Abstract

A xylanase gene, xynE2, was cloned from thermoalkaline Anoxybacillus sp. E2 and was expressed in Escherichia coli BL21 (DE3). The gene consisted of 987 bp and encoded a 328-residue xylanase with a calculated molecular weight of 38.8 kDa. On the basis of amino acid sequence similarities, this enzyme was assigned as a member of glycoside hydrolase family 10. Purified recombinant XynE2 showed maximal activity at pH 7.8 and 65°C, and was thermostable at 60°C. The enzyme was highly active and stable over a broad pH range, showing more than 90% of maximal activity at pH 6.6–pH 8.6 and retaining more than 80% of activity at pH 4.6–pH 12.0, 37°C for 1 h, respectively. These favorable properties make XynE2 a good candidate in the pulp and paper industries. This is the first report on gene cloning, expression and characterization of a xylanase from the genus Anoxybacillus.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hemicellulose is the second most abundant renewable polysaccharide after cellulose in nature (Beg et al. 2001). Xylan, the major component of hemicellulose, is a heterogeneous polysaccharide with a linear backbone comprised of β-1,4-d-xylopyranoside residues (Collins et al. 2005). Complete breakdown of xylan requires the action of several hydrolytic enzymes. Among them, endo-xylanase (β-1,4-d-xylanase, EC 3.2.1.8) is the most important enzyme that hydrolyze β-1,4-glycosidic linkages in the xylan backbone into short xylooligosaccharides (Biely 1985). Based on amino acid sequence homology and hydrophobic cluster analysis, xylanases have been mainly grouped into glycosyl hydrolase (GH) families 10 and 11 (Gilkes et al. 1991; Henrissat and Bairoch 1996).

Xylanases have been attracting extensive attention over the past two decades due to their widespread potential applications in the food, animal feed, textile, waste-treatment, paper, and biofuel industries (Buchert et al. 1992; Viikari et al. 1994; Prade 1996; Polizeli et al. 2005; Ninawe and Kuhad 2006; Zhao et al. 2006; Khandeparkar and Bhosle 2007). Numerous xylanases have been isolated and characterized from various microorganisms, and some xylanase-encoding genes have been cloned and expressed (Gat et al. 1994; Li and Ljungdahl 1994; Feng et al. 2000; Li et al. 2008a, b). Different application areas require xylanase with different properties. For example, xylanase is widely used in kraft pulp bleaching to remove the hemicellulose binding to pulp and release lignin from pulp, thus reducing the amount of chlorine required for conventional chemical bleaching and minimizing the toxic, chloroorganic waste (Zamost et al. 1991; Viikari et al. 1994). In order to be used in this field, xylanases should be completely free of any cellulase activity, be thermostable, and be active and stable under acidic to alkaline conditions (Beg et al. 2001). Xylanases from alkaliphilic bacteria including Aureobasidium pullulans (Christov et al. 1999), Bacillus subtilis (Khanongnuch et al. 1999), and Streptomyces lividans (Ragauskas et al. 1994) have been studied widely. Currently, many researchers are focusing on screening of xylanases with good thermostability and excellent adaptability and stability over a broad pH range.

In this paper, we reported on gene cloning and expression of a new xylanase from the thermoalkaline Anoxybacillus sp. E2. The purified recombinant enzyme had broad pH adaptability and excellent pH stability under acidic to alkaline conditions, and was stable at 60°C. These properties make this enzyme superior to known xylanases for potential application in the pulp and paper industry.

Materials and methods

Microorganism isolation

Water sample from a hot spring (latitude 22º54′827″; longitude 103º29′303″; altitude 153 m a.m.s.l.) in Baoshan City, Yunnan Province, China, was spread onto agar plates containing 0.2% peptone (w/v), 0.1% yeast extract (w/v) and 2% agar (w/v) (pH 12.0) and grown at 60°C for 48 h under static conditions. Xylanase-producing strains were screened on plates consisting of 2% agar (w/v) and 0.5% oat spelt xylan (w/v) (pH 10.0) using the Congo red method (Wood et al. 1988). The optimal conditions for growth of strain E2 with highest xylanase activity were determined in medium of 0.2% peptone (w/v) and 0.1% yeast extract (w/v). The taxon of strain E2 was identified by comparison of the 16S rDNA sequence amplified using primers 27f and 1492r (Monis et al. 2005) with that in GenBank.

