Abstract

Herein, the synthesis of hydrophobic macroinimer–based hybrid sorbents and their use in the removal of organic solvents from wastewater is explored. Polydimethylsiloxane (PDMS), 4,-4′-azobis-4-cyanopentanoyl chloride (ACPC), and methacryloyl chloride were reacted via bulk condensation polymerization to synthesize the macroinimer. The organogel systems were then prepared with macroinimer using different acrylic monomers of methyl acrylate, ethyl acrylate, and butyl acrylate without any additional crosslinker and initiator. The structural properties of the obtained final products were characterized by FT-IR, 1H-NMR, and TGA. The effect of alkyl chain length and macroinimer moieties in the organogel networks, as well as the swelling capacities of the prepared gels, was evaluated for different organic solvents and oils. The maximum solvent absorbencies of macroinimer-based organogels were determined as 85.3%, 100.9%, 1422.1%, 1660.0%, 3809.3%, and 5032.2% for diesel oil, gasoline, acetone, benzene, tetrahydrofuran (THF), and dichloromethane (DCM), respectively. Furthermore, adsorption-desorption kinetics, selective absorption from oil/water mixtures, temperature effect on the absorption capacity, and reusability tests were investigated. Obtained results showed that the prepared organogels possessed high swelling, efficient absorption capacity, and good oil separation performance in the removal of organic solvents from wastewater. The temperature-dependent absorption study shows no significant change in absorption capacity. Thus, the prepared macroinimer-based organogels in the present study demonstrate potential as prospective sorbents for organic pollutant cleanup from wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, the tremendous increase in oil exploration and transportation has resulted in significant environmental pollution from spillage (Lee and Rogers 2013; Yati et al. 2015). These activities have led to the continuous leakage of organic liquids into water systems thereby greatly impacting the terrestrial ecosystem. Amongst all, industrial discharges play the biggest role in water pollution, which possessed adverse effects on human health and aquatic organisms. Several methods such as biodegradation (Prince et al. 2016), in situ burning (Fritt-Rasmussen et al. 2015), the use of dispersants (Duan et al. 2018), sinking agents, solidifiers (Sundaravadivelu et al. 2016), skimmers (Song et al. 2015), booms, and sorbents (Erdem 2021; Kizil et al. 2015) have been developed and used in the removal organic liquids from water surfaces. However, low absorption ability, the use of complex reaction processes, and reusability efficiency have limited the applicability of some of these methods. Amongst all, polymeric-based sorbents have demonstrated to be the most efficient materials due to their fast absorption and reusability properties. So far, three different types of polymeric materials including inorganic (zeolite, silica aerogel, graphite) (Wang et al. 2016), natural organic (straw, wood fiber, cotton fiber, cellulose) (Zheng et al. 2016), and synthetic organic (polypropylene, polyester, polystyrene, polyurethane foam, polyacrylate, etc.) (Erdem 2021; Kizil et al. 2015, Nam et al. 2018, Sonmez and Wudl 2005) sorbents have been widely explored. However, studies on inorganic and natural organic sorbents have demonstrated demerits such as low oil absorbency and poor recovery while synthetic polymeric sorbents possess high oil absorbency, fast absorption rate, and high oil/water separation selectivity.

