Abstract

Purpose

The use and emission of chemicals and the intrinsic toxic properties of some of these chemicals are an important topic in the textile industry. Quantitative evaluation of toxic impacts is a life cycle assessment (LCA) approach, termed “toxic footprint” in this article. We ask whether calculation of toxic footprints is a useful method to steer the textile industry towards more sustainable use of chemicals.

Methods

Three different methods by which strategic product toxicity assessment can be performed within the context of LCA are illustrated and compared using a wet treatment process for a cotton T-shirt as the basis of a case study. The methods are the USEtox model chosen for the European Product Environmental Footprint work, the Score System presented in the European Commission’s Reference Document on Best Available Techniques for the Textiles Industry, and the Strategy Tool presented by Askham. The methods are compared in terms of their ease of use and whether the results give a consistent evaluation of a set of chemicals.

Results and discussion

New USEtox characterisation factors for textile chemicals were calculated and used for this article. The results show that the three methods do not give a consistent evaluation of the different wet treatment chemicals. Both the Score System and the Strategy Tool are very concerned with persistent contaminants such as the optical brightener in this case study, which is deemed to be less important by USEtox. The calculations also show how the results generated by the USEtox model depend on whether users apply (1) only the recommended characterisation factors or (2) these and the interim characterisation factors or (3) these and the new characterisation factors calculated for this article.

Conclusions and recommendations

With current policy initiatives such as the Product Environmental Footprint now being applied for textile products, toxicity assessment will by default be performed in the LCA of textiles. It is important that the results are relevant and representative as the intended users are supposed to take actions based on them. Confidence in the results is crucial for a scientific method, and therefore, this exploratory comparison exercise shows how benchmarking can be a tool to make the differences in background assumptions explicit, to better understand the differences in the results, and help create such confidence.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The textile industry is an intense user of chemicals, both for fibre production and during subsequent manufacturing processes (Munn 2011). The industry has launched several initiatives to reduce the negative impacts of chemicals in the textile production chain, most internationally known are perhaps the Roadmap to Zero Discharge of Hazardous Chemicals (ZDHC 2014) and the Chemicals Management Working Group (CMWG) (Outdoor Industry Association, 2014). Currently, the dominant methods and guidelines for evaluation of the chemical issues of textile product systems, such as the Higg’s Index from the Sustainable Apparel Coalition (SAC 2012) and the Chemicals Management Framework from the CMWG, are based on the evaluation of management procedures, and scores are given based on how well the management activities are implemented.

A complementary approach for evaluation of the chemical issues of textile product systems is to quantify and assess the toxic emissions from these processes. This life cycle assessment (LCA) approach is called “toxic footprint” in this article, which can be considered as a subset of the “chemical footprint” concept discussed previously in literature (Čuček et al. 2012; Hitchcock et al. 2012; Sala and Goralczyk 2013). The main advantage of calculating toxic footprints compared to scoring the management procedures is that it is the actual environmental performance that is quantitatively measured. In fact, implementing management activities (for example administrative procedures such as regularly monitoring the regulations on chemicals in products) is no guarantee of environmental performance even if the procedures are intended to lead to improvement. Quantitative toxic footprint evaluation also means that the economic cost of different management measures can be compared with their potential to improve environmental outcomes and thus guide product procurers, designers and other environmental decision-makers to take eco-efficient decisions. The quantitative toxic footprint evaluation can also be compared with the monetary price of a product, to guide consumers as well as professional buyers.

The EU Integrated Product Policy work identified LCA as the “best framework for assessing the potential environmental impacts of products currently available” (COM 2003). The LCA-based European Commission initiative for Product Environmental Footprint (PEF) (European Commission, 2013) is currently in a pilot phase where textiles are one of the pilot cases. The SAC (SAC 2012) also encourages LCA-based environmental product declarations (EPD) of textile products and is working with guidance material on how to create Product Category Rules (PCR). This article compares three alternative approaches for quantifying textile product system toxicity within the context of LCA by benchmarking them in a case study.

