Abstract

Purpose

This study performs an exploratory comparative evaluation of various animal and vegetable protein and lipid sources, used as feed in the aquaculture industry. The ingredients studied include fishmeal (FM) and fish oil (FO) from fisheries by-products, meal and fat by-products from poultry slaughter, FM and FO from Peruvian anchovy capture, and soybean meal and oil. The boundaries studied include the production or capture, the ingredient processing unit and the transport to the unit that processes the ingredients into aquafeeds in Portugal.

Methods

The LCA impact assessment method is the CML-IA baseline V3.04/EU25 and the results were obtained for the characterisation step. Some of the inventory data were collected from a Portuguese company (Savinor) that processes both by-products from local fisheries and by-products from poultry production. Savinor provided data specifically associated with the ingredients’ production. Obtained data were complemented with literature data from: fish capture and poultry production. Inventory data for the production of ingredients from Peruvian anchovy and soybeans were retrieved from literature. It was assumed that the transport of the ingredients produced from Peruvian anchovy, between Lima and Rotterdam, is made in a transoceanic vessel, and it is considered a transport by truck between Rotterdam and Ovar, for soybean ingredients and FM/FO produced from Peruvian anchovy.

Results and discussion

This paper shows that poultry meal and poultry fat from poultry slaughter by-products have the larger contribution to all environmental impact categories evaluated, being the production of poultry the life cycle stage that contributes most to the overall categories. On the other hand, FM and FO from Peruvian anchovy were the ingredients with a lower contribution to all impact categories, except for abiotic depletion category, for FM from Peruvian anchovy, and abiotic depletion, abiotic depletion (fossil fuels) and ozone layer depletion for FO from Peruvian anchovy. For these categories, soybean meal and oil had lower impacts, respectively. The ingredients were compared by classes (protein and lipid sources).

Conclusions

A general conclusion is that soybean meal and oil and FM/FO from Peruvian anchovy appear to be very interesting options for aquafeeds from an LCA perspective. However, some limitations identified for this study, as, for instance, that it does not account for the environmental benefits associated with the use of the mentioned by-products, that would otherwise be considered wastes (i.e. by-products from the fish canning sector and poultry slaughter) shall be evaluated in future studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Aquaculture plays a relevant role in the current status of the fish and seafood production systems. In comparison with other food industries, aquaculture had the largest growth rate (8.3%) between 1970 and 2009 (Duarte et al. 2007). According to FAO (2016), in 2014, about 44% of the fish consumed worldwide was from aquaculture, and an increase of 70% in aquaculture production was estimated for the future (FAO 2016). The increase in consumption of fish and seafood from aquaculture has some drawbacks, one of the most relevant being the required need of an accompanying growth in aquaculture feeds (Naylor et al. 2000). On one hand, the aquaculture’s great dependency from marine resources used to produce fishmeal (FM) and fish oil (FO) for aquafeeds may likely hinder the growth of this sector (Natale et al. 2013). On the other hand, the aquaculture industry has recently made great efforts to find alternative feed ingredients that resulted in a decrease in the incorporation of FM and FO in aquafeeds (Klinger and Naylor 2012). In fact, for some fish species, it is nowadays possible to produce aquafeeds mostly from vegetable ingredients (Izquierdo et al. 2003; Montero et al. 2005, 2008; Rana and Hasan 2009; Karalazos et al. 2011; Messina et al. 2013). Moreover, the use of some land animal meals in aquafeeds has recently been re-allowed in Europe, enabling the incorporation of land animal by-products as nutrient sources for fish diets (Klinger and Naylor 2012). FM and FO, however, which are obtained either from low commercial valued fish or from by-products (generally from the fish canning industry), still remain the preferred ingredients, because they (i) are still largely available; (ii) have an excellent palatability and digestibility for aquaculture fish; (iii) contain a suitable profile of amino acids and essential minerals; (iv) are a rich source of long chain highly unsaturated fatty acids (n-3 LC HUFA); and (v) bring health benefits to the animal, improving the immunological status, the survival rate and reducing the incidence of malformations (Rana and Hasan 2009; Rust et al. 2011). A more sustainable perspective for aquaculture will thus have to look at alternative ingredients that do not compromise the growth and quality of fish. These alternatives may be roughly divided into three groups: (i) FM and FO from processed by-products (generally from the fish canning industry), (ii) vegetable sources and (iii) land animal sources.

FM and FO from processed fish by-products have a quite similar nutritional profile to FM and FO produced directly from fisheries (Klinger and Naylor 2012); FM from by-products will generally have a higher mineral content (ash) and, consequently, lower protein levels. However, according to Ziegler et al. (2016), the yield is dependent of (i) the species fished, (ii) age, (iii) size and (iv) fishing season.

Vegetable alternatives to FM and FO have, among others, some limitations, such as (i) the presence of anti-nutritional factors, (ii) high fibre content, (iii) unbalanced amino acid profile and (iv) poor digestibility (Rana and Hasan 2009). However, some of these limitations can be overcome through technological manipulation (e.g. enzymatic treatment) (Olsen and Hasan 2012), or by using a natural selection process, where the individuals that demonstrate better feed conversion ratios using vegetable diets are selected (Rust et al. 2011; Klinger and Naylor 2012).

Other group of alternative ingredients to FM and FO are processed land animal by-products. In Europe, these ingredients have been recently reintroduced in aquafeeds, with some limitations mentioned in the Commission Regulation EU N° 56/2013 (2013). Only category 3 by-products can be used in aquafeeds, and these are parts of slaughtered animals suitable for human consumption, but that would otherwise be wasted (e.g. bruised meat, offal, bones). The benefits of using processed land animal proteins include their good amino acid profile and high digestibility for fish, resulting in an adequate fish growth (Klinger and Naylor 2012). The current market reality is already making use of ingredients made from vegetable and animal by-products. This is to say that most of the commercial aquafeeds include these protein and lipid sources.

The environmental impact associated with most FM and FO alternatives, as far as we are aware of, has been poorly evaluated. Nevertheless, it is an important issue that enables the comparison and evaluation of possible environmental enhancements. Life Cycle Assessment (LCA) has been used to evaluate the environmental impact associated with feed production (Pelletier and Tyedmers 2007; Davis et al. 2010; Iribarren et al. 2012; Samuel-Fitwi et al. 2013). Although results are not consensual, in general, a low/moderate substitution of FM and FO by vegetable ingredients leads to environmental benefits (Pelletier and Tyedmers 2007; Davis et al. 2010; Iribarren et al. 2012; Samuel-Fitwi et al. 2013). But it is not possible to generalise and assume that the total substitution of marine ingredients by vegetable sources will decrease the environmental impact of aquafeeds. This is related to the low digestibility and difficulty of some fish species in processing vegetable ingredients (Pelletier and Tyedmers 2007). According to Papatryphon et al. (2004), from an environmental impact perspective, the replacement of FM and FO with processed animal proteins and fats has advantages when compared with the use of vegetable alternatives. The energy supply type and country energy mix, the access to raw materials, commercial models, efficiency of production of the raw materials (fisheries, agricultural production) and type of fuel used are, among others, factors that also affect the environmental impacts associated with the various feedstuffs.

