Abstract

The solar energy produced by Scheffler parabola (10 m2) is not fully exploited by the solar distillation system of aromatic and medicinal plants. In this work, the optical losses in the primary and secondary reflectors, and the thermal losses at each part of this system (solar still, steam line, condenser) were determined. A thermal energetic and exergetic analysis were also performed for a solar distillation system of rosemary leaves. For average intensity radiation of 849.1W/m2 and 6 Kg of rosemary leaves during 4 h of distillation, exergy and optical efficiencies of the system achieved up to 26.62% and 50.97%, respectively. The thermal efficiency of the solar still, steam line, and condenser is about 94.80%, 94.30%, and 87.76%, respectively. The essential oil yield per unit of consumed energy and the total efficiency of the solar distillation system, taking into account the heat losses in the solar still, steam line, and condenser, as well as the optical losses in the two reflectors, is 6.18 mL/ kWh and 40.00%, respectively. The efficiency can be as high as 42.42 % if the steam line is insulated. Moreover, the comparison between the solar steam distillation and conventional steam distillation shows that solar distillation is much more efficient since it gives better results and especially it avoids the emission of 12.10 kg of CO2 during extraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world’s energy relies heavily on fossil fuels; according to researchers, each year, the energy consumption increases by 1% in the developed countries and 5% in developing countries. With those expectations, fossil fuel resources will not be able to meet the rising energy demand (Herez et al. 2018). The unsustainable and nonrenewable nature of fossil fuels coupled with environmental issues resulting from the use of these sources such as pollution, greenhouse effect, and global warming led to the alternative green source investigation. Presently, renewable energies have gained remarkable interest word widely, and it will play an important role in the world’s future. According to the global renewable energy scenario, the proportion of solar thermal applications will be about 480 million tons of oil equivalent by 2040 (Kralova and Johan 2010). Solar energy is one of the most promising sources in this category, currently used in numerous applications; several of them rely on the conversion of energy into thermal energy such as solar cooking (Panchal and Kishor 2020), drying, desalination ( Panchal and Thakkar 2016; Panchal 2017; Panchal et al. 2017), and extraction (Hilali et al. 2018, 2019). The ranges of all these processes lie between 60 and 280°C (Munir et al. 2010). Generally, the installation of a solar thermal or photovoltaic system depends on the latitude of a particular location. Therefore, there is a rule of thumb in solar thermal and solar photovoltaic technologies that the tilt angle of inclination should be equal to the latitude of the location (Panchal 2017).

Aromatic and medicinal plants (AMPs) are strongly linked to human civilization. Many AMPs contain antioxidant compounds used for food preservation instead of synthetic antioxidants, which have been the subject of numerous epidemiological studies on the negative impact of these synthetic products on human health (Giacometti et al. 2018). These plants can also be used to extract essential oils (EOs), with more than 3000 valorized species (Lubbe and Robert 2011). The extraction techniques have been used, according to researchers, since the discovery of fire. Traditional technologies for treating essential oils are necessary and widely used in many parts of the world. Hydro-distillation, steam-distillation, and maceration are the most used traditional methods.

The distillation of medicinal and aromatic plants by a decentralized solar system is an innovative technology that allows the use of solar energy for the extraction of EOs and facilitates the access of small farmers to this technique against the centralized exploitation with high investment and operating costs. Since, the energy costs for solar heat are 0.015 to 0.028 C£/kWh, and the annual energy gains is from 550 to 1100 kWh/m2 (Kalogirou 2003). Indeed, the exploitation of solar energy in this sector limits the consumption of conventional energies and encourages the use of renewable energies that reduce environmental pollution and the emission of carbon dioxide (Nandwani 1996).

Rosemary (Rosmarinus officinalis L.) is a perennial shrub native to the Mediterranean region. The plant is also cultivated in Spain, Morocco, Tunisia, and Southeast Europe. Rosemary leaves have an intense aromatic flavor and a bitter, slightly spicy taste. Rosemary is widely used in seasonings and flavors, as a preservative, and as an antioxidant. Pharmaceutical applications are also known (Wollinger et al. 2016).

Wolfgang Scheffler first developed the Scheffler reflector in 1986 in India and Kenya (Scheffler 2006); it was used for the distillation of AMPs to extract EOs by adding a second reflector, a solar still of distillation, and a condenser. The bottom of the solar still is painted with black paint to increase the absorption of solar radiation (Panchal et al. 2021). Moreover, an auxiliary biomass system has also been coupled to the distillation unit to complete the system in case of unfavorable climatic conditions (Afzal et al. 2017). Several studies to determine the thermal power and the efficiency of the system have been made. For an 8 m2 Scheffler reflector made of aluminum and for solar irradiation in the range of 700–800 W/m2, the average power and the efficiency of the solar distillation system were found to be 1.54 kW and 33.21%, respectively (Munir and Hensel 2010). In addition, the use of this solar distillation system for the production of steam is now an economically attractive possibility since the payback period of such a system does not exceed 2 years (Jayasimha 2006). However, the system has many losses that were ignored in previous studies (Kumar et al. 2019; Munir et al. 2014; Munir and Hensel 2010). Panchal mentioned that only 20% of solar energy was used for cooking and the portion of heat spent for vaporization of water and for convective heat losses from the vessel are 35% and 45%, respectively (Panchal and Kishor 2020). In addition, the most challenging point of Scheffler solar unit, unavailable to use when sun goes away, Hilali uses the same system and found that the useful energy on bright and clear days was 4429.9 W. Thus, we can say that the system delivers energy close to 4 kW on good weather condition days if we take the losses by convection, conduction, and radiation into consideration (Hilali et al. 2018).