1.1 State-of-the art of toxic footprint application within textile LCA

The development of the International Reference Life Cycle Data System (ILCD) led to the insight that the number of chemicals characterised by ecotoxicity and human toxicity models is a relatively small percentage of the chemicals in use (Sala et al. 2012). In a recent article on LCA on textiles, Terinte et al. (2014) excluded toxicity impacts and stated that both inventory data and characterisation factors (CF) were missing for textile chemicals, in particular for detergents and dyestuffs. It is common in LCA studies to neglect the production and use of chemicals according to Sala and Goralczyk (Sala and Goralczyk 2013) although their relevance is generally regarded as high (Hauschild et al. 2011; Čuček et al. 2012; Hitchcock et al. 2012; Laurent et al. 2012). Three commonly used life cycle impact assessment (LCIA) methods including USEtox were recently shown to generate inconsistent results for toxicity impacts (Owsianiak et al. 2014). To cope with the challenges in applying toxic footprints within LCA, previous attempts have included using hazard statements (formerly “risk phrases”) (Askham 2011) from the CLP (Classification, Labelling and Packaging) regulation (European Commission 2008) and calculating whole effluent toxicity (WET) (Raptis et al. 2008). However, the USEtox model (Rosenbaum et al. 2008) is the recommended for LCIA by the ILCD handbook (European Commission, 2011) and the PEF (European Commission 2013).

1.2 Challenges in applying toxic footprint within LCA on textile products

The challenges in applying toxic footprints within LCA on textile products can be summarised as follows:

-

(a)

The textile life cycle is long and complex. Many different materials, both natural and synthetic, are used in textile products. The variety of processes is also large: agricultural, chemical and mechanical processes are all included.

-

(b)

Many different chemicals are used. In the Textile Auxiliaries Buyers’ Guide, more than 5500 commercial products are reported, based on 400 to 600 active components (TEGEWA, 2008). This excludes pigments and dyestuffs, waste water treatment chemicals and chemicals used during raw material production and use.

-

(c)

Many LCA practitioners are “non-chemists”. The inventory of input and emitted chemicals is difficult to compile for a person who is not skilled in chemistry, especially since chemical reactions may transform the inputs during a process. Further, the effort required to determine whether a substance lacking a published CF needs one, and to calculate the factor, is high for a non-chemist.

-

(d)

Confidential information. The life cycle inventory (LCI) and LCIA of chemical products are often complicated by corporate confidentiality regarding the ingredients.

1.3 Benchmarking three different methods for toxic footprint

This article will examine the strengths and weaknesses of three alternative approaches for quantifying textile product system toxicity and explore the implications of the fact that the LCIA methods are developed from a different perspective than that of the CLP hazard statements. Hazard statements and Safety Data Sheets (SDS) are tools that the European industry is required by law to use. With the European Commission initiative for PEF (European Commission 2013) now being applied for textile products, the toxicity of chemicals (freshwater ecotoxicity and human toxicity) will by default be addressed in LCA of textiles. The foreseen uses of PEF for policy development, both legal and voluntary, make it important that the results are relevant and representative since the intended users are supposed to take actions based on the results, and the legal certainty around PEF evaluations will be important for companies.

The wet treatment process for production of a white cotton T-shirt is used as a case study where three different toxic footprint methods are applied. While strictly speaking there can be no experimental validation of environmental damage predicted in an LCA of a generic T-shirt, comparison of the results of three different methods can be considered a form of triangulation in LCA (Peters et al. 2013) which can potentially provide confidence in the individual methods. This article’s approach to benchmarking is based on comparing whether the methods identify the same hotspots in the product systems, i.e. whether they suggest similar advice to textile companies regarding which chemicals to prioritise for their chemical management work. This is crucial for the industry’s confidence in LCIA since both the CLP and PEF approaches now will be used in parallel.

An estimation of the workload on the LCA practitioner applying each toxic footprint method is provided in the discussion as this is an important parameter influencing whether the method will be viable and also correctly employed. The ILCD guidelines for LCA recommend that “the entirety of characterisation factors should have no relevant gaps in coverage of the impact category they relate to, as far as possible; relevant gaps shall be approximated, reported and explicitly be considered in the results interpretation” (European Commission 2010). This means that for textile chemicals, where both inventory data and CFs are often missing for toxicity (Terinte et al. 2014), the LCA practitioner will need to identify which chemicals, missing in publicly available LCA databases and software, should be covered by the LCA. The workload of the LCA practitioner can be reduced if the simpler methods provide the same advice regarding hotspots in the product system as USEtox.