Strains, plasmids and chemicals

Escherichia coli JM109 (TaKaRa, Dalian, China) and E. coli BL21 (DE3) (Novagen, Darmstadt, Germany) were cultivated at 37°C in Luria-Bertani (LB) medium. The plasmids pEASY-T3 (Trans Biotech, Beijing, China) and pET-22b(+) (Novagen, San Diego, CA, USA) were used for gene cloning and expression, respectively. The DNA purification kit, restriction endonucleases, T4 DNA ligase, and Taq DNA polymerase were purchased from TaKaRa. Oat spelt xylan and birchwood xylan were purchased from Sigma (St. Louis, MO, USA).

Gene cloning

Based on the amino acid sequence of two conserved regions of GH 10 xylanases (Baba et al. 1994; Fukumura et al. 1995), [Y/K/V]-[A/S/H]-[W/Y]-D-V-[V/C/N]-N-E and T-E-[L/I]-D-[I/V/M]-[S/R/A], two degenerate primers, xyl10-F and xyl10-R (see Table 1), were designed accordingly to amplify part of the GH 10 xylanase gene of strain E2.

The xylanase gene (xynE2) of strain E2 was cloned using a two-step PCR approach—a touchdown PCR and a thermal asymmetric interlaced-PCR (TAIL-PCR) (Liu and Whittier 1995) step. The genomic DNA of strain E2 was extracted using TIANamp Bacteria DNA Kit (TIANGEN, Beijing, China) and used as template for amplification. The touchdown PCR was performed with the degenerate primer set (xyl10-F, xyl10-R) as follows: 94°C for 5 min; followed by 10 cycles of 94°C for 30 s, 50–45°C for 30 s (decreased 0.5°C per cycle until 45°C), and 72°C for 1 min; followed by 28 cycles of 94°C for 30 s, 45°C for 30 s, and 72°C for 1 min, and then a final extension at 72°C for 10 min. The PCR product was purified and ligated into the pEASY-T3 cloning vector for sequencing. The 5′ and 3′ flanking regions of the core region were obtained using TAIL-PCR with six nested insertion-specific primers (xynE2-F1–3, xynE2-R1–3, see Table 1). Products of PCR reactions were sequenced and assembled with the core region.

Sequence analysis

The sequence assembly was performed using programs from Vector NTI Advance 10.0 software (Invitrogen, Carlsbad, CA, USA). The molecular mass of the mature peptide was calculated using Vector NTI 7.0 software. Homology searches were carried out with the BLAST program at the National Center for Biotechnology Information website. Properties of translated proteins based on the primary structure analysis were predicted using SWISS-MODEL programs (http://www.swissmodel.expasy.org/). The signal peptide in the deduced amino acid sequence was predicted by the SignalP 3.0 server (http://www.cbs.dtu.dk/services/SignalP/).

Expression of xynE2 in E. coli

The gene fragment encoding the mature protein (XynE2) was amplified by PCR using primers xynE2F and xynE2R (Table 1). The PCR product was digested with NcoI and HindIII, and ligated into the corresponding sites of the vector pET-22b(+). The recombinant plasmid with a six-His tag fused at its C terminus, pET-xynE2, was transformed into E. coli BL21 (DE3) competent cells. Xylanase-producing recombinants were identified by the Congo red method (Wood et al. 1988). The positive transformants were grown overnight at 37°C in the LB medium supplemented with 100 μg ml−1 ampicillin to an A600 of approximately 0.6. Xylanase expression was induced by addition of 0.8 mM Isopropyl-β-d-1-thiogalactopyranoside (IPTG) for an additional 12 h at 30°C. Protein expression in the culture supernatant was analyzed by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS–PAGE) and enzyme activity assay.

Purification and identification of recombinant XynE2

The induced culture was centrifuged at 4,000 ×g, 4°C for 10 min to remove cell debris. The cell-free supernatant was concentrated with a Hollow Fiber Membrane Module (Motian, Tianjin, China), and the crude enzyme was purified with Ni–NTA agarose (Qiagen, Beijing, China) according to the instructions of the manufacturer. Protein purity was verified by SDS–PAGE analysis using on a 12% running gel as described by Laemmli (1970). The protein concentration was determined by the Bradford method (1976). To identify the purified protein, the in-gel tryptic digestion of the protein after SDS–PAGE was analyzed using liquid chromatography-electrospray ionization-tandem mass spectrometry (LC-ESI-MS/MS) (Huang et al. 2009).

