Abstract

The zero-valent iron (ZVI) corrosion products and their functions were investigated in the combined ZVI and anaerobic sludge system. Results showed that ZVI corrosion occurred, and the reductive transformation and dechlorination of p-chloronitrobenzene (p-ClNB) by the anaerobic sludge were enhanced. In the combined systems with different types of ZVIs and mass ratios of anaerobic sludge to ZVI, a considerable amount of suspended iron compounds was produced and coated onto the microbial cells. However, the microbial cellular structure was damaged, and the p-ClNB reductive transformation was affected adversely after the long-term presence of nanoscale ZVI (NZVI) or reduced ZVI (RZVI) with a high concentration of 5 g L−1. The oxidized products of FeOOH and Fe3O4 were found on the surface of ZVI, which are speculated to act as electron mediators and consequently facilitate the utilization of electron donors by the anaerobic microbes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chloronitrobenzenes (ClNBs), as important intermediates for the synthesis of medicines, dyes, and pesticides, are widely produced and used in China. Lots of studies have confirmed that ClNBs are mutagenic, genotoxic, refractory, and bio-cumulative which could be accumulated in the sediments and soils and subsequently threaten ecological security and human health (Hartter 1985; Haderlein and Schwarzenbach 1995). Studies have also shown that ClNBs are difficult to be biodegraded under aerobic conditions due to the strong electrophilic characteristic of chloro- or nitro- groups on the benzene ring. However, ClNBs could be reductively transformed or even dechlorinated by sulfate-reducing, methanogenic, and homoacetogenic microorganisms under anaerobic or anoxic conditions (USEPA 1988). In general, the extent and rate of the above reactions are dependent on the nature of pollutants, character of electron donors, and their respective concentrations as well (Perkins et al. 1994). Among these factors, the selection of electron donor is demonstrated to have the greatest impact on the overall degradation reaction (Aulenta et al. 2007; Ma and Zhang 2008; He et al. 2009).

Since the 1980s, researchers have applied zero-valent iron (ZVI), bimetallic ZVI, and nanoscale ZVI (NZVI) in the treatment of chlorinated aromatic hydrocarbons, chlorinated aliphatic hydrocarbons (CAHs), azo dyes, insecticides, inorganic anions (notably nitrate), and heavy metals (As, Se, Cr, etc.) (Agrawal and Tratnyek 1996; Mantha et al. 2001; Xu et al. 2009; Olegario et al. 2010; Stieber et al. 2011; Liu et al. 2012; Chang et al. 2014; Liang and Zhao 2014; Velimirovic et al. 2014). Under the anaerobic condition, ZVI reduction follows the following equations in the aqueous system:

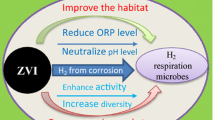

Studies have confirmed that the coexistence of ZVI could enhance the ability of anaerobic microbes in the degradation of various contaminants such as tetrachloroethene (PCE), trichloroethylene (TCE), and trichloroethylene (DCA) (Gandhi et al. 2002; Rosenthal et al. 2004; Min et al. 2009). Recently, different mechanisms of ZVI process combined with anaerobic sludge have been proposed including (1) direct reductive dechlorination on ZVI surface, (2) reductive dechlorination by surface-bounding Fe(II), and (3) hydrogen reduction via ZVI corrosion (Matheson and Tratnyek 1994; Shea et al. 2004). Thereinto, it has been well established that the reduction and coagulation caused by Fe2+ via the ZVI corrosion could enhance the pollutant degradation process (Zhang et al. 2007; Wang and Tseng 2009). Meanwhile, the hydrogen released from ZVI corrosion could be utilized by anaerobic microbes (Rosenthal et al. 2004).

Based on the previous study with respect to anaerobic reduction process and influencing factors of p-ClNB transformation in the combined ZVI-anaerobic sludge system (Zhu et al. 2012), the objectives are to reveal the function and effectiveness of ZVI and its corrosion products on the p-ClNB reductive transformation and anaerobic granular sludge growth in the combined ZVI-anaerobic sludge system. Furthermore, the synergetic effect of different ZVI types and dosages on the p-ClNB reduction was also investigated, which was helpful for the application of combined ZVI-anaerobic sludge process for enhanced refractory organic pollutant removal.

