Abstract

Solar distillation is a technology that uses solar energy to evaporate and condense water to remove salts and impurities, making it an efficient method of desalination. It is a clean, sustainable and environmentally friendly method. However, its low productivity and dependence on the weather conditions must be taken into account when designing solar distillation systems. This document therefore provides detailed information on the factors that affect solar still productivity. The main objective of this document is to review the most recent and most comprehensive research that addresses the factors that impact the performance of the different types of solar stills, the materials used in stills, and the design techniques for and possible applications of stills. In addition, this study offers some recommendations on the future prospects of solar distillation technology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water is essential for human life; however, it is a limited resource that is getting scarce in numerous regions of the world. As the world's population continues to grow and climate change alters rainfall patterns, water scarcity is an issue of growing concern (Kalogirou 2005). According to the United Nations, more than 2 billion people do not have access to drinking water, and this number is expected to increase in the coming years (Delyannis 2003). In many parts of the world, water scarcity leads to crop failure, hunger and malnutrition (Delyannis and Belessiotis 2000). It also contributes to the spread of waterborne diseases. Several factors contribute to water scarcity around the world. Climate change is the main driver, with rising temperatures and changing rainfall patterns affecting water availability and quality in many regions (Tiwari et al. 2023). Population growth and urbanization also lead to an increased demand for water for drinking, sanitation and agriculture. Poor water management practices, including overexploitation of rivers and groundwater as well as pollution from industrial and agricultural activities, also exacerbate water scarcity (Sayigh 1989). However, solutions do exist, including better water management policies, investment in water infrastructure and adaptation to climate change, but the most promising and common solution is to harness the brackish water that covers around 70.2% of the earth's surface, and solar distillation is playing an increasingly crucial role in meeting the planet's water needs despite its modest productivity (Malik et al. 1982).

Solar distillation is a technique used to obtain purified water from salty or contaminated water (Tiwari and Tiwari 2007). This process uses solar energy to heat water; the solar still works by creating a greenhouse effect inside the container, which traps hot air and causes water to evaporate. Water vapor rises and condenses on the inner surface of the lid, which is cooler than the water, and the water drips into the collection unit (Malik et al. 1985). All impurities present in the original water source are removed, resulting in purified water. The solar still consists of a few basic parts, including a glass or plastic container, a condensation unit and a reflector to concentrate sunlight on the water (Anburaj et al. 2013).

Despite these advantages, solar distillation has certain limitations that should be addressed. The main challenge of this technology is the low productivity of solar units compared to other desalination systems (Nebbia and Nebbia-Menozzi 1966). Solar units have lower evaporation rates than other energy-intensive methods such as reverse osmosis (Talbert et al. 1970a). This means they take longer to produce the same amount of water, making them a less efficient solution for large-scale projects or densely populated areas (Delyannis 1967). The distillation process can also be improved by adding reflective material to the bottom of the vessel or by using a larger collection unit to increase the yield of purified water (Tleimat 1980). Innovative designs and modifications can also help improve solar still efficiency (Parekh et al. 2003). This work aims to highlight the process of solar desalination by describing some types of solar stills and their operation, discussing parameters that affect the operation of a solar still, reviewing some research work in this field, and making proposals about the future prospects of solar distillation technology (Arunkumar et al. 2019).

Literature review

The use of solar stills to obtain fresh water from seawater dates back several centuries, although they were used over 2000 years ago to produce salt rather than drinking water (Talbert et al. 1970b). However, recent advances in technology (Eibling et al. 1970) have led to the development of more compact and efficient solar stills to address the low-productivity problem (Kalidasa et al. 2013; Maalej 1991). Kalpesh and Kuldeep (2020) investigated how forced evaporation methods can be used to increase the efficiency of solar stills. These methods of increasing the evaporation surface area include the use of specific evaporation surfaces or capillary structures as well as the optimization of the geometric design (Chauhan et al. 2022). In the same vein of increasing the efficiency of solar distillers, research work has also focused on the integration of other solar thermal systems, such as solar distillers integrated with flat-plate solar collectors (Rai and Tiwari 1983; Badran et al. 2005), with a parabolic concentrator (Singh et al. 1996; Abdel-Rehim and Lasheen 2023), with evacuated tube collectors (Singh et al. 2013; Kumar et al. 2014b) or with a solar pool (Velmurugan et al. 2009a, 2009b). As part of the innovative research performed in this field, different shapes of top covers for solar stills, like spherical (Dhiman 1988), hemispherical (Arunkumar et al. 2012a), V-shaped (Selva Kumar et al. 2008), triangular prism (Wassouf et al. 2011) and pyramidal (triangular and square) (Kumar et al. 2014a), have been tried to improve their solar energy absorption as well as energy efficiency.