Based on the aforementioned considerations, this work aims to identify and determine lost energy and power by convection and radiation at the solar still, in the steam line and condenser of a 10 m2 solar distillation unit to establish thermal balances of the solar unit studied during the distillation of rosemary leaves. Since it is very complicated to determine the convective exchange coefficient between the steam line and the ambient air, because no Nusselt correlation is found for a pipe bent at 45° (Fig. 3), this work may present a key to remedy this problem by making a total assessment between the condenser and the steam line. The optical losses (at the primary and secondary reflectors) and exergetic analysis were also performed. Moreover, a comparison of the different types of energy and composition of essential oils with a conventional butane-based system was also made.

Materials and methods

Solar distillation system

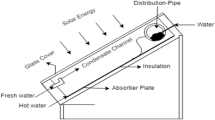

The solar distillation system is installed in the National Center for Studies and Research on Water and Energy (CNEREE) at the Cadi Ayyad University in Marrakech, Morocco (31° 37' 46 N, 7° 58' 52 O). This solar distillation system includes a 10-m2 fixed focal length Scheffler concentrator, a secondary reflector, a distillation still, a condenser, and a Florentine vase (Fig. 1). Also, the inclination of the glass cover depends on the latitude of the city (Panchal, Mevada, and Sadasivuni 2020b), so the axes of rotation of the reflector are set to the local latitude angle (31° 37' 46) such that the rotation axis of the reflector and the rotation axis of the earth are parallel to each other.

The energy available for the distillation process depends on the availability of the solar intensity and the optical and thermal efficiency of the solar distillery. The efficiency of the solar distillation system depends on the optical efficiency of the primary reflector and the absorbance of the distillation still (Afzal et al. 2017). In addition, Panchal found that the use of a copper plate in a solar still increases distillate production by 20% to 32% when distilling saline waters (Panchal and Shah 2014), Also the use of MgO nanofluid in a solar still increases distillate output is increased by 45.8% (Panchal et al. 2019). Panchal used evacuated tubes coupled to a double basin solar stills and solid fins, and he found that the distillate output increases by 25% (Panchal et al. 2020b, c). The reflective surface of the primary reflector is composed of glass mirrors with 85% of the specific surface of reflectance. The solar still has been insulated with 70 mm of rock wool to minimize heat loss. The 10-m2 parabolic reflector is equipped with an electronic small photovoltaic plate (PV) and mechanical system for the daily and seasonal monitoring of the sun. A pyranometer and thermocouples were used to register solar radiation and temperature, respectively, and were connected to a computer via a data recorder.

Energy distribution at the first reflector

The energy at the level of the first reflector is distributed in the form of absorbed radiation and reflected radiation. The reflected radiation of energy (Erp) depends upon the reflectivity of the used material. Hence, the energy produced by the first reflector is in the form of the following equation (Munir 2010):

where Rp is the mirror reflectivity of the primary reflector (0.85) and Etp is the total input energy available at the primary reflector; it is calculated via the following equation (Munir 2010):

where Gb (W/m2) is the direct irradiation measured by a pyranometer, At is the reflector surface (10 m2), and δ is the solar declination (Munir 2010).

Energy distribution at the secondary reflector

This section describes the available energy and losses at the secondary reflector. The main reflector reflects some radiation outside the focal point. The fraction available at the focal point (Ff) is in general calculated to be equal to 0.85. Thus, the energy available at the secondary reflector (Es) is given by:

Aluminum sheets with high reflectivity were used to reduce losses; the energy available after secondary reflection (Esr)

could be calculated by the equation below (Munir 2010):

where Rs is the reflectivity of the secondary reflector (0.83). A concrete foundation has been built to fix the secondary reflector in an optimal position in relation to the focal point.

Energy distribution at the distillation unit

The secondary reflector components are designed to reflect and distribute all the rays toward the bottom of the solar still; the energy available at the bottom of the distillation unit (Ebot) is given by (Munir 2010):

The useful energy and the energy losses of distillation unit include the reflectivity due to the incomplete absorbance and the heat losses of different parts of the still by conduction, convection, and radiation. The thermal energy available to operate the distillation system (Econd,b) is given by (Munir 2010):

where αb = 0.90 is the absorbance of the vessel. To determine the losses at the solar still, an electrical diagram will be evaluated as shown in Fig. 2.