Materials and methods

Chemicals

The reagents used in the study included p-ClNB (purity > 99.5 %; Shanghai Chemical Reagent Co. Ltd., China), ultrahigh-purity H2 (purity > 99.9 %; Hangzhou Specialty Gases Co. Ltd., China), methyl tert-butyl ether (MTBE) (chromatography grade; Merck, Germany), and anhydrous sodium sulfate (reagent grade, calcined at 450 °C for 4 h). The other chemicals were of reagent grade.

Three kinds of ZVI were used, such as the industrial ZVI (named as IZVI, particle size of 100–180 mesh, purity of more than 95 %; purchased from the Hangzhou Jiali Metal Co. Ltd., China), reduced ZVI (named as RZVI, particle size of about 100 mesh, purity of more than 98 %; purchased from Shanghai Jinshan Smeltery, China), and nanoscale ZVI (named as NZVI, particle size approximately 350 nm, purity of more than 99.9 %; purchased from Shenzhen Junye Nano Material Co. Ltd., China). The inoculum was the anaerobic sludge collected from an anaerobic digester at Sibao Sewage Treatment Plant, Hangzhou, China. The mixed liquor suspended solids (MLSS) and the mixed liquor volatile suspended solids (MLVSS) were 38 and 10 g L−1, respectively.

Batch experiments for ZVI product analysis in the combined system

The analysis of corrosion products was conducted under three different conditions: single anaerobic sludge system, single ZVI reduction system, and combined ZVI-anaerobic sludge system. p-ClNB of 0.275–0.30 mmol L−1 and a certain amount of micronutrient solution (the components were shown in Zhu et al. 2012) were initially added to a 100 mL serum bottle with the HEPES buffer (0.2 mol L−1, pH 7.0 ± 0.2), and the final liquid volume per bottle was maintained at 60 mL. The medium was purged with N2 to remove the dissolved oxygen in the system, and then the ZVI or acclimated anaerobic sludge was added into the serum bottle. The type and amount of ZVI and the amount of sludge added in the system were determined based on the purpose of different experiments. The serum bottles were sealed with butene rubber stoppers and placed onto an incubator at 150 r min−1 and 30 °C for the oscillatory reaction. The gas compositions, solution pH, oxidation-reduction potential (ORP), dissolved iron concentration, suspended iron concentration, as well as the surface property of ZVI and anaerobic sludge were regularly analyzed during the whole experiment. All the samples were tested in triplicate.

Analysis methods

The pH and ORP were measured using a Delta320 precision pH meter equipped with a pH electrode and a redox electrode (Shanghai Mettler-Toledo Instruments, China), respectively. The CODCr and biomass concentration (MLSS and MLVSS) were measured according to standard methods (APHA 1998).

Target pollutants as p-ClNB, p-ClAn, and AN were determined using a high-performance liquid chromatography (HPLC; Waters, Milford, MA, USA) equipped with a 2487-double-wavelength absorbance detector, a 717 autosampler, and a 4.6 mm × 150 mm, 5 μm Agilent ZORBAX Eclipse SB-C18 (Palo Alto, CA, USA). Water sample taken from serum bottle was treated as described in previous reports (Zhu et al. 2012). A sample of 1.0 mL was centrifuged for 10 min at 10,000 rpm, and subsequently 0.6 mL of supernatant was mixed with 0.9 mL methanol. Prior to analysis, the sample solution was filtered with a 0.22-μm filter membrane. The mobile phase was the mixture of CH3OH/H2O in the proportion of 60/40, and the flow rate was 1.0 mL min−1. Injection volume for each sample was adopted to 10 μL, and column temperature was set at 30 °C. The wavelengths for p-ClNB, p-ClAn, and AN were 254, 254, and 230 nm, respectively.

