Abstract

In this study, the effects of adding a condensing cavity in a passive single-basin solar still are investigated experimentally under the climate condition of Mashhad. The condensing cavity acts as an interior cooler. It is cooled by the natural convection heat transfer with the surroundings and accordingly; it keeps the evaporating chamber at a lower pressure. Hence, the condensing cavity increases the rate of evaporation. As a result, this still can increase the productivity of freshwater. The results show that the ratio of vapor condensation on the inner surface of the condensing cavity is about 43% of the vapor condensation on the inner surface of the glass cover, which is 30% of the total freshwater during one day of experiment. This modified solar still represents a simple system, and it can be easily manufactured at a low cost.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

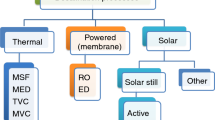

Water covers about 70% of the earth. About 97% of the water is found in the oceans, 2% is in Arctic snow, and 1% is contained in rivers, lakes, and groundwater, which is essential for human, animal, and plant life (Shankar and Kumar 2012). This small amount of fresh water is sufficient for all creatures on earth, but the vast increase in population, rapid industrial developments, and water pollution have restricted freshwater availability. The accessibility of potable water is a considerable challenge in many areas of the world because water resources are scarce and unevenly distributed (Shatat et al. 2013). To desalinate the water, renewable sources of energy can be used as an alternative to fossil fuels. Solar energy is suggested as a promising source of energy due to being abundant, environmentally friendly, and inexpensive (Alhusseny et al. 2020). Thus, to produce high-quality potable water, solar desalination is considered favorable due to being available on site, sustainable, pollution-free, and cost-effective. The process of distillation is one of the oldest and simplest technologies used as a solution to the drinking water problem by changing saltwater or river water into potable water using solar energy, especially in remote areas that lack electricity. Solar distillation systems have many advantages, including being clean, environmentally friendly, and free. The main disadvantage, however, is the lower output of distilled water in comparison with other desalination systems. The production capacity for a simple distillation system is only between 2 and 5 L/m2 a day, making it highly uneconomical (Velmurugan and Srithar 2011).

By 2025, 1.8 million people will be living in countries or regions with absolute water scarcity, and two-thirds of the world population could be under stress conditions. According to the list of international desalination plants No. 22, there are about 14451 direct desalination plants with an overall capacity of about 60 million m3/day (Xiao et al. 2013). In desalination plants, the dissolved solids and salts are separated from seawater by evaporation or mechanical filtration processes (Gude 2015 and Gude 2016). Therefore, there is an urgent necessity to improve the efficiency of desalination plants to meet the growing need for potable water. In so doing, rural and urban livelihood, health, hygiene, school attendance by children, and psychological comfort can be improved (Avvannavar et al. 2008). The most important factors considered in the design and construction of any system is the cost of construction, maintenance, and efficiency. Therefore, when designing a solar distillation system, the cost, distillation yield, and the feasibility of the design should be taken into account.

Low costs of construction and maintenance characterize solar distillation systems. Still, as they depend on solar energy, their productivity is varied in different regions and seasons of the year. Therefore, many researchers have tried a variety of modifications to enhance the productivity of these systems, including modifications made inside/outside solar stills to improve water evaporation and/or condensation. Some modifications are passive such as those made on absorber material, type of design, thermal insulation, fins, phase change materials, evacuated tubes, and multi-basin solar stills. Other scenarios incorporate the use of active extensions, including, but not limited to, the use of fans, pumps, solar collectors, and sun-tracking systems. Li et al. (2013) focused on solar-assisted desalination techniques. Their review showed that solar-assisted desalination is technically feasible, but it has not been commercialized yet. Due to its beneficial role in enhancing heat transfer, adding a condenser improves the performance of solar stills. It increases the temperature difference between the evaporating and condensing regions, which boost water productivity. Another benefit of condensers is the additional surface area available for condensation, which in turn, enhances the heat capacity for evaporation. Condensers integrated into solar stills can be classified into three types, namely built-in, external, and internal condensers.

