Abstract

The construction industry is a pillar industry of China’s national economy but its problems of high energy consumption, high pollution, and low energy efficiency are increasingly prominent. The study on the energy efficiency of the construction industry is of great significance for improving development quality and achieving the goal of energy saving and emission reduction. In this paper, a three-stage undesirable SBM-DEA model was employed to measure the energy efficiency in the construction industry during 2005-2016. The CO2 directly emitted by the construction industry and indirectly emitted in the production of building materials were used as the undesirable output and the three-stage framework was employed to analyze and eliminate the influence of external environment. The empirical results showed that low efficiency of management in the construction industry is an important factor leading to the low level of energy efficiency in China’s construction industry. For the energy efficiency value before and after adjustment, the “high-high” provinces have made full use of the superior external environment by their high management level, while the “high-low” provinces need to fully realize the potential in promoting energy efficiency of its external environment by improving its own management of the construction industry. On the contrary, the “low-high” provinces need to improve the external environment to ease its restrictions on the level of management in the construction industry. Environmental factors and management level should be considered simultaneously for different provinces to improve energy efficiency of the construction industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The problems of resources, energy, and environment have become increasingly prominent with the rapid development of economy and the acceleration of urbanization in China. As an important pillar industry of China’s national economy, the problems of high energy consumption, high pollution, and low energy efficiency in the construction industry were particularly highlighted. The total output of China’s construction industry reached 2139.54 billion in 2017 while the added value accounting for 6.7% of China’s GDP and its growth rate exceeded GDP growth by 3%.Footnote 1 At the same time, energy consumption in the construction industry reached 857 million tons of standard coal, accounting for 20% of China’s total energy consumption in 2015, and this number is still growing.Footnote 2 Figure 1 illustrates that the total construction carbon emission in China shows a trend of continuous growth, reaching 1.961 billion tons in 2016, which is about three times higher than 668 million tons in 2000, with an average annual growth of 6.96%, and the construction industry accounts for 20.6% of China’s energy consumption and 19.4% of its carbon emissions.Footnote 3 In addition, considering the energy consumption during heating, cooling, illumination, and the production of building materials, the construction industry will consume more than a third of China’s total energy consumption.Footnote 4 The construction industry is an important emitter of carbon dioxide, haze, and other pollutants (Lu et al. 2016; Feng et al. 2016), which will lead to a lot of grave consequences, such as lung diseases, traffic congestions in cities, and economic loss (Zhang and Crooks 2012). In view of the problems of high energy consumption, high pollution, and low energy efficiency in construction, promoting the energy efficiency in the construction industry is crucial for improving development quality and achieving the goal of energy saving and emission reduction.

In this paper, the energy efficiency of China’s construction industry was investigated by employing the three-stage undesirable SBM-DEA model, which was widely used in energy and environment modeling, for its superiority in dealing with the undesirable output, as well as in evaluating and eliminating the influence of external factors or random noises. Based on the measurement of energy efficiency in China’s construction industry, regional gaps, trends, and influencing factors are the three main concerns in the discussion of this paper, followed by some policy implications for the sustainable development of China’s construction industry. This paper contributes to current literature in two aspects. Firstly, the CO2 directly emitted by the construction industry and indirectly emitted in the production of building materials were selected as an undesirable output to shed light on the full life cycle environmental performance of the construction industry. Secondly, urbanization, economic level, environmental regulation, public investment, human capital, and industrial structure of each province were selected as external factors to analyze the influencing factors of energy efficiency in China’s construction industry within the three-stage framework.

This paper was organized as follows. The “Literature review” section provides a brief literature review of the development of DEA model and some research about energy efficiency in the construction industry. The methodology and data were then described in the “Methodology” section and the “Data description and variables” section respectively, followed by the empirical results in the “Empirical results” section, and the conclusion and policy implications in the “Conclusion and policy implications” section.

Literature review

Data envelopment analysis (DEA) and stochastic frontier analysis (SFA) are the main methods to measure energy efficiency. DEA is a non-parametric, linear, and programming method to measure the productivity of comparable multiple-input and multiple-output decision-making units (DMUs). Compared with SFA, DEA does not require a priori assumptions on the underlying functional form and information on prices, so it is widely employed for the measurement of the energy efficiency. The first published paper used this approach in energy efficiency issues by Färe et al. (1983) in the field of electricity generation plant energy. During the 2010s, there are 524 articles on energy and environment that applied the DEA methods (Sueyoshi et al. 2017), and this method has been adopted by more and more scholars. DEA model was widely employed to investigate energy efficiency or environmental performance in different countries and regions, and has been deeply modified and widely applied to many sectors such as agricultural sectors (Ullah and Perret 2014; Fei and Lin 2017; Li et al. 2017), industrial sectors (Liu and Wang 2015; Wu et al. 2019), transportation sectors (Cui and Li 2014, 2015; Feng and Wang 2018), energy-intensive industries (Lin and Tan 2016), power generation industry (Liu et al. 2016), ecosystem (Susaeta et al. 2016), construction sectors (Xue et al. 2015), service sectors (Lin and Zhang 2017), and commercial banks (Wang et al. 2014). These studies showed that DEA model provides an appropriate way in modeling the production with multiple-inputs and multiple-outputs, especially widely employed in the field of energy and environmental economics.