2 Methods

A complete LCA of a T-shirt was performed within the Mistra Future Fashion project (Mistra Future Fashion 2014). The inventory results for use and emission of textile wet treatment chemicals were then extracted and evaluated with three different quantitative or semi-quantitative LCIA methods for toxic footprints: USEtox, the Score System, and the Strategy Tool. In other words, the remainder of this article is based on a gate-to-gate LCI of the wet treatment of a white cotton T-shirt processed in a jet dyeing machine.

2.1 Life cycle inventory profile for the wet treatment process

Table 1 below shows the LCI profile related to use and emission of chemicals in the wet treatment which was used as input data for the comparison of the methods. All non-toxicity-related results are presented in the project report (to be published).

2.2 Selection of methods for toxic footprint benchmarking

The USEtox model (Rosenbaum et al. 2008) was selected because it is the LCIA method recommended by the ILCD handbook (European Commission 2011) and chosen for the PEF work (European Commission, 2013). USEtox is a global, nested box model of the transport and fate of contaminants which was developed for assessment of human toxicity and freshwater ecotoxicity within LCA. It is the consensus model resulting from extensive comparison of existing LCA methods for toxicity impact assessment by an international team of LCA experts (Rosenbaum et al. 2011).

The second method is the Score System developed in the 1990s by the Federation of Danish Textile and Clothing in Denmark (Laursen et al. 2002). It is a semi-quantitative multi-criteria analytical method (Rowley et al. 2012) for aggregating factors describing the intrinsic properties of chemicals and the scale of their use in a process. The method has been integrated into the waste water permit approval process of Ringkøbing County in Denmark. It has been selected on the basis that it is presented as a viable method in the Integrated Pollution Prevention and Control (IPPC) Reference Document on Best Available Techniques for the Textiles Industry (European Commission, 2003) and used as a simplified ecotoxicity assessment method in previous LCA studies (Krozer et al. 2011; Roos et al. 2015).

The third method is the Strategy Tool presented in Askham et al. (2012). The Strategy Tool is a semi-quantitative method developed to assist a paint production company making strategic decisions in product development. The Strategy Tool evaluates the chemical content of products in a simplified way, based on the available information in the SDS. This method is selected because it uses input data that is readily available for most chemicals and thus a user-friendly method also for LCA practitioners who are not experts in chemistry. This user-friendliness gives it considerable potential for being used correctly.

2.3 Inherent differences between the methods

The methods have inherent differences that are likely to affect the results. The two semi-quantitative methods (the Score System and the Strategy Tool) are based on classification of substances according to the CLP regulation (in two different ways) where discrete values are assigned for many properties. On the other hand, USEtox has a more realistic representation of environmental processes with continuous values. The spread in results is limited in the semi-quantitative methods by the assigned scores, while USEtox does not impart such limits. The input data to the USEtox model further includes breakdown products while the Score System and the Strategy Tool use only the input to the wet treatment process. The Strategy Tool covers a broader spectrum of hazard statements than both USEtox and the Score System, including working environment-related hazards.

2.4 Application of the USEtox model

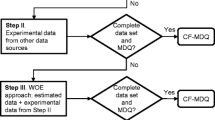

The substances emitted to water were matched against the substances covered by the latest officially released USEtox version (1.01). The USEtox team recommends employment of both “recommended” and “interim” CFs by default (Rosenbaum et al. 2011). It has been shown in previous studies that whether interim CFs are included or not influences the ranking of alternative products (Askham, 2011). In our case study, one substance was found to have a recommended CF: formaldehyde (CAS RN 50-00-0). Three substances were found to have interim CFs: formic acid (CAS RN 64-18-6), acetic acid (CAS RN 64-19-7) and diethanolamine (CAS RN 111-42-2). USEtox CFs were developed for the missing textile chemicals.

For the development of the missing factors, the physiochemical properties were primarily collected from EPIsuite (USEPA 2007), and secondarily from other sources, specified in the Electronic Supplementary Material. The toxicity properties were collected from the Handbook of Green Chemicals (Ash and Ash 2004), the Categorisation Results from the Canadian Domestic Substance List (CCRWEB) (OECD 2014), SDSs, the Handbook of Inorganic Chemicals (Perry 2011) and other public reports (OECD SIDS 2001). The resulting CFs are presented in Table 2.

The input data used for the calculation of CFs in USEtox 1.01 is found in Table S.1 in the Electronic Supplementary Material.