Solar distillation is a reliable and consistent method of water treatment (Garcia-Rodriguez 2003). The process is simple and easy to implement, requires minimal maintenance, and can produce clean water regardless of feed water quality (El-Dessouky and Ettouney 2000). The solar still method harnesses the sun's energy to create pure water (Tzen and Morris 2003). Evaporation and condensation are the fundamental concepts of any solar still. Salted water is put into the container, which is then exposed to the sun. The water in the container starts to evaporate when the sun heats it, leaving behind any impurities. The evaporated liquid then rises and condenses on the condenser's surface, where it is collected and cleaned (Shareef et al. 2018).

Types of distillers

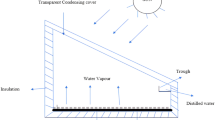

Inclined-plane solar still

This is a passive solar still; two different processes occur in the same equipment, namely the distillation and the heat recovery process. One of the main advantages of this equipment is that it supplies the water tank at a lower cost due to its simple design, as shown in Fig. 1. It consists of a black-painted basin sealed within a fully airtight surface created from a clear glass or plastic cover (Retiel 2008). Solar radiation passes through the cover and is absorbed by the black basin. Following the absorption of solar radiation, the water in the pond evaporates. Steam rises until it hits the inside surface of the lid and condenses into clean water. After that, it flows along the lower surface of the lid and is collected using the droplets (Sathyamurthy et al. 2016).

Aybar et al. (2005) experimentally studied an inclined solar still under the real environmental conditions in northern Cyprus.

The system consists of a flat and inclined solar absorption plate covered with glass, which creates a cavity. The absorber plate is made of galvanized steel and painted to form a matte black surface. However, all metal parts of the system that come into contact with water are made of stainless steel, copper or brass due to their better corrosion resistance. A black wick is placed on the absorber plate in order to evenly distribute the water on the plate and to increase the thickness of the water film. The absorber plate is insulated from below to prevent heat loss. The cavity is covered with 3-mm glass (with a transmissivity of about 0.88). The system is tilted at a 30° angle in order to run water over the absorber plate and increase the amount of solar radiation reaching the surface opening more frequently during the day. The system was tested with three variants: a bare plate, black fabric and black fleece. The effects of the wicks were observed. The rate of freshwater productivity increased by two to three times when wicks were used instead of a bare plate.

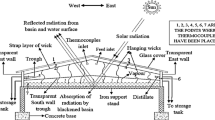

Cascading solar still

The waterfall solar distiller is a small water distiller powered by solar energy. It is designed to provide a solution to the problem of drinking water shortages in regions where access to drinking water is limited (Headley 1973). The principle of the cascading solar still is simple. It relies on the natural process of evaporation and condensation. Harnessing the power of the sun, the still heats the contaminated water, which then evaporates, leaving impurities. The difference from the flat still is that the absorber has a cascade structure. We find that if the body of water is tiny, the water heats up and evaporates faster (Velmurugan et al. 2008; Bernard 2004). The vapor then condenses on the inclined glass plates and this purified water flows down to be collected in a container (Khelif and Fethy 2000).

Khelif and Touati (2000) made an experimental study of a cascading solar still under the conditions in Adrar, Algeria. The system is shown in Fig. 2. It consists of a galvanized steel absorber formed of nine identical steps. This absorber contains a load of salt water and is covered with a transparent cover made of ordinary glass. The system is thermally insulated with a polystyrene coating and reinforced at the back with a second glass wool coating. On the edge surfaces are three holes connected with grooves. The first orifice is intended for supplying the distiller with salt water, the second for recovering the distillate, and the third for measuring and controlling the water level when the basin is full.

