Abstract

The present investigation describes microbial production of an alkaline protease and its use in dehairing of buffalo hide. Bacillus cereus produced extracellular protease when grown on a medium containing starch, wheat bran and soya flour (SWS). The ammonium sulphate precipitated (ASP) enzyme was applied for dehairing of buffalo hide. Microscopic observation of longitudinal section of buffalo hide revealed that the epidermis was completely removed and hair was uprooted leaving empty follicles in the hide. The ASP enzyme was stable for one month at ambient temperature between 25–35 °C. Enzymatic dehairing may be a promising shift towards an environment-friendly leather processing method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, over 30% of the world industrial enzyme market consists of alkaline proteases used in detergents, food processing and leather industry. Production of these enzymes using low cost substrates would reduce the cost of production. Oil seed cakes, which are a by product of oil extraction industry, are a potentially useful, low-cost substrate for the production of different enzymes (Kanekar et al. 1997; Tang et al. 2000; Alagarsamy et al. 2005). Keratinase, a type of bacterial protease, was produced by using cheap substrates such as hair, feathers and whey milk––a dairy byproduct (Alessandro et al. 2003; Roberta et al. 2006; Philippe et al. 1999; Prakasham et al. 2006). Yang et al. (2000) have reported deproteinization of crustacean waste by protease of B. subtilis.

Leather industry waste leads to environmental pollution and health hazards (Malathi and Chakraborty 1991). Major pollutants from the leather industry that may have significant environmental impact include lime, sulphide and chromium (Alessandro et al. 2003). Huge amounts of lime sludge and total solids formation are the main drawbacks of lime (Thanikaivelan et al. 2003). Untreated sulphide can cause major problem in sewers. The severe alkaline conditions constitute a health hazard for the worker (Purushotham et al. 1996). Sulphide also reduces the strength of hair, which directly hampers the recovery of this value-added byproduct. The tannery effluent has high dissolved solids (TDS), high biological oxygen demand (BOD) and high chemical oxygen demand (COD) (Palanisamy et al. 2004). Enzymatic dehairing is being increasingly looked upon as a reliable alternative to the conventional lime-sulphide process, avoiding the problems created by sulphide. The advantages of enzymatic dehairing are (i) total elimination of lime and sulphide from the effluent, (ii) recovery of hair as a byproduct which may be used for production of synthetic fibres, biogas, foaming agent for fire extinguishers; while hydrolyzed hair is used as agricultural fertilizer, soil conditioner, compost, additive in chrome tanning or retanning processes, animal/poultry feed and also for production of cosmetics, pharmaceuticals and amino acid like cysteine (Palanisamy et al. 2004), (iii) elimination of the bating process required during deliming. However, these benefits remain unfulfilled, since enzymes are more expensive than the conventional chemical process, and require careful control (Kanagaraj et al. 2006; Qing et al. 2003). The latter point has been identified as the main obstacle in the wider application of enzymes. Pal et al. (1996) reported an enzyme-assisted dehairing with lime and protease from R. oryzae, where lime acts as a swelling agent. The potential for commercial use of enzymes in leather production is considerable, because of their properties of being highly efficient and substrate specific. Thus, the substitution of chemical dehairing agents in the leather industry by proteolytic enzymes produced by microorganisms will have an important economic and environmental impact.

Earlier studies using commercial enzymes for sheep skin dehairing revealed a high correlation between dehairing activity and proteolytic activity (Qing et al. 2003). Some microorganisms producing extracellular enzyme with dehairing activity have been described, e.g., Streptomyces sp. isolated from soil, degraded human hair, chicken feather, silk, wool, and unhaired goatskin (Mukhopadhyay and Chandra 1993). Among bacteria, strains of B. subtilis and B. amylolequifaciens have been characterized for dehairing purposes (Varela et al. 1997; Nashy et al. 2005). However, many proteases are not suitable for dehairing, since they have collagen-degrading activity, which destroys the collagen structure of the hide. Therefore, it is essential to explore proteases with dehairing activity but no collagenolytic activity (Qing et al. 2003).

The present paper describes the production of an alkaline protease by B. cereus using inexpensive and easily available protein rich substrates, and its application in dehairing of buffalo hide.

Materials and methods

Microorganism

The bacterium used in this study was B. cereus MCM B-326, a buffalo hide isolate, deposited in MACS Collection for Microorganisms (MCM). The stock culture was maintained in 15% glycerol at −20 °C.

