Abstract

In this study, a photovoltaic/thermal (PVT) collector and a stepped solar still system were constructed and integrated. The PVT collector was used to improve the performance of a stepped solar still device. Saltwater enters into the PV-T system and the temperature of the solar panel declines, and then ultimately the efficiency of the PV-T collector increases. After leaving the PVT collector, the temperature of the saltwater increased and was used as a pre-heater for further evaporation in the solar still, which ultimately caused an increase in its efficiency. The more tremendous temperature difference generated between the stepped surface and the glass increases efficiency and produces more freshwater. A flow rate of 7.5 L/hour of saline water was used to study the efficiency of the solar still device and the PVT collector. The value of productivity of solar still system with photovoltaic/thermal collector was 0.76 kg/m2 more than that of conventional solar still. Despite the PVT collector, the daily efficiency of the solar still system increased to 34.8%, which shows an increase of 13.9% compared to the passive solar still device. Also, by cooling the PV-T system, the average electrical efficiency has increased from 13.1 to 13.7%. Production power reached 72.46 W from 65.96 W in two consecutive days at 11:15.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid population growth has suddenly increased the demand for freshwater (Mollahosseini et al. 2019). The continuous withdrawal of groundwater along with climate change (Huang et al. 2021) has also contributed significantly to the increase of this water shortage (Fath et al. 2008). The United Nations has estimated that about two-thirds of the world’s population will soon face water shortages. Seawater desalination is proposed as an effective solution for increasing water scarcity (Shatat et al. 2013). The desalination method is classified into membrane-based and heat-based processes (Panagopoulos 2022). The capacity of desalination plants installed worldwide has exceeded 100 × 106 m3/day (Panagopoulos 2022).

The solar still is a device which is used for desalination. The solar still works based on distillation process. Distillation is the process of separating the components of water through evaporation and condensation. A solar still is simple to build, and its initial and maintenance costs are low. However, the average efficiency of these devices is low (between 20 and 30%) compared to with other desalination devices (Naderipour et al. 2021). Many studies are conducted on solar stills with different structures, including single-slope solar still (Samee et al. 2007), cascade type solar still (Sadineni et al. 2008), and double-slope solar still (Dwivedi and Tiwari 2010). Numerous experiments were done to increase the efficiency of solar still (SS) by fins. Velmurugan et al. (2008) showed that to increase evaporation rate of solar still, fins were merged in its basin. It was found that the productivity is improved about 29.6% with wick type solar still, 15.3% with sponges, and 45.5% with fins. A cooling glass cover is also used by Khairat Dawood et al. (2022). Chow et al. (2009) investigated the effect of different variables on the energy efficiency, and exergy of a thermosyphon-type PVT-based water-heating PV/T system was carried out. They showed that improvement of PV cell efficiency, packing factor, water mass to collector area ratio, and airspeed are friendly for an unglazed system. In contrast, the increase of on-site solar radiation and ambient temperature is favorable for a glazed system. The photovoltaic/thermal system (PVT) works by using solar energy to create both electricity and heat. Sobhnamayan et al. (2014) investigated a PVT collector. They obtained the optimal diameter and the inlet flow velocity to achieve the highest exergy efficiency. The best inlet water velocity and pipe diameter in this study were 0.09 m s−1 and 4.8 mm, respectively. The maximum exergy efficiency was obtained 11.36%. Also, their modeling results agreed with the experimental results of Huang et al. (2001). Tiwari and Tiwari (2008) used a solar collector to enhance thermal processes (evaporation) in a solar water desalination device. Kabeel et al. (2014) modeled the basin-type solar desalination system with modified condensation method to perform the cooling process for condensation not just on the glass surface but also on the sidewalls. Circulating water through tubes cooled these sidewalls attached to the wall surface. Dehghan et al. (2015) lead a general study on the novel portable solar still using a thermoelectric module to increase the efficiency of solar still. Ayuthaya et al. (2013) conducted their experiment on the basin-type solar desalination system. They showed that the performance in outdoor conditions increased Because a basin solar still combined with a set of fin-plate placed in the basin for distillation. It was obtained that the productivity of the modified solar still was improved to 15.5%, in contrast a conventional desalination system. Abdallah and Badran (2008) implemented a solar tracking system to improve the efficiency of desalination plants and increase the efficiency by 22%. Voropoulos et al. (2001) doubled the efficiency of SS with solar collector and storage tank. Rashidi et al. (2017) focused on the effects of partitions in a solar water desalination device. Pounraja et al. (2018) showed that the SS with Peltier and the PVT collector has up to 30% higher efficiency than the efficiency of the passive desalination system. Also, the results showed that 38% efficiency of PV solar systems increased with the Peltier. PV solar systems have a big drawback and that their efficiency declines with increasing temperature. However, in the PVT, efficiency increases by cooling the glass cover by Peltier. Peltier is a thermoelectric module that has a cooling or heating effect by passing electrons between semiconductors. Peltier has no moving parts and can be used anywhere due to its high-temperature tolerance and solidity. Singh et al. (2011) developed an active SS. They integrated the SS with the collector. They found that the amount of production is 1.4 times that of a simple SS with a sloping surface. This design reduces the amount of investment. In the design of the current solar still, the main goal was to keep the cost as low as possible with improving the efficiency to provide the distilled water needed in remote isolated locations. Lowering the cost by increasing the performance of the solar still to provide freshwater needed in remote locations was one of the main goals of this research. The total fabrication cost of still is 39580 INR, including the fabrication cost, which is lower (about 14%) than the other solar stills. The results have shown that the parallel mode had better results and efficiency than the series. Dubey et al. (2021) reported the performance of an SS integrated by evacuated parallel tubes of a collector. The overall efficiency of energy and exergy was reported 33.8 and 49%, respectively. Mohammadi et al. (2020) investigated a double-slope SS. The results showed that the design of the heat exchanger is an important parameter in increasing the performance of the double slope SS.