Among these, the first one is usually the easiest and cheapest to configure. Therefore, great attention has been paid to improve its role in enhancing productivity. Fath and Hosny (2002) investigated the performance of a single-sloped basin still with an inherent built-in additional condenser. In that study, the condenser was placed parallel to the sunrays in the shaded area, and it was always cooler than the other glass cover sides and acted as an effective heat and mass sink. Black dye was used in the still basin to boost basin absorptivity and to increase the evaporation. The most influential parameters in evaporation were suggested to be solar intensity, base insulation effectiveness, basin mass, evaporation surface area, and condenser inner reflectivity. But, some considerations were found to be of less significance, including outer emissivity, cover angle, condenser material, mass, surface area, and wind speed. Fatani et al. (1994) investigated the performance of a simple solar still by modeling a passively cooled condenser. The results demonstrated that an auxiliary condensing surface diminished the daily yield. They noted that brine depths up to 5 cm increased the production, and the vapor was removed from the still by extending the condensing area, which consequently promoted productivity. In that study, a passively cooled condensing plate was integrated into a still, and the yield was evaluated. They reported a significant difference between the temperatures of the glass cover and the condensing plate. Also, they stated that the condensing surface was an efficient means for removing vapor.

To boost the yield, Fatani and Zaki (1995) incorporated an external condenser in a still. Their results indicated that the brine level and the surface area could affect yield improvement. They also reported that the daily yield, through minor thermal inertia, i.e., water depth moves toward zero, is reduced by using an auxiliary condensing surface at a temperature below the glass temperature, and brine levels up to 10 cm promote productivity. While above this level, additional heat removal from the still does not significantly improve. According to their findings, at a condenser to basin area ratio of 0.4 and a water depth of 0.3 cm, the daily yield was about 3.8 l/m2 day.

Fath and Elsherbiny (1993) integrated a passive condenser into a single-sloped solar still and analyzed its performance. They described that the transfer of water vapor from the still to the condenser was due to diffusion, purging, and natural circulation. They concluded that in natural circulation mode, the yield was enhanced by 70% when a condenser was employed. Madhlopa and Johnstone (2009) modeled passive solar still with a separate condenser. The system has one basin in the evaporation chamber (basin1) and two other basins in the condenser chamber (2 and 3). They used an opaque condensing for basin 3 and a glass cover for the evaporator basin. To maintain the cover temperature down, the top part of the condensing cover was shielded from solar radiation. They evaluated the performance of the still and compared it with that of a conventional still under similar meteorological conditions. They reported that the productivity of the modeled still was 62% greater than that of the traditional still. They also noted that the productivity of the solar still was sensitive to the absorption of the liner of basin 1 and water mass in basins 1 and 2, while wind speed and water mass in basin 3 has a negligible influence on distillate production.

Al-Hamadani and Shukla (2013) used an absorber plate with block shaped fins, condenser, and PCM and evaluated the performance of a single-slope solar still. They ascribed that using a secondary condenser enhanced condensation on the shaded side of the single-slope solar still. Further, the daily productivity of the modified still (5.71 kg/m2) was somewhat higher than that of a conventional still (4.295 kg/m2). Due to the high productivity of the modified still, they suggested that it was more suitable for sunny and partly cloudy days. Xiong et al. (2013) compared a novel multi-effect solar still with enhanced condensation surface with a traditional solar still. They reported more freshwater productivity of the novel still. They also developed a numerical model for the heat and mass transfer processes in the solar still and found a good agreement between the model prediction and experimental data. Bhardwaj et al. (2015) increased the condensation surface area of a solar still to maximize water production. At a constant energy input of 625 W/m2, a 65% increase was observed in water production. In the experiments conducted under the sun, the use of an additional condensation area increased water production by 50%.

To enhance output productivity, many researchers investigated adding an external condenser into a solar still. El-Samadony et al. (2015) used a stepped solar still with internal and external reflectors and an external condenser. They indicated that the still productivity was boosted by the incorporation of an external condenser. Their results demonstrated confirmed the higher productivity of stepped still with a condenser than that of the conventional still. Also, internal and external (top and bottom) reflectors caused an increase in glass temperature and enhancement in condensation resistance. In another study, to enhance output productivity, an external condenser was integrated into a solar still. The condensation occurred due to the temperature change on the four sidewalls, which could be cooled by water circulation through the tubes attached to the wall surface for efficiency enhancement (Tiwari et al. 2003).

Nijegorodov et al. (1994) added a passive condenser and investigated its impact on the performance of a single-slope solar still. In that study, a low-power exhaust fan was used to move saturated air and water vapor from a basin-type. Compared to the conventional still, the thermal efficiency of the still was amplified more than twice. Rahim (1995) studied a solar still that included four main parts. The water vapor was removed before reaching the glass cover, and it was allowed to condense in a separate unit at a much lower temperature. They reported thermal and overall efficiencies to be about 70% and 60%, respectively.

