Abstract

Limited information about the sludge quality is a major constraint for its usage and proper disposal. This study investigated the occurrence of 49 elements in sludge from 11 wastewater treatment plants (WWTPs) in Chongqing and Xiamen cities of China. The concentration of 46-detected elements ranged from 16.2 μg kg−1 (Pt) to 55.0 g kg−1 (Al) on dry solid basis in the sludge. The enrichment factor of most of the elements was > 1.5, indicating their possible anthropogenic origin. The precious metals had considerably higher enrichment factor ranging from 56.3 to 200,000. Principal component analysis clustered the samples from Chongqing and Xiamen separately to suggest strong spatial variations. Contamination factor, pollution loading index, and integrated pollution degree were calculated to evaluate the elemental pollution risk. The pollution loading index indicated unpolluted to highly polluted levels of the elements in the sludge. In addition, results from the ecotoxicological risk index showed an individual low to very high ecotoxicological risk posed by eight metal(loid)s (As, Cd, Cr, Cu, Mn, Ni, Pb, and Zn) in the WWTPs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sludge is a semi-solid biomass separated as a by-product of the wastewater treatment process (USEPA 1995; Zhang et al. 2009; Feng et al. 2014). In China, over the past few years, the number of wastewater treatment plants has increased manifolds to deal with the burgeoning wastewater yields resulting from rapid industrialization and urbanization (Yang et al. 2014). The number of wastewater treatment plants (WWTPs) increased from 1250 to 3340 in just 6 years (2007–2013) (NBSC 2013; Yang et al. 2015); consequently, the annual sludge production increased over 68% from 2007 to 2013 (Yang et al. 2015). A total of 6.25 million tons of dry solid (DS) was produced during 2013 that accounted for 4.6 kg per capita DS (Yang et al. 2015). Hence, sludge disposal has emerged as one of the major environmental challenges to draw more and more attention in China.

Thickening, conditioning, and dewatering are the major sludge treatment processes, while stabilization (via anaerobic digestion) and drying are also applied to a less extent in China (Jin et al. 2014). The treated sludge is mainly disposed of through sanitary landfill (13.4%), land application (2.4%), incineration (0.36%), and for building material production (0.24%) (Yang et al. 2015). However, due to the high cost of sludge treatment, 83.6% of the total sludge is improperly dumped (Yang et al. 2015). The hazardous materials, not limiting to the metallic pollutants, are great concern with their potential release into the receiving environments during the sludge disposal (Chanpiwat et al. 2010).

Several studies investigated the levels of metallic pollutants in the sludge. The elements (Cd, Cr, Cu, Pb, Hg, As, Ni, Zn, and Mn) enlisted in the environmental monitoring criterion or national standards of the People’s Republic of China (GB 4284-84) and national environmental protection bureau environmental quality standard for soils (GB 15618-1995) were frequently reported with the concentrations ranging from mg kg−1 to 172.3 g kg−1 of the DS (Wong and Selvam 2006; Dong et al. 2013; Wu et al. 2015; Suanon et al. 2016). Recent investigation on broad range of metallic elements in the sludge has raised great attention (Westerhoff et al. 2015; Suanon et al. 2017). Westerhoff and associates reported the presence of various metallic and metal oxide colloids with impressive economic value including platinum and rare earth elements in the sewage sludge in the USA (Westerhoff et al. 2015). Results indicated that the economic returns from elemental recovery might provide a potential way to compensate the ever increasing cost of sludge disposal mainly due to stringent regulations. Recently, Suanon and associates investigated the spatial and temporal variations of large number of metallic elements in the sludge in Xiamen City, China. The sludge disposal operations were suggested based on the elemental distribution (Suanon et al. 2017). Further investigations on the occurrence of a broad range of elements in the sludge are needed to address the large number of WWTPs in different cities/provinces across China.

This study was aimed (i) to analyze the concentration of a broad range of elements in sludge samples collected in 11 WWTPs in Chongqing and Xiamen cities of China, (ii) to investigate the spatial variations of the elements between the two cities, and (iii) to evaluate the enrichment, pollution levels, and potential environmental risks associated with the elements in sludge. A total of 49 metals and metalloids were divided into three groups, including six precious metals (Pd, Ag, Au, Ru, Ir, and Pt), 15 rare earth elements (Ce, Nd, La, Y, Sc, Pr, Sm, Gd, Dy, Er, Yb, Eu, Ho, Tm, and Lu), and other 28 industrial elements (Al, Fe, P, Ca, K, Mg, Na, Mn, W, Ba, Sr, Zn, Cu, Sn, Ni, Cr, Pb, V, Co, As, Rb, Nb, Mo, Cd, Sb, Hf, Re, and Tl).

