Abstract

In this experimental work, the performance of hemispherical distiller has been enhanced via phosphate pellets. To investigate the best approach to the phosphate pellet utilization in a basin of hemispherical distiller to achieve the highest performance, the present study was carried out in two stages. In the first stage, 250 g of phosphate pellets was arranged in a layer of 5 mm thickness placed at the bottom of the basin. In the second stage, the phosphate pellets were distributed in a homogeneous manner in basin salt water with two concentrations 1% (10 g/L) and 2% (20 g/L) without aggregation on the basin. To achieve this idea, in the first test stage, two distillers were compared, the first is the conventional hemispherical distiller which represents the reference distiller (CHSS) and the second is the modified hemispherical distiller with a phosphate layer (MHSS-PL). In the second test stage, three distillers were compared, the first is the CHSS which represents the reference distiller, the second is the modified hemispherical distiller which contained 1% phosphate (MHSS-1), and the third is the modified hemispherical distiller which contained 2% phosphates (MHSS-2). The experimental results show that the cumulative yield was 4.6, 6.32, 6.15, and 6.85 L/m2·day for CHSS, MHSS-PL, MHSS-1, and MHSS-2, respectively. The results showed that the utilization of the phosphate pellets as a storage medium enhanced the performance of the hemispherical distiller. The enhancement in the distiller productivity was 37.4, 33.7, and 47.9% for MHSS-PL, MHSS-1, and MHSS-2, respectively, compared to conventional hemispherical solar still (CHSS). The peak enhancement in the productivity was achieved in the case of modified hemispherical solar still with 2% (20 g/L) phosphate pellets (MHSS-2).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Modern science is now heading to research the possibility of exploiting renewable energy in all industrial fields, including desalination (Kabeel et al. 2018). Since the sun is the main source of energy in the universe, it is possible to take advantage of solar energy directly or indirectly by converting it into another type of energy (thermal, mechanical, electrical, or chemical) (Khechekhouche et al. 2020a). Thus, we reduce the dependence on traditional energy sources such as oil, gas, coal, and nuclear energy, as the use of such elements causes environmental problems (Manokar et al. 2018). The lack of clean water and the scarcity of natural resources caused by drought and overexploitation of groundwater have become a major problem threatening people’s lives. Therefore, desalination of the brackish water or seawater was used by solar distillation techniques (Kabeel et al. 2017; Khechekhouche et al. 2020b; Dumka et al. 2019; Rabhi et al. 2017; Elango et al. 2015; Al-Molhem and Eltawil 2020; Hassan et al. 2020; El-Sebaii and Khallaf 2020; Balachandran et al. 2020a). Distillation in greenhouses is one of the applications of low-temperature thermal energy that involves converting solar (radiative) energy into thermal energy to produce fresh water from salt water (Kabeel et al. 2020; Khechekhouche et al. 2019a). Madhu et al. (2018) investigated the effect of sand cuboidal boxes in single slope solar still. The experimental results showed that the cumulative yield from single slope solar still with and without sand cuboidal boxes is found to be 3.3 and 1.89 L/m2·day, respectively. Results showed that the maximum exergy efficiency with sand cuboidal boxes is found as 13.2%, and it is less than the conventional solar still without sand cuboidal boxes. Sakthivel and Shanmugasundaram (2008) used the absorbing materials (black granite gravel) as a thermal storage material in the solar still. The results showed that the utilization of black granite gravel increased productivity by 17% compared to the conventional solar distiller. Naima and Abd El Kawi (2002a) used charcoal particles of different sizes (coarse, medium, and fine) as storage materials in modified solar stills. They concluded that the daily throughput of improved solar images with coarse charcoal particles is greater than that of the shots without a storage medium. Khechekhouche et al. (2019b) placed a layer of sand in a solar still with a thickness of the salt water of 1 cm. The results showed that the distiller without a sand layer produced 3.8708 L/m2·day and the distiller with a sand layer produced 2.7352 L/m2·day. Naima and Abd El Kawi (2002b) used a mixture of paraffin wax, paraffin oil, and water with aluminum