working group under the umbrella of UNEP-SETAC Life Cycle Initiative) and represents the most up-to-date understanding of water use impact assessment in LCA, where both potential human and ecosystem deprivation are assessed.

3 Results

Impacts were assessed in terms of GWP, AC, EP, CED and AWARE. Figure 2 and Table 6 summarize the results and show the impacts of PBM, IM, DMB_TETRA and DMB_TISO (with two scenarios each) in terms of absolute values and contribution analysis. These results are presented below highlighting first the performance ranking among the four protein sources and then the contribution to impacts of the main sub-categories.

Life cycle impact assessment of the four meals considered (poultry by-product meal, PBM; insect meal, IM; dry microalgae biomass from Tetraselmis suecica, DMB_TETRA, and from Tisochrysis lutea, DMB_TISO), with 2 scenarios each (S1 and S2). The 6 sub-categories contributing to the overall impact are highlighted. The functional unit is 1 t of protein contained in the meal. The impacts considered are the following: global warming (GWP), acidification (AP), eutrophication (EP), cumulative energy demand (CED), water use (AWARE)

The production of Tisochrysis lutea dried meal using pure CO2 (DMB_TISO S2) performed the worst and received the highest scores in four impacts of the five analyzed: GWP, AP, CED, AWARE. The same meal also appears to be the second worst option in terms of EP. A comparison between the S1 and S2 scenarios reveals that the former always performs better in both microalgae species: in DMB_TETRA, the use of S1 rather than S2 leads to an impact reduction ranging from − 21% (in AWARE) to −42% (in EP); and, in DMB_TISO, impact reduction ranges from − 14% (in AWARE) to − 33% (in EP). The best microalgae scenario is DMB_TETRA S1, which is comparable with the animal meals in only three cases: to IM S2 in AP and CED, and to PBM S1 in EP. Indeed, the performances of animal meals in all the other impacts are at least 50% less than those of the microalgae (with the only other exception being IM S2 in EP).

The performance of IM S2 fluctuates. Good results are obtained in GWP and AWARE; worse results in AP and CED, where the performances are comparable with those of the best microalgae meal (DMB_TETRA S1) and obtain the worst result among all the systems in EP. The cross-comparison of IM S1 with IM S2 reveals the former to be much more sustainable than the latter and to have an impact reduction of the following: − 58% in GWP; − 79% in AP; − 86% in EP; − 51% in CED. The only exception is AWARE, where S2 is smaller than S1 (− 63%).

The other three animal meals appear to be the best-performing options. Among them, the production of the PBM modelled on an economic partitioning of impacts (PBM S2) ranks first, as it has the lowest impacts in all the impacts considered. PBM S1 ranks second in terms of CED and AWARE, while IM S1 ranks second in GWP, AP and EP. The cross-comparison of PBM S1 with PBM S2 proves the latter to have the best performances in all the impacts considered: − 86% in GWP; − 95% in AP; − 95% in EP; − 89% in CED; − 94% in AWARE.

The results in Fig. 2 and Table 6 also provide the share of the 6 sub-categories to the overall impacts thus allowing an analysis of their contributions. The performances of the two animal protein sources, PBM and IM, were similar. Indeed, the “Main consumables” sub-category, which includes either the feed for farmed animals or fertilizer for microalgae, accounted for more than 50% of the total impact, the only exceptions being GWP and CED in PBM S2 (26.5% and 34.7% respectively). With regard to microalgae production, the “Main consumables” sub-category contributed greatly on climate change and eutrophication, ranging from 27.1 to 72.7%. The other three impacts considered here, namely AP, CED and AWARE, were mainly influenced by “Energy consumption” which accounted from 44.6 to 83.2% of the overall impact. Overall, the cumulative impact of the sub-categories “Main consumables” and “Energy consumption” accounts for at least 76.3% of the overall environmental burdens, regardless of the type of meal and the scenario considered.

Looking at the other sub-categories, the “Transportation” of consumable goods had a negligible effect, while the sub-category “Capital goods” affected the impact of DMB, with an impact contribution range of 3.5–13.4%, and of IM production, with an impact contribution range of 0.5–17.2%. The “Water consumption and emission” sub-category had no impact on DMB and minor ones for both the PBM and IM systems.

4 Discussion

The interpretation of these LCA results is divided into five sections. First, considerations about the environmental performances of each meal are provided (Sections 4.1, 4.2 and 4.3). Then, a comparison with previous literature is carried out to check if our findings are in line with previous LCA researches on these systems (Section 4.4). Finally, several actions for improvement are discussed (Section 4.5).

4.1 Performance analysis of DMB

DMB_TISO performed worse than DMB_TETRA mainly because of the lower yield of Tisochrysis lutea (which is more fragile and has an average annual production of 31% lower than that of Tetraselmis suecica). As expected, the environmental impact decreases when flue gas is used as a carbon source, thus avoiding the impact of the production of pure CO2 (9 t of CO2 per each tonne of DMB) in both cases. However, microalgal protein sources are less sustainable than IM and PBM irrespective of the CO2 source used.

