Abstract

This work evaluated the degradation efficiency of the most used commercial pesticide chlorpyrifos (CP) by UV/H2O2 and UVC photolysis processes. Photodegradation was carried out with 200 μg L−1 of commercial CP for 30, 60, 90, 120, 240, 360, and 480 min. The samples were submitted to the liquid–liquid extraction technique and analyzed by HPLC–DAD. Bioassays were performed using two organisms, Daphnia magna and Aedes aegypti larvae, at all the degradation times. The degradation rate was 98% and 99% after 30 min of reaction for the UV/H2O2 process and UVC photolysis, respectively. Moreover, during treatment, the main CP by-product, chlorpyrifos oxon (CPO), was identified among other unknown by-products. Acute toxicity with D. magna showed a decrease in the immobility at 480 min by the UV/H2O2 process, while in UVC photolysis, 100% immobility was observed for up to 90 min of treatment, and the endpoint oscillated until the end of the process. Bioanalytical monitoring with A. aegypti showed no toxic effects on samples treated by the UV/H2O2 process at 60, 90, 120, and 480 min of degradation. Despite the detection of CPO after UVC photolysis from 60 min onwards, no toxicity was verified, indicating that the by-products generated were not toxic to this organism. Therefore, even though high CP degradation rates were reached, for both processes, it was noted that bioassays and the ecotoxicological effect after degradation effluent are important to complement analytical tools.

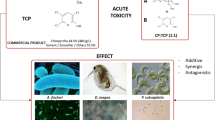

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Chlorpyrifos (O, O-diethyl O-3, 5,6-trichloro-2-pyridyl phosphorothioate) (CP) is one of the most used pesticides in the world as the active compound of more than 900 commercial formulations and in soil treatment pre- and post-planting for agriculture production, lawn protection, ornamental plants, and animal protection products (Álvarez et al., 2013; Kumar et al., 2017; Solomon et al., 2014). Due to its extensive use and persistence in the environment, this pollutant is most frequently detected in surface water, soils, and sediments, as well as in foods, fish, and processed products (Kumar et al., 2017; Rigueira et al., 2013; Vagi & Petsas, 2020).

The compound CP has been detected in aquatic ecosystems in the concentration range from 0.01 to 10 μg L−1 (Bonifacio et al., 2017; Ferrario et al., 2018) and may cause a variety of nervous disorders in humans and toxicity to various species of invertebrate and vertebrate organisms (Cáceres et al., 2007; Sparling & Fellers, 2007). Moreover, even low concentrations (μg L−1—ng L−1) can result in toxic effects to different endpoints depending on the test organism, such as immobility, modification, and death (Demetrio et al., 2014; Fatma et al., 2018; Marigoudar et al., 2018; Rebechi et al., 2014). Therefore, UVC photolysis (Utzig et al., 2019) and advanced oxidation processes (AOPs), such as TiO2/H2O2/UVA (Thind et al., 2018), photo-Fenton, TiO2/H2O2, O3/H2O2 and O3 (Dutta et al., 2015; Murillo et al., 2010), TiO2/UV (solar radiation) (Amiri et al., 2018; Gar Alalm et al., 2015), and UV/H2O2 (Femia et al., 2013; Utzig et al., 2019), have been studied as alternative technologies to its treatment.

The evaluation of these processes’ efficiency has been based mainly on analytical monitoring by liquid chromatography of the target pollutant following treatment. However, studies with commercial formulations as well as investigations of the toxicity of the by-products generated by AOPs are needed as these transformation products can result in a more toxic response than their parental molecules (Rizzo, 2011). The major degradation by-products of CP, CPO (chlorpyrifos oxon), and TCP (3,5,6- trichloro-2-pyridynol) are generated under UV radiation and are more water-soluble than CP itself. Also, CPO can be formed by oxidizing agents such as H2O2, which convert CP (P = S) into CPO (P = O) (Dhiraj et al., 2020).