Kabeel et al. (2014) made some modifications to a single-basin solar to enhance performance through integrating an external condenser into a solar still and mixing aluminum oxide nanoparticles with the basin water. Their findings showed that the distillate water yield was enhanced by about 53.2%. Also, using the nanofluid promoted the solar still water productivity by about 116% when an external condenser was integrated into the still. A single-basin vacuum solar still made of copper was tested with and without nanofluids by Gnanadason et al. (2012). The solar still made of copper showed a higher efficiency, which could be further improved by adding nanofluids. The modified still operating under low pressure had a better performance in comparison with the still working at atmospheric pressure. Omara et al. (2015) examined the performance of a hybrid solar distillation consisting of a conventional solar still, corrugated wick solar still with internal reflectors, an external condenser with different types of nanomaterials. Experimentations clarified the distillate water production of the corrugated wick solar still with reflectors when providing vacuum was about 180% higher than that of the conventional solar still. In addition, the use of nanomaterials increased the corrugated wick solar still yield by approximately 285.10 %.

Al-Kharabsheh and Yogi^Goswami (2003) used a novel water desalination system using low-grade solar heat. The system used gravity and atmospheric pressure to form a vacuum under which water can be evaporated with less energy and at much lower temperatures than the conventional techniques. Monowe et al. (2011) designed a portable thermal electrical solar still with an external reflecting booster and an external condenser. Latent heat loss of condensation to the environment was reduced in that system, and the latent condensation heat was amassed in a condenser to operate the still during nights or to preheat saline water for domestic purposes. The impact of integrating passive external condensers into a single-slope basin solar still was examined by Ahmed (2012). They reported a 15–30% increase in water production when using the external passive condensers.

Mahmoudi et al. (2010) developed a mathematical model for a new proposed passive condenser in order to enhance the performance of a humidification-dehumidification seawater greenhouse desalination system. Refalo et al. (2016) employed a solar chimney and condensers to increase the productivity of a solar still. In that study, water vapor passed through some ducts immersed in seawater. It was noted that water-cooled external condensers separated and shifted the condensation process from the evaporation chamber to the condensers, and thereby, enhanced condensation. Also, it was pointed out that the solar still with the solar chimney and condensers had higher efficiency compared to the conventional still.

As for studying the effect of adding an internal passive condenser on the distillation amount, there are many studies. Khalifa et al. (1999) aimed to enhance distillate water production by making some modifications into the conventional solar still using an internal condenser. They evaluated the condensate water quality and found that the distillate water quality was on par with the standards. Also, the condensation process was improved by cooling the wall surfaces. They reported a daily efficiency of 54% for the solar still with an internal condenser. Kumar and Bai (2008) designed and built a basin-type solar still and evaluated the performance with different samples such as tap water, seawater, and dairy industry effluent. Two cases were considered for data collection, including solar still working with condensation on the sidewalls and solar still operating without condensation on the sidewalls. They calculated the maximum daily production of the solar still at about 1.4 L/m2 and its efficiency at about 30%.

Ahmed (1988) carried out an experimental study to investigate the effect of an internal condenser on the performance of a single-effect solar still. They examined two different experiments on the basin still with the first one based on water vapor condensation without condenser and the second one based on water vapor condensation with a condenser. They found that still performance was improved by combining an internal condenser with basin-type solar still. Kerfah et al. (2012) simulated a modular still comprising of a condensation chamber and a plane streaming solar collector. They used the weather data (10 years) in the region of Bouzareah, Algeria, to perform the simulations. The highest average daily efficiency of the condensation chamber was recorded during May.

To meet the compactness requirements while designing a portable solar still, Esfahani et al. (2011) used a thermoelectric cooler to increase the condensation rate and reduce the space occupied by the condenser. The proposed design was tested experimentally during winter and summer, and it was found that the cost per liter of potable water using the suggested configuration was lower than required for sun-tracking or transportable hemispherical solar units. However, such solar units are still more expensive than conventional stills. Rahbar and Esfahani (2012) used a thermoelectric module to improve the temperature difference between evaporating and condensing areas. Also, the thermoelectric cooler was combined with a heat-pipe device on its hot side to dispel the heat accumulated there. The performance merit of this design was tested, and it was found that it could increase the productivity of portable solar stills. Rashidi et al. (2017), using this technique, found that the yield could increase by up to 8.16%.