Energy distribution at the steam line and the condenser

Most studies focus more on losses in the solar still, whereas losses in the steam line could be of equivalent importance and should not be overlooked. Since it is very complicated to determine the convective exchange coefficient between the steam line and the ambient air, because no Nusselt correlation is found for a pipe bent at 45° (Fig. 3), this work may present a key to remedy this problem by making a total assessment between the condenser and the steam line. In the condenser, the cooling water and the steam coming from the steam line circulate against the current. A simple calculation shows that this relative flow system is more efficient. Additionally, the inlet temperature of the condenser cooling water must be as cold as possible so that the amount of heat transferred is maximized. In this case, the temperature difference between the water inlet and outlet of the condenser is minimized, resulting in cooling energy (MacPhee and Dincer 2009):

The following diagram presented in Fig. 3 has been used for the determination of heat losses in the solar system (Fig. 4).

The energy required for the condensation of the entire vapor and found in the out of the condenser Eoc can be expressed as:

While the energy received by the condenser from the out of pipe Eop can be expressed as:

Thus, it is possible to determine the energy lost in the steam line Elp:

Performance evaluation of the solar distillation system

The main expression for calculating the efficiency of the solar distillation system, taking into account losses in the steam line and the condenser, is given below:

where ηo is the optical efficiency of the two reflectors, ηstill is the thermal efficiency of the still, ηpipe is the thermal efficiency of the steam line, and ηcond is the thermal efficiency of the condenser. The thermal efficiencies are calculated using the following relationships:

In addition, the efficiency of the distillation system is the volume of essential oil recovered per unit of energy consumed (mL/kWh); this efficiency links useful solar energy to useful thermal energy through by the following equation:

Exergy analysis for solar distillation system

Exergy is the useful part of the energy. The exergy balance of the solar distillation system for stable flow conditions depends on the rate of solar exergy delivered by the sun to the concentrator (Ex,in) (Kumar, Vishwanath, and Gupta 2011; Öztürk 2004; Petela 1964). It depends also on the exergy required to heat the water in the solar still (Ex,out) (Kumar et al. 2011; MacPhee and Dincer 2009; Öztürk 2004), which are expressed as follows:

where Tamb, and Ts are the ambient temperature and the temperature of the sun (Ts = 5762 K) (Venkatachalam and Cheralathan 2019). Tout and Tin are the final and initial water temperature in the solar still, respectively, ∆t is the distillation time (s), m is the mass of water in (kg), and Cp is the heat capacity of water in (kJ. kg-1.K-1). The exergetic efficiency of the AMPs solar distillation system represents the ratio between the exergy required by the distillation system and the exergy of solar radiation (Cuce and Pinar 2013):

Conventional steam distillation

The conventional system used is made of the same components as the solar system, except that a butane gas cylinder linked to an injector that burns this gas with a spark replaces the Scheffler and the secondary reflectors. In this system, the steam produced passes through the rosemary leaves and is charged with essential oil; it is then condensed and recuperated in a Florentine flask. Extraction continues until no more essential oil is obtained. The recovered essential oil is dried with anhydrous sodium sulfate and stored at 4°C until it is used. The energy produced by this system is calculated by Eq. 19, where LCV is the lower calorific value of butane gas used for water heating (12.61 kWh/Kg) and mb is the masse of butane gas consumed in four hours of experience.

Results and discussion

System energy balance

Optical losses

Several experiments were carried out to determine the optical efficiency of the Scheffler 10 m2 reflector. With a solar radiation intensity of 849.1 W/m2 and during 4 h of operation, the energy collected by the reflector is 20.23 kWh in a sunny day (Table 3), slightly higher than 18.6 kWh found by Munir for an 8 m2 reflector (Munir and Hensel 2010). Only 10.31 kWh becomes available at the bottom of the solar still.

Scheffler’s parabola reflects 85% (reflectivity of the mirrors used) of the direct radiation collected by its surface, of which only a fraction of 85% will reach the second reflector due to adjustment errors. The second reflector will also reflect a portion of 83% of the radiation it has received, of which only 85% will reach the bottom of the solar still. The optical efficiency ηo = 50.97% higher than 47.3% obtained by Veynandt (Veynandt 2008) using an 8 m2 Scheffler parabola for an irradiance of 850 W/m2. Moreover, this rate is in agreement with Scheffler (Scheffler 2006) who showed that about half of the solar energy collected by the reflector finally becomes available at the bottom of the solar still.

In terms of power (energy), the Scheffler reflector has been able to collect 5057.98 W (20.23 kWh) of which 4299.28 W (17.20 kWh) is reflected to the second reflector, i.e., 758.70 W (3.03 kWh) has been lost at the first reflector. The power (energy) available on the secondary reflector is 3654.39 W (14.62 kWh), so 644.89 W (2.58 kWh) was lost on its way to the secondary reflector due to the scattering of rays from the focal point. In addition, the power (energy) available after the secondary reflection is 3033.14 W (12.13 kWh), i.e., 621.25 W (2.49 kWh) was lost due to aluminum reflectivity. Finally 2578.17 W (10.31 kWh) reaches the bottom of the still, so 454.97 W (1.82 kWh) was lost on the way to the bottom of the still due to ray scattering.