Enzyme assay

Xylanase activity was determined by measuring the release of reducing sugar from oat spelt xylan using 3,5-dinitrosalicylic acid (DNS) method (Miller 1959). The assay mixture consisting of 0.1 ml appropriately diluted enzyme solution and 0.9 ml of McIlvaine buffer (0.2 M Na2HPO4/0.1 M citric acid, pH 7.8) containing 1% (w/v) oat spelt xylan was incubated at 65°C for 10 min. The reaction was terminated with 1.5 ml of DNS reagent (1% dinitrosalicylic acid, 0.2% phenol, 0.05% sodium sulfite, and 1% sodium hydroxide). The mixture was boiled for 5 min and cooled to room temperature, and the absorption at 540 nm was measured. One unit of xylanase activity was defined as the amount of enzyme that released 1 μmol of reducing sugar equivalent to xylose per minute under the assay conditions. Each reaction and its control were run in triplicate. The control was 0.9 ml of McIlvaine buffer containing 1% (w/v) oat spelt xylan, 1.5 ml of DNS reagent and 0.1 ml inactivated enzyme solution.

Enzyme characterization

The optimum pH of purified recombinant XynE2 for enzyme activity was determined in buffers of pH ranging from 2.6 to 12.0 at 37 and 65°C, respectively. The buffers used were McIlvaine buffer for pH 2.6–pH 7.8, 0.1 M Tris-HCl for pH 8.2–pH 8.8, and 0.1 M glycine-NaOH for pH 9.0–pH 12.0. The effect of pH on enzyme stability was estimated by measuring the residual activity at pH 7.8, 65°C after pre-incubation of the purified enzyme in different buffer of pH 3.8–pH 12.0 at 37°C for 1 h.

To determine the temperature for maximal activity at pH 5.8, pH 7.8 and pH 9.2, the xylanase activity was measured by varying the temperatures from 35 to 75°C in McIlvaine buffer for 10 min. Thermostability of XynE2 was assessed by measuring the residual enzyme activity under standard conditions (pH 7.8, 65°C, 10 min) after incubation of the enzyme in McIlvaine buffer (pH 7.8) at 60°C or 70°C in the absence of substrate.

The effects of different metal ions and chemical reagents on the enzymatic activity of purified recombinant XynE2 were determined by measuring the residual activity after incubation of the enzyme solution with various metal ions and chemical reagents (1 or 10 mM, see Table 2) at 65°C for 10 min.

The substrate specificity of XynE2 was determined by measuring the enzyme activity in McIlvaine buffer (pH 7.8) containing 1.0% of each substrate (oat spelt xylan, birchwood xylan, and carboxymethyl cellulose (CMC)) under standard conditions. The amount of reducing sugars produced was estimated using the DNS method as described above.

The K m, V max, and k cat values for the purified recombinant XynE2 were determined by measuring the enzymatic activity in McIlvaine buffer (pH 7.8) containing 1–10 mg ml−1 oat spelt xylan or birchwood xylan at 65°C for 5 min. A Lineweaver–Burk plot (1934) was constructed to determine kinetic parameters. Three independent experiments were averaged, and each experiment included three replicate samples.

Nucleotide sequence accession numbers

The nucleotide sequences for the Anoxybacillus sp. E2 16S rDNA and the GH 10 xylanase gene (xynE2) were deposited in the GenBank database under accession numbers GQ240231 and GQ240232, respectively.

Results

Microorganism isolation and identification

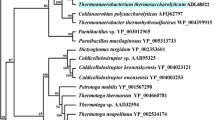

Twenty-one strains (E1–E21) were isolated from the water sample of the hot spring in Yunnan, China, and thirteen strains showed xylanolytic activity. Among them, strain E2 showed highest xylanase activity of 1.23 U ml−1 after xylan induction at 60°C and pH 10.0. Strain E2 showed optimal growth at 60°C and pH 7.0–pH 10.0. The nucleotide sequence of strain E2 16S rDNA gene was 99% identical to Anoxybacillus sp. SW (GenBank FJ842661.1), indicating that strain E2 belonged to the genus Anoxybacillus. The strain was deposited in the China General Microbiological Culture Collection Center (CGMCC) under CGMCC 3148.

