Abstract

A novel dispersive liquid–liquid microextraction (ILDLLμE) method using an extracting solvent (ionic liquid) and dispersant (Triton X-114) was developed for the separation and preconcentration of hexavalent chromium (Cr6+) in artificial saliva extract (ASE) of chewing tobacco products, gutkha, and mainpuri (n = 23). In the proposed method, the extraction of Cr6+ was accomplished by using ammonium pyrrolidinedithiocarbamate (APDC) as complexing agent and 1-butyl-3-methylimidazolium hexafluorophosphate [C4MIM] [PF6] as extracting solvent. The tiny droplet of metal chelate was then dispersed into TX-114 emulsion, using vortex mixer. Various parameters such as concentration of APDC, pH of the solution, volume of [C4MIM] [PF6], and TX-114 as well as extraction time were studied. Under the most favorable conditions, the limit of detection was found to be 0.068 μg/L with the relative standard deviation <5 %. The enrichment factor of developed method was found as 62.5, and method has been effectively applied for the analysis of Cr species in artificial saliva extract of gutkha and mainpuri products. The Cr6+ was quantitatively recovered (<97 %) under optimal conditions, while the recovery of trivalent specie (Cr3+), at the same experimental conditions, was observed to be <5 %. The Cr3+ was determined by the difference of total Cr and Cr6+ in artificial saliva extract of selected STP. Health risks associated with the intake of total Cr in gutkha and mainpuri were assessed in terms of estimated daily intake, such as carcinogenic and noncarcinogenic risks. Estimated daily intake of Cr via chewing 10 g/day of gutkha and mainpuri was found to be below the maximum tolerable daily intake, whereas the calculated risk of cancer for Cr was observed in the acceptable range of 10E−6–10E−4, except some brands of gutkha.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nicotiana tabacum is the Latin name for the tobacco plant. Tobacco belongs to the genus Nicotiana rustica, a mild flavored plant and some improved specie, and was originally raised in Virginia (Reddy and Gupta 2004). The leaves of tobacco are famous for smoking, chewing, or sniffing in different forms, all over world (Atrens 2001). It is estimated that more than 300 million people worldwide use several forms of smokeless tobacco products (STP). Miscellaneous varieties of STP are accessible worldwide varying in their composition, methods of preparation, intake ways, and related health risks (Siddiqi et al. 2015). Use of STP through oral/ nasal routes has been common in many regions of the world.

It is well documented that heavy metals in biological and environmental samples are categorized as group 1 carcinogens for human (IARC 2006; Kazi et al. 2013). The low concentrations of heavy metals are important to retain several physiological and biochemical tasks in living beings; however, their higher concentration develops harmful effects (Savarino et al. 2002; Kusy 2004). To define the metal ions actions in living beings, metal speciation is very important. In the case of chromium (Cr), the oxidative form Cr3+ is essential in trace levels for normal glucose metabolism, but Cr6+ has been found to be toxic for humans (Sun and Liang 2008; Tuzen et al. 2007). As both species have opposite biological effects (Zhu et al. 2005). The Cr6+ can enter through the cell membrane due to which it can impose adverse impact, Cr6+ cross the cell membrane through channels for isoelectric and isostructural anions (SO4 2− and HPO4 2−), and these chromates are taken up through phagocytosis (Jaishankar et al. 2014). Cr6+ can be reduced to give short-lived species of pentavalent and tetravalent Cr that are different from Cr3+. The reactions between Cr6+ and organic reducing agents (i.e., thiols and ascorbate) that produce reactive oxygen species such as hydrogen peroxide, superoxide ion, and hydroxyl radical, eventually leading to oxidative stress in the cell, bring about destruction to proteins and DNA (Stohs and Bagchi 1995; Jaishankar et al. 2014). Because of its ability to cause permanent changes in genetic material, Cr6+ is considered as a group 1 carcinogen for human by IARC (Jaishankar et al. 2014).

It was stated in a study that tobacco contains >300 μg/g, but significant description is not available on the amount of Cr inhaled through smoking/chewing tobacco (Jaishankar et al. 2014). The different harmful constituents of STP have been evaluated by the IARC as a group 1 carcinogen, which might contribute a significant health risk (Al-Mukhaini et al. 2014).

The analysis of metals in food, different biological and environmental samples, has appealed the major consideration due to their important roles, such as the dietary necessities of essential metals and the toxic properties related with the excess of these metals or their complexes (Hague et al. 2008; Tuzen and Soylak 2007; Uluozlu et al. 2009a; Iwegbue 2010). Chemical separation and preconcentration steps are often compulsory before trace or ultra-trace level analysis of Cr species in environmental and biological sample, such as solid phase extraction (Tuzen and Soylak 2006; Saygi et al. 2008), coprecipitation (Uluozlu et al. 2009b; Duran et al. 2011), dispersive liquid–liquid microextraction (Hemmatkhah et al. 2009), high-performance liquid chromatography (Martınez-Bravo et al. 2001), and capillary electrophoresis (Stewart and Olesik 2000).