Khelif and Touati performed a detailed study of the parameters that characterize the cascade solar still. The study led to the suggestion of some methods of improving the efficiency of the system: reduce optical and thermal losses to the environment, promote condensation by controlling the cooling of the glazing, avoid salt deposition in the absorber basin by draining, and reduce the inertia of the system by using light materials.

Solar wick still

A solar wick still is a device that transforms salt water into drinking water using solar energy (Yeh and Chen 1986). The principle of operation is simple: the salt water is poured into the tank of the distiller, which is exposed to the rays of the sun. The latter heat the liquid, thus evaporating the water, which is then recovered in the form of vapor on a wick placed inside the device. This vapor then condenses on the cold wick, turning into pure, drinkable water (Arunkumar et al. 2012b).

The existence of the porous lining (wick) ensures slow circulation of the brackish water by drawing up the water, which increases the amount of energy it can absorb (Oualid 2009; Janarthanana et al. 2006).

Matrawy et al. (2015) made an experimental study of the wavy-wick-type solar still shown in Fig. 3 for comparison with a simple basin-type solar still. The main components of the proposed solar still are as follows: (1) a 6-mm-thick glass cover to transmit solar radiation incident on and reflected by the reflector to both a porous material and pond water (the steam generated condenses along the lower surface of the cover and is collected at the lower end); (2) a porous material made of 2-mm-thick black cloth in a corrugated form (the porous material is partially immersed in and wetted by the pool water via the capillary effect in order to increase the rate of evaporation); (3) a basin that contains the hot water; (4) the outer frame, a cubic wooden box with sides of 1.35 m, which is used to protect the system from the external ambient conditions; and (5) a flat, inclined stainless steel reflector 0.5 m in height and 0.8 m in width. The study led to the conclusion that the daily productivity of the solar wick was about 34% higher than that of the simple basin.

Spherical still

A spherical solar still is frequently used in desert regions. It is solar powered and uses the evaporation–condensation cycle to operate. The distiller receives water, which is heated by the rays of the sun, causing the evaporation of the water, which rises to the top of the sphere. When water vapor comes into contact with the cold, reflective surface of the sphere, it condenses and collects in a depression around the equator. Salt and other contaminants are then flushed out of the cleaned water and it is directed to a storage tank (Rabah 2012; Chaker and Menguy 2001).

Brahim and Chouchene (2014) conducted a study in Sousse, Tunisia, relating to the productivity and testing of a spherical solar still (shown in Fig. 4) for the productivity of water. The distiller consisted of an absorbent copper tank that was coated in black and had a surface area of 0.18 m2, a thickness of 2 mm, a thermal conductivity of 384 W m−1 K−1 and an absorption coefficient equal to 0.85; a plexiglass pane with an area of 0.785 m2, a thickness of 3 mm and a thermal conductivity of 0.19 W m−1 K−1; and expanded polystyrene insulation with a thickness of 2 cm and a thermal conductivity of 0.04 W m−1 K−1 that was used to avoid losses from the lower part of the tank. The results were taken over a period of 7 h in order to measure the daily productivity, which was approximately 0.8 L/day in this case.

From the interpretation of the experimental results obtained, the authors found that the productivity of distilled water obviously depended on the incident solar energy and the absorbing surface, and it allowed a distillate of very good quality to be obtained. There was also a strong temperature gradient between the water table and the glass, which promoted condensation and evaporation. A mathematical model where all the parameters characterizing the performance of the system are evaluated instantaneously during the period of sunshine can confirm the results of this study.

Vertical solar still

The vertical solar still is a device that uses the power of the sun to purify water. It consists of a clear, cone-shaped, upright plastic container that is placed over a basin of salty or contaminated water. Sunlight heats the water, causing it to evaporate and rise to the top of the cone. When it reaches the top, the water condenses on the plastic surface and drips into a collection basin, leaving behind contaminants and salt (Ameur and Ait Allaoua 2015; Tiwari 1992) (Fig. 5).

Boukar et al. (2007) constructed a single-effect indirect vertical solar still and experimented with it under the desert climate conditions of Adrar. This distiller is basically made up of a solar collector, a supply tank and a support. Tests carried out from December 2005 until February 2006 led to the conclusion that improvements in the the performance of the distiller could be achieved through the improvement of the design, the control of the brackish water supply and the improvement of the artifice used to track solar radiation.