Gene cloning and sequence analysis

A 359 bp DNA fragment of xynE2 was amplified using the degenerate primers xyl10-F and xyl10-R. The deduced amino acid sequence of this fragment was aligned with available protein sequences from the GenBank, and showed extensive homology (72% identity) to an endo-1,4-β-xylanase (ABI49937.2) belonging to the GH 10 family. The full-length gene was obtained by a modified TAIL-PCR. As a result, the complete ORF consisted of 987 bp and encoded a 328 amino acids peptide with a calculated molecular mass of 38.8 kDa. The overall G + C content of the ORF was 38.4%.

The deduced amino acid sequence of the ORF was aligned with available protein sequences from the GenBank and SWISSPROT databases as well as previous literatures. The xylanases from Geobacillus stearothermophilus (ABI49937.2), Geobacillus sp. Y412MC61 (ACX79292.1), Geobacillus sp. MT-1 (AAZ74783.1) and Bacillus sp. strain N137 (CAA84631.1) exhibited 72, 72, 71 and 60% identities to that of XynE2 from Anoxybacillus sp. E2, respectively. Sequence analysis revealed that XynE2 was a single-domain enzyme. Two putative catalytic residues, Glu131 and Glu238, were located in the catalytic site (Solomon et al. 2007). Alignment of XynE2 with XynB from Paenibacillus sp. BP-23 also identified two additional conserved regions beside the flanking region VI, indicating that XynE2 should belong to a new subclass of GH 10 xylanases (Gallardo et al. 2003). No signal peptide was predicted in XynE2 based on SignalP 3.0 analysis.

Expression and purification of XynE2 in E. coli

The gene encoding the mature xylanase was expressed in E. coli BL21 (DE3) competent cells. Xylanase activity was detected in the culture supernatant of positive clones after IPTG induction. And the medium supernatant showed higher xylanase activity than the cell lysate. The uninduced transformant or transformant harboring the empty pET-22b(+) vector showed no xylanase activity.

Recombinant XynE2 was purified to electrophoretic homogeneity by Ni–NTA chromatography (Fig. 1). The molecular mass including the molecular weights of XynE2 and C-terminal His·Tag® sequence was about 40.3 kDa.

Four trypic peptides of XynE2 from mass spectrometry, EADPNALLFYNDYNESFPEKR, DLLVSHVNSITAENHMK, VYCWDVVNEAVADEGNDLLR, and GHTLVWHNQTPTWMFYDR, perfectly matched the amino acid sequence of XynE2, confirming that the purified protein was recombinant XynE2.

Effects of pH and temperature on XynE2 activity and stability

The purified recombinant XynE2 showed maximal activity at pH 7.8 (at 65°C), and remained over 90% of the peak activity at pH 6.6–pH 8.6 (Fig. 2a). When assayed at 37°C, XynE2 showed maximal activity at pH 5.8, and remained over 80% of the peak activity at pH 5.0–pH 10.0 (Fig. 2a). The enzyme was stable over a broad pH range, retaining more than 80% of the initial activity after incubation in buffers of pH 4.6–pH 12.0 at 37°C for 1 h (Fig. 2b). The optimal temperature for enzyme activity was 65°C at pH 7.8 and pH 9.2, and 60°C at pH 5.8, respectively (Fig. 2c). The purified recombinant XynE2 was thermostable at 60°C, retaining almost the initial activity after incubation at pH 7.8 for 1 h, and lost all activity after incubation at 70°C for 15 min (Fig. 2d).