DEA model has experienced a series of evolutions, from radial slacks to non-radial slacks, from Shepard distance function (SDF) to directional distance function (DDF) and non-radial directional distance function (NDDF) (Zhang and Choi 2014). During the evolution of DEA model, the disposal of undesirable outputs and the impact of external factors and random error were two concerned issues and the argument around these two problems promoted the development of DEA model.

Traditional DEA models, such as BCC and CCR, are radial models and hence cannot solve the coexistent of desirable and undesirable outputs. The endeavor to solve this problem promoted the improvement of DEA model from SDF to DDF and NDDF. Early scholars took undesirable outputs as inputs, or turned it into the desired outputs by SDF, implying the assumption that the desirable output changed in the same proportion as the undesirable output, which violated the actual production process. Some scholars proposed a more practical technology for weak disposability production, and employed DDF to improve the deficiency of SDF (Zhou et al. 2008). Furtherly, NDDF was employed to relax the constraints about undesirable output of DDF, making the measurement of efficiency more in line with reality (Zhou et al. 2012); then, capital, labor, and energy were all incorporated into the framework of NDDF, and the calculation of total factor energy and environmental efficiency is realized (Zhang et al. 2014).

In addition to the improvement of DDF, a slack-based measurement (SBM) model proposed by Tone (2001) gave another way to deal with different inputs and outputs, which allowed input reduction and output expansion at the same time, and does not stick to a proportionate change of input and output. And the duality form of SBM model was proposed to model the shadow price of pollution and the substitution between production factors (Zhang et al. 2015a). Considering the treatment of undesirable outputs, the SBM-undesirable model was proposed by Tone (2004), which is a new non-radial and non-oriented DEA approach and employed by a lot of studies to investigate the efficiency (Zhang and Choi 2013a; Apergis et al. 2015; Zhang et al. 2016). On this basis of SBM-DEA model, some new methods have been proposed in recent years. Considering the technological gaps between different DMUs and the movement of technological frontier, the meta-frontier slack-based efficiency measure (MSBM) and meta-frontier undesirable SBM were proposed to incorporate group heterogeneities (Zhang et al. 2015b). On the contrary of SBM, which require a DMU was evaluated at maximum distance to the frontier, a minimum distance to the weak efficiency frontier method (MinDW) was proposed to evaluate DMU at minimum distance to the frontier, allowing a DMU to reach the frontier at a less adjustment of inputs and outputs (Wang et al. 2013). In addition, considering the different importance of each inputs and outputs, an epsilon-based measure (EBM) model was proposed by setting a series of parameters to express the relative importance of inputs and desirable and undesirable outputs (Tone and Tsutsui 2010). Yu et al. (2019) synthetically studied these models (SBM, EBM, and MinDW) and their meta-frontier forms, then employed them to investigate the eco-efficiency of cities in China, and found there were small differences of the measured eco-efficiency in different models.

Another argument which promoted the development of DEA model was that the traditional DEA method does not consider the impact of external environment and random error on the efficiency value, and the results obtained are not comparable. In response, the three-stage and four-stage DEA models were the most widely used approach to investigate energy efficiency. The four-stage model proposed by Fried et al. (1999) eliminates the influence of environmental factors on technical efficiency, but it cannot eliminate the influence of statistical noise. In recent years, the three-stage model proposed by Fried et al. (2002) has effectively eliminated the interference of environmental factors and managers’ luck on the measurement of technical efficiency.

DEA model was also widely used to study the energy efficiency in the construction industry. Xue et al. (2015) employed a DEA-based Malmquist productivity index (MPI) to measure the energy efficiency of the construction industry in 26 provinces in China during 2004 to 2009. They found that energy efficiency gaps existed different regions and it is necessary for the Chinese government to develop policies to strengthen the energy management. Chen et al. (2016) employed a three-stage DEA and discriminant analysis (DA) model to measure the energy efficiency and trends of the construction industry in 30 provinces during 2003 and 2011. A constant fluctuate in the efficiency was found in most of provinces during the sample years, for the overall efficiency decreased after the peak in 2004. In addition, they found that the regional economic level has no significant impact on the energy efficiency in the construction industry and the gaps among the eastern, central, and west regions were not obvious. Zhang et al. (2018) employed the undesirable SBM-DEA model to measure the provincial energy efficiency of the construction industry from 2011 to 2015 and empirically reveal that environmental regulation has a significant impact on the energy efficiency in the construction industry.

In view of the studies about energy efficiency in China’s construction industry, DEA model provides a good way to measure the energy efficiency and can help policy-makers to improve strategies of sustainable development in China. However, there were some gaps in current research. Firstly, various DEA models were employed in these research, while few of them considered the disposal of undesirable outputs and the elimination of external influences simultaneously. Secondly, indirect CO2 emissions from the production of building materials, which was an important source of emissions, were often overlooked when CO2 emissions were considered an undesirable output of the construction industry. Thirdly, existing studies were not comprehensive enough to examine the factors influencing energy efficiency in the construction industry. Therefore, this paper combined undesirable SBM-DEA and three-stage DEA framework to accurately measure the energy efficiency of the China’s construction industry, then distinguish and eliminate the impact of external factors.