To the best of our knowledge, few studies have evaluated the ecotoxicological effects of CP after AOP treatment. Femia et al. (2013) studied UV/H2O2 degradation of the commercial pesticide CP (15 mg L−1) in ultrapure water and assessed the ecotoxicity response of Aliivibrio fischeri. The authors observed oscillation of toxicity throughout the degradation processes, even though 93% of the CP was degraded in the first 20 min of treatment. Despite the efficiency (93%) resulting in the remaining CP of 1.05 mg L−1, this value is below the A. fischeri EC50 (2.84 mg L−1), which may indicate the generation of toxic by-products (Palma et al., 2008). Utzig et al. (2019) achieved 97% degradation of standard CP (200 μg L−1) by the UV/H2O2 process and UVC photolysis in 20 and 60 min of treatment, respectively. However, the samples treated by the UV/H2O2 process increased the toxicity to both Aedes aegypti larvae and Lactuca sativa seeds. These studies demonstrate the relevance of monitoring the degradation process by AOPs not only by analytical methods but also by bioanalytical assays.

Chromatographic techniques have allowed the presence of CP to be determined at concentrations of 150 ng L−1 (Pelit et al., 2012), 30 ng L−1 (Demetrio et al., 2014) by GC/ECD, and 16 ng L−1 by GC/MS (Pelit et al., 2012), at which some of these values are above the commercial CP EC50 for both organisms (D. magna and A. aegypti larvae) obtained in this work. This evidence reveals that bioassays are more sensitive than most analytical techniques, especially in a complex mixture of molecules, in which analysis of the individual target compound is not sufficient to infer ecotoxicological effects (Neale et al., 2017). For these cases, the use of specific indicator organisms related to the mechanism of action of the target compound is an alternative means of verifying the sample toxicity when the pollutant is below the analytical limit of detection. In this sense, we used A. aegypti larvae as a neuroactive insecticide indicator, since it is sensitive to organophosphates such as CP (WHO, 1981).

For this purpose, this work aims to evaluate the photodegradation of the commercial pesticide chlorpyrifos by UV/H2O2 and UVC photolysis using chromatographic analysis and toxicity responses using two different organisms, Daphnia magna and A. aegypti larvae.

2 Materials and Methods

2.1 Chemical Reagents and Solutions

All solutions were prepared in ultrapure water (MegaPurity). The chemicals chlorpyrifos (CP) (99.9% purity, Sigma-Aldrich, pka = − 4.24), chlorpyrifos oxon (CPO) (98.8% purity, ChemService), 3,5,6-trichloro-2-pyridynol (TCP) (99.2% purity, Sigma-Aldrich), Peroxide-test®, acetonitrile (J. T. Baker), NaOH (Merck), and H2SO4 (Merck) were of analytical grade or higher. Hydrogen peroxide (35% w/v) and Allper® reagent were purchased from Peróxidos do Brasil Ltda. Bovine liver catalase (4% w/v) was supplied by Sigma-Aldrich. The commercial pesticide (48% w/v CP) used in this work contains naphtha solvent, a mix of heavy aromatic hydrocarbons and other compounds not specified by the supplier.

For chromatographic analysis, analytical CP and CPO standards (200 μg L−1) were prepared in 0.2% acetonitrile and stored at − 20 °C in an amber flask. For the photodegradation experiments, a stock solution (240 mg L−1) was prepared from the commercial pesticide in ultrapure water. The working solution was diluted daily to 200 μg L−1 from a stock solution in purified water, and the final pH was adjusted to 5 ~ 6 (Rizzo et al., 2019; Utzig et al., 2019). All of these chemicals were used without any further purification.