The concurrent production of freshwater and electricity, improving the performance of the stepped solar still using the PVT collector as a preheater and improving the performance of the thermal photovoltaic system by cooling the system, is the novelty of this study. This study combines the PVT collector with the stepped solar still for concurrent production of freshwater and electricity for the first time.

Experimental setup

Design and construction of the system

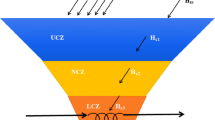

The system includes a solar water still system, recycling water tank, PVT collector, flow meter, connection of thermocouples, rheostat, and hoses. The solar water still system is made entirely of glass. The dimensions of the floor of the SS are 0.73 m × 0.5 m. The inner walls and floor of the basin of the desalination system are covered with black paint so that the water absorbed better the sunlight passing through the inclined glass. The thickness of the glass cover is 6 mm. Vapor is condensed on the glass cover and is collected in a tank by flowing down to the end of the desalination system. The role of the PVT collector is to preheat the saltwater before it enters the SS.

The saltwater enters to the PVT collector to cool down the PV panel and improves the efficiency. This water preheats in the PVT collector and joins the SS.

A detailed examination of the effect of temperature on the PV system was conducted by Kumar and Tiwari (1998), Dubey et al. (2013), Alobaid et al. (2018), Kabeel et al. (2017), and Aruldoss et al. (2023), and it was checked out that increasing the temperature of panel declines the voltage of the solar panel and increases the current. Therefore, cooling of PV panels is required to avoid voltage drop due to temperature increasing. In the standard conditions where the panel temperature is 25 °C and radiation intensity is 1000 W/m2, the features of the PV panel of this study are given in Table 1.

Figure 1 illustrates the PVT collector integrated with a stepped solar water still system and an objective view of the setup during the experiment.

Measuring devices

In this study, the following measuring devices were used:

-

1.

Rheostat made by JRM company in Japan with power of 100 W and resistance of 25 ohms

-

2.

Thermometer manufactured by Benetech company, model GM1312

-

3.

Proskit multimeter model MT-1280

-

4.

Kipp and Zonen pyranometer model CMP6

-

5.

Lambrecht anemometer model 14,522

-

6.

Flowmeter 2 to 20 l/h made by DGOzone company

-

7.

Lambrecht temperature-humidity sensor model 8092

-

8.

K type thermocouple

Experimental procedure

The stepped SS with the PV system was launched in Semnan University located in Semnan City, Iran. Semnan was at a latitude of 35°. The experiments were conducted for two consecutive days on October 24 and 25 (autumn season) of 2022 from 10:00 am to 3:00 pm in the autumn season for 5 h with data measurement every 30 min. The environmental parameters were received from the nearest station of the Semnan Meteorological Department. The flow rate measured in this experiment was determined to be 7.5 l/h. The thermocouples were installed on the glass cover of the SS and the inlet and outlet of both the PVT collector and SS. During the test period, different environmental parameters and the amount of freshwater production were measured. Finally, it should be mentioned that the average of the optimal installation angles obtained in the four seasons of the year for the PVT collector is equal to 35°, and the panel was installed with this angle.