Thermal losses in the solar still

For the calculation of the different powers, it was considered that the system works by natural convection around the solar still. For this purpose, it was necessary to calculate the side surface, bottom, and cone of the alembic while taking into account the geometrical shape of each part in order to choose the correct Nusselt correlation (Munir 2010). So, an iterative calculation was made in order to determine the various parameters necessary for the calculation of losses by convection, radiation, and conduction.

Taking the date 05/29/2019 as a reference, with Tamb = 38.5°C, Tin = 102.9°C, and Gb = 849.1 W/m2, the different powers and energies lost by conduction, convection, and radiation were calculated at the solar still for 4 h solar distillation period (Table 1).

The energy 𝑬bot = 10.31 kWh is the energy available at the bottom of the alembic in 4 h of distillation, with 𝜼still = 94.83% (Table 3), and the useful energy is 9.78 kWh (Table 1). While the energy consumed by water is 6.49 kWh, which means that the useful energy can cover not only the needs demanded by water but also produce energy that will be consumed by the AMPs, as well as an additional energy that the system does not use.

Thermal losses in the steam line and the condenser

Figure 3 shows the different thermal energies lost at the level of the alembic, steam line, and the condenser. The temperature difference between the inlet and outlet water of the condenser is about 0.7°C, resulting in cooling energy Elc=0.75 kWh. The energy required for the condensation of the steam produced in the still is Eoc=5.36 kWh. Therefore, the energy received by the condenser from the steam line is the sum of both Eop=6.11 kWh (Fig. 5).

No previous studies have determined the losses in the steam line and in the condenser of a solar AMP distillation system; a simple calculation shows that 0.37 and 0.75 kWh were lost in the steam line and in the condenser, respectively.

Efficiency of the solar distillation system

The results, as shown in Table 3, indicate that the thermal efficiency of the steam line and the condenser were ηpipe = 94.30% and 𝜼𝒄𝒐𝒏𝒅 = 87.76%, respectively, for the distillation of 6 Kg of rosemary leaves with 15 L of water. It was found that losses in the steam line present 6.92% of the energy consumed, while the efficiency of the system, assuming that the AMPs will process all the energy produced by the still, 𝜼sys = 40.00%. However, if the steam line is insulated; the efficiency becomes 42.42%, which allows the system to benefice up to 2.43% of the energy consumed (Table 3). Moreover, using 6 Kg of rosemary, the EO extracted in this experiment is about 50 mL, while the energy consumed by the water has been calculated at 6.49 kWh. This gives an important essential oil yield per unit of consumed energy ηEO = 6.18 mL/ kWh, much more effective than 1.13 mL / kWh obtained by Munir (Munir and Hensel 2010) for a quantity of 3 Kg of rosemary leaves; the essential oil extracted volume is 4.6 ml via 8 m2 solar reflector and for a consumed energy of 4.04 kWh. While the mass yield in EO is 0.83%, slightly higher than 0.82% that found by Hilali with the same solar system (Hilali et al. 2018).

Variation effect of some measured quantities

The beam radiation (Gb), the temperature at the focal point (Tf), and the volume of floral water (Qdist) are measured from 10.12 a.m. to 2.12 p.m. during the distillation of 6 Kg of rosemary leaves with 15 Kg of water. The variations of beam radiation, the temperature at the focal point, and the volume of floral water during this time period are shown in Fig. 6.

During this period, the irradiation has changed slightly due to the passage of the clouds. The variation of irradiance has influenced the temperature at the focal point, and their variations are similar. The maximum beam radiation and temperature at the focal point recorded are 863 W/m2 and 400°C, respectively. The volume of the floral water is at its minimum of about 250 mL at the beginning of distillation because of preheating of the water and then increases significantly to about 450 mL at the end of the operation.

In fact, three experiments were made, with the aim of comparing the effect of increasing the quantity of AMPs. It has been proven that the more the quantity of AMPs is important, the time to produce steam increases. Table 2 shows the time needed to obtain the first floral water drop. Therefore, for the same weather conditions, the evaporation time needed for 15L, for a giving quantity of AMPs (MAMPs) can be calculated using the following correlation:

In Table 3, for the same amount of water, an increase in plant mass increases the time needed for the evaporation of water from 40 to 50 min, which increases the energy of sensitization and decreases the energy of the latent phase from 1.00 and 5.65 to 1.14 and 5.37 kWh, respectively. i.e., decrease in the energy consumed by water and AMPs from 6.66 to 6.49 kWh and consequently decrease in the losses in the steam line from 0.75 to 0.37 kWh. As already mentioned, the plants prevent the dispersion of the steam, which consequently increases the time needed for the boiling. Therefore, the time needed for the appearance of the first drop of floral water increases.