As mentioned above, most LCA studies focus on fish diets and analyse ingredient replacement, comparing a standard diet with experimental formulations, with varying amounts of alternative ingredients (Papatryphon et al. 2004; Davis et al. 2010; Boissy et al. 2011). The few studies that analyse a single ingredient do not make use of any company specific data. Iribarren et al. (2012) have, in fact, used real values with the collaboration of a specific company, including the production of feeds for a specific fish species, but lost the focus on the individual ingredient.

The LCA of some of the most common protein and fat sources used in aquafeeds (fishmeal (FM) and fish oil (FO) from by-products from Portugal, poultry by-products’ meal and fat from Portugal, FM and FO from Peru, and soybean meal and oil from Brazil) has, to our knowledge, never been determined. To evaluate the environmental impact of the Peruvian anchovy ingredients and of the ingredients resulting from soybean processing, inventory data available in the published literature was used. In order to cover all the other ingredients, specific data from a Portuguese company (Savinor), that produces meals and fats from animal by-products, were collected and used to assess their respective environmental impacts. This study aimed at providing a robust comparative analysis among various ingredients currently used in aquafeeds.

2 Methods

According to NP EN ISO 14040 2008, and following this method’s mandatory steps, this study assesses the environmental impacts of ingredients from animal and vegetable sources used in aquaculture feeds. Four protein sources (FM from fisheries by-products, poultry meal from poultry by-products, FM from Peruvian anchovy and soybean meal) and four lipid sources (FO from fisheries by-products, poultry fat from poultry by-products, FO from Peruvian anchovy and soybean oil) were considered.

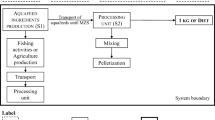

The data related with the industrial processes associated with fishmeal from fisheries by-products, poultry by-product meal, FO from fisheries by-products and poultry by-product fat were collected in a Portuguese company (Savinor S.A.). Savinor is a Portuguese company specialised in the collection, treatment and valorisation of animal by-products. The company produces ingredients (meals and fats) for aquafeeds and pet food and is responsible for around 30 and 65% of the Portuguese production of ingredients from poultry and fish by-products, respectively. Figure 1 presents the system boundaries considered for each ingredient.

In this study, the crude contents (of protein and lipids) for each ingredient is the following: FM from fisheries by-products and from Peruvian anchovy have, respectively, approximately, 65% (Savinor) and 65.4% crude protein (NRC 2011). Poultry by-products meal has about 70% (Savinor) and soybean meal has 44% (NRC 2011). All fat sources have about 99–100% of crude lipids.

Our study is attributional and thus uses allocation. Mass allocation was used and the results obtained are expressed by metric ton of aquafeed ingredient produced. This approach, together with the details on the crude contents for each ingredient, may assist to an informed environmental decision concerning the overall impacts of ingredients currently in use in the formulation of aquafeeds.

The physical unit (mass, expressed in metric tons) chosen for the present study is considered the most appropriate approach for co-product allocation over other options, from an aquafeed industry perspective. Energy-based allocation was not considered adequate, since the aquafeed industry uses ingredient mass as a reference when formulating the aquafeeds. The results obtained with mass allocation fulfill the needs of the aquafeed industry when the aim is the comparison among ingredients (either lipid or protein) from different origins. Similarly, economic allocation was not considered adequate, since this type of allocation may result in increased complexity in the interpretation of LCA results. The available literature on this subject state that, for some cases, prices summarise complex attributes of product not easily correlated with physical units (Ardente and Cellura 2012). This is valid for the present study, due to the large fluctuation of market prices observed for some of the ingredients in focus (e.g. fishmeal meal and fish oil—Tacon and Metian (2008); FAO (2012)). The price fluctuations throughout time for these ingredients are a good example of a low correlation between prices and physical units. For these reasons, we chose to our results in a physical unit, i.e. mass of the aquafeed ingredient.

2.1 Scope definition

For the selected ingredients, the stages considered include fishing (in the case of fish used to produce FM and FO), the transportation to the processing unit and the processing steps to produce the ingredient. This is valid for the ingredients sourced from fisheries’ by-products and the ones resulting from the use of Peruvian anchovy. In the case of the poultry by-products, the poultry production, slaughter and processing of by-products were all taken into account. Finally, for the case of ingredients obtained from soybeans, the boundaries included the crop production and the processing unit in Brazil, as well as the transport to the aquafeed production unit in Europe (Ovar, Portugal). A more detailed description of the boundaries per ingredient was made (see Fig. 1). The construction and maintenance of infrastructures and equipment, consumption of resources or the production of emissions and wastes from administration, laboratory, canteen or offices are out of the scope of this study.

The data refer to 1 t of ingredient used as the functional unit. In the production of all ingredients mentioned above, the capital goods production, maintenance and end of life were not considered.

2.1.1 FM and FO production using by-products from fisheries

The production of FM and FO includes two main systems: the fishing stage (S.1.) and the processing operations to obtain the ingredients (S.2.). The by-products transportation between S.1. and S.2. was also considered. This included the fish transportation from the canning industry that supplies the by-products to the processing unit where FM and FO are produced.

S.1. refers to the fishing stage. According to Savinor, the main species used to produce FM and FO from by-products are sardine and tuna fish. These species are essentially captured by using the purse seine fishing method that was herein considered for the inventory of the fishing stage. After landing, the fish is transported to the canning industries (generally located close to the harbours). According to Almeida et al. (2015) in the canning industry, the fish is adjusted to the can size and the head, tail and guts are cut off by using manual work. The environmental impact of the manual work is not relevant, neither is its energy consumption and, as such, it was not considered in the present study. The by-products of the canning industry are then collected and transported by road to Savinor. For the inventory, the fuel consumed, the detergents and disinfectants used in cleaning the trucks that transport the by-products were all considered. System S.2. reflects the processing operations needed to obtain the two feed ingredients: FM and FO from by-products.