Several studies based on synthetic polymers such as styrene (Kiatkamjornwong et al. 1999) rubber (Kangwansupamonkon et al. 2001; Zhou et al. 2001), and acrylate (Atta and Arndt 2005; Farag and El-Saeed 2008) organogel sorbents have been extensively used as hydrophobic cross-linked networks for cleaning application towards organic liquid spills. In general, these organic liquids are rapidly absorbed into these cross-linked networks due to hydrophobic interactions. Accordingly, synthetic polymeric cross-linked network structures are mainly obtained either via rubber vulcanization (Ceylan et al. 2009) or by the crosslinking of styrene (Kiatkamjornwong et al. 1999) and acrylates (Farag and El-Saeed 2008). Amongst all, acrylate-based organogels have proven to be widely applicable due to ease in modification to form different derivatives. Conventional initiators such as benzoyl peroxide, azobisisobutyronitrile (Ida et al. 2017), and acrylate monomers have been greatly applied to form cross-linked networks using methylene bisacrylamide (MBA) as a crosslinker (Kabir et al. 2016). In recent years, different methods involving the use of macroinimers that consists of macrocrosslinker, initiator, and macromonomer units have been investigated as suitable alternatives (Hazer et al. 1994). Yamatomo et al. reported the use of different macroinimers during gel synthesis. Results showed that the swelling properties drastically increase by increasing the branched gel network (Yamamoto et al. 2003). Another study by Okay et al. demonstrated that during gel formation macroinimer molecules can be used as both an initiator and crosslinker thereby obtaining high strength material with excellent swelling properties (Melekaslan et al. 2004). Also, Hazer et al. reported the successful synthesis of different macroinimers with hydrophilic character (Hazer et al. 1993; Yildiz and Hazer 1998; Yıldız and Hazer 2000; Yildiz et al. 2012; Yildiz et al. 2010). Hazer et al. also described the preparation and characterization of polydimethylsiloxane (PDMS)-based hydrophobic macroinimers (Hamurcu et al. 1997). Results showed that the prepared materials possess high swelling and robustness.

Herein, we report the synthesis of different novel acrylic based (methyl acrylate, ethyl acrylate, and butyl acrylate) organogels via bulk polymerization using with hydrophobic macroinimers to produce hybrid sorbents. Considering the prepared macroinimers do not require any additional initiator, crosslinker or catalyst supports a simple and cost-effective procedure over conventional commercial techniques that involve the use of crosslinkers and initiators. The aim of this study is to compare the oil absorbency of prepared organogels based on the hydrophobic effect of monomers and the effect of the different macroinimer moieties. The affinity of the different gels towards a variety of organic solvents and oils is systematically investigated. In addition, absorption-desorption kinetics of the hybrid sorbents and temperature effect on the absorbency are studied by determination of their swelling rates, absorption capacities, and reusability.

Experimental

Materials

4,4′-Azobis-4-cyanopentanoic acid (ACPA), acryloyl chloride, 2,2′-Azobis (2-methylpropionitrile) (AIBN), and methylene bisacrylamide (MBA) were supplied by Sigma-Aldrich. 4,4′-Azobis-4-cyanopentanoyl chloride (ACPC) was obtained by the chlorination of ACPA using phosphorus pentachloride (PCl5) as described in the previous study (Hamurcu et al. 1997). Aminopropyl terminated polydimethylsiloxane (DMS-A11) of Mn 850–900 g/mol was purchased from Gelest. Methyl acrylate (Me), ethyl acrylate (Et), and butyl acrylate (Bu) were used in alkyl chain length variation and were supplied by Sigma-Aldrich. The solvents including dichloromethane (DCM), tetrahydrofuran (THF), benzene, and acetone were purchased from Sigma-Aldrich. Ninety-five octane gasoline and euro diesel were supplied by Royal Dutch Shell. All solvents were used without further purification.

Synthesis of macroinimer

The macroinimer (MIM) in the present study was synthesized by reacting ACPC, DMS-A11, and acryloyl chloride as detailed in the previous study (Hamurcu et al. 1997). The reaction steps and the final products are represented in Scheme 1.

Preparation of organogels

In order to prepare the different polymeric sorbents, 2 g of methyl acrylate (Me), ethyl acrylate (Et), and butyl acrylate (Bu), as well as determining amounts of prepared macroinimer (MIM), were transferred into different test tubes, while slowly introducing nitrogen to remove the air. The amount of MIM to be used was calculated based on the monomer to MIM mole ratio as 1/200, 1/300, and 1/400 (Table 1). To achieve gelation, polymerization of the different monomers was performed at 70 °C for 8 h. The obtained gels obtained were labeled as MeMIM, EtMIM, and BuMIM as shown in Fig. 3. Control gels (MA) of the different monomers were synthesized using MBA (M) as the crosslinker and AIBN (A) as the initiator. Typically, the gels were prepared by adding a calculated amount of AIBN and MBA into 2 g solutions of the different monomers (Me, Et, and Bu). Based on reaction stoichiometry, the amount of AIBN and MBA was calculated using monomer to AIBN and MBA molar ratios as 1/200, of 1/300, and 1/400 (Table 1) as in the case of MIM. The control gels were then produced as described previously and labeled as MeMA, EtMA, and BuMA as shown in Fig. S1.