Methodology

A three-stage SBM-DEA model was adopted to evaluate the energy efficiency of the construction industry. Compared with the traditional DEA model, this method can eliminate the impact of external environment and random error on the efficiency value and conduct input and output slacks at the same time. Considering other types of updated DEA models, such as meta-frontier slack-based efficiency measure (Zhang et al. 2014), which incorporates the movement of technological frontier caused by the technological gaps between different groups of DMU, and the duality form of SBM model was proposed to model the shadow price of pollution and the substitution between production factors (Zhang et al. 2014), the three-stage undesirable SBM-DEA was more consistent with our research goals. Further studies can be carried out on the basis of these updated DEA models.

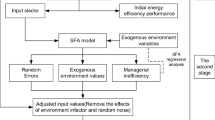

The specific framework of the three-stage undesirable SBM-DEA model is shown in Fig. 2. In stage I, the energy efficiency of each DMU is initially evaluated based on the SBM-DEA model. In stage II, SFA method was employed to decompose the influence of environmental factors and random error factors, and then adjust the input variables according to the SFA results to exclude the influence of environmental factors and random error factors. In stage III, the energy efficiency of each DMU was re-estimated using the adjusted input variables and the SBM-DEA model.

The SBM-undesirable model

The slack-based measurement (SBM) model proposed by Tone (2001) can deal with input reduction and output expansion at the same time, and does not stick to a proportionate change of input and output. However, the SBM model cannot deal with undesirable outputs. Tone (2004) proposed the SBM-undesirable model to deal with undesirable output. As a new non-radial and non-oriented DEA model, the SBM-undesirable model can conduct input and output slacks at the same time, while does not need strict proportional changes of inputs and outputs.

According to Tone’s model, a system with n decision-making units (DMUs) has three indicators: inputs, desirable outputs, and undesirable outputs, represented by three vectors ∈Rm, yg ∈ Rs1, and yb ∈ Rs2, respectively. Matrices X, Yg, and Yb were defined as follows:

where X, Yg, and Yb are greater than 0.

Then, the production possibility set P was defined as:

According to the production possibility set P, the energy efficiency of SBM-undesirable model was modified as follows:

In this model, ρ∗ represents the energy efficiency value, and \( {s}_i^{-} \), \( {\mathrm{s}}_r^g \), and \( {s}_r^b \) represent the slack of inputs and two various outputs; λ represents a weight vector used to conduct the frontier; 0 ≤ ρ∗ ≤ 1 and it strictly decreases with respect to \( {s}_i^{-} \), \( {\mathrm{s}}_r^g \), and\( {s}_r^b \). The DMU is efficient only when ρ∗ = 1 and \( {s}_i^{-} \), \( {\mathrm{s}}_r^g \), and \( {s}_r^b \) are equal to 0; this DMU is most efficient.

Stochastic frontier analysis

The energy efficiency value in stage I cannot eliminate the impact of external environment and random error, so it is not credible. In general, SFA and Tobit model are commonly employed in stage II to adjust input or output variables for more accurate efficiency values. However, Tobit model cannot eliminate the influence of random error; Fried et al. (2002) proposed a three-stage DEA model and employ the cost function SFA model in stage II, and to separate the effects of management inefficiencies, environmental factors, and random errors, they used environmental variables and a combined error term to regression the slack variables obtained in stage I.

The regression equation for the slack variables and environmental variables can be set to:

where \( {S}_{ni}^{\ast } \) is the slack variable for the n-th input of the i-th DMU, and fi(Zi, βn) represents the effect of the environment variable on the slack variable. Let fi(Zi, βn) = Ziβn and vni + Uni be the mixed error term. We assume that \( {v}_{ni}\sim N\left(0,{\sigma}_{vn}^2\right) \) represents the impact of random error and \( {u}_{ni}\sim {N}^{+}\left({\mu}^n,{\sigma}_{un}^2\right) \) obey the truncated normal distribution, representing the impact of management inefficiencies, and the two error terms are independent. When \( \gamma =\frac{\sigma_{un}^2}{\sigma_{un}^2+{\sigma}_{vn}^2} \) tends to 1, this indicates that management inefficiency dominates the slack variables; when γ tends to 0, this indicates that random error dominates the slack variables.

Then, the results of the SFA will be employed to adjust the inputs of each DMU by putting all DMUs in the same environment and luck. There are two ways of adjustment: The first way is to increase the inputs of DMUs in relatively good environment and good luck; the other way is to decrease the inputs of DMUs in relatively bad environment and bad luck. When the outputs are constant, increased inputs mean lower efficiency value while decreased inputs mean higher efficiency value. Considering the regional gaps in the construction industry and some DMUs are at extreme disadvantages, the downward adjustment may make their inputs very small, even close to 0, and the first approach was employed for the adjustment in the SFA regression. That is, put all DMUs under the worst environment and luck to increase the inputs of DMUs in relatively good environment and good luck, so their efficiency value will decrease.