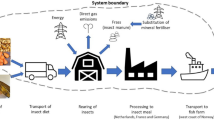

2.1.2 FM and FO production from Peruvian anchovy fishing

Two main systems associated with FM and FO production were studied. S.1. refers to anchovy fishing and the data were retrieved from Fréon et al. (2014). S.2. refers to the processing unit where anchovies are processed into FM and FO, and its description used data from Fréon et al. (2017), who assessed the impacts associated with three different options of FM and FO production from the Peruvian anchovy. For this study, we assume the data of Fréon et al. 2017, choosing only Prime option, due to be the option more similar to FM/FO from fisheries by-products, nutritionally, and about manufacturing processes. S.1. has similar inputs and outputs to the corresponding system in 2.1.1. The nets and the construction of the fishing vessels used for fishing were not considered, as they only represent about 2.9% of all environmental impacts of fisheries (Fréon et al. 2014). No local transportation is required between the dock and the processing unit in Peru. A pumping system redirects the fish into the processing unit, located only hundreds of meters from the ferry pier (Fréon et al. 2017). However, the transport of FM and FO from Lima (Peru) to the unit where the aquaculture feeds are produced, located in Ovar (Portugal), was considered. This includes maritime transport from Lima (Peru) to Rotterdam (The Netherlands), and finally the road transport connecting Rotterdam to Ovar (Portugal).

2.1.3 Poultry meal and fat production using by-products from poultry slaughter

The poultry meal and poultry fat production system include the poultry production (S.1.), the transportation of live poultry to the slaughterhouse at Savinor, the activities occurring at the slaughterhouse (S.2.) and finally, all processing steps needed (S.3.) to obtain the feed ingredients. Savinor also has a poultry slaughterhouse unit that provides category 3 by-products directly to the rendering unit, where they are processed into the above-mentioned ingredients. In this case, transportation was not considered for the inventory purposes, since the plants are located on the same industrial site.

Poultry production occurs in several units external to Savinor. The system also includes road transport from the different production sites to the slaughterhouse facilities of Savinor. System S.2. refers to the processes occurring at the slaughterhouse. Only category 3 by-products from poultry slaughter are used to produce feed ingredients. In System S.3. cat. 3 by-products from other poultry slaughterhouses that are sent to Savinor for processing, together with this company’s own by-products, were considered. The fuel consumed, detergents and disinfectants used in cleaning trucks were considered for the inventory.

2.1.4 Soybean meal and oil production

Two main soybean meal and soybean oil production systems were studied. The first one (S.1.) considered the agricultural production of soya, and the second one (S.2.) the processing unit transforming the soya beans into ingredients to be used in aquafeeds. The soya produced in Brazil was selected since this country is one of the largest world producers of soya. The information from the two systems was retrieved and adapted from the study by Cavalett (2008). The processing unit was located 150 km away from the soya agro-production site and the transportation was done by road. The railroad transportation (distance of 1000 km), between the soya processing unit and the Santos dock (Brazil) was considered. Transportation from Brazil to Rotterdam was maritime and from Rotterdam to Ovar transport was done by road.

2.2 Inventory analysis

The inventory analysis was performed using SimaPro software (version 8.3.0.). The Ecoinvent database (version 3.3.) was employed as the principal source of background data. For the fishing activities, data were retrieved from either Cavadas (2013) or Fréon et al. (2014). The inventory data for the fishing stage provided by Cavadas (2013) was selected due to the fact that it is comparatively more complete than the data presented in other studies (e.g. Almeida et al. 2014). Cavadas (2013) covers the emissions of a wider number of fishing activities, namely, ice production, painting and antifouling agents. In addition, data from Cavadas (2013) has greater representativeness in terms of national fish captures. According to INE (2012), the Matosinhos dock represents 35 to 40% of the overall sardine landings by Portuguese fishing vessels. Data from poultry production was collected from Lopes (2011). Data from poultry slaughtering was made available by Savinor. The inventory data from the processing units (for ingredients from by-products of fisheries and poultry production) were supplied by Savinor or estimated using activity data from the company. The data from the processing units for the ingredients from the Peruvian anchovy were collected from Fréon et al. (2017) and that from soya of Cavalett (2008). Data related to transportation were obtained from either Savinor, MapQuest (2017) or SeaRates (2017). This paper considers the most recent electricity mix for Portugal available in IEA (2014). We have included in the inventory tables the amount of the wastes produced in each phase but we did not model the type of end of life options each waste goes through. The reason for the exclusion of the end of life options for the solid wastes from the ingredients processing units is due to the lack of certainty associated with the type of treatments that these wastes may go through after being produced. Figure 2 describes the mass conversion relations for all the ingredients analysed.

The inventory tables were built based on mass conversion relations identified in Fig. 2. The same process (processing/production units) will give origin to both ingredients (meal and oil). We have used a conversion ratio to express mass relation within the life cycle stages. This ratio was taken from the literature for Peruvian anchovy and soybean-derived ingredients and from the personal contact with the Portuguese company (Savinor, SA) for fish and poultry by-products ingredients. When using this conversion factor, both inputs (materials, water and energy) and outputs (emissions and wastes) were allocated to the mass (1 metric ton) of ingredients (either protein or lipid).

2.2.1 Production of FM and FO using by-products from fisheries

Table 1 represents the inventory chart used for the fishing system (S.1.), the processing unit (S.2) and the transportation from S.1. to S.2. (to Savinor). Data for the fishing system were adapted from Cavadas (2013) and for the processing unit obtained from Savinor. The processing unit includes the following processes: reception and storage of the raw material, milling, cooking and pressing. At the end of the pressing stage, two types of products are obtained: solid and liquid. FM is obtained from the solid products, after drying and milling the processed by-products. FO is obtained from the liquid products after they are centrifuged to separate water from oil.

The by-products are transported using Savinor’s own vehicle fleet of trucks, with a load capacity between 3.5 and 20 t. Information on the diesel consumption per vehicle and distance was made available by Savinor. The diesel consumption was estimated and reported to 1 t of each ingredient produced. Transport emissions were estimated by using background data from SimaPro (version 8.3.0.). The inventory also considered the use of cleaning agents used to clean the transportation containers (agent Divosan Detcide).

At Savinor, several energy sources were used, such as electric energy and fuel and biomass energy. For biomass energy, wood pellets were used. The water used in the production unit mostly came from a groundwater hole. Savinor has a wastewater treatment station. The treated residual and industrial waters were unloaded in a nearby brook. In this study, all solid residues not related to maintenance operations were considered, including the production of scrap and ordinary industrial waste. This study also included the production of big-bags, used for storage and transport of meal ingredients from Savinor to the final client.

For the inventory, it was considered that the consumption of energy, water and other materials was proportional to the mass of the by-product used to produce each ingredient. This mass allocation considered that to produce 1 t of fishmeal around 5 t of fish by-products are required, while for the production of 1 t of FO around 23 t of fish by-products are necessary. The amount of fresh fish required was calculated considering that around 50% of the fish used in the canning industry is discarded as by-products. Therefore, 10 and 45 t of fresh fish are required to produce, respectively, 1 t of FM and FO.