Materials and methods

Reagents and materials

Stock solutions of the targeted elements were obtained from National Center of Analysis and Testing for Nonferrous metals and Electronic Materials, China (NCATN). There were four groups of the stock solutions, where group 1 (GNM-M27867-2013) included Ag, Al, As, Ba, Ca, Cd, Co, Cr, Cu, Fe, K, Mg, Mn, Mo, Na, Ni, P, Pb, Rb, Re, Sb, Sr, Tl, V, and Zn, group 2 (GNM-M16181-2013) included La, Ce, Pr, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb, Lu, Y, and Sc, group 3 (GSB 04-1769-2004) included Au, Pd, Pt, Ir, and Ru, and group 4 (GNM-M05868-2013) had Hf, Nb, Sn, and W. Working standard solutions were prepared by proper dilution with 2% (v/v) nitric acid for calibration purpose. The nitric acid and hydrochloric acid of analytical grade were purchased from Merck KGaA (Darmstardt, Germany). The reagent water was obtained from Milli-Q system (Millipore, USA).

Sample collection

Chongqing is the third largest city in China with a population of 28.8 million (2010) inhabiting an area of 82,000 km2. It is one of the most important financial and economic centers in the Western China. Xiamen is the major city in the southeast of China, and one of the five special economic zones. Xiamen had a population of 2.48 million in 2010 and an area of 1700 km2. Dewatered sludge samples were collected in plastic bags from six WWTPs of Chongqing (W1-W6) and five WWTPs in Xiamen (W7-W11) during 2010. These WWTPs serve a population of 0.06–0.33 million (Ye et al. 2012) and 0.30–1.0 million (Sun et al. 2016) in Chongqing and Xiamen cities, respectively. The treatment processes, daily processing capacity, and the daily sludge production of each WWTP are shown in Table S1 in the supporting information (SI) (Ye et al. 2012).

Physicochemical characterization of sludge samples

Sludge samples were pretreated by preserving under − 80 °C followed by freeze drying at − 50 °C for 60 h using a lyophilisator (Beijing Boyikang Laboratory Instruments Co., Ltd.). Freeze dried samples were ground by agate mortar and sieved by using a nylon sieve (diameter < 2 mm). The pulverized samples were used for physicochemical characterization, including pH, electrical conductivity (EC), and carbon, nitrogen, and sulfur composition. The filtrate obtained from the sludge suspension (1/10 m/v) prepared in Milli-Q water followed by 45 min of horizontal shaking was used to determine EC and pH by multi-parameter (HACH, HQ40d). Carbon, nitrogen, and sulfur contents were analyzed by using the macro elemental CNHS/O Analyzer (Vario MAX; Elementar, Germany). The results of the physicochemical characterization are shown in Table S2.

Sample digestion and element determination

All the cleanup procedure, sample digestion, element quantification, and quality control (QC) were carried out in the clean operating labs. The digestion vessels (fluoropolymer digestion tube) were pre-cleaned by leaching with 10 mL aqua regia at 90 °C for 2 hours followed by rinsing before use as recommended by the USEPA 3051A method (USEPA 3051A 2007). Furthermore, the digestion tubes and all glassware were carefully acid soaked/washed overnight in 10% nitric acid followed by washing in 10% hydrochloric acid and finally rinsing with Milli-Q water before use as recommended by Westerhoff (Westerhoff et al. 2015).

The samples were extracted following the USEPA 3051A (USEPA 3051A 2007) method using microwave digestion with a MARS X system (MARS 5 Version 194A05, CEM Corporation). Sludge sample (0.100 g) and 12.0 mL freshly prepared aqua regia were sequentially added into the digestion tube. The mixture was allowed to react for 30 min at room temperature, and then the digestion was completed under microwave system. The digestion program includes a temperature rise to 180 °C (20 °C/min) for 10.0 min followed by 45.0 min of residence time. After cooling, the digested solution with no visible particles was recuperated, filtered and diluted to 50.0 mL with 2% nitric acid. The samples were stored at 4 °C prior to detection.

Inductively coupled plasma-mass spectrometry (ICP-MS, Agilent 7500CX) and inductively coupled plasma optical emission spectrometry (ICP-OES, PerkinElmer Optima 7000 DV, USA) were used for the quantification of elements.