The equation for adjusting input variables is as follows:

where \( {X}_{ni}^{\ast } \) is the adjusted input, and Xni is the input value from stage I. The first brackets on the right hand side of the equation indicate that all DMUs were adjusted to the worst observation environment in the sample. The second brackets indicate that all DMUs were adjusted to the most unfortunate observation state in the sample. Through this adjustment, all DMUs face the same operating environment and external luck, so it can be obtained that the impact of external environment and random error were eliminated when measuring the energy efficiency in stage III.

Data description and variables

This paper collected the data of the construction industry of China’s 30 provinces over 2005-2016 (except Tibet, Hong Kong, Macao, Taiwan), which are mainly from China Statistical Yearbook, China Energy Statistical Yearbook, China Architecture Yearbook, and China’s provincial statistical yearbooks. Table 1 shows the descriptive statistics of the data, and input and output variables are selected in the second half of this section.

Input

Considering about the existing literature on energy efficiency evaluation of China’s construction industry, the input indicators mainly cover the four aspects of labor, capital, equipment, and energy consumption (Xue et al. 2015; Chen et al. 2016; Zhang et al. 2018). In this paper, the labor of the construction industry (labor), total assets of the construction industry (capital), total power of machinery (equipment), and energy consumption converted to standard coal (energy) were used as inputs to investigate energy efficiency of the construction industry.

Desirable output

The gross output value of construction, the total profits, and the completed floor area are the main indicators of outputs in the construction industry and they are correlated with each other. In this paper, gross output value of the construction industry (GDP) was selected as a desirable output in the process of measuring energy efficiency.

Undesirable output

Carbon dioxide is a typical undesirable output of the construction industry. This paper needs to calculate the carbon dioxide emissions of the construction industry before calculating the energy efficiency of China’s provincial construction industry.

It can be seen from the relevant literature (Yan et al. 2010; Acquaye and Duffy 2010; Wu et al. 2012) that the measurement standards for carbon dioxide emissions of the construction industry have not been unified, and the current studies were always focused on the national level, and there was no comparative analysis of the carbon dioxide emissions of the construction industry in the provinces.

Carbon dioxide emissions of the construction industry are divided into direct emissions and indirect emissions. Direct carbon emissions refer to the carbon emissions generated by energy consumption in the activities of the construction industry. Indirect carbon emissions refer to the carbon emissions generated from the production of building materials. Therefore, this paper takes the concept of the whole life cycle of buildings for reference and, on the basis of measuring the direct carbon emissions of the construction industry, puts the carbon dioxide generated during the production of building materials into the carbon emission measurement framework of the construction industry. At the provincial level of the construction industry, considering the possibility of data acquisition and the practicability of model establishment, this paper calculated the indirect carbon emission of the construction industry caused by the production of steel, aluminum, wood, cement, and glass, which are the most widely used building materials. The direct carbon emission of the construction industry is caused by the consuming of twelve types of energy sources. Among them, raw coal, briquette coal, coke, gasoline, kerosene, diesel oil, fuel oil, lubricating oil, liquefied petroleum gas, natural gas, and other ten kinds of energy sources are primary energy, and heat and electricity are secondary energy sources. Based on the above, this paper establishes the following carbon dioxide emission measurement approach of the construction industry:

where \( {E}_{co_2} \) is the total carbon dioxide emissions of the construction industry, Ci is the total energy consumption of energy i, βi is the carbon dioxide emission factor of each kind of energy,Gi is the usage amount of building materials i, εi is the unit carbon dioxide emission coefficient of each kind of building material, and α is the recovery coefficient of some metal material; for the steel, α is 0.8 and for aluminum, it is 0.85. Carbon dioxide emission factor comes from Energy Information Administration of United States Department of Energy, and emission coefficient and recovery coefficient of each kind of building material come from the research of Yan et al. (2010).

Empirical results

The initial energy efficiency (stage I)

This stage employed the SBM-undesirable model in the MaxDEA software to measure the initial energy efficiency of China’s construction industry between 2005 and 2016. Table 2 shows the results, ignoring the effects of random errors and external environmental variables.

It can be seen that Beijing, Tianjin, Zhejiang, Jiangxi, Shanghai, Jiangsu, Heilongjiang, and Jilin have higher energy efficiency, and the average efficiency values of these provinces are close to 1. Guizhou, Qinghai, Inner Mongolia, Gansu, and Yunnan are less energy efficient for their average efficiency value below 0.6. Among them, the energy efficiency values of Beijing, Tianjin, Zhejiang, and Shanghai are almost 1 from 2005 to 2016, indicating that the energy efficiency of the construction industry in these provinces is high and very stable. These four provinces constitute the frontier of energy efficiency of China’s provincial construction industry. There are 113 DMUs with an efficiency value of 1; accounting for 31.4% of all the DMUs, only 21 DMUs are less than 0.5, and the overall situation of energy efficiency of China’s provincial construction industry is good but the gaps between regions are obvious. According to the estimation results, the energy efficiency of Gansu, Guangxi, Hainan, Hubei, and Chongqing has been improved obviously, while other provinces have not experienced significant fluctuations. By comparing the energy efficiency of 30 provinces horizontally, it can be seen that the highest energy efficiency is 1.000 and the lowest is below 0.500, indicating that the provinces with low energy efficiency have potential for improvement.