The LCA results highlighted that DMB production also has other drawbacks. First, even when resorting to flue gas as a carbon source (S1), the “Main consumables” contribution on climate change and eutrophication remains high (27–61%) due to the use of fertilizers. The amount of fertilizer needed (approximately 90 kg and 40 kg per tonne of fresh harvested biomass for Tetraselmis suecica and Tisochrysis lutea, respectively) leads to impacts exclusively due to industrial fertilizer production (a background process). In fact, microalgae cultivation (a foreground process) does not involve nutrient discharge in the surrounding environment unlike what happens with soil-based agriculture (where fertilizers are partly lost through deep percolation in soil). Rather, nitrogen and phosphorus compounds are injected into the photobioreactors in controlled quantities and used with full efficiency (Section 2.2.3), leading to a negligible nutrient concentration in the wastewater discharged in the sea. The second, and more important, reason why DMB systems are not yet competitive is represented by their high energy needs. Indeed, the four systems rely on a high amount of electricity, as shown by the inventory data: 12,000 and 22,700 kWh consumed per 1 t of MDB produced (for Tetraselmis suecica and Tisochrysis lutea, respectively), against 3400 kWh consumed per 1 t of IM and 282 kWh plus 429 Nm3 of natural gas needed per 1 t of PBM. Due to this high amount of energy, the “Energy consumption” sub-category shows impacts of one or even two orders of magnitude greater than in the animal meal systems (Fig. 2).

The findings presented in Fig. 2 and Table 6 show that infrastructure contribution to impacts is higher than 3.5% (and up to 13.4% for CED in DMB_TETRA S1). This finding may be said to complement those presented in Grierson et al. (2013) and Medeiros et al. (2015) who did not take infrastructure contribution into account. The contribution of the “Water consumption and emission” sub-category is null in all four of the microalgae scenarios analyzed. This is because no water treatments are required (since it was assumed that the whole amount of nutrients is used with full efficiency) and all the water used in the production of DMB, sourced directly from nature (as salt water from the sea), is fully returned to the environment.

4.2 Performance analysis of IM

In IM production systems, differences between the two scenarios (S1 and S2) are due to the growing substrate used as feed. The two substrates tested here represent the “best fit” compromise between the information given by the insect company and literature findings. According to the data provided by the company’s staff, the diet formulation is entirely based on cereal by-products (plus some additives), the amount of water added to the ingredients is equal to their weight and the whole fly production cycle is swift. Moreover, although black soldier fly larvae can process almost any type of organic material, insect feed formulation and quality can strongly affect the nutritional composition of the IM (Van Huis et al. 2013). Thus, a formulation with fairly high nutritional characteristics was assumed. Despite looking quite similar, the two substrates chosen led to different environmental impacts, with IM S1 showing halved impacts compared with those of S2 in four out of five impacts. The comparison of IM performances with those of the other protein sources confirms the importance of the role played by the growing substrate. Indeed, the second scenario (IM S2) appears the worst option among the animal meals, reaching microalgal levels in AP and CED and showing out-of-scale impact in EP (due to the high impact of rye meal production). For the same reason, IM S1 appears more sustainable than the poultry alternative modelled with the mass partitioning approach (PBM S1) in three out of five impacts (GWP, AP, EP). Finally, although it does not make a decisive contribution to the overall performances, the “Energy consumption” sub-category is a second important aspect and is a sign of the company’s high energy requirements (as already mentioned in Section 4.1).

4.3 Performance analysis of PBM

Differences between the two scenarios (S1 and S2) are due to a methodological approach i.e. the partitioning adopted to solve multifunctionality. As explained in paragraph 2.2.2, there are two nodes where the production chain splits into multiple outputs (Fig. 1). Poultry by-products, which are an output of the first multifunctional process, represent the main input of the second. In the first node, the mass partitioning scenario (S1) allocates 30.1% of the background impacts (i.e. the impacts due to poultry farming and slaughter) to the poultry by-products, whereas the economic partitioning scenario (S2) allocates a far lower share of impacts (1.4%) to poultry by-products. In the second node, both scenarios allocate approximately the same percentage of impacts (26.3% in S1 and 31.5% in S2) to the PBM. Thus, poultry by-products are the key issue in the whole production chain and, when modelled by resorting to economic partitioning (PBM S2), turn out to have a lower share of impacts thus making the whole PBM S2 scenario markedly more sustainable. Therefore, allocation methodology can make a difference but, in both cases, this protein source looks very promising (with performances on a par only with those of IM S1). These high performances are due to the ecological and economic efficiency of the production process. For instance, during the rendering process, the technical potential of both liquid and gaseous outputs is fully exploited: nutrient-rich fluids are treated before flowing into wastewater and nutrients are recovered while the gaseous phase is exploited to recover heat by means of a heat exchanger.

4.4 Literature comparison

Most papers concerning aquafeed sustainability deal with high-value fish species and compare the LCA results of alternative aquafeed formulations: aquafeeds for trout and salmon (Pelletier and Tyedmers 2007; Pelletier et al. 2009; Boissy et al. 2011; Samuel-Fitwi et al. 2013); salmon aquafeed performances assessed by means of thermodynamic indicators (Draganovic et al. 2013); an aquafeed formulation based on food waste, generated and processed on board a ship (Strazza et al. 2015); feed formulations for gilthead seabream (Basto-Silva et al. 2019); and salmon feed based on methanotrophic bacteria, yeast ingredients or protein from soy (Couture et al. 2019). A small number of studies deal with an evaluation of feed components on an individual basis namely those studies looking into the following: alternative ingredients meant for salmon aquafeed formulations (Pelletier and Tyedmers 2007); FM and FO production in Peru (Fréon et al. 2017); several aquafeed ingredients commonly used in Indonesia (Henriksson et al. 2017); and alternative meal and fat (or oil) sources (Basto-Silva et al. 2018). Given the little research on individual aquafeed ingredients, our results may also be compared with LCAs on systems producing microalgae, insects and poultry for other purposes (Table 7).