With radiation intensities (three different days) of 983.88, 824.95, and 849.10 W/m2, the Scheffler reflector receives energies of the order of 24.21, 20.25, and 20.23 kWh, respectively, during 4 h of operation of which 12.34, 10.32, and 10.31 kWh will be available at the bottom of the still, including the optical losses of each reflector. This means that 49.03% of the energy collected has been wasted, but the useful energy and the efficiency of the still after calculating the losses by conduction, convection, and radiation are 11.86, 9.78, and 9.78 kWh and 96.07%, 94.73%, and 94.83%, respectively, for 2, 4, and 6 Kg of rosemary leaves. On the other hand, the thermal energy gained by water and AMPs during the two phases of sensitization and latency during 4 h is 6.66, 6.51, and 6.49 kWh for 2, 4, and 6 Kg of AMPs, respectively. Munir found 9.13 kWh for the distillation of 20 Kg of water for 6 h with an 8 m2 parabola Scheffler (Munir et al. 2014).

As shown in Table 3, the quantities of EOs recovered are 17, 35, and 50 mL, and essential oil extraction yields are 0.85%, 0.88%, and 0.83%, respectively, for 2, 4, and 6 Kg of AMPs, slightly higher than 0.82% that found by Hilali with the same solar distillation unit (Hilali et al. 2018). These fluctuations and variations found in the yield can be attributed not only to the origin of the plant but also to the interweaving of a multitude of factors such as plant spacings, weed control, mineral amendments, drying time, and the extraction method.

The total efficiency of the distillation system, taking into account the heat losses (at the still, the steam line, and the condenser) and the optical losses at the level of the two reflectors, is 41.55%, 39.81%, and 40.00%, respectively for 2, 4 and 6 Kg of rosemary, higher than 33.21% found by Munir (Munir et al. 2014). In addition, if the steam line has been insulated, an efficiency of 46.86%, 44.12%, and 42.42% will be obtained, respectively. Therefore, the energy gain can reach 5.31%. Table 3 gives a total overview of the different energies, powers, and yields calculated for the three experiments. However, these results have not been described previously.

Ozturk (Öztürk 2004) experimentally examined the energy and exergy efficiency of a solar parabola with dimensions 90×100 cm under the climatic conditions of Adana, located in the south of Turkey. It was constructed of steel profile and Cr–Ni alloy sheet; he showed an energy efficiency of 15.7%. Moreover, Arenas (Arenas 2007) described a portable solar cooker with a parabolic solar reflector that folds into a small volume. The experimental study indicated that the solar stove reached an average power of 175 W, with an energy efficiency of 26.6%. Desale designed and developed a Scheffler reflector with a surface area of 2 m2 with a receiver containing 2 L of water storage capacity. He performed experiments on the Scheffler reflector to determine the average power and efficiency of the solar Scheffler reflector and achieved a power of 1.30 kW and an efficiency of 21.61% (Panchal et al. 2018). In addition, Phate developed and tested a Scheffler reflector with a surface area of 2.7 m2 and a container as a receiver to store 10 L of water. Their main objective was to determine the average power and efficiency depending on the boiling of the water. After many experiments, he found that the average power and efficiency were around 550 W and 19%, respectively (Panchal et al. 2018). Moreover, Shinde tested a 16-m2 Scheffler reflector surface with a 0.5 m diameter receiver in the climatic conditions of Mumbai, India. From the experiments, he concluded that providing a conical collar angle of 30° was appropriate to reduce various heat losses and increase the efficiency of the Scheffler reflector up to 47.20% (Panchal et al. 2018). It is clear that our solar distillation unit is more efficient, especially if the steam line is insulated.

Exergy analysis

Energy and exergy analysis offers an alternative way to evaluate and compare systems. The exergy analysis was more convenient than the energy analysis for predicting systems efficiency.

An exergetic analysis is carried out to evaluate the useful part of energy by this system. For this purpose, 6 kg of rosemary has been trained with the steam of 15 Kg of water. Figure 7 shows that during the 4 h of the experiment, there is a slight difference between the input energy and the input exergy of the system; it can be concluded that the energy losses at the investigated Scheffler parabola are low.

Figure 8 illustrates a significant difference between the energy at the output (0.13 kWh) and the exergy at the output (0.03 kWh) at the start of the measurements. This proves that there are significant losses at the start because of the non-insulation and preheating of the bottom of the still. These losses are minimized and the two curves are stabilized at a common value at 11h22min. The losses are generated by the difference in temperature of the water to that of the still during the time intervals considered.

Table 4 summarizes the average values of the exergetic quantities calculated for the distillation system for an average radiation intensity between 838.02 and 863 W/m2. It is clear that the input exergy (19.43 kWh) and output exergy (5.17 kWh) are significant and almost equal to the input energy (20.95 kWh) and output energy (5.715 kWh), respectively. However, the major losses are optical losses at the two reflectors (first and secondary) which are 49.03% of the energy produced, but the heat loss in the still by conduction, convection, and radiation is only 5.2% confirmed by Veynandt (Veynandt 2008). These losses reduce the energy produced, 20.95 kWh to the energy consumed 5.71 kWh, and consequently reduce the input exergy 19.59 kWh to the output exergy 5.17 kWh. Therefore, the exergetic efficiency of the solar distillation unit is about 26.62% and is more efficient than 1.25% obtained by Ozturk, when he showed that energy output varied between 20.9 (0.084 kWh) and 78.1 W (0.31 kWh), whereas the exergy output was in the range 2.9–6.6 W (0.011–0.026 kWh) in 4 h of operation (Öztürk 2004). The exergetic efficiency obtained in this work is also higher than 0.027% and 0.028% using an truncated pyramid-type solar cooker and an solar box cooker, respectively (Kumar et al. 2011). It is clear that the increase of the reflector surface increases the exergy efficiency, so the investigated solar distillation unit is very efficient.