Quality control

The instrumental blank and procedural blank were applied for each sample batch to ensure the absence of contamination of the target elements. The certified reference materials with known elemental concentrations (GBW07309, GSD-9, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China) were conducted following the same procedures to calculate the recoveries. The recoveries were in the range of 73.2–102.5% (Table S3). All experiments were carried out in triplicate.

Data processing

The data was first normalized by using vegan package to alleviate the negative effect caused by extremely non-uniform distribution of some elements. Principal components analysis (PCA), conducted by R software (Version 3.2.2), was used to identify the spatial variability of the 49 elements in the sludge samples collected from WWTPs across two cities. Results obtained were then used to draw PCA plots by using PAST Version 2.17 and Origin 9.0.

Enrichment factor

Since, we do not dispose the local background concentration of the elements in the sludge in China, therefore, enrichment factor (EF) of an element (X) was calculated relative to the average composition of the crustal abundance (Taylor 1964; Rudnick and Gao 2003) using Al as the reference element as shown in Eq. 1.

[X]sludge and [Al]sludge are the detected concentrations of an element X and Al in the sludge, and [X]crust and [Al]crust are their respective value in the upper earth crust, respectively. Depending on the EF value, soil or sludge can be classified into six different groups: EF < 1 no enrichment,< 3 minor enrichment, 3–5 moderate enrichment, 5–10 moderate-to-severe enrichment, 10–25 severe enrichment, 26–50 very severe enrichment, and > 50 extremely severe enrichment (Müller 1969; Abrahim and Parker 2008).

Pollution indices

In order to apportion the sources of metals and metalloids in the sludge and to assess the ecotoxicological risk, various pollution indices including contamination factor (Cf), integrated pollution degree (IPD), and pollution loading index (PLI) were evaluated for each element. Specifically, ecological risk index (Ei) and potential ecological risk index (PERI) were evaluated only for heavy metals (As, Cd, Cr, Cu, Mn, Ni, Pb, and Zn) of greater environmental concern.

Contamination factor, pollution loading index, and integrated pollution degree

The pollution level related to a given heavy metal (X) was evaluated with the single contamination factor, calculated as the ratio between the metal concentration [X] in a sludge sample and its reference background concentration [X]crust (Eq. 2).

Based on the intensities, the contamination levels were classified on a scale ranging from 1 to 6: low degree (CfX < 1), moderate degree (1 ≤ CfX < 3), considerable degree (3 ≤ CfX < 6), and very high degree (CfX ≥ 6) (Luo et al. 2007; Islam et al. 2015; Yessoufou et al. 2017).

On the other hand, PLI is an integrated approach to assess the quality of sludge with respect to multiple contaminants. PLI was calculated as the product of nth root of the contamination factor (CfX) of contaminants (Tomlinson et al. 1980; Bhuiyan et al. 2010; Islam et al. 2015); where n is number of metals involved.

Based on the intensity of PLI, it can be classified into five different groups as described in Table 1 (Håkanson 1980; Luo et al. 2007).

The IPD is a polymetallic contamination index also used to evaluate the level of pollution. It is calculated as the sum of contamination factors (Luo et al. 2007).

The state of sludge is considered as low contamination if IPD < 5, moderate contamination if 5 ≤ IPD < 10, considerable if 10 ≤ IPD < 20, and high contamination if IPD ≥ 20.

Ecological risk index and potential ecological risk

The Ei and PERI were introduced by Hakanson (1980) to represent the ecological toxicity risk of a given pollutant and the integrated risk of toxicity of all considered pollutants, respectively. PERI method comprehensively considers the synergy, toxic level, concentration of the heavy metals, and the ecological sensitivity of heavy metals (Singh et al. 2010; Douay et al. 2013). Ei and PERI were evaluated for eight (n = 8) most reported heavy metals of great environmental concern (As, Cd, Cr, Cu, Mn, Ni, Pb, and Zn). The calculation of these two indices was limited to eight elements due to lack of data with respect to the toxic-response factor (Tr) for the other elements. The Tr for As, Cd, Cr, Cu, Mn, Ni, Pb, and Zn are 10, 30, 2, 5, 1, 6, 5, and 1 (Hakanson 1980, Guo et al. 2010), respectively. Ei and PERI were calculated by using the following equations:

Based on the intensity, Ei and PERI can be classified into five and four different groups, respectively as described in Table 1 (Håkanson 1980; Luo et al. 2007).