DMB

Our findings may be compared with those of Sevigné-Itoiz et al. (2012), who applied LCA to three species of marine microalgae cultivated in Spain from mid-November to the end of May in a bubble column photobioreactor under outdoor environmental conditions: 22,900–23,800 kg CO2 eq. in GWP; 194–201 kg SO2 eq. in AP; 10.9–11.4 kg PO43− eq. in EP; 139,000–148,000 MJ in CED per tonne of DMB. Another paper (Medeiros et al. 2015) investigated the environmental impacts of Nannochloropsis sp. dried biomass production, including its cultivation in flat plate photobioreactors, harvest (through flocculation, decantation and centrifugation) and drying. Besides being a marine microalga, this species is supplied with flue gas and commercial fertilizers. The GWP impact was found to be of one order of magnitude smaller than ours (1810–3140 kg CO2 eq. per tonne of dried alga). This could be due to reduced energy consumption based on estimates taken from literature (1900 kWh per tonne of dried biomass, against the 12,000–22,700 kWh per tonne used in our model). A third LCA analysis, focusing on a real pilot-scale multi-tubular photobioreactor (Mata et al. 2018), gives GWP results much closer to ours: 68,338 kg CO2 eq. per tonne of dried biomass. Construction materials are included in the inventory and the electricity used for both pump operation and thermoregulation is considered. Data is mainly sourced from real production conditions in a Portuguese company and, as in our systems, impacts are mainly due to the production of electricity with nutrient production as the second main hotspot.

IM

Insects are known to cause impacts highly dependent on the following: (i) their species, as the gas emissions produced by their metabolism may vary considerably (Oonincx et al. 2010); (ii) their diet (Smetana et al. 2016); and (iii) their life cycle stage, temperature and level of activity (Halloran et al. 2016). As a consequence, our focus was directed to papers which deal with LCA on the black soldier fly (BSF) fed on similar substrates. The only two studies found to be suitable for a viable comparison analyse the production of BSF fed either on co-products that are generally provided to livestock (Bosch et al. 2019) or on several food industry by-products (Smetana et al. 2019). The impacts assessed by the former are in line with ours (Table 7): 3.000 kg CO2 eq. (GWP) and 84.000 MJ (CED). And, with regard to the latter, despite the LCA being performed by choosing the single score assessment methodology IMPACT 2002+ (thus preventing a comparison in terms of absolute values), the contribution analysis provided corroborates our findings as feed production and energy appear to be the greatest sources of impacts. Finally, besides the studies specifically addressing BSF, a review on 8 papers (Smetana et al. 2016) reports the contribution of different insect species to GWP impact, and the results of the LCAs on both our IM scenarios fall within the range.

PBM

Although this part of the model is not entirely based on primary data, this aspect does not compromise the reliability of the results since the poultry production chain has been operating on an industrial scale for a long time now and is grounded on well-established technologies that have been thoroughly described in literature and in the Agribalyse LCI record. Our results are comparable with published LCA studies on the broiler poultry production chain in different countries: Italy (Cesari et al. 2017), Brazil and France (da Silva et al. 2014), Serbia (Skunca et al. 2018), Portugal (González-García et al. 2014), the UK (Leinonen et al. 2012) and the continental USA (Pelletier 2008). Results remain comparable even when the analysis is extended to include meat processing and packaging (da Silva et al. 2014) or beyond, to comprise conservation in shops and even to household use (Skunca et al. 2018). This can be easily explained by the fact that, in all cases, most of the environmental impact is due to the farming stage and to the related feed provided to the poultry with percentage contributions varying from study to study but always ranging around 70–90% of the overall impacts. To the author’s knowledge, a recent paper on the processing of poultry by-products into meal to be used as a FM substitute (Basto-Silva et al. 2018) represents the only exception. The system boundaries adopted in this publication are a bit wider than those used here (as they also include the transpotation of meal to the aquafeed plant) but, as it was done in our study, the maintenance and end of life of capital goods are not considered, and the impact assessment is performed via the CML-IA method and scaled on 1 t of PBM, thus allowing a meaningful comparison. Notwithstanding, the results are of two orders of magnitude higher than ours. The reason for this difference probably lies in the inventory used and which is not disclosed in the published paper.

4.5 Actions for improvement

The results on IM and DMB revealed that the main nutrients used (i.e. a growing substrate for insect and a fertilizer for both the microalgae) are the main drivers of impact, together with the amount of energy needed to power the foreground system. Therefore, a way to reduce environmental burdens would be to increase the growth efficiency and the overall annual production by improving the nutrient characteristics. This goal can be achieved through either a change in the nutrient formulation or by adding supplements (prebiotics and probiotics) which may act as immunostimulants and growth enhancers. However, attention must be paid when switching to new nutritional formulations. For instance, in the case of insect farming, the shift to a diet entirely composed of vegetal wastes (i.e. biomasses not suitable for other livestock) may have drawbacks. This option will undoubtedly affect some impacts positively (Bosch et al. 2019) but, in addition to being currently unfeasible in Europe due to legislative constraints, it could lead to an increased total impact due to an annual yield reduction (if the diet is not sufficiently nutritious).