Comparison between the SSD and the CSD

As shown in Table 5, the energies produced in 4 h of distillation of 2 kg of rosemary leaves are 24.21 and 15.13 kWh respectively for solar steam distillation (SSD) and conventional steam distillation (CSD). In addition, half of the energy produced by the Scheffler reflector is lost on its way to the bottom of the solar still, but for the CSD, all the energy produced reaches the bottom of the still because the butane gas injector is placed under it. Therefore, the efficiency of the system is 73.99 % for the CSD higher than 41.55 % for the SSD, but the essential oil yield per unit of consumed energy is 1.69 mL/kWh for the SSD higher than 1.57 mL/kWh obtained with CSD. Moreover, with the SSD, energy consumption has been completely eliminated as it is a sustainable and free source, while the CSD consumes about 1.2 kg of butane gas (in 4 h) or 12.10 kg of CO2 released during the extraction period (Li et al. 2013). It can be said that the SSD is a sustainable and economical process for the extraction of essential oils.

Using GC-MS analysis method, a total of 52 compounds were identified in rosemary essential oils extracted with SSD and CSD techniques. As shown in Table 6, essential oil compounds such as monoterpenes and sesquiterpenes were ranked according to their retention time. In general, oxygenated compounds are more valuable because of their high odor characteristic, thus adding to the essential oil’s fragrance. The essential oils obtained by the two processes are qualitatively similar. α-Pinene was mainly detected in both essential oils: 42.27% for CSD and 46.98% for SSD, eucalyptol, also in similar amounts of 22.66% for CSD and 22.63% for SSD. Therefore, the identification rate of compounds by the GC-MS analysis method is in favor of SSD 97.42% against 96.07% for CSD. SSD method can be considered as a more efficient procedure because it uses a green and renewable energy.

Conclusion

In this work, optical losses at two solar reflectors and thermal losses at the solar still, the steam line, and the condenser were studied. The results showed that for the distillation of 6 kg of rosemary leaves with 15 L of water and with an average radiation intensity of 849.1 W/m2, the solar reflector could produce 20.23 kWh during 4 h of operation. Of which 10.31, 9.78, 6.11, and 5.36 kWh were, respectively, available at the bottom of the solar still, inside the solar still, at the outlet of the steam line, and at the outlet of the condenser. As a result, the optical efficiency of the two reflectors and the thermal efficiency of the still, the steam line, and the condenser were 50.97, 94.83%, 94.30%, and 87.76%, respectively. However, the total efficiency of the solar distillation system (10 m2) investigated was approximately 40.00%. When the steam line has been insulated, this rate reached up to 42.42% with an energy gain of 5.31%, depending on the quantity of the plant. The exergy efficiency was 26.62%, with radiation intensity between 838.02 and 863 W/m2. The comparison between SSD and CSD shows that SSD is much more efficient since it gives better results and especially it avoids the emission of 12.10 kg of CO2 during the extraction period.

The future work

The future work is to increase the efficiency and performance of the solar distillation unit by isolating the pipe during the distillation of pelargonium graveolens growing in Morocco in order to extract the essential oils and antioxidants (polyphenol, flavonoid, etc.)

Abbreviations

- At :

-

Total area of the elliptical frame of primary reflector (m2)

- A0 :

-

Aperture area of Scheffler reflector (m2)

- Etp :

-

Total input energy available at the reflector face (kWh)

- Erp :

-

Energy produced by the first reflector (kWh)

- Es :

-

Energy available at the secondary reflector (kWh)

- Esr :

-

Energy available after secondary reflection (kWh)

- Ebot :

-

Energy available at the bottom of the distillation (kWh)

- Ep :

-

Thermal energy available to operate the distillation system (kWh)

- Rp, Rs :

-

Reflectivity of the mirrors and the secondary reflector

- Ff, Fb :

-

Fraction available at the focal point and fraction of energy available at the bottom of the distillation

- Cond,h:

-

Conduction at the top of the still

- Cond,b:

-

Conduction at the bottom of the still

- Conv,h:

-

Convection at the top of the still

- Conv,b:

-

Convection at the bottom of the still

- Rad:

-

Radiation

- Bot:

-

Bottom

- Elp :

-

Thermal energy lost in the pipe (kWh)

- Elc :

-

Thermal energy lost in the condenser (kWh)

- Eop :

-

Thermal energy available at the pipe outlet (kWh)

- Eoc :

-

Thermal energy available at the condenser outlet (kWh)

- Cp:

-

Specific heat capacity of heat transfer fluid (J/kgK)

- Tamb :

-

Ambient temperature (K)

- Tout,cond :

-

Water temperature at the inlet of the condenser (K)

- Tin,cond :

-

Water temperature at the outlet of the condenser (K)