Figures 5, 6 show the operating principle and the experimental setup, respectively.

Conditions that affect productivity

The selection of the type of solar still to use is mainly based on its productivity, which is impacted by several parameters (Shadi et al. 2016). In their review, Muftah et al. (2014) cited a number of factors (as shown in Fig. 6), including geographic location, general weather conditions, solar still design, position of the sun and exploitation technique.

History of solar stills

In their review, Panchal and Patel (2017) studied the factors that affect the distillate productivity of a solar still. The most important factors are climate and design parameters. Solar still productivity was found to be directly correlated to total solar radiation, air temperature and wind speed.

Based on several research works (Selvaraj and Natarajan 2018; Velmurugan et al. 2008; Ghoneyem and Ileri 1997; Tiwari and Madhuri 1985; Manokar et al. 2014; Velmurugan and Srithar 2011; Abdenacer and Nafila 2007; Muftah et al. 2014; Nafey et al. 2000; Velmurugan et al. 2009c) that studied the parameters affecting the performance of a solar still, we can draw the following conclusions. The appropriate orientation of the glass cover depends on the latitude of the location. In northern latitudes it should be south facing, and in southern latitudes it should be north facing. The inclination of the cover should be optimized to maximize the rate of condensation of water on the lower surface of the cover and to collect the water without the mass of accumulated drops falling back into the basin. This therefore depends on the intensity of the solar radiation, the rates of evaporation and condensation, the material used for the cover, and its wetting properties. Lowering the cover temperature helps increase productivity. The temperature of the glass cover is reduced by having a film of cooling water flowing continuously over the glass or by having an intermittent flow of cooling water on the lid. The dependence of distillate productivity on water depth is strongly dependent on the initial water temperature in the basin. Still productivity decreases with increasing water depth during the day, but the reverse is the case with nighttime productivity. Still performance is associated with the thermal conductivity of the cover material. A thinner thickness of the condensation glass cover is preferable. Optimizing the tilt of the glass cover is very important for increasing productivity. It is suggested that a larger angle of coverage inclination is preferable in winter and a smaller angle is preferable in summer, and it is observed that the best angle of coverage inclination is close to that of the latitude of the location. Black granite gravel and black rocks are good energy-absorbing materials for storing solar energy and increasing productivity. The use of an asphalt basin coating increases the productivity of the solar as it presents higher absorption compared to black paint. The integration of the flat plate collector with the still increases its efficiency. The output of a multi-basin solar still is higher than that of single-basin still because of the greater difference between water temperature and glass cover temperature. The double-basin solar still coupled with vacuum tubes gives better performance.

Table 1 summarizes some research works that have studied the parameters that affect the productivity of a solar still.

Economic study

The economic analysis of a solar still is a crucial step in calculating the cost of producing distilled water and the time required to recover the investment (Mukherjee and Tiwari 1986). The cost of distilling water and its use determine the best return on a company's investment. To carry out an economic study, we propose the method of Kabeel et al. (2010); which is based on desalination unit cost analysis: the main calculation elements used in the cost analysis of the desalination unit are the CRF (capital recovery factor), FAC (fixed annual cost), SFF (sinking fund factor), ASV (annual salvage value), average annual productivity (M) and CA (annual cost). The annual maintenance cost (AMC) of a solar still covers regularly filling the still with brackish water, collecting distilled water, cleaning the glass cover, removing salt deposits (scaling) and maintaining the DC pump. The frequency of pond filling will decrease as the water depth increases. As a system ages, the amount of maintenance required increases. This is why the maintenance cost was calculated as 10% of the current net cost. The annual cost of the AC system is divided by the annual solar still yield (M), and the result is the CPL (cost of distilled water per liter). The parameters of the calculation described above can be represented as follows:

where P is the current capital cost of the desalination system; i is the interest per year, which is assumed to be 12%; and n is the number of years of life, assumed equal to 10 years in this analysis. Commodity prices depend on the country considered.