Characterization methods

The chemical structures of the macroinimer and gels were verified using FT-IR (Shimadzu 8201 FT infrared spectrophotometers) and 1H-NMR (Bruker AVANCE 300 MHz) spectrometers. Thermal stability of the prepared materials was analyzed via thermal gravimetric analysis (TGA) operated on a Perkin Elmer model TG500 under nitrogen atmosphere in a temperature range from 25 to 700 °C at a heating rate of 20 °C/min. To increasing polymer-solvent interaction, a VWR water bath shaker was used at 25 °C at a speed of 80 strokes/min.

Soluble fraction

The presence of monomeric and polymeric moieties unable to crosslink during gel network formation is known as soluble fractions (SF). The extraction of SF molecules from the gel networks was performed by immersing weighted amounts of each gel into DCM with a solvent interval that changed every 6 h over a period of 24 h. Once extraction was complete, the swollen organogels were dried at room temperature under vacuum for 24 h. Subsequently, SF was calculated using the mathematical formulation in Eq. 1.

where W0 and W are the weights of the organogels before and after extraction, respectively.

Swelling analysis

The swelling capacities of the prepared organogels were determined gravimetrically in THF, DCM, acetone, gasoline, diesel, and benzene. In brief, 0.1 g of dried gel samples was placed separately in selected solvents and kept to reach equilibrium swelling at room temperature. After 24 h, the samples were removed from the solvents, blotted with filter paper, weighed in triplicates and the average value recorded. The equilibrium swelling percentages of the gels were calculated using Eq. 2.

where Wd and Ws are the weights of dried and swollen gels, respectively.

Evaluation of swelling kinetic

The swelling kinetics of the prepared organogels was investigated as a function of time using the solvent with the highest absorptivity. At varying time intervals, the gel samples were removed from the solvent, blotted with filter paper, weighed in triplicates and the average values recorded. This procedure was repeated until equilibrium swelling was reached. The first- and second-order kinetic models were then applied to best describe the absorption process. The swelling rates of the gels were expressed using Eq. 3.

where Qt is the swelling percentage of organogel at time t and Qmax is the equilibrium swelling percentage of the organogel. By integrating Eq. 3, the following mathematical formulation was obtained.

where a plot of ln(Qmax/(Qmax − Qt)) vs time (t) generates a straight line indicates that the swelling process followed first-order kinetics. Equation 5 describes the second-order kinetic model as a function of the swelling rates of the gels.

By integrating Eq. 5, the following linear (Eq. 6) was derived.

where a plot of t/Qt vs time (t) deduces a straight line that describes the second-order kinetics swelling mechanism.

Desorption kinetic study

Desorption investigation of the prepared gels was performed as a function of time using swollen gels. Desorption kinetic data was obtained by recording the average weight loss of gel samples at various time intervals. Desorption experiments were continuously performed until the final weights of the gels equal their initial weights.

Solvent selective performance of sorbents

To analyze the solvent selective absorption ability of prepared sorbents, a mixture of 20 mL toluene and 30 mL water was mixed. 0.2 g organogel was placed on the surface of the solution mixture and the weight of the gel measured as a function of time. The absorption capacities of the organogels were then calculated using Eq. 2.

Reusability capacity of sorbents

The reusability efficiency of synthesized gels was analyzed via absorption and desorption experiments by dipping the sorbents into studied organic liquids to reach maximum absorbency. This process was repeated for 10 cycles and the regeneration efficiency of the organogels was calculated using Eq. 7.

where Qc is the total absorption capacity for each cycle and Qmax is the total absorption capacity in the first cycle.