Substrates

Different industrial deoiled cakes like soya cake, saffola cake, rape seed cake, groundnut cake, wheat bran and flours like soya flour, bengal gram flour were purchased from local market. Soybean meal was procured from HiMedia Laboratories, Mumbai.

Production of enzyme

The enzyme was produced in 250 mL capacity Erlenmeyer flask using 100 mL medium, containing 1% starch and 0.3% CaCO3 along with one of the following different cheap nitrogen sources: deoiled soyabean cake, saffola cake, rape seed cake, groundnut cake, soya flour, wheat bran, bengal gram flour, bengal gram flour combined with wheat bran, bengal gram flour combined with deoiled groundnut cake, bengal gram flour combined with soybean meal, wheat bran combined with deoiled ground nut cake, wheat bran combined with soya flour, and soybean meal, in the medium at 1% level. The media at pH 9.0 were inoculated with 1% of 21 h old inoculum (2.8 × 108 cells mL−1) and incubated at 30 °C for 36 h under shake culture conditions. The broth was centrifuged at 13,000g for 10 min to obtain cell free supernatant (CFS). The CFS was then partially purified by 60% saturation of ammonium sulphate. Ammonium sulphate precipitated (ASP) enzyme was applied for dehairing of buffalo hide.

Partial purification and zymogram

The proteins from CFS were precipitated with ammonium sulphate (60% saturation) followed by membrane dialysis. The enzyme pattern of precipitated proteins was obtained by zymogram with 1% casein substrate and detected using comassive brilliant blue R250. The molecular weight of the protease was determined by comparing with mobility of standard molecular weight marker proteins (bovine albumin 66 kDa, chicken ovalbumin 45 kDa, glyceroldehyde-3-phosphate dehydrogenase 36 kDa, trypsinogen 24 kDa, cytochrome C 12.4 kDa).

Protease assay

The protease activity was determined by caseinolytic assay (Nilegaonkar et al. 2000). One mL of the cell free supernatant was mixed with 4 mL of casein (0.625% w/v) and incubated at 37 °C for 30 min. The reaction was stopped by addition of 5 mL of 5% trichloroacetic acid (TCA). Enzymatically hydrolyzed casein was measured by modified Folin–Ciocalteu method (Jayaraman 2003) against casein treated with inactive enzyme as blank. The TCA precipitated reaction mixture was centrifuged and 0.1 mL of supernatant was mixed with 0.9 mL of distilled water and 0.5 mL of alkaline copper tartarate solution, and incubated for 10 min. Two mL of 1N Folin–Ciocalteu reagent was added and the absorbance read at 660 nm after 20 min of incubation. A standard graph was generated using standard tyrosine solutions of 5–50 μg mL−1. All the incubations were carried out at room temperature. One unit of protease activity was defined as the amount of enzyme, which liberated 1 μg tyrosine per min at 37 °C.

Protein estimation

The protein content of the cell free supernatant was estimated using Biuret method, with bovine serum albumin as a standard (Jayaraman 2003).

Enzyme storage stability

The storage stability of the crude enzyme was assessed by storing the enzyme at room temperature (28 ± 2 °C) and estimating the activity at different time intervals up to 90 days. This was done by conducting caseinolytic assay.

Dehairing activity

The salted buffalo hide pieces of size 2.5 cm2 or weight 3 g were soaked overnight in tap water (400% v/w of salted hide) with 0.3% calcium carbonate. The soaked hide pieces were incubated with the enzyme (1% w/w of hide) in tap water having pH 7.0 at room temperature (28 ± 2 °C) along with control i.e., hide piece incubated without enzyme, under the same conditions. For comparison, chemical dehairing was also carried out with 10% lime and 2% sodium sulphide. After 21 h, pieces were dehaired by mechanical means and visually analyzed for color, smoothness and silkiness of the pelt.

Histological study

The pelts were prepared for histopathalogical analysis by fixing in 10% (w/v) formaldehyde. The pelt was dehydrated with 80, 95 and 100% (v/v) of alcohol gradients followed by xylene treatment, and then embedded in paraffin. Longitudinal sections (L.S.) of hide embedded in paraffin wax were obtained using a microtome. The sections were fixed on slides using starch paste containing thymol, which acts as a preservative. The sections were stained with Harris’s haematoxylin stain followed by 0.5% (v/v) HCl and dilute ammonia (John and Merriline 2002). The slides were observed microscopically (Labophot 2 microscope, Japan) for (a) epidermis, (b) hair root follicles, and (c) corium (collagen layer).