Characterization of the purified rencombinant XynE2. a Effect of pH on XynE2 activity. The assay was performed in buffers at pH 2.6–pH 12.0 and 37 or 65°C, respectively. b Effect of pH on stability of XynE2. pH stability of the enzyme was determined by measuring the residual activity in McIlvaine buffer (pH 7.8) at 65°C after incubation in buffers of pH 3.8–pH 12.0 at 37°C for 1 h. c Effect of temperature on XynE2 activity in McIlvaine buffer at pH 5.8, pH 7.8 and pH 9.2, respectively. d Effect of temperature on stability of XynE2. Thermal stability of the enzyme was determined by measuring the residual activity after pre-incubation at 60 and 70°C in McIlvaine buffer (pH 7.8) for 5, 10, 15, 30 and 60 min

Effect of various chemicals on enzyme activity

The xylanase activity in the presence of different metal ions and chemical reagents was shown in Table 2. The enzymatic activity was absolutely inhibited by Ag+, Hg2+ and SDS, and was strongly inhibited by Cu2+ and Zn2+ even at 1 mM concentration. Mg2+, Fe3+, β-mercaptoethanol, EDTA and Pb2+ enhanced the enzymatic activity at 1 mM concentration, and Cr3+ and Mg2+ enhanced the activity at the concentration of 10 mM.

Substrate specificity and kinetic parameters

XynE2 showed activity on oat spelt xylan and birchwood xylan, and no activity was detected against the polysaccharide CMC. The specific activity of XynE2 was 1,390 U mg−1 on oat spelt xylan.

Using the double reciprocal plot of Lineweaver and Burk, the K m, V max, and k cat values of XynE2 on substrate oat spelt xylan were 1.55 mg ml−1, 6,161 μmol min−1 mg−1, and 3,902 s−1, respectively, and 0.61 mg ml−1, 2,478 μmol min−1 mg−1, and 1,602 s−1, respectively, for substrate birchwood xylan.

Discussion

The genus Anoxybacillus was firstly separated from Bacillus by Pikuta et al. (2000) based on the phenotypic properties and 16S rDNA sequence. Many microorganisms belonging to Anoxybacillus have been isolated, including A. flavithermus (Pikuta et al. 2000), A. pushchinoensis (Pikuta et al. 2003), A. gonensis (Belduz et al. 2003), A. contaminans (De Clerck et al. 2004), A. voinovskiensis (Yumoto et al. 2004), and A. rupiensis (Derekova et al. 2007), and most of them were thermoalkaliphilic. Some enzymes with favorable properties from Anoxybacillus have been reported. For example, the fructose-1,6-bisphosphate aldolase (Ertunga et al. 2007) and thermoalkaliphilic esterase (Colak et al. 2005) from A. gonensis G2 exhibited maximal activity at pH 8.5 and 60°C, and pH 7.5 and 60°C, respectively. In this study, we isolated a thermostable and alkali-tolerant strain, Anoxybacillus sp. E2. Strain E2 showed optimal growth at pH 7.0–pH 10.0 and could survive even at pH 12.0. Substantial xylanase activity was detected after incubation in the presence of xylan, and the xylanase gene (xynE2) was cloned and expressed in E. coli. This is the first report that describes cloning and expression of a xylanase gene from the genus Anoxybacillus.

The deduced amino acid sequence of xynE2 is highly homologous to GH 10 endo-β-1,4-xylanases and shares high identity with the endo-β-1,4-xylanase from Geobacillus sp. MT-1 (71% identity) and XyaA from an alkalophilic Bacillus sp. strain N137 (60% identity). Compared with the two xylanases, XynE2 showed some distinct enzymatic properties. For example, the purified recombinant XynE2 showed optimal activity at pH 7.8, was highly stable over a wide pH range (pH 4.6–pH 12.0), and was thermostable at 60°C. Xylanase from Geobacillus sp. MT-1 exhibited an optimum pH of 7.0, but was stable only under neutral conditions (pH 6.0–pH 8.0) (Wu et al. 2006). XyaA showed optimal activity at pH 8.0, was stable within a narrower pH range (pH 6.0–pH 11.0), and lost over 45% activity after incubation at 40°C for 1 h (Tabernero et al. 1995). Many xylanases from the genus Bacillus had been reported. However, most of them had optimal activity at pH 5.0–pH 6.0 and temperature 40–50°C, and were only stable over a narrow pH range and low temperature (Nakamura et al. 1993; Blanco et al. 1995; Gallardo et al. 2004; Huang et al. 2006; Jalal et al. 2009). Although the xylanase from B. stearothermophilus T-6 had good thermostability at 65°C, it showed high activity within a relatively narrow range (more than 80% of maximal activity at pH 5.5–pH 7.5) (Khasin and Alchanati 1993). Moreover, the V max value of XynE2 to oat spelt xylan (6,161 μmol min−1 mg−1) and birchwood xylan (2,478 μmol min−1 mg−1) were higher than that of other xylanases (Nakamura et al. 1993; Lee et al. 2005; Levasseur et al. 2005; Wu et al. 2006). Therefore, the superior properties of XynE2, such as high activity and stability over a wide pH range and good thermostability, might make it potential in more widespread applications.