2.2 Photodegradation Experiments

The UV/H2O2 and UVC photolysis experiments were performed in a bench borosilicate reactor with water-cooling and a working solution of 600 mL. The photodegradation processes were accomplished using a high-pressure mercury vapor lamp (125 W) as a source of UVC-Vis radiation (200–800 nm). The lamp was covered with a quartz bulb and immersed in the solution for different treatment times (30, 60, 90, 120, 240, 360, and 480 min). Both experiments were carried out in an aqueous solution containing 200 μg L−1 of commercial CP (Rizzo et al., 2019) at pH 5 ~ 6. The UV/H2O2 process was performed with an initial concentration of H2O2 at 100 mg L−1, which is the optimal concentration for the degradation of the commercial formulation by this process (Femia et al., 2013; Utzig et al., 2019). The residual H2O2 was monitored by means of spectrophotometric methodology using Allper® reagent (Brandhuber & Korshin, 2009) (LOD 0.50 mg L−1 and r2 = 0.999, n = 3, λ = 395 nm). Following the H2O2 consumption profile (data not shown), the same initial concentration of H2O2 was re-added every 15 min of treatment. At the end of the process, the residual H2O2 was removed using bovine liver catalase (1% w/v).

The chromatographic analysis was based on a method validated by our research group (Utzig et al., 2019) using high-performance liquid chromatography (HPLC, Agilent Technologies) with a Poroshell 120 EC-C18 column (4.6 × 150 mm, 2.7 μm, Agilent, USA) coupled to a diode array detector. Purification and preconcentration by liquid–liquid extraction (LLE) were performed on treated samples before HPLC–DAD analysis. The procedure was carried out using 100 mL of sample and ethyl acetate (4 × 10 mL). The extracts were evaporated and reconstituted in purified water with 0.2% acetonitrile (preconcentration factors between 20 and 250 ×). For LLE recovery, validation was accomplished at three concentrations in the linear range (between 15 and 200 μg L−1), obtaining acceptable recoveries (99%) of CP.

The efficiency of treatments was calculated according to Eq. 1, where Co (μg L−1) is the initial concentration of CP and C (μg L−1) is the concentration of CP determined after every treatment time.

2.3 Bioassays

For bioanalytical assays, samples were collected in clean glass flasks, and bovine liver catalase (1% w/v) was added to remove the residual H2O2 immediately after UVC/H2O2 treatment. All samples were then immediately frozen (− 20 °C) and kept that way for a maximum of 20 days until the tests were performed. Two organisms were used for bioassays: D. magna and A. aegypti larvae. The EC50 values were determined for both standard and commercial CP.

2.3.1 Acute Ecotoxicity with Daphnia magna

Tests were carried out with D. magna following the NBR 12,713 (ABNT, 2016). To determine the 50% effective concentration (EC50) of the CP analytical standard, solutions (0.05 to 0.3 µg L−1) were prepared from the stock solution (standard CP, 200 µg L−1, in ultrapure water with 0.2% ACN). For the commercial CP, solutions were prepared by diluting the commercial pesticide in ultrapure water. Both solutions were diluted in the culture medium. Ten neonatal organisms (2–26 h) were used in each of the three replicates (n = 3). Samples before and after treatment were diluted in the culture medium at 100, 50, 25, 12.5, and 6.25% (v/v). Culture medium and ultrapure water with 0.2% ACN were used as negative and solvent control, respectively. All tests were maintained at 20 ± 2 °C. After 48 h of exposure, the number of immobile organisms was recorded, and the percent inhibition was calculated. The EC50 values for the standard and commercial CP were calculated by Probit statistical analysis using BioEstat 5.0 free software. Toxicity results were expressed in terms of the toxicity factor (TF), equivalent to the lowest dilution at which the immobility was lower than 10%.

2.3.2 Larvicidal Activity in Aedes aegypti

Tests with A. aegypti larvae (Rockefeller strain) followed the methodology described by the World Health Organization (WHO, 1981) and adapted by Utzig et al. (2019). To determine the EC50 for standard CP, solutions (0.2 to 2.0 µg L−1) were prepared from a stock solution (standard CP, 200 µg L−1, in ultrapure water with 0.2% ACN). For the commercial CP, solutions were prepared by diluting the commercial pesticide. Both solutions were diluted in bottled mineral water. For bioassays, larvae were used in the 3rd and 4th stages of development (Bar & Andrew, 2013; Christophers, 1960). Each sample was tested in quadruplicate. Bottled mineral water and 0.2% ACN solution were used as negative and solvent controls, respectively.