To study the regional differences in energy efficiency of the construction industry, 30 provinces were divided into six regions: North China, Northeast, East China, Middle of South, Southwest, and Northwest. Table 3 shows the division of these regions and Fig. 3 shows the regional differences and tendency of these regions. It is illustrated that the efficiency of the construction industry in Northeast and East China is relatively higher, and the efficiency value in Southwest and Northwest is at a lower level though it has been growing for these years. The Northeast has been declining in recent years while East China is relatively stable, and efficiency gaps between regions are decreasing by year.

SFA regression (stage II)

In stage II, an SFA model was employed to eliminate the influence of external environment as well as statistical noise. Urbanization, per capita GDP, environmental regulation, government public investment, human capital, and industrial structure were selected as environmental variables. The description of each variable and the indicators for selecting the variable were listed in Table 4.

Frontier 4.1 was used to carry out the SFA analysis and Table 5 shows the results. It was illustrated that there was a significant σ2 for each year and γ was also significantly bigger than 0.5, indicating that the impact of external factor accounted for a large proportion of the total variance, meaning the adjustment in this stage is necessary to eliminate the impact of external environment and random error. Based on the results, the impact of each environmental variable was discussed as below.

Urbanization

Table 5 shows that the level of urbanization is significantly negatively correlated with all of the four slack variables, especially the slacks of equipment and capital for the coefficients are −5.52 and −7.49, respectively. Therefore, the higher degree of urbanization will reduce the use of production factors and increase the efficiency of the construction industry. It can be explained that higher urbanization level was benefit to the efficient use of labor, equipment, capital, and energy in the construction industry.

Environmental regulation

It is showed that environmental regulation is negatively correlated with the slack of equipment and energy, while positively correlated with slack of labor and capital. In other words, environmental regulation will limit the use of equipment and energy in the construction industry, which produce more pollution and consume more energy, making construction firms to substitute equipment and energy with cleaner production factors such labor and capital. Environmental regulation is generally believed to improve the total and industrial energy efficiency (Mandal 2010; Bi et al. 2014; Zhang et al. 2016), but the promotion effect may not exist due to specific environmental regulation policies and the enforcement force (Dirckinck 2015; Lin and Xu 2017), and this impact has regional differences (Lin and Xu 2017). This section studies the correlation between environmental regulation and energy efficiency by investigating its impact on the slack variables; however, the measurement of energy efficiency in this paper was based on the frame of total factor energy efficiency (TFEE), so the substitution between these production factors resulted in the uncertain effect of environmental regulation on energy efficiency in the construction industry.

Per capita GDP

It is shown that per capita GDP do not have significant impact on each input slacks, indicating that economic development will not promote energy-environment efficiency in the construction industry, which is different form general belief. It may be explained that with the improvement of economic, the construction industry’s dependence on energy has not weakened, and the energy structure of the construction industry has not been well optimized.

Industrial structure

It is illustrated from Table 5 that industrial structure is negatively correlated with the slack of labor, while positive correlated with slack of equipment, capital, and energy, indicating that the proportion of tertiary industry is higher, the labor in the construction industry will decrease, and construction companies tend to use more equipment, capital, and energy to cover the decline in labor. This may be explained that the increase of the proportion of the tertiary industry will lead to the increase of the price of labor and the expansion of financing channels at the same time, so construction firms tend to substitute labor with relatively inexpensive production factors and it is easier for them to raise their capital through financing and loans, so the influence of industrial structure on the efficiency of the construction industry is uncertain due to the substitution between these production factors. At present, the impact of industrial structure on energy efficiency is mostly concerned on the provincial level and industrial sector (Li and Lin 2014; Xiong et al. 2019), and the influence of industrial structure on energy efficiency in the construction industry needs to be further studied.

Government public investment

This variable is positively correlated with all of the four slack variables, indicating the government fixed asset investment is not conducive to the reduction of waste of construction resources and the improvement of efficiency. This is a bit of a deviation from people’s expectations. It can be explained from another perspective, that is, the production of the construction industry is greatly affected by policies, and the government’s regulatory policies will have an important impact on the development of the construction industry. At present, the main body of the construction industry is still the government and large construction state-owned enterprises, the market economy requires the government to reduce its intervention in the market, and the government public investment to infrastructure construction or public buildings is not conducive to the improvement of the relative efficiency of the construction industry in China in the long term, indicating that construction industry may get better performance in energy and environment when government relax the intervention towards construction and give them more market incentives. The conclusion was conformed to the research on stated-owned power plants (Zhang and Choi 2013a, b; Zhang et al. 2014).

Human capital

It is illustrated that human capital is negatively correlated with all of the four slack variables, indicating that the improvement of human capital will reduce various input indicators, so as to improve the efficiency of the construction industry.