The gaseous H2 and CH4 were determined using a gas chromatograph (GC 9800; Shanghai Tianmei Technology Co. Ltd., China) equipped with a thermal conductivity detector (TCD) and a packed Porapak q column. Temperatures of the column, gasification chamber, and detector were 40, 80, and 60 °C, respectively. The carrier gas was high-purity nitrogen, and the injection volume was 1 mL.

The concentration of dissolved iron was determined using the 1,10-phenanthroline spectrometric method (APHA 1998). The total iron concentration was determined based on the method of Vlyssides et al. (2009). Briefly, the mixed liquor was acidified with 10 mL concentrated hydrochloric acid and heated until complete dissolution after MLSS and MLVSS measurement, and then the dissolved iron was analyzed via 1,10-phenanthroline spectrometric method. The suspended iron concentration was calculated from the difference between the total iron and dissolved iron concentrations.

The morphology of anaerobic sludge and surface appearance of ZVI were observed using scanning electron microscopy/energy-dispersive X-ray spectroscopy (SEM/EDX, FEI SIRON 0308947Q; Netherlands) and transmission electron microscopy (TEM, JEOL JEM-1230; Japan). The pretreatment of anaerobic sludge for SEM analysis was as follows: The sludge sample was fixed overnight in 2.5 % glutaraldehyde at 4 °C, washed three times with 0.1 mol L−1 at pH 7.0 of phosphate buffer solution (PBS) (15 min each wash), fixed with a 1 % osmic acid solution for 1–2 h, and washed three additional times with PBS (15 min each wash). After a series of ethanol dehydrations (50, 70, 80, 90, 95, and 100 %), the sample was further treated in a mixture of ethanol and iso-amyl acetate (V/V = 1/1) for 30 min and pure iso-amyl acetate for 1–2 h, dried at a critical point, and coated for use. The TEM sample was pretreated as follows: The sludge was dehydrated through a series of ethanol solutions, pretreated in pure acetone for 20 min and treated in an embedding agent and acetone mixture for 1 h (V/V = 1/1) and 3 h (V/V = 3/1), respectively. After overnight infiltration in pure embedding agent, the sample was heated to 70 °C overnight, sectioned into 70–90-nm slices, and sequentially stained for 15 min with lead citrate, uranyl acetate, and a 50 % ethanol solution.

The surface property of ZVI was characterized using a X-ray diffraction (XRD) equipment. The ZVI particles were selected from different batch systems at the end of experiments and were ultrasonically cleaned in deoxygenated water for 30 min with a C5860 ultrasonic cleaner (Nanjin Kejie Analysis Instrument Co. Ltd., China). Subsequently, the suspension was centrifuged at 104 r min−1 (Sigma 3K18 centrifuge) for 10 min, and the supernatant was discharged. The ZVI sample was finally dried by N2 before the analysis by a XRD equipment (Rigaku Dmax-2550PC multi-crystal X-ray diffractometer, Japan).

Results and discussion

To reveal the interaction of ZVI and its corrosive productions with anaerobic microorganisms during anaerobic p-ClNB reductive process, the pH, ORP, and H2 concentration were analyzed and the ZVI corrosion products were investigated in the combined ZVI and anaerobic sludge system.

Corrosion and hydrogen production in the combined ZVI-anaerobic sludge system

Three kinds of ZVI were used for p-ClNB reductive transformation in the combined system, and different dosages were designed for the ZVIs under the same condition of initial p-ClNB concentration at approximately 0.30 mmol L−1 and anaerobic sludge concentration at 1.5 g VSS L−1. The addition of IZVI, RZVI, and NZVI was 1.0–10.0, 0.5–5.0, and 0.5–2.0 g L−1, respectively. Results showed that different ZVIs exhibited distinct activity for hydrogen production, which was ordered as NZVI > RZVI > IZVI. Meanwhile, the production of hydrogen increased correspondingly with the increase of ZVI dosage. Numerous studies have reported that the reductive transformation of ZVI belonged to the surface reaction and its surface characteristics influenced the rate of reaction (Agrawal and Tratnyek 1996; Crane and Scott 2012). Under the condition without the additional carbon source, the standard Gibbs free energy for production of hydrogen through ZVI corrosion was as low as −5.02 kJ mol Fe−1 under anaerobic condition, and the accumulation of H2 had a negative effect on the reductive reaction (Karri et al. 2005). However, anaerobic microbes could decrease H2 partial pressure by utilization in the combined ZVI-anaerobic sludge system and, therefore, accelerated the corrosion of ZVI and increased the available reaction sites (Ryu et al. 2011; Shirin and Balakrishnan 2011).