2.5 Application of the Score System

The Score System is a semi-quantitative method based on multi-criteria analysis with implicitly equal weighting (Rowley et al. 2012) of four criteria. According to the Score System, each substance is given a score from 1 to 4 for each of four different criteria: A—amount of substance discharged weekly, B—biodegradability, C—bioconcentration factor and D—toxicity (see (European Commission 2003) for more details). The four scores are then multiplied with each other so that the lowest possible value is 1 (best environmental performance) and the highest possible value is 256 (worst environmental performance). Missing information invokes the highest score, i.e. in case of data missing for a property; the value of 4 should be given to the substance for that property. The input data used for the calculation of the Score System is found in Table S.2 in the Electronic Supplementary Material.

2.6 Application of the Strategy Tool

The Strategy Tool from Askham (2011) was developed before the implementation of the Global Harmonized System (GHS) (United Nations 2011) for labelling of physical, health and environmental hazards of chemicals. Therefore, a translation to the current labelling system was necessary, as shown in Table S.3 in the Electronic supplementary Material. The data in the SDS of each chemical was used for data on the chemical products. The Strategy Tool also considers the number of exposure scenarios (ES) that must be developed under the CLP regulation (European Commission 2008). The number of ES was set to the number of classified substances, which means that it is assumed that they are all used within the EU/EEA at a volume above 10 tonnes/year somewhere in the supply chain and that they are only emitted via the waste water. The input data to the Strategy Tool is shown in Table S.4 in the Electronic Supplementary Material.

2.7 Practical usability of the methods

The practical usability of a method is best measured by the rate at which it is used in reality. A method that is frequently used obviously fills some function, whether it is the function intended by the designers or not. A method that on the contrary is not frequently used presumably lacks some important property, whether it is lack of a (sufficiently) desired function, a lack of user confidence in the results, a lack of recognition among the potential users or perhaps that it has a difficult user interface.

The ability for a non-expert to understand the result is also a parameter that is relevant to discuss. An evaluation method that is transparent, also to a non-expert, can be perceived as more reliable. Transparent calculation methods can be easily error-checked, and thus mathematical errors can be excluded in the cases where the results are unexpected.

3 Results

The results for the calculations of the toxicity footprint using the three methods are shown below. Data is grouped in the figures based on the function of the input chemicals and the different chemical mixtures. Details of the input grouping are provided in Table S.5 in the Electronic Supplementary Material.

3.1 USEtox results

USEtox calculates results in three impact categories which are displayed on a logarithmic scale in Fig. 1.

The USEtox result for a human toxicity, carcinogenic impacts; b human toxicity, non-carcinogenic impacts; and (c) freshwater ecotoxicity, expressed in Comparative Toxic Units (CTU), human toxicity, carcinogenic impacts (CTUhcarc.), human toxicity, non-carcinogenic impacts (CTUhnon-carc.) and ecotoxicity impacts (CTUe). Please note that the scales are logarithmic and the units not comparable with each other

The first impact category, (a) human toxicity, carcinogenic impacts, has a non-zero result for only one substance, formaldehyde, which is a common breakdown product of acrylamides (crease-preventing agents). Formaldehyde has a recommended CF which means that the results would look the same regardless of whether only recommended or recommended as well as interim CFs are used, and also whether the LCA practitioner has actively worked to provide the missing CFs or not. For (b) human toxicity, non-carcinogenic impacts, the peroxide stabiliser dominates due to the impact from the phosphonic acid disodium salt and the magnesium chloride (MgCl). The crease-preventing agent is also important for the non-carcinogenic impact due to the formaldehyde emissions. The impact from the optical brightener is also visible, though two orders of magnitude lower than the peroxide stabiliser. Formaldehyde has a recommended CF (indicated by ** in Fig. 1), while formic acid, acetic acid and diethanolamine have interim CFs (indicated by * in Fig. 1). This means that formaldehyde would dominate regardless of whether interim CFs are included or not. In the case where the LCA practitioner has actively worked to fill the gaps of lacking CFs (substances in the legend without *s) the result will be different. The results for (c) (freshwater) ecotoxicity impact are dominated by the diethanolamine emission from the softener, the two acids, the peroxide stabiliser and the crease-preventing agent in decreasing importance. The impact from the optical brightener is also visible, though three orders of magnitude lower than the softener. Since formaldehyde has a recommended CF, while formic acid, acetic acid and diethanolamine have interim CFs, this means that formaldehyde would dominate totally in the case where only recommended CFs are used. In the second case when both recommended and interim CFs are used, the ecotoxicity will be dominated by the softener and the acids. In the third case where the LCA practitioner has actively worked to fill the gaps of lacking CFs, the result will not be very different.

