Abstract

This study investigated the levels of persistent toxic substances, such as 16 polycyclic aromatic hydrocarbons (Σ16PAHs) and heavy metals (Cu, As, Cd, Zn, Pb, Ni, Mo, and Cr) in biochars produced from crop residues (walnut shell, corn cob, corn straw, rice straw, and rice husk) at different heat treatment temperatures (HTTs, 250, 400, and 600 °C). The levels of Σ16PAHs in different biochars were 0.47–7.11 mg kg−1, with naphthalene and phenanthrene contributing the most. The Σ16PAHs had the positive correlations with H/C and (O + N)/C, but had negative correlations with biochar surface areas. This finding indicates the increasing hydrophobic π-π interactions between the PAHs and the aromatic sheets of biochars and even the trapping of PAHs within the micropores with the increase of HTTs. The levels of heavy metals in rice residue-derived biochars were significantly higher than those in other biochars. The heavy metals had positive correlations with ash contents in the biochars, indicating the enrichment of heavy metals in the ash. The potential ecological risks of PAHs and heavy metals (dosage: 1%, w/w; frequency: 1) were minimal according to the risk quotient of negligible concentrations (RQNCs: 2.50–47.40, << 800) and maximum permissible concentrations (RQMPCs: 0.02–0.48, << 1) for PAHs and the potential ecological risk indexes (PERI: 0.01–0.28, << 150) for heavy metals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The interest toward biochar as adsorbent and soil ameliorant sharply increases in recent years because of not only its renewable, low cost, and sustainable nature but also its effective removal and immobilization of various contaminants and improvement of soil fertility and crop yield (Hussain et al. 2016; Rajapaksha et al. 2016). Although it makes a series of advantages to environment and agriculture, it is indispensable to emphasize that biochar also has drawbacks because of its carrying various persistent toxic substances, especially polycyclic aromatic hydrocarbons (PAHs) and heavy metals (Hussain et al. 2016; Qiu et al. 2015). Studies have indicated that the levels of PAHs and heavy metals vary in different biochars and may considerably exceed the threshold values of biosolids for land application (Hale et al. 2012; Zielińska and Oleszczuk 2015). Therefore, persistent toxic substances (e.g., PAHs and heavy metals) in biochars have been widely concerned by researchers recently.

The PAHs in biochars are formed during the pyrolysis of feedstocks, and their levels largely depend on the heat treatment temperatures (HTTs) (Freddo et al. 2012; Hale et al. 2012; Keiluweit et al. 2012; Qiu et al. 2015). Additionally, several studies indicated that the straw-derived biochars generally had higher levels of total PAHs than wood-derived biochars (Keiluweit et al. 2012; Quilliam et al. 2013). Moreover, the levels of total PAHs in biochars were generally higher than in corresponding feedstocks (Hale et al. 2012; Keiluweit et al. 2012; Qiu et al. 2015). A recent study reported that biochar application to soils for 3 years significantly raised the PAH levels as compared with untreated soil (Quilliam et al. 2013). However, another study revealed that biochar addition to soils for 2.5 years resulted in an increase of the total PAH levels at first, and then the PAH levels decreased to a level characteristic for the control soil (Kuśmiez et al. 2016). It has been reported that the yield and composition of PAHs in biochars depends on many factors, such as feedstocks, pyrolysis temperatures, residence time, and mineral content (Wang et al. 2017). Thus, it is necessary to understand the effect of feedstock and pyrolysis temperature on the formation of PAHs in biochars.

Different from PAHs, heavy metals are not formed during the pyrolysis of feedstocks, but concentrated in the formed biochars. During pyrolysis, although the heavy metals (e.g., Ni, Zn, Cr, Cu, Co, Cd, Pb) partitioned into the solid (biochar), liquid (bio-oil), and gaseous phases (biogas), the major amounts of them were enriched in the biochars, resulting in their higher levels in the biochars as compared with their corresponding feedstocks (Devi and Saroha 2014; Zielińska and Oleszczuk 2015). Furthermore, the heavy metal levels in the biochars considerably varied depending on the feedstocks, HTTs, and speciation of the heavy metals. For example, levels of most heavy metals in the animal waste-derived biochars were remarkably higher than those in the plant residue-derived biochars (Qiu et al. 2015). It was also reported that the levels of heavy metals in the sewage sludge-derived biochars commonly considerably exceeded the threshold values relating to biosolids for land application and posed potential risk to ecosystems (Devi and Saroha 2014; Zielińska and Oleszczuk 2015). Some studies indicated that HTTs had minimal effects upon the heavy metal levels in the biochars (Freddo et al. 2012; Qiu et al. 2015). However, some others revealed that with the increase of HTTs there was an increase in the levels of Cr, Cu, Zn, and Pb, but a decrease in the level of Cd owing to the volatilization of Cd to the gas stream at higher temperatures (Devi and Saroha 2014; Zielińska and Oleszczuk 2015). It should be noted that the application of biochars to soils does not always decrease but increase the bioavailability of heavy metals to organisms, such as plants (Rizwan et al. 2016). A recent research revealed that the bioavailability of heavy metals to the plant in biochar-amended soils was significantly related to the heavy metal levels in the biochars (Shen et al. 2016). Therefore, examination of heavy metals in the biochars to assess the potential ecological risk after conversion the biomass into biochars is crucial before them being applied to soils.

