Abstract

Solar desalination is one of the most sustainable solutions to produce freshwater from brackish water. The present research work aims to experimentally investigate the effect of a V-shape concentrator integrated with solar still (SS). The V-shape concentrator integrated with the conventional solar still (CSS) is used to supply the saline water at elevated temperature to the basin of SS, which augments the freshwater yield compared to CSS. The experimental investigation was performed at different brackish water depths of 0.01, 0.02, and 0.03 m, respectively. The SS system was evaluated based on water yield, energy, exergy, concentrator efficiency, and economic analysis. The freshwater yield of the solar still integrated with V-shape concentrator (SSVC) was found to be 5.47, 5.10, and 4.89 L/m2.day, whereas the yield of the CSS was 3.73, 3.27, and 2.91 L/m2 .day at the water depths of 0.01, 0.02, and 0.03 m, respectively. The daily energy and exergy efficiency of CSS were 38.5, 33.5, and 29.4% and 1.9, 1.5, and 0.97 % in the case of 0.01, 0.02, and 0.03m water depth , respectively. However, the integration of concentrator significantly augmented the energy efficiency to 57.4, 51.7, and 44.9% and exergy efficiency to 3.8, 3.3, and 2.8% for the respective water depths . Life cycle studies demonstrated that the freshwater cost per liter for CSS and SSVC were 0.0102 $ and 0.0117 $ respectively, at a water depth of 0.01 m. It was concluded that the addition of V-shape concentrator and minimum water depth is useful to augment the energy efficiency, exergy efficiency, and yield of the SS in the very economical way.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The severe difficulty faced by the world in the present century is to supply sufficient fresh water. Around two third of the earth is cover with water, but only one percent of this water is used for drinking and household purpose. As the worldwide demand for water consumption is greatly increasing, groundwater resources are tremendously exploited and the quantity of available water is reducing. The groundwater in different regions is not normally utilized for drinking purposes since there is a tremendous number of suspended solids and minerals. To improve the quality and solve the shortage of drinking water, several desalination techniques have been employedsuch as reverse osmosis (Boulahfa et al. 2019), multi-effect desalination (Doornbusch et al. 2019), humidifcation-dehumidification (Hamed et al. 2015; Kabeel et al. 2014), multi-stage flashing (El-Ghonemy 2018), and hybrid system (Sharshir et al. 2016a; Sharshir et al. 2016c). However, the major concerns of these techniques are a high amount of energy consumption.

Amongst the various available desalination methods, solar desalination is a good source due to the abundant solar availability, with yearly solar irradiance higher than 2000 kWh/m2/year in most parts of the world, except in Russia, Canada, Japan, and South Korea (Trieb et al. 2009). Solar still (SS) has been considered as one of the most effective techniques for desalination due to its lower construction and maintenances costs. However, the major limitation of the SS is its low productivity of distilled water as compared with other distillation processes. Various types of SS with different properties have been designed and developed to augment the freshwater yield such as passive SS (Thakur et al. 2020; Thaur et al. 2018b; Kumar Thakur and Kumar Pathak 2017; Balachandran et al. 2019a; Sharshir et al. 2016d; Singh et al. 2019), SS with phase change materials (Sharshir et al. 2017b; Sharshira et al. 2019), wick solar still (Sharshir et al. 2016b), active SS (Pounraj et al. 2018), stepped doublesteeped SS (Sharshir et al. 2020e), pyramid SS (Sharshir et al. 2020a; Sharshir et al. 2020b), active SS with concentrated SS (Muraleedharan et al. 2019), tubulars (Kabeel et al. 2019; Sharshir et al. 2019a), flat plate SS (Tanaka 2018), pyramid SSwith evacuated tubes (Sharshir et al. 2019b), and other miscellaneous-designed SS with a continuous flow of water (Balachandran et al. 2019b) and SS using heat-localized materials (Peng et al. 2020; Peng et al. 2018; Sharshir et al. 2020c; Sharshir et al. 2020d).

Kabeel et al. (2020a) investigated the effect of cylindrical parabolic concentrators (CPC) and energy storage materials on the freshwater yield of tubular solar still (TSS) under climatic conditions of Tanta, Egypt. The results showed that full-day freshwater yield was 5.79–5.94 L/m2 and 9.56 – 9.81 L/m2 in the case of traditional solar still and SS with CPC- energy storage material, respectively. Also, a daily efficiency augmented by 19.1% with the integration of CPC-energy storage materials, compared with conventional SS. A modified TSS using trough in the shape of two half concentric cylinders combined with CPC for clean water production was designed and investigated by Kabeel et al. (2020b). The result illustrated daily efficiency enhancement of 61.4 % at a water depth of 2 cm in the case of modified SS, while it was only 32.2 % for conventional tubular still. Thakur and Chandramohan (2020) investigated the freshwater yield of modified SS using copper absorber plate with Al2O3 nanofluid in the basin under the climatic conditions of Jaipur, India. Results showed that the combined effect of copper absorber plate and nanofluid in the basin augmented the water productivity to 4.77 L, while it was 4.41 L for aluminum absorber plate based solar still.