The impacts of fisheries are allocated by mass between the edible portion for canning and the by-products formed during the processing unit that are used to produce FM/FO. The outcomes of the fishing activity we have looked at include edible fish used in canning and by-products.

2.2.2 Production of FM and FO from Peruvian anchovy

The fishing/capture system (S.1.), the production system (S.2.), the inventory for the maritime transport from Lima to Rotterdam and finally, the road transport between Rotterdam and Ovar (Portugal) are presented in Table 2. The fishing/capture system (S.1.) was adapted from Fréon et al. (2014) and data for the production system (S.2.) were taken from Fréon et al. (2017). The industrial process to produce FM and FO from Peruvian anchovy is similar to the already described production of FM and FO from by-products from fisheries. The road and maritime distances were determined by using online tools (MapQuest 2017; SeaRates 2017). Transport emissions were estimated by using background data from SimaPro (version 8.3.0.), assuming the transport was done by truck with a load capacity from 3.5 to 20 t. For maritime transport, it was assumed that a transatlantic cargo ship was used.

The relation between the amount of anchovy needed to produce the functional unit of this study was suggested by Fréon et al. (2017). According to this study, 4.21 t of Peruvian anchovy are needed to produce 1 t of FM, and 22 t are needed to produce 1 t of FO.

2.2.3 Production of poultry meal and fat using by-products from poultry slaughter

Table 3 represents the inventory table. The poultry production system (S.1.) was taken from Lopes (2011). Data from the slaughterhouse activities were collected from Savinor (system S.2.). After stunning, slaughter, automatic plucking and evisceration, the by-products are removed and directed to the ingredient production unit (S.3.). The specific poultry by-products used consisted of all parts not intended for human consumption, including necks, bruised meat, livers and other visceral parts, with the exception of feathers.

Within the processing unit, the considered activities include crushing and cooking of the by-products. The process is similar to the one used in the FM and FO plant, and two types of products (solid and liquid) are obtained. The solid products result in poultry meal and the liquids are converted into poultry fat. The solids go through several operational processes such as cooling, grinding and sieving, until they are transformed into poultry meal. The fats go through dehydration and centrifugation, to separate the small solid particles. These return to the poultry meal production system.

Table 3 describes the inventory of the transport phase between S.1. and S.2. and between S.2. and S.3. The transport of poultry by-products from other slaughterhouses, using Savinor’s fleet, was also considered. The distance covered and diesel consumption for each vehicle was estimated and reported to 1 t of each ingredient produced. Transport emissions were estimated by using background data from SimaPro (version 8.3.0.). The inventory also considered the use of cleaning agents used to clean the transportation containers, namely P3-INCIDIM 03, P3-MIP CF and Divosan Detcide.

Mass allocation was carried out and it was estimated that to produce 1 t of poultry meal, 6 t of poultry by-products are necessary, while to produce 1 t of poultry fat, 9 t of by-products are required. To obtain the by-products, it is necessary to have 22 t (for meal) and 33 t (for fat) of dead poultry, in the slaughterhouse, corresponding to 33 t (for production of poultry meal) and 50 t (for poultry fat) of live poultry. In Savinor, only 18% of the live poultry are discarded as category 3 by-products and directed to the processing unit. In this study, it was assumed, in line with data from the national poultry production, that 1 t of dead poultry corresponds to 1.5 t of live poultry (Lopes 2011).

2.2.4 Production of soybean meal and oil

Table 4 shows the inventory for soya production (S.1.), and for the processing unit (S.2.), expressed in 1 t of ingredient. The production of soybean meal and soybean oil includes common steps. The first process includes the cleaning and drying of wet soy. After that, soy grains are peeled and laminated. Finally, the extraction process needs hexane to separate meal and oil (Cavalett 2008). Table 4 also includes the road transport between S.1. and S.2., the train transport between S.2. and Santos (Brazil) and the transport to Rotterdam. The inventory data for soybean meal and oil is mostly taken from Cavalett (2008). The only exception is for the estimation of the impact associated with the road transport between Rotterdam and Ovar. For this case, the road distances were determined by using online tools (MapQuest 2017). Transport emissions were estimated by using background data from SimaPro (version 8.3.0.) assuming the transport was done by truck that has a load capacity from 3.5 to 20 t. Information retrieved from the study by Cavalett (2008) in respect to the distances associated with transport reveal the following. For road transport, the distance between S.1 and S.2 is 150 km. The train transport from the processing unit (S.2) until Santos (Brazil) is equal to 1000 km. The maritime transport from Brazil to Rotterdam is equal to 21,031 km. The transport between Rotterdam and Ovar (Portugal) by road is identical to the one estimated before for FM and FO.

According to Cavalett (2008), 1.23 t of wet soya are necessary to produce 1 t of soybean meal, and 5.55 t of wet soya are necessary to have 1 t of soybean oil.

SimaPro (version 8.3.0.) was used to model the life cycle of the ingredients, using midpoint indicators of environmental impact (method CML-IA baseline V3.04/EU25 (from September 2016)). Results are obtained for the characterisation step. The environmental impact categories available were abiotic depletion (ADP), abiotic depletion (fossil fuels) (ADP fossil fuels), acidification (AP), eutrophication (EP), fresh water aquatic ecotoxicity (FAETP), global warming (GWP100a), human toxicity (HTP), marine aquatic ecotoxicity (MAETP), ozone layer depletion (ODP), photochemical oxidation (POP) and terrestrial ecotoxicity (TETP). This is a widely accepted method and makes use of the most updated characterisation factors (as in CML 2017). Included in the impact category climate change are the emissions associated with direct and indirect land use change. Only soybean meal and soybean oil incur in direct and indirect land use change, which make this option less attractive in terms of global warming. The methods used for estimating CO2 emissions from dLUC and iLUC are Novaes et al. (2017) and Schmidt (2015), respectively.

3 Results and discussion

Table 5 represents the contribution of each ingredient to the distinct environmental impact categories per life cycle stage.

The present results show that poultry meal and fat are the largest contributors to all the environmental impact categories studied, while FM and FO ingredients from Peruvian anchovy and soybeans have comparatively lower contributions to the categories analysed.