In pulp and paper industries, the ideal xylanase should have good pH stability and activity over a borad pH range, especially under alkaline conditions, and be free of cellulase activity to avoid hydrolysis of the cellulose fibers (Bajpai 1999; Georis et al. 2000; De Clerck et al. 2004). XynE2 under study showed these favorable properties, such as good pH adaptability (>90% activity at pH 6.6–pH 8.6) and excellent stability at pH 4.6–pH 12.0, good thermostability at 60°C, and no cellulase activity. These properties make XynE2 a promising candidate for application in bleaching of kraft pulp in the pulp and paper industries.

In conclusion, a new xylanse gene, xynE2, was cloned from Anoxybacillus sp. E2 and expressed in E. coli in this study. This is the first report to our knowledge on the cloning and expression of a xylanase from the genus Anoxybacillus. The xylanase xynE2 showed high activity and stability under acidic to alkaline conditions, was thermostable at 60°C, and had no cellulase activity. These superior properties make xynE2 promising for application in many industries, especially in paper and pulp industry.

References

Baba T, Shinke R, Nanmori T (1994) Identification and characterization of clustered genes for thermostable xylan-degrading enzymes, beta-xylosidase and xylanase, of Bacillus stearothermophilus 21. Appl Environ Microbiol 60:2252–2258

Bajpai P (1999) Application of enzymes in the pulp and paper industry. Biotechnol Prog 15:147–157

Beg QK, Kapoor M, Mahajan L, Hoondal GS (2001) Microbial xylanases and their industrial applications: a review. Appl Microbiol Biotechnol 56:326–338

Belduz AO, Dulger S, Demirbag Z (2003) Anoxybacillus gonensis sp. nov., a moderately thermophilic, xylose-utilizing, endospore-forming bacterium. Int J Syst Evol Microbiol 53:1315–1320

Biely P (1985) Microbial xylanolytic systems. Trends Biotechnol 3:286–290

Blanco A, Vidal T, Colom JF, Pastor FI (1995) Purification and properties of xylanase A from alkali-tolerant Bacillus sp. strain BP-23. Appl Environ Microbiol 61:4468–4470

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Buchert J, Ranua M, Kantelinen A, Viikari L (1992) The role of two trichoderma reesei xylanases in the bleaching of pine kraft pulp. Appl Microbiol Biotechnol 37:825–829

Christov LP, Myburgh J, O’Neill FH, Van Tonder A, Prior BA (1999) Modification of the carbohydrate composition of sulfite pulp by purified and characterized beta-xylanase and beta-xylosidase of Aureobasidium pullulans. Biotechnol Prog 15:196–200

Colak A, Sisik D, Saglam N, Guner S, Canakci S, Belduz AO (2005) Characterization of a thermoalkalophilic esterase from a novel thermophilic bacterium, Anoxybacillus gonensis G2. Bioresour Technol 96:625–631

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

De Clerck E, Rodriguez-Diaz M, Vanhoutte T, Heyrman J, Logan NA, De Vos P (2004) Anoxybacillus contaminans sp. nov. and Bacillus gelatini sp. nov., isolated from contaminated gelatin batches. Int J Syst Evol Microbiol 54:941–946

Derekova A, Sjoholm C, Mandeva R, Kambourova M (2007) Anoxybacillus rupiensis sp. Nov., a novel thermophilic bacterium isolated from rupi basin (Bulgaria). Extremophiles 11:577–583

Ertunga NS, Colak A, Belduz AO, Canakci S, Karaoglu H, Sandalli C (2007) Cloning, expression, purification and characterization of fructose-1, 6-bisphosphate aldolase from Anoxybacillus gonensis G2. J Biochem 141:817–825

