Abstract

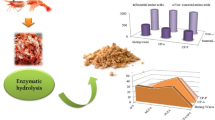

The study aimed to develop an effective and eco-friendly enzymatic process to extract carotenoproteins from shrimp waste. The optimization of enzymatic hydrolysis conditions to maximize the degree of deproteinization (DDP) of carotenoprotein from shrimp head waste (SHW) and shrimp shell waste (SSW) was conducted separately using the Box-Behnken design of response surface methodology (RSM). To achieve a maximum DDP of 92.32% for SSW and 96.72% for SHW, the optimal hydrolysis conditions were determined as follows: temperature (SSW: 53.13 °C; SHW: 45.90 °C), pH (SSW: 7.13; SHW: 6.78), time (SSW: 90 min; SHW: 61.18 min), and enzyme/substrate ratio (SSW: 2 g/100 g; SHW: 1.18 g/100 g). The carotenoprotein effluent obtained was subjected to spray drying and subsequently assessed for color, nutritional, and functional characteristics. The carotenoprotein from shrimp shell (CpSS) contained a higher essential amino acid score than carotenoprotein from shrimp head (CpSH). CpSS had a higher whiteness index of 82.05, while CpSH had 64.04. Both CpSS and CpSH showed good functional properties viz solubility, emulsion, and foaming properties. The maximum solubility of CpSH and CpSS was determined to be 92.94% and 96.48% at pH 10.0, respectively. The highest emulsion capacity (CpSH: 81.33%, CpSS: 70.13%) and stability (CpSH: 57.06%, CpSS: 63.05%) were observed at 3% carotenoprotein concentration. Similarly, the highest values of foaming capacity (CpSH: 27.66%, CpSS: 105.5%) and stability (CpSH: 23.83%, CpSS: 105.33%) were also found at the same 3% carotenoprotein concentration. In conclusion, the carotenoproteins obtained from shrimp waste showed favorable attributes in terms of color, amino acid composition, and functional properties. These findings strongly suggest the potential applicability of CpSS and CpSH as valuable resources in various domains. CpSS, with its higher whiteness index, greater amino acid content, and superior functional characteristics, may find suitability as functional ingredients in human food products. Conversely, CpSH could be considered for incorporation into animal feed formulations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During shrimp processing, a substantial portion of the raw materials, which includes shells, heads, and tails, is typically discarded, accounting for roughly 40–60% (Haque et al. 2021; Dayakar et al. 2022). This disposal practice presents a significant challenge for the shellfish industry. It is important to recognize that shrimp processing waste represents a valuable resource containing carotenoproteins, minerals, flavor compounds, and chitin (Pattanaik et al. 2021; Dayakar et al. 2021). Proper utilization of this waste is crucial due to its perishable nature and the environmental pollution it can cause if disposed of in water bodies. The seafood processing industry is introduced to the concept of a circular economy by focusing on the valorization of these leftovers instead of their disposal or combustion (Jacob et al. 2021). The circular economy method entails considerable material savings throughout value chains and production processes and the creation of additional value and opens up new economic prospects (Pinheiro et al. 2021). In addition, treated waste can have multiple applications and offer solutions to environmental hazards and revenue to the seafood sector (Simpson et al. 1994; Rao and Stevens 2005).

Presently, the predominant component extracted from shrimp waste among its various valuable constituents is chitin, a highly abundant polymer composed of N-acetyl-glucosamine (Deng et al. 2020; Ngasotter et al. 2023a). Chitin, in its natural state, is firmly bound to proteins and minerals found in crustacean shells (Ngasotter et al. 2022). The conventional industrial method for extracting chitin from shrimp waste relies on the use of harsh chemicals, including alkalis and acids, for deproteinization and demineralization (Sampath et al. 2022a; Ngasotter et al. 2023b). Unfortunately, these chemicals are released into aquatic ecosystems, causing harm to aquatic flora and fauna (Prameela et al. 2010). Moreover, using such chemicals results in a significant loss of other valuable bioactive compounds, such as carotenoids and proteins, which can be isolated from shrimp waste (Mao et al. 2013). To circumvent the loss of these valuable compounds during the chemical chitin extraction process, alternative methods like enzymatic approaches can be employed. These enzymatic methods effectively deproteinize shrimp shell waste while facilitating the recovery of proteins containing carotenoids, known as carotenoproteins, during chitin production. This approach offers a more environmentally friendly and sustainable way to harness the full potential of shrimp waste without causing harm to aquatic ecosystems or sacrificing other valuable components.

In shrimp and other crustaceans, unstable carotenoids are attached to proteins as carotenoproteins, which increases the stability of the carotenoids (Pattanaik et al. 2020). To recover carotenoproteins from shrimp waste, many researchers have standardized different methods such as supercritical carbon dioxide extraction (Cardenas-Toro et al. 2015), autolytic process (Cahú et al. 2012), lactic fermentation (Armenta-López et al. 2002), and enzymatic hydrolysis (Dayakar et al. 2022). Among these methods, enzymatic hydrolysis using proteolytic enzymes such as pepsin, trypsin, protease, and papain avoids extreme response conditions generally used in chemical hydrolysis and also minimizes the formation of toxic substances like lysinoalanine (Clemente 2000; Chakrabarti 2002; Pattanaik et al. 2020). Carotenoproteins contain a high amount of proteins and are abundant in essential amino acids such as lysine, glutamic acid, aspartic acid, and leucine (Pattanaik et al. 2020). In addition, carotenoproteins have excellent antioxidant ability because of the presence of carotenoids, mainly astaxanthin (Dayakar et al. 2022). Therefore, producing carotenoproteins from shrimp waste rather than discarding it can be valuable for application in animal feed to enhance growth, color, and immunity (Pattanaik et al. 2021) and also as a functional ingredient in foods and beverages (Poonsin et al. 2017).