The efficiency of solar stills and photovoltaic/thermal system

The active solar still (ASS) was combined with the PVT collector, and passive solar still (PSS) was separately tested without integrating the PVT system.

The efficiency of SS (\({\eta }_{ss}\)) is (Grewal and Kumar 2022)

where L denotes the latent heat of evaporation and is calculated by

With the measurements made, the hourly efficiency of SS was calculated from 10 am to 3 pm for both active and passive systems. The flow rate of saltwater was 7.5 l/h. The production power of the PV panel was obtained by calculating the current and voltage during a certain time using a rheostat in certain resistances.

Electrical efficiency is a standard parameter of PVT collectors. This parameter is calculated according to the PV temperature by Alobaid et al. (2018) and Najah et al. (2016):

The efficiency of the reference temperature in 25° is reported equal to 0.15. β is the temperature coefficient of PV panel efficiency calculated experimentally and reported as 0.0045 for crystal panels.

Energy wastage is omitted because the system is made so that the water under the panel is in contact with the entire surface of the panel, and the insulation is considered behind the PV system. Equation (4) is used to calculate thermal efficiency:

where \({\dot{Q}}_{u}\) denotes the rate of heat absorbed by the working fluid that flows in the ducts. \({\dot{Q}}_{u}\) is obtained from the following equation:

The total efficiency of the PVT collector is

Uncertainty analysis

Type B uncertainty is used to conduct uncertainty analysis. The standard uncertainty is (Rahbar et al., 2012)

Here, a denotes the instrument’s accuracy and u denotes the standard uncertainty. The uncertainty of measuring devices is given in Table 2.

Uncertainty about solar still efficiency

When the variable y is a function of some input values xi, the uncertainty value u is calculated by Kirkup and Frenkel (2006) and Dhivagar and El-Sapa (2022)

In the above relationship, \(u({x}_{i})\) is the measurement uncertainty related to the input variable \({x}_{i}\). The uncertainty of SS efficiency is

The highest measurement uncertainty in calculating the hourly efficiency for all experiments in this study is equal to 0.43%.

Uncertainty of photovoltaic/thermal collector efficiency

Based on the measurement of solar radiation and panel temperature and saltwater inlet and outlet temperatures, the uncertainty related to electrical efficiency and the uncertainty related to thermal efficiency were measured by the following equation (Najah et al. 2016):

According to Eq. (9), the maximum uncertainty of measurement in calculating electrical efficiency of the PVT collector is equal to 0.054%. The maximum uncertainty of measurement in calculating thermal efficiency of the PVT collector is equal to 0.144%.

Results and discussion

In solar stills, the effect of energy transfer by the blackened area (direct transfer) rises the fluid temperature. As fluid temperature rises, evaporation of fluid (water) starts and vapors (via heat transfer mechanism) at the inner surface of the glass cover get condensed after leaving latent heat to the glass cover. Due to the difference in temperature and concentration between the surface of the glass and the water, a natural movement takes place. In the PVT collector, water enters from the bottom of the system, and after a certain period, the heat of the surface of the recrystallized coating is removed from the top. Cooling in PVTs improves electrical efficiency, reduces cell erosion over time, and ultimately maximizes the lifespan of photovoltaic modules. The excess heat captured by the cooling operation is used to preheat the saltwater for the distillation in the solar still.

The first aim of the proposed system is to increase the temperature of the saltwater with the presence of the PVT collector as a pre-heater of the SS to improve its efficiency. The second aim is to cool the PV panel to increase its power output. The PV panel heats the saltwater. It means that the water moves through the built-in channels in the PVT collector, and then by cooling the panel, it gives heat to the saltwater. Indeed, this heat is used to preheat the saltwater before entering the SS. For evaluating this proposed system, the efficiency of ASS in the integrated system is compared with the efficiency of PSS without integrating with PVT collector. Constant changes of factors beyond the control of sunlight, airspeed, and ambient temperature affect the efficiency of solar still. The water temperature is related to the amount of absorption of solar radiation by the bottom of SS. The airspeed and ambient temperature effectively create a temperature difference between the saltwater and the glass cover in the SS. Note that this temperature difference provides the double-diffusive natural convection in the SS, which leads to move the vapor from the saltwater towards the glass cover. Indeed, the operation of SS depends on this temperature difference.