Results and discussion

Characterization of macroinimer

The synthesis of macroinimer was performed with slight modification as described in previous study (Hamurcu et al. 1997). Typically, this involves the reaction between ACPC and methacryloyl chloride (Scheme 1) to obtain a 92.4 wt% yield. The prepared macroinimer was subsequently characterized by FT-IR (Fig. 1a) and 1H-NMR (Fig. 1b) spectroscopy techniques. According to 1H-NMR spectral analysis, the presence of acrylic double bond protons was observed at 5.28 and 5.65 ppm. The signals in the peak range of 2.11–2.41 and 1.72–1.78 ppm were attributed to -CH2 and -CH3 groups of ACPC, respectively. The peaks at 5.9 and 6.6 ppm were assigned to -NH groups present in the macroinimer. The signal peaks of -CH2 and -CH3 groups for PDMS were also observed in the range 3.08–3.62 ppm. The molecular weight of the synthesized macroinimer was calculated using the integral ratio of vinylic/methyl protons of ACPC/PDMS (0.92/1.90/2) and was determined as ≈ 1300 g/mol. For the FT-IR spectrum, the peaks at 3330, 1655, and 1545 cm−1 are assigned to -NH stretching vibration, carbonyl stretching, and -NH bending in the backbone of the synthesized macroinimer, respectively. The C=C vibrations signal peak was observed at 1625 cm−1. In addition, the peaks at 1265 and 810 cm−1 are related to Si-CH3 deformation, while that at 1028 cm−1 is related to the Si-O-Si asymmetric stretching vibration. Based on the FT-IR and 1H-NMR spectral analysis, it was confirmed that the macroinimer was successfully synthesized.

Synthesis of organogels

In the present study, the effect of MIM on synthesized organogels was compared to gels prepared using a conventional commercial crosslinker/initiator (MA) system as control. For better comparison, the mole ratio of initiator to crosslinker in the MA and MIM systems was kept constant. Considering that the crosslinker ratio directly affects the swelling capacity of the organogels (Jin et al. 2012), the mole ratios of MIM and MA for the different monomers were determined as 1/200, 1/300, and 1/400. Gel formation was achieved by bulk polymerization under nitrogen atmosphere at 70 °C for 8 h without using of any solvent or catalyst. Three different monomers (methyl acrylate, ethyl acrylate, and butyl acrylate) were used in order to determine the effect of alkyl chain length in the organogels (Fig. 2). This is because the presence of alkyl chains on the backbone of the polymer is vital towards increasing hydrophobic interaction of the gel network with organic solvents (Jin et al. 2012). Theoretically, increasing the length of alkyl chains increases the hydrophobicity of the organogel that intends to enhances the overall hydrophobicity of the gel network. On the other hand, purification of the gels to remove unreacted molecules also known as soluble fractions (SF) may affect final structure of the material (Karadag et al. 2016). The purification process was performed for 48 h at room temperature using DCM solvent as the eluent and the SF percentage determined (Ahmed 2015). According to obtained results, the SF values of the synthesized organogels decreased with increasing crosslinker ratio and decreasing alkyl chain length of the monomers used. That is BuMA400 and BuMIM400 contained the highest SF, while MeMA200 and MeMIM200 depicted the lowest values.

Characterization of organogels

The chemical functionality of the synthesized organogels was characterized by FT-IR spectroscopy and the results shown in Fig. 3a. Following the FT-IR spectrum of PDMS based organogels, the peak at approximately 2927 cm−1 was assigned to the stretching vibrations of aliphatic C–H bonds. This characteristic peak was observed to increase in intensity with increasing monomer chain length. The incorporation of PDMS in the organogels was confirmed by the presence of Si-CH3 deformation peak at 810 cm−1. However, this peak was observed to decrease with monomer chain length. This decrease may be attributed to the decrease in macroinimer concentration as seen in Table 1.

Thermal degradation of the prepared organogels was evaluated by TGA under nitrogen atmosphere and the results are shown in Fig. 3b and S3, respectively. According to TGA thermograms, all synthesized organogels proved to be thermally stable at temperatures less than 320 °C. However, the thermal stability of the prepared organogels increased with increasing monomer chain length. In addition, increasing monomer chain length increased the char yield of the prepared organogels.