Analysis of ZVI corrosion products in anaerobic system

The variations in pH, ORP, and dissolved and suspended iron concentrations in different anaerobic systems are shown in Fig. 1. The concentration of anaerobic sludge was maintained at 1.5 g MLVSS L−1 and those of IZVI, RZVI, and NZVI were 0–10, 0.5–5, and 0.5–2 g L−1, respectively. As shown in Fig. 1, the addition of ZVI increased the pH value in the system and decreased the ORP of the solution, coupling with the improvement of dissolved and suspended iron concentrations in anaerobic sludge. The above parameters showed obviously change with ZVI dosage increase, and the affecting extent was in accordance with the reductive ability of ZVI as NZVI > RZVI > IZVI.

The pH values in combined NZVI, RZVI, and IZVI-sludge systems were 7.05–7.62, 7.17–7.38, and 7.15–7.21, respectively. The pH in the combined systems was kept within the range by PBS and did not disturb the normal growth of anaerobic microbes. With regards to the ORP, the anaerobic microbes have strict ORP requirement generally. For example, methanogens prefer an ORP that is approximately between −150 and −400 mV. The addition of NZVI, RZVI, and IZVI decreased the ORP in the system from −124 to −240 ~ −480 mV, −237 ~ −363 mV, and −184 ~ −260 mV, respectively, which were precisely among the range for methanogens. Lee and Cho (2001) and Zhang et al. (2011) found that the enhanced dechlorination of TCE by ZVI and methanogenesis were correlated with low ORP that resulted from the presence of ZVI. However, the enhancement of IZVI and NZVI on the dechlorination is obviously inferior to that of RZVI in the anaerobic sludge system; therefore, there was little correlation between the enhancement and ORP in the batch test.

For the iron concentration in different systems, the combined NZVI, RZVI, and IZVI-anaerobic sludge systems had dissolved iron concentrations of 24.45–160.17, 20.2–41.3, and 14.5–30.47 mg L−1, respectively. Meanwhile, the suspended iron concentrations in the systems were 121.7–208.4, 97.4–174.8, and 57.7–147.3 mg L−1. These data clearly demonstrated that the majority of oxidized irons were transformed to suspended compounds via further oxidation or coagulation. The concentrations of both dissolved and suspended iron compounds in the NZVI system were greater than those in the IZVI and RZVI systems, which might be attributed to the higher specific surface area of NZVI.

As one of the essential nutrients for the microbial growth, iron participates in many metabolic processes and has a positive effect on microbial activity. Batch test with different Fe2+ concentrations was conducted to investigate the effect of Fe2+ concentration on the rate of p-ClNB reduction in the anaerobic sludge system (shown in Fig. 2).

The transformation rate of p-ClNB in all the systems could be well described by pseudo-first-order kinetic of Eq. 4:

where [p-ClNB] is the concentration of p-ClNB and k p-ClNB is the pseudo-first-order rate coefficient.

In order to illustrate the enhancement of Fe2+ on the transformation of p-ClNB by the anaerobic sludge, a strengthening factor Q′ was employed in Eq. 5:

where k p-ClNB + Fe 2+ is the rate coefficient of p-ClNB transformation in Fe2+-added anaerobic sludge system, and k p-ClNB is the rate coefficient of p-ClNB transformation in the controlled system.