Among the numerous methods employed for the extraction and preconcentration of elements targeting at speciation for advanced analysis, dispersive liquid–liquid microextraction using ionic liquid as an extracting solvent could be specified, which comprises the quick addition of both dispersing and extracting solvents simultaneously into a sample solution (Liu et al. 2005; Andruch et al. 2013). The dispersion of extracting solvent (IL) in samples by a surfactant creates cloudy solution which ensure the extraction and preconcentration within a single step (Andruch et al. 2013). Ionic liquids are used in place of organic solvents because they are ecologically safe alternatives due to their specific physical and chemical properties like viscosity, vapor pressure, immiscibility with organic solvents, and water (Liu et al. 2005).

The aim of the current study is to develop a method for the extraction of Cr in artificial saliva extract (ASE) of chewing tobacco products (gutkha and mainpuri) and risk assessment. An efficient, IL-based dispersive liquid–liquid microextraction (ILDLLμE), using a vortex probe, for the preconcentration of Cr6+ in ASE of STP was developed. The final volume of analyte enriched solvent is then analyzed by FAAS. The ASE of STP was treated with 1 mol/L HNO3 to oxidize Cr specie, for the determination of total Cr. The potential affecting variables for proposed method, such as concentration of complexing reagent, sample pH, volume of [C4MIM] [PF6] and surfactant, salt effect, and extraction time, were studied. The risk assessment methodology established by the US Environmental Protection Agency (USEPA), associated with intake of Cr in selected STP, was also studied. The possible health hazards related with Cr contents by chewing selected STP (gutkha and mainpuri) was estimated using the daily intake, target hazard quotient, and carcinogenic risk, in order to evaluate possible alert regarding adverse effects of these STP.

Experimental work

Reagents and glassware

Analytical grade ethanol and concentrated HNO3 (65 %) have been acquired from Merck (Darmstadt, Germany). The standard solutions of both species, Cr6+ and Cr3+, were prepared by dissolving corresponding K2 Cr2 O7 and Cr (NO3)3, obtained from Merck, in ultra-pure water and 0.5 mol/L HNO3, respectively. Ammonium pyrrolidine dithiocarbamate (APDC) was acquired from Merck (Darmstadt, Germany), and its solution of 0.1 to 1.0 (% w/v) was prepared by mixing suitable quantity in deionized water. 1-Butyl-3-methylimidazolium hexafluorophosphate [C4MIM] [PF6] and Triton X-114 were acquired from Sigma-Aldrich (St. Louis, MO, USA). Ultrapure water was used during the experimental work, taken from the ELGA LabWater system (Bucks, UK). The artificial saliva was prepared by the formulation as reported in literature (McKnight-Hanes and Whitford 1992; Chou and Hee 1994), and detailed composition of artificial saliva has been mentioned in our previous study (Arain et al. 2014). Polyethylene bottles were used to store the solutions at 4 °C. Certified reference material (CRM) named Virginia tobacco leaves (ICHTJ-cta-VTL-2) was used to assure the determination total Cr in STP. Glasswares and polyethylene containers were washed with distilled water after soaking them in nitric acid solution (10 %) for 24 h and dried to remove the remaining contaminants.

Instrumentation

A PerkinElmer flame atomic absorption spectrometer AAnalyst 700 (Norwalk, CT, USA) (air-acetylene flame) worked at the 358.0 nm was used for determination of Cr. A pH-meter (Ecoscan Ion 6, Malaysia) provided with a glass-combined electrode was used to determine the pH. For thorough mixing of solutions, a MX-E vortex mixer (Dragon Lab instrument, Beijing 101,318 China) was used. The task of phase separation was achieved by using Centurion Scientific Centrifuge (Model Andreas Hettich D72, Tuttlingen, Germany).

Sampling

Two main forms of chewing tobacco products/STP were selected for the present study. Ten samples of each brands of STP, mainpuri (n = 12) and gutkha (n = 11), were purchased at different time intervals (quarterly) during December to March 2016, from the native market, as per their accessibility by the public of South Eastern Region of Pakistan. Five compound samples of each brand of mainpuri and gutkha were prepared by homogenizing the mixture. The names of brands for each STP have not been mentioned in the manuscript due to authorized necessities. The samples were dried out at 80 °C and were pulverized by means of agate mortar and pestle. The nylon sieve, with a mesh width of 125 μm, was used to sieve the samples. Finally, the samples were stored in the sealed plastic bags.

Digestion of STP samples

The organic matrixes of each STP were carried out to use acid mixture followed by heating in microwave oven, in order to attain a smaller digestion time. Six replicate samples of CRM (0.2 g of Virginia tobacco leaves) and triplicate of each composite sample of different brands of selected STP (0.2 g) were taken distinctly in polytetrafluoroethylene (PTFE) flasks (25 mL in capacity). The combination of concentrated nitric acid and hydrogen per oxide (2:1, v/v) was added to the samples, reserved at room temperature for 10 min. Then, flasks were placed in covered PTFE container and heated at 80 % of total power (900 W) for 3–4 min. The volume was made up to 10 mL with 0.1 mol/L of HNO3. A blank extraction (without sample) was carried out through the complete procedure.