Figure 2 shows the hourly environmental parameters for two days of the experiment. On Oct 24, 2022, the PSS was tested and on Oct 25, 2022, the ASS integrated with PVT collector was tested. The solar radiation increased with a gentle rate in the early hours, and then decreased from noon to the afternoon with a steeper rate. On Oct 24, The ambient temperature trends during the test hours was upward, and with time, the slope became downward. Also, the average air speed on Oct 25 was slightly higher than on Oct 24. During two days, the minimum amount of solar radiation intensity (G = 308 W/m2) occurs at 3 pm, the minimum airspeed (Va = 0.7 m/s) occurred at 11 am, and the minimum ambient temperature (Ta = 22.2°C) was reported at 10:30 am on Oct 24. Also, the maximum solar radiation intensity (G = 862 W/m2) occurred at 12:30, top airspeed (Va = 3.6 m/s) occurred at 10:00 am on Oct 25 for ASS, and the maximum ambient temperature (Ta = 26°C) occurred at 2:30 pm on Oct 24 for the PSS.

The hourly temperature difference between the condensing and evaporating zones for ASS and PSS is compared in Fig. 3. As mentioned earlier, the easiest way to increase the temperature difference of the evaporation and distillation area in SSs is two methods that should be taken. These methods are rising the temperature of the inlet saltwater, and then the temperature of the glass cover is declining. This temperature difference improves the productivity and the efficiency of the SS. The results in Fig. 3 show that the PVT collector, as a generating thermal energy source, heats the incoming saltwater and creates a more tremendous temperature difference between the evaporation and distillation area, thereby increasing the efficiency of the SS. For calculating the saltwater temperature on the steps, the average temperature of the input and output saltwater of the SS was considered. The highest temperature of saltwater on the steps was related to the ASS at 1 pm Oct 25 (Tb = 57.3°C), and the lowest temperature of saltwater on the steps was related to the PSS at 3 pm on Oct 24 (Tb = 34.9°C).

The hourly productivity rates of ASS and PSS are compared in Fig. 4. The higher production rate distilled water by the SSs is related to two factors. These factors are the evaporation rate of saltwater and the condensation rate of water vapor. As shown in Fig. 4, the ASS produces more freshwater than the passive one The highest productivity rate of (mev = 0.223 \(\frac{kg}{{m}^{2}}\)) for ASS at 12:30 am and the lowest productivity of (mev = 0.043 \(\frac{kg}{{m}^{2}}\)) for PSS at 3 pm was obtained. The amount of freshwater accumulation during one day for the ASS is (mev = 1.770 \(\frac{kg}{{m}^{2}}\)) the amount of freshwater accumulation during one day for the ASS was (mev = 1.007 \(\frac{kg}{{m}^{2}}\)). The presence of the PVT collector for preheating the saltwater increased the productivity rate in SS. The productivity rate was recorded from 10 am to 3 pm on Oct 24 and Oct 25 in Fig. 4.

At first, the tests were conducted for the PV panel without cooling system on Oct 24, and all data including PV panel surface temperature, voltage, current, and radiation were recorded every half hour. Then, on Oct 25, for the PVT collector the inlet and outlet temperature of saltwater was measured. In the PVT collector, channels are placed for the flow of fluid. The results show that radiation and wind speed are effective on the temperature of the PV panel. The temperature is higher than the ambient temperature, and increasing the temperature of the panel reduces the power of the PV system. Therefore, the construction of ducts embedded in the PVT collector decreases the operating temperature and increases the power. The temperatures of the inlet and outlet saltwater in the PVT collector are illustrated in Fig. 5. The highest outlet saltwater temperature was recorded at 1:30 pm (ToutPVT = 53.6 \(^\circ {\text{C}}\)), and the lowest outlet saltwater temperature was recorded at 10 am on Oct 25 (ToutPVT = 41.4 \(^\circ {\text{C}}\)). The hourly temperatures of glass cover of the PV panel without cooling and PVT collector with cooling are compared in Fig. 6. With cooling in the PVT collector, the temperature of the PV panel decreases significantly. The highest amount of difference between the temperature of glass cover for two cases was observed in the early hours of the morning on two days. The results showed that this difference reached 16.4 degree at 10:45 am. The lowest difference was observed in the last hours of the day.

The efficiency of ASS and PSS is measured at different hours and shown in Fig. 7. The presence of a PV system as a pre-heater was increased the efficiency of ASS. The highest efficiency was at 3 pm on Oct 25th (\(\eta\) ss = 49.7 \(\mathbf{\%}\)), and the lowest was at 11 am on Oct 24th (\(\eta\) ss = 14.9 \(\mathbf{\%}\)). The average daily efficiency of ASS was reported as 34.8% and daily average efficiency of PSS was 20.9% from 10 am to 3 pm. The noteworthy point is that in the last hours of Oct 25, owing to the sharp drop in solar radiation intensity, the heat capacity of water, and the resulting evaporation, the efficiency of solar still increased significantly.