The second environmental hotspot is represented by energy consumption. The Green Wall Panel photobioreactors used for microalgal cultivation guarantee a higher control of the main variables affecting growth (e.g. temperature, pH) than open cultivation systems. Moreover, they ensure higher volumetric productivities are attained (Leite et al. 2013) thus lowering harvesting operation costs. Still, they require a high amount of energy due to mixing and cooling. With regard to IM, black soldier flies are native to the warm temperate zone of America (with a growth optimum temperature ranging from 24 to 29 °C) and their farming thus requires a high amount of energy to heat the structures. To reduce the direct energy consumed in IM and DMB systems, the production chain could be improved by using better insulation materials so as to reduce energy consumption related to both heating (in insect farming) and to pumping water into the coils used for photobioreactor thermoregulation (in microalgae cultivation). Another option is to change the energy source since the Italian and French Country energy mix still rely on a high amount of fossil and/or nuclear sources of energy (although renewable sources are slowly taking hold). For instance, the possibility of integrating solar panels in the microalgae plant to produce the necessary energy would have a high impact in terms of the energy balance of algae production as calculated for Tetraselmis suecica (Tredici et al. 2015) and would positively affect LCA results. A commercial facility growing the green alga Haematococcus pluvialis for astaxanthin production (Algatechnologies, Kibbutz Ketura, Israel) is already adopting solar panels to obtain energy to operate the plant and further ways of integration may be devised in the future. Last but not least, the environmental cost of capital goods (infrastructures and machinery) is usually not considered within LCA analyses, but present results prove them to contribute partially to overall impacts in the case of both insect and microalgae production. Despite the shift from the use of finite natural resources to the recycling of waste materials also being a good option for infrastructure sustainability (Bribián et al. 2011), the high impact share in this case is simply due to a low annual yield of the IM and DMB systems.

5 Conclusion

The two microalgal species emerged as the less sustainable protein sources with one insect and one poultry meal scenarios being the most sustainable options. Results regarding the microalgal systems prove that farmed species plays an important role too, since the environmental performance of Tisochrysis lutea dried biomass always appears worse than that of Tetraselmis suecica, despite both being cultivated using identical technologies. The inventory used represents at the same time the main strength and the weakness of the study. Since the present study is an attributional LCA, the inventory drawn up for each production process is based on a large number of primary data (collected directly from the companies) and reflects the real-life situation and current knowledge in the field. However, nowadays, the systems analyzed have a different technology level and a different production scale where PBM production is already optimized and IM and DMB productions are still in their infancy. It is therefore difficult to find ways to further improve the poultry production chain, whereas several strategies can be adopted to increase the sustainability of insect and microalgal production. For instance, their impacts are likely to decrease with an increase in plant size, improvement in nutrient efficiency (i.e. the type of feed or CO2 source and the way it is provided) and optimization of the farming process and equipment used, paying particular attention to technologies capable of increasing energy efficiency. Further research to complete the picture outlined here would be desirable by assessing, for instance, impact change due to a production scale increase or due to a shift to other energy sources. Still, the present results undoubtedly constitute a solid starting point and are a reasonably faithful representation of the current situation.

References

Aubin J (2013) Life cycle assessment as applied to environmental choices regarding farmed or wild-caught fish. CAB Rev Perspect Agric Vet Sci Nutr Nat Resour 8:1–10. https://doi.org/10.1079/PAVSNNR20138011

Barry T (2004) Evaluation of the economic, social, and biological feasibility of bioconverting food wastes with the black soldier fly (Hermetia illucens). University of North Texas

Basto-Silva C, Valente LMP, Matos E et al (2018) Life cycle assessment of aquafeed ingredients. Int J Life Cycle Assess 23:995–1017. https://doi.org/10.1007/s11367-017-1414-8

Basto-Silva C, Guerreiro I, Oliva-Teles A, Neto B (2019) Life cycle assessment of diets for gilthead seabream (Sparus aurata) with different protein/carbohydrate ratios and fishmeal or plant feedstuffs as main protein sources. Int J Life Cycle Assess 24:2023–2034. https://doi.org/10.1007/s11367-019-01625-7

Batista AP, Niccolai A, Fradinho P, Fragoso S, Bursic I, Rodolfi L, Biondi N, Tredici MR, Sousa I, Raymundo A (2017) Microalgae biomass as an alternative ingredient in cookies: Sensory, physical and chemical properties, antioxidant activity and in vitro digestibility. Algal Research 26:161–171

Boissy J, Aubin J, Drissi A, van der Werf HMG, Bell GJ, Kaushik SJ (2011) Environmental impacts of plant-based salmonid diets at feed and farm scales. Aquaculture 321:61–70. https://doi.org/10.1016/j.aquaculture.2011.08.033

Bosch G, van Zanten HHE, Zamprogna A, Veenenbos M, Meijer NP, van der Fels-Klerx HJ, van Loon JJA (2019) Conversion of organic resources by black soldier fly larvae: legislation, efficiency and environmental impact. J Clean Prod 222:355–363. https://doi.org/10.1016/j.jclepro.2019.02.270

Boulay A-M, Bare J, Benini L, Berger M, Lathuillière MJ, Manzardo A, Margni M, Motoshita M, Núñez M, Pastor AV, Ridoutt B, Oki T, Worbe S, Pfister S (2018) The WULCA consensus characterization model for water scarcity footprints: assessing impacts of water consumption based on available water remaining (AWARE). Int J Life Cycle Assess 23:368–378. https://doi.org/10.1007/s11367-017-1333-8

Bribián IZ, Capilla AV, Usón AA (2011) Life cycle assessment of building materials: comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build Environ 46:1133–1140. https://doi.org/10.1016/j.buildenv.2010.12.002