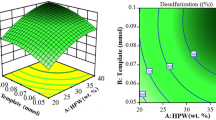

Oil absorbency of organogels

It has been previously reported that the oil absorption of materials essentially relies on the bulkiness of their alkyl chain length that provides good affinity towards organic liquids (Atta and Arndt 2005). This is because the length of the alkyl substituent enhances polymeric hydrophobicity, which results in van der Waals force interaction between the organic liquid and polymer leading to increase in oil absorption by polymer. The synthesized gels in the present study demonstrated not to be soluble in various organic solvents such as ethylbenzene, acetone, xylene, toluene, and dichloromethane as well as fuels such as gasoline and diesel. Thus, swelling tests were completed for each sorbent in these organic liquids and their swelling percentages deduced as shown in Fig. 4. The highest swelling percentage was obtained as 85.3%, 100.9%, 1422.1%, 1660.0%, 3809.3%, and 5032.2% for diesel, gasoline, acetone, benzene, THF, and DCM, respectively, using BuMIM400. As observed, all the synthesized organogels showed high swelling abilities. One of the aims of the present study was to demonstrate the influence of different monomeric alkyl molecules on the prepared sorbents. Increasing the alkyl chain carbon number of the used monomers resulted in higher swelling potential. This could be attributed to the increasing hydrophobicity of the polymer structure. As earlier described, MIM played a great role in the synthesis of the gels not only as an initiator but also as a crosslinker. Thus, increasing the mole ratio of MIM increases gel fraction that decreases the free volume of the gels. This decrease is attributed to the formation of high cross-linked structures, similar to results reported in a previous study (Yildiz et al. 2010). In essence, the increase in crosslinking density results in low swelling of the organogels. Figure 4 shows the absorption of oils (gasoline, diesel) was the lowest, which is related to the limited oil-polymer interactions, while DCM, a widely used solvent in industrial applications, showed the highest absorbency. In the highest absorbency of DCM, the main role belongs to the solvent-solute interactions which determined with different parameters such as polarity, hydrogen bonding ability, density, etc. Hildebrand value is perhaps the most widely applicable parameter to understand swelling behavior of gel network. Due to the less difference in Hildebrand value of DCM and our organogels, DCM absorbency of organogels is higher than the other solvents (Ghobashy et al. 2018). It is supposed that this high absorbency occurs by diffusion mechanism into the interconnected micropores of organogels (Scheme 2) (Kilic et al. 2019). Comparing the swelling capacities of the organogels prepared using MIM to that of conventional initiator-crosslinker pair (MA), Fig. 4 and S4 show better swelling ability for MIM-based gels in all organic solvents and oils to that of MA. Overall, MIM-based gels depicted higher absorption capacities compared to MA-based organogels (Fig. 5). This was mainly due to increase free volume and hydrophobicity interaction in the organogels incorporated due to the presence of PDMS. Comparative results of the fabricated gels, absorption capacity, and reusability cycles for oils/solvents removal efficiency with other polymeric sorbents are presented in Table 2. The results show that the synthesized hybrid sorbents in the present study are competitive with those from other polymeric systems in the literature.

Absorption-desorption kinetic study

Figure 6a and b shows adsorption-desorption studies of the prepared organogels as a function of time in DCM. According to obtained absorption kinetic results, the prepared organogels showed high and fast solvent uptake capabilities. The maximum swelling of all organogels was achieved within the first 60 min and equilibrium swelling was reached after 300 min. Comparatively, MIM-based organogels demonstrated higher absorption than MA sorbents. However, to better understand the absorption kinetics between MIM- and MA-based sorbents, the experimental data was evaluated using first- and second-order kinetic models. Following a plot of t/Q versus t using Eq. (4), a linear relationship was established, confirming that the absorption processes were best fitted second-order kinetics (Fig. 6d). By extrapolating the linear plots, k2 and Qmax values were determined as presented in Table 3 and S2. In addition, the correlation coefficient (R2) values for all sorbents were determined to be ≥ 0.99, which indicates a close agreement between predicted and experimental values. On the other hand, desorption kinetics for the swollen gels in DCM was examined. The retention kinetics of MIM- and MA-based organogels was evaluated by calculating the evaporation percentage of DCM from the swollen gels at room temperature (Fig. 6b). Overall, more than 95% solvent was released within 35–40 min with a complete release of absorbed DCM by the organogels achieved after 60 min. Comparison between MIM- and MA-based organogels showed that MIM organogels possessed slower desorption rate than MA. This was due to the incorporated hydrophobic character of PDMS that improve the retention of DCM in the gel network.