With the presence of the PVT collector, the daily efficiency of the SS increases by 13.9%. Even though the solar radiation decreases drastically at the end of the day, the efficiency reduction of SS will be lower than the radiation reduction. It is owing to the heat capacity of water and the evaporation caused by it. The presence of the PVT collector for the ASS reduces the rate of efficiency reduction far less, and this makes it possible to see a higher efficiency in the final hours compared to the PSS.

The comparison of hourly efficiency for the previous solar stills and the suggested one in this study is given in Table 3. It was observed that the overall efficiency and daily efficiency are reasonable compared to most of previous solar stills. The experiments in this study were conducted in the fall season, and the amount of radiation was low.

Figure 8 compares the I-V diagram at 11:15 am for the PV panel without cooling and the PVT collector with cooling. the temperature increases for the case of the PV panel without cooling as compared to the PVT collector with cooling, the electric current intensity increases slightly. However, its changes are so small that it can be considered constant, and the output voltage decreases significantly using the PV panel without cooling instead of the PVT collector. The output power, which is obtained from the product of the current and voltage of the panel, generally decreases with the increasing of the panel temperature for the case of PV panel without cooling compared to the PVT collector with cooling.

The comparison of P–V diagram at 11:15 am for the PV panel without cooling and the PVT collector is conducted in Fig. 9. It is observed that the cooling of the panel has a significant effect on its output power. The maximum output power of 72.46 W was reported at 11:15 am in a resistance of 4 ohms on Oct 25 in the PVT collector. The output power of the PV panel without cooling at 11:15 am on Oct 24 was 65.96 W. At 11:15 am on Oct 24, for the PV panel without cooling, the panel temperature reached 58.3 °C. On Oct 25 for the PVT collector with cooling, the panel temperature reached 43.4 °C. The decrease in panel temperature from 58.3 to 43.4 °C was improved the produced power by 7 W. Also, according to Fig. 2, the airspeed on Oct 25 was higher than that on Oct 24, which can be considered as one of the factors affecting the cooling of the PV panel, and this natural action was increased the power of the PV system. Daily electrical efficiency reached 13.8% from 12.8% for two days in a row at 11:15 am.

The hourly electrical efficiency of the PV panel without cooling and the PVT collector is shown in Fig. 10. The results indicated that the electrical efficiency increases by using the PVT system with cooling instead of PV panel without cooling. Increasing the temperature of the PV panel declines the electrical efficiency. In the early and late hours of experiments, the electrical efficiency obtained higher values.

Figure 11 also shows the hourly thermal efficiency of the PVT collector with cooling. The results show that the thermal efficiency of the PVT collector increases during the time despite the decrease in solar radiation intensity. It is owing to the heat capacity of water.

The daily thermal efficiency of the entire hybrid system is obtained from the sum of the thermal efficiencies of the SS and the PVT collector (Pounraja et al. 2018), equal to 85.3% in this study.

The effects of saltwater flow rate on the daily efficiency and efficiency of solar still are investigated in Table 4 on the 26th Oct for the PSS and the 29th Oct for the ASS. It should be noted that more tests were taken, but 7.5 and 10 are given in the article. The experiment was conducted in autumn, and the average amount of solar radiation was lower than in spring and summer.

The results show that with the increase in the flow rate, the daily efficiency of PSS remains almost constant, but when the fluid passes through the photovoltaic system, due to the rise in the flow rate, the temperature of the leaving the photovoltaic system has decreased, and this caused the saltwater which enters ASS will be heated less, and the evaporation process will take place at a lower speed; as a result, the amount of freshwater produced will be lower.

Economic analysis

Economic analysis of solar still

Economic analysis of SS is presented by Kumar and Tiwari (2009a, b) and Kabeel et al. (2010). If P is the initial capital and CRF is the Capital Recovery Factor, the Annual Cost Factor or FAC is obtained through the following relationship by Groosen et al. (2000):

Here, i denotes the interest rate (20% in Iran) related to bank loans, and n denotes the life of the device (10 years). The salvage value of the device or S is equal to 20% of the cost of usable equipment that is saved after the life of the device. Sinking fund factor (SFF) is

Annual salvage value (ASV) is defined by

Annual maintenance operational cost (AMC) is

Annual cost of device (AC) is

Eventually, cost per litter (CPL) or the cost required to produce each liter of freshwater by the device is

where M denotes the average annual productivity of SS. The results of the economic analysis of both SSs are given in Table 5. It can be seen that the production costs of each liter of freshwater for the PSS and ASS are 0.13 $/kg/m2 and 0.07 $/kg/m2, respectively.