Artificial saliva extraction of Cr

Triplicate of each brands of STP (0.5 g) was then added 25 mL of artificial saliva to the contents of PTFE flasks. All samples were inverted several times to wet the sample surface and placed in an ultrasonic water bath (Sonicor, Deep Park, NY, USA), incubated at <40 °C for 30 min. The extractant was separated from residual mass by a centrifuge (Mechanika Precyzyjna, Poland) for 5 min at 3500 rpm to sediment the solids. The supernatant/extract was withdrawn from each tube with the help of Pasteur pipette. Suspended solids were separated by vacuum filtration of the samples through a Buchner funnel containing Whatman no. 42 filter paper.

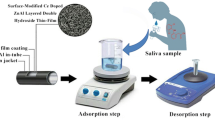

Ionic liquid based dispersive liquid–liquid microextraction procedure

Screw cap glass tube was used to store 10 mL of standard solution having 10 μg/L of Cr6+/Cr3+ (n = 6), separately. The desired pH of solutions was maintained by using 2 mL of acetate and phosphate buffer (3–9). After that, 1 mL of APDC (0.1–1 %) solution was added to content of each tubes followed by the addition of (50–200 μL) of 0.04 % TX-114 and [C4MIM] [PF6] (25–150 μL). The mixture of the tube was vigorously shaken for 10–60 s by means of vortex mixer. The cloudy solutions of tubes were immersed in the ice bath for 10 min. The complexes of Cr6+/Cr3+ with APDC have been taken out into the fine droplets of IL [C4MIM] [PF6]. Centrifugation of the solution was carried out at 3500 rpm for 5 min to attain the separation of both phases. The aqueous phase was discarded by using glass pipette, and desired analyte containing IL-phase was withdrawn with a micropipette. The acidic ethanol (0.2 mL) was mixed in order to ease the determination via FAAS by decreasing the viscosity of IL phase.

To determine the total Cr content, 2 mL of 1 mol/L HNO3 was added to each artificial extract of STP. Then, solution was heated for 1 h at 80 °C, on an electric hot plate, and made the volume up to 25 mL with deionized water, kept at 4 °C until analysis through FAAS, whereas the Cr3+ was calculated by the difference of total Cr and Cr6+ in artificial saliva extracts of STP.

Statistical analysis

Different programs of computer including Excel 2003 (Microsoft Office ®), XL State (Addin soft, NY, USA ), Minitab 13.2 (Minitab Inc., State College, PA), were used for data processing and statistical analysis. The resulted data of triplicate samples of each composite STP samples were given as means ± std. Student’s t test was used to evaluate the significant difference of understudy metal in certified and experimentally found values of CRM. The difference between total and Cr species among different STP was evaluated by unpaired two-sample t test. A p < 0.05 was considered a significant difference.

Human health risk assessment

Estimated daily intake of Cr

Estimated daily intake (EDI) is based on the total Cr concentration in chewing tobacco product. The following equation was used for the determination of EDI.

Calculations of EDI were established on the standard statement suggested by USEPA. Cr concentration in the STP is mentioned in micrograms per kilogram body weight; average body weight is stated in kilogram and daily intake of Cr through ingesting 10 g of STP/person/day.

Exposure dose

Exposure dose for Cr was computed by the following equation. Average daily exposure dose (ADD) for Cr through chewing the different STP (μg/Kg/day).

whereas concentration of Cr in STP is represented by the C (μg/g), ED represents exposure duration of 30 year for adults in this study, EF is the exposure frequency which corresponding to 365 days/year, IngR is the ingestion rate (μg/day), BW is the weight of the body for adults (60 kg), and AT is the average time for noncarcinogenic risk, calculated as ED × EF, whereas CF is the conversion factor for Cr, which was about 10−6 μg/kg. All these factors are available in the previous reports of US EPA (USEPA 2004a, b, 2007, 2009).

Carcinogenic and noncarcinogenic risk assessment

Target hazard quotient (THQ) is basically the proportion among the exposure and reference dosage, which is calculated by the following equation for the risk estimation. The THQ value >1 shows adverse health effects as per reported by USEPA (1989).

The cancer risk was calculated by using the following equation,

In the above equation, EF represents the exposure frequency for STP as (365 days/year), C is the concentration of Cr in STP (μg/g), ED is the exposure duration (30 years), Ms is the STP size (adults, 0.01 kg/day), BW is the adults body weight (60 kg), RfDo is the oral reference dose (μg/g/day), and CSF is the cancer slope factor (μg/g/day) recommended by US-EPA. CSF and RfDo for Cr are established by EPA’s Integrated Risk Information System (IRIS 2012) online database.