- Ts:

-

Surface temperature of sun (K)

- m:

-

Mass of water in the still (Kg)

- Mv:

-

Mass of steam produced (Kg)

- Lv:

-

Latent heat of vaporization of water at atmospheric pressure (kJ/ kg)

- \(\dot{\boldsymbol{m}}\text{cond}\) :

-

Mass flow rate of heat transfer from cooling water (L/s)

- Ex,in:

-

Exergy at the entrance of the solar system (kWh)

- Ex,out:

-

Exergy at the output of the solar system (kWh)

- LCV:

-

Lower calorific value of butane gas (kWh/Kg)

- GC-MS:

-

Gas chromatography-mass spectrometry

References

Afzal A, Anjum M, Abdul G, Jorge LA (2017) Development of hybrid solar distillation system for essential Oil extraction. Renew Energy 113:22–29. https://doi.org/10.1016/j.renene.2017.05.027

Arenas JM (2007) Design, development and testing of a portable parabolic solar kitchen. Renew Energy 32(2):257–266. https://doi.org/10.1016/j.renene.2006.01.013

Cuce E, Pinar MC (2013) A comprehensive review on solar cookers. Appl Energy 102:1399–1421. https://doi.org/10.1016/j.apenergy.2012.09.002

Giacometti J, Danijela B, Predrag P, Domagoj G, Tea B, Greta K, Francisco JB, Farid C, Gustavo BC, Anet R (2018) Extraction of bioactive compounds and essential oils from Mediterranean herbs by conventional and green innovative techniques: a review. Food Research Int 113:245–262. https://doi.org/10.1016/j.foodres.2018.06.036

Herez A, Mohamad R, Mahmoud K (2018) Review on solar cooker systems: economic and environmental study for different Lebanese scenarios. Renew and Sust Energy Rev 81:421–432. https://doi.org/10.1016/j.rser.2017.08.021

Hilali S, Anne Sylvie FT, Elmaataoui M, Emmanuel P, Hejjaj A, Aitnouh F, Idlimam A, Magali JN, Antoine B, Mandi L, Chemat F (2018) Deodorization by solar steam distillation of rosemary leaves prior to solvent extraction of rosmarinic, carnosic, and ursolic acids. ACS Sust Chem and Eng 6(8):10969–10979. https://doi.org/10.1021/acssuschemeng.8b02347

Hilali S, Anne Sylvie FT, Karine R, Hejjaj A, Ait Nouh F, Idlimam A, Antoine B, Mandi L, Chemat F (2019) Green extraction of essential oils, polyphenols, and pectins from orange peel employing solar energy: toward a zero-waste biorefinery. ACS Sust Chem Eng. https://doi.org/10.1021/acssuschemeng.9b02281

Jayasimha B (2006) Application of Scheffler reflectors for process industry. Int Solar Cooker Conference 8:1–2

Kalogirou S (2003) The potential of solar industrial process heat applications. Appl Energy 76(4):337–361. https://doi.org/10.1016/S0306-2619(02)00176-9

Kralova I, Johan S (2010) Biofuels-renewable energy sources: a review. J of Dispers Sci Technol 31(3):409–425. https://doi.org/10.1080/01932690903119674

Kumar N, Vishwanath G, Anurag G (2011) An exergy based test protocol for truncated pyramid type solar Box cooker. Energy 36(9):5710–5715. https://doi.org/10.1016/j.energy.2011.06.046

Kumar S, Yadav V, Sahoo U, Singh SK (2019) Experimental investigation of 16 square meter Scheffler concentrator system and its performance assessments for various regions of India. Therm Sci Engin Prog 10:103–111. https://doi.org/10.1016/j.tsep.2019.01.006

Li Y, Anne Sylvie FT, Maryline AV, Chemat F (2013) Solvent-free microwave extraction of bioactive compounds provides a tool for green analytical chemistry. TrAC - Trends Anal Chem 47:1–11. https://doi.org/10.1016/j.trac.2013.02.007

Lubbe A, Robert V (2011) Cultivation of medicinal and aromatic plants for specialty industrial materials. Ind Crops Prod 34(1):785–801. https://doi.org/10.1016/j.indcrop.2011.01.019

MacPhee D, Dincer I (2009) Thermal modeling of a packed Bed thermal energy storage system during charging. Appl Therm Eng 29(4):695–705. https://doi.org/10.1016/j.applthermaleng.2008.03.041

Munir A, Hensel O (2010) On-farm processing of medicinal and aromatic plants by solar distillation system. Biosyst Eng 106(3):268–277. https://doi.org/10.1016/j.biosystemseng.2010.03.016

Munir A, Hensel O, Scheffler W (2010) Design principle and calculations of a Scheffler fixed focus concentrator for medium temperature applications. Sol Energy 84(8):1490–1502. https://doi.org/10.1016/j.solener.2010.05.011

Munir A (2010) Design, development and modeling of a solar distillation system for the processing of medicinal and aromatic plants. Dissertation, University of Kassel