Results and discussions

Elemental concentrations

Precious metals

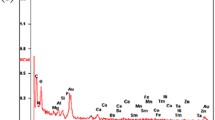

Significant quantities of Pd, Ag, and Au were detected in the sludge with the concentrations in range of 1.25–23.9 mg kg−1, 0.72–14.9 mg kg−1, and 0.56–6.89 mg kg−1 of DS, respectively (Fig. 1, Table S4 in SI). In addition, Ru and Pt were in the range of 43.0–131 μg kg−1 and 16.2–47.2 μg kg−1, respectively (Table S4), while Ir was below the detection limit (< 6.30 × 10−3 μg kg−1). Ag levels in this study are comparable with those from Sweden (0.72–3.3 mg kg−1 DS) (Östman et al. 2017) and in the sewage sludge in another study (14.7 mg kg−1 DS) (Eriksson 2001). Comparatively, higher concentrations of Ag (17–102 mg kg−1) were reported in the USA (Westerhoff et al. 2015). The concentration of Au detected in this study was similar to that reported by Suanon et al. in an earlier study (Suanon et al. 2017) in China and relatively higher than those reported from Sweden (0.26–1.20 mg kg−1 DS) (Östman et al. 2017) and the USA (0.3–2.4 mg kg−1) (Westerhoff et al. 2015).

Generally, sludge from W7, W8, and W9 showed high contents of the precious metals. For example, the highest Au concentration was observed in the sludge samples from W9 (6.89 mg kg−1 DS), followed by W8 (3.74 mg kg−1 DS). The highest Ag concentration was observed in W8 (14.9 mg kg−1 DS) followed by W7 (12.3 mg kg−1 DS), while the highest Pd concentration was detected in W8 (23.9 mg kg−1 DS) followed by W7 (21.3 mg kg−1 DS). Although, the precious metals are mainly utilized in the jewelry and investments, however, they are also used in the industrial production due to their high chemical stability, corrosion resistance, and electrical conductivity (Cayumil et al. 2016). For example, Au is used to produce the corrosion-free electrical connectors for electrical devices (Cayumil et al. 2016), Pd is used as a catalyst and to produce the electrodes and other electronic devices (Cayumil et al. 2016; Diallo et al. 2015), and Ag is used to manufacture electrical products due to its superior electrical conductivity and to manufacture the solar panels as reflective coating to concentrate solar reflectors (Cayumil et al. 2016; Cui and Roven 2011). Since, the electromotor manufacturing, power transformation devices, luminaries, solar panel, glasses manufacturing, etc. are some of the dominant industries in Xiamen City, therefore, the higher concentrations of precious metals in W7–W9 could be attributed to the high inflow of industrial wastewater containing high concentrations of the precious metals (Yearbook of Xiamen Special Economic Zone 2011).

Rare earth elements

The concentrations of rare earth elements are shown in Fig. 2. Y, Gd, Dy, Er, Yb, Eu, Ho, Tm, Sc, Ce, La, Pr, Sm, and Nd were in the range of 8.05–130 mg kg−1, 3.79–26.3 mg kg−1, 2.30–8.58 mg kg−1, 1.05–3.95 mg kg−1, 0.880–3.18 mg kg−1, 0.890–15.8 mg kg−1, 0.390–1.22 mg kg−1, 0.140–0.470 mg kg−1, 1.42–4.96 mg kg−1, 33.5–1490 mg kg−1, 12.9–589 mg kg−1, 3.88–106 mg kg−1, 3.85–10.9 mg kg−1, and 15.4–48.0 mg kg−1 of DS, respectively. Generally, the present study demonstrated comparatively higher levels of rare earth elements in the sludge from WWTPs in China compared to those in the USA (0.10–36 mg kg−1 of DS) (Westerhoff et al. 2015). Similar levels were also reported in the sewage sludge from the Republic of Benin (Yessoufou et al. 2017) and in the sludge from three different WWTPs of Xiamen City in China collected in 2014 (Suanon et al. 2017). The high concentrations of the rare earth metals detected in this study might be from the waste water contributed by industries associated with machinery, electronics, computer and communication manufacturing, etc. both in Xiamen (Yearbook of Xiamen Special Economic Zone 2011) and Chongqing (Yearbook of Chongqing 2011). In fact, the rare earth elements are widely used as oxidizing agents, rare earth magnets, catalysts and coloring agents, etc. in the industrial manufacturing of luminous materials, electronic devices, glass and ceramics, and so on (Diallo et al. 2015; Romero and McCord 2012). The released rare earth elements via industrial wastewater may have concentrated in the sludge to cause higher concentrations of these elements in the present study.