Rabhi et al. (2017) investigated the effect of putting pin fins in the basin liner water and adding an external condenser on the performance of a simple solar still. They observed up to 12.9%, 9.7%, and 3.1% increase in the hourly efficiency for the system with the pin fins and external condenser, the system accommodated with the pin fins, and the system with the condenser, respectively. This enhancement in productivity is about 41.95%, 23.39%, and 11% for those cases, respectively. As mentioned before, with different modifications to the system design, the productivity of solar desalination units can be increased. However, these modifications cause an inevitable upturn in the initial, operation, and maintenance costs, which should be justified from an economic point of view. Thus, performing a cost analysis is necessary to assess the value of the modifications adopted to produce a certain amount of freshwater. In a comparative study by Kabeel et al. (2010), the annual production cost of 17 different designs of solar stills was appraised using a basic methodology devised for this purpose. Among the configurations evaluated, the pyramid-shaped still was found to provide superior annual productivity of 1533 l/m2 with the lowest cost of distilled water of 0.0135 $/l. In contrast, the solar still with a sun-tracking system had the lowest annual productivity, making it the costliest solar desalination unit with 0.23 $/l of distilled water. Bhardwaj et al. (2013) studied the effect of condensation surfaces on the amount of total distilled water production. It has found each of dropwise, filmwise, inclination angle, and wiping did not have any significant effect on the production of distilled water using solar energy. But there is a substantial influence of the condensation surface contact angle, surface tension, on the distillation amount of solar stills.

In general, a wide range of studies has been performed to enhance the water yield of solar stills. In this experimental study, a novel single-slope solar still was used to boost freshwater production. In this technique, an inclined galvanized metal plate is positioned between the evaporation chamber and the condensing cavity. The plate avoids the penetration of solar radiation into the condensing cavity and keeps it at low temperature. It also reflects the solar radiation towards the saline water to intensify its temperature, and consequently, increase the evaporation and condensation rates. At the same time, the right wall of the condensation chamber was cooled by ambient air to increase the rate of condensation, which increased the system productivity and efficiency. To the best of our knowledge, this is the first attempt to design this simple and low-cost solar still. The following sections are included in this paper: experimental setup, uncertainty analysis, and results.

Experimental setup

A schematic view and typically built of the solar water distillation system proposed in this study is shown in Fig. 1. The device is made by the galvanized metal sheet, which is recommended by Malaiyappan and Elumalai (2015). The structure has a rectangular shape with dimensions 0.6 × 0.6 × 0.45 m3. A condensing cavity is designed in the shaded area of solar still (see Fig. 1). The area of the water basin is about 0.319 m2, and the depth of the saline water is 0.0125 m with impurity of 1000 mg/l. All sides of the solar still are thermally insulated except condensing cavity face that is exposed to the surrounding air. The thickness of heat insulation is 0.005 m. A glass lid with a thickness of 0.004 m and an inclination angle of 36° to the horizontal axis is placed on the top section of the system. Note that it is better to select the inclination of glass lid equal to the latitude of the experiment site to absorb the maximum solar radiation incident on the glass lid. All tests are performed in Mashhad, Iran. Latitude and longitude coordinates of Mashhad are 36° 18′ 56.12″ N and 59° 34′ 4.66″ E, respectively.

An inclined galvanized metal plate is located between the evaporation chamber and the wall condensing cavity to prevent the penetration of solar radiation into the condensing cavity and maintain it at low temperatures, too. Besides, this plate can reflect the radiation towards the saline water to increase its temperature and also the evaporation and condensation rates. After passing the solar radiation through the glass cover, it is absorbed by the basin of solar still. After that, the saline water is evaporated, and the vapor is produced. A fraction of the vapor can condense on the inner surface of the glass cover, while the remaining vapor goes towards the condensing cavity and is condensed on the inner surface of the cavity. As a result, the evaporation rate and the productivity of the system can increase. The condensate makes a flow filmwise condensation. Reminding the type of condensation, dropwise or fimewise, does not affect the distillate yield (Bhardwaj et al. 2013).

In this study, the solar power meter, Model TES-1333, is employed to measure the solar intensity. A digital mass scale, Model selves-DH-05L-White-5Kg, is used to measure the mass of freshwater during the distillation process. The thermocouples type K, TP-01 model, are fixed in the specific location on the apparatus to record the temperatures. The data is recorded by Lutron TM 497SD data logger.