The objectives of this study were (1) to examine the effect of HTTs, feedstocks, and biochar properties on the levels of PAHs and heavy metals in the biochars produced from crop residues at different HTTs, and (2) to assess the potential ecological risks of biochars produced from crop residues for soil application in terms of PAHs and heavy metals.

Materials and methods

Biochar preparation and characterization

Biochars were produced from walnut shell (WS), corn cob (CC), corn straw (CS), rice straw (RS), and rice husk (RH). The CC, CS, and RS were cut to less than 3 cm before further treatment. Each feedstock was washed and dried in an oven at 80 °C. For biochar production, the feedstocks were pyrolyzed at 250 °C, 400 °C, and 600 °C, respectively, for 4 h in a muffle under an oxygen-limited condition. The HTTs were raised to the target values (250 °C, 400 °C, and 600 °C) at a ramp rate of 15 °C min−1. The biochars were then cooled to room temperature inside the furnace. The prepared biochars were referred to as CS250, CS400, CS600, CC250, CC400, CC600, RS250, RS400, RS600, RH250, RH400, RH600, WS250, WS400, and WS600, respectively. Their corresponding feedstocks were accordingly named as CS0, CC0, RS0, RH0, WS0, respectively. The biochars and their corresponding feedstocks were milled to pass a 0.15-mm sieve for further analyses.

Before characterization, both biochars and feedstocks was washed with 0.1 M HCl to remove some soluble salts, carbonates, and dissolved organic matter, followed by being flushed until neutral pH with ionized water, and subsequently oven-dried and milled (Sun et al. 2013). After pre-treatment, the element composition (C, H, and N) of biochars and feedstocks was determined with an elemental analyzer (Flash EA 1112) via complete combustion. Ash content was measured by heating the biochars and feedstocks in a muffle at 750 °C for 4 h. The oxygen content was calculated from the mass difference. The N2-BET surface areas (SA) were determined by an ASAP-2020 surface area analyzer (Micromeritics Instrument Corporation, USA).

Extraction and quantification PAHs

In the present study, 16 PAHs were determined, including naphthalene (Nap; 2-ring), acenaphthene (Ace; 3-ring), acenaphtylene (Acy; 3-ring), fluorine (Flu; 3-ring), phenanthrene (Phe; 3-ring), anthracene (Ant; 3-ring), fluoranthene (Fla; 4-ring), pyrene (Pyr; 4-ring), chrysene (Chr; 4-ring), benzo[a]anthracene (BaA; 4-ring), benzo[b]fluoranthene (BbF; 5-ring), benzo[k]fluoranthene (BkF; 5-ring), benzo[a]pyrene (BaP; 5-ring), dibenz[a,h]anthracene (DahA; 5-ring), indeno[1,2,3-cd]pyrene (IcdP; 6-ring), and benzo[ghi]perylene (BghiP; 6-ring). The total PAHs were extracted with Soxhlet using acetone/cyclohexane (1:1, v/v) for 36 h (4 cycles h−1) (Fabbri et al. 2013). The PAHs in all extracts were analyzed with a Shimadzu GCMS-2010 Plus apparatus equipped with a RTX-5MS capillary column (30 m × 0.32 mm × 1 μm) in the selective ion monitoring mode. The mass spectrometer was operated under electron ionization (70 eV). High-purity He was used as carrier gas at a flow rate of 1.0 mL min−1. The temperature program was as follows: initial temperature of 65 °C, held for 2 min, increased at a rate of 5 °C min−1 to 290 °C, and then maintained for 20 min. Finally, 1 μL of the extract was injected in the splitless mode. More details can be found in the Supplementary Information.