Statistical analysis

Analysis of variance with repeated measures was carried out using GLM command of software SPSS (SPSS version 10, Windows 98). Activity means and standard deviation were calculated (Table 1). Univariate analysis of variance (ANOVA) was applied to the data on supplementation of different cheap nitrogen sources and protease activity.

Results and discussion

Protease production

Enzyme, as a biological catalyst, depends upon various factors for its activity. Most of the enzymes used for the dehairing process have been obtained from microorganisms isolated from soil adjacent to tanneries, and decomposing skins (George et al. 1995; Dayanandan et al. 2003).

Earlier, B. cereus MCM B-326 was grown in starch-soybean meal and calcium carbonate medium revealing an alkaline metalloprotease, non-collagenolytic and non-keratinolytic in nature. Ammonium sulphate precipitated enzyme showed two bands, viz., Cereus 1 and Cereus 2, with approximate molecular weights 45-kDa and 36-kD on non-denaturing PAGE (Fig. 1). It is reported that B. cereus has two proteases with molecular masses of approximately 38-kDa and 36-kDa (Kim et al. 2001). A calcium dependent protease from B. cereus BG1 was reported to have molecular weight of 34-kDa (Ghorbel et al. 2005). According to Qing et al. (2003) the molecular weight of the purified dehairing protease from B. pumilus was 32-kDa. Thus molecular weight of Cereus 2 is similar to the molecular weight reported for other proteases from B. cereus, while molecular weight of Cereus 1 is different (Nilegaonkar et al. 2007).

The same organism is studied for production of protease with inexpensive substrates and its application in dehairing of buffalo hide. Bacillus cereus MCM B-326 has maximum protease production of 176.05 ± 4.24 U mL−1 in medium containing starch, wheat bran, soya flour (1% each) and 0.3% CaCO3, at pH 9.0 within 36 h, under shake culture condition (Table 1). Wheat bran can be used in combination with other substrates like bengal gram flour or soya flour or soybean meal or groundnut cake for the production of protease. In our previous study, it was observed that B. cereus shows protease activity of 126.87 ± 1.32 U mL−1 in starch, soybean meal and calcium carbonate medium under identical experimental conditions (Nilegaonkar et al. 2007). Earlier, protease with 3541.66 U L−1 h−1 productivity using nug-meal––a byproduct of oil extraction from seeds of Guizotia abyssinica, using Bacillus sp. AR-009 was reported (Amare 1997). Sweet potato residue and peanut meal residue were also reported as substrates for the production of protease (17.5–26.7 U) at 200–250 h using Streptomyces rimosus TM-55 in submerged and solid state cultivations method (Yang and Wang 1999). As reported here, the protease from B. cereus MCM B-326 has similar activity to that reported on nug meal substrates, and higher activity than that produced using sweet potato residue and peanut residue. B. licheniformis, when grown at 50 °C on oil seed cakes of linseed, caster and groundnut, yielded low levels of enzyme activities, against a combination of soybean meal and wheat bran (Sinha and Satyanarayana 1991). Bacillus sp. JB 99 when grown in solid state on wheat bran and rice bran exhibited enzyme activities of 7836 and 7540 U ml−1 respectively (Johnvesly et al. 2002).

Storage stability

The ASP enzyme retained 80, 70 and 60% activity after one, two and three months respectively, when stored at room temperature. Our laboratory data (Nilegaonkar et al. 2007) suggests that Ca+2 is not necessary for the activity/stability of the enzyme, but enzymes reported and used in leather processing were stabilized by addition of calcium or co-polymers (Jaquess et al. 1999). In Streptomyces moderatus NRRL 3150, the enzyme activity of multiple proteinase concentrate was found to be stable with calcium chloride and sodium azide up to six months at 4 °C (Chandrasekaran and Dhar 1985).

Enzymatic dehairing of buffalo hide

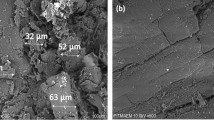

Enzyme precipitated with ammonium sulphate (60% saturation) was used for dehairing of buffalo hide. In our previous studies, the enzyme was shown to be an alkaline metalloprotease, non-collagenolytic and non-keratinolytic in nature (Nilegaonkar et al. 2007). The presence of lime or sulphide was not required for this process. The enzyme-treated hide showed visible dehairing activity after 12 h of incubation and complete dehairing at 21 h. In the control sample, hair loosening was not observed, even by mechanical means such as plucking by forceps (Fig. 2).