Uncertainty analysis

The type B uncertainty is employed in this experimental study (Kirkup and Frenkel 2006). Type B uncertainty is described by a supposed probability distribution depending on available information. Without the novel records or a histogram, to conclude in what way the data is considered based on your information sources. Most of the time, you are not given much information. Therefore, people typically assume a rectangular distribution. Most of the Type B method used to estimate uncertainty for calibration reports, proficiency testing reports, manufacturer’s manuals, datasheets, standard methods, calibration procedures, industry guides, and other available information. So, in the present study, the accuracy represents calibration reports, and the below equations took from other journal articles. All measures are adopted as uncertainty distribution. Thus, the standard uncertainty is defined as follows:

where u and a indicate the standard uncertainty and the accuracy of the tools, respectively. The uncertainty of measuring tools is provided in Table 1. The solar power meter for the solar intensities in the range of 0 to 2000 w/m2 has an accuracy of ± 10 w/m2. The accuracy of temperature amounts, determined by the thermocouples in the range of − 100 to 1300 °C, is 0.1 °C. Finally, a digital mass scale is employed to determine the water yield with the accuracy of 1 g for masses in the range of 0 to 5000 g. The uncertainty for daily efficiency is described as

By using Eq. (2) in this work, and the accuracy of the devices, the highest uncertainty in distillate yield and efficiency is about 4.7% and 0.8%, respectively.

Cost analysis

To investigate the economic feasibility of the proposed device, the procedure presented by Kumar and Tiwari (2009) are employed. The following factors are used to perform the cost analysis in this study:

Funds recovery factor (FRF) is defined by

where y and i are the life of solar still and interest rate of lending banks, respectively.

Fixed yearly cost (FYC) is calculated by

where M is the maximum cost. The following equation is used to determine the drowning fund factor (DFF):

Yearly salvage value (YSV) is defined by

where d is the salvage value of the solar still. Yearly repair procedure cost (YRC) can be calculated by

Yearly cost (YC) is defined as follows:

Price per liter (PPL) can be obtained by using the following equation:

where P is the average annual production.

Results and discussion

The experimental results are presented in this section. The hourly variations of weather parameters in Mashhad, with latitude and longitude coordinates of 36° 18′ 56.12″ N and 59° 34′ 4.66″ E, respectively, on 25 July 2019 are shown in Fig. 2. The surrounding temperature is varied between 31 and 39 °C, where the maximum happened at 13.00. The sharp variation on surrounding temperature happens due to a decrease in wind speed at noon. The solar radiation intensity has about the parabolic shape, where it is maximum of 926 w/m2 can be achieved at 13:00, too.

The variations of hourly temperatures of water surface (Tw), glass cover (Tg), and condensing cavity wall (Tc) of the proposed solar still are shown in Fig. 3 on July 25, 2019. As shown in this figure, all temperatures have the same trend. The differences between the temperatures of water surface and glass lid and between the temperatures of water surface and condensing cavity wall are up to 4 °C and up to 10 °C, respectively. As a result of these temperature differences, the vapor condenses on both inner surfaces of the glass lid and the condensing cavity wall. The maximum solar radiation intensity of 926 w/m2 can be achieved at 13:00. At this time, the temperature of water surface is 67.9 °C. The temperature of condensing cavity wall is much lower than the glass and water temperatures. Thus, the partial pressure of vapor in the condensing cavity is lower than the still. This difference causes the purge of vapor from the still to the condensing cavity.

Figure 4 discloses the variations of the hourly amount of freshwater condensed on the inner surface of glass cover and the inner surface of cavity wall and their summation for July 25, 2019. Reminding, the surface area of the glass (60 cm ∗ 53 cm) is equal to the surface area of the condensing wall. As shown in this figure, all variables have the same trend. Their maximum occurs at the 13.00, at the same maximal of solar intensity and temperatures, depicted in Figs. 2 and 3, respectively. Besides, it can be found that the amount of hourly solar intensity, depicted in Fig. 5, and surrounding temperature, depicted in Fig. 6, has more effects on the amount of freshwater yield during the daylight as compared with the wind speed, depicted in Fig. 7. In the early morning, the water yield on glass and condensing cavity wall are the same because the lower vapor generation can be distributed smoothly in the space. But at noon, the temperature of the water and consequently the vapor generation is enhanced. Thus, the glass distillate production is higher because of the less resident time for water-glass than for water-condensing cavity wall. The hourly variation of distillate in the condenser is less disturbed with the environmental conditions than the distillate on glass. Anyway, both the accumulative yield in the condenser and glass are not sensitive to the environmental conditions, depicted in Fig. 8. Because of the higher amount of accumulated water can diminish the fluctuations in the glass yields.

The daily experimental results given for seven days from July 17 to 25, 2019, are graphically represented in Figs. 9 and 10. When the daily solar irradiation and the surrounding temperature values increase, the amount of condensed water increases. In addition, the trends of the amount of freshwater mimic the trend of the amount of solar energy incident during the daytime. This observation shows that the amount of distillate water is directly related to the amount of solar energy. The trends of the amount of freshwater do not mimic the trend of the surrounding temperature, depicted in Fig. 10, as well as the trend of the amount of solar energy incident during the daytime, in Fig. 9. This behavior means the dependency of the distillate to solar irradiation is more than its dependency on the surrounding temperature.