Based on the discussion for the impact of some external factors, it can be found that these factors, expect per capita GDP, would have an impact on the energy efficiency of the construction industry. Among the environmental factors, urbanization and human capital have a positive impact on energy efficiency, while government direct investment has a negative impact on energy efficiency. The impact of environmental regulation and industrial structure was uncertain on different provinces due to the substitution of production factors. Environmental regulation does not necessarily improve environmental efficiency and may have a negative impact on the development of the construction industry. Economic development has little impact on energy efficiency in the construction industry, possibly because that the energy structure and technological innovation in the construction industry are not significantly promoted in the process of economic development in recently years.

Therefore, external environment has a certain impact on energy efficiency; when the external environment became relatively equitable, the real energy efficiency will better reflect the internal management efficiency of the construction industry. Specially, the efficiency value of the construction industry in provinces facing better external environment and good luck may be higher, while provinces facing a poor external environment and luck will have lower construction efficiency. When evaluating the efficiency of the construction industry, it is necessary to adjust the external environment factors and random error factors, making all DMUs under the influence of unified external environment and random error; then, its real efficiency level is investigated more accurately in stage III.

Environmental-adjusted energy efficiency (stage III)

The input-output data in stage I can be adjusted according to the results of the SFA model regression to provide new input-output data to stage III for the evaluation and Table 6 shows the efficiency of each DMU in stage III. It is illustrated that when all provinces are facing the worst external environment and luck, there has been a decrease in overall efficiency. Among the eight provinces with higher efficiency in stage I, Beijing, Zhejiang, Shanghai, and Jiangsu are still at the frontier with the efficiency value of 1, while the efficiency values of Tianjin, Jiangxi, Heilongjiang, and Jilin have a significant decline. This phenomenon indicated that the management level of the construction industry in these provinces is not well and their efficiencies were high in stage I because they faced better external environment, while traditionally developed provinces Beijing, Zhejiang, Shanghai, and Jiangsu have a high level of management in the construction industry so their efficiency did not decrease after adjustment. There are 73 DMUs with an efficiency value equal to 1, 40 less than the number of stage I and DMUs with an efficiency below 0.5 which is more than 50%, showing that management inefficiency is widespread in the construction industry.

Figure 4 shows the change of energy efficiency of China’s construction industry in six regions of China. It is illustrated that the efficiency of the construction industry in Northeast and East China is relatively higher; the efficiency value in Northwest China is at a lowest level. Energy efficiency in East China, Middle of China, and North China was on the rise, while other regions are clearly fluctuating, and there was a sharp drop after 2011 in Northeast China, indicating that the management level of its construction industry has deteriorated.

Figure 5 shows the changes of average efficiency in stage I and stage III. When all DMUs are faced with the worst external environment and luck, the average efficiency has decreased in most provinces. In terms of the “high-low” provinces, such as Hainan, Ningxia, and Qinghai, the dramatic decrease of energy efficiency when facing the poorest external environment and luck showed that their relatively higher energy efficiency in stage I was benefit from their superior external environment, but the management level in their construction industry limits the potential to be realized. The “high-high” provinces, especially Beijing, Zhejiang, and Shanghai, have an efficiency value of 1 in both stage I and stage III, indicating that their environmental conditions and management level reached a high level. In terms of limited “low-high” provinces (Jiangsu, Hubei, and Guangdong), there was a slight increase after the adjustment, indicating that the external environment limits the contributions of the management level in their construction industry, and the improvement of energy efficiency needs to start from improving external environment.

At the regional level, in the eastern region, the construction industry management level is high and the environmental conditions are good, so the efficiency level is very high; of central and northern region, the management level has also been gradually improve; in the western region, construction efficiency is low not only because of its natural and social environment, the management level of the construction industry itself is also the important reasons of the low efficiency. Although the natural and social environment in Northeast China is better, its management level is low, which limits its efficiency in the construction industry.

Conclusion and policy implications

This paper employed the three-stage undesirable SBM-DEA to evaluate the energy efficiency of the construction industry of 30 provinces in China from 2005 to 2016 and discussed the influence of external factors by SFA approach in stage II. The following conclusions could be obtained through the empirical results. Firstly, after the adjustment which let each DMU facing the poorest external factors and random error, the energy efficiency of China’s construction industry showed a significant decline, indicating that the low efficiency of management in the construction industry is an important factor leading to the low level of energy efficiency in China’s construction industry. Secondly, compared with the “high-high” provinces, which has made full use of the superior external environment by their high management level, the “high-low” provinces need to fully realize the potential in promoting energy efficiency of its external environment by improving its own management of construction. On the contrary, the “low-high” provinces need to improve the external environment to ease its restrictions on the level of management in the construction industry. Thirdly, among the external environmental factors, urbanization and human capital have a positive impact on energy efficiency, while government direct investment has a negative impact on energy efficiency. The impact of environmental regulation and industrial structure was uncertain on different provinces due to the substitution of production factors. Environmental regulation does not necessarily improve environmental efficiency and may have a negative impact on the development of the construction industry. Economic development has little impact on energy efficiency in the construction industry, possibly because that the energy structure and technological innovation in the construction industry are not significantly promoted in the process of economic development in recently years. In response to the above conclusions, some policy applications were proposed. (1) The promotion of the energy efficiency of the construction industry should not only rely on improving the external environment, but also take full account of the internal management level. The potential to improve the energy efficiency relies on improving the management level in Northeast China, while in “low-high” province, this should shed light on improving external environment. (2) Improving the urbanization level and the technical level of the construction industry will promote the improvement of the energy efficiency of the construction industry. (3) The government should reduce intervention in the construction industry and focus on ensuring fair competition in the market. At the same time, the characteristics of the construction industry should be taken into account when carrying out environmental regulation. (4) In the process of economic development, construction enterprises need to optimize the energy structure and enhance the human capital investment, which will help Chinese construction industry to improve energy efficiency and achieve the goal of energy conservation and emission reduction.