turning added as storage material in nonconventional solar stills. The results concluded that the daily productivity of the nonconventional solar stills with the mixture of energy storage materials is greater than the productivity of the distillers without the mixture of storage materials. Rahim (2003) devised a new method of storing thermal energy in horizontal solar distillers via aluminum sheets as thermal storage materials. The results showed that using aluminum sheet was effective. Kabeel et al. (2019) compared the daily yield from single slope solar still for water depth of 20, 30, 40, and 50 with modified solar still with cement-coated red bricks. Bassam et al. (2003) studied the effect of yellow sponge, black sponge, and black steel and black coals as absorbers in solar distillate products. The results showed that the daily productivity when using a yellow sponge was much better compared to using other materials. Salah et al. (2009) compared the productivity of the solar distillate when using a black uncoated metal sponge and black rocks as absorbents. The results concluded that the daily productivity using black rocks is better than the daily productivity of the distillate when using the black uncoated metal sponge. Kalidasa et al. (2010) studied the effect of different materials and sizes (quartz rocks, concrete pieces, and washed stones) as thermal storage materials in a single basin, double slope solar still, with the minimum depth of the basin. The experimental results showed that large-sized quartz rock achieved the largest daily accumulation. Attia et al. (2020) studied the effect of 42 aluminum balls as energy storage materials on the performance of the solar still. The results concluded that the daily productivity was 5.09 L/m2/day when using aluminum balls, while it was 3.71 L/m2·day without using aluminum balls. Kalidasa and Srithar (2011) compared the effect of different types of wick (light cotton cloth, sponge sheet, coir mate, and waste cotton pieces) on the cost-effectiveness of the solar distillate. The results concluded that the daily productivity when using light black cotton cloth was higher than the daily productivity when using the rest of the wick. Panchal and Shah (2011) studied the effect of aluminum panels and galvanized iron as absorbents. The results showed that the cumulative distillation of solar still containing aluminum panels gave a 30% increase in the productivity compared to conventional still, and the cumulative distillation of solar still containing galvanized iron improved the productivity 12% more than conventional still. Balachandran et al. (2020b) empirically examined the influences of hybrid composite insulation and water film cooling on a yield of solar distiller integrated with a photovoltaic cell. They conducted that the accumulative yield improved by 35% for utilizing the hybrid composite insulation and water film cooling compared to the traditional distiller. Kabeel et al. (2016) studied the impact of a glass cover angle on the yield of a pyramid distiller. Kabeel and Abdelgaied (2017a) improved the yield of a traditional solar distiller by utilizing the multigroups of concentric pipes fixed in the basin. Thakur et al. (2020) empirically studied the effect of a V-type concentrator on a yield of the solar distiller. They found that the utilization of a V-type concentrator integrated with a solar distiller improved the yield by 68.6% at water depth 3 cm compared to the traditional distiller. Sharshir et al. (2020) studied the influences of exfoliated graphite flakes, carbon foam, and exfoliated graphite flakes and carbon foam on a yield of a solar distiller with wick. Kabeel and Abdelgaied (2017b) empirically studied the behavior of solar still with storage materials integrated with cylindrical concentrators. Malik et al. (2020) theoretically studied the behavior of a weir-type solar distiller with storage materials. Kabeel and Abdelgaied (2019) empirically examined the impact of hot air injection technology on the yield of a solar distiller coupled photovoltaic panel with cooling technology and reflectors. Mohaisen et al. (2020) examined empirically the impact of adding the condensing cavity on a yield of solar distiller. They conducted that the yield improved by 30% due to utilization of the condensing cavity. Abdelgaied et al. (2020) improved the yield of the tubular distiller by utilizing the inclined pin fins and external condenser. They conducted that the yield improved by 70.2% for utilizing the inclined pin fins and external condenser.