Bruni L, Pastorelli R, Viti C, Gasco L, Parisi G (2018) Characterisation of the intestinal microbial communities of rainbow trout (Oncorhynchus mykiss) fed with Hermetia illucens (black soldier fly) partially defatted larva meal as partial dietary protein source. Aquaculture 487:56–63. https://doi.org/10.1016/j.aquaculture.2018.01.006

Cao L, Diana JS, Keoleian GA (2013) Role of life cycle assessment in sustainable aquaculture. Rev Aquac 5:61–71. https://doi.org/10.1111/j.1753-5131.2012.01080.x

Cardinaletti G, Messina M, Bruno M, Tulli F, Poli BM, Giorgi G, Chini-Zittelli G, Tredici M, Tibaldi E (2018) Effects of graded levels of a blend of Tisochrysis lutea and Tetraselmis suecica dried biomass on growth and muscle tissue composition of European sea bass (Dicentrarchus labrax) fed diets low in fish meal and oil. Aquaculture 485:173–182. https://doi.org/10.1016/J.AQUACULTURE.2017.11.049

Cesari V, Zucali M, Sandrucci A, Tamburini A, Bava L, Toschi I (2017) Environmental impact assessment of an Italian vertically integrated broiler system through a life cycle approach. J Clean Prod 143:904–911. https://doi.org/10.1016/j.jclepro.2016.12.030

Čičková H, Newton GL, Lacy RC, Kozánek M (2015) The use of fly larvae for organic waste treatment. Waste Manag 35:68–80. https://doi.org/10.1016/j.wasman.2014.09.026

Collotta M, Champagne P, Mabee W, Tomasoni G (2018) Wastewater and waste CO2 for sustainable biofuels from microalgae. Algal Res 29:12–21. https://doi.org/10.1016/J.ALGAL.2017.11.013

Commission Regulation (EU) No 56/2013 (2013) amending Annexes I and IV to Regulation (EC) No 999/2001 of the European Parliament and of the Council laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies

Commission Regulation (EU) No 68/2013 (2013) on the Catalogue of feed materials

Commission Regulation (EU) No 893/2017 (2017) amending Annexes I and IV to Regulation (EC) No 999/2001 of the European Parliament and of the Council and Annexes X, XIV and XV to Commission Regulation (EU) No 142/2011 as regards the provisions on processed animal protein

Couture JL, Geyer R, Hansen JØ, Kuczenski B, Øverland M, Palazzo J, Sahlmann C, Lenihan H (2019) Environmental benefits of novel nonhuman food inputs to salmon feeds. Environ Sci Technol 53:1967–1975. https://doi.org/10.1021/acs.est.8b03832

da Silva VP, van der Werf HMG, Soares SR, Corson MS (2014) Environmental impacts of French and Brazilian broiler chicken production scenarios: an LCA approach. J Environ Manag 133:222–231. https://doi.org/10.1016/j.jenvman.2013.12.011

Davies SJ, Laporte J, Gouveia A, Salim HS, Woodgate SM, Hassaan MS, el-Haroun ER (2019) Validation of processed animal proteins (mono-PAPS) in experimental diets for juvenile gilthead sea bream (Sparus aurata L.) as primary fish meal replacers within a European perspective. Aquac Nutr 25:225–238. https://doi.org/10.1111/anu.12846

dos Santos SKA, Schorer M, de Souza Moura G et al (2019) Evaluation of growth and fatty acid profile of Nile tilapia (Oreochromis niloticus) fed with Schizochytrium sp. Aquac Res 50:1068–1074. https://doi.org/10.1111/are.13979

Dossey AT, Morales-Ramos JA, Guadalupe Rojas M (eds) (2016) Insects as sustainable food ingredients: production, processing and food applications. Elsevier

Draganovic V, Jorgensen SE, Boom R et al (2013) Sustainability assessment of salmonid feed using energy, classical exergy and eco-exergy analysis. Ecol Indic 34:277–289. https://doi.org/10.1016/j.ecolind.2013.05.017

Ecoinvent (2017) Ecoinvent 3.4 Database. Released October 4th 2017. Retrieved from: https://www.ecoinvent.org/database/older-versions/ecoinvent-34/ecoinvent-34.html

Enzing C, Ploeg M, Barbosa M, Sijtsma L (2014) Microalgae-based products for the food and feed sector: an outlook for Europe. Report EUR 26255. Publications Office of the European Union, Luxembourg

FAO (2018) The state of world fisheries and aquaculture 2018. Meeting the sustainable development goals. Rome, Italy

FAO (2019) Fishery and Aquaculture Statistics. Global production by production source 1950–2017 (FishstatJ). FAO Fish. Aquac. Dep. [online]. Rome. Updat. 2019. www.fao.org/fishery/statistics/software/fishstatj/en

Fréon P, Durand H, Avadí A, Huaranca S, Orozco Moreyra R (2017) Life cycle assessment of three Peruvian fishmeal plants: toward a cleaner production. J Clean Prod 145:50–63. https://doi.org/10.1016/j.jclepro.2017.01.036

Frischknecht R, Jungbluth N, Althaus HJ, et al (2007) Implementation of life cycle impact assessment methods: data v2.0. Ecoinvent report no. 3

Gerber PJ, Steinfeld H, Henderson B et al (2013) Tackling climate change through livestock – a global assessment of emissions and mitigation opportunities. Food and Agriculture Organization of the United Nations (FAO), Rome