3.1 Ingredients from fisheries by-products

For both ingredients obtained from fisheries by-products, S.1. (fishing) was the phase with the largest contribution for the overall impact. S.1. contribution was larger than 50% for the majority of the evaluated categories. In this study, the exception is for MAETP. According to Almeida et al. (2014), the fuel use is responsible for at least 80% of the environmental impacts in all categories analysed. However, fuel consumption can be improved if the best efficiency practices are implemented by the crew (González-García et al. 2015). For the latter category, the system S.2. (processing unit) had the largest contribution for the environment impact. Transport between S.1. and S.2. was shown to have negligible impacts compared to the other systems. Further investigation shows that the amount of NOx released during the S.1. Fishing stage is much larger when compared to the NOx released during the Processing unit (S.2). This is due to the amount of fuels (diesel and fuel oil) are much larger for the fishing stage. This is the reason behind the fact eutrophication to be higher for the fishing stage when compared to the processing unit.

3.2 Ingredients from Peruvian anchovy

For FM, the road transport from the Netherlands to Portugal showed the largest contribution for all the environmental impact categories. This phase has a contribution that is larger than 62% for all environmental impact categories. Processing unit (S.2.) is the step with a lower contribution for a majority of impact categories; the exceptions are ADP fossil fuels, GWP100a, ODP and TETP. The maritime transport from Peru to the Netherlands has a contribution range being between 0.2 and 25%, for, respectively, ADP and AP. Additionally, the anchovy fishing (S.1.) has a contribution between 4 and 33% for, respectively, GWP100a/TETP and ADP.

In respect to FO, the road transport from the Netherlands to Portugal showed the largest contribution for some of environmental impact categories. The contribution of this step ranged between 28%, for ADP, and 61%, for MAETP and TETP. Anchovy fishing (S.1.) was the largest contributor for three of the environmental categories (namely, ADP (72%), ADP (including also fossil fuels) (42%) and ODP (41%)). The processing unit (S.2) has a contribution between 1 and 37%, for, respectively, ADP and GWP100a. Lastly, the maritime transport from Peru to the Netherlands has a relatively a minor contribution to the overall environmental impact, ranging between 0.1% for ADP and 16% for AP category.

Further analysis for the FM/FO from the Peruvian anchovy shows again fisheries to contribute most to the eutrophication when compared to the processing unit. The pollutants in the basis of eutrophication are the phosphate (from the fishing net production and fuel combustion) and NOx (from fuel oil combustion). The reason behind that is that both activities (fishing net production and fuel oil combustion) are in the basis of the larger contribution of the fishing stage when compared to the processing unit. For the processing unit, the larger contribution is from NOx resulting from fuel oil combustion.

The FM and FO from Peruvian anchovy were shown to have a lower impact than FM and FO from fisheries by-products for all impact categories. This is in line with a previous study by Pelletier and Tyedmers (2007). This result is expected since, according to Fréon et al. (2014), this low impact is associated with the high efficiency of the fishing technique used to catch the Peruvian anchovies. This high efficiency results in a lower environmental impact when expressed per mass of fish caught (Tyedmers et al. 2005). Fréon et al. (2014) have analysed the environmental impact of fishing Peruvian anchovy and suggest that its higher efficiency is connected to natural conditions, namely (i) an annual higher abundance of fish due to the El Niño phenomenon and (ii) an excellent accessibility to fish, as anchovy schools approach the coast. According to the above-mentioned author, these natural conditions allow the Peruvian fishing fleet to reduce the fuel consumption during the catch. Despite of the advantages of the efficient fuel efficiency of the fishery of Peruvian anchovy, it shows to present some problems when we take in account some biological issues. According to Parker and Tyedmers (2012), the Peruvian fisheries are not the most efficient for biological aspects, when comparing with other fisheries as Gulf menhaden and Antarctic krill. However, more studies focusing on the biological aspects of fisheries are needed in order to allow more robust conclusions on the sustainability of current fisheries.

Due to the high efficiency of Peruvian anchovy fisheries, it was the road transport between the Netherlands and Portugal that contributed the most for all environmental categories impacts. According to Schipper et al. (1997), transport by aeroplane and road have higher environmental impacts when compared with train or maritime transport. Maritime transport is the transport route with the lowest environmental impacts (Schipper et al. 1997 cited by Pelletier and Tyedmers 2007). Besides the high efficiency of the Peruvian anchovy fishing, there is interaction and integration between the fishing and the processing unit, since there is a mechanical channel that takes the caught fish from the dock directly to the processing plant, without the need for transportation. In summary, the above-mentioned factors are the reasoning underlining the fact that FM and FO from Peruvian anchovy appear to be environmentally more sustainable than FM and FO from fish by-products. Moreover, the present study has some limitations as, for instance, it does not account for the environmental benefits associated with the use of fish by-products that would otherwise be considered wastes.

3.3 Ingredients from poultry slaughter by-products

Poultry meal and fat were the ingredients that contribute most to the large majority of the environmental impact categories. Result show that although the absolute value for environmental impact categories is lower for poultry meal, the relative contribution (expressed in percentage) is identical for both feed ingredients (meal and fat).

The poultry production phase (S.1) of poultry by-products meal and fat had the largest contribution for all environmental impact categories studied. The contribution of S.1. was always higher than 80%. This value was calculated for the MAETP impact category for both ingredients. The contribution of S.2. (slaughterhouse) was found to be the second larger contributor for the majority of the impact categories, also in both ingredients.

The processing unit (S.3) had the lowest contributions (< 2% for both ingredients) for the impact categories studied. For transports (S.1. to S.2. and S.2. to S.3.) the contributions were negligible. Results show contributions always lower than 0.5% for the single impact categories.

When comparing the results obtained with previously published studies, the calculated impacts of meal and fat from poultry slaughter by-products are higher than the ones reported by Pelletier and Tyedmers (2007). This is not surprising, since the present study includes the collection and transport of by-products from the slaughterhouse to the production plant, whereas this stage was not accounted for in the above-mentioned study. Poultry production was identified as the phase that contributes most for all environmental categories, corroborating the results from Pelletier and Tyedmers (2007). This larger impact of the poultry production is mainly associated with poultry feeds. Poultry feeds include several agriculture ingredients; consequently, both the production of these ingredients and the processing into feed pellets for the poultry industry contribute to the increase in the associated environmental impacts. This process contribution is corroborated by Lopes (2011).

3.4 Ingredients from soybeans

For soybean meal, crop production (S.1.) and road transport from the Netherlands to Portugal are shown to have significant contributions for the impact categories. The road transport between the Netherlands and Portugal was the first contributor for eight of the 11 categories analysed. Crop production (S.1.) was the larger contributor for three of the overall categories studied. Transportation from the harbour in Brazil to the Netherlands was the largest contributor for only one impact category (46% for AP). The remaining phases (processing unit (S.2.), transport from S.1. to S.2. and from S.2. to the harbour in Brazil) showed a negligible contribution.