The aim of the experimental work is to enhance the performance of the hemispherical distillation unit by phosphate pellets. The spherical distiller has the advantage of minimum volume with peak surface area. To achieve the best technique on the phosphate pellet utilization in the hemispherical distillation basin, the present study included two stages. In the first stage, 250 g of the phosphate pellets with dimensions 0.1-2 mm was used as a layer of 5 mm thickness fixed at the bottom of the hemispherical distillation basin, and salt water was placed on top of the phosphate layer. In the second stage, the phosphate pellets (their dimensions within 1.5 mm) were distributed in an organized manner with the salt water in the hemispherical distillation basin with two different concentrations of 1% (10 g/L) and 2% (20 g/L). The experiments have been executed in April and May 2020.

Experimental setup

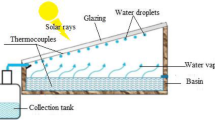

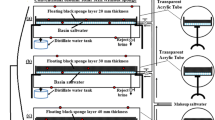

This experiment studies the effect of phosphate pellets in different sizes on hemispherical solar still performance. To obtain the finest way for phosphate pellet utilization in the hemispherical distillation basin to achieve the highest performance, the present study was done in two stages. In the first stage, 250 g of phosphate pellets of 0.1-2 mm dimensions was arranged in a layer of 5 mm thickness placed at the bottom of the hemispherical distillation basin covered with the salt water. In the second case, phosphate pellets (their dimensions within 1.5 mm) were distributed in an organized manner within the salt water in the hemispherical distillation basin with two different concentrations 1% (10 g/L) and 2% (20 g/L) without aggregation on the bottom of the basin. To achieves this idea, in the first test stage, two distillers were compared, the first is the conventional hemispherical distiller which represents the reference distiller (CHSS) and the second is the modified hemispherical distiller with a phosphate layer (MHSS-PL). In the second test stage, three distillers were compared, the first is the CHSS which represents the reference distiller, the second is the modified hemispherical distiller which contained 1% phosphate (MHSS-1), and the third is the modified hemispherical distiller which contained 2% phosphates (MHSS-2). For this purpose, three hemispherical basins, each of 0.1 m2 basin area, were made of wood with a thickness of 7 cm. The basin was mounted on a wooden base with a depth of 3.5 cm and a diameter of 38 cm, and a channel was formed to collect the condensed distilled water on the plastic cover. For better absorption of solar energy, the interior surfaces of the basins are painted black. The basin of the hemispherical solar distiller was covered by transparent plastic with 3 mm thick and 40 cm diameter. The density and thermal conductivity of the transparent plastic are 1270 kg/m3 and 0.3 W/m K, respectively. Figs. 1 and 2 show the schematic diagram and photographic view of hemispherical solar still.

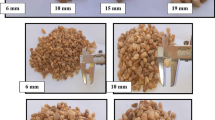

Phosphate is available in many regions of the world, and credit to its component and property, it is a material for storing energy. Phosphates are found in nature rocks and can be easily divided into dark gray pellets. In Fig. 3, a microscopic image of the phosphate granules appeared with whose dimensions utilized in the present work. Table 1 shows the natural minerals that make up the phosphate rocks (Jasinski et al. 2020; Syers et al. 1986). Table 2 shows the physical properties of phosphate (Jasinski et al. 2020; Syers et al. 1986).

Fig. 4 shows the experimental test rig for the first case of CHSS and MHSS-PL while Fig. 5 shows the experimental test rig for the second case of CHSS, MHSS-1, and MHSS-2. The experiments were conducted in the first test stage on April 30, 2020, and in the second test stage on May 25, 2020, in the southeast of Algeria (06° 47′ E and 33° 30′ N). Table 3 shows the weather conditions for April 30, 2020, and May 25, 2020. The experiments were conducted for 12 hours with initial salt water depth of 2 cm in the three basins (CHSS, MHSS-PL, MHSS-1, and MHSS-2). Table 4 shows measurement devices, their accuracy, and standard uncertainties. The only generated experimental result is the productivity with a standard uncertainty of 0.6 mL.

Results and discussions

Solar radiation as a heat source for water desalination and the ambient temperature for condensation on glass surface daily variation are given in Fig. 6. The maximum peak solar intensity reached 1004 W/m2 and 1008 W/m2 at 12:00 AM for 30 April and 25 May 2020, respectively. While the average daily solar radiation intensity reached 633 W/m2 and 647 W/m2 for 30 April and 25 May 2020, respectively, this gives a good indication of high daily solar energy. The measured solar radiation and the ambient temperature are recorded experimentally and displayed in Fig. 1, to indicate the actual climatic conditions surrounding the experimental test-ring at the testing time.