Feng JX, Karita S, Fujino E, Fujino T, Kimura T, Sakka K, Ohmiya K (2000) Cloning, sequencing, and expression of the gene encoding a cell-bound multi-domain xylanase from Clostridium josui, and characterization of the translated product. Biosci Biotechnol Biochem 64:2614–2624

Fukumura M, Sakka K, Shimada K, Ohmiya K (1995) Nucleotide sequence of the Clostridium stercorarium xynB gene encoding an extremely thermostable xylanase, and characterization of the translated product. Biosci Biotechnol Biochem 59:40–46

Gallardo O, Diaz P, Pastor FI (2003) Characterization of a Paenibacillus cell-associated xylanase with high activity on aryl-xylosides: a new subclass of family 10 xylanases. Appl Microbiol Biotechnol 61:226–233

Gallardo O, Diaz P, Pastor FI (2004) Cloning and characterization of xylanase A from the strain Bacillus sp. BP-7: comparison with alkaline pI-low molecular weight xylanases of family 11. Curr Microbiol 48:276–279

Gat O, Lapidot A, Alchanati I, Regueros C, Shoham Y (1994) Cloning and DNA sequence of the gene coding for Bacillus stearothermophilus T-6 xylanase. Appl Environ Microbiol 60:1889–1896

Georis J, Giannotta F, De Buyl E, Granier B, Frere JM, De Buyl E (2000) Purification and properties of three endo-beta-1, 4-xylanases produced by Streptomyces sp. strain S38 which differ in their ability to enhance the bleaching of kraft pulps. Enzyme Microb Tech 26:178–186

Gilkes NR, Henrissat B, Kilburn DG, Miller RC Jr, Warren RA (1991) Domains in microbial beta-1,4-glycanases: sequence conservation, function, and enzyme families. Microbiol Rev 55:303–315

Henrissat B, Bairoch A (1996) Updating the sequence-based classification of glycosyl hydrolases. Biochem J 316(Pt 2):695–696

Huang J, Wang G, Xiao L (2006) Cloning, sequencing and expression of the xylanase gene from a Bacillus subtilis strain B10 in Escherichia coli. Bioresour Technol 97:802–808

Huang H, Shao N, Wang Y, Luo H, Yang P, Zhou Z, Zhan Z, Yao B (2009) A novel beta-propeller phytase from Pedobacter nyackensis MJ11 CGMCC 2503 with potential as an aquatic feed additive. Appl Microbiol Biotechnol 83:249–259

Jalal A, Rashid N, Rasool N, Akhtar M (2009) Gene cloning and characterization of a xylanase from a newly isolated Bacillus subtilis strain R5. J Biosci Bioeng 107:360–365

Khandeparkar R, Bhosle NB (2007) Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresour Technol 98:897–903

Khanongnuch C, Lumyong S, Ooi T, Kinoshita S (1999) A noncellulase producing strain of Bacillus subtilis and its potential use in pulp biobleaching. Biotechnol Lett 21:61–63

Khasin A, Alchanati Shoham Y (1993) Purification and characterization of a thermostable xylanase from Bacillus stearothermophilus T-6. Appl Environ Microbiol 59:1725–1730

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Lee CC, Wong DW, Robertson GH (2005) Cloning and characterization of the xyn11A gene from Lentinula edodes. Protein J 24:21–26

Levasseur A, Asther M, Record E (2005) Overproduction and charachterization of xylanase B from Aspergillus niger. Can J Microbiol 51:177–183

Li XL, Ljungdahl LG (1994) Cloning, sequencing, and regulation of a xylanase gene from the fungus Aureobasidium pullulans Y-2311-1. Appl Environ Microbiol 60:3160–3166

Li N, Meng K, Wang Y, Shi P, Luo H, Bai Y, Yang P, Yao B (2008a) Cloning, expression, and characterization of a new xylanase with broad temperature adaptability from Streptomyces sp. S9. Appl Microbiol Biotechnol 80:231–240

Li N, Yang P, Wang Y, Luo H, Meng K, Wu N, Fan Y, Yao B (2008b) Cloning, expression, and characterization of protease-resistant xylanase from Streptomyces fradiae var. k11. J Microbiol Biotechnol 18:410–416

Lineweaver H, Burk D (1934) The determination of enzyme dissociation constants. J Am Chem Soc 56:658–666