Reusability of organogels

As known, reusability of any polymeric sorbent stands to show a very important parameter in terms applicability. In this study, EtMIM400 gel was selected as a representative example owing to its high swelling ability and low soluble fraction compared to others. The reusability efficiency of EtMIM400 organogel was investigated by repeatedly measuring absorption and desorption capacities of the sample in DCM. This adsorption-desorption process was performed for 10 repeated cycles at room temperature. As seen in Fig. 7, the results of the synthesized sorbent retained its absorption capacity after 10 cycles. According to the results obtained, it was deduced that the prepared organogel can be used at least 10 times without any capacity loss.

Effect of temperature on absorption

Figure 8a depicts the effect of temperature on the absorption capacity of EtMIM400 in DCM investigated at different temperatures of 4, 14, and 24 °C. As shown, absorption capacity slightly decreased with increase in temperature due to the increasing diffusive mass transfer resistance with temperature (Zhang et al. 2015). The effect of temperature on the equilibrium absorption of DCM by EtMIM400 organogel was then analyzed using Gibbs–Helmholtz equation (Eq. 8) (Lin et al. 2007).

where Qmax is the equilibrium DCM absorption capacity at temperature T, ΔHa is the absorption enthalpy, and R is the gas constant (8.314 J K−1 mol−1). According to Fig. 8b, the plots of lnQmax vs 1/T resulted in straight lines with positive slopes for EtMIM400 organogels between. ΔHa of EtMIM400 was obtained from the slopes as − 1.49 kJ mol−1. The negative value of ΔHa indicates that the absorption process with chlorinated solvents was exothermic in the range of 277.15–297.15 K. In addition, the deduced small values of ΔHa are indicative of the high absorption capacity of the organogels and the strong polymer–solvent interaction.

Separation of water–organic solvent mixture

With continuous efforts to ameliorate environmental hazards, the absorption selectivity of organic liquids such as oils from water surfaces using suitable sorbents is a significant parameter for the cleaning of water during oil spillage. In this study, the reusability efficiency of EtMIM400 based on oil absorption selectivity from the surface of water was investigated. In order to illustrate the absorption capability of the sorbents, benzene (dyed with methyl red) as the model solvent was mixed with water. As seen in Fig. 9, EtMIM400 gel quickly absorbed benzene within a time interval of 10 min without absorbing water. The benzene absorbed gel could then be easily separated from the water surface by filtration (Fig. 9b). This implies that EtMIM400 gel possesses potential ability to be used in removing organic solvents from water surfaces.

Conclusion

In conclusion, a facile bulk polymerization technique was applied to synthesize hybrid organogel sorbents using different alkyl chain monomers and hydrophobic macroinimers. The effect of the monomers on the properties of the sorbents was investigated. The prepared hybrid organogels showed good swelling, high and quick organic liquid absorption ability, and efficient reusability properties. Owing to their hydrophobic features, the fabricated hybrid organogel sorbents showed exceptional absorption for different oils and organic solvents. In addition, the organogel sorbents can selectively absorb organic liquids from a mixture of wastewater, suggesting their efficacy as absorbing materials for water purification. The results showed that the synthesized sorbents are promising materials for the selective removal of organic pollutant spills on water surfaces.

Data availability

The data and materials that support the findings of this study are available on request from the corresponding author.