Elashmawy and Alshammari (2020) fabricated TSS integrated with a parabolic solar concentrator to augment the freshwater yield under the low humid conditions of Hail city, Saudi Arabia. It was observed that the integration of the parabolic concentrator significantly increased the freshwater yield of tubular solar still from 0.13 to 0.51 L/kg, an augmented yield of 292 % compared with the simple tubular still. Also, efficiency was enhanced from 13.5 to 24.6 % with the addition of concentrator. The improved performance still was achieved due to the supplementary energy provided by the concentrator through direct solar radiation that enhanced the total heat energy entering the tubular still, and the performance of tubular solar still was tremendously improved. Authors concluded that proposed compact and portable solar still could be easily operated in a remote and isolated desert area with no requirement for water sources. The performance of TSS integrated with the parabolic concentrator solar tracking system was experimentally investigated by Elashmawy (2020) using gravel as energy storage material. The author observed that the usage of gravel along with the concentrator in solar still was highly beneficial towards achieving high performance of the still. It was concluded that the addition of gravel augmented the freshwater yield and thermal efficiency by 4.51 L/m2/day and 36.3 %, respectively compared to 3.96 L/m2/day and 31.9% without gravel in the tubular solar still. The improved performance was achieved due to sensible heat absorbed by the gravel, which got released after the low solar radiation and the still was able to prolong the freshwater production even after sunset. Hassan et al. (2019) experimentally investigated the freshwater production of conventional SS integrated with a parabolic concentrator solar tracking system. The authors noticed that the addition of concentrator increased that basin water temperature by 26 and 16 °C in summer and winter, respectively. The maximum freshwater yield of 12.47 L/m2.day in summer and 5.81 L/m2.day in winter was observed, and this improvement was due to the extra energy supplied by the concentrator. Bahrami et al. (2019) designed a novel SS with a parabolic dish collector system, and the outcomes showed that for a collector with an aperture of 2 m, the freshwater productivity increased up to 120 and 80 %, when the reflectivity of the absorber plate reduced from 0.7 to 0.4, respectively. Fathy et al. (2018) experimentally examined the freshwater yield and thermal performance of SS using oil-heat exchanger integrated with parabolic concentrator-tracking system. It was found that a combined effect of heat exchanger along with the concentrator augmented the yield by 142.3%. Abu-Arabi et al. (2018) examined a SS integrated with solar collectors and sodium thiosulfate pentahydrate as the phase change material (PCM). It was inferred from the outcomes that cooling water flowing through the top glass cover improved the freshwater production by 37 %, owing to the higher driving potential between water basin and glass cover, which improved the freshwater yield. The freshwater yield of an inclined SS-combined flat plate collector (FPC) was experimentally studied by Manokar et al. (2018), and the result showed significantly improved yield compared with conventional-inclined SS. The freshwater yield of FPC combined with SS was found to be and 7.9 kg/day, whereas it was 4.3 kg/day in the case of conventional inclined SS. Hassan and Abo-Elfadl (2017) examined the yield of double slope SS attached with parabolic trough collector (PTC), and the results showed an advanced yield output of 10.93 kg/m2 using SS-PTC combinations. However, the full-day yield was found to 4.51 kg/m2, in the case of conventional SS. Al-harahsheh et al. (2018) experimentally investigated the yield of SS using PCM and the solar collector at various depths of water. The results depicted that the usage of PCM was most effective at the lower water depth. It was also observed that productivity decreased with increasing the water level inside the basin of the SS, and freshwater yield of 4.3 L/m2/day was observed. Kabeel and Abdelgaied (2017) investigated experimentally the influence of latent heat energy storage material integrated with a cylindrical concentrator on the freshwater yield of SS. It was found that the utilization of energy storage material along with concentrator augmented the water yield by 140.4% . Kabeel et al. (2017) used paraffin wax as PCM and integrated parabolic solar concentrator with SS to augment the thermal performance and freshwater production. It was found that using PCM and concentrator with SS enhanced the daily freshwater production by 55–65% and 35–45% in summer and winter, respectively compared to the conventional SS. The improved performance was due to the synergetic effect of PCM and concentrator, which augmented brackish water temperature and increased the evaporation rate from basin to glass. Elashmawy (2017) investigated the performance of tubular solar still using a parabolic concentrator solar tracking system under the climatic condition of Hail city, Saudi Arabia. It was observed that tubular SS using a rectangular black trough with black clothing as an absorber medium has produced the freshwater of 0.28 L/day along with the efficiency of 36.6%. However, the integration of the parabolic concentrator has significantly augmented the water yield by 1.66 L/day with an efficiency of 28.5 %. The enhanced thermal performance was achieved owing to the integration of concentrator that increased the amount of solar radiation absorbed by the basin of SS. Arunkumar et al. (2013) studied the freshwater yield performance of single basin solar still using PCM and compound parabolic concentrator. Authors observed that freshwater production of SS was achieved even after the sunset owing to the energy stored during the peak hours by PCM and yield was found to be 3.5 L/m2/day. Several other researchers such as Gorjian et al. (2014), Rajaseenivasan et al. (2016), and Shanmugan et al. (2008) have also investigated the effect of different collector attachments in SS to augment the freshwater yield. The usage of nano-coating on the concentrator and the condensed glass surface is also being explored in recent years. Mateen et al. (2017) experimentally investigated edge emission enhancement of solar concentrator using metal oxide nanoparticles coating. It was found that silver and gold nanoparticle with a mass concentration of 0.010% exhibited the maximum emission characteristics, due to the near field augmentation effect. Also, total power efficiency augmented by 10.37%, compared with the conventional concentrator. Zanganeh et al. (2020) explored the role of silicon nanoparticles coated condensation glass surface to change the condensation method from film-wise to dropwise. It was found that coated condensed surface in solar still promoted dropwise condensation and the water yield was augmented to 5.807 L/m2, while it was 4.82 L/m2 for solar still without coating.

From the literature review above, various designs modification were perfromed to improve the overall performance of the solar still. To increase the area exposed to solar radiation, some designs require additional components such as reflectors and collectors. The results illustrate that the freshwater yield was reasonably high in the case of tubular still, compared with other designs of SSs. Furthermore, there is still a lack of studies submitted on the integration of V-type water collector with solar still . The present research work aims to experimentally investigating the effect of a V-shape concentrator integrated with solar still (SS). The V-shape concentrator integrated with the conventional solar still (CSS) is used to supply the saline water at a elevated temperature to the basin of SS, which augments the freshwater yield compared with CSS. The experimental investigation was performed at different brackish water depths of 0.01, 0.02, and 0.03 m, respectively. The SS system was evaluated based on water yield, energy, exergy, concentrator efficiency, and cost analysis.

Experimental work

In the present studies, a V-shape concentrator was integrated with SS to elevate the brackish water temperature, and afterward, the heated water from the collector was forced into the water basin of the SS. Tropical countries like India received solar radiation of 200 MW/km2, and it varies according to the geographical location of the places. Moreover, the highest annual global solar radiation of ≥ 2400 kWh/m2 is being received in the states of Rajasthan and Gujarat (Purohit and Purohit 2010). The solar radiation of 6.0–7.0 kWh/m2 is received in Rajasthan, and due to the low rainfall area, good sunshine of more than 300 days in a year is observed (Singh et al. 2005). Considering the above, present location for conducting the experimentation was selected as Jaipur, Rajasthan, India