Economic analysis of photovoltaic/thermal system

The economic analysis of the PVT collector is presented by Hadipour et al. (2021) and Marfia (2001). The levelized cost of electricity (LCOE) is calculated by

The parameters required to calculate LOCE can be found in Table 6.

The results of economic analysis of the PVT collector are given in Table 7. It can be seen that the levelized cost of electricity (LCOE) in the PVT system and the PV system is 250.02 and 238.52 $/kWh, respectively.

Conclusions

In this study, a photovoltaic/thermal (PVT) collector and a stepped solar still system were constructed and integrated. The purpose of this research is to produce more freshwater by using a solar still system combined with a solar collector as a preheater. Also, the simultaneous production of freshwater and electricity has been one of the other goals of this experimental work. Increasing the efficiency of the PVT system was also on the agenda. The following outcomes are achieved from the study on the cogeneration system:

-

The efficiency of ASS was 13.9% higher than the efficiency of passive one without integrating with the PVT collector. The amount of daily productivity of freshwater produced by ASS integrated with the PVT collector was 0.76 kg/m2, more than that of PSS.

-

The average water temperature on the steps of SS increased by about 9° by integrating that with the PVT collector.

-

The maximum output power of the PVT collector at 11:15 am was 7 W more than the output power of the conventional PV system without cooling.

-

The average temperature on the surface of the PVT collector with cooling was 9° lower than the PV panel without cooling.

-

With the help of the PVT collector, in addition to increasing the evaporation rate in SS, we will have hot water with a higher temperature at the output of SS, which can be used for heating purposes.

-

The daily electrical efficiency of the PVT collector with cooling from 9:45 am to 2:45 pm increased by 0.6%.

-

The average annual productivity of ASS was about 132 kg/m2.year more than PSS.

-

The levelized cost of electricity (LCOE) for the PVT system and the PV system is 250.02 and 238.52 $/kWh, respectively.

-

The production costs of each liter of freshwater for the PSS and ASS are 0.13 $/kg/m2 and 0.07 $/kg/m2, respectively.

Finally, it should be mentioned that the water and electricity cogeneration system driven by solar energy is suitable for arid remote and rural areas. It is expected that the proposed system is a low-cost, eco-friendly, and efficient one, which does not need any additional costs and skills for its operation and maintenance. By using this system, the power transmission and distribution systems can be eliminated. The adverse effects of fossil fuels consumption on environment can be decreased by using such solar driven system. Technical innovations of this study have the potential to contribute to sustainable improvement in the living conditions of people who live in vulnerability and arid remote areas.

Data availability

Data can be made available on request.

Abbreviations

- PVT :

-

Photovoltaic/thermal

- SS :

-

Solar still

- PSS :

-

Passive solar still

- ASS :

-

Active solar still

- A b :

-

Area of basin, m.2

- A c :

-

Area of collector, m.2

- t :

-

Time, h

- T b :

-

Basin water temperature of SS, °C

- T inss :

-

Inner water temperature of SS, °C

- T outss :

-

Outer water temperature of SS, °C

- T gss :

-

Glass surface temperature of SS, °C

- T a :

-

Ambient temperature, °C

- T mss :

-

Mean temperature of basin and glass surface, °C

- T gpv :

-

Temperature of solar PV surface, °C

- T inpv/t :

-

Inner water temperature of PVT, °C

- T outpv/t :

-

Outer water temperature of PVT, °C

- G :

-

Solar irradiance, W/m.2

- \(\dot{m}\) :

-

Water flow, l/h

- m ev :

-

Distillate water output, kg/m.2

- v :

-

Distillate water output, cc

- V a :

-

Air speed, m/s

- u :

-

Standard uncertainty

- L :

-

Latent heat vaporization, J/kg

- \({\dot{Q}}_{u}\) :

-

Heat gain, W

- I :

-

PV output current, A

- V :

-

PV output voltage, V

- \({\eta }_{th}\) :

-

Thermal efficiency of PVT, %

- \({\eta }_{el}\) :

-

Electrical efficiency of PVT, %

- \({\eta }_{ss}\) :

-

SS efficiency, %

- \(\beta\) :

-

Temperature coefficient of PV panel efficiency

References

Abdallah S, Badran OO (2008) Sun tracking system for productivity enhancement of solar still. Desalination 220:669–676