With this background, this study emphasizes the environmentally friendly recovery of valuable carotenoproteins from SSW and SHW separately using an enzymatic hydrolysis process, and its physicochemical and functional characteristics are explored from the perspective of the circular economy concept. The rationale to utilize shrimp shell and head waste separately was because, in the current scenario, the Indian shrimp processing industry presently exports shrimps, particularly Litopenaeus vannamei, in various processed forms, including headless (HL), shell-on, peeled tail-on (PTO), peeled and undeveined (PUD), and peeled and deveined (PD). Consequently, the availability of raw material (shrimp waste) can consist of either head waste, shell waste, or a combination of both. Additionally, heads and shells are significantly different in their composition, and therefore, the obtained carotenoprotein powders will also differ in their functional properties, amino acid score and color attributes. The enzymatic hydrolysis process was optimized using the Box-Behnken design (BBD) of response surface methodology (RSM) to maximize the response variable, degree of deproteinization (DDP). Finally, the effluent carotenoprotein extract obtained from shrimp waste after enzymatic hydrolysis were further spray-dried to obtain carotenoprotein powder and its characteristics, such as amino acid profiles, color analysis, and functional properties were evaluated with a viewpoint of its potential application in animal feed or human food.

Materials and methods

Raw materials

Shrimp shell and head (cephalothorax) waste from L. vannamei was obtained from Naik Oceanic Exports, Maharashtra, India. The shells and heads were transported to the ICAR-CIFE, Mumbai, in sanitized containers with ice. The shell and head waste were washed with potable water, packed, and stored at – 20 °C until further study. Papain, an enzyme with 30,000 USP units/mg activity, extracted from papaya latex (Carica papaya), was purchased from Hi-Media, India. The enzyme papain was used for enzymatic hydrolysis because of its abundant availability and low cost. All chemicals employed in the experiment were of analytical grade and were supplied by Merck (Germany).

Optimization of enzymatic hydrolysis parameters

The BBD of RSM was used to design a series of experiments to investigate the effect of various enzymatic hydrolysis parameters on the DDP of shrimp waste. Four independent variables or factors, i.e., temperature (X1), time (X2), pH (X3), and enzyme to substrate (E/S) ratio (X4), and two responses, i.e., DDP of SSW (Y1) and SHW (Y2) were evaluated. The independent variables and their levels were chosen on the basis of preliminary experiments. After preliminary experiments, the temperature of 50 °C, the hydrolysis time of 60 min, the pH of 7.0, and E/S ratio of 1.5 were chosen as the centre points. Subsequently, the range of the factors was determined, as shown in Table 1. The selection of ranges was deliberate, with careful consideration given to avoiding both excessively narrow and excessively wide ranges. This approach was adopted to mitigate the risk of excluding potential optimal conditions while concurrently striving for the establishment of a model with strong predictive capabilities. Each independent variable was categorized into three levels: low, mid, and high, which were represented as − 1, 0, and 1, respectively. The coded values for these levels are presented in Table 1. The entire design was executed in a random manner in order to prevent systematic errors and encompassed a total of 27 combinations. This included twelve factorial points, twelve axial points, and three replicates at a central point, as detailed in Table 2. Model construction and statistical analysis were performed using Design Expert software, version 12 (StatEase, Inc). RSM was employed to explore both the individual and interactive effects of the independent variables on the response variable, which is the DDP. To predict the optimal conditions for establishing a correlation between the independent and response variables, a quadratic polynomial function was applied. The equation is presented as follows:

where Y is the predicted response; β0 is the model constant; X1, X2, X3, and X4 are independent variables; β1, β2, β3, and β4 are linear coefficients; β12, β23, β34, β24, and β14 are cross-product coefficients; β12, β22, β32, and β42 are quadratic coefficients; and e is the experimental error.

Determination of degree of deproteinization

The degree of deproteinization (DDP) was determined according to the method of Dhanabalan et al. (2021). The protein and mass of the residue left in the hydrolysate were determined at the end of the hydrolytic reaction. The sample’s initial protein content and its mass before hydrolysis were also determined. Following this, the DDP was calculated by the following equation and expressed as a percentage.

where PO and PR are the protein content (%) before and after hydrolysis; O and R represent the mass (g) of the original sample and hydrolyzed residue, respectively. The Micro Kjeldahl technique was used to evaluate the protein content before and after hydrolysis (AOAC 2005).

Carotenoprotein extraction

The carotenoprotein was extracted by enzymatic hydrolysis using the technique described by Dayakar et al. (2022) with a few minor changes. SSW and SHW were chopped separately with a silent cutter, and 250 g of residue was homogenized with water [1:3 (w/v) ratio] using a homogenizer (Polytron-PT MR 2100). The homogenized mixture was heated at 90 °C for 10 min to inactivate the endogenous enzymes. After cooling, the samples were hydrolyzed under various extraction conditions according to the RSM design. During the hydrolytic reaction, continuous stirring was done, and the temperatures were maintained using a digital water bath. By heating the mixture once more for 10 min at 90 °C, enzymatic hydrolysis was terminated. This was followed by filtering the mixture with a muslin cloth and centrifuging the filtrate at 6000 \(\times\) g for 15 min at 4 °C using an Eltek centrifuge (Electro craft MP 400R). The supernatant obtained after centrifugation was spray-dried to get the carotenoprotein powder.

Spray drying of effluent carotenoprotein

The effluent carotenoprotein obtained from the hydrolyzed head and shell waste through optimized enzymatic conditions was spray-dried and converted into powder with the help of a tabletop spray drier (SM SciTech, Kolkata) under the 170 °C inlet temperature and 80 °C outlet temperatures. The clear supernatant was fed into the drying chamber through a 3-mm nozzle diameter with the help of a peristaltic pump. The process was continued by maintaining a feeding rate of 4 mL/min, drying airflow of 0.5 L/h, and pressure of 6 bars. Further, these operational conditions were kept throughout the process. The powder collected was weighed and stored in an airtight centrifuge tube under refrigerated conditions for further use.

Total carotenoid content determination

The total carotenoid content (TCC) was assessed following the procedure outlined by Dayakar et al. (2022). The carotenoid content (C) of the samples was calculated using the following equation:

where A468 is the absorbance at 468 nm; 0.2 is the absorbance value of the 1 μg/mL astaxanthin standard.

Amino acid profiling

The amino acid profile was analyzed according to the method of Pattanaik et al. (2020). The results were expressed in terms of g/100 g of CpSS and CpSH.

Instrumental color analysis

The color analysis of the spray-dried carotenoprotein powder was done using a Hunter LabScan XE-spectrocolorimeter. From the lightness (L*), redness (a*), and yellowness (b*) values, the whiteness index (WI), chroma (C*), and hue angle (H*) were determined using the following equations (Sampath et al. 2022b).