Other industrial elements

Other industrial elements were also detected in this study. Based on their concentration in the sludge, we classified them as major industrial elements and minor industrial elements. Concentration of the major industrial elements reached up to gram per kilogram of DS (Fig. 3, Table S4). This group included Al (15.9–55.0 g kg−1 DS), Fe (13.9–51.4 g kg−1 DS), P (10.5–24.3 g kg−1 DS), Ca (13.5–193 g kg−1 DS), K (2.38–9.16 g kg−1 DS), Mg (4.26–12.4 g kg−1 DS), Na (0.815–7.35 g kg−1 DS), and Mn (0.233–3.35 g kg−1 DS). The high concentration of Fe and Ca might be due to the addition of dewatering chemicals (for example, FeCl3 and CaO) in the sludge samples. Among the minor industrial elements (Fig. 3), W, Ba, Sr, Zn, Cu, Sn, Ni, Cr, Pb, V, Co, As, Rb, Nb, Mo, Cd, Sb, Hf, and Tl were detected in the range of 2.38–2590, 231–491, 187–464, 110–419, 34.9–1590, 28.6–800, 11.3–1070, 18.1–3080, 25.6–78.1, 13.3–26.1, 3.14–18.5, 3.57–6.53, 15.2–42.1, 3.86–9.82, 5.47–256, 0.790–1.43, 0.530–8.35, 2.38–4.25, and 0.164–0.499 mg kg−1 of DS, respectively. However, the concentration of Re was below the detection limit (< 8.60 × 10−3 μg kg−1).

Principal component analysis

PCA was conducted to identify the variations in the occurrence and distribution of the targeted elements among 11 WWTPs. The principal components PC1, PC2, and PC3 explained 71.6%, 15.5%, and 10.5% of the variance for the normalized elemental concentration data. The sludge samples collected from Chongqing and Xiamen clustered into separate groups, indicating strong spatial variations between the cities (Fig. 4). It is important to notice that in Xiamen city, sludge samples could be clustered into two subgroups (W7 and W9) and (W8, W10, and W11). The different wastewater sources especially the wastewater received from different types of manufacturing industry might be a contributing factor for this variation.

Enrichment factors

The EF values for the metals detected from different WWTPs are given in Table S5. The EF values for majority of the elements were > 1.5 with the exception of Al, Fe, K, Na, Rb, V, and Tl. The higher EF values indicated the anthropogenic source of the investigated elements in the sludge (Upadhyay et al. 2011).

The EF values varied among the elements in different groups as well as within the individual groups. Na, V, and Tl showed lower level enrichment compared to their crustal abundance with EF < 1 in the sludge samples from most WWTPs. Fe, P, Ca, K, Mn, Ba, Sr, Co, As, Cr, Rb, Hf, and Nb showed minor to moderate levels of enrichment (1.5 < EF < 5) in the sludge from most of the WWTPs. However, Mg, Zn, Ga, Pb, Cu, Cd, Mo, and Sb showed moderate-to-severe to very severe levels of enrichment. Extremely severe enrichment was observed in the case of W and Ni in most of the sludge samples (EF > 50). To be noticed, some elements, including Ni, Cr, Cu, Mo, Cd, and Sb, also showed extremely severe enrichment in some sludge samples, especially in W4, W5, W8, or W9.

In the case of rare earth elements, minor to moderate enrichment was observed in most of the sludge samples with the exception of samples from W7 and W8, where moderate-to-severe enrichment was observed. However, Pr did not show any enrichment in the sludge with EF < 1. It is worth mentioning that an extreme enrichment of all the precious metals in the sludge was observed. The EF values ranged from 56.3 (Pt in W11) to 200,000 (Pd in W8). Considering the high economic value of precious metals, the recovery of the precious metals from the sludge might have potential economic value and importance (Westerhoff et al. 2015; Suanon et al. 2017), especially for the sludge from W7 and W8, where extremely severe enrichment of precious elements was observed.

Ecotoxicological risk assessment

Contamination factor, pollution loading index, and integrated pollution degree

Cf gives an idea about the contamination level from a single specific element. Most of industrial elements showed low contamination level with Cf < 1 in all the WWTPs (Table 2). However, elements such as Mg, W, Zn, Sn, Pb, Mo, Cd, and Sb exhibited a moderate (1 ≤ Cf <3) to very high level of contamination (Cf ≥ 6). The Cf for rare earth elements was generally low in most of the WWTPs with the exception of W7, W8, and W9, where considerable to very high level of contamination was observed for Ce, Nd, La, Y, Pr, Gd, and Eu.