The CSF was employed for the estimation of CR for Cr. The accepted range anticipated lifetime risks for carcinogens is 10−6 to 10−4, predicted by USEPA (USEPA 2011b). If the risk factor is below than 10−6 for a chemical, that could be excluded from hazardous concern. The risk related with the toxicity of any element is stated as the additional chance of contracting cancer over a 70-year lifespan (Nkpaa et al. 2016).

Analytical figures of merit

The methodological features of the ILDLLμE, reproducibility, quantification, enhancement and preconcentration factor, limit of detection, calibration graph, linear range, and precision were determined to assess its performance. Linearity was acquired for concentration of Cr6+ specie, in the range of 10–100 μg/L. The regression equation is linear, A = 0.0232C + 0.0645 (where C is the concentration of Cr6+ in the final solution and A is the absorbance) with a correlation coefficient of 0.998. The enhancement and preconcentration factors were calculated as 77.3 and 62.5, respectively. The limit of detection and quantification for total and Cr6+ were determined by 10Sb/m and 3Sb/m, respectively, where S b is the standard deviation of the blank (n = 10) and m is the slope of the linear section of the calibration graphs. The LOD of total Cr and Cr6+ were calculated to be 2.2 and 0.068 μg/L, respectively. The relative standard deviation (RSD) for six replicate measurements at 10.0 μg/L of Cr6+ was <5.0 %. The efficiency of the proposed method for total Cr was tested with certified values of Virginia tobacco leaves (ICHTJ-cta-VTL-2). Student’s paired t test shows that t experimental value is lesser than t critical (2.75) at 95 % confidence interval (p > 0.05) and shows a nonsignificant variance between certified and experimental values of Cr (Table 1). Due to the inaccessibility of reference material for Cr speciation, the validity of proposed ILDLLμE method was accomplished on replicate (n = 6) subsamples of ASE of a gutkha (G2) and mainpuri (M2), spiked with standards of Cr6+ at three concentration levels (Table 2) with recoveries >98.5 %. The unpaired t test at different degrees of freedom for contents of Cr, between gutkha and mainpuri samples, was considered at altered possibilities. The calculated t-value was found to be higher than that of the t critical value at 95 % confidence intervals, which showed the notable alterations among mean values of Cr in different brands of selected STP (p < 0.001). The analytical characteristics of developed method for the assessment of Cr6+ in artificial saliva extracts of STP (gutkha and mainpuri) samples were related with formerly documented enrichment methods in various sample matrixes (Table 3 ). The resulted enhancement factor was comparable with that of the formerly reported methods. The resulted analytical parameters, such as LOD and enhancement factors, are much better than reported work. The found LOD of the proposed method was adequately low and suitable for detection of Cr6+ in several environmental and biological samples.

Results and discussion

The extraction efficiency of total Cr by artificial saliva has been studied at different time intervals such as 10 to 60 min in an ultrasonic bath at 40 °C. The maximum recovery of Cr was observed after 40 min. There was no significant effect on Cr recovery observed on increasing the sonication time after 40 min (P > 0.05). For later extraction of total Cr in artificial saliva, a time of 40 min was used. For quantitative extraction of Cr6+ via ILDLLμE, influences of various variables have been investigated; those affect the efficiency of developed method. These variables comprise of pH, concentration of complexing agent, vortex time, centrifugation time, volume of IL, and surfactant.

The consequence of pH on the extraction of Cr6+ from the ASE of STP was considered within the pH range of 3 to 9. For the adjustment of each working anticipated pH value, 0.1 mol/L HCl and/or NaOH was used. It is seen in Fig.1 that the higher extraction was achieved at pH 6, so the pH 6 was carefully chosen for later experimental work.

The concentration of complexing agent is an important variable because it has an influence on the extraction recovery of the formed Cr complex. The extraction efficiency of Cr depends on the concentration of APDC in the range of 0.1–1 %. The maximum extraction efficiency was achieved at 0.6 % solution of APDC. Further enhancement of the APDC concentration caused no significant effect on the signals as shown in Fig. 2. Hence, 0.6 % of the APDC was used for quantitative Cr6+ extraction for further work. APDC forms complex with Cr6+ at pH < 7 and forms a Cr (PDC)2 complex (Andrle et al. 1997). On the other hand, Cr3+ is nonreactive toward APDC under the experimental conditions (reaction time and temperature) employed for the chelation of Cr6+ (Kumar and Riyazuddin 2009). The inertness of Cr3+ to APDC is because of trouble in displacing the coordinated water molecules of [Cr (H2O)6]3+complex (Wai et al. 1987; Baig et al. 2012).