In respect to soybean oil, crop production (S.1.) is the phase with the largest contribution for a majority of environmental impact categories. Its contribution range between 32%, for ADP fossil fuels, and 97% for TETP. Transport from the Netherlands to Portugal was the largest contributor for three of 11 environmental categories, as ADP (58%), ADP fossil fuels (47%) and ODP (45%). Again, as in soybean meal, transportation from the harbour in Brazil to the Netherlands has a relatively relevant contribution for only one impact category (32% for AP). The remaining phases (processing unit (S.2.), transport from S.1. to S.2. and from S.2. to the harbour in Brazil) showed a negligible contribution.

Novaes et al. (2017) estimated CO2 emissions from dLUC in each and every of the 27 Brazilian states, with reference to national statistics on changes in crop land use over the past 20 years. In Mato Grosso, the area under soybeans increased almost tripled over the last 20 years (from 2.0 Mha in 1995 to 7.8 Mha in 2014). According to the model, emissions range between 11.8 and 12.9 t CO2/ha/year, depending on the assumptions made regarding previous land use. In this study, we adopted the worst scenario, which assumes that soybean expands onto natural ecosystems. Other scenarios include a small share of soybean expanding onto other arable land (< 10%). Emissions for dLUC are estimated to be 4615 kg CO2 per metric ton of either soybean meal or soybean oil, which account for 70 and 58%, respectively, of the total climate change impact.

Estimating iLUC emissions is fraught with difficulties due to, among others, the uncertainties associated to estimating the share between land use change and intensification, land requirements and land reference systems, ascribing LUC to their drivers, time for amortisation and treatment of by-products. Several attempts have been made, resulting in values that are notoriously in a wide range, for example from − 200 to 600 g CO2-eq/MJ in the context of biofuels, as calculated with different economic-equilibrium models (De Cara et al. 2012). We adopted the Schmidt (2015) approach, which provides robust values for both attributional and consequential modelling and avoids the uncertainties associated with general and partial economic-equilibrium models. Indirect land use change (iLUC) was estimated at a much lower value: 25 kg CO2 per metric ton of either soybean meal or soybean oil, which corresponds to less than 1% of the total climate change impact of each system. This is because the attributional approach to accounting for iLUC includes land already in use in the land-supply mix.

Cavalett (2008) study included the transport between Brazil and Rotterdam and, in that case, the agriculture production represented 73% of all environmental related impacts. Actually, the author explains that this step is the one that consumes the most material and energy resources and it is also responsible for a large amount of the carbon dioxide released into the atmosphere. The same author, mentions that, in Brazil, about 8.4 million of hectares per year are necessary to supply the requirements of soya for the European Union, this is possible to land conversion to agricultural purposes, however the study by Cavalett (2008) does not assess the impact associated with land use change. Similarly, Pelletier and Tyedmers (2007) refer that, in their study, the agriculture production is a major concern, because it showed a significant contribution for the selected environmental impact categories. In industrial agriculture, the use of heavy agricultural machinery is necessary, as well as more fertilisers and available area, resulting in increased impacts (Pelletier and Tyedmers 2007). The production of soy promotes deforestation and illegal burns to create new agricultural areas, being therefore very important to consider a correct compliance with the applicable legislation (Cavalett 2008). These factors, in the long run, can compromise the environmental benefits in evidence. In the present study, the agriculture production had always a high contribution for all impact categories. However, it is worth mentioning the high environmental impact of the transport between Rotterdam and Portugal. This long step, in general, increased the magnitude of the environmental impacts. This impact results from the long distance travelled by road, when compared with other transports considered for the same ingredient in previous studies that did not take into account the road transport until the processing unit.

3.5 Comparison among ingredients

The present study compared all ingredients within each nutritional category: protein and lipid sources. Since protein and lipid ingredients have different functionalities when used in fish diets, the comparison between protein and lipid sources was not considered relevant. Within each nutritional category, ingredients were compared in order to assess which have the lowest environmental impact.

When comparing the different protein ingredients considered in the present study (Fig. 3), poultry meal was the larger contributor for all the environmental impact categories. In opposition, FM from Peruvian anchovy was the ingredient that had the lowest contribution for all of the environmental impact categories, except for ADP. The comparison of ingredients originated from fish sources showed that the fishmeal obtained from Peruvian anchovy had lower contributions for all impacts than the fishmeal from by-products. Soybean meal was a lower contributor too for the majority of environmental impacts categories, being the ingredient with lowest contribution for ADP.

When comparing the different lipid ingredients, poultry fat was the ingredient that showed the largest contribution for all environmental impact categories (Fig. 4). Fish oil obtained from Peruvian anchovy was the ingredient with the lowest contribution for all environmental impacts, with the exception of ADP, ADP fossil fuels and ODP. Moreover, the comparison of ingredients originated from fish sources showed that the FO obtained from Peruvian anchovy had lower contributions for all impact categories than the FO from by-products. For soybean oil, smaller overall contributions for impact were identified for only a few impact categories. This includes ADP, ADP fossil fuels and ODP.

General remarks may be done from the present results looking at the distinct sources of these ingredients without distinguishing between protein and lipids. For instance, FM and FO from Peruvian anchovy are produced directly from fish catches and the processing steps needed to produce the final ingredients are minimal. However, direct fisheries of small pelagic fish for FM and FO production, even if well managed, explore the base of the food chain of the Peruvian aquatic ecosystem, which could potentially affect negatively the higher trophic levels. When comparing both sources of fish ingredients, FM/FO from fisheries by-products have higher impacts for all environmental categories than FM/FO from Peruvian anchovy. Nonetheless, when calculating the impacts of the production of FM and FO from fisheries by-products, the fact that they constitute an economically viable solution to lower a potential environmental problem was not assessed and, consequently, the environmental benefit from the use of by-products from the fish canning industry was not taken into account. Another explanation for the higher impact is the use of more materials and more energy to producing FM/FO from fisheries by-products than during production of FM/FO from Peruvian anchovy.

Conclusions from previous studies evaluating the environmental benefits of the use of animal or vegetable ingredients in aquafeeds are not consensual. Samuel-Fitwi et al. (2013) showed that, in general, the ingredients derived from fish have larger environmental impacts, being the categories of GWP100a and AP the most significant. Vegetable ingredients, on the other hand, perform better environmentally, being the EP and land occupation the categories of most concern. Regarding the formulation and composition of the diets, the authors concluded that a low rate of substitution of marine animal protein sources by vegetable sources leads to an environmental improvement of fish diets. Similarly, Papatryphon et al. (2004) also indicated that the partial replacement of animal ingredients for vegetable ingredients is a good environmental strategy, while contrary views are presented by Boissy et al. (2011). These authors have shown that a diet (for Atlantic salmon and rainbow trout) with very low amounts of FM results in the largest environmental impacts for most of the impact categories studied. Further studies are hence required to help the industrial sector take informed decisions on the choice of the most suitable ingredients.