Munir A, Hensel O, Scheffler W, Heike H, Waseem A, Abdul G (2014) Design, development and experimental results of a solar distillery for the essential oils extraction from medicinal and aromatic plants. Sol Energy 108:548–559. https://doi.org/10.1016/j.solener.2014.07.028

Nandwani SS (1996) Solar cookers - cheap technology with high ecological benefits. Ecol Econ 17(2):73–81. https://doi.org/10.1016/0921-8009(96)00021-3

Öztürk HH (2004) Experimental determination of energy and exergy efficiency of the solar parabolic-cooker. Sol Energy 77(1):67–71. https://doi.org/10.1016/j.solener.2004.03.006

Panchal HN, Thakkar H (2016) Theoretical and experimental validation of evacuated tubes directly coupled with solar still. Therm Eng 63(11):825–831. https://doi.org/10.1134/S0040601516110045

Panchal H, Kishor KS, Suresh M, Satyapal Y, Shivani B (2020a) Performance analysis of evacuated tubes coupled solar still with double basin solar still and solid fins. Int J of Ambient Energy 41(9):1031–1037. https://doi.org/10.1080/01430750.2018.1501745

Panchal H, Dinesh M, Kishor KS (2020b) Recent advancements in condensers to enhance the performance of solar still: a review. Heat Trans 49(6):3758–3778. https://doi.org/10.1002/htj.21799

Panchal H, Dinesh M, Kishor KS, Essa FA, Shanmugan S, Mohammand K (2020c) Experimental and water quality analysis of solar stills with vertical and inclined fins. Groundw for Sust Develop 11:100410. https://doi.org/10.1016/j.gsd.2020.100410

Panchal HN (2017) Life cycle cost analysis of a double-effect solar still. Int J of Ambient Energy 38(4):395–399. https://doi.org/10.1080/01430750.2015.1132767

Panchal HN, Shah PK (2014) Improvement of solar still productivity by energy absorbing plates. J Renew Energy Environ Article History Jree 1(1):1–7

Panchal H, Heri N, Kishor KS, Sanil SH, Essa FA, Mohammad K, Swapnil D, Shanmugan S (2021) Experimental investigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Studies in Therm Eng 25(January):100905. https://doi.org/10.1016/j.csite.2021.100905

Panchal H, Jay P, Kiran P, Mayank P (2018) Different applications of Scheffler reflector for renewable energy : a comprehensive review. Int J Ambient Energy 0(0):1–31. doi: https://doi.org/10.1080/01430750.2018.1472655.

Panchal H, Nikunj P, Hemin T (2017) Various techniques for improvement in distillate output from active solar still: a review. Int J Ambient Energy 38(2):209–222. https://doi.org/10.1080/01430750.2015.1076518

Panchal H, Kishor KS (2020) Investigation and performance analysis of Scheffler reflector solar cooking system integrated with sensible and latent heat storage materials. Int J Ambient Energy 41(10):1096–1105. https://doi.org/10.1080/01430750.2018.1501754

Panchal H, Ravishankar S, Kabeel A E, El-Agouz S A, DSilva S R, Arunkumar T, Manokar A M, Winston D P, Sharma A, Nishant T, Kishor K S (2019) Annual performance analysis of adding different nanofluids in stepped solar still. J Therm Anal Calorim 138(5):3175–3182. doi: https://doi.org/10.1007/s10973-019-08346-x.

Petela R (1964) Exergy of heat radiation. J Heat Transf 86(2):187–192. https://doi.org/10.1115/1.3687092

Scheffler W (2006) Introduction to the revolutionary design of Scheffler reflectors. Int Solar Cooker Conference

Venkatachalam T, Cheralathan M (2019) Effect of aspect ratio on thermal performance of cavity receiver for solar parabolic dish concentrator: an experimental study. Renew Energy 139:573–581. https://doi.org/10.1016/j.renene.2019.02.102

Veynandt F (2008) Essential oil extraction with concentrating solar thermal energy global dimension in engineering education

Wollinger A, Élodie P, Chahboun J, Valérie J, Didier T, Werner K (2016) Antioxidant activity of hydro distillation water residues from Rosmarinus officinalis L. leaves determined by DPPH assays. Comptes Rendus Chimie 19(6):754–765. https://doi.org/10.1016/j.crci.2015.12.014

Acknowledgements

The authors would like to thank the National Center for Studies and Research on Water and Energy (Cadi Ayyad University-Morocco) for the scientific and technical support of this research.

Availability of data and material

None.

Code availability

None.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Kamal Ezzarrouqy, Abdessamed Hejjaj, Ali Idlimam, and Fatima Ait Nouh performed material preparation, data collection, and analysis. Ezzarrouqy kamal wrote the first draft of the manuscript, and Laila Mandi commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

None

Consent to participate

None

Consent for publication

None

Conflicts of interest

None.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ezzarrouqy, K., Hejjaj, A., Idlimam, A. et al. Study of the energetic, exergetic, and thermal balances of a solar distillation unit in comparison with a conventional system during the distillation of rosemary leaves. Environ Sci Pollut Res 29, 25709–25722 (2022). https://doi.org/10.1007/s11356-021-17612-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-17612-1