Liu YG, Whittier RF (1995) Thermal asymmetric interlaced PCR: automatable amplification and sequencing of insert end fragments from P1 and YAC clones for chromosome walking. Genomics 25:674–681

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Monis PT, Giglio S, Saint CP (2005) Comparison of SYTO9 and SYBR Green I for real-time polymerase chain reaction and investigation of the effect of dye concentration on amplification and DNA melting curve analysis. Anal Biochem 340:24–34

Nakamura S, Wakabayashi K, Nakai R, Aono R, Horikoshi K (1993) Purification and some properties of an alkaline xylanase from alkaliphilic Bacillus sp. strain 41 M–1. Appl Environ Microbiol 59:2311–2316

Ninawe S, Kuhad RC (2006) Bleaching of wheat straw-rich soda pulp with xylanase from a thermoalkalophilic Streptomyces cyaneus SN32. Bioresour Technol 97:2291–2295

Pikuta E, Lysenko A, Chuvilskaya N, Mendrock U, Hippe H, Suzina N, Nikitin D, Osipov G, Laurinavichius K (2000) Anoxybacillus pushchinensis gen. nov., sp. nov., a novel anaerobic, alkaliphilic, moderately thermophilic bacterium from manure, and description of Anoxybacillus flavitherms comb. nov. Int J Syst Evol Microbiol 50(6):2109–2117

Pikuta E, Cleland D, Tang J (2003) Aerobic growth of Anoxybacillus pushchinoensis K1(T): emended descriptions of A. pushchinoensis and the genus Anoxybacillus. Int J Syst Evol Microbiol 53:1561–1562

Polizeli ML, Rizzatti AC, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Prade RA (1996) Xylanases: from biology to biotechnology. Biotechnol Genet Eng Rev 13:101–131

Ragauskas AJ, Poll KM, Cesternino AJ (1994) Effects of xylanase pretreatment procedures on nonchlorine bleaching. Enzyme Microb Tech 16:492–495

Solomon V, Teplitsky A, Shulami S, Zolotnitsky G, Shoham Y, Shoham G (2007) Structure-specificity relationships of an intracellular xylanase from Geobacillus stearothermophilus. Acta Crystallogr D Biol Crystallogr 63:845–859

Tabernero C, Sanchez-Torres J, Perez P, Santamaria RI (1995) Cloning and DNA sequencing of xyaA, a gene encoding an endo-beta-1, 4-xylanase from an alkalophilic Bacillus strain (N137). Appl Environ Microbiol 61:2420–2424

Viikari L, Kantelinen A, Sundquist J, Linko M (1994) Xylanases in bleaching: from an idea to the industry. FEMS Microbiol Rev 13:335–350

Wood PJ, Erfle JD, Teather RM (1988) Use of complex formation between congo red and polysaccharide in detection and assay of polysaccharide hydrolases. Methods Enzymol 160:59–74

Wu S, Liu B, Zhang X (2006) Characterization of a recombinant thermostable xylanase from deep-sea thermophilic Geobacillus sp. MT-1 in East Pacific. Appl Microbiol Biotechnol 72:1210–1216

Yumoto I, Hirota K, Kawahara T, Nodasaka Y, Okuyama H, Matsuyama H, Yokota Y, Nakajima K, Hoshino T (2004) Anoxybacillus voinovskiensis sp. nov., a moderately thermophilic bacterium from a hot spring in kamchatka. Int J Syst Evol Microbiol 54:1239–1242

Zamost BL, Nielsen HK, Starnes RL (1991) Thermostable enzymes for industrial applications. J Ind Microbiol Biotechnol 8:71–81

Zhao J, Li X, Qu Y (2006) Application of enzymes in producing bleached pulp from wheat straw. Bioresour Technol 97:1470–1476

Acknowledgment

This work was supported by the National High Technology Research and Development Program of China (863 Program; grant no. 2007AA100601) and the National Key Technology Program of China (grant no. 2006BAD12B05-03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Bai, Y., Yang, P. et al. A new xylanase from thermoalkaline Anoxybacillus sp. E2 with high activity and stability over a broad pH range. World J Microbiol Biotechnol 26, 917–924 (2010). https://doi.org/10.1007/s11274-009-0254-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-009-0254-5