The distilled water productivity is measured during the day, and at day end, the distillate water productivity is collected to give daily productivity. As a comparative study, the experimentation was conducted in two stages. In the first test stage, two distillers were compared, the first is (CHSS) which represents the reference distiller and the second is the modified hemispherical distiller with a phosphate layer (MHSS-PL). In the second test stage, three distillers were compared, the first is the CHSS which represents the reference distiller, the second is the modified hemispherical distiller which contained 1% phosphate (MHSS-1), and the third is the modified hemispherical distiller which contained 2% phosphates (MHSS-2). In the two experimental stages, the glass and basin water temperatures are measured during the day representing the main motive heat transfer within the distiller domain. Natural convection heat transfer within the air in the distiller is mainly dependent on the buoyancy effect due to the temperature difference between the basin water and distiller glass cover. The higher the temperature difference, the larger the heat transfer coefficient, and consequently the higher the water yield. The glass temperature is mainly dependent on the ambient temperature which is approximately the same for the two test cases; however, the basin temperature is surely more sensitive to the energy storage in the basin. The higher the energy storage, the higher the basin water temperature; this will cause high productivity due to the enhanced natural convection effect. So, the addition of phosphate pellets will enhance the distiller productivity. Fig. 7 represents the temperature difference between the basin water and the glass cover. The addition of phosphate pellets increases the basin water temperature with a high-temperature difference level at day end due to the energy storage. As shown in Fig. 7, the use of phosphate pellets as an energy store increases the temperature difference between basin water and the glass cover, while the MHSS-PL gives the higher rate up to 3.3 times CHSS; MHSS-1 gives the higher rate up to 2.9 times CHSS; and MHSS-2 gives the higher rate up to 3.2 times CHSS. With the measured results in Fig. 7, the hourly daily productivity of the CHSS, MHSS-PL, MHSS-1, and MHSS-2 is given in Fig. 8. The hourly daily productivity variation has the same trend as the solar radiation with the peak at 1:00 PM but with a large scale in the presence of phosphate pellets. The peak hourly productivity in the case of MHSS-PL is 1150 mL/m2·h, 1100 mL/m2·h in the case of MHSS-1, and 1200 mL/m2·h in the case of MHSS-2, while the conventional case CHSS is 900 mL/m2·h. The presence of phosphate pellets enhanced the distiller productivity.

The hourly productivity presented in Fig. 8 is integrated during the day to give the total daily productivity, Fig. 9. MHSS-PL gives the high productivity up to 6320 mL/m2·day, MHSS-1 gives productivity up to 6150 mL/m2·day, and MHSS-2 gives the high productivity up to 6800 mL/m2·day, while the conventional one CHSS gives 4600 mL/m2·day. The overall accumulated daily productivity enhanced by 37.4%, 33.7%, and 47.9% for MHSS-PL, MHSS-1, and MHSS-2, compared to CHSS, respectively. Table 5 shows the results of the cumulative yield for CHSS, MHSS-PL, MHSS-1, and MHSS-2 recorded during trial hours. The results conducted that distributing the phosphate pellets in an organized manner within the salt water in the hemispherical distillation basin by 2% (20 g/L) represented the better method for utilization of the phosphate pellets to achieve the highest cumulative yield of the hemispherical distillation.

One of the important concluded results in the use of phosphate as a storage medium in the solar still is the limitation of its amount and its arrangement. MHSS-2 with only 2% (20 g/L) pellet phosphate is more effective than MHSS-PL with 250 g of phosphate pellets arranged in a layer of 5 mm thickness. This result is explained as phosphate absorbing heat as sensible (no phase change), and hence, a small amount with a high surface area (pellet MHSS) will be more effective than a large amount with only a small surface area in contact with the basin water surface (MHSS-PL).