3.2 Score System results

The Score System points out the crease-preventing agent and the optical brightener as the two most significant chemicals for environmental impacts, as is shown in Fig. 2a. The poor performance of both the crease-preventing agent and the optical brightener is attributable to their attaining the worst possible scores for bioaccumulation and biodegradability.

3.3 Strategy Tool results

The Strategy Tool indicates that the detergent is the most significant chemical based on both health and environmental impact, as is shown in Fig. 2b. If only environmental impact is considered, it is instead the optical brightener that is of greatest importance. This result aligns well with the result with the Score System, but the crease-preventing agent scores zero here, despite its significance under the Score System.

4 Discussion

4.1 Comparison of the result from the methods

The results show that the three methods do not give a consistent evaluation of the different wet treatment chemicals, and for USEtox, the result also depends on the practitioner. The difference in results can to some extent be explained in the difference in scope, as has been explained in Section 2.

The implications of the relatively equal importance of the chemicals under the two semi-quantitative methods deserve reflection. The USEtox scores for different chemicals differ by orders of magnitude, which is why it is presented on a logarithmic scale in Fig. 1. The semi-quantitative methods on the other hand could be wrongly interpreted to say that the impact from the chemicals is not very different, i.e. the choice of chemicals does not matter much.

The most interesting chemical to discuss in terms of how the results differ may be the optical brightener. The Score System is very concerned with persistent contaminants. Therefore, the crease-preventing agent and the optical brightener, which are not readily biodegradable, receive a high score. The optical brightener is also the only chemical that has an environmental hazard statement score in the Strategy Tool. But the USEtox score is very low, mainly because the property of environmental persistence of organic chemicals is handled differently in this method. Indeed, it has recently been reported that the inherent toxicity of the chemical, the avlogEC50 is the input parameter which contributes most to the freshwater toxicity in USEtox (Alfonsín et al. 2014; Igos et al. 2014).

Optical brighteners have long been considered an environmental problem in the textile industry due to their designed persistence; they are intended to be retained by textile products to provide the function of making the textile look whiter. The CLP classification of the substance in question is classified “Aquatic Chronic 3 (H412)” which means that it is harmful to aquatic life with long-lasting effects. The advice from USEtox, that the optical brightener is not a chemical to prioritise for work towards improved sustainability, may seem doubtful in light of the classification and the advice from the other methods.

The way degradation is modelled today in USEtox is based on degradation probability in half-lives, recommended to be collected from EPI Suite™ and multiplication factors of 1:4:9 to extrapolate degradation half-lives for water, soil and sediment compartments, respectively (Rosenbaum et al. 2008). It is recommended to use data from EPI SuiteTM—primarily experimental data if available and secondarily modelled data, an approach followed by this article. Gouin et al. (2004) have however shown that the persistence of more persistent chemicals is often underestimated in the EPI SuiteTM. The CLP classification used in the Strategy Tool is instead based on biodegradation studies using standardised test methods such as OECD 302B (European Commission 2008).

Another difference between the methods is that the USEtox fate model is time-integrated (Rosenbaum et al. 2008). This means that the model calculates steady-state concentrations in the environment based on initial dilution at the local scale, transfer and dilution at a continental scale, and further transfer and dilution at the global scale. Persistence is accounted for in these nested boxes in USEtox by giving persistent chemicals lower degradation rates and thus higher steady-state concentrations, and subsequently higher fate factors (FF) compared to degradable chemicals. The fate factor will then impact the CF result, as can be seen from the standard equation CF = FF*XF*EF, where XF = exposure factor and EF = effect factor. Thus, the persistence of chemicals is not treated as a single criterion for risk in USEtox, but the property is integrated into the potential to cause harm. The question of which approach is more appropriate boils down to whether the inaccuracy associated with having a more complex model with a more realistic representation of environmental processes but larger risk for errors due to data gaps or incorrect use is greater or less than the inaccuracy associated with using less data-intensive methods based on semi-quantitative association of hazard statements that are less representative of environmental processes.