Conclusion

The solar still is an environmentally friendly solution to the problem of contaminated water. It requires no external power source and emits zero carbon emissions (Singh et al. 2020). It is easy to install and use, making it an ideal solution for rural areas where electricity is scarce. Additionally, it provides a long-term solution to the problem, as it requires minimal maintenance and has a long service life. The solar still is a great example of how we can harness the power of nature to provide sustainable solutions to the challenges we face. The performance and accessibility of solar stills can be significantly improved by taking into account the parameters influencing productivity (Kabeel et al. 2022). The creation of more efficient advanced collection materials, such as specific coatings or nanomaterials that can improve the condensation process and produce more water (Akkala et al. 2021), could make solar stills more portable and compact by increasing the distillation efficiency achieved with a smaller collection area (Mohammed and Mourad 2022). Research carried out into the use of sensor technology to automatically change the parameters according to the external circumstances shows that integrating sensors and automatic control systems into solar stills can improve their performance (Pisitsungkakarn and Neamyou 2022). Solar stills can also be used in conjunction with thermal storage systems, such as phase change materials or hot water tanks, to more efficiently use solar energy when the sun shines while allowing access to drinking water on cloudy days or at night. Using this method, solar stills would be more reliable and ideal for places with poor sunlight conditions.

The following conclusions were obtained upon analyzing the research works dealing with different aspects of the parameters influencing the productivity of solar stills:

-

Daily productivity increases when the water depth is reduced by 2 cm, but nighttime productivity decreases. On the other hand, when the water depth is increased, productivity increases at night and decreases during the day. Overall, a 2-cm depth is the best option for maximum productivity.

-

When the thickness of the glass is lower, the productivity increases. This is because of thee cooler temperature of the thinner glass, as there is more heat transfer with the outside environment and less radiation absorption inside the glass.

References

Abdel-Rehim ZS, Lasheen A (2023) Experimental and theoretical study of a solar desalination system located in Cairo, Egypt. Desalination 217:52–64

Abdenacer PK, Nafila S (2007) Impact of temperature difference (water-solar collector) on solar-still global efficiency. Desalination 209(1–3):298–305

Abdullah AS, Younes MM, Omara ZM, Essa FA (2020) New design of trays solar still with enhanced evaporation methods: comprehensive study. Sol Energy 203:164–174

Akkala SR, Kaviti AK, Arun Kumar T, Sikarwar VS (2021) Progress on suspended nanostructured engineering materials powered solar distillation—a review. Renew Sustain Energy Rev 143:110848

Al-Hinai H, Al-Nassri MS, Jubran BA (2002) Effect of climatic, design and operational parameters on the yield of a simple solar still. Energy Convers Manag 43:1639–1650

Ali Aljubouri A (2017) Design and manufacturing of single sloped solar still: study the effect of inclination angle and water depth on still performance. J Al-Nahrain Univ 20(2):60–70

Ameur A, Ait Allaoua R (2015) Etude et réalisation d’un distillateur solaire. Mémoire de Master en Génie Mécanique. Université Mouloud Mammeri, Tizi-Ouzou

Anburaj P, Hansen RS, Murugavel KK (2013) Performance of an inclined solar still with rectangular grooves and ridges. Appl Solar Energy 49(1):22–26

Arunkumar T, Jayaprakash R, Denkenberger D, Amimul Ahsan MS, Okundamiya TSKH, Aybar HS (2012a) An experimental study on a hemispherical solar still. Desalination 286:342–348

Arunkumar T, Vinothkumar K, Amimul Ahsan R, Jayaprakash SK (2012b) Experimental study on various solar still designs. ISRN Renew Energy 2012:10

Arunkumar T, Raj K, Rufuss DDW, Denkenberger D, Tingting G, Xuan L, Velraj R (2019) A review of efficient high productivity solar stills. Renew Sustain Energy Rev 101:197–220

Aybar H, Egeliofglu F, Atikol U (2005) An experimental study on an inclined solar water distillation system. Desalination 180:285–289

Azooz AA, Younis GG (2016) Effect of glass inclination angle on solar still performance. J Renew Sustain Energy 8(3):33702

Badran AA, Al-Hallaq IA, Eyal Salman IA, Odat MZ (2005) A solar still augmented with a flat-plate collector. Desalination 172:227–234

Bernard J (2004) Génie énergétique, Energie solaire, calculs et optimisation. Éditions Ellipses, Paris

Boukar M et al (2007) Construction et expérimentation d’un distillateur solaire vertical indirect à simple effect. On: ICRESD-07, Tlemcen, Algeria, 21–24 May 2007, pp 75–81