The daily thermal and exergy efficiencies of the four different configurations of hemispherical solar distillers (CHSS, MHSS-PL, MHSS-1, and MHSS-2) are presented in Table 6. As presented in this table, the daily thermal and exergy efficiencies of CHSS are 40.1% and 3.63%; MHSS-PL is 55% and 5.31%; MHSS-1 is 53.5% and 5.2%; and MHSS-2 is 59.6% and 5.96%, respectively. The utilization of the phosphate pellets with concentration 2% (MHSS-2) increases in the daily thermal and exergy efficiencies up to 48.6% and 64.2%, respectively, as compared to CHSS. The daily thermal and exergy efficiencies of hemispherical solar distiller are calculated as follows.

Daily thermal efficiency ηdaily of hemispherical solar distiller was calculated as follows:

The daily exergy efficiency ηdaily,exe was calculated as follows (Manokar et al. 2018):

The hourly exergy energy output Exoutput was calculated as follows (Manokar et al. 2018):

The hourly exergy energy input Exinput was calculated as follows (Manokar et al. 2018):

The latent heat hfg followed by Kabeel and Abdelgaied (2017b):

where \( {\dot{m}}_{ev} \) is the hourly productivity (kg/m2·h), I(t) is the solar intensity (W/m2), As is the absorber area (m2), Ta is ambient temperature (°C), and Tw is water temperature (°C).

The cumulative yield of the proposed hemispherical solar distillers is compared with the previous modification of the hemispherical distiller’s systems in Table 7. It is clear that the proposed modified hemispherical distiller with phosphate pellets (MHSS-2) gives the higher productivity as compared to the previous modifications.

Economic evaluation

A comprehensive economic study was conducted to determine the time period required to recover the total cost for each CHSS, MHSS-PL, MHSS-1, and MHSS-2 as shown in Table 8. As shown, the recovery period required to recover the total cost for each CHSS, MHSS-PL, MHSS-1, and MHSS-2 reached 33, 24, 25, and 22 days, respectively.

Conclusions

This study aims to enhance the performance of the hemispherical solar distillers by utilizing phosphate pellets. The experiments were conducted on April 30 and May 25, 2020, for a period of 12 hours per day. Based on the experimental results, we conclude the following:

-

Phosphate pellets improve the hemispherical solar still efficiency well.

-

The daily accumulation resulting from CHSS is 4.6 L/m2·day, 6.32 L/m2·day for MHSS-PL, 6.15 L/m2·day for MHSS-1, and 6.8 L/m2·day for MHSS-2.

-

The overall accumulated daily productivity enhanced by 37.4%, 33.7%, and 47.9% for MHSS-PL, MHSS-1, and MHSS-2, compared to CHSS, respectively.

-

The distributed phosphate pellets in an organized manner within the salt water in the hemispherical distillation basin by 2% (20 g/L) represented the better method for utilization of the phosphate pellets to achieve the highest cumulative yield of the hemispherical distillation.

Finally, it can be concluded that increasing phosphate pellets which are distributed in an organized manner within the salt water significantly enhances the productivity in hemispherical solar distillation, increasing efficiency and productivity, and this is better compared to the phosphate pellets arranged in a layer fixed at the bottom of hemispherical distillation basin.

Availability of data and materials

Not applicable

Abbreviations

- CHSS:

-

Conventional hemispherical solar still

- MHSS-PL:

-

Modified hemispherical solar still with a phosphate layer

- MHSS-1:

-

Modified hemispherical solar still with 1% (10 g/L) phosphate pellets

- MHSS-2:

-

Modified hemispherical solar still with 2% (20 g/L) phosphate pellets

References

Abdelgaied M, Harby K, Eisa A (2020) Performance improvement of modified tubular solar still by employing vertical and inclined pin fins and external condenser: an experimental study. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-11585-3

Al-Molhem YA, Eltawil MA (2020) Enhancing the double-slope solar still performance using simple solar collector and floatable black wicks. Environ Sci Pollut Res 27:35078–35098

Arunkumar T, Jayaprakash R, Denkenberger D, Ahsan A, Okundamiya MS, Kumar S, Tanaka H, Aybar HS (2012) An experimental study on a hemispherical solar still. Desalination 286:342–348