4 Conclusions, limitations and future research

The present study analyses the impacts associated with several aquafeed ingredients, including the production of FM and FO from by-products from fisheries, FM and FO from Peruvian anchovy, meal and fat using poultry slaughter by-products and meal and oil originated from soybean from Brazil. This analysis allowed the identification of the ingredient(s) with the lowest environmental impact within each nutritional category (i.e. meals and fat-based ingredients). The analysis performed considered the life cycle stages from fish capture (for fish based ingredients), animal production (for poultry based ingredients) or crop production (in the case of soybeans) until the location where each ingredient was used to produce aquafeeds (Ovar, Portugal). A general conclusion from the present study is related to the mass of the source-components needed to obtain the two types of ingredients studied. In fact, lipid ingredients need more mass of the ingredient source-component to be produced. Consequently, this always results in a higher impact associated with the production of fats when compared to the impact of producing meals. The conversion rates for the ingredients studied are (i) fish by-products, 0.1 t FM/t caught fish and 0.02 t FO/t caught fish; (ii) fish caught from Peruvian fisheries, 0.23 t FM/t caught fish and 0.05 t FO/t caught fish; (iii) poultry by-products, 0.03 t poultry meal/t live poultry and 0.02 t poultry fat/t live poultry; and (iv) wet soya, 0.81 t meal/t soya and 0.18 t oil/t soya.

Ingredients from poultry slaughter by-products were shown to have the largest contribution to all the environmental impact categories. This is valid for both protein and lipid sources. The poultry production phase (S.1) of poultry by-products meal and fat had the largest contribution for all environmental impact categories studied. The reason for the larger contribution of poultry production is associated with the agricultural production to produce the poultry feeds. As such, improvements of the environmental profile of poultry meal and fat should be sought through optimization of the poultry production, with a focus on the composition and processing of the poultry feeds.

For both classes (protein and lipid), the ingredient that contributed less for the majority of impact categories was the FM/FO from Peruvian anchovy, respectively. This is due to the relative low contribution of these ingredients to the production and processing phases when compared to the other ingredients analysed.

The soybean meal and oil appear to be very interesting options for aquafeeds when compared with the other analysed ingredients, such as by-products ingredients. Although it is not expected that these ingredients will totally replace the use of traditional fish feed ingredients, the use of soybean-derived ingredients in aquafeeds is likely to bring environmental benefits. Nevertheless, being the agriculture production the step that most contributes for the environmental impacts analysed, this is the phase that requires the most attention for the purpose of impact reduction. Another aspect to be taken into account is the fact that vegetable ingredients are, as mentioned above, less interesting from a nutritional point of view, due to the presence of anti-nutritional factors, high fibre content, unbalanced amino acid profile and poor digestibility (Rana and Hasan 2009), resulting in lower fish performance and economic return.

A limitation of the present study is that it does not take into account the reduction of impact associated with the use of by-products, i.e. the relative environmental benefit from its use (from fish and from poultry production) to produce aquafeed ingredients (i.e. poultry fats and meals, FM and FO from fishery by-products). When considering the use of these ingredients in aquaculture feeds, it should be taken into account that the production of fats and meals from by-products is removing otherwise unused agro-food industry residues, providing a solution to an environmental problem. In fact, these agro-food by-products are being transformed into economically viable feed ingredients, avoiding the release of these waste streams into the environment and promoting a circular economy.

Another limitation of this study relates to the fact that LCA does not assess the impact on biodiversity related to eventual marine resources overexploitation. This is mainly relevant for the ingredients originated from marine resources, such as the ingredients from Peruvian anchovy and from by-products from fisheries. The impact these fisheries might have on the ecosystem, specifically on the trophic chain, may result in some uncertainty related to the environmental impact of the fishing stage.

Several aspects concerning aquafeed ingredients would benefit from future research. It would be important to carry out an LCA analysis considering the positive environmental impact brought by the use of by-products (from poultry production and from the fish canning sector), when compared to the scenario when these by-products are not incorporated in aquafeeds. Additionally, the LCA analysis should be extended to other ingredients used in the aquaculture industry, in order to provide relevant support to the sustainable strategy in feed formulation companies. Furthermore, the analysis of the economic impact of the several ingredients and aquafeeds would be warranted, in order to provide the knowledge the aquaculture industries need to make informed decisions and promote more environmental friendly actions and economic sustainable paths.

References

Almeida C, Vaz S, Cabral H, Ziegler F (2014) Environmental assessment of sardine (Sardina pilchardus) purse seine fishery in Portugal with LCA methodology including biological impact categories. Int J Life Cycle Assess 19:297–306

Almeida C, Vaz S, Ziegler F (2015) Environmental life cycle assessment of a canned sardine product from Portugal. J Ind Ecol 19(4):607–617

Ardente F, Cellura M (2012) Economic allocation in life cycle assessment. J Ind Ecol 16(3):387–398

Boissy J, Aubin J, Drissi A, van der Werf HMG, Bell GJ, Kaushik SJ (2011) Environmental impacts of plant-based salmonid diets at feed and farm scales. Aquaculture 321:61–70

Cavadas A (2013) Environmental assessment of seafood consumption patterns in Portugal. Oporto University, Porto

Cavalett O (2008) Análise do Ciclo de Vida da Soja. Universidade Estadual de Campinas, Campinas

CML (2017) CML-IA Characterisation factors. https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors. Accessed 20 May 2017

Davis J, Sonesson U, Baumgartner DU, Nemecek T (2010) Environmental impact of four meals with different protein sources: case studies in Spain and Sweden. Food Res Int 43:1874–1884

De Cara S, Goussebaïle A, Grateau R, Levert F, Quemener J, Vermont B, Bureau JC, Gabrielle B, Gohin A, Bispo A (2012) Revue critique des études évaluant l’effet des changements d’affectation des sols sur les bilans environnementaux des biocarburants. rapport de l’ADEME

Duarte CM, Marbá N, Holmer M (2007) Rapid domestication of marine species. Science, publish by AAAS. 316:382–383

EU CR (2013) (N° 56/2013) amending annexes I and IV to regulation (EC) no 999/2001 of the European Parliament and of the council laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies. Off J Eur Union

FAO (2012) The state of world fisheries and aquaculture. doi: 978-92-5-107225-7FAO (2014) The state of world fisheries and aquaculture. doi: 978–92–5-108275-1