The calculations also show how the USEtox results differ depending on whether the analyst uses (1) only recommended CFs or (2) recommended and interim CFs or (3) user-developed CFs according to the recommendations in the ILCD handbook. In the case with human toxicity, non-carcinogenic impacts, the greatest difference in results is found when the user develops their own CFs (using the approved USEtox model). For ecotoxicity, the result is found to be mostly dependent on whether interim CFs are used or not. Such dependence on decisions made by the user strengthens the argument that user-friendliness is an important parameter for the method to be viable and also to be correctly used.

4.2 Comparison of the practical usability of the methods

The practical usability of the three methods is discussed in terms of “understandability” to the end user and the work load for the practitioner below.

4.2.1 USEtox

USEtox is a difficult model for non-chemists to handle. The time frame for implementation and use for an estimated average LCA practitioner in a case study of the scale shown here could be weeks (if proper support is given) to months depending on the complexity of the chemistry.

The main advantage with USEtox is that it is a versatile method where it is possible to model and evaluate the toxicity of the actual emitted substances to different compartments. In the current unofficial beta version of USEtox, emissions to indoor air are covered. In the future, it will be possible to address the workplace environment with this method, and coverage of dermal exposure is developing. USEtox can also model the full content of chemical products, including breakdown products and other contaminants (if this is known by the LCA practitioner) while the other two methods are based on the nominal content of the chemical products.

4.2.2 Score System

The Score System has the advantage of simplicity. The time frame for implementation and use for a typical average LCA practitioner would be days to weeks. The Score System does however require knowledge of the quantitative (aqueous) emissions from the site, in contrast to the Strategy Tool that only requires knowledge of the input chemicals.

The Score System is very limited in terms of scope as it only addresses emissions of environmentally hazardous substances to water. The original purpose of the Score System was to evaluate onsite emissions, and it can be adapted to be relevant for product-related emissions by excluding criterion A (discharged substances). The site-specific load is however a very important factor for the assessment of possible site-specific impacts and can, if properly interpreted, be a means to achieve local specificity.

4.2.3 The Strategy Tool

The Strategy Tool as presented by Askham (2011) is the simplest method to use of the three methods investigated in this article. The time frame for implementation and correct use for an estimated average LCA practitioner would be a few days. As long as SDSs are available for the chemicals that are to be assessed, this is a user-friendly method with a short learning curve. Another advantage is that exposures in the working environment are included.

The drawback with the Strategy Tool is that it is not universally applicable over the whole life cycle. The use and emissions of hazardous chemicals in background processes, e.g. the electricity and energy production systems, are difficult to compare. The Strategy Tool, as it is designed today, does not further handle the unwanted and sometimes undocumented breakdown products from chemicals, such as emissions of formaldehyde from acrylamides, or emissions of exhaust gases from combustion processes. Further, the Strategy Tool does not consider any differences between the actual and the possible uses of substances and emissions of substances to different compartments: air, water, sludge etc. The number of exposure scenarios is the only parameter to cover the severity of an emission, and this is not case specific (European Commission 2008).

Table 3 summarises the results of the benchmark of the three methods that were analysed.

5 Conclusions and recommendations

This article began with a discussion of whether toxic footprints are useful in order to steer the textile industry towards more sustainable chemical management. The quantitative calculations of toxic footprints that are performed in LCA can reduce the risk that both financial and other resources are spent on management procedures that do not contribute to any actual improvement of the environmental performance.

However, several challenges must be overcome to make toxic footprints a useful method. With PEF and other initiatives being implemented, in which the toxicity of textile chemicals will be addressed in LCA, it is important that the methods are user-friendly and that the results are relevant and representative, as the intended users are supposed to take actions based on the results. Benchmarking with CLP-based methods is a useful approach in making the differences in background assumptions explicit, to better understand the differences in the results and to model limitations of different LCIA methods. In this case, we showed that the three methods do not give a consistent evaluation of the different wet treatment chemicals. The benchmarking visualised an important difference in how exotoxicity is evaluated in USEtox compared to the two CLP-based methods, particularly in relation to how persistence is handled.