Determination of functional properties

Solubility

The solubility of carotenoprotein powder samples were measured according to the method of Hassan et al. (2018). The solubility was evaluated at different pH in the range of 2.0–10.0 using the following equation:

Emulsifying properties

The emulsifying capacity and stability were measured according to the method of Dhanabalan et al. (2020). The emulsion was prepared with 50 mL of cold distilled water (4 °C) containing carotenoprotein powder at different concentrations of 0.5, 1.0, 2.0, and 3.0% (w/v) and 50 mL of sunflower oil. The emulsifying capacity and stability were calculated using the following equations:

Foaming properties

The foaming properties of CpSS and CpSH were determined using the method of Hassan et al. (2019). Foaming properties (capacity and stability) of carotenoprotein powder at 0.5, 1.0, 2.0, and 3.0% (w/v) were calculated according to the following equations:

where A is the volume after whipping (mL) and B is the volume before whipping (mL).

where A is the volume after standing (mL) and B is the volume before whipping (mL).

Statistical analysis

The SPSS version 23 statistical software was used for data analysis. All of the measurements were conducted in triplicates. The multiple range test was applied to perform post hoc comparisons among various treatments in order to evaluate their statistical significance (p < 0.05).

Results and discussion

Optimization and validation of enzymatic hydrolysis conditions

The impact of temperature, hydrolysis duration (time), pH, and E/S ratio on papain-assisted deproteinization was determined using the BBD of RSM. The selection of factors or independent variables included temperature, time, pH and E/S ratio because these variables significantly influence the peptide composition of the protein hydrolysate, and their optimization is essential to achieve the desired degree of hydrolysis. The BBD was chosen for optimizing the independent variables for two primary reasons. First, it is advantageous for obtaining extensive information while conducting a limited number of tests and for analyzing the interactive effects between independent variables and the response variable (Bezerra et al. 2008). Second, the BBD necessitates that all independent factor values align with three levels (− 1, 0, and + 1), with equidistant intervals between them (Yingngam 2023), a requirement that was met in our study.

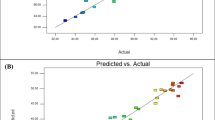

The measured values of DDP at different runs of the independent parameters are shown in Table 2. Table 3 displays the estimated coefficients of the model's variables and the associated R2 values using analysis of variance (ANOVA). The response surface plots for the effect of the X1, X2, X3, and X4 combined effect on the dependent variable (DDP) are shown in Fig. 1 and Fig. 2. A low p value (p < 0.05) in the ANOVA for the model shows that it is significant. The R2 values obtained for the DDP of SSW and SHW were 0.783 and 0.820, respectively. These values indicate that the model can account for 78.3% and 82.0% of the variation in the data, respectively. Based on these values, it is evident that the selected model effectively represents the relationships among the selected variables (Das et al. 2023; Chattopadhyay et al. 2023). For calculating the maximum DDP of SSW (Eq. 12) and SHW (Eq. 13), the experimental data were fitted into a quadratic polynomial equation:

The DDP is the amount of protein removed from shell waste following enzymatic hydrolysis. During protein hydrolysis, the covalent bonds between protein chitin complexes are broken down into peptide and amino acid chains (Dhanabalan et al. 2020). The effectiveness of protein removal employing enzymes was found to be adequate in prior investigations (Cano-Lopez et al. 1987; Hamdi et al. 2017). The optimum hydrolysis conditions for the maximum DDP from shell waste were found to be 7.13 (pH), 2 g/100 g (E/S ratio), 53.13 °C (temperature), and 90 min (time) of hydrolysis, and the maximum expected DDP was 94.56%. The actual measured value of deproteinization was 92.32%. The optimum conditions for the maximum DDP from head waste were pH 6.78; E/S ratio, 1.18 g/100 g; temperature, 45.90 °C, and time 61.16 min of hydrolysis for a maximum expected DDP of 98.42%. The actual measured value of deproteinization was 96.72%. Younes et al. (2012) optimized the DDP from Metapenaeus monoceros shrimp shells using a protease enzyme and found 94% predicted and 88% experimental deproteinization. This was in close agreement with the present study. The deproteinization activity of papain using RSM was better than many proteases reported in previous studies of Hongkulsup et al. (2016), who reported 91.10% removal of protein efficiency using Streptomyces griseus from L. vannamei shell waste. However, there was no complete deproteinization since a small number of C-2 amino groups of chitin and peptides are connected by covalent bonds, rendering specific proteins inaccessible to enzymes (Hammami et al. 2017). From this result, we can conclude that the optimum requirement of E/S ratio and time is more in the case of shell waste deproteinization than head waste, but the removal of protein efficiency is lesser than head waste.

Total carotenoid content

The TCC values for shrimp waste (SHW and SSW) derived from L. vannamei and carotenoprotein powder (CpSH and CpSS) are presented in Supplementary Table S1. It is important to note that carotenoid content in crustaceans can vary significantly by species. For instance, in the case of shell waste from four different shrimp species, the carotenoid content exhibited notable variations (p < 0.05), with values of 40.30 ± 0.01 µg/g, 51 ± 0.02 µg/g, 100.6 ± 0.02 µg/g, and 114 ± 0.03 µg/g for Nematopalemon tenuipes, Penaeus monodon, Metapenaeus affinis, and Parapenaeopsis stylifera, respectively (Pattanaik et al. 2020). In our study, we observed that the carotenoid content of SSW and SHW from L. vannamei measured at 81.48 ± 1.31 µg/g and 109.08 ± 1.22 µg/g, respectively. However, in contrast, the carotenoid content in the spray-dried carotenoprotein powder obtained from SSW and SHW was notably lower, with values of 5.91 ± 0.33 µg/g and 9.86 ± 0.47 µg/g for CpSS and CpSH, respectively. The reduced carotenoid content observed in the carotenoprotein powder compared to the shell waste may be attributed to the removal of carotenoids from shrimp waste during the carotenoprotein preparation process (Dayakar et al. 2022). Sinthusamran et al. (2020) also reported a decline in the carotenoid content of protein hydrolysates derived from shrimp (L. vannamei) cephalothorax. The initial carotenoid content of the raw material (cephalothorax) was measured at 150.58 ± 2.65 µg/g, which subsequently decreased to a range of 3.37 ± 0.05 µg/g to 6.11 ± 0.30 µg/g following autolysis and Alcalase hydrolysis processes. The decline in carotenoid content is a result of the lipophilic nature of carotenoids, which caused them to predominantly concentrate in the lipid-containing solid residue following the centrifugation process. Since only the supernatant was utilized for spray-drying to produce carotenoprotein, the carotenoids were separated, resulting in reduced carotenoid levels in the carotenoprotein powder. Furthermore, when subjected to conditions involving light, heat, and oxygen during processing and storage, carotenoids exhibit significant instability and susceptibility (Eun et al. 2020). Therefore, some carotenoids must have undergone oxidation during the spray-drying of the carotenoprotein effluent.