In the developed procedure, the volume of IL ([C4MIM] [PF6]) is another important variable to acquire a high amount fraction of the phases. The volume of IL was studied in the range of 25–150 μL. The quantitative recovery of Cr6+ was achieved at 50 μL, as shown in Fig. 3. After further increase, volume of IL does not show any significant improvement in the recovery, so 50-μL volume was used for further experimental work. The optimization of the volume of dispersing solvent (TX-114) was carried out in the range of 50 to 200 μL of 0.04 %. Maximum recovery was obtained at 150 μL as shown in Fig. 4. So, for further study, 150 μL of nonionic surfactant was used.

The vortex time was studied in the range of 10–60 s, and optimum recovery of Cr6+ specie was achieved at 30 s. For further work, the vortex-assisted shaking time of 30 s was selected. Samples were centrifuged for a time range of 2–10 min and the maximum recovery was achieved at centrifugation time of about 5 min. The lower recoveries of Cr6+ at lower and higher centrifugation time assure the incomplete phase separation and the provoking of ionic liquid to back disperse in aqueous phase, respectively. A maximum recovery was obtained at centrifugation speed of 3500 rpm. The precision of proposed method was accomplished by using Virginia tobacco leaves (CRM), whereas the optimum recovery of Cr6+ was achieved by spiking standards at three concentration levels in ASE extracts of two STP products as shown in Table 2. Interference study was also carried out for which different concentrations of cations/ions were added to standard solutions of Cr6+ (10 μg/L) following the same procedure. The recoveries were above 95 % in all cases. Table 4 reveals that the coexisting ions have almost negligible effect on the quantitative determination of Cr6+ which justifies the application of the proposed method for its analysis in different samples.

Application

The ILDLLμE method was applied on the real sample of artificial saliva extract of gutkha and mainpuri products for the extraction of Cr6+. The mean concentration values of Cr (total), total extractable, and its species along with the standard deviation are given in Tables 5, 6, and 7). The total Cr contents in all samples of mainpuri (n = 12) and gutkha (n = 11) were observed in the range of 3.53–6.05 μg/g and 3.68–13.6 μg/g, respectively. The concentration of Cr in ASE of different varieties of gutkha and mainpuri was observed in the range of 1.18–3.90 and 1–2.76 μg/g, corresponding to 23.6–50.2 and 22–50 % of total contents, respectively. However, the concentration range of 0.64–2.25 and 0.72–2.02 μg/g of extractable Cr6+ was present in gutkha and mainpuri products, respectively. The obtained figures showed that the Cr6+ present in ASE of gutkha and mainpuri corresponds to 68.4–74.9 and 69.7–75.4 % of total extractable Cr contents, respectively. The Cr3+ specie was resolute after the subtraction of Cr6+ from total Cr content in ASE, which was ranged from 0.26 to 0.64 and 0.27 to 0.79 μg/g, corresponding to 25.2–32.0 % in artificial saliva extracts of gutkha and mainpuri, respectively.

Exposure dose and risk assessment

Assessment of possible hazards to human health in current study is distributed into noncarcinogenic and carcinogenic effects which arise due to Cr present in STP. These approaches are generally established as target hazard quotients (THQs) and estimated daily intake (EDI). The estimated daily intake (EDI) of total Cr content via ingestion of both STP is represented in Table 6. The EDI for Cr via ingestion of gutkha and mainpuri (10 g/day) ranged from 0.59 to 2.27 μg/kg/BW with the maximum ingestion of Cr via chewing gutkha products (2.27 μg/kg/BW). The calculated EDI values of Cr in studied STP were lower than the tolerable daily intake level of Cr (1500 μg/kg/BW), recognized by USEPA (2011a,b), USDOE (2011), and FAO/WHO (1993). The mean values of total Cr content in different STP, calculated exposure doses (ADD), and risk assessments (THQ and CR) are represented in Table 6. The average daily dose (ADD) for gutkha and mainpuri was calculated in the range of 0.61–2.27 and 0.59–1.01 μg/kg/day, respectively. THQ values for gutkha and mainpuri were ranged from 3.92 × 10−05 to 1.51 × 10−04. The THQ value has binary functions; THQ may be greater or lesser than 1, where higher THQ values specify a cause of risk for human (Bassey et al. 2014; Nkpaa et al. 2016). In present study, THQ values for Cr were found to be <1 in both STP, meaning that no significant health risk develops due to assimilation of Cr by chewing 10 g/day of different STP. Zhang et al. (2014) described that high THQ value shows quite complex possible risk to human health particularly the residents of highly metal polluted areas.

The THQ data indicates the hazard linked with lifetime exposure to chemicals which relies on the nontoxic reference upper limits. It was immensely investigated that the possible adverse impact on human health was linked with extensive exposure of different inorganic and organic contaminants by numerous scientists and is known to be informative to take precaution about these contaminants (Naughton and Petróczi 2008; Mahmood and Malik 2014; Copat et al. 2012; Chien et al. 2002; Yi et al. 2011; Harmanescu et al. 2011; Wang et al. 2005).