The implication of the fact that the methods differ is that the CLP regulation and LCA will provide different messages to the industry. The CLP regulation puts up a number of requirements for what will be classified as hazardous substances. When a substance is classified, it is regulated by legislation. The optical brightener has been classified as an environmentally hazardous substance, while none of the other substances has such a classification. If on the other hand the industry takes actions based strictly on the advice from an LCA study performed using USEtox, then the emissions of the optical brightener would not be handled. But USEtox could provide additional advice compared to the two other methods, by indicating that one of the substances could be more environmentally problematic than signalled by the current CLP classification. Further investigation is desired on how the methods differ and whether a more similar concern for the property of persistence can be achieved for consistent guidance to the industry and policymakers.

The differing results obtained from USEtox show how important user-friendliness and the decisions made by the LCA practitioner are. The feasibility of reducing the workload of the LCA practitioner by using any of the two simplified methods instead of USEtox was not indicated. If the calculation of toxic footprints is to be a viable approach for steering the textile industry towards more sustainable chemical management, it will have to be practicable for LCA practitioners who are not experts in either chemistry or textile technology.

References

Alfonsín C, Hospido A, Omil F, Moreira MT, Feijoo G (2014) PPCPs in wastewater—update and calculation of characterization factors for their inclusion in LCA studies. J Clean Prod 15:245–255

Ash M, Ash I (2004) Handbook of green chemicals, 2nd ed. Endicott, NY : Synapse Information Resources, New York

Askham C (2011) Environmental product development combining the life cycle perspective with chemical hazard information. Aalborg University, Department of Planning, Aalborg, Denmark

Askham C, Gade AL, Hanssen OJ (2012) Combining REACH, environmental and economic performance indicators for strategic sustainable product development. J Clean Prod 35:71–78

COM (2003) Communication from the Commission to the Council and the European Parliament. Integrated Product Policy. Brussels

Commission E (2003) Integrated pollution prevention and control (IPPC) reference document on best available techniques for the textiles industry. European IPPC Bureau, Seville

Čuček L, Klemeš JJ, Kravanja Z (2012) A review of footprint analysis tools for monitoring impacts on sustainability. J Clean Prod 34:9–20

European Commission (2008) Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC). Off. J. Eur. Union 353

European Commission (2010) International Reference Life Cycle Data System (ILCD) Handbook—general guide for life cycle assessment—detailed guidance, 1st ed. Publications Office of the European Union, Luxembourg. 10.2788/38479

European Commission (2011) International Reference Life Cycle Data System (ILCD) Handbook—recommendations for life cycle impact assessment in the European context, 1st ed. EUR 24571 EN. Publications Office of the Europe, Luxemburg

European Commission (2013) Commission Recommendation of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations. Off. J. Eur. Union 56

Gouin T, Cousins I, Mackay D (2004) Comparison of two methods for obtaining degradation half-lives. Chemosphere 56:531–5

Hauschild MZ, Jolliet O, Huijbregts MAJ (2011) A bright future for addressing chemical emissions in life cycle assessment. Int J Life Cycle Assess 16:697–700

Hitchcock K, Panko J, Scott P (2012) Incorporating chemical footprint reporting into social responsibility reporting. Integr Environ Assess Manag 8:386–388

Igos E, Moeller R, Benetto E, Biwer A, Guiton M, Dieumegard P (2014) Development of USEtox characterisation factors for dishwasher detergents using data made available under REACH. Chemosphere 100:160–166

Krozer A, Björk A, Hanning A-C, Wendel A, Magnusson E, Persson F, Holmberg K, Jelse K (2011) Clean development and demonstration—sustainable domestic washing—s’wash. Final report. IVL Swedish Environmental Research Institute, Stockholm, Sweden

Laurent A, Olsen SI, Hauschild MZ (2012) Limitations of carbon footprint as indicator of environmental sustainability. Environ Sci Technol 46:4100–4108

Laursen SE, Hansen J, Andersen TA, Knudsen HH (2002) Danish experience. Best Available Techniques—BAT—in the clothing and textile industry, Working Re. ed. Danish EPA, Copenhagen, Denmark

Munn K (2011) The chemicals in products project: case study of the textiles sector. Switzerland, Geneva

OECD SIDS (2001) SIDS initial assessment report on fluorescent brightener 220. Bern, Switzerland