The efficiency of solar still can be obtained by using the following equation:

where \( {\dot{m}}_i \), Lh,and Id are the rate of water produced by solar system, the latent heat of water vaporization, and the solar intensity, respectively. Besides, Ab and ∆t are the area of the basin and the time interval, respectively.

Figure 11 shows the variation of solar intensity and efficiency with the moment. The efficiency increases in the morning with the time elapse. Because this starts from zero at 8.00 while the irradiation is about 200 W/m2. At 12.00, the variation of the solar intensity slows down, while the water yield is growing drastically, depicted in Fig. 6. Thus, there is a high increase in efficiency at noon. Following that the efficiency keeps about constant till 16.00. However, there is a sudden increase in efficiency after 16:00. This is due to the growing difference between the temperatures in the water basin and the inner surface of glass cover, and the difference between the temperatures of water in basin and the cavity wall after 16:00. Faster cooling of glass than the water and condensing cavity is depicted in Fig. 3. Also, solar intensity decreases higher than water production.

Figures 12 and 13 disclose the variations of daily solar irradiation, daily mean surrounding temperature, and daily efficiency. The daily efficiency closely mimics the daily solar irradiation and daily mean surrounding temperature. When there is the maximum daily solar irradiation on the fifth day of experiment, there is a maximum daily mean surrounding temperature and daily efficiency. These variations during the seven days of experiment for daily solar irradiation, daily mean surrounding temperature, and daily efficiency are 3%, 3.8%, and 0.4%, respectively

Comparison of the proposed solar still with previous systems

Generally, the costs of construction and maintenance are the most important factors in designing any system. For a solar still, the economic feasibility can be achieved by producing more distilled water at a lower cost. The cost analysis is performed for the proposed solar still in this section. The costs of different components of solar still are presented in Table 2. The total cost of the system in the present study is 37.79 $.

The results of economic analysis of the proposed solar still are presented in Table 3. The average annual amount of distilled water has been estimated based on 260 clear days. It is also assumed the 10 years of life cycle with the moderate yearly productivity to be 10 years and 1180 L/m2 year, respectively. It can be found that the price per liter of the proposed solar still is 0.006 $/L/m2.

The yearly productivity and the price per liter of the proposed solar still are compared with the previous distillation systems in Table 4. It can be found that the proposed solar still has high yearly productivity and a very low price per liter of the distilled water among the previous distillation systems.

Conclusion

In the current experimental study, a new design of passive solar still was presented. Accordingly, a condensing cavity was added in the single basin solar still to improve the productivity of the system. The new solar still is investigated experimentally under the climate condition of Mashhad, Iran. The condensing cavity acts as an interior cooler. It is cooled by the natural convection heat transfer with the surrounding, and accordingly, it increases the rate of evaporation. The main results of this study are presented as follows:

-

The condensing cavity keeps the evaporating chamber at lower pressure. As a result, this cavity can increase the productivity of freshwater.

-

The productivity of solar still is about 4.53 kg/m2 day by using the condensing cavity.

-

The ratio of vapor condensation on the inner surface of the condensing cavity is about 43% of the vapor condensation on the inner surface of the glass cover and 30% of the total freshwater during one day of the experiment.

-

The cost of construction for this sample solar still is about 37.79 $, and the price per liter for ten years is about 0.006 $/L/m2.

-

The productivity of solar still is more related to solar intensity rather than the surrounding temperature.

-

The new technique used in the solar still is very simple and cheap technology, which can be used easily to provide more freshwater.

Data availability

The data are available from the corresponding author by request

Abbreviations

- a :

-

Standard uncertainty

- A bl :

-

Area of the basin-liner (m2)

- AC :

-

Annual cost

- AMC :

-

Annual maintenance cost

- ASV :

-

Annual salvage value

- CPL:

-

Cost per litter

- CRF:

-

Capital recovery factor

- FAC:

-

First annual cost

- h fg :

-

Latent heat of water vaporization

- I :

-

Initial cost

- I d :

-

Daily averaged solar irradiation (W/m2)

- I i :

-

Hourly solar intensity (W/m2)

- M :

-

Average annual productivity

- \( {\dot{m}}_c \) :

-

Hourly distillate yield on condenser wall (kg/s)

- \( {\dot{m}}_d \) :