Amino acid profiles

To evaluate their significance in human nutrition and quantify the correct nitrogen-protein conversion factors, it was essential to determine the amino acid composition of the obtained carotenoproteins. Amino acid composition influences both the nutritional value and functional qualities of fish protein hydrolysates (Dos Santos et al. 2011). The essential amino acids have a crucial role in growth, metabolic pathways, and development (WHO 2007; Wu 2009). Table 4 shows the amino acid profiles of carotenoproteins derived from shrimp shell and head waste. The spray-dried carotenoprotein powders were found to contain a total of 17 different amino acids. Notably, tryptophan was detected in CpSS but was absent in CpSH. The predominant amino acid present in both carotenoproteins was glutamine. Additionally, lysine was detected, and it is recognized for its antioxidant properties (Farvin et al. 2016). It is expected that specific antioxidant properties are associated with amino acids such as methionine, cysteine, tyrosine, arginine, glutamic acid, lysine, serine, aspartic acid, proline, alanine, phenylalanine, and histidine. The presence of these amino acids enhances the antioxidant capabilities of polypeptides (Triantis et al. 2007). In this study, it was observed that CpSS exhibited relatively lower levels of tryptophan (1.40) and phenylalanine (1.77). Conversely, in the case of CpSH, the tyrosine content was notably low (0.9), and tryptophan was entirely absent. Histidine was detected in minimal quantities in both carotenoproteins, while cysteine was not detected at all. During acidic hydrolysis, tryptophan undergoes degradation, and there is also partial degradation of serine and threonine. Consequently, this process leads to lower residual levels of amino acids in comparison to the total amino acid content (Alinejad et al. 2017). The antioxidant capabilities and other functional attributes of polypeptides are influenced by the type, composition, and hydrophobic properties of the amino acids they contain (Guo et al. 2009). The results of amino acid composition in this study demonstrate that shrimp waste can be considered an excellent source of protein, as both CpSS and CpSH exhibited significantly high levels of essential amino acids in their composition. The higher essential amino acids score also indicates the suitability of obtained carotenoproteins for incorporation in animal feed and human diets as functional food ingredients.

Instrumental color parameters

The color of carotenoprotein powder is a critical factor that influences its visual attractiveness and physical attributes, and its significance can vary depending on its intended applications. In the context of food products, the color of these items has a significant effect on their overall acceptability (Dhanabalan et al. 2020). Table 5 shows the instrumented color values of CpSS and CpSH. CpSS showed a higher whiteness index of 82.05 ± 0.24, a chroma of 13.55 ± 0.05, and a hue of 88.81 ± 0.11, whereas CpSH exhibited values of 64.04 ± 0.30, 22.94 ± 0.89, and 84.39 ± 0.27 for whiteness index, chroma, and hue, respectively. The greater whiteness index in CpSS can be attributed to the lower concentration of carotenoids in the shrimp shell waste (Supplementary Table S1). Contrarily, higher values of a*, b*, and chroma were observed in CpSH, which can be attributed to the extracted carotenoid (astaxanthin) along with protein (Pourashouri et al. 2021). This observation is consistent with the higher carotenoid content in CpSH relative to CpSS (Supplementary Table S1). Consequently, due to the presence of carotenoids in carotenoprotein powder, CpSS and CpSH exhibited a light-yellow color. A comparable color pattern was observed in the enzymatically hydrolyzed spray-dried protein hydrolysate powder derived from cobia (Rachycentron canadum, a pelagic fish) waste (Amiza et al. 2012). Likewise, the lightness value and whiteness index of carotenoprotein powders closely resembled the values reported for protein hydrolysate from shrimp (Acetus indicus), which were 86.86 ± 0.3 for lightness and 83.25 ± 0.2 for whiteness index (Dhanabalan et al. 2020). Sinthusamran et al. (2020) reported color values resembling those of CpSH in protein hydrolysates derived from L. vannamei cephalothorax (head waste) through autolysis and enzymatic hydrolysis using Alcalase. Their study showed L*, a*, and b* values ranging from 76.17 ± 0.06 to 78.75 ± 0.28, 1.25 ± 0.08 to 2.41 ± 0.03, and 17.34 ± 0.06 to 22.54 ± 0.38, respectively. Senphan et al. (2014) also reported comparable color values in carotenoprotein isolated from shrimp (L. vannamei) shells.

Functional properties

The functional properties of carotenoprotein powder, including solubility, emulsification, and foaming abilities, are directly impacted by the nature and composition of the peptides generated during the hydrolysis process. Through either chemical or enzymatic methods, proteins undergo a transformation into smaller peptide fragments consisting of 2 to 20 amino acids, resulting in the formation of protein hydrolysates, which are low molecular weight nitrogenous substances (Dhanabalan et al. 2020). To attain desired protein functionality, the solubility of the protein plays a vital role, and this attribute is influenced by various factors, including the composition and sequence of amino acids. Proteins have excellent emulsifying characteristics due to their amphiphilic nature. Exposure to more hydrophobic residues improves flexibility and creates a stable interfacial layer and air–water contact may enhance the foaming abilities of proteins. The functionality of protein powders can be significantly impacted by several variables, encompassing hydrolysis conditions (such as pH, temperature, hydrolysis duration, and enzyme concentration), the specific enzyme employed, and the choice of raw materials (Hettiarachchy et al. 2012; Klompong et al. 2007). To improve the quality and stability characteristics of nutritional formulations relying on protein hydrolysates, it is imperative to undertake research to uncover the relationship between the physicochemical properties and the functional attributes of proteins. Hence, we evaluated the functional properties of carotenoproteins, and the findings are elaborated upon in the following sub-sections.