Gong Y, Bandara T, Huntley M, Johnson ZI, Dias J, Dahle D, Sørensen M, Kiron V (2019) Microalgae Scenedesmus sp. as a potential ingredient in low fishmeal diets for Atlantic salmon (Salmo salar L.). Aquaculture 501:455–464. https://doi.org/10.1016/j.aquaculture.2018.11.049

González-García S, Gomez-Fernández Z, Dias AC, Feijoo G, Moreira MT, Arroja L (2014) Life cycle assessment of broiler chicken production: a Portuguese case study. J Clean Prod 74:125–134. https://doi.org/10.1016/j.jclepro.2014.03.067

Grierson S, Strezov V, Bengtsson J (2013) Life cycle assessment of a microalgae biomass cultivation, bio-oil extraction and pyrolysis processing regime. Algal Res 2:299–311. https://doi.org/10.1016/j.algal.2013.04.004

Guinée J, Gorrée M, Heijungs R et al (2002) Handbook on life cycle assessment. Operational guide to the ISO standards, vol 1, 2a, 2b and 3. Springer, Netherlands

Halloran A, Roos N, Eilenberg J, Cerutti A, Bruun S (2016) Life cycle assessment of edible insects for food protein: a review. Agron Sustain Dev 36:57–69. https://doi.org/10.1007/s13593-016-0392-8

Hannon M, Gimpel J, Tran M, Rasala B, Mayfield S (2010) Biofuels from algae: challenges and potential. Biofuels 1:763–784. https://doi.org/10.4155/bfs.10.44

Hekmatpour F, Kochanian P, Marammazi JG, Zakeri M, Mousavi SM (2018) Inclusion of poultry by-product meal in the diet of Sparidentex hasta: effects on production performance, digestibility and nutrient retention. Anim Feed Sci Technol 241:173–183. https://doi.org/10.1016/j.anifeedsci.2018.02.010

Henriksson PJG, Guinée JB, Kleijn R, De Snoo GR (2012) Life cycle assessment of aquaculture systems - a review of methodologies. Int J Life Cycle Assess 17:304–313. https://doi.org/10.1007/s11367-011-0369-4

Henriksson PJG, Mohan CV, Phillips MJ (2017) Evaluation of different aquaculture feed ingredients in Indonesia using life cycle assessment. Indones J Life Cycle Assess Sustain 1:13–21

Henry MA, Gai F, Enes P, Peréz-Jiménez A, Gasco L (2018a) Effect of partial dietary replacement of fishmeal by yellow mealworm (Tenebrio molitor) larvae meal on the innate immune response and intestinal antioxidant enzymes of rainbow trout (Oncorhynchus mykiss). Fish Shellfish Immunol 83:308–313. https://doi.org/10.1016/j.fsi.2018.09.040

Henry MA, Gasco L, Chatzifotis S, Piccolo G (2018b) Does dietary insect meal affect the fish immune system? The case of mealworm, Tenebrio molitor on European sea bass, Dicentrarchus labrax. Dev Comp Immunol 81:204–209. https://doi.org/10.1016/j.dci.2017.12.002

Herrero M, Gerber P, Vellinga T, Garnett T, Leip A, Opio C, Westhoek HJ, Thornton PK, Olesen J, Hutchings N, Montgomery H, Soussana JF, Steinfeld H, McAllister TA (2011) Livestock and greenhouse gas emissions: the importance of getting the numbers right. Anim Feed Sci Technol 166–167:779–782. https://doi.org/10.1016/j.anifeedsci.2011.04.083

ISO (2006a) ISO 14044: environmental management - life cycle assessment - life cycle impact assessment. Geneva, Switzerland

ISO (2006b) ISO 14040: environmental management - life cycle assessment - principles and framework. Paris, France

Jain KK (2007) Feed ingredients in aqua feeds. In: CAS Training Manual on “Nutritional strategies and feeding management in finfish and shellfish.” Central Institute of Fisheries Education, Mumbai, pp 6–15

Karapanagiotidis IT, Psofakis P, Mente E, Malandrakis E, Golomazou E (2019) Effect of fishmeal replacement by poultry by-product meal on growth performance, proximate composition, digestive enzyme activity, haematological parameters and gene expression of gilthead seabream (Sparus aurata). Aquac Nutr 25:3–14. https://doi.org/10.1111/anu.12824

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Factories 17:36. https://doi.org/10.1186/s12934-018-0879-x

Koch P, Salou T (2016) AGRIBALYSE®: Rapport Méthodologique – Version 1.3. November 2016. Angers. France

Kumaraguru vasagam KP, Ramesh S, Balasubramanian T (2005) Dietary value of different vegetable oil in black tiger shrimp Penaeus monodon in the presence and absence of soy lecithin supplementation: effect on growth, nutrient digestibility and body composition. Aquaculture 250:317–327. https://doi.org/10.1016/j.aquaculture.2005.02.035

Leinonen I, Williams AG, Wiseman J, Guy J, Kyriazakis I (2012) Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: broiler production systems. Poult Sci 91:8–25. https://doi.org/10.3382/ps.2011-01634

Leite GB, Abdelaziz AEM, Hallenbeck PC (2013) Algal biofuels: challenges and opportunities. Bioresour Technol 145:134–141. https://doi.org/10.1016/j.biortech.2013.02.007

Macombe C, Le Feon S, Aubin J, Maillard F (2019) Marketing and social effects of industrial scale insect value chains in Europe: case of mealworm for feed in France. J Insects Food Feed 5:215–224. https://doi.org/10.3920/JIFF2018.0047