Extraction and quantification of heavy metals

The heavy metals were extracted using an automatic digestion apparatus (ST-60, Polytech Instrument Ltd., Beijing, China). The target heavy metals, including Cu, Mo, As, Cd, Pb, Cr, Ni, and Zn were analyzed via ICP-AES (SPECTRO ARCOS EOP, SPECTRO Analytical Instruments GmbH). More details can be found in the Supplementary Information.

Models for assess the potential ecosystem risk of PAHs and heavy metals

The application amount of biochar as the soil amendment and contaminant adsorbent into soil was generally around or lower than 1% (w/w) (Hussain et al. 2016; Rizwan et al. 2016). In the present study, the potential ecological risk of PAHs and heavy metals caused by biochars after application into soil was assessed based on 1% application rate per year. To date, no models and reference quality values exist for the ecological risk assessment of PAHs and heavy metals in biochars; thus, the methods for soil were used.

To assess the potential ecosystem risk of PAHs caused by biochars, the risk quotient of negligible concentration (RQNCs) and maximum permissible concentration (RQMPCs) was calculated using the Eqs. (1) and (2), respectively (Cao et al. 2010):

where CQV(NCs) and CQV(MPCs) are the quality values of the NCs and MPCs of PAHs in the medium, respectively.

The potential ecological risk index (PERI) is used to assess the degree of heavy metal pollution in soil according to their toxicity and response of the environment (Hakanson 1980). This index as shown in Eq. (3) was introduced to assess the potential ecological risk of heavy metals in biochars after application into soil.

where Cfi is the pollution index of the heavy metal i; Csi is the average concentration of heavy metal i in the soil samples; Cni is the evaluation reference value of the heavy metal i; Tri is the toxic response factor of the heavy metal i; Eri is the potential ecological risk of the heavy metal i; PERI is the potential heavy metal ecological risk index and the sum of the individual heavy metal potential ecological risk. The values of Cni (mg kg−1) and Tri for heavy metals were previously reported (Devi and Saroha 2014; Hakanson 1980).

Statistical analysis

Differences between independent samples were analyzed by one-way ANOVA using IBM SPSS Statistics 19. Tukey’s post hoc test was used for the mean comparisons. Statistical significance was determined at a 95% confidence interval with the significance level at 0.05.

Results and discussion

PAHs in the biochars and corresponding feedstocks

Figure 1 presents the levels of Σ16PAHs in the biochars and their feedstocks. The Σ16PAHs in the feedstocks ranged from 0.27 to 1.09 mg kg−1, which were increased by 25–92% in their corresponding biochars (0.47–7.11 mg kg−1 with the exception of CS600 and RS600), indicating the formation of PAHs during the pyrolysis. The Σ16PAHs in the biochars depending on the feedstocks decreased as RS > CS > CC > WS, although the difference was not significant for the biochars produced at 400 and 600 °C (p > 0.05). It is interesting to note that this variation is in consistent with the variation of the ash contents in the biochars in terms of feedstocks (Table S1). A recent study reported that the high mineral content in biochar was responsible for the depolymerization of organic matter, which facilitated the high production of PAHs (Qiu et al. 2015). Although there was the absent correlation between Σ16PAHs and ash contents in the biochars (Fig. 2a), the positive correlation between Σ16PAHs in the biochars under a given HTT and their ash contents was observed (Fig. S1), indicating the positive role of minerals in the formation of some PAHs (Qiu et al. 2015).

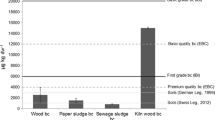

Levels of Σ16PAHs concentrations (mg kg−1) in biochars produced from walnut shell (WS), corn cob (CC), corn stem (CS), and rice straw (RS) at 250 °C (WS250, CC250, CS250, RS250), 400 °C (WS400, CC400, CS400, RS400), and 600 °C (WS600, CC600, CS600, RS600) and their corresponding feedstocks (WS0, CC0, CS0, RS0). Different lowercase letters indicate significant difference among the samples (p < 0.05)

The concentrations of Σ16PAHs in the biochars produced at 250 °C were significantly higher than those in other biochars and feedstocks (p < 0.01, Fig. 1). This finding disagreed with previous studies, where the maximum occurred between 350 and 550 °C (Hale et al. 2012; Keiluweit et al. 2012; Qiu et al. 2015). This difference was presumably attributed to the different oxygen contents in the reactors because the Nap but not Phe that contributed the most to the PAHs in the biochars produced at low HTTs (e.g., 250 °C) (Qiu et al. 2015). Another reason was the removal of PAHs from biochars via volatilization to gas phase, since the boiling point temperatures of the analyzed PAHs cover the range from 96.2 (ACE) to 530 °C (IcdP) (Zielińska and Oleszczuk 2015). With the increase of HTTs from 400 to 600 °C, the concentrations of Σ16PAHs in biochars decreased, but the differences were not significant (p > 0.05, Fig. 1). There were also no significant differences between the concentrations of Σ16PAHs in the feedstocks and biochars produced at 400 and 600 °C (p > 0.05, Fig. 1).