Attia MEH, Driss Z, Manokar AM, Sathyamurthy R (2020) Effect of aluminum balls on the productivity of solar distillate. Journal of Energy Storage 30:101466

Bassam A, Abu-Hijleh K, Hamzeh M, Rababa H (2003) Experimental study of a solar still with sponge cubes in basin. Energy Convers Manag 44:1411–1418

Balachandran GB, David PW, Mariappan RK, Kabeel AE, Athikesavan MM, Sathyamurthy R (2020a) Improvising the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. Environ Sci Pollut Res 27:32191–32204

Balachandran GB, David PW, Vijayakumar ABP, Kabeel AE, Athikesavan MM, Sathyamurthy R (2020b) Enhancement of PV/T-integrated single slope solar desalination still productivity using water film cooling and hybrid composite insulation. Environ Sci Pollut Res 27:32179–32190

Dumka P, Sharma A, Kushwah Y, Singh Raghav A, Mishra DR (2019) Performance evaluation of single slope solar still augmented with sand-filled cotton bags. Journal of Energy Storage 25:100888

El-Sebaii A, Khallaf AE (2020) Mathematical modeling and experimental validation for square pyramid solar still. Environ Sci Pollut Res 27:32283–32295

Elango T, Kannan A, Murugavel K (2015) Performance study on single basin single slope solar still with different water nanofluids. Desalination 360:45–51

Hassan H, Yousef MS, Ahmed MS, Fathy M (2020) Energy, exergy, environmental, and economic analysis of natural and forced cooling of solar still with porous media. Environ Sci Pollut Res 27:38221–38240

Jasinski SM, Rock P, Survey USG (2020) Mineral commodity summaries MC. PP:122–123

Kabeel AE, Abdelgaied M, Eisa A (2018) Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J Clean Prod 183:20–25

Kabeel AE, Teamah MA, Abdelgaied M, Abdel Aziz GB (2017) Modified pyramid solar still with v-corrugated absorber plate and PCM as a thermal storage medium. J Clean Prod 161:881–887

Kabeel AE, El-Agouz E, Athikesavan MM, Ramalingam RD, Sathyamurthy R, Prakash N, Prasad C (2020) Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: an experimental approach. Environ Sci Pollut Res 27:32218–32228

Kabeel AE, El-Agouz ES, Athikesavan MM, Ramalingam RD, Sathyamurthy R, Prakash N, Prasad C, (2019) Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: an experimental approach. Environmental Science and Pollution Research, 1-11.

Kabeel AE, Abdelgaied M, Almulla N, (2016). Performances of pyramid-shaped solar still with different glass cover angles: experimental study, 7th International Renewable Energy Congress (IREC). IEEE 1–6.

Kabeel AE, Abdelgaied M (2017a) Performance enhancement of modified solar still using multi-groups of two coaxial pipes in basin. Appl Therm Eng 118:23–32

Kabeel AE, Abdelgaied M (2017b) Observational study of modified solar still coupled with oil serpentine loop from cylindrical parabolic concentrator and phase changing material under basin. Sol Energy 144:71–78

Kabeel AE, Abdelgaied M (2019) Performance enhancement of a photovoltaic panel with reflectors and cooling coupled to a solar still with air injection. J Clean Prod 224:40–49

Kalidasa MK, Srithar K (2011) Performance study on basin type double slope solar still with different wick materials and minimum mass of water. Renew Energy 36:612–620

Kalidasa MK, Sivakumar S, Riaz AJ, Chockalingam KKSK, Srithar K (2010) Single basin, double slope, solar still with minimum basin depth and energy Storing materials. Appl Energy 87:514–523

Khechekhouche A, Kabeel AE, Benhaoua B, Attia MEH, El-said EMS (2020a) Traditional Solar distiller improvement by a single external refractor under the climatic conditions of the El Oued region, Algeria. Desalin Water Treat 177:23–28

Khechekhouche A, Benhaoua B, Attia MEH, Driss Z, Manokar M, Ghodbane M (2020b) Polluted groundwater treatment in southeastern Algeria by solar distillation. Algerian Journal of Environmental Science and Technology 6(1):1207–1211