Brahim L, Chouchene S (2014) Fabrication et expérimentation d’un distillateur solaire sphérique. In: Troisième Congrès tunisien de Mécanique (COTUME 2014), Sousse, Tunisia, 24–26 Mar 2014

Chaker A, Menguy G (2001) Efficacité interne d'un distillateur solaire sphérique. Rev Energ Renouv (Numéro Spécial, 10ème Journée International de Thermique) 53–28

Chauhan V, Shukla S, Rathore PKS (2022) A systematic review for performance augmentation of solar still with heat storage materials: a state of art. J Energy Storage 47:103578

Delyannis A (1967) Solar stills provide island inhabitants with water. Sun Work 10(1):6–8

Delyannis E (2003) Historic background of desalination and renewable energies. Sol Energy 75(5):357–366

Delyannis E, Belessiotis V (2000) The history of renewable energies for water desalination. Desalination 128:147–159

Dhiman NK (1988) Transient analysis of a spherical solar still. Desalination 69:47–55

Diab MR, Abou-Taleb FS, Essa FA (2022) Effect of basin water depth on the performance of vertical discs’ solar still—experimental investigation. Environ Sci Pollut Res 29:91368–91380

Edeoja AO, Fadoo U, Acheyini J (2023) Investigation of the effect of cover thickness on the yield of a single basin solar still under Makurdi climate. Int J Eng Sci Invent 4(1):1–8

Eibling JA, Talbert SG, Löf GOG (1970) Distillateurs solaires à usage communautaire—résumé de la technologie. Sol Énergie 13(2):263–276

El-Dessouky H, Ettouney H (2000) MSF development may reduce desalination costs. Water Wastewater Int 20:1679–1706

El-Sebaii AA (2004) Effect of wind speed on active and passive solar stills. Energy Convers Manag 45:1187–1204

Feilizadeh M, Karimi Estahbanati MR, Ahsan A, Jafarpur K, Mersaghian A (2016) Effects of water and basin depths in single basin solar stills: an experimental and theoretical study. Energy Convers Manag 122:174–181

Garcia-Rodriguez L (2003) Renewable energy applications in desalination: state of the art. Sol Energy 75(5):381–393

Ghoneyem AL, Ileri A (1997) Software to analyse solar stills and an experimental study on the effects of the cover. Desalination 114:37–44

Headley OSC (1973) Cascade solar still for distilled water production. Sol Energy 15(3):245–252

Jabbar A, Khalifa N, Ali MAW (2015) Indoor tests on the effect of wind speed on still performance. Int J Energy Environ 6(3):299–308

Jamal JW, Siddiqui MA (2012) Effect of water depth and still orientation on productivity for passive solar distillation. Int J Eng Res Appl 2(2):1659–1665

Janarthanana B, Chandrasekarana J, Kumar S (2006) Performance of floating cum tilted-wick type solar still with the effect of water flowing over the glass cover. Desalination 190:51–62

Kabeel AE, Hamed AM, El-Agouz SA (2010) Cost analysis of different solar still configurations. Energy 35(7):2901–2908

Kabeel AE, Attia MEH, Zayed ME, Abdelgaied M, Abdullah AS, El-Maghlany WM (2022) Performance enhancement of a v-corrugated basin hemispherical solar distiller combined with reversed solar collector: an experimental approach. Renew Energy 190:330–337

Kalidasa K, Anburaj P, Samuel R, Elango T (2013) Progresse en type incline alambics solaires. Énergie Durable Renouv Rev 20:364–377

Kalogirou AS (2005) Seawater desalination using renewable energy sources. Prog Energy Combust Sci 31:242–281

Kalpesh VM, Kuldeep HN (2020) Efficacy of forced condensation and forced evaporation with thermal energy storage material on square pyramid solar still. Renew Energy 153:1307–1319

Keshtkar M, Eslami M, Jafarpur K (2020) Effect of design parameters on performance of passive basin solar stills considering instantaneous ambient conditions: a transient CFD modeling. Sol Energy 201(1):884–907

Khelif C, Fethy C (2000) Dynamic modelization of cascades solar distiller greenhouse. In: Renewables: the Energy for the 21st Century (World Renewable Energy Congr VI), Brighton, UK, 1–7 July 2000, pp 2255–2260