PLI and IPD were conducted to evaluate the contamination level for multiple elements. Based on the PLI values, sludge from W1, W2, W3, W6, and W10 can be classified as unpolluted/moderately polluted (1 ≤ PLI < 2) and that from W4, W5, W7,W8, W9, and W11 can be classified as moderately to highly polluted (2 ≤ PLI < 4, Table 3). In addition, results of IPD indicated very high degree of contamination (IPD > 20) in all the samples. It is worth mentioning that the high values of PLI and IPD were mainly contributed by the precious elements (Table 3 and Table S6). Considering the relatively low levels of precious metals in the sludge samples and their low toxicity, Ei and PERI were conducted to evaluate the elemental risk in the sludge.

Potential ecological risk index and potential ecological risk

The evaluation of Ei and PERI was limited to the elements of great environmental concerns, viz As, Cd, Cr, Cu, Mn, Ni, Pb, and Zn. Among the given elements, Mn, Pb, and Zn showed no ecotoxicological risk in all the WWTPs (Ei < 40, Table 4). The value of Ei for the other elements varied from one WWTP to another (Table 4). For example, there was no ecotoxicological risk for As an Cr in most of the WWTPs with the exception of W7 and W8, where a moderate risk was observed (40 ≤ Ei < 80). Similarly, Cu and Ni showed ecotoxicological risk only in W4 and W8. Cu showed a higher potential ecological risk in both the WWTPs with Ei values of 144.0 and 280.0 for W4 and W8, respectively. While the risk posed by Ni was moderate in W4 (Ei = 67.9) and considerable in W8 (Ei = 136.0). Cd was the highest ecotoxicological risk-posing element among all the elements. In short, As, Cr, Cu, Mn, Ni, Pb, and Zn exhibited very weak individual ecotoxicological risk in most of the sludge samples from WWTPs. However, high to very high ecotoxicological risk were observed for Cd in almost all the sludge samples from all WWTPs.

PERI, which take into account all the eight elements to predict the ecotoxicological risk, indicated a potentially high ecotoxicological risk (327.0–1020.0) in all the 11 WWTPs across Xiamen and Chongqing cites. Cd, Cu, and Ni generally contributed to the higher values of PERI. This could be due to the influence of anthropogenic activities as these elements that are widely used in industrial activities (Luo et al. 2012; Rodríguez Martín et al. 2013). Consequently, deeper investigation would be of utmost importance for further detailed assessment of elements in the WWTPs.

Environmental implication

The investigation on a broad range of elements not limited to only regular heavy metals but including rare earth elements, precious metals, and some other metals provided a clear picture of the occurrence and distribution of metallic and metalloid elements in the sludge samples from the 11 WWTPs in two important cities of China. The pollution levels and ecological risk assessment indicated a potential environmental risk posed by various elements in the sludge. A land application of such sludge (in its present state) might lead to soil contamination with these metals which can further aggravate the soil health problems to affect the quality and quantity of agricultural produce. The present study provided an insight of the quality of the sludge from different WWTPs in the study areas and consequent ecotoxicological risks. This information further highlights the importance of proper waste management. As the ecotoxicological risk evaluation was based on the total concentrations of the elements in the sludge, therefore, an investigation of chemical fractionations of the heavy metals and trace elements is suggested to provide more detailed information on their bioavailability, mobility, and toxicity. In addition, strong enrichment of precious metals in the sludge also indicates the potential high economic value of sludge. However, the availability of cost-efficient technique for the precious metal recovery is a great challenge to harvest this potential.

Conclusions

Broad range of the metallic and metalloid elements were detected in the sludge samples collected from 11 WWTPs from Chongqing and Xiamen cities of China. PCA showed strong spatial variations, where samples from each city were clustered separately. Higher enrichment compared to the earth’s crust was observed for most of the elements which indicated their anthropogenic contribution. Various risk-assessment criteria, including contamination factor, pollution loading index, integrated pollution degree, potential ecological risk index, and potential ecological risk, indicated potential ecotoxicology risk of the investigated sludge unless disposed of properly.