Experimentation setup and measurements

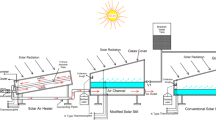

Two identical distillation setup including conventional single basin solar still (CSS) and single basin solar still integrated with V-shape concentrator (SSVC) were fabricated and tested under the climatic conditions of Jaipur, Rajasthan, India (26.9124° N latitude and 75.7873°E longitude) from 7:00 AM to 7:00 PM in 2017. The schematic diagram of the CSS and SSVC is represented in Fig. 1 (a–b). It is interesting to note that single basin solar still is preferable under the geographical condition of altitude higher than 20°, and due to this, the present experimental investigation was carried out using a single basin still. Under the geographically north latitude oriented cities, the single basin still is placed with a south-facing glass cover to receive maximum solar radiation throughout the year (Fath et al. 2003). Considering the above, the fabricated test setups were placed on the roof of Mechanical Engineering Department, Arya College of Engineering and Information Technology, Jaipur, Rajasthan, India with glass cover oriented towards the south direction. The absorber plate of the SS was made up to 1.25-mm thickness GI (galvanized iron) sheet and the basin area of 1 m2. The aperture of the constructed V-shape concentrator was 0.7 m with the 2-m collector length and 0.02-m receiver tube diameter. The V-shape concentrator consists of glass surface inclined at a 45° angle and a glass evacuated tube . The concentrator received the solar radiation and reflected it to the tube filled with brackish water and the temperature of the water inside the tube significantly increased before reaching the basin.

The circulation of brackish water from the concentrator to the basin was maintained using a pump and control valves. Initially, the basin is filled with 0.01-m depth of water, and a hole inside the SS basin exactly above 0.01-m height is provided for the exit brackish water. Once the water level reached above the hole, it passed through it and recirculated using pump. Similar process was used in the case of 0.02-m and 0.03-m water depth SS. In order to absorb the maximum solar radiation from the sun, the basin is black painted to absorb maximum solar radiation. Water was refilled every day in the early morning by an inlet provided in the SS. . All the walls and the basin of the SS were insulated by 3-cm thick fiberglass and support by a 2-cm thickness plywood box to shield the outside heat loss. The glass cover of the SS was 4-mm thick with the transmissivity of 94%.

The inclination angle of the glass surface is the most important factor affecting the received solar intensity and, thus, very important in the determination of freshwater yield. The inclination angle of 26° towards the south, which is similar to the experimental site latitude, has been given to the glass cover to make sure that solar still captures maximum average radiations during the year.

The similar inclination of glass cover in Jaipur, Rajasthan, was also tested by Kumar Thakur and Kumar Pathak (2017) and Thakur et al. (2018a) and reported that maximum solar radiation was received by using this inclination angle. It is well known that glass has hydrophilic properties, which in turn prevent the distilled water to fall back into the water basin. In order to remove the deposited salt after the repetitive cycle of evaporation and condensation from the water basin of SS, a sponge unit was utilized. Moreover, the lack of water basin cleaning process will certainly influence the overall efficiency of the SS. Further, deposited salt and dust particles may decrease the absorber plate absorptivity, which in turn decrease the freshwater yield of SS resulted due to the heat loss factors. The deposited salts along with other dust particles are tightly packed and disposed of properly. To maintain a better freshwater yield of SS, cyclic cleaning interval will be needed once in every 8 days of the SS operation and absorber plate and upper and lower glass surface of SS along with the concentrator glass, the evacuated glass tube is properly cleaned after every cycle of operation. The temperature at various locations of SS was measured by K-type thermocouples, and the position of the thermocouples was T1- glass upper surface temperature; T2 - glass lower surface temperature; T3- ambient air temperature; T4- absorber plate temperature; T5- concentrator outlet temperature of water and T6- concentrator inlet temperature of the water. A pyranometer was used to record solar radiation. In the present studies, varying water depth inside the CSS and SSVC of 0.01, 0.02, and 0.03 m, i.e., water quantity of 10, 20, and 30 L inside the basin of CSS and SSVC, have been investigated, and the flow was controlled using the flow control valve positioned outside the basin.

Uncertainty and error analysis

The present attempt was involved to experimentally measure the important factors such as temperature, freshwater yield, and solar radiation. In the present study, based on the range, precision, percentage inaccuracy, and uncertainty of the appliances have been illustrated in Table 1, and the uncertainty in the present study (uet) is calculated in Eq. (1) (Taylor 1982) as follows:

where n is the numeral of variables and u is the measuring apparatus standard uncertainty.

Mechanism

The productivity of the solar still increases with a rise in the evaporation rate of the water inside the basin, which rises with increasing the water temperature. So, the idea of the present work is to increase the brackish water temperature by preheating it using the V-shape concentrator before it enters the SS basin. The V-shape concentrator reflects the solar radiation incident on it to the pipe for preheating the water flowing into water basin. Water temperature is augmented as it goes to the water basin, and the heat transfer rate increased. Moreover, the solar radiation passed from the glass surface of SS reaches the basin water, and the temperature of water further increases in the basin of SS.

Thermal analysis

The daily efficiency of SS in all experimental analyses was calculated by the following equation:

where md is the sum of hourly freshwater yield throughout the day (kg/s); hfg is the latent heat of evaporation (kJ/kg), which is determined from Eq. (3) (Sharshir et al. 2020c); Abs is the basin area (m2); and It is average daily solar radiation (kW/m2):

The energy and exergy analysis of the SS turns out to be a significant technique to estimate and evaluate the processes by recognizing their deficiency due to thermodynamic irreversibility, and thus, the exergy analysis can be used to aid in improving and optimizing SS designs. The equation of exergy for the SS can be written as Eq. (4) or Eq. (5) (Hassan and Abo-Elfadl 2017).The solar radiation is considered to be the input exergy for the SS, and it is determined using Eq. (6) (Elshamy and El-Said 2018). The exergy output of the SS can be evaluated using Eq. (7) (Elbar et al. 2019).

where Tsun is the sun temperature in K, Tw is the water temperature in K, and the exergy of work rate, (εx, work)∈x,work in the case of the SS is considered to be zero. The exergy efficiency is then calculated using the following equation (Sharshir et al. 2017a):

The efficiency of a solar concentrator is very vital to decide the collector area for solar desalination. The efficiency of the concentrator was determined using Eq. (9) (Riffat and Mayere 2013)

where d is the receiver tube diameter, Cp is the specific heat capacity of water, μ is the viscosity of water, and xcmin and L are the aperture and length.