Because of the formation of PAHs during the pyrolysis of biochars, concentrations of PAHs in biochars were related to pyrolysis conditions (Hale et al. 2012; Qiu et al. 2015). The properties of biochars has remarkable influence on the sorption of PAHs (Sun et al. 2013), which could influence the extractability of PAHs. Thus, in order to figure out the mechanisms underlying the impact of biochar properties on extractable PAHs, it is necessary to examine the variation of PAHs concentrations with the properties of biochars. The significantly positive correlation between Σ16PAHs and H/C (p < 0.01, Fig. 2b) indicates that the greater carbonization degree of biochars results in the lower levels of Σ16PAHs (Fig. 1). The greater carbonization degree of biochars indicates that the more aromatic carbon and less aliphatic carbon in the biochars, leading to more micropore structures in the biochars (Zhang et al. 2016). Furthermore, the significantly positive correlation between Σ16PAHs and (O + N)/C (p < 0.01, Fig. 2c) indicates that hydrophobic interaction facilitates the bonding of PAHs to biochars. The concentration of Σ16PAHs exponentially declined with SA of biochars (Fig. 2d), further indicating that the trapping of PAHs within the micropores could result in the decrease of extractable PAHs. Thus, the stronger PAH sorption by biochars produced at higher HTTs via π-π interactions between the aromatic sheets of biochars and planar aromatic PAHs and the trapping of PAHs within the micropores caused the decline of extractable PAHs (Qiu et al. 2015).

As shown in Fig. S2, the low molecular weight PAHs (2- and 3-ring PAHs) in both feedstocks and biochars were significantly more abundant (p < 0.05) than the high molecular weight PAHs (4-, 5-, and 6-ring PAHs). The abundance of PAHs with different rings in the feedstocks and the biochars produced at 250 and 400 °C generally decreased as 2-ring > 3-ring > 4-ring > 5-ring > 6-ring. Among the biochars produced at 600 °C, the 3-ring PAHs were significantly more abundant (p < 0.01) than the 2- and 4-ring PAHs, whereas the 5- and 6-ring PAHs were not detectable.

The significantly positive correlation between the proportion of 2-ring PAH (Nap) and H/C (p < 0.01, Fig. 3) indicates that Nap is easy to be formed at lower HTTs (Keiluweit et al. 2012). This was attributed to that the initial organic matter in the feedstocks degraded to small unstable radicals at lower HTTs, and then they combined into non-substituted and thermodynamically more stable native hydrocarbons with low molecular mass, such as Nap (Zielińska and Oleszczuk 2015). By contrast, the significantly negative correlations between the proportions of 3-/4-ring PAHs and H/C (p < 0.01/p < 0.05, Fig. 3) indicate that larger molecules of PAHs are formed with the increase of carbonization degree (Qiu et al. 2015; Zielińska and Oleszczuk 2015). The 3-ring PAHs, such as Phe and Ant, are produced the most at 500 °C and serve as precursors for the 4- and 5-ring segments of pyrolytic PAHs (Keiluweit et al. 2012). This explained the reason for the dominant 3-ring PAHs in the biochars produced at 600 °C (Fig. 3), with the highest contribution from Phe (Fig. S3). There was the absent correlation between the proportion of 5-ring PAHs and H/C (Fig. 3), which might be due to no detection of them in some biochars.

In terms of the individual PAHs (Fig. S3), Nap was the most abundant compound in all of the biochars and the feedstocks (except for the more abundant Phe in WS600 and RS600 and Acy in CS600), with its levels ranging from 0.15 to 5.83 mg kg−1 for the biochars and from 0.23 to 0.94 mg kg−1 for the feedstocks. The second most abundant compound in all of the biochars (except for CC250) and feedstocks was Phe (0.06–0.38 mg kg−1 for biochars and 0.04–0.09 mg kg−1 for feedstocks), which was followed by Flu, Ace, Fla., Pyr, and Acy. The levels of Nap and other compounds in all of the biochars (except for those produced at 600 °C) and feedstocks showed significant differences (p < 0.05) regardless of the feedstocks and HTTs. The heaviest PAHs (e.g., DahA, IcdP, and BghiP) were not detectable in the studied biochars.