The cancer risk (CR) was observed in the range of 3.9 × 10−04 to 1.13 × 10−03 for gutkha and mainpuri; it was found that the values of different brands of both STP falling within the acceptable limit, except two gutkha products (G2 and G10), have high CR, i.e., 1.13 × 10−03 and 1.07 × 10−03. As the THQ and CR were calculated on the dose of 10 g/day, whereas many people consume these products for 5–10 times and high intake of Cr might create adverse impact on human health. It was reported that smokeless tobacco keratosis occurs at the site of STP placement in up to 60 % of their users (Sinusas et al. 1992). The harmful substances in STP can originate cancer and other complications in oral cavity, because inner lining of the mouth experiences direct contact with these harmful substances present in STP, for several hours (Trivedi et al. 1996). It was stated in the literature that several toxic metals might be present in STP which, during chewing/ingesting (gutkha and mainpuri), can cause severe infections and mouth cancer (Kazi et al. 2010). It is representative that reactive oxygen species, such as hydroxyl radical, are produced in mouth during mastication STP and their activity influences oxidative DNA damage, which transmuted into oral cancer (Hecht 2003). The Cr6+ can encourage carcinogenesis for the reason that it can cross biological membranes and rejoin with nucleic acids inside the cell and protein constituents (Sun and Liang 2008).

Conclusion

In this study, proposed ILDLLμE based on IL was successfully used for preconcentration of hexavalent chromium (Cr6+) in artificial saliva extracts of different STP and analyzed by FAAS with high sensitivity and accuracy. The established procedure delivered various advantages for instance low detection limit, good enrichment factor, and RSD values. The Cr3+ was evaluated by the difference of total and Cr6+. The observed EDI, ADD, and THQ for Cr through consumption of different types of STP were found to be within the safe limit. Cancer risks calculated for STP consumer were found to be within the standard acceptable level (10−4–10−6). This observation is revealing that users of STP based on single dose of 10 g/day/person are not at risk from intake of Cr except two products of gutkha, whereas on consuming 5 to 10 times as these STP enhances the CR risk. According to the above outcomes, strategy makers and other concerned legal authorities must uphold in making judgmental policies and justifying actions to avoid these nonfood items.

References

Al-Mukhaini N, Ba-Omar T, Eltayeb E, Al-Shehi A (2014) Determination of heavy metals in the common smokeless tobacco Afzal in Oman. Sultan Qaboos Univ Med J 14:349–355

Andrle CM, Jakubowski N, Broekaert JAC (1997) Speciation of chromium using reversed phased-high performance liquid chromatography coupled to different spectrometric detection methods. Spectrochim Acta - part B. At Spectrosc 52:189

Andruch V, Balogh IS, Kocúrová L, Šandrejová J (2013) The present state of coupling of dispersive liquid–liquid microextraction with atomic absorption spectrometry. J Anal At Spectrom 28:19–32

Arain SS, Kazi TG, Arain JB, Afridi HI, Brahman KD (2014) Preconcentration of toxic elements in artificial saliva extract of different smokeless tobacco products by dual-cloud point extraction. Microchem J 112:42–49

Atrens DM (2001) Nicotine as an addictive substance: a critical examination of the basic concepts and empirical evidence. J Drug Issues 31:325–394

Baig JA, Hol A, Akdogan A, Kartal AA, Divrikli U, Kazi TG, Elci L (2012) A novel strategy for chromium speciation at ultra-trace level by microsample injection flame atomic absorption spectrophotometry. J Anal At Spectrom 27:1509–1517

Bassey FI, Oguntunde FC, Iwegbue C, Osabor VN, Edem CA (2014) Effects of processing on the proximate and metal contents in three fish species from Nigerian coastal waters. Food science & nutrition 2:272–281

Chen H, Du P, Chen J, Hu S, Li S, Liu H (2010) Separation and preconcentration system based on ultrasonic probe-assisted ionic liquid dispersive liquid-liquid microextraction for determination trace amount of chromium(VI) by electrothermal atomic absorption spectrometry. Talanta 81:176–179

Chien LC, Hung TC, Choang KY, Yeh CY, Meng PJ, Shieh MJ, Han BC (2002) Daily intake of TBT, Cu, Zn, Cd and as for fishermen in Taiwan. Sci Total Environ 285:177–185

Chou CC, Hee SSQ (1994) Bioassay-driven analysis of chewing tobacco extracts. Environ toxicol & chem 13:1177–1186

Copat C, Bella F, Castaing M, Fallico R, Sciacca S, Ferrante M (2012) Heavy metals concentrations in fish from Sicily (Mediterranean Sea) and evaluation of possible health risks to consumers. Bull Environ Contam Toxicol 88:78–83

Duran A, Tuzen M, Soylak M (2011) Speciation of Cr (III) and Cr (VI) in geological and water samples by ytterbium (III) hydroxide coprecipitation system and atomic absorption spectrometry. Food Chem Toxicol 49:1633–1637

FAO/WHO (1993) Evaluation of certain food addictives and contaminants. WHO Tech Report 837:1–53