Result and discussions

Temperature variation and yield analysis of CSS

The solar radiation and temperatures at all the junctions such as upper glass, lower glass, absorber plate, and the freshwater yield were measured on an hourly basis. Solar radiation plays a noteworthy role in generating the distilled water output of the SS, and Fig. 2 shows the solar radiation distribution through the days in the case of all water depths. It was observed that the highest solar radiation values exist in the period of 12 noon to 2:30 PM in all three cases and declined gradually till evening.

Temperature variation inunder all three water depth conditions of CSS is explained in Fig. 3. It is observed that the average ambient temperature is 34.7 °C in the case of 0.01-m CSS, as shown in Fig. 3 (a). Temperatures of absorber plate inside the water basin, lower glass, and upper glass basin augmented with raise in solar radiation, and it attained its highest value at 1 PM, thereafter value declined. The maximum temperatures of the absorber plate, glass lower, and glass upper basin were found to be 73, 68, and 62 °C, respectively, in the case of 0.01-m CSS. It is well known that solar radiation received from the glass surface to the basin augments the water temperature and the absorber plate shows the highest temperature values compared with all other positions inside the CSS. Once the water is heated, the evaporation commences and the vapor film was formed in the inner glass surface, so the next highest temperature profile was observed at the inner glass surface, followed by the glass outer surface . To maximize the freshwater output from the still, temperature difference of water basin and the lower glass surface inside the SS must be increased to improve the natural circulation along with the rate of condensation. Water depth of 0.01 m inside the CSS promoted the maximum temperature difference of 8 °C between glass lower surface and absorber plate at 1 PM, which augment the condensation rate and the hourly freshwater yield. Fig. 4 shows an hourly freshwater yield of CSS and the highest freshwater yield of 0.50 L/h was achieved with a water depth of 0.01-m CSS. The full-day distilled output in the case of 0.01 m CSS was found to be 3.73 L/m2.day. The experimental results achieved using a minimum water depth of 0.01 m in the present study is comapred with the results reported by Hassan et al. (2019) and Morad et al. (2015). The result demonstrate that distilled output of SS is inversely proportional to the water depth . However, too little water inside the basin may lead to the development of the dry spots in the water basin, which may have a negative influence on distilled water production. The development of dry spots inside the water basin may lead to the outgassing of water basin material which is not desirable (Kopperdal 2015). Variations of the absorber plate, lower glass, upper glass, and ambient air temperature in the case of 0.02-m CSS are plotted in Fig. 3 (b). It was found that the the average ambient temperature is 35 °C. Temperatures of the absorber plate, glass lower, and glass upper augmented with increase in solar radiation, and attained maximum value of 67, 61, and 55 °C, respectively, at 1 PM. With an increase in a water depth of CSS, the maximum attained temperature across all the junction significantly reduced.

It can be explained due to the fact that increasing water capacity decreases the rise in water temperature. Due to the large mass of water in the basin, heat transfer reduced, and rise in water temperature was restricted. This leads to a lower water vaporization rate from basin to glass surface, which reduced the quantity of collected freshwater from glass lower temperature. It was found that the maximum freshwater yield is 0.45 L/h at 1 PM, as shown in Fig. 4 and maximum yield is reduced by 10% as compared with 0.01-m CSS . The full-day freshwater yield was found to be 3.27 L/m2.day. It is noted that increasing the water depth from 0.01 to 0.02 m reduced the full-day freshwater yield by 12%, owing to the low-evaporation rate resulted from the high water level. Similar trends of results have been reported by Hoqueet al. (2019). Variations of the absorber plate, lower glass, upper glass, and ambient air temperature in the case of 0.03-m CSS are plotted in Fig. 3 (c). It was found that the average ambient temperature is 35.6 °C. Temperatures of the absorber plate, glass lower, and glass upper augmented with increases in ambient temperature along with solar radiation and it attained its maximum value of 63, 59, and 52 °C, respectively at 1 PM. . The maximum freshwater yield of 0.41 L/h and a full-day yield of 2.91 L/m2.day was achieved. It was construed from the above results that lower water depth supports higher freshwater yield, owing to the lower volume of saline water which resulted in a higher heat transfer rate from the basin to the condensed glass surface, and this generates more freshwater. As the depth of water increased, the heat transfer rate reduced from the basin to the glass surface, and the lower evaporation rate caused the lesser freshwater output.

Temperature variation and yield analyses of the SSVC

In the present work, a novel experimental approach utilizing V-shape concentrators with conventional solar still was explored in order to augment the oveall performanceunder the water depths of 0.01, 0.02, and 0.03 m. The water basin of the solar still gets radiation owing to their direct exposure to the sun, and it gets additional energy from the supplied brackish water into the basin, which is passed through the concentrator tube that receives direct radiation and concentrates it onto the tube through which the brackish water is forced to flow through basin using pump . As the water basins are black painted, the majority of the solar radiation is converted into heat energy, and this heat flows to the brackish water, glass tubes, and glass surface. Thus there is a significant temperature gradient across the different parts of the CSS attached to the V-shape concentrator as shown in Fig. 5 (a-c). Temperature distribution of the SSVC at different locations including inlet brackish water in solar still, glass upper surface, glass lower surface, absorber plate, and ambient air in the case of 0.01 m SSVC is shown in Fig. 5 (a). At the maximum ambient temperature , the maximum temperature value of the inlet water, absorber plate, glass lower, and glass upper was found to be 85, 80, 73, and 67 °C, respectively. It has been seen that the integration of the concentrator significantly improved the temperature distribution across the entire junction in the SS. The peak temperature of brackish water flowing into the basin attained the highest value among all the temperature junction of SS. The concentrator focused the solar radiation into the evacuated tube, where the brackish water flow through and it significantly raised the temperature of the water inside it. The augmented temperature at all junction in SSVC was attained due to the integration of concentrator, which preheated the brackish water inside the evacuated glass tube flowing into the basin, and it augments the natural circulation inside the still along with condensation rate. The higher temperature of the absorber plate supports higher evaporation and condensation rate inside the still, which leads to augmented freshwater yield. It was found that the maximum hourly distilled output attained at 1 PM is 0.79 L/m, as shown in Fig. 6, and it was improved by 39% as compared with CSS. Also, the full day freshwater yield achieved by 0.01 m SSVC was 5.47 L/m2.day, and it was augmented by 1.47 L/m2.day compared with CSS. It has been seen from the results that significant freshwater yield improvement is possible with the integration of concentrator in CSS in dry and humid climatic conditions of Jaipur, India.