Solubility

The first characteristic to be evaluated while developing a novel protein ingredient is solubility, which is regarded as a crucial functional attribute (Mccarthy et al. 2013). The solubility of a protein gives insight into a variety of applications, including emulsions and foams. The solubility of carotenoprotein powders at different pH are displayed in Fig. 3. The carotenoprotein solubility significantly increased with increasing pH value from 2.0 to 4.0 in both CpSH and CpSS and reached the maximum solubility of 90.38 and 92.10% at pH 4.0. The amino and carboxyl groups of amino acids that are exposed during protein hydrolysis are what give the ensuing hydrolysate its greater hydrophilicity and higher solubility. At pH 5.0–6.0, the solubility of carotenoproteins decreased due to weak electrostatic repulsion between neighboring protein hydrolysate molecules. This decrease in solubility can be correlated to the isoelectric point, which is roughly between pH 5.5 and 6.0 and, therefore, the lowest net charge at this pH (Liu et al. 2019). On further increase in the pH from 7.0 to 10.0, the solubility increased drastically in both the carotenoproteins, reaching 92.94% and 96.48% in CpSH and CpSS, respectively. The increase in solubility can be attributed to two factors. Firstly, it may result from the generation of smaller peptides and a reduction in molecular size. Secondly, the hydrophilicity of the carotenoproteins was enhanced because of the formation of amino and carboxylic groups from amino acids, in addition to the removal of the least soluble proteins during the centrifugation process (Noman et al. 2018). These results align well with a previous study conducted by Dhanabalan et al. (2020), where reduced solubility was observed at pH 3.0, while greater solubility was evident at pH 12.0. The reduced solubility in acidic pH is attributed to the positively charged net electrical charge of the proteins. In contrast, the alkaline pH leads to the dissociation and detachment of the proteins, thereby increasing their solubility. In contradistinction to the findings of Naqash and Nazeer (2013), who reported lower solubility (74% and 77%) in the muscle protein of pink perch (Nemipterus japonicus) when extracted using papain and pepsin, respectively, our study found increased solubility of carotenoproteins. Given the elevated solubility levels observed in CpSS and CpSH, they can serve as valuable ingredients in a range of food applications, functioning as sources of antioxidants and serving as fortifying agents for juices and beverages (Alavi et al. 2019).

Emulsifying properties

Emulsifying properties in various concentrations of carotenoproteins (0.5, 1.0, 2.0, and 3.0%) are shown in Fig. 4A and B. “The emulsifying properties are the ability of the emulsion (defined as the capacity of the material to form the emulsion) and the stability of the emulsion (defined as the ability to preserve the emulsion formed)” (Witono et al. 2016). With increasing carotenoprotein concentration, the emulsion stability and capacity increased significantly. The highest values of emulsion capacity (81.33% for CpSH and 70.13% for CpSS) and stability (57.06% for CpSH and 63.05% for CpSS) were observed at a 3% carotenoprotein concentration. According to de Castro and Sato (2015), an increase in hydrolysis promotes the activity of buried functional groups of proteins that can enhance the emulsifying properties further, making them more suitable for stabilizing food emulsions. Additionally, the development of minute droplets within protein emulsions enhances their emulsifying capabilities and emulsion stability (Kimura et al. 2008). Low ionic strengths are associated with decreased droplet coalescence, which may apply to the present study. A peptide’s solubility, amino acid sequence, molecular size, degree of hydrolysis (DH), acetylation, extraction solvent, and types of enzymes utilized are all factors that affect emulsifying properties (Halim et al. 2016).

Changes in emulsion and foaming properties of carotenoprotein powders prepared from shell and head waste of shrimp with different concentrations. A emulsion capacity, B emulsion stability, C foaming capacity, and D foaming stability. Bars represent the standard deviation (n = 3), Different letters on the bars indicate the significant differences (p < 0.05)

Foaming properties

The foaming properties of carotenoproteins in different concentrations (0.5, 1.0, 2.0, and 3.0%) are shown in Fig. 4C and D. As concentration gradually increased, all of the treatments’ foaming characteristics improved. The highest values of foaming capacity (27.66% for CpSH and 105.5% for CpSS) and stability (23.83% for CpSH and 105.33% for CpSS) were observed at a 3% carotenoprotein concentration. The increase in the foaming capacity suggests that more hydrophobic residues are exposed, which decreases surface tension (Phongthai et al. 2016). Foaming capacity exhibited an increasing trend with the addition of increased concentration of carotenoproteins in both cases. It can be attributed to the smaller hydrolysates ease of migration to the interface, which lowers surface tension and causes an increase in foam expansion (Jain and Anal 2016). The higher concentration of proteins in the emulsion solution leads to denser, more stable foams due to the increase in the thickness of the interfacial films (Sila et al. 2014).

Conclusion

In this study, an environmentally friendly process was developed to extract carotenoprotein with improved functional properties and nutritional value from shrimp heads and shell waste portions separately, utilizing papain-assisted hydrolysis. When comparing CpSS and CpSH, it is evident that CpSS is well-suited for functional food applications primarily owing to its higher whiteness index, greater amino acid content, and superior functional characteristics, whereas CpSH is more appropriate for animal feed purposes. The findings of this research will contribute to the more effective utilization of shrimp processing waste. Other potential applications of this study include adding carotenoprotein powder to various fish feeds to improve the color patterns and bioactivities of the fish. Furthermore, this research presents the potential for environmentally friendly chitin extraction concurrent with carotenoprotein extraction. Nonetheless, it is essential to emphasize that this study has some noteworthy limitations. Firstly, the carotenoprotein powder produced is inherently hygroscopic, making it susceptible to clumping and potentially impacting shelf life. Secondly, there is a challenge in achieving complete carotenoprotein extraction through the enzymatic hydrolysis process.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Alavi F, Jamshidian M, Rezaei K (2019) Applying native proteases from melon to hydrolyze kilka fish proteins (Clupeonella cultriventris caspia) compared to commercial enzyme Alcalase. Food Chem 277:314–322. https://doi.org/10.1016/j.foodchem.2018.10.122

Alinejad M, Motamedzadegan A, Rezaei M, Regenstein JM (2017) The impact of drying method on the functional & antioxidant properties of Whitecheek Shark (Carcharhinus dussumieri) protein hydrolysates. J Food Process Preserv 41:12972. https://doi.org/10.1111/jfpp.12972