-

Daily distillate yield (kg/day)

- \( {\dot{m}}_g \) :

-

Hourly distillate yield on glass cover (kg/s)

- \( {\dot{m}}_i \) :

-

Hourly distillate yield (kg/s)

- n :

-

Lifetime (Years)

- N :

-

Number of daylight hours

- P :

-

Initial cost

- r :

-

Annual interest rate

- S :

-

Salvage value

- SFF:

-

Sinking fund factor

- T :

-

Temperature (°C)

- u :

-

Accuracy of instrument

- U(\( \dot{m} \)):

-

Maximum combined uncertainty for the distillate yield

- U(η):

-

Maximum combined uncertainty for the device efficiency

- η :

-

Efficiency

- a :

-

Ambient

- c :

-

Condenser wall

- d :

-

Daily

- g :

-

Glass cover

- i :

-

Hourly

- E :

-

East

- N :

-

North

References

Abdallah S, Badran OO (2008) Sun tracking system for productivity enhancement of solar still. Desalination 220(1-3):669–676

Abdallah S, Badran O, Abu-Khader MM (2008) Performance evaluation of a modified design of a single slope solar still. Desalination 219(1-3):222–230

Abdel-Rehim ZS, Lasheen A (2007) Experimental and theoretical study of a solar desalination system located in Cairo, Egypt. Desalination 217(1-3):52–64

Ahmed ST (1988) Study of single-effect solar still with an internal condenser. Sol Wind Technol 5(6):637–643

Ahmed HM (2012) Seasonal performance evaluation of solar stills connected to passive external condensers. Sci Res Essays 7(13):1444–1460

Al-Hamadani AA, Shukla SK (2013) Performance of single slope solar still with solar protected condenser. Distributed Generation Alternat Energy J 28(2):6–28

Alhusseny A, Al-Zurfi N, Nasser A, Al-Fatlawi A, Aljanabi M (2020) Impact of using a PCM metal-foam composite on charging/discharging process of bundled-tube LHTES units. Int J Heat Mass Transf 150:119320

Al-Kharabsheh S, Yogi^Goswami D (2003) Analysis of an innovative water desalination system using low-grade solar heat. Desalination 156(1-3):323–332

Avvannavar SM, Mani M, Kumar N (2008) "An integrated assessment of the suitability of domestic solar still as a viable safe water technology for India" Environmental Engineering & Management Journal (EEMJ), 7(6).

Badran OO, Al-Tahaineh HA (2005) The effect of coupling a flat-plate collector on the solar still productivity. Desalination 183(1-3):137–142

Bhardwaj R, Ten Kortenaar MV, Mudde RF (2013) Influence of condensation surface on solar distillation. Desalination 326:37–45

Bhardwaj R, Ten Kortenaar MV, Mudde RF (2015) Maximized production of water by increasing area of condensation surface for solar distillation. Appl Energy 154:480–490

El-Samadony YAF, Abdullah AS, Omara ZM (2015) Experimental study of stepped solar still integrated with reflectors and external condenser. Exp Heat Transf 28(4):392–404

Esfahani JA, Rahbar N, Lavvaf M (2011) Utilization of thermoelectric cooling in a portable active solar still—an experimental study on winter days. Desalination 269(1-3):198–205

Fatani AA, Zaki GM (1995) Analysis of roof type solar stills with assisting external condensers. Int J Solar Energy 17(1):27–39

Fatani AA, Zaki GM, Al-Turki A (1994) Improving the yield of simple basin solar stills as assisted by passively cooled condensers. Renew Energy 4(4):377–386

Fath HE, Elsherbiny SM (1993) Effect of adding a passive condenser on solar still performance. Energy Convers Manag 34(1):63–72

Fath HE, Hosny HM (2002) Thermal performance of a single-sloped basin still with an inherent built-in additional condenser. Desalination 142(1):19–27

Gnanadason MK, Kumar PS, Jemilda G, Jasper SS (2012) Effect of nanofluids in a modified vacuum single basin solar still. Int J Sci Eng Res 3:2229–5518

Gude VG (2015) Energy storage for desalination processes powered by renewable energy and waste heat sources. Appl Energy 137:877–898

Gude VG (2016) Geothermal source potential for water desalination–current status and future perspective. Renew Sust Energ Rev 57:1038–1065

Ismail BI (2009) Design and performance of a transportable hemispherical solar still. Renew Energy 34(1):145–150

Kabeel AE, Hamed AM, El-Agouz SA (2010) Cost analysis of different solar still configurations. Energy 35(7):2901–2908