The effect of varying water depth on yield performance of still has been also studied in the case of SSVC and presented in the following section. Figure 5 (b) shows the temperature curve of SSVC with 0.02-m water depth. The temperatures of the inlet brackish water, absorber plate, glass lower, and glass upper were found to be 77, 74, 66, and 59 °C. It is well known that increasing the water depth has reduced the maximum attained temperature across all the junctions in SSVC and reason is already explained in the previous section of CSS. . The maximum freshwater yield at 1 PM was 0.71 L/h, and it was augmented by 36% as compared with 0.02 m CSS, as shown in Fig. 6. The full-day freshwater yield was found to be 5.10 L/m2.day. An increase in water depth from 0.01 to 0.02 m in the case of SSVC has reduced the full-day freshwater yield by 6.7 %, which is due to the lower heat transfer rate caused by the larger mass of water in the basin. Though the results are not encouraging compared with the yield output of 0.01 m SSVC, integration of concentrator will be the most suitable option for achieving the maximum freshwater yield in solar still. Full-day freshwater yield augmentation of 1.8 L was achieved, compared with that of CSS. Therefore, the integrated concentrator leads to additional energy supplied inside the basin, and it augmented the freshwater yield significantly.

Temperature variation in the case of 0.03 m SSVC has been presented in Fig. 5 (c). The maximum ambient temperature was attained at 1 PM, and the highest temperature at inlet brackish water, absorber plate, lower glass, and upper glass surface was found to be 75, 71, 63, and 55 °C. It is seen from the results that higher water depth hindered the evaporation and condensation rate, owing to the higher mass of water resulted in a lower heat transfer rate. The rise in different junction temperatures compared with CSS was predominantly due to the additional energy supplied by the concentrator. Fig. 5 (d) shows the varation in inlet saline water temperature in the case of CSS and SSVC at the best water depth in terms of yield (0.01 m). As seen from the figure, the maximum temperature difference between both the inlet brackish water was found to be 39 °C at peak solar radiation due to the higher solar radation collected by V concentrator, which augmented the inlet water temerpature considerably. This increased temperature of the inlet water helped to initiate the evaporation at a faster rate, and thus, the fresh water productivity was high for all cases of SSVC. The maximum freshwater yield of 0.65L/h was achieved by 0.03 m SSVC as shown in Fig. 6, and the peak hour yield augmented by 36 % as compared with the CSS. Full-day distilled output was 4.89 L/m2.day. However, the increase in water depth inside SSVC up to 0.03 m has reduced the full-day freshwater yield by 10 and 4% as compared with 0.01 and 0.02-m SSVC, respectively.

It has been inferred from the above results that the freshwater yield of SS can be significantly improved with the integration of concentrator. Concentrator helps to augments the temperature of the saline water coming inside the basin of SS. Also, the rate of heat transfer during evaporation from the water basin to the glass surface is mainly subjected to the surface area of the absorber, and the rate of vaporization primarily depended on the water basin, glass surface, and surrounding temperature. The rate of evaporation from the basin to the condensed surface significantly improved due to the preheated/elevated saline water temperature in the basin, and it improved the yield of distilled water.

Thermal analysis

Figure 7 presents the average full-day thermal efficiencies of CSS and SSVC, which is determined using Eq. (2). The result showed average full-day efficiency of 38.5, 33.5, and 29.4% in the case of CSS with 0.01, 0.02, and 0.03-m water depth, respectively. It is noted that efficiency mainly depends on the freshwater yield collected throughout the day and solar radiation. Due to lower water depth in the case of 0.01-m CSS, the maximum freshwater yield was achieved which leads to the highest full-day efficiency. It is also interesting to note that the augmented yield of freshwater was achieved not only due to the rise in water vapor temperature resulted from a lower depth of water inside the still chamber, but also due to the ambient conditions such as ambient temperature and wind speed. For SSVC, the collected solar intensity from the concentrator preheated the brackish water before entering the basin of solar still. This leads to maximum gain in the temperature across various junction. Further, a rise in the water temperature initiated the evaporation at a faster rate, which in turn produced maximum freshwater, and therefore, significant augmented daily efficiency was achieved. Full-day energy efficiency of SSVC under the water depth of 0.01, 0.02, and 0.03 m was found to be 57.4, 51.7, and 44.9%, respectively.

Figure 8 (a–c) depicts the hourly exergy efficiency of the CSS and SSVC under the water depths of 0.01, 0.02, and 0.03 m. As seen from the results, the hourly exergy begins to augment at the start of the experiment and attained the peak value at approximately 1 PM for 0.01-m water depth CSS and SSVC. The maximum hourly exergy was found to be 7.2% and 3.6% in the case of 0.01-m water depth SSVC and CSS, respectively. It was obvious that augmented heat transfer from basin to the glass surface provides the optimum evaporation and condensation rate in SSVC, and the hourly exergy was significantly improved. The peak hourly exergy in the case of 0.02- and 0.03-m water depth SSVC were 5.4 and 4.01%, respectively. However, in the case of CSS, the peak hourly exergy was found to be 2.81 and 2.3%, respectively.

It is noted that the addition of the concentrator improved the hourly exergy in all the cases. Moreover, with increasing the depth of water in the basin, the peak hourly exergy dropped remarkably and, therefore, minimal depth of water is needed to augment the performance of SSs. Fig. 9 illustrates the daily exergy efficiency of the SSVC and CSS under the different water depths. The highest daily exergy efficiency of 3.8% was found in the case of 0.01-m water depth SSVC. However, it reduced to 1.98% in the case of CSS. The integration of concentrator improved the energy efficiency of SS and it augmented the full-day exergy efficiency of SS. Further, the exergy efficiency of 3.3 and 2.4% was found in the case of 0.02- and 0.03-m water depth SSVC, respectively. However, it was found to be 1.54 and 0.97% in the case of CSS. Results showed that exergy efficiency can be improved significantly with the integration of concentrator in the existing SSs.

The efficiency of the solar concentrator for different water depths in basin of still was calculated using Eq. (9) and presented in Fig. 10. Maximum efficiency of concentrator was found to be 36.7% in the case of 0.01 m water depth. However, it was reduced to 34.9 and 33.3% in the case of 0.02 and 0.03 m, respectively. The selection of an optimum solar concentrator configuration to augment the freshwater yield is very important. A most important factor for the selection of concentrators is high transmittance through the tube, minimizing heat loss from the concentrator system. The role of various factors affecting the efficiency and performance of the concentrator is under progress.