Amiza MA, Kong YL, Faazaz AL (2012) Effects of degree of hydrolysis on physicochemical properties of Cobia (Rachycentron canadum) frame hydrolysate. Int Food Res J 19(1):199–206

AOAC (2005) Official methods of analysis. (13th Edition). Association of Official Analytical Chemists. AOAC International Gaithersburg, Maryland, USA

Armenta-López R, Guerrero IL, Huerta S (2002) Astaxanthin extraction from shrimp waste by lactic fermentation & enzymatic hydrolysis of the carotenoprotein complex. J Food Sci 67:1002–1006. https://doi.org/10.1111/j.1365-2621.2002.tb09443.x

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5):965–977. https://doi.org/10.1016/j.talanta.2008.05.019

Cahú TB, Santos SD, Mendes A, Córdula CR, Chavante SF, Carvalho LB Jr, Nader HB, Bezerra RS (2012) Recovery of protein, chitin, carotenoids & glycosaminoglycans from Pacific white shrimp (Litopenaeus vannamei) processing waste. Process Biochem 47:570–577. https://doi.org/10.1016/j.procbio.2011.12.012

Cano-Lopez A, Simpson BK, Haard NF (1987) Extraction of carotenoprotein from shrimp process wastes with the aid of trypsin from Atlantic cod. J Food Sci 52:503–504. https://doi.org/10.1111/j.1365-2621.1987.tb06656.x

Cardenas-Toro FP, Alcázar-Alay SC, Coutinho JP, Godoy HT, Forster-Carneiro T, Meireles MAA (2015) Pressurized liquid extraction & low-pressure solvent extraction of carotenoids from pressed palm fiber: experimental & economical evaluation. Food Bioprod Process 94:90–100. https://doi.org/10.1016/j.fbp.2015.01.006

Chakrabarti R (2002) Carotenoprotein from tropical brown shrimp shell waste by enzymatic process. Food Biotechnol 16(1):81–90. https://doi.org/10.1081/FBT-120004202

Chattopadhyay K, Xavier KM, Ngasotter S, Karmakar S, Balange A, Nayak BB (2023) Chitosan gel prepared with citric acid as the food acidulant: effect of the chitosan concentration and gel pH on physicochemical and functional properties of fish protein emulsion sausages. ACS Omega 8(8):7829–7837. https://doi.org/10.1021/acsomega.2c07538

Clemente A (2000) Enzymatic protein hydrolysates in human nutrition. Trends Food Sci Technol 11:254–262. https://doi.org/10.1016/S0924-2244(01)00007-3

Das R, Mehta NK, Ngasotter S, Balange AK, Nayak BB, Murthy LN, Xavier KM (2023) Process optimization and evaluation of the effects of different time-temperature sous vide cooking on physicochemical, textural, and sensory characteristics of whiteleg shrimp (Litopenaeusvannamei). Heliyon 9(6):e16438. https://doi.org/10.1016/j.heliyon.2023.e16438

Dayakar B, Xavier KM, Das O, Porayil L, Balange AK, Nayak BB (2021) Application of extreme halophilic archaea as biocatalyst for chitin isolation from shrimp shell waste. Carbohydr Polym Technol Appl 2:100093. https://doi.org/10.1016/j.carpta.2021.100093

Dayakar B, Xavier KM, Ngasotter S, Layana P, Balange AK, Priyadarshini B, Nayak BB (2022) Characterization of spray-dried carotenoprotein powder from Pacific white shrimp (Litopenaeus vannamei) shells & head waste extracted using papain: Antioxidant, spectroscopic, & microstructural properties. LWT 159:113188. https://doi.org/10.1016/j.lwt.2022.113188

de Castro RJS, Sato HH (2015) A response surface approach on optimization of hydrolysis parameters for the production of egg white protein hydrolysates with antioxidant activities. Biocatal Agric Biotechnol 4:55–62. https://doi.org/10.1016/j.bcab.2014.07.001

Deng JJ, Mao HH, Fang W, Li ZQ, Shi D, Li ZW, Zhou T, Luo XC (2020) Enzymatic conversion and recovery of protein, chitin, and astaxanthin from shrimp shell waste. J Clean Prod 271:122655. https://doi.org/10.1016/j.jclepro.2020.122655

Dhanabalan V, Xavier KM, Eppen S, Joy A, Balange A, Asha KK, Murthy LN, Nayak BB (2021) Characterization of chitin extracted from enzymatically deproteinized Acetes shell residue with varying degree of hydrolysis. Carbohydr Polym 253:117203. https://doi.org/10.1016/j.carbpol.2020.117203

Dhanabalan V, Xavier M, Murthy LN, Asha KK, Balange AK, Nayak BB (2020) Evaluation of physicochemical & functional properties of spray-dried protein hydrolysate from non-penaeid shrimp (Acetes indicus). J Sci Food Agric 100:50–58. https://doi.org/10.1002/jsfa.9992

dos Santos SDA, Martins VG, Salas-Mellado M, Prentice C (2011) Evaluation of functional properties in protein hydrolysates from bluewing searobin (Prionotus punctatus) obtained with different microbial enzymes. Food Bioproc Tech 4:1399–1406. https://doi.org/10.1007/s11947-009-0301-0

Eun JB, Maruf A, Das PR, Nam SH (2020) A review of encapsulation of carotenoids using spray drying and freeze drying. Crit Rev Food Sci Nutr 60(21):3547–3572. https://doi.org/10.1080/10408398.2019.1698511

Farvin KS, Andersen LL, Otte J, Nielsen HH, Jessen F, Jacobsen C (2016) Antioxidant activity of cod (Gadus morhua) protein hydrolysates: Fractionation and characterisation of peptide fractions. Food Chem 204:409–419. https://doi.org/10.1016/j.foodchem.2016.02.145

Guo H, Kouzuma Y, Yonekura M (2009) Structures & properties of antioxidative peptides derived from royal jelly protein. Food Chem 113:238–245. https://doi.org/10.1016/j.foodchem.2008.06.081

Halim NRA, Yusof HM, Sarbon NM (2016) Functional & bioactive properties of fish protein hydolysates & peptides: A comprehensive review. Trends Food Sci Technol 51:24–33. https://doi.org/10.1016/j.tifs.2016.02.007