Results showed that k p-ClNB increased from 0.036 to 0.052 h−1 along with the Fe2+ concentration increased from 0 to 100 mg L−1, and meanwhile, the strengthening factor Q′ increased from 1.00 to 1.44. The result revealed that a suitable Fe2+ concentration could improve the anaerobic microbial metabolism. Nevertheless, the effect of H2 (Q′ was at 4.12–5.65) was considerably more significant (Zhu et al. 2012). The t test (paired) differences also indicated no significant difference between the reduction of p-ClNB and H2 and production of dissolved and suspended irons, with a t test p value of 0.221–0.246, respectively, which were >0.05. Results confirmed that H2 produced via ZVI corrosion could be used as an electron donor to enhance the reduction of p-ClNB in the ZVI-sludge combined system. It is noteworthy that the majority of oxidized irons existed in the suspended forms, and the systems with NZVI had the highest concentration of suspended irons. In view of the inhibitory effect from NZVI and high concentration of RZVI on the anaerobic sludge, the significant amount of suspended irons generated from ZVI oxidation may negatively affect the metabolism of the anaerobes.

Composition of iron oxides and their effect on p-ClNB reductive transformation

To determine the distribution of iron in the anaerobic sludge and its potential inhibitory mechanism, the surface property of anaerobic sludge was analyzed. As shown in Fig. 3, SEM images revealed that the anaerobic sludge surface was relatively smooth in the controlled group, while in the combined NZVI (0.5 g L−1)-sludge and RZVI (5.0 g L−1)-sludge systems, precipitates are exhibited on the sludge surface. EDX analysis revealed elemental iron existing in sludge surface precipitates with the value of 1.27, 2.41, 3.11, 3.61, and 8.62 % for the controlled sludge, IZVI (1.0 g L−1)-sludge, RZVI (1.0 g L−1)-sludge, RZVI (5.0 g L−1)-sludge, and NZVI (1.0 g L−1)-sludge systems, respectively. Thereby, the richness followed the order of NZVI-sludge > RZVI-sludge > IZVI-sludge > sludge. TEM analysis (shown in Fig. 4) also indicated that there were particulate precipitates coating onto the cell surface in the combined IZVI-sludge and RZVI (1.0 g L−1)-sludge systems. Furthermore, the amount of precipitates increased with the RZVI concentration up to 5.0 g L−1; however, the microbial cells were deformed under a concern pressure. In the combined NZVI-sludge system, the deformation was more significant, and the cellular structure of anaerobic microbes was even damaged. The results indicated that high ZVI concentrations, especially in the case of NZVI, had a negative effect on the anaerobic microbial cells.

In recent years, lots of studies have reported that NZVI had a certain extent of inhibition or even toxic effects on the microorganisms. Xiu et al. (2010) observed that NZVI suppressed the dechlorination of TCE by Dehalococcoides. Diao and Yao (2009) concluded that the mechanisms for inhibition or toxicity could be (1) physical precipitation of iron on the cell surface, (2) damage to the cell membrane induced by iron oxides, and (3) formation of radicals such as O · from the NZVI reaction with dissolved oxygen in the cytoplasm. Current studies revealed that NZVI and high concentration of RZVI could also significantly inhibit the dechlorination of p-ClAn (Zhu et al. 2012). In the prolonged operation under a fed-batch mode, the presence of RZVI caused obvious inhibition on low concentration of anaerobic sludge. Coupling the analysis on ZVI oxidation products to the surface characterization, the inhibition mechanism was speculated that iron oxides coating onto the cell surface were capable of interfering the transport of nutrients as well as pollutants and also did damage to the structure of cell membrane, which consequently deactivated the microorganisms. With a gradual increase in the concentration of anaerobic sludge and a constant dosage of ZVI, the precipitations contained in microorganisms could be decreased and the inhibition be ultimately alleviated.

To consolidate the biochemical cooperation between anaerobic microbes and ZVI, the inhibitory effect from ZVI had to be taken into consideration for establishing a stable combined ZVI-anaerobic sludge system. The selection of an appropriate ZVI or the ratio of anaerobic sludge to ZVI could be performed to improve the reductive performance of combined system.