Assessment of earlier results with current work

The freshwater yield analysis of previous research carried out by many novelists using various arrangements in the conventional solar still such as reflector and concentrator for augmented basin water temperature and enhanced the yield of clean water in shown in Table 2, and all the previous results have been compared with the present experimental result.

Economic analysis

The primary annual charge (PAC) of the SS is determined by using Eq. (10) (Petela 2003), in which the capital recovery aspect (CRA) of the SS is determined by Eq. (11) (Sharshir et al. 2020c). The first early salvage value (YSV) of the SS is determined using Eq. (12) (Elbar et al. 2019; Sharshir et al. 2020c):

where C stands for the capital cost of the SS; i and l signify the rate of interest and life of the SS, respectively; and SC and SFA specify the salvage cost of the SS and sinking fund aspect, and they are determined by using Eq. (13) and (14), respectively (Gorjian et al. 2014):

The annual upholding cost (YUC) is expressed by Eq. (15). The overall annual cost (OAC) of the SS is obtained by Eq. (16). Lastly, the distill water cost per liter (CPL) is determined by Eq. (17):

where M is the mean annual production.

The fabrication costs of CSS and SSVC are shown in Table 3. The life span of the still was 15 years with 80 % of the average sunny days per year and a bank interest rate of 8 % in India (experimental site). The entire cost of the simple SS for the water profundity of 0.01 m would be about 52 USD/m2. With the still productivity of 3.73 L/m2/day, cost of freshwater was 0.0102 $/L . The addition of the V-shape concentrator increased the cost of water by 14.70%/L (0.0117 $/L) with a tremendous increment in the yield productivity of 47 %. Therefore, the marginal increase in the cost of SS showed a tremendous increment in the yield productivity in the case of the SSVC with 0.01-m water depth. From the perspective of societal-based technology, Rajasthan being a hot and dry state in India faces the severe problem of freshwater due to poor rainfall and it excessively exploited the groundwater for drinking purpose. The proposed experimental setup for freshwater production from brackish water resources will helpful to develop low-cost, renewable energy-based solar desalination systems. It will be highly useful for providing freshwater to the rural and remotely located population in a state like Rajasthan and Gujarat, where solar energy is available throughout the year.

Conclusions

Single basin solar still integrated with a V-shape concentrator was designed and fabricated to improve the freshwater yield. In the developed single basin solar still, the concentrator was used to increase the basin water temperature. The comparison between a developed solar still integrated with a concentrator and a conventional single basin solar still under three water depth of 0.01, 0.02, and 0.03 m in the basin were carried out to evaluate the enhancement in the freshwater yield under the same ambient conditions of the Jaipur, Rajasthan, India. According to the results obtained by experimental investigation, the following major conclusions were derived:

-

Integration of concentrator augmented the temperature at all the locations inside the basin of SS, and the maximum rise in absorber plate temperature of 7 °C during peak solar radiation hour in all the water depth conditions was attained, compared with the CSS; this is due to the combined effect of direct solar radiation received by absorber plate and the supplementary energy provided by the concentrator.

-

CSS freshwater yield was found to be 3.73, 3.27, and 2.91 L/m2.day in the case of 0.01, 0.02, and 0.03-m water depth, respectively. Moreover, the integration of concentrator has significantly augmented the freshwater yield to 5.47, 5.10, and 4.89 L/m2.day respectively, owing to the extra energy supplied by the concentrator which enhanced the evaporation rate, and thus, maximum yield was achieved.

-

The energy efficiency of CSS was 38.5, 33.5, and 29.4% for a water depth of 0.01, 0.02, and 0.03 m, respectively, and it increased to 57.4, 51.7, and 44.9% for the respective cases of SSVC. Concentrator efficiency was found to be 36.7, 34.9, and 33.3% with a water depth of 0.01, 0.02, and 0.03 m respectively in the basin of SS.

-

The hourly exergy efficiency increases with solar radiation and peak daily exergy reached 7.2% in the case of 0.01 m water depth SSVC. However, it was only 3.6% for CSS. The full-day exergy was found to be 3.8, 3.3, and 2.8% in the case of SSVC with a water depth of 0.01, 0.02, and 0.03 m, respectively, while it was drastically reduced to 1.9, 1.5, and 0.97% in the case of CSS.

-

The cost of water/liter produced from SS and SSVC was 0.0102 and 0.0117 $/L, respectively. From the economic analysis, the rate of freshwater production is found to be cheapest for both the cases.

Abbreviations

- T1 :

-

upper glass cover temperature (°C)

- T2 :

-

lower glass cover temperature (°C)

- T3 :

-

ambiant air température (°C)

- T4 :

-

absorber plate température (°C)

- T5 :

-

V-shape concentrator outlet température (°C)

- T6 :

-

V-shape concentrator inlet température (°C)

- TS :

-

sun température (°C)

- ϵin :

-

input exergy

- ϵx, evap :

-

output exergy

- ϵx, work :

-

work rate exergy

- ηd :

-

daily energy efficiency

- CSP:

-

concentrated solar power

- CSS:

-

conventional solar still

- FPC:

-

flat plate collectors

- FPR:

-

flat plate reflector

- PCM:

-

phase change materials

- PTC:

-

parabolic trough collectors

- SS:

-

solar still

- TSS:

-

tubular solar still

- SSVC:

-

solar still attached with V-shape concentrator

- VMEDS:

-

vertical multiple-effect diffusion solar still

References

Abu-Arabi M, Al-harahsheh M, Mousa H, Alzghoul Z (2018) Theoretical investigation of solar desalination with solar still having phase change material and connected to a solar collector. Desalination 448:60–68

Al-harahsheh M, Abu-Arabi M, Mousa H, Alzghoul Z (2018) Solar desalination using solar still enhanced by external solar collector and PCM. Appl Therm Eng 128:1030–1040

Arunkumar T, Denkenberger D, Ahsan A, Jayaprakash R (2013) The augmentation of distillate yield by using concentrator coupled solar still with phase change material. Desalination 314:189–192

Arunkumar T, Velraj R, Denkenberger D, Sathyamurthy R, Vinothkumar K, Porkumaran K, Ahsan A (2016) Effect of heat removal on tubular solar desalting system. Desalination 379:24–33

Bahrami M, Avargani VM, Bonyadi M (2019) Comprehensive experimental and theoretical study of a novel still coupled to a solar dish concentrator. Appl Therm Eng 151:77–89