References

Abrahim GMS, Parker RJ (2008) Assessment of heavy metal enrichment factors and the degree of contamination in marine sediments from Tamaki Estuary, Auckland. New Zealand Environ Monit Assess 136:227–238

Bhuiyan MAH, Parvez L, Islam M, Dampare SB, Suzuki S (2010) Heavy metal pollution of coal mine-affected agricultural soils in the northern part of Bangladesh. J Hazard Mater 173:384–392

Cayumil R, Khanna R, Rajarao R, Mukherjee PS, Sahajwalla V (2016) Concentration of precious metals during their recovery from electronic waste. Waste Manag 57:121–130

Chanpiwat P, Sthiannopkao S, Kim KW (2010) Metal content variation in wastewater and biosludge from Bangkok’s central wastewater treatment plants. Microchem J 95:326–332

Cui J, Roven HJ (2011) Electronic waste. In: Letcher V (ed) Waste: a handbook for management. Academic Press, Boston, pp 281–296

Diallo MS, Kotte MR, Cho M (2015) Mining critical metals and elements from seawater: opportunities and challenges. Environ Sci Technol 49:9390–9399

Dong B, Liu X, Dai L, Dai X (2013) Changes of heavy metal speciation during high-solid anaerobic digestion of sewage sludge. Bioresour Technol 131:152–158

Douay F, Pelfrêne A, Planque J, Fourrier H, Richard A, Roussel H, Girondelot B (2013) Assessment of potential health risk for inhabitants living near a former lead smelter, part 1: metal concentrations in soils, agricultural crops, and homegrown vegetables. Environ Monit Assess 185:3665–3680

Eriksson J (2001) Concentrations of 61 trace elements in sewage sludge, farmyard manure, mineral fertiliser, precipitation and in oil and crops (no. 5159).Swedish Environmental Protection Agency

Feng Y, Zhang Y, Quan X, Chen S (2014) Enhanced anaerobic digestion of waste activated sludge digestion by the addition of zero valent iron. Water Res 52:242–250

Guo W, Liu X, Liu Z, Li G (2010) Pollution and potential ecological risk evaluation of heavy metals in the sediments around Dongjiang Harbor. Tianjin Prog Environ Sci 2:729–736

Håkanson L (1980) An ecological risk index for aquatic pollution control: a sedimentological approach. Water Res 14:975–1001

Islam MS, Ahmed MK, Al-Mamun MH, Hoque MF (2015) Preliminary assessment of heavy metal contamination in surface sediments from a river in Bangladesh. Environ Earth Sci 73:1837–1848

Jin L, Zhang G, Tian H (2014) Current state of sewage treatment in China. Water Res 66:85–98

Luo W, Lu Y, Gisey JP, Wang T, Shi Y, Wang G, Xing Y (2007) Effects of land use on concentrations of metals in surface soils and ecological risk around Guanting Reservoir. China Environ Geochem Health 29:459–471

Luo XS, Yu S, Zhu YG, Li XD (2012) Trace metal contamination in urban soils of China. Sci Total Environ 421–422:17–30

Müller G (1969) Index of geoaccumulation in sediments of the Rhine River. Geojourna l2:108–118

National Environmental Protection Bureau Environmental quality standard for soils. GB 15618–1995, 1995

National Standards of People’s Republic of China. Control standards for pollutants in sludges from agricultural use. GB 4284–84. http://www.testrust.com/update/news/info/20151116_082513.pdf (accessed on 18/12/2017)

NBSC (National Bureau of Statistics of China) (2013) China statistical yearbook (2013). China Statistics Press, Beijing, China (in Chinese)

Östman M, Lindberg RH, Fick J, Björn E, Tysklind M (2017) Screening of biocides, metals and antibiotics in Swedish sewage sludge and wastewater. Water Res 115:318–328

RodríguezMartín JA, Ramos-Miras JJ, Boluda R, Gil C (2013) Spatial relations of heavy metals in arable and greenhouse soils of a Mediterranean environment region (Spain). Geoderma 200–201:180–188

Romero LJ and McCord AS (2012) Rare earth elements: procurement, application, and reclamation, p8. http://prod.sandia.gov/techlib/access-control.cgi/2012/126316.pdf (accessed on 18/12/2017)

Rudnick RL and Gao S (2003) The composition of the continental crust, pp. 1-64. In The Crust (ed. R.L. Rudnick) Volume. 3, Treatise on Geochemistry (eds. H.D. Holland and K.K)

Singh A, Sharma RK, Agrawal M, Marshall FM (2010) Health risk assessment of heavy metals via dietary intake of foodstuffs from the wastewater irrigated site of a dry tropical area of India, Food Chem. Toxicology 48, 611–619