Heavy metals in the biochars and corresponding feedstocks

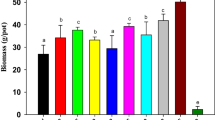

Figure 4 shows the levels of heavy metals in the biochars and their corresponding feedstocks. The levels of heavy metals in the biochars were distinctly dependent on their levels in the corresponding feedstocks. Previous researches demonstrated that the levels of heavy metals in the feedstocks could mirror the heavy metal contamination in the sampling sites. The relatively high levels of Zn, Cr, and Cu in the biochars irrespective of feedstock suggest their relatively heavy pollution in their sampling area. The significantly higher heavy metal levels in the RS and RH biochars were in agreement with their high levels in the corresponding feedstocks.

Levels of heavy metals (mg kg−1) in biochars produced from walnut shell (WS), corn cob (CC), corn stem (CS), rice straw (RS), and rice husk (RH) at 250 °C (WS250, CC250, CS250, RS250, RH250), 400 °C (WS400, CC400, CS400, RS400, RH400), and 600 °C (WS600, CC600, CS600, RS600, RH600) and their corresponding feedstocks (WS0, CC0, CS0, RS0, RH0). Different lowercase letters indicate significant difference among the samples (p < 0.05)

The levels of heavy metals in the biochars in ascending order were Cd (0.003–0.27 mg kg−1), Ni (0.14–1.73 mg kg−1), Mo (0.09–2.80 mg kg−1), Pb (0.15–2.93 mg kg−1), As (0–13.92 mg kg−1), Cu (2.41–19.15 mg kg−1), Cr (1.42–51.85 mg kg−1), and Zn (4.91–173.50 mg kg−1), which were generally higher than in the corresponding feedstocks (Fig. 4). Of these heavy metals, only Ni was found at a similar level in the biochars (except for RH600) and their corresponding feedstocks (p > 0.05). Arsenic was not detected in the WS, CC, CS, and their biochars, while its levels in the RS and RH biochars significantly increased by 7–75% as compared with their feedstocks (p < 0.05). The remaining heavy metals in the biochars generally significantly increased by 11–95% as compared with their feedstocks (p < 0.05), except for Cr in the WS and CS biochars and Pb and Cd in the WS and CC biochars (p > 0.05). The RS and RH biochars exhibited high levels of heavy metals as compared with other biochars (with the exception of Cu in RH and its biochars), which was in consistent with their high levels in RS and RH.

With respect to the HTTs, Koppolu et al. (2003) reported that the levels of heavy metals in biochars significantly increased, whereas Freddo et al. (2012) revealed that the HTTs exerted negligible influence on the heavy metals in the biochars. However, in the present study, the levels of heavy metals in the biochars increased with the increase of HTTs depending on both metal properties and feedstocks (Fig. 4). The levels of Cd and Ni in the biochars produced at higher HTTs were relative low as compared with those in the biochars produced at lower HTTs. Similar results were also reported by others (Devi and Saroha 2014; Zielińska and Oleszczuk 2016). This was attributed to that Ni and Cd could volatilize to the gas stream at higher HTTs (Devi and Saroha 2014). However, the levels of Cu in the biochars from all feedstocks (except for CC600) significantly increased with the increase of HTTs (p < 0.05). Except for Cd, the remaining heavy metals in the RS and RH biochars significantly increased with the increase of HTTs (except for RH400, p < 0.05). This could be explained by the following reasons: firstly, during the pyrolysis, both hemicellulose and cellulose in the plants rapidly decomposed at relatively low HTTs (230–400 °C), and lignin decomposed over a wider HTT range (160–900 °C) (Keiluweit et al. 2010). The decomposition of organic matter in the plant with the increase of HTTs released the heavy metals bound to the organic matter and precipitated in the biochar matrix (Devi and Saroha 2014; Qiu et al. 2015). Secondly, the weight loss of the heavy metals was lower than the organic matter during pyrolysis, resulting in their enrichment in the biochar matrix (Devi and Saroha 2014). In contrast, the HTTs exerted no or just a slight effect on the levels of heavy metals in the WS, CC, or CS biochars (except for Cu).

All of the heavy metals studied had no obvious correlations with H/C ratios of biochars (Table S2). There were also no obvious correlations between heavy metals and (O + N)/C ratios of biochars as well as between heavy metals and SAs of biochars (Table S2). These results indicate that biochar carbonization degree, polar functional groups, and surface area had little influence on the enrichment of heavy metals in the biochars. However, it is noteworthy to note that significantly positive correlations between heavy metals and ash contents of biochars were observed (p < 0.01, Fig. 5), indicating heavy metals in the biochars mainly enriched in the ash matrix during pyrolysis.