Hague T, Petroczi A, Andrews PL, Barker J, Naughton DP (2008) Determination of metal ion content of beverages and estimation of target hazard quotients: a comparative study. Chem Cent J 2:1–9

Harmanescu M, Alda LM, Bordean DM, Gogoasa I, Gergen I (2011) Heavy metals health risk assessment for population via consumption of vegetables grown in old mining area; a case study: Banat County, Romania. Chem Cent J 5:1–10

Hecht SS (2003) Tobacco carcinogens, their biomarkers and tobacco induced cancer. Nat Rev Cancer 3:733–744

Hemmatkhah P, Bidari A, Jafarvand S, Hosseini MRM, Assadi Y (2009) Speciation of chromium in water samples using dispersive liquid–liquid microextraction and flame atomic absorption spectrometry. Microchim Acta 166:69–75

IARC (2006) Monographs on the overall evaluations of carcinogenicity to humans (pp. 1–95). Lyon: International Agency for Research on Cancer.

IRIS (2012) Integrated risk information system. <http://cfpub.epa.gov/ ncea/iris/index.cfm?fuseaction = iris.showSubstanceList > .

Iwegbue C (2010) Composition and daily intakes of some trace metals from canned beers in Nigeria. J Inst Brew 116:312–315

Jaishankar M, Tseten T, Anbalagan N, Mathew BB, Beeregowda KN (2014) Toxicity, mechanism and health effects of some heavy metals. Interdiscip Toxicol 7:60–72

Kazi TG, Wadhwa SK, Afridi HI et al (2010) Interaction of cadmium and zinc in biological samples of smokers and chewing tobacco female mouth cancer patients. J Hazard Mater 176:985–991

Kazi TG, Arain SS, Afridi HI, Brahman KD, Kolachi NF, Mughal MA (2013) Analysis of cadmium, nickel, and lead in commercial moist and dry snuff used in Pakistan. Environ Monit Assess 185:5199–5208

Kumar AR, Riyazuddin P (2009) The effect of Cr (III)-organic complexes on the determination of inorganic chromium species in groundwater by ammonium pyrrolidinedithiocarbamate–methylisobutylketone extraction procedure. Microchem J 92:145–149

Kusy RP (2004) Clinical response to allergies in patients. Am J Orthod Dentofac Orthop 125:544–547

Liu JF, Jiang GB, Jönsson JÅ (2005) Application of ionic liquids in analytical chemistry. Trends Anal Chem 24:20–27

Mahmood A, Malik RN (2014) Human health risk assessment of heavy metals via consumption of contaminated vegetables collected from different irrigation sources in Lahore, Pakistan. Arab J Chem 7:91–99

Martınez-Bravo Y, Roig-Navarro AF, López FJ, Hernández F (2001) Multielemental determination of arsenic, selenium and chromium (VI) species in water by high-performance liquid chromatography–inductively coupled plasma mass spectrometry. J Chromatogr A 926:265–274

McKnight-Hanes C, Whitford GM (1992) Fluoride release from three glass ionomer materials and the effects of varnishing with or without finishing. Caries Res 26:345–350

Naughton DP, Petróczi A (2008) Heavy metal ions in wines: meta-analysis of target hazard quotients reveal health risks. Chem Cent J 2:1–7

Nkpaa KW, Patrick-Iwuanyanwu KC, Wegwu MO, Essien EB (2016) Health risk assessment of hazardous metals for population via consumption of seafood from Ogoniland, rivers state, Nigeria; a case study of Kaa, B-dere, and Bodo City. Environ Monit & Asses 188:1–10

Paleologos EK, Stalikas CD, Tzouwara-Karayanni SM, Pilidis GA, Karayannis MI (2000) Micellemediated methodology for speciation of chromium by flame atomic absorption spectrometry. J Anal At Spectrom 15:287–291

Reddy KS, and Gupta PC (2004) Report on tobacco control in India. New Delhi, India: Ministry of Health & Family Welfare, Government of India; Centers for Disease Control and Prevention, USA. & World Health Organization.

Savarino L, Granchi D, Ciapetti G, Cenni E, Nardi Pantoli A, Rotini R, Giunti A (2002) Ion release in patients with metal-on-metal hip bearings in total joint replacement: a comparison with metal-on-polyethylene bearings. J Biomed Mater Res 63:467–474

Saygi KO, Tuzen M, Soylak M, Elci L (2008) Chromium speciation by solid phase extraction on Dowex M 4195 chelating resin and determination by atomic absorption spectrometry. J Hazard Mater 153:1009–1014

Siddiqi K, Shah S, Abbas SM, Vidyasagaran A, Jawad M, Dogar O, Sheikh A (2015) Global burden of disease due to smokeless tobacco consumption in adults: analysis of data from 113 countries. BMC medicine 13:1

Sinusas K, Coroso JG, Sopher MD, Crabtree BF (1992) Smokeless tobacco use and oral pathology in a professional baseball organization. J Fam Pract 34:713–718