Kabeel AE, Omara ZM, Essa FA (2014) Enhancement of modified solar still integrated with external condenser using nanofluids: an experimental approach. Energy Convers Manag 78:493–498

Kerfah R, Ghalia Filali E, Belkacem Z (2012) Modelling and simulation of a modular solar still constituted of a streaming plate collector and a condensation chamber. Mechanics 18(1):49–55

Khalifa AJ, Al-Jubouri AS, Abed MK (1999) An experimental study on modified simple solar stills. Energy Convers Manag 40(17):1835–1847

Kirkup L, Frenkel RB (2006) An introduction to uncertainty in measurement: using the GUM (guide to the expression of uncertainty in measurement). Cambridge University Press

Kumar KV, Bai RK (2008) Performance study on solar still with enhanced condensation. Desalination 230(1-3):51–61

Kumar S, Tiwari GN (2009) Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl Energy 86(10):1995–2004

Li C, Goswami Y, Stefanakos E (2013) Solar assisted sea water desalination: a review. Renew Sust Energ Rev 19:136–163

Madhlopa A, Johnstone C (2009) Numerical study of a passive solar still with separate condenser. Renew Energy 34(7):1668–1677

Mahmoudi H, Spahis N, Abdul-Wahab SA, Sablani SS, Goosen MF (2010) Improving the performance of a Seawater Greenhouse desalination system by assessment of simulation models for different condensers. Renew Sust Energ Rev 14(8):2182–2188

Malaiyappan P, Elumalai N (2015) Single basin and single slope solar still: 362 various basin material thermal researches. J Chem Pharm Sci 7:48–51

Monowe P, Masale M, Nijegorodov N, Vasilenko V (2011) A portable single-basin solar still with an external reflecting booster and an outside condenser. Desalination 280(1-3):332–338

Nijegorodov N, Jain PK, Carlsson S (1994) Thermal-electrical, high efficiency solar stills. Renew Energy 4(1):123–127

Omara ZM, Kabeel AE, Essa FA (2015) Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers Manag 103:965–972

Rabhi K, Nciri R, Nasri F, Ali C, Bacha HB (2017) Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 416:86–93

Rahbar N, Esfahani JA (2012) Experimental study of a novel portable solar still by utilizing the heatpipe and thermoelectric module. Desalination 284:55–61

Rahim NHA (1995) Utilization of a forced condensing technique in a moving film inclined solar desalination still. Desalination 101(3):255–262

Rashidi S, Esfahani JA, Rahbar N (2017) Partitioning of solar still for performance recovery: experimental and numerical investigations with cost analysis. Sol Energy 153:41–50

Refalo P, Ghirlando R, Abela S (2016) The use of a solar chimney and condensers to enhance the productivity of a solar still. Desalin Water Treat 57(48-49):23024–23037

Shankar P, Kumar S (2012) Solar distillation a parametric review. VSRD Int J Mech Automobile Prod Eng 2(1):17–33

Shatat M, Worall M, Riffat S (2013) Opportunities for solar water desalination worldwide. Sustain Cities Soc 9:67–80

Tiwari GN, Singh HN, Tripathi R (2003) Present status of solar distillation. Sol Energy 75(5):367–373

Velmurugan V, Srithar K (2011) Performance analysis of solar stills based on various factors affecting the productivity—a review. Renew Sust Energ Rev 15(2):1294–1304

Xiao G, Wang X, Ni M, Wang F, Zhu W, Luo Z, Cen K (2013) A review on solar stills for brine desalination. Appl Energy 103:642–652

Xiong J, Xie G, Zheng H (2013) Experimental and numerical study on a new multi-effect solar still with enhanced condensation surface. Energy Convers Manag 73:176–185

Author information

Authors and Affiliations

Contributions

Conception and design of study: Javad Abolfazli Esfahani, Mohammad Bagher Ayani

Acquisition of data: Hashim Sahar Mohaisen

Analysis and/or interpretation of data: Hashim Sahar Mohaisen, Javad Abolfazli Esfahani, Mohammad Bagher Ayani

Drafting the manuscript: Hashim Sahar Mohaisen

Revising the manuscript critically for important intellectual content: J.A. Esfahani,

Supervision: J.A. Esfahani

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

The author guarantees that the contribution to the work has not been previously published elsewhere.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohaisen, H.S., Esfahani, J.A. & Ayani, M.B. Effect of condensing cavity on the performance of a passive solar desalination system: an experimental study. Environ Sci Pollut Res 28, 5080–5091 (2021). https://doi.org/10.1007/s11356-020-10866-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-10866-1