Surface characteristics of ZVI and its effect on reductive transformation of p-ClNB

SEM images of the RZVI system and combined RZVI-anaerobic sludge system are shown in Fig. 5. Results showed that a significant change happened, and flakes were observed on the RZVI surface after reaction. Analysis of the precipitates on ZVI surface using XRD (shown in Fig. 6) revealed that ZVI surface was oxidized to various extents among different anaerobic systems. The primary precipitates were FeOOH and Fe3O4, which suggested that the coexistence of ZVI with anaerobic sludge did not affect the composition of precipitates on the ZVI surface. FeOOH and Fe3O4 were deemed to be efficient electron mediators and capable of accelerating electron transportation when they are absorbed on the ZVI surface. At the same time, the transformation rates of contaminants were also increased (Huang and Zhang 2005; Liu et al. 2006). In preliminary studies, the activity of p-ClNB transformation was enhanced with k p-ClNB increasing from 0.72 to 0.92 h−1 (indicated as 1.28 times). It was speculated that the enhancement of k p-ClNB resulted from FeOOH and Fe3O4 forming on the ZVI surface, which accelerated the transport of electrons during the reduction of p-ClNB by ZVI. In comparison with the ZVI-control system, the combined ZVI-anaerobic sludge system had an increase of k p-ClNB from 0.86 to 3.51 h−1 in the first cycle to 2.69–9.53 h−1. The rate of p-ClNB reduction improved as the sludge concentration increased. Therefore, it was deduced that FeOOH and Fe3O4 improved the utilization rate of electron donors by anaerobic sludge on the ZVI surface and consequently promoted the biochemical synergistic effect of ZVI with the anaerobic sludge. According to the results of the inhibitory effect involved in the dechlorination under the condition of low sludge/iron mass ratio, the effect of ZVI oxidized products included two aspects: (1) FeOOH and Fe3O4 facilitated the transport of electron donors, and (2) a large amount of FeOOH and Fe3O4 precipitating on the cell surfaces caused damage to the cellular structure (Watanabe et al. 2013). Studies about iron-reducing bacteria and sulfate-reducing bacteria showed that the enhanced dechlorination of TCE and CT was mainly due to the microorganisms capable of increasing the oxidation rate of ZVI or forming highly active products on the ZVI surface (Gerlach et al. 2000; Min et al. 2009; Wang and Tseng 2009). However, increasing the anaerobic biomass could not only enhance the cooperation between ZVI and anaerobic microbes but also improve the resistance to inhibitory effect of iron oxides, which suggests that increasing the anaerobic biomass might be a key for optimizing the combined ZVI-anaerobic sludge system for better reductive performance.

Conclusions

In the combined ZVI-anaerobic sludge system, the concentrations of dissolved and suspended iron were significantly increased and the reductive transformation and dechlorination of p-ClNB were enhanced simultaneously. A considerable amount of suspended iron compounds was produced and coated onto the microbial cells. The oxidized products of FeOOH and Fe3O4 were found on the surface of ZVI, which was speculated to act as the electron mediators and consequently facilitate the utilization of electron donors by anaerobic microbes. However, the microbial cellular structure was deformed or damaged in the long-term presence of nanoscale ZVI or reduced ZVI with a high concentration of 5 g L−1, and the reductive transformation of p-ClNB was affected adversely. Results revealed that an appropriate type of ZVI and optimal mass ratio of anaerobic sludge to ZVI were important to improve the performance of the conventional anaerobic sludge process for refractory organic pollutant degradation.