In the chemically treated pelt, epidermis was removed (Fig. 3a). Microscopic examination of the pelt treated with enzyme showed complete removal of epidermis and presence of empty hair follicles (Fig. 3b) suggesting removal of hair from hair root follicle. Collagen layer was not damaged or modified in both chemical and enzyme-treated pelts. Microscopic examination of the pelt after lime-sulphide dehairing showed presence of parts of disintegrated shaft and entire bulb in the follicles. Similar results were observed by using multiple proteinase concentrate in goat skin (Chandrasekaran and Dhar 1985). In our studies, it was also observed that protease treated pelt swells moderately with adequate opening up of collagen fibre. Results showed that for Rhizopus oryzae, the protease required liming treatment for desired swelling (Pal et al. 1996).

Enzymatic dehairing did not damage the collagen layer. Likewise, a novel keratinase obtained from B. subtilis S14 exhibited remarkable dehairing capabilities without damage to bovine skin collagen, which was confirmed on SDS–PAGE using control collagen, and collagen treated with standard keratinase, collagenase and test enzymes (Alexandre et al. 2005).

When hair is removed from buffalo hide by chemical method, it was observed microscopically that the hair was distorted or broken into small pieces (Fig. 4a) while enzyme-treated hair was intact, with hair root, shaft, and sheath (Fig. 4b). In previous reports, the epidermis, hair shaft and bulbs were completely removed with better splitting of fibre bundles by the action of multiple protease concentrate (Chandrasekaran and Dhar 1985). Our study indicates that the hair loosening was due to enzyme action and not due to the swelling up or modification of the sheath.

Conclusion

Production of an efficient dehairing enzyme from B. cereus MCM B-326 with inexpensive and easily available substrates is reported. Enzymatically removed intact hair can be used as a value-added byproduct. Along with dehairing, the enzyme exhibited opening up of collagen bundles. Use of this enzyme in the dehairing process will reduce the time of the process, and yield better quality leather. Simultaneously, it will reduce the pollution load of leather manufacturing process.

References

Alagarsamy S, Chandran S, George S, Carlos RS, Ashok P (2005) Production and partial purification of a neutral metalloprotease by fungal mixed substrate fermentation. Food Technol Biotechnol 43:313–319

Alessandro R, Silvia O, Adriano B (2003) Dehairing activity of extracellular proteases produced by keratinolytic bacteria. J Chem Technol Biotechnol 78:855–859

Alexandre JM, Walter O, Beys DS, Renata G, David D, Joao A, Pegas H, Carlos T (2005) Novel Keratinase from Bacillus subtilis S14 exhibiting remarkable dehairing capabilities. Appl Environ Microbiol 71:594–596

Amare G (1997) The use of nug meal as a low-cost substrate for the production of alkaline protease by the alkaliphilic Bacillus sp. AR-009 and some properties of the enzyme. Biores Technol 62:59–61

Chandrasekaran S, Dhar SC (1985) Studies on the development of a multiple proteinase concentrate and its application in the depilation of skin. Leath Sci 32:297–304

Dayanandan A, Kanagaraj J, Lesley S, Govindaraju R, Rajkumar GS (2003) Application of an alkaline protease in leather processing: an ecofriendly approach. J Clean Product 11:533–536

George S, Raju V, Krishnan MRV, Subramanian TV, Jayaraman K (1995) Production of protease by Bacillus amyloliquefaciens in solid state fermentation and its application in the unhairing of hides and skins. Proc Biochem 30:457–462

Ghorbel FB, Sellami KA, Fakhfakh N, Haddar A, Manni L, Nasri M (2005) Production and purification of a calcium-dependent protease from Bacillus cereus BG1. J Ind Microbiol Biotechnol 32:186–194

Jaquess PA, Elmore ME, Miguel NB (1999) Advances in stabilized enzymes for leather processing. J Am Leath Chem Asso 94:355–361

Jayaraman J (2003) Biuret method of protein estimation and Lowry’s method. In: Laboratory manual in biochemistry, New Age international (P) ltd., New Delhi. pp 78–79

John DB, Merriline J (2002) Theory and practice of histopathalogical techniques. 5th edn. Churchill publishing company

Johnvesly B, Manjunath BR, Naik GR (2002) Pigeon pea waste as novel inexpensive, substrate for production of a thermostable alkaline protease from thermoalkalophilic Bacillus sp. JB-99. Biores Technol 82:61–64

Kanagaraj J, Velappan KC, Chandra Babu NK, Sadulla S (2006) Solid waste generation in the leather industry and its utilization for cleaner environment- a review. J Sci Ind Res 65:541–548