Assessing the potential ecological risk of biochars

Comparing with PAHs and heavy metals in other biosolids and their relevant legal threshold

The levels of Σ16PAHs in this study (0.47–7.16 mg kg−1) were within the range of levels for other previously reported slow-pyrolysis biochars (Freddo et al. 2012; Hale et al. 2012; Hilber et al. 2012; Keiluweit et al. 2012; Qiu et al. 2015). These levels were generally comparable to and occasionally lower than their previously reported levels in background soil, some sewage sludge, and compost (Freddo et al. 2012; Keiluweit et al. 2012). The levels of Σ16PAHs in biochars were significantly lower than the maximum acceptable PAH levels in biochars of 16 mg kg−1 as recommended by International Biochar Initiative. This sole threshold of PAHs in biochars has been recommended if the biochar is to be sold and marked to possess desirable properties (Hale et al. 2012). Further comparison with the environmental quality standards for PAHs in soil indicated that the levels of Σ16PAHs in the studied biochars were generally lower than the threshold of PAHs for soil in Norway (8 mg kg−1) and other European countries (5–50 mg kg−1) (supporting information from Hale et al. 2012). The BaP levels in the biochars (0–0.07 mg kg−1) were several orders of magnitude lower than threshold of BaP for soil in Canada (0.6 mg kg−1), Denmark (3 mg kg−1), Germany (2–10 mg kg−1), Norway (0.5 mg kg−1), UK (0.15 mg kg−1), other European countries (0.1–7.5 mg kg−1), and the USA (1.1–1.8 mg kg−1) (supporting information from Hale et al. 2012). The conversion of plant residues into biochars under high HTT (e.g., 600 °C) decreased the bioavailable PAHs as compared to the feedstocks, and thus the potential ecological risk of biochars in terms of PAHs. Similar result also reported by a previous study (Zielińska and Oleszczuk 2016).

The comparison of heavy metals with those in biosolids reported by literature and their legal threshold in China is given in Table 1. The levels of heavy metals in biochars (except for sewage sludge biochar) were commonly lower than in the sewage sludge and the compost. The heavy metals in present study were lower than the biochars derived from other sources (e.g., sewage sludge and animal waste, Table 1). The heavy metals in the sewage sludge- and animal waste-derived biochars were generally higher than those in the plant residue-derived biochars, which could be responsible for the higher heavy metal levels in their feedstocks (Qiu et al. 2015; Zielińska and Oleszczuk 2016). The levels of heavy metals in the sewage sludges and their biochars (Table 1) frequently exceeded the grade II standard values (pH < 6.5) for heavy metals in soil according to the Environmental Quality Standard for Soil (GB15618-1995) of China and occasionally exceeded the standard values (pH < 6.5) for sludge based on the Control Standards for Pollutants in Sludges from Agricultural Use (GB4284-1984). By contrast, the heavy metals in plant residue-derived biochars (Table 1) seldom exceeded the soil standard values (grade II, GB15618-1995) and were significantly lower than the maximum permissible concentration for sludge (GB4284-1984).

Potential ecological risk assessment of PAHs and heavy metals in the biochars after field application

The mean values of RQNCs and RQMPCs for individual PAHs and Σ16PAHs are listed in Table S3. The RQNCs and RQMPCs values for Σ16PAHs in biochars were 2.50–47.40 and 0.02–0.48, respectively, which were higher than the RQNCs and RQMPCs values for Σ16PAHs in their corresponding feedstocks with their values of 1.63–7.24 and 0.01–0.07, respectively. Additionally, both RQNCs values for Σ16PAHs significantly decreased when HTTs increased from 250 to > 400 °C (p < 0.05), indicating the decrease of ecological risk of biochars in terms of PAHs. However, there were no significant differences between RQNCs values for Σ16PAHs in feedstocks and their biochars produced at 400 and 600 °C (p > 0.05). Regarding RQMPCs values for Σ16PAHs, there were no significant differences between biochars and their corresponding feedstocks (p > 0.05, with exception of Nap in biochars produced at 250 °C). In fact, the RQNCs and RQMPCs values for Σ16PAHs in all biochars were over one order of magnitude lower than 800 and 1.00, respectively, thereby indicating the low ecological risk of all studied biochars (Cao et al. 2010). The RQNCs and RQMPCs for individual PAHs in the biochars were generally higher than the RQNCs and RQMPCs for individual PAHs in their corresponding feedstocks with exception of RQMPCs for Nap in the biochars produced at 600 °C. Both RQNCs and RQMPCs values for individual PAHs also generally decreased with the increase of HTTs. The RQNCs values for Nap in the biochars and their corresponding feedstocks were higher than 1.0, with the exception of WS0, ES600, CS600, and RS600. The RQMPCs values for Nap were significantly lower than 1.0. These results indicate the low risk of Nap in both biochars and their corresponding feedstocks. The RQNCs values for Acy, Ace, and Flu in biochars produced at 250 °C were commonly higher than 1.0, but their RQMPCs values were over one order of magnitude lower than 1.0, indicating their low ecological risk. The RQNCs = 0 or RQNCs < 1.0 and RQMPCs = 0 or RQMPCs < 1.0 for other individual PAHs in all biochars, suggesting their free or relatively low risk. Collectively, there is relatively low potential ecological risk in terms of PAHs after the conversion of crop residues into biochars for environmental and agricultural application.