Khelif C, Touati B (2000) Semi-empirical characterization of a greenhouse-effect cascades solar distiller. Renew Energy 19:103–110

Kumar V, Nagarajan PK, Paulson D, Chitharthan RK, Narashimulu Y (2014a) Performance evaluation of triangular pyramid solar still for enhancing productivity of fresh water. Res J Pharm Biol Chem Sci 5(2):764–771

Kumar S, Dubey A, Tiwari GN (2014b) A solar still augmented with an evacuated tube collector in forced mode. Desalination 347:15–24

Maalej AY (1991) Solar still performance. Desalination 82:197–205

Malik MAS, Tiwari GN, Kumar A, Sodha MS (1982) Solar distillation, 1st edn. Pergamon, Oxford

Malik MAS, Tiwari GN, Kumar A, Sodha MS (1985) Solar distillation. Pergamon, Oxford

Manokar AM, Murugavel KK, Esakkimuthu G (2014) Different parameters affecting the rate of evaporation and condensation on passive solar still—a review. Renew Sustain Energy Rev 38:309–322

Matrawy KK, Alosaimy AS, Mahrous A-F (2015) Modeling and experimental study of corrugated wick type solar still: comparative study with a simple basin type. Energy Convers Manag 105(15):1261–1268

Modi KV, Nayi KH, Sharma SS (2020) Infuence of water mass on the performance of spherical basin solar still integrated with parabolic refector. Groundw Sustain Dev 10:100299

Mohammed M, Mourad TJ (2022) Development of solar desalination units using solar concentrators or/and internal reflectors. Int J Eng Technol Innov 12(1):45–61

Muafag S, Tarawneh K (2007) Effect of water depth on the performance evaluation of solar still. JJMIE 1(1):23–29

Muftah AF, Alghoul MA, Fudholi A, Abdul-Majeed MM, Sopian K (2014) Factors affecting basin type solar still productivity: a detailed review. Renew Sustain Energy Rev 32:430–447

Mukherjee K, Tiwari GN (1986) Economic analyses of various designs of conventional solar stills. Energy Convers Manag 26(2):155–157

Nafey AS, Abdelkader M, Abdelmotalip A, Mabrouk AA (2000) Parameters affecting solar still productivity. Energy Conver Manag 41(16):1797–1809

Nebbia G, Nebbia-Menozzi G (1966) A short history of water desalination. In: Acqua Dolce dal Mare, II Inchiesta Internazionale, Milan , Italy, 18–19 Apr 1966, pp 129–172

Oualid S (2009) Etude des caractéristiques de fonctionnement et de la performance d'un distillateur solaire, Mémoire de Magister en physique ecole doctorale. Université Mentouri, Constantine. Accessed 31 Jan 2009

Panchal H, Patel S (2017) An extensive review on different design and climatic parameters to increase distillate output of solar still. Renew Sustain Energy Rev 69:750–758

Panchal NH, Shah PK (2011) Effect of varying glass cover thickness on performance of solar still: in a winter climate conditions. Int J Renew Energy Res 1(4):212–223

Parekh S, Farid MM, Selman RR, Al-Hallaj S (2003) Solar desalination with humidification–dehumidification technique—a comprehensive technical review. Desalination 160:167–186

Pisitsungkakarn SSH, Neamyou P (2022) Efficiency of semi-automatic control ethanol distillation using a vacuum-tube parabolic solar collector. Energies 15(13):4688

Rabah K (2012) Contribution à l’étude d’un distillateur solaire modulaire constitue d’un capteur solaire à ruissellement et d’une chambre à condensation. PhD thesis. Université des Sciences et de la Technologie Houari Boumediene, Bab Ezzouar

Rai SN, Tiwari GN (1983) Single basin solar still coupled with flat plate collector. Energy Convers Manag 23(3):145–149

Retiel N (2008) Etude expérimentale d’un distillateur solaire plan amélioré. Rev Energ Renouv 11(4):635–642

Sathyamurthy R, Harris Samuel DG, Nagarajan PK, Arunkumar T (2016) Geometrical variations in solar stills for improving the fresh water yield—a review. Desalination Water Treat 57(45):21145–21159