References

Ahmed EM (2015) Hydrogel: preparation, characterization, and applications: a review. J Adv Res 6(2):105–121

Atta AM, Arndt KF (2005) Swelling and network parameters of high oil-absorptive network based on 1-octene and isodecyl acrylate copolymers. J Appl Polym Sci 97(1):80–91

Ceylan D, Dogu S, Karacik B, Yakan SD, Okay OS, Okay O (2009) Evaluation of butyl rubber as sorbent material for the removal of oil and polycyclic aromatic hydrocarbons from seawater. Environ Sci Technol 43(10):3846–3852

Duan J, Liu W, Zhao X, Han Y, O’Reilly S, Zhao D (2018) Study of residual oil in Bay Jimmy sediment 5 years after the Deepwater Horizon oil spill: persistence of sediment retained oil hydrocarbons and effect of dispersants on desorption. Sci Total Environ 618:1244–1253

Erdem A (2021) Synthesis and characterization of polypropylene glycol-based novel organogels as effective materials for the recovery of organic solvents. J Appl Polym 138(7)

Farag RK, El-Saeed SM (2008) Synthesis and characterization of oil sorbers based on docosanyl acrylate and methacrylates copolymers. J Appl Polym Sci 109(6):3704–3713

Fritt-Rasmussen J, Wegeberg S, Gustavson K (2015) Review on burn residues from in situ burning of oil spills in relation to Arctic waters. Water Air Soil Pollut 226(10):329

Ghobashy MM, Younis SA, Elhady MA, Serp P (2018) Radiation induced in-situ cationic polymerization of polystyrene organogel for selective absorption of cholorophenols from petrochemical wastewater. J Environ Manag 210:307–315

Hamurcu EE, Hazer B, Baysal B (1997) Polystyrene-b-polydimethyl siloxane (PDMS) multicomponent polymer networks: styrene polymerization with macromonomeric initiators (macroinimers) having PDMS units. Polym 38(12):2981–2987

Hazer B, Örs Y, Alma MH (1993) Improvement of wood properties by impregnation with macromonomeric initiators (macroinimers). J Appl Polym Sci 47(6):1097–1103

Hazer B, Erdem B, Lenz RW (1994) Styrene polymerization with some new macro or macromonomeric azoinitiators having peg units. J Polym Sci A 32(9):1739–1746

Ida S, Kimura R, Tanimoto S, Hirokawa Y (2017) End-crosslinking of controlled telechelic poly (N-isopropylacrylamide) toward a homogeneous gel network with photo-induced self-healing. Polym J 49(2):237–243

Jin HX, Dong B, Wu B, Zhou MH (2012) Oil absorptive polymers: where is the future? Polym Plast Technol Eng 51(2):154–159

Kabir MH, Ahmed K, Furukawa H (2016) The effect of cross-linker concentration on the physical properties of poly (dimethyl acrylamide-co-stearyl acrylate)-based shape memory hydrogels. Microelectron Eng 150:43–46

Kangwansupamonkon W, Damronglerd S, Kiatkamjornwong S (2001) Effect of the third acrylated vinyl comonomer on absorption and desorption properties of styrene–divinylbenzene–alkyl acrylate terpolymers, imbibing solvent on a water surface. J Appl Polym Sci 79(3):504–516

Karadag K, Yati I, Sonmez HB (2016) Effective clean-up of organic liquid contaminants including BTEX, fuels, and organic solvents from the environment by poly (alkoxysilane) sorbents. J Environ Manag 174:45–54

Kiatkamjornwong S, Traisaranapong S, Prasassarakich P (1999) Styrene-divinylbenzene copolymers: influence of the diluents on absorption and desorption properties. J Porous Mater 6(3):205–215

Kilic D, Karaca Balta D, Saloglu D, Temel G (2019) Synthesis and characterization of POSS hybrid organogels using Menschutkin quaternization chemistry. Polym Int 68(3):369–376

Kizil S, Karadag K, Aydin GO, Sonmez HB (2015) Poly (alkoxysilane) reusable organogels for removal of oil/organic solvents from water surface. J Environ Manag 149:57–64

Lee P, Rogers MA (2013) Phase-selective sorbent xerogels as reclamation agents for oil spills. Langmuir 29(18):5617–5621

Lin Z, Wu W, Wang J, Jin X (2007) Studies on swelling behaviors, mechanical properties, network parameters and thermodynamic interaction of water sorption of 2-hydroxyethyl methacrylate/novolac epoxy vinyl ester resin copolymeric hydrogels. React Funct Polym 67(9):789–797