Mata TM, Cameira M, Marques F et al (2018) Carbon footprint of microalgae production in photobioreactor. In: Energy Procedia. pp 432–437

Medeiros D, Sales E, Kiperstok A (2015) Energy production from microalgae biomass: carbon footprint and energy balance. J Clean Prod 96:493–500. https://doi.org/10.1016/j.jclepro.2014.07.038

Meeker DL, Hamilton CR (2006) An overview of the rendering industry. In: Meeker DL (ed) Essential rendering. National Renderers Association

Mente E, Pierce GJ, Santos MB, Neofitou C (2006) Effect of feed and feeding in the culture of salmonids on the marine aquatic environment: a synthesis for European aquaculture. Aquac Int 14:499–522. https://doi.org/10.1007/s10499-006-9051-4

Messina M, Bulfon C, Beraldo P, Tibaldi E, Cardinaletti G (2019) Intestinal morpho-physiology and innate immune status of European sea bass (Dicentrarchus labrax) in response to diets including a blend of two marine microalgae, Tisochrysis lutea and Tetraselmis suecica. Aquaculture 500:660–669. https://doi.org/10.1016/j.aquaculture.2018.09.054

Naylor RL, Goldburg RJ, Primavera JH, Kautsky N, Beveridge MCM, Clay J, Folke C, Lubchenco J, Mooney H, Troell M (2000) Effect of aquaculture on world fish supplies. Nature 405:1017–1024. https://doi.org/10.1038/35016500

Naylor RL, Hardy RW, Bureau DP, Chiu A, Elliott M, Farrell AP, Forster I, Gatlin DM, Goldburg RJ, Hua K, Nichols PD (2009) Feeding aquaculture in an era of finite resources. Proc Natl Acad Sci U S A 106:15103–15110. https://doi.org/10.1073/pnas.0905235106

Oonincx DGAB, Van Itterbeeck J, Heetkamp MJW et al (2010) An exploration on greenhouse gas and ammonia production by insect species suitable for animal or human consumption. PLoS One 5:e14445. https://doi.org/10.1371/journal.pone.0014445

Pelletier N (2008) Environmental performance in the US broiler poultry sector: life cycle energy use and greenhouse gas, ozone depleting, acidifying and eutrophying emissions. Agric Syst 98:67–73. https://doi.org/10.1016/j.agsy.2008.03.007

Pelletier N, Tyedmers P (2007) Feeding farmed salmon: is organic better? Aquaculture 272:399–416. https://doi.org/10.1016/j.aquaculture.2007.06.024

Pelletier N, Tyedmers P, Sonesson U, Scholz A, Ziegler F, Flysjo A, Kruse S, Cancino B, Silverman H (2009) Not all salmon are created equal: life cycle assessment (LCA) of global salmon farming systems. Environ Sci Technol 43:8730–8736. https://doi.org/10.1021/es9010114

PRé (2012) SimaPro by PRé consultants. Amersfoort, The Netherlands

Rana KJ, Siriwardena S, Hasan MR (2009) Impact of rising feed ingredient prices on aquafeeds and aquaculture production. Fisheries and Aquaculture Technical Paper. No. 541. FAO, Rome, Italy

Renaud SM, Thinh L-V, Lambrinidis G, Parry DL (2002) Effect of temperature on growth, chemical composition and fatty acid composition of tropical Australian microalgae grown in batch cultures. Aquaculture 211(1-4):195–214

Salomone R, Saija G, Mondello G, Giannetto A, Fasulo S, Savastano D (2017) Environmental impact of food waste bioconversion by insects: Application of Life Cycle Assessment to process using Hermetia illucens. Journal of Cleaner Production 140:890–905

Samuel-Fitwi B, Meyer S, Reckmann K, Schroeder JP, Schulz C (2013) Aspiring for environmentally conscious aquafeed: comparative LCA of aquafeed manufacturing using different protein sources. J Clean Prod 52:225–233. https://doi.org/10.1016/j.jclepro.2013.02.031

Schrijvers DL, Loubet P, Sonnemann G (2016) Developing a systematic framework for consistent allocation in LCA. Int J Life Cycle Assess 21:976–993. https://doi.org/10.1007/s11367-016-1063-3

Secci G, Mancini S, Iaconisi V, Gasco L, Basto A, Parisi G (2019) Can the inclusion of black soldier fly (Hermetia illucens) in diet affect the flesh quality/nutritional traits of rainbow trout (Oncorhynchus mykiss) after freezing and cooking? Int J Food Sci Nutr 70:161–171. https://doi.org/10.1080/09637486.2018.1489529

Sevigné-Itoiz E, Fuentes-Grünewald C, Gasol CM et al (2012) Energy balance and environmental impact analysis of marine microalgal biomass production for biodiesel generation in a photobioreactor pilot plant. Biomass Bioenergy 39:324–335. https://doi.org/10.1016/J.BIOMBIOE.2012.01.026

Shah MR, Lutzu GA, Alam A, Sarker P, Kabir Chowdhury MA, Parsaeimehr A, Liang Y, Daroch M (2018) Microalgae in aquafeeds for a sustainable aquaculture industry. J Appl Phycol 30:197–213. https://doi.org/10.1007/s10811-017-1234-z

Skunca D, Tomasevic I, Nastasijevic I, Tomovic V, Djekic I (2018) Life cycle assessment of the chicken meat chain. J Clean Prod 184:440–450. https://doi.org/10.1016/J.JCLEPRO.2018.02.274