References

Agrawal A, Tratnyek PG (1996) Reduction of nitro aromatic compounds by zero-valent iron metal. Environ Sci Technol 30:153–160

American Public Health Association (1998) Standard methods for the examination of water and wastewater. American Public Health Association/American Water Works Association/Water Environment Federation, Washington

Aulenta F, Catervi A, Majone M, Panero S, Reale P, Rossetti S (2007) Electron transfer from a solid-state electrode assisted by methyl viologen sustains efficient microbial reductive dechlorination of TCE. Environ Sci Technol 41:2554–2559

Chang DY, Chen TH, Liu HB, Xi YF, Qing CS, Xie QQ, Frost RL (2014) A new approach to prepare ZVI and its application in removal of Cr(VI) from aqueous solution. Chem Eng J 244:264–272

Crane RA, Scott TB (2012) Nanoscale zero-valent iron: future prospects for an emerging water treatment technology. J Hazard Mater 211–212:112–125

Diao M, Yao M (2009) Effects of nano-scale zero-valent iron particles on a mixed culture dechlorinating trichloroethylene: use of zero-valent iron nanoparticles in inactivating microbes. Water Res 43:5243–5251

Gandhi S, Oh BT, Schnoor JL, Alvarez PJJ (2002) Degradation of TCE, Cr(VI), sulfate, and nitrate mixtures by granular iron in flow-through columns under different microbial conditions. Water Res 36:1973–1982

Gerlach R, Cunningham AB, Caccavo F (2000) Dissimilatory iron-reducing bacteria can influence the reduction of carbon tetrachloride by iron metal. Environ Sci Technol 34:2461–2464

Haderlein SB, Schwarzenbach RP (1995) Environmental processes influencing the rate of abiotic reduction of nitroaromatic compounds in the subsurface. In: Biodegradation of Nitroaromatic Compounds. Spain J, New York, pp. 199–225

Hartter DR (1985) The use and importance of nitroaromatic chemicals in the chemical industry. Toxicity of nitroaromatic compounds. Hemisphere, Washington, pp 1–13

He N, Li PJ, Zhou YC, Fan SX, Ren WX (2009) Degradation of pentachlorobiphenyl by a sequential treatment using Pd coated iron and an aerobic bacterium (H1). Chemosphere 76:1491–1497

Huang YH, Zhang TC (2005) Effects of dissolved oxygen on formation of corrosion products and concomitant oxygen and nitrate reduction in zero-valent iron systems with or without aqueous Fe2+. Water Res 39:1751–1760

Karri S, Sierra-Alvarez R, Field JA (2005) Zero valent iron as an electron-donor for methanogenesis and sulfate reduction in anaerobic sludge. Biotechnol Bioeng 92:810–819

Lee DK, Cho IC (2001) Characterization of TiO2 thin film immobilized on glass tube and its application to PCE photocatalytic destruction. Microchem J 68:215–223

Liang QQ, Zhao DY (2014) Immobilization of arsenate in a sandy loam soil using starch-stabilized magnetite nanoparticles. J Hazard Mater 271:16–23

Liu CC, Tseng DH, Wang CY (2006) Effects of ferrous ions on the reductive dechlorination of trichloroethylene by zero-valent iron. J Hazard Mater 136:706–713

Liu HB, Chen TH, Chang DY, Chen D, Liu Y, He HP, Yuan P, Frost RL (2012) Nitrate reduction over nanoscale zero-valent iron prepared by hydrogen reduction of goethite. Mater Chem Phys 133:205–211

Ma LM, Zhang WX (2008) Enhanced biological treatment of industrial wastewater with bimetallic zero-valent iron. Environ Sci Technol 42:5384–5389

Mantha R, Taylor KE, Biswas N, Bewtra JK (2001) A continuous system for Fe0 reduction of nitrobenzene in synthetic wastewater. Environ Sci Technol 35:3231–3236

Matheson LJ, Tratnyek PG (1994) Reductive dehalogenation of chlorinated methanes by iron metal. Environ Sci Technol 28:2045–2053

Min JE, Park IS, Ko S, Shin WS, Park JW (2009) Effect of phosphate and sediment bacteria on trichloroethylene dechlorination with zero valent iron. J Environ Sci Health A 44:362–369

Olegario J, Yee N, Miller M, Sczepaniak J, Manning B (2010) Reduction of Se(VI) to Se(−II) by zerovalent iron nanoparticle suspensions. J Nanoparticle Res 12:2057–2068