Melekaslan D, Kasapoglu F, Ito K, Yagci Y, Okay O (2004) Swelling and elasticity of hydrogels based on poly (ethylene oxide) macroinimer. Polym Int 53(3):237–242

Nam C, Zhang G, Chung TM (2018) Polyolefin-based interpenetrating polymer network absorbent for crude oil entrapment and recovery in aqueous system. J Hazard Mater 351:285–292

Prince RC, Coolbaugh TS, Parkerton TF (2016) Oil dispersants do facilitate biodegradation of spilled oil. PNAS 113(11):E1421–E1421

Song J, Lu Y, Luo J, Huang S, Wang L, Xu W, Parkin IP (2015) Barrel-shaped oil skimmer designed for collection of oil from spills. Adv Mater Interfaces 2(15):1500350

Sonmez HB, Wudl F (2005) Cross-linked poly (orthocarbonate) s as organic solvent sorbents. Macromol 38(5):1623–1626

Sundaravadivelu D, Suidan MT, Venosa AD, Rosales PI (2016) Characterization of solidifiers used for oil spill remediation. Chemosphere 144:1490–1497

Wang J, Geng G, Liu X, Han F, Xu J (2016) Magnetically superhydrophobic kapok fiber for selective sorption and continuous separation of oil from water. Chem Eng Res Des 115:122–130

Yamamoto Y, Nakao W, Atago Y, Ito K, Yagci Y (2003) A novel macroinimer of polyethylene oxide: synthesis of hyper branched networks by photoinduced H-abstraction process. Eur Polym J 39(3):545–550

Yati I, Karadag K, Sonmez HB (2015) Amphiphilic poly (ethylene glycol) gels and their swelling features. Polym Adv Technol 26(6):635–644

Yildiz U, Hazer B (1998): Free radical crosslinking copolymerization. Gelation behavior of macromonomeric azoinitiators versus macrocrosslinkers. Macromol Chem Phys 199(2): 163–168

Yıldız U, Hazer B (2000) Dispersion redox copolymerization of methyl methacrylate with macromonomeric azoinitiator as a macrocrosslinker. Polym 41(2):539–544

Yildiz U, Kemik ÖF, Hazer B (2010) The removal of heavy metal ions from aqueous solutions by novel pH-sensitive hydrogels. J Hazard Mater 183(1–3):521–532

Yildiz U, Hazer B, Tauer K (2012) Tailoring polymer architectures with macromonomer azoinitiators. Polym Chem 3(5):1107–1118

Zhang L, Zhang B, Wu T, Sun D, Li Y (2015) Adsorption behavior and mechanism of chlorophenols onto organoclays in aqueous solution. Colloids Surf A Physicochem Eng Asp 484:118–129

Zheng Y, Zhu Y, Wang A, Hu H (2016) Potential of Calotropis gigantea fiber as an absorbent for removal of oil from water. Ind Crop Prod 83:387–390

Zhou MH, Hoang T, Kim IG, Ha CS, Cho WJ (2001) Synthesis and properties of natural rubber modified with stearyl methacrylate and divinylbenzene by graft polymerization. J Appl Polym Sci 79(13):2464–2470

Acknowledgments

A great thanks to Polymer characterization research laboratory in Kocaeli University Chemical Engineering Department for TGA measurements.

Funding

This work is funded by the Kocaeli University for the financial support (BAP 2017/090 HD, 2017/086 HD, and 2018/001).

Author information

Authors and Affiliations

Contributions

A. E. and U. Y. conceived and planned the experiments. A. E. and N. M. carried out the experiments. A. E. and U. Y. contributed to the interpretation of the results. A. E. took the lead in writing the manuscript. All authors provided critical feedback and helped shape the research, analysis, and manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable

Additional information

Responsible Editor: Angeles Blanco

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 2945 kb)

Rights and permissions

About this article

Cite this article

Erdem, A., Mammadli, N. & Yildiz, U. Preparation of hydrophobic macroinimer–based novel hybrid sorbents for efficient removal of organic liquids from wastewater. Environ Sci Pollut Res 28, 22064–22076 (2021). https://doi.org/10.1007/s11356-020-11841-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-11841-6