FAO (2016) The state of world fisheries and aquaculture. doi:978–92–5-109185-2

Fréon P, Avadi A, Vinatea Chavez RA, Iriarte Ahon F (2014) Life cycle assessment of the Peruvian industrial anchoveta fleet: boundary setting in life cycle inventory analyses of complex and plural means of production. Int J Life Cycle Assess 19(5):1068–1086

Fréon P, Durand H, Avadí A, Huaranca S, Orozco Moreyra R (2017) Life cycle assessment of three Peruvian fishmeal plants: toward a cleaner production. J Clean Prod 145:50–63

González-García S, Villanueva-Rey P, Belo S, Vázquez-Rowe I, Moreira MT, Feijoo G, Arroja L (2015) Cross-vessel eco-efficiency analysis. A case study for purse seining fishing from North Portugal targeting European pilchard. Int J Life Cycle Assess 20:1019–1032

IEA (2014) Electricity heat in Portugal, available from the International Energy Agency, 2014

INE (2012) Estatísticas da Pesca 2012. Instituto Nacional de Estatística, I.P. Statistics Portugal, Lisboa

Iribarren D, Moreira MT, Feijoo G (2012) Life cycle assessment of aquaculture feed and application to the turbot sector. Int J Environ Res 6(4):837–848

Izquierdo MS, Obach A, Arantzamendi L, Montero D, Robaina L, Rosenlund G (2003) Dietary lipid sources for seabream and seabass: growth performance, tissue composition and flesh quality. Aquac Nutr 9(6):397–407

Karalazos V, Bendiksen E, Bell JG (2011) Interactive effects of dietary protein/lipid level and oil source on growth, feed utilisation and nutrient and fatty acid digestibility of Atlantic salmon. Aquaculture 311(1–4):193–200

Klinger D, Naylor R (2012) Searching for solutions in aquaculture: charting a sustainable course. Annu Rev Environ Resour 37:247–276

Lopes I (2011) Life cycle assessment of chicken. MSc. Master dissertation in environmental engineer. University of Aveiro, Portugal (in Portuguese)

MapQuest (2017) Official MapQuest http://www.mapquest.com/. Accessed 25 Mar 2017

Messina M, Piccolo G, Tulli F, Messina CM, Cardinaletti G, Tibaldi E (2013) Lipid composition and metabolism of European sea bass (Dicentrarchus labrax L.) fed diets containing wheat gluten and legume meals as substitutes for fish meal. Aquaculture 376–379:6–14

Montero D, Robaina L, Caballero MJ, Ginés R, Izquierdo MS (2005) Growth, feed utilization and flesh quality of European sea bass (Dicentrarchus labrax) fed diets containing vegetable oils: a time-course study on the effect of a re-feeding period with a 100% fish oil diet. Aquaculture 248(1–4):121–134

Montero D, Grasso V, Izquierdo MS, Ganga R, Real F, Tort L, Caballero MJ, Acosta F (2008) Total substitution of fish oil by vegetable oils in gilthead sea bream (Sparus aurata) diets: effects on hepatic Mx expression and some immune parameters. Fish Shellfish Immunol 24(2):147–155

Natale F, Hofherr J, Fiore G, Virtanen J (2013) Interactions between aquaculture and fisheries. Mar Policy 38:205–213

Naylor RL, Goldburg RJ, Primavera JH, Kautsky N, Beveridge MCM, Clay J, Folke C, Lubchenco J, Mooney H, Troell M (2000) Effect of aquaculture on world fish supplies. Nature 405:1017–1024

Novaes RML, Pazianotto RAA, Brandão M, Alves BJR, May A, Folegatti-Matsuura MIS (2017) Estimating 20-year land-use change and derived CO2 emissions associated with crops, pasture and forestry in Brazil and each of its 27 states. Glob Chang Biol 23(9):3716–3728

NP EN ISO 14040 (2008) Environmental management, life cycle assessment, principles and framework. International organisation for standardisation (ISO), Geneve

NRC (2011) Nutrient Requirements of Fish and Shrimp. The National Academies Press. Washington DC. https://doi.org/10.17226/13039

Olsen RL, Hasan MR (2012) A limited supply of fishmeal: impact on future increases in global aquaculture production. Trends Food Sci Technol 27(2):120–128

Papatryphon E, Petit J, Kaushik SJ, van der Werf HMG (2004) Environmental impact assessment of salmonid feeds using life cycle assessment (LCA). Ambio 33(6):316–323

Parker RWR, Tyedmers PH (2012) Uncertainty and natural variability in the ecological footprint of fisheries: a case study of reduction fisheries for meal and oil. Ecol Indic 16:76–83

Pelletier N, Tyedmers P (2007) Feeding farmed salmon: is organic better. Aquaculture 272:399–416

Rana KJ, Hasan MR (2009) Impact of rising feed ingredient prices on aquafeeds and aquaculture production. FAO - Fisheries and Aquaculture Technical Paper. 541. ISBN 978-92-5-106422-1

Rust MB, Barrows FT, Hardy RW, Lazur A, Naughten K, Silverstein J (2011) The future of aquafeeds NOAA/USDA

Samuel-Fitwi B, Meyer S, Reckmann K, Schroeder JP, Schulz C (2013) Aspiring for environmentally conscious aquafeed: comparative LCA of aquafeed manufacturing using different protein sources. J Clean Prod 52:225–233

Schmidt JH (2015) User manual for the 2.-0 LCA iLUC model (Version 4.1.). In: 2. 0 LCA consultants, Aalborg, Denmark

SeaRates (2017) International container shipping http://www.searates.com/. Accessed 25 Mar 2017

Tacon AGJ, Metian M (2008) Global overview on the use of fish meal and fish oil in industrially compounded aquafeeds: trends and future prospects. Aquaculture 285(1–4):146–158

Tyedmers PH, Watson R, Pauly D (2005) Fueling global fishing fleets. Ambio 34(8):635–638

Ziegler F, Hornborg S, Green BS, Eigaard OR, Farmery AK, Hammar L, Hartmann K, Molander S, Parker RWR, Skontorp Hognes E, Vázquez-Rowe I, Smith ADM (2016) Expanding the concept of sustainable seafood using life cycle assessment. Fish Fish 17(4):1073–1093

Acknowledgements

We acknowledge the Savinor S.A. team for providing us all data needed to carry on this study and the IJUP program that provided the financial support (PP-IJUP2012-SOJA DE PORTUGAL-08).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Friederike Ziegler

Rights and permissions

About this article

Cite this article

Silva, C.B., Valente, L.M.P., Matos, E. et al. Life cycle assessment of aquafeed ingredients. Int J Life Cycle Assess 23, 995–1017 (2018). https://doi.org/10.1007/s11367-017-1414-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1414-8