Data Availability

The datasets analyzed during the current study are available from China National Bureau of Statistics.

Notes

The data come from China Statistical Yearbook (2018), National Bureau of Statistics of China.

The data come from China Statistical Yearbook (2018), National Bureau of Statistics of China.

The data and figure come from China building energy consumption report (2018), China Association of Building Energy Efficiency.

The data come from China building energy consumption report (2018), China Association of Building Energy Efficiency.

References

Acquaye AA, Duffy AP (2010) Input-output analysis of Irish construction sector greenhouse gas emissions. Build Environ 45(3):784–791

Apergis N, Aye GC, Barros CP, Gupta R, Wanke P (2015) Energy efficiency of selected OECD countries: a slacks based model with undesirable outputs. Energy Econ 51:45–53

Bi GB, Song W, Zhou P, Liang L (2014) Does environmental regulation affect energy efficiency in China’s thermal power generation? Empirical evidence from a slacks- based DEA model. Energy Policy 66:537–546

Chen Y, Liu B, Shen Y, Wang X (2016) The energy efficiency of China’s regional construction industry based on the three-stage DEA model and the DEA-DA model. KSCE J Civ Eng 20(1):34–47

Cui Q, Li Y (2014) The evaluation of transportation energy efficiency: an application of three-stage virtual frontier DEA. Transp Res Part D: Transp Environ 29:1–11

Cui Q, Li Y (2015) Evaluating energy efficiency for airlines: an application of VFB-DEA. J Air Transp Manag 44–45:34–41

Dirckinck K (2015) The options of local authorities for addressing climate change and energy efficiency through environmental regulation of companies. J Clean Prod 98(1):175–184

Färe R, Grosskopf S, Logan J (1983) The relative efficiency of Illinois electric utilities. Resour Energy 5(4):349–367

Fei R, Lin B (2017) Technology gap and CO2 emission reduction potential by technical efficiency measures: a meta-frontier modeling for the Chinese agricultural sector. Ecol Indic 73:653–661

Feng C, Wang M (2018) Analysis of energy efficiency in China’s transportation sector. Renew Sust Energ Rev 94(June):565–575

Feng F, Li Z, Ruan Y, Xu P (2016) An empirical study of influencing factors on residential building energy consumption in Qingdao City, China. Energy Procedia 104:245–250

Fried H, Schmidt S, Yaisawarng S (1999) Incorporating the operating environment into a nonparametric measure of technical efficiency. J Prod Anal 12:249–267

Fried H, Lovell C, Schmidt S, Yaisawarng S (2002) Accounting for environmental effects and statistical noise in Data Envelopment Analysis. J Prod Anal 17:157–174

Li K, Lin B (2014) The nonlinear impacts of industrial structure on China’s energy intensity. Energy 69:258–265

Li N, Jiang Y, Yu Z, Shang L (2017) Analysis of agriculture total-factor energy efficiency in China based on DEA and Malmquist indices. Energy Procedia 142:2397–2402

Lin B, Tan R (2016) Ecological total-factor energy efficiency of China’s energy intensive industries. Ecol Indic 70:480–497

Lin J, Xu C (2017) The impact of environmental regulation on total factor energy efficiency: a cross-region analysis in China. Energies 10(10):1578

Lin B, Zhang G (2017) Energy efficiency of Chinese service sector and its regional differences. J Clean Prod 168:614–625

Liu Y, Wang K (2015) Energy efficiency of China’s industry sector: an adjusted network DEA (data envelopment analysis)-based decomposition analysis. Energy 93:1328–1337

Liu J, Liu H, Yao X-L, Liu Y (2016) Evaluating the sustainability impact of consolidation policy in China’s coal mining industry: a data envelopment analysis. J Clean Prod 112:2969–2976

Lu Y, Cui P, Li D (2016) Carbon emissions and policies in China’s building and construction industry: evidence from 1994 to 2012. Build Environ 95:94–103

Mandal SK (2010) Do undesirable output and environmental regulation matter in energy efficiency analysis? Evidence from Indian cement industry. Energy Policy 38(10):6076–6083

Sueyoshi T, Yuan Y, Goto M (2017) A literature study for DEA applied to energy and environment. Energy Econ 62:104–124