The Eri and PERI for heavy metals are listed in Table S4. The Eri values for individual heavy metals in biochars and their corresponding feedstocks were < 0.03 for Cu, < 0.16 for Cd, < 0.09 for As, < 0.01 for Pb and Ni, < 0.02 for Cr and Zn. The PERI values of heavy metals in the biochars and their corresponding feedstocks were 0.01–0.28 and 0.02–0.12, respectively. For a given feedstock and its biochars, there were no significant differences for both Eri and PERI values. However, the PERI values of heavy metals in RS and RS biochars were significantly higher than other biochars and feedstocks (p < 0.05). The results revealed that the Eri for individual heavy metals and the PERI for heavy metals in all biochars were generally more than two orders of magnitude lower than 40 and 150, respectively, indicating the minimal potential ecological risk in terms of heavy metals after the conversion of crop residues into biochars for environmental and agricultural application (Devi and Saroha 2014).

Conclusions

The levels of PAHs in biochars remarkably decreased with the increase of HTTs. By contrast, the levels of heavy metals mainly depended on the initial heavy metal levels in their feedstocks. The effects of HTTs on heavy metal levels in biochars depended on both the types of heavy metals and biochar feedstocks. The levels of PAHs in the studied biochars were generally comparable with or even lower than other biosolids and the relevant legal threshold. Subsequent ecological risk assessment revealed the minimal potential ecological risk of PAHs and heavy metals associated with biochar application to soil based on 1% application rate. The results of this study can help to evaluate the potential ecological risk after biochar application to soil and guide the future production of biochar in environmental and agricultural applications.

References

Cao Z, Liu J, Luan Y, Li Y, Ma M, Xu J, Han S (2010) Distribution and ecosystem risk assessment of polycyclic aromatic hydrocarbons in the Luan River, China. Ecotoxicology 19:827–837

Devi P, Saroha AK (2014) Risk analysis of pyrolyzed biochar made from paper mill effluent treatment plant sludge for bioavailability and eco-toxicity of heavy metals. Bioresour Technol 162:308–315

Fabbri D, Rombolà AG, Torri C, Spokas KA (2013) Determination of polycyclic aromatic hydrocarbons in biochar and biochar amended soil. J Anal Appl Pyrolysis 103:60–67

Freddo A, Cai C, Reid BJ (2012) Environmental contextualization of potential toxic elements and polycyclic aromatic hydrocarbons in biochar. Environ Pollut 171:18–24

Fuentes A, Lloréns M, Sáez J, Soler A, Aguilar MI, Ortuño JF, Meseguer VF (2004) Simple and sequential extractions of heavy metals from different sewage sludges. Chemosphere 54:1039–1047

Hakanson L (1980) An ecological risk index for aquatic pollution control: a sedimentological approach. Water Res 14:975–1001

Hale SE, Lehmann J, Rutherford D, Zimmerman AR, Bachmann RT, Shitumbanuma V, O’Toole A, Sundqvist KL, Arp HPH, Cornelissen G (2012) Quantifying the total and bioavailable polycyclic aromatic hydrocarbons and dioxins in biochars. Environ Sci Technol 46:2830–2838

Hilber I, Blum F, Leifeld J, Schmidt H-P, Bucheli TD (2012) Quantitative determination of PAHs in biochar: a prerequisite to ensure its quality and safe application. J Agric Food Chem 60:3042–3050

Hseu Z-Y (2004) Evaluating heavy metal contents in nine composts using four digestion methods. Bioresour Technol 95:53–59

Hussain M, Farooq M, Nawaz A, Al-Sadi AM, Solaiman ZM, Alghamdi SS, Ammara U, Ok YS, Siddique KHM (2016) Biochar for crop production: potential benefits and risks. J Soils Sediments 17:685–716