Stewart II, Olesik JW (2000) Investigation of Cr (III) hydrolytic polymerisation products by capillary electrophoresis- inductivelycoupled plasma–mass spectrometry. J Chromatogr A 872:227–246

Stohs SJ, Bagchi D (1995) Oxidative mechanisms in the toxicity of metal ions. Free Radic Biol Med 18:321–336

Sun Z, Liang P (2008) Determination of Cr (III) and total chromium in water samples by cloud point extraction and flame atomic absorption spectrometry. Microchim Acta 162:121–125

Trivedi AH, Balart DB, Shah PM et al (1996) Carcinogenic and genotoxic effects of the tobacco substitute pan masala: present status and likely future impact on the Indian population. Canc. Treat Rev 22:345–354

Tuzen M, Soylak M (2006) Chromium speciation in environmental samples by solid phase extraction on Chromosorb 108. J Hazard Mater 129:266–273

Tuzen M, Soylak M (2007) Multiwalled carbon nanotubes for speciation of chromium in environmental samples. J Hazard Mater 147:219–225

Tuzen M, Uluozlu OD, Soylak M (2007) Cr (VI) and Cr (III) speciation on Bacillus Sphaericus loaded diaion SP-850 resin. J Hazard Mater 144:549–555

U.S. EPA (U.S. Environmental Protection Agency) (2004a) Region 9, Preliminary Remediation Goals, AireWater Calculations

U.S. EPA (U.S. Environmental Protection Agency) (2004b) Risk Assessment Guidance for Superfund Volume I: Human Health Evaluation Manual (Part E, Supplemental Guidance for Dermal Risk Assessment). Office of Superfund Remediation and Technology Innovation, Washington, D.C.

U.S. EPA (U.S. Environmental Protection Agency) (2007) Guidance for Evaluating the Oral Bioavailability of Metals in Soils for Use in Human Health Risk Assessment.

U.S. EPA (U.S. Environmental Protection Agency) (2009) Risk Assessment Guidance for Superfund Volume I: Human Health Evaluation Manual (Part F, Supplemental Guidance for Inhalation Risk Assessment). Office of Superfund Remediation and Technology Innovation, Washington, D.C

Uluozlu OD, Tuzen M, Soylak M (2009a) Speciation and separation of Cr (VI) and Cr (III) using coprecipitation with Ni 2+/2-Nitroso-1-naphthol-4-sulfonic acid and determination by FAAS in water and food samples. Food Chem Toxicol 47:2601–2605

Uluozlu OD, Tuzen M, Mendil D, Kahveci B, Soylak M (2009b) 3-ethyl-4-(p-chlorobenzylidenamino-4, 5-dihydro-1H-1, 2, 4-triazol-5-one (EPHBAT) as precipitant for carrier element free coprecipitation and speciation of chromium (III) and chromium (VI). J Hazard Mater 172:395–399

USDOE (2011) The risk assessment information system (RAIS), U.S. Department of energyork ridge operations office (ORO)

USEPA (1989) Guidance manual for assessing human health risks from chemically contaminated, fish and shellfish, U.S. Environmental Protection Agency, Washington, D.C.EPA503/8–89-002

USEPA (2011a) USEPA Regional Screening Level (RSL) Summary Table: November 2011. Available at: http://www.epa.gov/regshwmd/risk/human/Index.htm, last update: 6 th December

USEPA (2011b) Screening level (RSL) for chemical contaminant at superfound sites, U.S. Environmental Protection Agency

Wai CM, Tsay LM, Jim CY (1987) A two-step extraction method for differentiating chromium species in water. Microchim Acta 92:73–78

Wang X, Sato T, Xing B, Tao S (2005) Health risks of heavy metals to the general public in Tianjin. China via consumption of vegetables and fish. Sci. Total Environ 350:28–37

Yi Y, Yang Z, Zhang S (2011) Ecological risk assessment of heavy metals in sediment and human health risk assessment of heavy metals in fishes in the middle and lower reaches of the Yangtze River basin. Environ Pollut 159:2575–2585

Zhang L, Zhang D, Wei Y, Luo L, Dai T (2014) Risk assessment of trace elements in cultured freshwater fishes from Jiangxi province, China. Environ Monit Assess 186:2185–2194

Zhu X, Hu B, Jiang Z, Li M (2005) Cloud point extraction for speciation of chromium in water samples by electrothermal atomic absorption spectrometry. Water Res 39:589–595

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was not funded by any funding agency.

Conflict of interest

All authors declare no conflict of interest.

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Akhtar, A., Kazi, T.G., Afridi, H.I. et al. Vortex-assisted ionic liquid-based dispersive liquid–liquid microextraction for assessment of chromium species in artificial saliva extract of different chewing tobacco products. Environ Sci Pollut Res 23, 25288–25298 (2016). https://doi.org/10.1007/s11356-016-7700-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7700-3