Hamdi M, Hammami A, Hajji S, Jridi M, Nasri M, Nasri R (2017) Chitin extraction from blue crab (Portunus segnis) & shrimp (Penaeus kerathurus) shells using digestive alkaline proteases from P. segnis viscera. Int J Biol Macromol 101:455–463. https://doi.org/10.1016/j.ijbiomac.2017.02.103

Hammami A, Hamdi M, Abdelhedi O, Jridi M, Nasri M, Bayoudh A (2017) Surfactant- & oxidant-stable alkaline proteases from Bacillus invictae: characterization & potential applications in chitin extraction & as a detergent additive. Int J Biol Macromol 96:272–281. https://doi.org/10.1016/j.ijbiomac.2016.12.035

Haque R, Sawant PB, Sardar P, Xavier KM, Varghese T, Chadha NK, Pattanaik SS, Jana P, Naik VA (2021) Synergistic utilization of shrimp shell waste-derived natural astaxanthin with its commercial variant boosts physio metabolic responses & enhances colouration in discus (Symphysodon aequifasciatus). Environ Nanotechnol Monit Manag 15:100405. https://doi.org/10.1016/j.enmm.2020.100405

Hassan M, Deepitha RP, Xavier KA, Gupta S, Nayak BB, Balange AK (2019) Evaluation of the properties of spray dried visceral protein hydrolysate from Pangasianodon hypophthalmus (Sauvage, 1978) extracted by enzymatic & chemical methods. Waste Biomass Valori 10:2547–2558. https://doi.org/10.1007/s12649-018-0302-1

Hettiarachchy NS, Sato K, Marshall MR, Kannan A (2012) Food proteins and peptides: chemistry, functionality, interactions, and commercialization. CRC Press

Hongkulsup C, Khutoryanskiy VV, Niranjan K (2016) Enzyme assisted extraction of chitin from shrimp shells (Litopenaeus vannamei). J Chem Technol Biotechnol 91:1250–1256. https://doi.org/10.1002/jctb.4714

Jacob C, Noirot C, Anglada C, Binet T (2021) The benefits of integrating socioeconomic dimensions of circular economy practices in the seafood sector. Curr Opin Environ Sci Health 22:100255. https://doi.org/10.1016/j.coesh.2021.100255

Jain S, Anal AK (2016) Optimization of extraction of functional protein hydrolysates from chicken egg shell membrane (ESM) by ultrasonic assisted extraction (UAE) & enzymatic hydrolysis. LWT-Food Sci Technol 69:295–302. https://doi.org/10.1016/j.lwt.2016.01.057

Kimura A, Fukuda T, Zhang M, Motoyama S, Maruyama N, Utsumi S (2008) Comparison of physicochemical properties of 7S & 11S globulins from pea, fava bean, cowpea, & french bean with those of soybean French bean 7S globulin exhibits excellent properties. J Agric Food Chem 56:10273–10279. https://doi.org/10.1021/jf801721b

Klompong V, Benjakul S, Kantachote D, Shahidi F (2007) Antioxidative activity and functional properties of protein hydrolysate of yellow stripe trevally (Selaroides leptolepis) as influenced by the degree of hydrolysis and enzyme type. Food Chem 102(4):1317–1327. https://doi.org/10.1016/j.foodchem.2006.07.016

Liu H, Han G, Zhang H, Liu Q, Kong B (2019) Improving the physical & oxidative stability of emulsions based on the interfacial electrostatic effects between porcine bone protein hydrolysates & porcine bone protein hydrolysate-rutin conjugates. Food Hydrocoll 94:418–427. https://doi.org/10.1016/j.foodhyd.2019.03.037

Mao X, Liu P, He S, Xie J, Kan F, Yu C, Li Z, Xue C, Lin H (2013) Antioxidant properties of bio-active substances from shrimp head fermented by Bacillus licheniformis OPL-007. Appl Biochem Biotechnol 171:1240–1252. https://doi.org/10.1007/s12010-013-0217-z

McCarthy AL, O’Callaghan YC, O’Brien NM (2013) Protein hydrolysates from agricultural crops—bioactivity & potential for functional food development. Agriculture 3:112–130. https://doi.org/10.3390/agriculture3010112

Naqash SY, Nazeer RA (2013) Antioxidant & functional properties of protein hydrolysates from pink perch (Nemipterus japonicus) muscle. J Food Sci Technol 50:972–978. https://doi.org/10.1007/s13197-011-0416-y

Ngasotter S, Sampath L, Xavier KM (2022) Nanochitin: an update review on advances in preparation methods and food applications. Carbohydr Polym 291:119627. https://doi.org/10.1016/j.carbpol.2022.119627

Ngasotter S, Xavier KM, Meitei MM, Waikhom D, Pathak J, Singh SK (2023a) Crustacean shell waste derived chitin and chitin nanomaterials for application in agriculture, food, and health–A review. Carbohydr Polym Technol Appl 6:100349. https://doi.org/10.1016/j.carpta.2023.100349

Ngasotter S, Xavier KM, Porayil L, Balange A, Nayak BB, Eapen S, Adarsh KJ, Sreekala MS, Sharma R, Ninan G (2023b) Optimized high-yield synthesis of chitin nanocrystals from shrimp shell chitin by steam explosion. Carbohydr Polym 316:121040. https://doi.org/10.1016/j.carbpol.2023.121040

Noman A, Xu Y, AL-Bukhaiti WQ, Abed SM, Ali AH, Ramadhan AH, Xia W (2018) Influence of enzymatic hydrolysis conditions on the degree of hydrolysis & functional properties of protein hydrolysate obtained from Chinese sturgeon (Acipensersinensis) by using papain enzyme. Process Biochem 67:19–28. https://doi.org/10.1016/j.procbio.2018.01.009

Pattanaik SS, Sawant PB, KA MX, Srivastava PP, Dube K, Sawant BT, Chadha NK (2021) Dietary carotenoprotien extracted from shrimp shell waste augments growth, feed utilization, physio-metabolic responses & coloration in Oscar, Astronotusocellatus (Agassiz, 1831). Aquaculture 534:736303. https://doi.org/10.1016/j.aquaculture.2020.736303

Pattanaik SS, Sawant PB, Xavier KM, Dube K, Srivastava PP, Dhanabalan V, Chadha NK (2020) Characterization of carotenoprotein from different shrimp shell waste for possible use as supplementary nutritive feed ingredient in animal diets. Aquaculture 515:734594. https://doi.org/10.1016/j.aquaculture.2019.734594