Smetana S, Mathys A, Knoch A, Heinz V (2015) Meat alternatives: life cycle assessment of most known meat substitutes. Int J Life Cycle Assess 20:1254–1267. https://doi.org/10.1007/s11367-015-0931-6

Smetana S, Palanisamy M, Mathys A, Heinz V (2016) Sustainability of insect use for feed and food: life cycle assessment perspective. J Clean Prod 137:741–751. https://doi.org/10.1016/J.JCLEPRO.2016.07.148

Smetana S, Schmitt E, Mathys A (2019) Sustainable use of Hermetia illucens insect biomass for feed and food: Attributional and consequential life cycle assessment. Resour Conserv Recycl 144:285–296. https://doi.org/10.1016/j.resconrec.2019.01.042

Strazza C, Magrassi F, Gallo M, Del Borghi A (2015) Life cycle assessment from food to food: a case study of circular economy from cruise ships to aquaculture. Sustain Prod Consum 2:40–51. https://doi.org/10.1016/j.spc.2015.06.004

Tacon AGJ (2020) Trends in global aquaculture and aquafeed production: 2000–2017. Rev Fish Sci Aquac 28:43–56. https://doi.org/10.1080/23308249.2019.1649634

Tacon AGJ, Metian M (2008) Global overview on the use of fish meal and fish oil in industrially compounded aquafeeds: trends and future prospects. Aquaculture 285:146–158. https://doi.org/10.1016/j.aquaculture.2008.08.015

Thévenot A, Rivera JL, Wilfart A, Maillard F, Hassouna M, Senga-Kiesse T, le Féon S, Aubin J (2018) Mealworm meal for animal feed: environmental assessment and sensitivity analysis to guide future prospects. J Clean Prod 170:1260–1267. https://doi.org/10.1016/J.JCLEPRO.2017.09.054

Tillman A-M (2000) Significance of decision-making for LCA methodology. Environ Impact Assess Rev 20:113–123. https://doi.org/10.1016/S0195-9255(99)00035-9

Tredici MR, Bassi N, Prussi M, Biondi N, Rodolfi L, Chini Zittelli G, Sampietro G (2015) Energy balance of algal biomass production in a 1-ha “Green Wall panel” plant: how to produce algal biomass in a closed reactor achieving a high net energy ratio. Appl Energy 154:1103–1111. https://doi.org/10.1016/J.APENERGY.2015.01.086

Tredici MR, Rodolfi L, Biondi N, Bassi N, Sampietro G (2016) Techno-economic analysis of microalgal biomass production in a 1-ha Green Wall Panel (GWP®) plant. Algal Res 19:253–263. https://doi.org/10.1016/J.ALGAL.2016.09.005

Van Huis A, Van Itterbeeck J, Klunder H et al (2013) Edible insects. Future prospects for food and feed security. FAO, Rome

van Zanten HHE, Mollenhorst H, Oonincx DGAB, Bikker P, Meerburg BG, de Boer IJM (2015) From environmental nuisance to environmental opportunity: housefly larvae convert waste to livestock feed. J Clean Prod 102:362–369. https://doi.org/10.1016/j.jclepro.2015.04.106

Venero JA, Davis D, Lim CE (2008) Use of plant protein sources in crustacean diets. In: Lim CE, Webster CD, Lee CS (eds) Alternative protein sources in aquaculture diets. Haworth Press, New York, pp 163–203

Wu YB, Ren X, Chai XJ, Li P, Wang Y (2018) Replacing fish meal with a blend of poultry by-product meal and feather meal in diets for giant croaker (Nibea japonica). Aquac Nutr 24:1085–1091. https://doi.org/10.1111/anu.12647

Yaakob Z, Ali E, Zainal A, Mohamad M, Takriff M (2014) An overview: biomolecules from microalgae for animal feed and aquaculture. J Biol Res 21:6. https://doi.org/10.1186/2241-5793-21-6

Zarantoniello M, Bruni L, Randazzo B, Vargas A, Gioacchini G, Truzzi C, Annibaldi A, Riolo P, Parisi G, Cardinaletti G, Tulli F, Olivotto I (2018) Partial dietary inclusion of Hermetia illucens (black soldier fly) full-fat prepupae in Zebrafish feed: biometric, histological, biochemical, and molecular implications. Zebrafish 15:519–532. https://doi.org/10.1089/zeb.2018.1596

Acknowledgements

The authors would like to express sincere thanks to Guillaume Gras from Innovafeed (http://innovafeed.com/) and to Pierluigi Perantoni, Emiliano Campara, Andrea Di Biase and Luca Zenari from AIA—Agricola Italiana Alimentare S.p.A. (http://www.aiafood.com/en) for providing the raw data concerning Insect and Poultry productive chains, respectively. Finally, the authors would like to thank the reviewers, whose comments and criticisms contributed significantly to improving the quality of the paper.

Funding

This work was partially supported by the SUSHIN project (SUstainable fiSH feeds INnovative ingredients) funded by Ager AGER2-SUSHIN, Cod 2016-0112.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ian Vázquez-Rowe

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(XLSX 23 kb)

Rights and permissions

About this article

Cite this article

Maiolo, S., Parisi, G., Biondi, N. et al. Fishmeal partial substitution within aquafeed formulations: life cycle assessment of four alternative protein sources. Int J Life Cycle Assess 25, 1455–1471 (2020). https://doi.org/10.1007/s11367-020-01759-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-020-01759-z