Kanekar PP, Nilegaonkar SS, Sarnaik, SS, Kelkar AS (1997) Process for production of protease using deoiled soybean cake and alkaliphilic bacteria Arthobacter ramosus and Bacillus alkalophilus. Indian Patent No.188072

Kim SS, Kim YJ, Rhee IK (2001) Purification and characterization of a novel extracellular protease from Bacillus cereus KCTC 3674. Arch Microbiol 175:458–461

Malathi S, Chakraborty R (1991) Production of alkaline protease by a new Aspergillus flavus isolate under solid substrate fermentation conditions for use as a depilation agent. Appl Environ Microbiol 57:712–716

Mukhopadhyay RP, Chandra A (1993) Protease of a keratinolytic streptomycete to unhair goat skin. Ind JExpt Biol 1:557–558

Nashy EHA, Ismail SA, Ahmady AM, Fadaly HE, Sayed NH (2005) Enzymatic bacterial dehairing of bovine hide by a locally isolated strain of Bacillus licheniformis. J Soc Leath Technol Chem 89:242–249

Nilegaonkar SS, Kanekar PP, Sarnaik SS, Kelkar AS (2000) Production, isolation and characterization of extracellular protease of an alkaliphilic protease of an alkaliphilic strain of Arthrobacter ramosus, MCM B-351 isolated from the alkaline lake of Lonar, India. World J Microbiol Biotechnol 18:785–789

Nilegaonkar SS, Zambare VP, Kanekar PP, Dhakephalkar PK, Sarnaik SS (2007) Production and partial characterization of dehairing protease from Bacillus cereus MCM B-326. Biores Technol 98:1238–1245

Pal S, Banerjee R, Bhattacharyya BC (1996) Application of a proteolytic enzyme in tanneries as a depilating agent. J Am Leather Chem As 91:59–63

Palanisamy T, Jonnlagadda RR, Balachandran UN, Thirumalachari T (2004) Progress and recent trends in biotechnological methods for leather processing. Trend Biotechnol 22:181–188

Philippe B, Franccois L, Maria U, Bernard V (1999) Purification and Characterization of a Keratinolytic Serine Proteinase from Streptomyces albidoflavus. Appl Environ Microbiol 65:2570–2576

Prakasham RS, Rao CS, Sharma PN (2006) Green gram husk—an inexpensive substrate for alkaline protease production by Bacillus sp. in solid-state fermentation. Biores Technol 97:1449–1454

Purushotham H, Malathi S, Rao PV, Rai CL, Immanuel MM, Raghavan KV (1996) Unhairing enzyme by solid-state fermentation. J Soc Leath Technol Chem 80:52–56

Qing H, Yong P, Xin L, Haifeng W, Yizheng Z (2003) Purification and characterization of an extracellular alkaline serine protease with dehairing function from Bacillus pumilus. Curr Microbiol 46:169–173

Roberta CST, Samanta OG, Florencia CO, Adriano B (2006) Optimization of protease production by Microbacterium sp. in feather meal using response surface methodology. Proc Biochem 41:67–73

Sinha N, Satyanarayana T (1991) Alkaline protease production by thermophilic Bacillus licheniformis. Ind J Microbiol 31:425–430

Thanikaivelan P, Raghava Rao J, Nair U, Ramasami T (2003) Approach towards zero discharge tanning: role of concentration on the development of eco-friendly liming-reliming processes. J Clean Product 11:79–90

Varela H, Ferrai MD, Belobrajdic L, Vazquez A, Loperena ML (1997) Skin unhairing proteases of Bacillus subtilis: production and partial characterization. Biotechnol Lett 19:755–758

Yang JK, Shih IL, Tzeng YM, Wang SL (2000) Production and purification of protease from a Bacillus subtilis that can deproteinize crustacean waste. Enz Microb Technol 26:406–411

Yang SS, Wang JY (1999) Protease and amylase production of Streptomyces rimosus in submerged and solid state cultivations. Bot Bull Acad Sin 40:259–265

Acknowledgement

The work was carried out under NMITLI project on “Biotechnology for leather-towards cleaner processing”, sponsored by CSIR, Govt. of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zambare, V.P., Nilegaonkar, S.S. & Kanekar, P.P. Production of an alkaline protease by Bacillus cereus MCM B-326 and its application as a dehairing agent. World J Microbiol Biotechnol 23, 1569–1574 (2007). https://doi.org/10.1007/s11274-007-9402-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-007-9402-y