OECD (2014) Categorization results from the Canadian Domestic Substance List (CCRWEB) [WWW Document]. URL http://webnet.oecd.org/CCRWEB/Default.aspx (accessed 6.1.14)

Outdoor Industry Association (2014) Chemicals Management Working Group (CMWG) [WWW Document]. URL http://outdoorindustry.org/responsibility/chemicals/index.html (accessed 6.1.14)

Owsianiak M, Laurent A, Bjørn A, Hauschild MZ (2014) IMPACT 2002+, ReCiPe 2008 and ILCD’s recommended practice for characterization modelling in life cycle impact assessment: a case study-based comparison. Int J Life Cycle Assess 19:1007–1021

Perry DL (2011) Handbook of inorganic compounds, 2nd ed. CRC Press

Peters GM, Blackburn NJ, Armedion M (2013) Environmental assessment of air to water machines—triangulation to manage scope uncertainty. Int J Life Cycle Assess 18:1149–1157

Raptis CE, Juraske R, Hellweg S (2008) Aquatic ecotoxicity of whole effluents effect factor: methodology 1–4

Roos S, Posner S, Jönsson C, Peters GM (2015) Is unbleached cotton better than bleached? Exploring the limits of life cycle assessment in the textile sector. Cloth Text Res J. doi:10.1177/0887302X15576404

Rosenbaum RK, Bachmann TM, Gold LS, Huijbregts MAJ, Jolliet O, Juraske R, Koehler A, Larsen HF, MacLeod M, Margni M, McKone TE, Payet J, Schuhmacher M, Meent D, Hauschild MZ (2008) USEtox—the UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int J Life Cycle Assess 13:532–546

Rosenbaum RK, Huijbregts MAJ, Henderson AD, Margni M, McKone TE, Meent D, Hauschild MZ, Shaked S, Li DS, Gold LS, Jolliet O (2011) USEtox human exposure and toxicity factors for comparative assessment of toxic emissions in life cycle analysis: sensitivity to key chemical properties. Int J Life Cycle Assess 16:710–727

Rowley HV, Peters GM, Lundie S, Moore SJ (2012) Aggregating sustainability indicators: beyond the weighted sum. J Environ Manag 111:24–33

SAC (2012) Sustainable Apparel Coalition (SAC) [WWW Document]. URL http://www.apparelcoalition.org/ (accessed 8.24.13)

Sala S, Goralczyk M (2013) Chemical footprint: a methodological framework for bridging life cycle assessment and planetary boundaries for chemical pollution. Integr Environ Assess Manag 9:623–32

Sala S, Pant R, Hauschild M, Pennington D (2012) Research needs and challenges from science to decision support lesson learnt from the development of the International Reference Life Cycle Data system (ILCD) recommendations for Life Cycle Impact Assessment. Sustainability 4:1412–1425

Mistra Future Fashion (2014) Mistra future fashion [WWW Document]. URL http://www.mistrafuturefashion.com (accessed 6.1.14)

TEGEWA (2008) TEGEWA’s International Textile Auxiliaries Buyer’s Guide 2008/09. Deutscher Fachverlag GmbH, Frankfurt am Main

Terinte N, Manda BMK, Taylor J, Schuster KC, Patel MK (2014) Environmental assessment of coloured fabrics and opportunities for value creation: spin-dyeing versus conventional dyeing of modal fabrics. J Clean Prod 72:127–138

United Nations (2011) Globally Harmonized System of classification and labelling of chemicals (GHS), 4th ed, US Environmental Agency, Arlington USA. United Nations, New York and Geneva

USEPA (2007) Estimation Programs Interface EPI Suite [WWW Document]. URL http://www.epa.gov/oppt/exposure/pubs/episuitedl.htm (accessed 6.1.14)

ZDHC (2014) Roadmap to Zero Discharge of Hazardous Compounds (ZDHC) [WWW Document]. URL http://www.roadmaptozero.com/ (accessed 6.1.14)

Acknowledgements

The researchers acknowledge the support of the Swedish funding agency Mistra in the Mistra Future Fashion programme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ralph K. Rosenbaum

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 49 kb)

Rights and permissions

About this article

Cite this article

Roos, S., Peters, G.M. Three methods for strategic product toxicity assessment—the case of the cotton T-shirt. Int J Life Cycle Assess 20, 903–912 (2015). https://doi.org/10.1007/s11367-015-0895-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-015-0895-6