Susaeta A, Adams DC, Carter DR, Dwivedi P, Adams DC, Carter DR (2016) Climate change and ecosystem services output efficiency in Southern Loblolly pine forests. Environ Manag 58(3):417–430

Tone K (2001) Theory and Methodology A slacks-based measure of efficiency in data envelopment analysis. Eur J Oper Res 130:498–509

Tone K (2004) Dealing with undesirable outputs in DEA: a slacks-based measure (SBM) approach. North American Productivity Workshop 2004, Toronto, 23-25 June 2004, 44-45

Tone K, Tsutsui M (2010) An epsilon-based measure of efficiency in DEA – a third pole of technical efficiency. Eur J Oper Res 207:1554–1563

Ullah A, Perret SR (2014) Technical- and environmental-efficiency analysis of irrigated cotton-cropping systems in Punjab, Pakistan using data envelopment analysis. Environ Manag 54(2):288–300

Wang K, Huang W, Wu J, Liu Y-N (2014) Efficiency measures of the Chinese commercial banking system using an additive two-stage DEA. Omega 44:5–20

Wang Q, Zhao Z, Zhou P, Zhou D (2013) Energy efficiency and production technology heterogeneity in China: a meta-frontier DEA approach. Econ Model 35:283–289

Wu HJ, Yuan ZW, Zhang L et al. (2012) Life cycle energy consumption and CO2 emission of an office building in China. Int J Life Cycle Assess 17(2):105–2118

Wu J, Li M, Zhu Q, Zhou Z, Liang L (2019) Energy and environmental efficiency measurement of China’s industrial sectors: a DEA model with non-homogeneous inputs and outputs. Energy Econ 78:468–480

Xiong S, Ma X, Ji J (2019) The impact of industrial structure efficiency on provincial industrial energy efficiency in China. J Clean Prod 215:952–962

Xue X, Wu H, Zhang X, Dai J, Su C (2015) Measuring energy consumption efficiency of the construction industry: the case of China. J Clean Prod 107:509–515

Yan H, Shen Q, Fan LCH, Wang Y, Zhang L (2010) Greenhouse gas emissions in building construction: a case study of One Peking in Hong Kong. Build Environ 45(4):949–955

Yu Y, Huang J, Zhang N (2019) Modeling the eco-efficiency of Chinese prefecture-level cities with regional heterogeneities: a comparative perspective. Ecol Model 402(March):1–17

Zhang N, Choi Y (2013a) Environmental energy efficiency of China’s regional economies: a non-oriented slacks-based measure analysis. Soc Sci J 50(2):225–234

Zhang N, Choi Y (2013b) Total-factor carbon emission performance of fossil fuel power plants in China: a metafrontier non-radial Malmquist index analysis. Energy Econ 40:549–559

Zhang N, Choi Y (2014) A note on the evolution of directional distance function and its development in energy and environmental studies 1997-2013. Renew Sust Energ Rev 33:50–59

Zhang Q, Crooks R (2012) Toward an environmentally sustainable future: country environmental analysis of the People’s Republic of China. Asian Development Bank, Manila

Zhang N, Kong F, Choi Y, Zhou P (2014) The effect of size-control policy on unified energy and carbon efficiency for Chinese fossil fuel power plants. Energy Policy 70:193–200

Zhang N, Kong F, Kung CC (2015a) On modeling environmental production characteristics: a slacks-based measure for China’s Poyang Lake ecological economics zone. Comput Econ 46(3):389–404

Zhang N, Kong F, Yu Y (2015b) Measuring ecological total-factor energy efficiency incorporating regional heterogeneities in China. Ecol Indic 51:165–172

Zhang C, He W, Hao R (2016) Analysis of environmental regulation and total factor energy efficiency. Curr Sci 110(10):1958–1968

Zhang J, Li H, Xia B, Skitmore M (2018) Impact of environment regulation on the efficiency of regional construction industry: a 3-stage Data Envelopment Analysis (DEA). J Clean Prod 200:770–780

Zhou P, Ang, BW, Poh KL (2008) Measuring environmental performance under different environmental DEA technologies. Energy Econ 30(1):1–14

Zhou P, Ang BW, H Wang (2012) Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur J Oper Res 221(3):625–635

Funding

This work was supported by the National Natural Science Foundation of China (No. 71673250); Zhejiang Foundation for Distinguished Young Scholars (LR18G030003); Major Projects of the Key Research Base of Humanities under the Ministry of Education (No. 14JJD 790019); and Zhejiang Philosophy and Social Science Foundation (No. 18NDJC184YB).

Author information

Authors and Affiliations

Contributions

Yufeng Chen: conceptualization; methodology; software; writing—reviewing and editing.

Lihua Ma: data curation; writing—original draft preparation; visualization.

Zhitao Zhu: formal analysis; writing—reviewing and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Roula Inglesi-Lotz

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Ma, L. & Zhu, Z. The environmental-adjusted energy efficiency of China’s construction industry: a three-stage undesirable SBM-DEA model. Environ Sci Pollut Res 28, 58442–58455 (2021). https://doi.org/10.1007/s11356-021-14728-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-14728-2