Abu-Arabi M, Zurigat Y, Al-Hinaib H (2002) Modeling and performance analysis of a solar desalination unit with double glass cover cooling. Desalination 143:173–182

Alobaid MS, Hughes B, O`Connor D, Calautit J, Heyes A (2018) Improving thermal and electrical efficiency in photovoltaic thermal systems for sustainable cooling system integration energy water and environment systems. J Sustain Dev Energy Water Environ Syst 6(2):305–322

Aruldoss WJ, Sankaramurthy P, Chokkalingam B (2023) Performance studies of a solar thermal-electric hybrid desalination system: 4E (energy-exergy-economics-enviroeconomics) analysis. Environ Sci Pollut Res 30:73451–73468

Ayuthaya R, Panomwan Na, Namprakai P, Ampun W (2013) The thermal performance of an ethanol solar still with fin plate to increase productivity. Renew Energy 54(6):227–234. https://doi.org/10.1016/j.renene.2012.08.004

Chow T, Pei G, Fong K, Lin Z, Chan A, Ji J (2009) Energy and exergy analysis of photovoltaic-thermal collector with and without glass cover. Appl Energy 86(3):310–316

Dehghan AA, Afshari A, Rahbar N (2015) Thermal modeling and exergetic analysis of a thermoelectric assisted solar still. Sol Energy 115:277–288. https://doi.org/10.1016/j.solener.2015.02.038)

Dhivagar R, El-Sapa S (2022) A case study on thermal performance analysis of a solar still basin employing ceramic magnets. Case Stud Therm Eng 39:102–402

Dubey A, Kumar S, Arora A (2021) Envro- energy- exergo- economic analysis of ETC augmented double slope solar still with N parallel tubes under forced mode: environmental and economic feasibility. J Clean Prod 279:123859

Dubey S, Jatin Narotam S, Bharath S (2013) Temperature dependent photovoltaic (PV) effciency and its effect on PV production in the world – a review. Energy Procedia 33(311–2):1

Dwivedi VK, Tiwari GN (2010) Experimental validation of thermal model of a double slope active solar still under natural circulation mode. Desalination 250:49–55

Esfahani JA, Rahbar N, Lavvaf M (2011) Utilization of thermo- electric cooling in a portable active solar still — an experimental study on winter days. Desalination 269:198–205

Fath HES, Elsherbiny SM, Hassan AA, Rommel M, Wieghaus M, Koschikowski J, Vatansever M (2008) PV and thermally driven small scale stand alone solar desalination systems with very low maintenance needs. Desalination 225:58–69

Goosen MFA, Sablani SS, Shayya WH, Paton C, Al-Hinai H (2000) Thermodynamic and economic considerations in solar desalination. Desalination 129:63–89

Grewal R, Kumar M (2022) A comprehensive review on stepped solar still and induction heating applications. Mater Today: Proceed 56(5):2696–2703

Hadipour A, Rajabi M, Rashidi S (2021) An efficient pulsed-spray water cooling system for photovoltaic panels: experimental study and cost analysis. Renew Energy 164:867–875

Huang B, Lin T, Hung W, Sun F (2001) Performance evaluation of solar photovoltaic/thermal systems. Sol Energy 70(5):443–448

Huang Z, Yuan X, Liu X (2021) The key drivers for the changes in global water scarcity: water withdrawal versus water availability. J Hydrol 601:126658

Kabeel AE, Hamed AM, El-Agouz SA (2010) Cost analysis of different solar still configurations. Energy 35:2901–2908

Kabeel AE, Omara ZM, Essa FA (2014) Enhancement of modified solar still integrated with external condenser using nanofluids: an experimental approach. Energy Convers Manage 78:493–498. https://doi.org/10.1016/j.enconman.2013.11.013

Kabeel AE, Arunkumar T, Denkenberger DC, Sathyamurthy R (2017) Performance enhancement of solar still through effcient heat exchange mechanism - a review. Appl Therm Eng 114:815–836

Khairat Dawood MM, Helmy Omar A, Ismail Shehata A, Samir Shehata A, Abd-Elsalam Taha A, Nabil El-Shaib M, Kamel MM (2022) Energy and exergy analysis of conventional acrylic solar still with and without copper fins. Environ Sci Pollut Res 29:65787–65805

Kirkup L, Frenkel RB (2006) The importance of uncertainty in science and technology. In: An introduction to uncertianty in measurement uisng the GUM (Guide to the Expression of Uncertianty in Measurement). Cambridge University Press, pp 1–10