Khechekhouche A, Benhaoua B, Kabeel AE, Attia MEH, El-Maghlany WE (2019a) Improvement of solar distiller productivity by a black metallic plate of zinc as a thermal storage material. J Test Eval 49(2) (in press)

Khechekhouche A, Benhaoua B, Manokar M, Sathyamurthy R, Kabeel AE, Driss Z (2019b) Sand dunes effect on the productivity of a single slope solar distiller. Heat Mass Transf:1–10

Khan MZ, Nawaz I, Tiwari GN, Meraj M, (2020) Effect of top cover cooling on the performance of hemispherical solar still, Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2020.07.513

Manokar AM, Winston DP, Kabeel AE, Sathyamurthy R (2018) Sustainable fresh water and power production by integrating PV panel in inclined solar still. J Clean Prod 172:2711–2719

Madhu B, Balasubramanian E, Sathyamurthy R, Nagarajan PK, Mageshbabu D, Bharathwaaj R, Manokar AM (2018) Exergy analysis of solar still with sand heat energy storage. Applied Solar Energy 54(3):173–177

Malik MZ, Musharavati F, Saber K, Shoaib K, Nguyen DD (2020) Solar still desalination system equipped with paraffin as phase change material: exergoeconomic analysis and multi-objective optimization. Environ Sci Pollut Res 28:220–234. https://doi.org/10.1007/s11356-020-10335-9

Mohaisen HS, Esfahani JA, Ayani MB (2020) Effect of condensing cavity on the performance of a passive solar desalination system: an experimental study. Environ Sci Pollut Res 28:5080–5091. https://doi.org/10.1007/s11356-020-10866-1

Naima MM, Abd El Kawi MA (2002a) Non-conventional solar stills Part 1. Non-conventional solar stills with charcoal particles as absorber medium. Desalination 153:55–64

Naima MM, Abd El Kawi MA (2002b) Non-conventional solar stills part 2 non-conventional solar stills with energy storage element. Desalination 153:71–80

Panchal HN, Shah PK (2011) Charperformance analysis of different energy absorbing plates on solar stills. Iran J Energy Environ 2(4):297–301

Rabhi K, Nciri R, Nasri F, Ali C, Bacha HB (2017) Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 416:86–93

Rahim NHA (2003) A new method to store heat energy in horizontal solar desali- nation still. Renew Energy 28:419–433

Sakthivel M, Shanmugasundaram S (2008) Effect of energy storage medium (black granite gravel) on the performance of a solar still. Energy Res 32:68–82

Salah A, Abu-Khader MM, Badran O (2009) Effect of various absorbing materials for the thermal performance of solar stills. Desalination 242:128–137

Sharshir SW, Elsheikh AH, Ellakany YM, Kandeal AW, Edreis EMA, Sathyamurthy R, Thakur AK, Eltawil MA, Hamed MH, Kabeel AE (2020) Improving the performance of solar still using different heat localization materials. Environ Sci Pollut Res 27(2020):12332–12344

Syers JK, Mackay AD, Brown MW, Currie LD (1986) Chemical and physical characteristics of phosphate rock materials of varying reactivity. J Sci Food Agric 37:1057–1064

Thakur AK, Sharshir SW, Ma Z, Thirugnanasambantham A, Christopher SS, Vikram MP, Li S, Wang P, Zhao W, Kabeel AE (2020) Performance amelioration of single basin solar still integrated with V type concentrator: energy, exergy, and economic analysis. Environ Sci Pollut Res 28:3406–3420. https://doi.org/10.1007/s11356-020-10625-2

Author information

Authors and Affiliations

Contributions

Abd Elnaby Kabeel had the idea for the article; Mohammed El Hadi Attia did the literature search and data analysis; Mohamed Abdelgaied drafted; and Wael M. El-Maghlany and Zied Driss critically revised the work.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interests

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Attia, M.E.H., Kabeel, A.E., Abdelgaied, M. et al. Enhancement of the performance of hemispherical distiller via phosphate pellets as energy storage medium. Environ Sci Pollut Res 28, 32386–32395 (2021). https://doi.org/10.1007/s11356-021-12920-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-12920-y