Balachandran GB, David PW, Mariappan RK, Kabeel AE, Athikesavan MM, Sathyamurthy R (2019a) Improvising the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. Environ Sci Pollut Res:1–14

Balachandran GB, David PW, Vijayakumar ABP, Kabeel AE, Athikesavan MM, Sathyamurthy R (2019b) Enhancement of PV/T-integrated single slope solar desalination still productivity using water film cooling and hybrid composite insulation. Environ Sci Pollut Res:1–12

Boulahfa H, Belhamidi S, Elhannouni F, Taky M, El Fadil A, Elmidaoui A (2019) Demineralization of brackish surface water by reverse osmosis: The first experience in Morocco. J Environ Chem Eng 7:102937

Doornbusch G, Tedesco M, Post J, Borneman Z, Nijmeijer K (2019) Experimental investigation of multistage electrodialysis for seawater desalination. Desalination 464:105–114

Elashmawy M (2017) An experimental investigation of a parabolic concentrator solar tracking system integrated with a tubular solar still. Desalination 411:1–8

Elashmawy M (2020) Improving the performance of a parabolic concentrator solar tracking-tubular solar still (PCST-TSS) using gravel as a sensible heat storage material. Desalination 473:114182

Elashmawy M, Alshammari F (2020) Atmospheric water harvesting from low humid regions using tubular solar still powered by a parabolic concentrator system. J Clean Prod 256:120329

Elbar ARA, Yousef MS, Hassan H (2019) Energy, exergy, exergoeconomic and enviroeconomic (4E) evaluation of a new integration of solar still with photovoltaic panel. J Clean Prod 233:665–680

El-Ghonemy A (2018) Performance test of a sea water multi-stage flash distillation plant: case study. Alex Eng J 57:2401–2413

Elshamy SM, El-Said EM (2018) Comparative study based on thermal, exergetic and economic analyses of a tubular solar still with semi-circular corrugated absorber. J Clean Prod 195:328–339

Fath HE, El-Samanoudy M, Fahmy K, Hassabou A (2003) Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 159:69–79

Fathy M, Hassan H, Ahmed MS (2018) Experimental study on the effect of coupling parabolic trough collector with double slope solar still on its performance. Sol Energy 163:54–61

Gorjian S, Ghobadian B, Hashjin TT, Banakar A (2014) Experimental performance evaluation of a stand-alone point-focus parabolic solar still. Desalination 352:1–17

Hamed MH, Kabeel AE, Omara Z, Sharshir S (2015) Mathematical and experimental investigation of a solar humidification–dehumidification desalination unit. Desalination 358:9–17

Hassan H, Abo-Elfadl S (2017) Effect of the condenser type and the medium of the saline water on the performance of the solar still in hot climate conditions. Desalination 417:60–68

Hassan H, Ahmed MS, Fathy M (2019) Experimental work on the effect of saline water medium on the performance of solar still with tracked parabolic trough collector (TPTC). Renew Energy 135:136–147

Kabeel AE, Abdelgaied M (2017) Observational study of modified solar still coupled with oil serpentine loop from cylindrical parabolic concentrator and phase changing material under basin. Sol Energy 144:71–78

Kabeel AE, Hamed MH, Omara Z, Sharshir S (2014) Experimental study of a humidification-dehumidification solar technique by natural and forced air circulation. Energy 68:218–228

Kabeel AE, Elkelawy M, El Din HA, Alghrubah A (2017) Investigation of exergy and yield of a passive solar water desalination system with a parabolic concentrator incorporated with latent heat storage medium. Energy Convers Manag 145:10–19

Kabeel AE, Sharshir SW, Abdelaziz GB, Halim MA, Swidan A (2019) Improving performance of tubular solar still by controlling the water depth and cover cooling. J Clean Prod 233:848–856

Kabeel AE, Harby K, Abdelgaied M, Eisa A (2020a) Augmentation of a developed tubular solar still productivity using hybrid storage medium and CPC: An experimental approach. J Energy Storage 28:101203

Kabeel AE, Harby K, Abdelgaied M, Eisa A (2020b) Performance of the modified tubular solar still integrated with cylindrical parabolic concentrators. Sol Energy 204:181–189

Kopperdal HH (2015) Design, prototyping and field testing of solar stills in remote areas in Afghanistan. Norwegian University of Life Science, Ås

Kumar Thakur A, Kumar Pathak S (2017) Single basin solar still with varying depth of water: optimization by computational method. Iranica Journal of Energy and Environment(IJEE) 8(3):216–223

Manokar AM, Winston DP, Mondol JD, Sathyamurthy R, Kabeel AE, Panchal H (2018) Comparative study of an inclined solar panel basin solar still in passive and active mode. Sol Energy 169:206–216

Mateen F, Oh H, Jung W, Binns M, Hong S-K (2017) Metal nanoparticles based stack structured plasmonic luminescent solar concentrator. Sol Energy 155:934–941

Morad M, El-Maghawry HA, Wasfy KI (2015) Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Desalination 373:1–9

Muraleedharan M, Singh H, Udayakumar M, Suresh S (2019) Modified active solar distillation system employing directly absorbing Therminol 55–Al2O3 nano heat transfer fluid and Fresnel lens concentrator. Desalination 457:32–38

Peng G, Ding H, Sharshir SW, Li X, Liu H, Ma D, Wu L, Zang J, Liu H, Yu W, Xie H, Yang N (2018) Low-cost high-efficiency solar steam generator by combining thin film evaporation and heat localization: Both experimental and theoretical study. Appl Therm Eng 143:1079–1084

Peng G, Deng S, Sharshir SW, Ma D, Kabeel AE, Yang N (2020) High efficient solar evaporation by airing multifunctional textile. Int J Heat Mass Transf 147:118866

Petela R (2003) Exergy of undiluted thermal radiation. Sol Energy 74:469–488

Pounraj P, Winston DP, Kabeel AE, Kumar BP, Manokar AM, Sathyamurthy R, Christabel SC (2018) Experimental investigation on Peltier based hybrid PV/T active solar still for enhancing the overall performance. Energy Convers Manag 168:371–381

Purohit I, Purohit P (2010) Techno-economic evaluation of concentrating solar power generation in India. Energy Policy 38:3015–3029

Rajaseenivasan T, Tinnokesh A, Kumar GR, Srithar K (2016) Glass basin solar still with integrated preheated water supply–theoretical and experimental investigation. Desalination 398:214–221