Keiluweit M, Nico PS, Johnson MG, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253

Keiluweit M, Kleber M, Sparrow MA, Simoneit BRT, Prahl FG (2012) Solvent-extractable polycyclic aromatic hydrocarbons in biochar: influence of pyrolysis temperature and feedstock. Environ Sci Technol 46:9333–9341

Koppolu L, Agblevor FA, Clements LD (2003) Pyrolysis as a technique for separating heavy metals from hyperaccumulators. Part II: lab-scale pyrolysis of synthetic hyperaccumulator biomass. Biomass Bioenergy 25:651–663

Kuśmiez M, Oleszczuk P, Kraska P, Palys E, Andruszczak S (2016) Persistence of polycyclic aromatic hydrocarbons (PAHs) in biochar-amended soil. Chemosphere 146:272–279

Liu T, Liu B, Zhang W (2014) Nutrients and heavy metals in biochar produced by sewage sludge pyrolysis: its application in soil amendment. Pol J Environ Stud 23:271–275

Oleszczuk P, Jośko I, Kuśmierz M (2013) Biochar properties regarding to contaminants content and ecotoxicological assessment. J Hazard Mater 260:375–382

Qiu M, Sun K, Jin J, Han L, Sun H, Zhao Y, Xia X, Wu F, Xing B (2015) Metal/metalloid elements and polycyclic aromatic hydrocarbon in various biochars: the effect of feedstock, temperature, minerals and properties. Environ Pollut 206:298–305

Quilliam RS, Rangecroft S, Emmett BA, Deluca TH, Jones DL (2013) Is biochar a source or sink for polycyclic aromatic hydrocarbon (PAH) compounds in agricultural soils? GCB Bioenergy 5:96–103

Rajapaksha AU, Chen SS, Tsang DCW, Zhang M, Vithanage M, Mandal S, Gao B, Balan NS, Ok YS (2016) Engineered/designer biochar for contaminant removal/immobilization from soil and water: potential and implication of biochar modification. Chemosphere 148:276–291

Rizwan M, Ali S, Qayyum MF, Ibrahim M, Zia-ur-Rehman M, Abbas T, Ok YS (2016) Mechanisms of biochar-mediated alleviation of toxicity of trace elements in plants: a critical review. Environ Sci Pollut Res 23:2230–2248

Shen X, Huang D-Y, Ren X-F, Zhu H-H, Wang S, Xu C, He Y-B, Luo Z-C, Zhu Q-H (2016) Phytoavailability of Cd and Pb in crop straw biochar-amended soil is related to the heavy metal content of both biochar and soil. J Environ Manag 168:245–251

Sun K, Kang M, Zhang Z, Jin J, Wang Z, Pan Z, Xu D, Wu F, Xing B (2013) Impact of deashing treatment on biochar structural properties and potential sorption mechanisms of phenanthrene. Environ Sci Technol 2013:11473–11481

Wang C, Wang Y, Herath HMSK (2017) Polycyclic aromatic hydrocarbons (PAHs) in biochar-their formation, occurrence and analysis: a review. Org Geochem 114:1–11

Zhang G, Guo X, Zhao Z, He Q, Wang S, Zhu Y, Yan Y, Liu X, Sun K, Zhao Y, Qian T (2016) Effects of biochars on the availability of heavy metals to ryegrass in an alkaline contaminated soil. Environ Pollut 218:513–522

Zielińska A, Oleszczuk P (2015) The conversion of sewage sludge into biochar reduces polycyclic aromatic hydrocaron content and ecotoxicity but increase trace metal content. Biomass Bioenergy 75:235–244

Zielińska A, Oleszczuk P (2016) Effect of pyrolysis temperatures on freely dissolved polycyclic aromatic hydrocarbon (PAH) concentrations in sewage sludge-derived biochars. Chemosphere 153:68–74

Funding

This research was supported by the National Natural Science Foundation of China (Project Nos. 41402305 and 41401584) and the Science Technology Research and Extension Project of Shanxi Provincial Water Resources Department (Project No. 2015SHJ3).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Hailong Wang

Electronic supplementary material

ESM 1

(DOC 376 kb)

Rights and permissions

About this article

Cite this article

Zhang, G., Zhao, Z., Guo, X. et al. Levels of persistent toxic substances in different biochars and their potential ecological risk assessment. Environ Sci Pollut Res 25, 33207–33215 (2018). https://doi.org/10.1007/s11356-018-3280-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3280-8