Suanon F, Sun Q, Dimon B, Mama D, Yu C-P (2016) Heavy metal removal from sludge with organic chelators: comparative study of N, N-bis(carboxymethyl) glutamic acid and citric acid. J Environ Manag 166:341–347

Suanon F, Sun Q, Yang X, Chi Q, Mulla IS, Mama D, Yu C-P (2017) Assessment of the occurrence, spatiotemporal variations and geoaccumulation of fifty-two inorganic elements in sewage sludge: a sludge management revisit. Sci Report 7:5698

Sun Q, Li M, Ma C, Chen Q, Xie X, Yu C-P (2016) Seasonal and spatial variations of PPCP occurrence, removal and mass loading in three wastewater treatment plants located in different urbanization areas in Xiamen, China. Environ Pollut 208:371–381

Taylor SR (1964) Abundance of chemical elements in the continental crust: a new table. Geochim Cosmochim Acta 28:1273–1285

Tomlinson DL, Wilson JG, Harris CR, Jeffrey DW (1980) Problems in the assessment of heavy-metal levels in estuaries and the formation of a pollution index. Helgoländer Meeresun 33:66–575

Upadhyay N, Clements A, Fraser M, Herckes P (2011) Chemical speciation of PM2.5 and PM10 in south Phoenix, AZ. J. Air Waste Manage. Assoc 61, (3), 302–310

USEPA (1995) A guide to the biosolids risk assessments for the EPA part 503 rule; U.S. Environmental Protection Agency: Washington, DC, September, 1995; p 144

USEPA 3051A (2007) Microwave assisted acid digestion of sediments, sludge, soils, and oils. https://www.epa.gov/sites/production/files/2015-12/documents/3051a.pdf (Accessed on 18/12/2017)

Westerhoff P, Lee S, Yang Y, Gordon G, Hristovski K, Halden R, Herckes P (2015) Characterization, recovery opportunities, and valuation of metals in municipal sludges from U.S. wastewater treatment plants nationwide. Environ Sci Technol 49(16):9479–9488

Wong JWC, Selvam A (2006) Speciation of heavy metals during co-composting of sewage sludge with lime. Chemosphere 63:980–986

Wu Q, Cui Y, Li Q, Sun J (2015) Effective removal of heavy metals from industrial sludge with the aid of a biodegradable chelating ligand GLDA, J. Hazard. Mater.283, 748-754

Yang G, Fan M, Zhang G (2014) Emerging contaminants in surface waters in China short review. Environ Res Lett 9:074018

Yang G, Zhang G, Wang H (2015) Current state of sludge production, management, treatment and disposal in China. Water Res 78:60–73

Ye X, Guo X, Cui X, Zhang X, Zhang H, Wang MK, Qiu L, Chen S (2012) Occurrence and removal of endocrine-disrupting chemicals in wastewater treatment plants in the three gorges reservoir area, Chongqing, China. J Environ Monit 14:2204–2211

Yearbook of Chongqing (2011) http://www.cqtj.gov.cn/tjnj/2011/yearbook/indexxls.htm (accessed on 18/11/2016)

Yearbook of Xiamen Special Economic Zone, 2011. http://www.stats-xm.gov.cn/2011/ (accessed on 14/11/2016)

Yessoufou A, Ifon BE, Suanon F et al (2017) Rare earth and precious elements in the urban sewage sludge and lake surface sediments under anthropogenic influence in the Republic of Benin. Environ Monit Assess 189(2017):625

Zhang G, He J, Zhang P, Zhang J (2009) Ultrasonic reduction of excess sludge from activated sludge system II: urban sewage treatment. J Hazard Mater 164:1105–1109

Acknowledgements

The authors would like to appreciate the technical support from Mr. YiJun Yan and the sampling support from Prof. Shaohua Chen.

Funding

This work was funded by the STS Project of Fujian-CAS (2016T3004), China Postdoctoral Science Foundation, Chinese Academy of Sciences-The World Academy of Sciences (CAS-TWAS) president’s fellowship program for developing countries, and Youth Innovation Promotion Association CAS (2016280).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 76 kb)

Rights and permissions

About this article

Cite this article

Suanon, F., Chi, Q., Yang, X. et al. Diagnosis and ecotoxicological risk assessment of 49 elements in sludge from wastewater treatment plants of Chongqing and Xiamen cities, China. Environ Sci Pollut Res 25, 29006–29016 (2018). https://doi.org/10.1007/s11356-018-2888-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2888-z