Perkins PS, Komisar SJ, Puhakka JA, Ferguson JF (1994) Effects of electron-donors and inhibitors on reductive decholorination of 2,4,6-trichlorophenol. Water Res 28:2101–2107

Rosenthal H, Adrian L, Steiof M (2004) Dechlorination of PCE in the presence of Fe-0 enhanced by a mixed culture containing two Dehalococcoides strains. Chemosphere 55:661–669

Ryu A, Jeong SW, Jang A, Choi H (2011) Reduction of highly concentrated nitrate using nanoscale zero-valent iron: effects of aggregation and catalyst on reactivity. Appl Catal B Environ 105:128–135

Shea PJ, Machacek TA, Comfort SD (2004) Accelerated remediation of pesticide-contaminated soil with zerovalent iron. Environ Pollut 132:183–188

Shirin S, Balakrishnan VK (2011) Using chemical reactivity to provide insights into environmental transformations of priority organic substances: the Fe-0-mediated reduction of Acid Blue 129. Environ Sci Technol 45:10369–10377

Stieber M, Putschew A, Jekel M (2011) Treatment of pharmaceuticals and diagnostic agents using zero-valent iron—kinetic studies and assessment of transformation products assay. Environ Sci Technol 45(11):4944–4950

USEPA (1988) In: Agency EP (ed) National pollutant discharge elimination system, code of federal regulations. US Government Printing Office, Washington

Velimirovic M, Simons Q, Bastiaens L (2014) Guar gum coupled microscale ZVI for in situ treatment of CAHs: continuous-flow column study. J Hazard Mater 265:20–29

Vlyssides A, Barampouti EM, Mai S (2009) Influence of ferrous iron on the granularity of a UASB reactor. Chem Eng J 146:49–56

Wang SM, Tseng SK (2009) Dechlorination of trichloroethylene by immobilized autotrophic hydrogen-bacteria and zero-valent iron. J Biosci Bioeng 107:287–292

Watanabe M, Yoneda M, Morohashi A, Hori Y, Okamoto D, Sato A, Kurioka D, Nittami T, Hirokawa Y, Shiraishi T, Kawai K, Kasai H, Totsuka Y (2013) Effects of Fe3O4 magnetic nanoparticles on A549 cells. Int J Mol Sci 14:15546–15560

Xiu ZM, Jin ZH, Long TL, Mahendra S, Lowry GV, Alvarez PJJ (2010) Effects of nano-scale zero-valent iron particles on a mixed culture dechlorinating trichloroethylene. Bioresour Technol 101:1141–1146

Xu XH, Wo JJ, Zhang JH, Wu YJ, Liu Y (2009) Catalytic dechlorination of p-NCB in water by nanoscale Ni/Fe. Desalination 242:346–354

Zhang W, Chen L, Chen H, Xia SQ (2007) The effect of Fe-0/Fe2+/Fe3+ on nitrobenzene degradation in the anaerobic sludge. J Hazard Mater 143:57–64

Zhang YB, Jing YW, Zhang JX, Sun LF, Quan X (2011) Performance of a ZVI-UASB reactor for azo dye wastewater treatment. J Chem Technol Biotechnol 86:199–204

Zhu L, Lin HZ, Qi JQ, Xu XY, Qi HY (2012) Effect of H2 on reductive transformation of p-ClNB in a combined ZVI-anaerobic sludge system. Water Res 46:6291–6299

Acknowledgments

The works were funded by the National Natural Science Foundation of China (Nos. 50778158 and 51378454) and National Key Technologies Research and Development Program of China (No. 2013BAC16B04).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Angeles Blanco

Rights and permissions

About this article

Cite this article

Zhu, L., Gao, K., Jin, J. et al. Analysis of ZVI corrosion products and their functions in the combined ZVI and anaerobic sludge system. Environ Sci Pollut Res 21, 12747–12756 (2014). https://doi.org/10.1007/s11356-014-3215-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-3215-y