Sayigh AAM (1989) Solar energy activities in the Arab countries. In: Congress of the International Solar Energy Society, Kobe City, Japan, 4-8 Sept 1989, pp 1851–1865

Selva Kumar B, Kumar S, Jayaprakash R (2008) Performance analysis of a V-type solar still using a charcoal absorber and a boosting mirror. Desalination 229:217–230

Selvaraj K, Natarajan A (2018) Factors influencing the performance and productivity of solar stills—a review. Desalination 435:181–187

Shadi M, Abujazar A, Fatihah S, Rakmi AR, Shahrom MZ (2016) The effects of design parameters on productivity performance of a solar still for seawater desalination: a review. Desalination 385:178–193

Shareef AS, Rashid FL, Alwan HF (2018) Experimental study of new design solar still in Karbala-Iraqi weathers. Int J Mech Eng Technol 9(13):1465–1472

Singh SK, Bhatnagar VP, Tiwari GN (1996) Design parameters for concentrator assisted solar distillation system. Energy Convers Manag 37(2):247–252

Singh RV, Kumar S, Hasan MM, Khan ME, Tiwari GN (2013) Performance of a solar still integrated with evacuated tube collector in natural mode. Desalination 318:25–33

Singh AK, Yadav RK, Mishra D, Prasad R, Gupta LK, Kumar P (2020) Active solar distillation technology: a wide overview. Desalination 493:114652

Talbert SG, Eibling JA, Lof GOG (1970a) Manual on solar distillation of saline water. R&D Progress Report no. 546. Battelle Memorial Institute, Columbus Laboratories, Columbus

Talbert SG, Eibling JA, Lof GOG, Wong C (1970b) Manual on solar distillation of saline water. United States Department of the Interior, Washington, DC

Tiwari GN (1992) Chapter II: Recent advances in solar distillation. In: Raj K, Maheshwari KP, Sawhney RL (eds) Solar energy and energy conservation. Wiley Eastern Ltd, New York

Tiwari GN, Madhuri HP (1985) Effect of water flow over the glass cover of a single basin solar still with an intermittent flow of waste hot water in the basin. Energy Convers Manag 25:315–322

Tiwari GN, Tiwari A (2007) Pratique de distillation solaire pour les systèmes de dessalement de l’eau. Anamaya, New York

Tiwari GN, Singh HN, Tripathi R (2003) Present status of solar distillation. Sol Energy 75(5):367–373

Tleimat MW (1980) Freezing methods. In: Spiegler KS, Laird ADK (eds) Principles of desalination, part B, 2nd edn. Academic, New York, pp 359–400

Tzen E, Morris R (2003) Renewable energy sources for desalination. Sol Energy 75(5):375–379

Velmurugan V, Srithar K (2011) Performance analysis of solar stills based on various factors affecting the productivity—a review. Renew Sustain Energy Rev 15(2):1294–1304

Velmurugan V, Senthil Kumaran S, Niranjan Prabhu V, Srithar K (2008) Productivity enhancement of stepped solar still—performance analysis. Therm Sci 12(3):153–163

Velmurugan V, Srithar K, Mandlin J, Stalin B (2009a) Augmentation of saline streams in solar stills integrating with a mini solar pond. Desalination 249:143–149

Velmurugan V, Naveen Kumar KJ, Noorul Haq T, Srithar K (2009b) Performance analysis in stepped solar still for effluent desalination. Energy 34(9):1179–1186

Velmurugan V, Pandiarajan S, Guruparan P, Harihara Subramanian L, David Prabaharan C, Srithar K (2009c) Integrated performance of stepped and single basin solar stills with mini solar pond. Desalination 249:902–909

Wassouf P, Peska T, Singh R, Akbarzadeh A (2011) Novel and low cost designs of portable solar stills. Desalination 276:294–302

Yeh H-M, Chen L-C (1986) The effects of climatic, design and operational parameters on the performance of wick-type solar distillers. Energy Convers Manag 26(2):175–180

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Chedly Tizaoui.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nasrdine, S., Benchrifa, M., Ben-Lhachemi, N. et al. Effect of various factors on the productivity of solar stills: mini review. Euro-Mediterr J Environ Integr 9, 977–987 (2024). https://doi.org/10.1007/s41207-024-00465-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41207-024-00465-8