Phongthai S, Lim ST, Rawdkuen S (2016) Optimization of microwave-assisted extraction of rice bran protein & its hydrolysates properties. J Cereal Sci 70:146–154. https://doi.org/10.1016/j.jcs.2016.06.001

Pinheiro ACDAS, Martí-Quijal FJ, Barba FJ, Tappi S, Rocculi P (2021) Innovative non-thermal technologies for recovery & valorization of value-added products from crustacean processing byproducts—an opportunity for a circular economy approach. Foods 10:2030. https://doi.org/10.3390/foods10092030

Poonsin T, Simpson BK, Benjakul S, Visessanguan W, Klomklao S (2017) Albacore tuna (Thunnus alalunga) spleen trypsin partitioning in an aqueous two-phase system & its hydrolytic pattern on Pacific white shrimp (Litopenaeus vannamei) shells. Int J Food Prop 20:2409–2422. https://doi.org/10.1080/10942912.2016.1240180

Pourashouri P, Mirsadeghi H, Khodanazary A (2021) Extracting and physicochemical properties of carotenoprotein from shrimp processing waste by proteases-mediated hydrolysis. Waste Biomass Valori 13:1169–1178. https://doi.org/10.1007/s12649-021-01561-4

Prameela K, Murali Mohan C, Smitha PV, Hemalatha KPJ (2010) Bioremediation of shrimp biowaste by using natural probiotic for chitin & carotenoid production an alternative method to hazardous chemical method. Int J Appl Biol Pharm Technol 1:903–910

Rao MS, Stevens WF (2005) Chitin production by Lactobacillus fermentation of shrimp biowaste in a drum reactor & its chemical conversion to chitosan. J Chem Technol Biotechnol 80:1080–1087. https://doi.org/10.1002/jctb.1286

Robinson HW, Hogden CG (1940) The biuret reaction in the determination of serum proteins: I. A study of the conditions necessary for the production of a stable color which bears a quantitative relationship to the protein concentration. J Biol Chem 135:707–725. https://doi.org/10.1016/S0021-9258(18)73134-7

Sampath L, Ngasotter S, Layana P, Balange AK, Nayak BB, Xavier KM (2022a) Effect of chemical treatment duration on physicochemical, rheological, and functional properties of colloidal chitin. Food Hydrocoll Health 2:100091. https://doi.org/10.1016/j.fhfh.2022.100091

Sampath L, Ngasotter S, Porayil L, Balange AK, Nayak BB, Eappen S, Xavier KM (2022b) Impact of extended acid hydrolysis on polymeric, structural and thermal properties of microcrystalline chitin. Carbohydr Polym Technol Appl 4:100252. https://doi.org/10.1016/j.carpta.2022.100252

Senphan T, Benjakul S, Kishimura H (2014) Characteristics & antioxidative activity of carotenoprotein from shells of Pacific white shrimp extracted using hepatopancreas proteases. Food Biosci 5:54–63. https://doi.org/10.1016/j.fbio.2013.11.004

Sila A, Sayari N, Balti R, Martinez-Alvarez O, Nedjar-Arroume N, Moncef N, Bougatef A (2014) Biochemical & antioxidant properties of peptidic fraction of carotenoproteins generated from shrimp byproducts by enzymatic hydrolysis. Food Chem 148:445–452. https://doi.org/10.1016/j.foodchem.2013.05.146

Simpson BK, Gagne N, Simpson MV (1994) Bioprocessing of chitin and chitosan. In Fisheries processing. Springer, Boston, MA, pp 155–173. https://doi.org/10.1007/978-1-4615-5303-8_7

Sinthusamran S, Benjakul S, Kijroongrojana K, Prodpran T, Kishimura H (2020) Protein hydrolysates from Pacific white shrimp cephalothorax manufactured with different processes: compositions, characteristics and antioxidative activity. Waste Biomass Valori 11:1657–1670. https://doi.org/10.1007/s12649-018-0517-1

Triantis TM, Yannakopoulou E, Nikokavoura A, Dimotikali D, Papadopoulos K (2007) Chemiluminescent studies on the antioxidant activity of amino acids. Anal Chim Acta 591:106–111. https://doi.org/10.1016/j.aca.2007.03.054

WHO (2007) Protein & amino acid requirements in human nutrition. (WHO technical report series no. 935). World Health Organ Tech Rep Ser Geneva, Switzerland

Witono Y, Taruna I, Windrati WS, Azkiyah L, Sari TN (2016) “Wader” (Rasbora jacobsoni) protein hydrolysates: production, biochemical, & functional properties. Agric Agric Sci Procedia 9:482–492. https://doi.org/10.1016/j.aaspro.2016.02.167

Wu G (2009) Amino acids: metabolism, functions, & nutrition. Amino Acids 37:1–17. https://doi.org/10.1007/s00726-009-0269-0

Yingngam B (2023) Modern solvent-free microwave extraction with essential oil optimization and structure-activity relationships. Stud Nat Prod Chem 77:365–420. https://doi.org/10.1016/B978-0-323-91294-5.00011-7

Younes I, Ghorbel-Bellaaj O, Nasri R, Chaabouni M, Rinaudo M, Nasri M (2012) Chitin & chitosan preparation from shrimp shells using optimized enzymatic deproteinization. Process Biochem 47:2032–2039. https://doi.org/10.1016/j.procbio.2012.07.017

Acknowledgements

The authors thank the Vice-Chancellor & Director, ICAR-Central Institute Fisheries Education, for providing the necessary facilities for this work.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Material preparation, data collection, analysis, and draft preparation were performed by Dayakar Bandela. Conceptualization, supervision, writing— review and editing were done by K. A. Martin Xavier. Software application, writing—review and editing were done by Soibam Ngasotter and Vignaesh Dhanabalan. Supervision, project administration, writing—review and editing were done by Layana Porayil, Amjad Khansaheb Balange, and Binaya Bhusan Nayak. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dayakar, B., Xavier, M., Ngasotter, S. et al. Extraction, optimization, and functional quality evaluation of carotenoproteins from shrimp processing side streams through enzymatic process. Environ Sci Pollut Res (2023). https://doi.org/10.1007/s11356-023-30232-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-023-30232-1