Kumar S, Tiwari GN (1998) Optimization of collector and basin areas for a higher yield for active solar stills. Desalination 116:1–9

Kumar S, Tiwari GN (2009a) Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl Energy 86:1995–2004

Kumar S, Tiwari GN (2009b) Parametric Study of an Active and Passive Solar Distillation System: Energy and Exergy Analysis. Desalination 242:1–18. https://doi.org/10.1016/j.desal.2008.03.027

Kumar S, Dubey A, Tiwari GN (2014) A solar still augmented with an evacuated tube collector in forced mode. Desalination 347:15–24

Kumar RA, Esakkimuthu G, Murugavel K (2016) Performance enhancement of a single basin single slope solar still using agitation effect and external condenser. Desalination 399:198–202

Marafia H (2001) Feasibility study of photovoltaic technology in Qatar. Renew Energy 24:565–567

Mohammadi K, Taghvaei H, Goshtasbi E (2020) Experimental investigation of a double slope active solar still: effect of a new heat exchanger design performance. Appl Therm Eng 180:115875

Mollahosseini A, Abdelrasoul A, Sheibany S, Amini M, Salestan SK (2019) Renewable energy driven desalination opportunities – a case study. J Environ Manage 239:187–197

Naderipour A, Arabi Nowdeh S, Babanezhad M, Seifi Najmi E, Kamyab H, AbdulMalek Z (2021) Technical-economic framework for designing of water pumping system based on photovoltaic clean energy with water storage for drinking application. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-16342-8

Najah Al-Shamani A, Sopian K, Mat S, Abdulrasool HH (2016) Experimental studies of rectangular tube absorber photovoltaic thermal collector with various types of nanofluids under the tropical climate conditions. Energy Convers Manage 124:528–542

Panagopoulos A (2022) Brine management (saline water & wastewater effluents): sustainable utilization and resource recovery strategy through Minimal and Zero Liquid Discharge (MLD & ZLD) desalination systems. Chem Eng Process Process Intensif 176:108944

Pounraja P, Winston DP, Kabeel AE (2018) Experimental investigation on Peltier based hybrid PV/T active solar still for enhancing the overall performance. 168:371–381

Rashidi S, Esfahani JA, Rahbar N (2017) Partitioning of solar still for performance recovery: experimental and numerical investigations with cost analysis. Sol Energy 153:41–50

Sadineni SB, Hurt R, Halford CK, Boehm RF (2008) Theory and experimental investigation of a weir-type inclined solar still. Energy 33:71–80

Samee MA, Mirza UK, Majeed T, Ahmad N (2007) Design and performance of a simple single basin solar still. Renew Sustain Energy Rev 11:543–549

Shatat M, Worall M, Riffat S (2013) Opportunities for solar water desalination worldwide: review. Sustain Cities Soc 9:67–80

Singh G, Kumar S, Tiwari G (2011) Design fabrication and performance evaluation of a hybrid photovoltaic thermal (PVT) double slope active solar still. Desalination 227:399–406

Singh RV, Kumar S, Hasan MM, Khan ME, Tiwari GN (2013) Performance of a solar still integrated with evacuated tube collector in natural mode. Desalination 318:25–33

Sobhnamayan F, Sarhaddi F, Alavi MA, Farahat S, Yazdanpanahi J (2014) Optimization of a solar photovoltaic thermal (PV/T) water collector based on exergy concept. Renew Energy 68:356–365

Tiwari GN, Tiwari AK (2008) Solar Distillation Practice for Water Desalination Systems. Anshan, New Delhi

Velmurugan V, Deenadayalan CK, Vinod H, Srithar K (2008) Desalination of effluent using fin type solar still. Energy 33:1719–1727

Voropoulos K, Mathioulakis E, Belessiotis V (2001) Experimental investigation of a solar. Desalination 138:103–110

Funding

This work is based upon research funded by Iran National Science Foundation (INSF) under project No. 4005829.

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology: Shahabeddin Ashtiani; writing original draft preparation: Shahabeddin Ashtiani; writing review and editing: Faramarz Hormozi, Amir Hossein Zamzamian, and Saman Rashidi; resources: Shahabeddin Ashtiani; supervision: Faramarz Hormozi, Seyed Amir Hossein Zamzamian, and Saman Rashidi.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ashtiani, S., Hormozi, F., Zamzamian, S.A.H. et al. Experimental study on a solar-powered cogeneration system for freshwater and electricity production. Environ Sci Pollut Res 31, 30703–30715 (2024). https://doi.org/10.1007/s11356-024-33166-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-33166-4