Riffat S, Mayere A (2013) Performance evaluation of v-trough solar concentrator for water desalination applications. Appl Therm Eng 50:234–244

Shanmugan S, Rajamohan P, Mutharasu D (2008) Performance study on an acrylic mirror boosted solar distillation unit utilizing seawater. Desalination 230:281–287

Sharshir S, Peng G, Yang N, El-Samadony M, Kabeel AE (2016a) A continuous desalination system using humidification–dehumidification and a solar still with an evacuated solar water heater. Appl Therm Eng 104:734–742

Sharshir SW, El-Samadony MOA, Peng G, Yang N, Essa FA, Hamed MH, Kabeel AE (2016b) Performance enhancement of wick solar still using rejected water from humidification-dehumidification unit and film cooling. Appl Therm Eng 108:1268–1278

Sharshir SW, Peng G, Yang N, Eltawil MA, Ali MKA, Kabeel AE (2016c) A hybrid desalination system using humidification-dehumidification and solar stills integrated with evacuated solar water heater. Energy Convers Manag 124:287–296

Sharshir SW, Yang N, Peng G, Kabeel AE (2016d) Factors affecting solar stills productivity and improvement techniques: A detailed review. Appl Therm Eng 100:267–284

Sharshir SW, Elsheikh AH, Peng G, Yang N, El-Samadony MOA, Kabeel AE (2017a) Thermal performance and exergy analysis of solar stills – A review. Renew Sust Energ Rev 73:521–544

Sharshir SW, Peng G, Wu L, Essa FA, Kabeel AE, Yang N (2017b) The effects of flake graphite nanoparticles, phase change material, and film cooling on the solar still performance. Appl Energy 191:358–366

Sharshir SW, Ellakany YM, Algazzar AM, Elsheikh AH, Elkadeem MR, Edreis EMA, Waly AS, Sathyamurthy R, Panchal H, Elashry MS (2019a) A mini review of techniques used to improve the tubular solar still performance for solar water desalination. Process Saf Environ Prot 124:204–212

Sharshir SW, Kandeal AW, Ismail M, Abdelaziz GB, Kabeel AE, Yang N (2019b) Augmentation of a pyramid solar still performance using evacuated tubes and nanofluid: Experimental approach. Appl Therm Eng 160:113997

Sharshir SW, Abd Elaziz M, Elkadeem M (2020a) Enhancing thermal performance and modeling prediction of developed pyramid solar still utilizing a modified random vector functional link. Sol Energy 198:399–409

Sharshir SW, Elkadeem M, Meng A (2020b) Performance enhancement of pyramid solar distiller using nanofluid integrated with v-corrugated absorber and wick: An experimental study. Appl Therm Eng 168:114848

Sharshir SW, Ellakany YM, Eltawil MA (2020c) Exergoeconomic and environmental analysis of seawater desalination system augmented with nanoparticles and cotton hung pad. J Clean Prod 248:119180

Sharshir SW, Elsheikh AH, Ellakany YM, Kandeal AW, Edreis EMA, Sathyamurthy R, Thakur AK, Eltawil MA, Hamed MH (2020d) Improving the performance of solar still using different heat localization materials. Environ Sci Pollut Res:1–13

Sharshir SW, Eltawil MA, Algazzar AM, Sathyamurthy R, Kandeal A (2020e) Performance enhancement of stepped double slope solar still by using nanoparticles and linen wicks: Energy, exergy and economic analysis. Appl Therm Eng, 115278.

Sharshira SW, Elsheikhd AH, Edreise EM, Alig MKA, Sathyamurthyh R, Kabeel AE, Zanga J, Yangb N (2019) Improving the solar still performance by using thermal energy storage materials: A review of recent developments. Desalin Water Treat 165:1–15

Singh H, Singh A, Chaurasia P, Singh A (2005) Solar energy utilization: A key to employment generation in the Indian Thar Desert. Int J Sustain Energy 24:129–142

Singh AK, Singh D, Mallick A, Sharma SK, Kumar N, Dwivedi V (2019) Performance analysis of specially designed single basin passive solar distillers incorporated with novel solar desalting stills: A review. Sol Energy 185:146–164

Tanaka H (2018) Analyzing the effect of an enlarged flat plate reflector (FPR) on a vertical multiple-effect diffusion solar still’s (VMEDS) performance. Appl Therm Eng 142:138–147

Taylor J (1982) An Introduction to Error Analysis: The Study of Uncertainties in.

Thakur AK, Chandramohan V (2020) Productivity Enhancement of Passive Type Solar Still Using Copper and Aluminum Based Absorber Plate with Al 2 O 3 NanoFluid in Water Basin, Advances in Energy Research, Vol. 2. Springer, pp. 273-281.

Thakur AK, Agarwal D, Khandelwal P, Dev S (2018a) Comparative study and yield productivity of nano-paint and nano-fluid used in a passive-type single basin solar still, Advances in Smart Grid and Renewable Energy. Springer, pp. 709-716.

Thakur AK, Khandelwal P, Sharma B (2018b) Productivity comparison of solar still with nano fluid and phase changing material with same depth of water. In: Anand G, Pandey J, Rana S (eds) Nanotechnology for Energy and Water. ICNEW 2017. Springer Proceedings in Energy. Springer, Cham. https://doi.org/10.1007/978-3-319-63085-4_17

Thakur AK, Vikrama MP, Christopher S (2020) Augmented yield productivity of solar still using energy storage materials: Experimental investigation under the climatic conditions of Rajasthan. In: Bhoi A, Sherpa K, Kalam A, Chae GS (eds) Advances in Greener Energy Technologies. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-15-4246-6_51

Trieb F, Schillings C, O’sullivan M, Pregger T, Hoyer-Klick C (2009) Global potential of concentrating solar power. German Aerospace Centre (DLR)

Zanganeh P, Goharrizi AS, Ayatollahi S, Feilizadeh M (2020) Nano-coated condensation surfaces ٍenhanced the productivity of the single-slope solar still by changing the condensation mechanism. J Clean Prod, 121758.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thakur, A.K., Sharshir, S.W., Ma, Z. et al. Performance amelioration of single basin solar still integrated with V- type concentrator: Energy, exergy, and economic analysis. Environ Sci Pollut Res 28, 3406–3420 (2021). https://doi.org/10.1007/s11356-020-10625-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-10625-2