After 48 h of exposure, the number of immobile organisms was recorded, and the percent inhibition was calculated. The EC50 values were calculated using Probit statistical analysis with BioEstat 5.0 free software.

3 Results and Discussion

3.1 Photodegradation Experiments

For the analysis of the compound and its degradation by-products, both the retention times and the spectral profiles of CP, CPO, and TCP standards (purity > 99%) were evaluated by HPLC–DAD, under the same chromatographic conditions. The chromatographic absorption of CP, CPO, and TCP corresponds to 290 nm, as shown in Fig. 1.

After 15 min of reaction, 90% of the H2O2 was consumed, and the residual concentration remained constant (10%). Therefore, to maintain the initial H2O2 concentration, the reactant was re-added every 15 up to 480 min of reaction.

Chromatographic analysis identified the corresponding peaks of CP and CPO eluted at retention times of 8.3 and 5.2 min, respectively, under the same chromatographic conditions. However, for all treatment times studied, no TCP was detected, as shown in Fig. 2.

Chromatograms of commercial pesticide degradation by UV/H2O2 (a) and UVC photolysis (b) processes at different treatment times (A = 0 min, B = 30 min, C = 60 min, D = 90 min, E = 120 min, F = 240 min, G = 360 min, and H = 480 min). a UV/H2O2 (times A = no PCF, B = 50 × PF, and C–H = 250 × PCF). b UVC photolysis (times A = no PCF, B = 20 × PCF, and C–H = 250 × PCF). PCF = preconcentration factor

After 30 min of treatment of UV/H2O2, the CP decreased from 200 to 3.51 μg L−1, achieving a degradation efficiency of 98.24%. After 60 min, the CP was no longer detected by the analytical method (< LOD, 0.02 µg L−1), resulting in a degradation rate higher than 99.99%. At 60 and 240 min of treatment, one of the main CP by-products was identified, the chlorpyrifos oxon (CPO). However, at the end of the treatment (480 min), the CPO was completely degraded, and it could not be detected on the chromatogram (Fig. 2a). These results are in agreement with Robles-Molina et al. (2012), who identified the by-product CPO by electrochemical oxidation of the P = S bond of CP. Besides, unknown by-products were formed throughout the degradation process that could be attributed either to the CP compound or to the commercial pesticide formulation.

UVC photolysis performed for 30 min resulted in a residual CP concentration of 1.65 μg L−1, which corresponds to a degradation efficiency of 99%. After 60 min of treatment, CP was no longer detected, indicating concentrations below the LOD (< 0.02 μg L−1), i.e., greater than 99.99% CP degradation. Unknown by-products were also observed at all treatment times. The by-product CPO was identified at 240 and 480 min of treatment, under the same chromatographic conditions as for the UV/H2O2 process, with similar spectral profiles and retention times (Fig. 2b).

Slotkin et al. (2009) reported on the UVC photodegradation of standard CP (550 mg L−1 in methanol) using four low-pressure mercury vapor lamps (λ = 254 nm). The removal efficiency achieved was 50% and 70% after 60 and 120 min, respectively. However, compared with this work, the difference in the degradation rate was approximately 30% for the same treatment times. Femia et al. (2013) reached 93% commercial CP degradation (15 mg L−1 in aqueous solution) in 120 min of treatment by UVC photolysis using a 20-W lamp at λ = 253.7 nm. These results are related to the dependence of CP photodegradation on the energy of the radiation source. Thus, the results obtained in this work prove that using a radiation source with a higher energy power (125 W) as well as the light in the spectral range of 220 to 800 nm improves CP photodegradation performance.

Regarding the degradation rate, the use of hydrogen peroxide in the photocatalytic process may produce additional drawbacks when photodegradation is performed with complex mixtures of compounds, as observed in this work. Besides the active ingredient CP in the solution system, there are high concentrations of unknown organic compound mixtures (mainly petroleum-derived solvents) and adjuvants present in the commercial pesticide, which may generate hydroxyl radical scavengers, thus affecting the oxidation rate (Lescano et al., 2021). The excess of H2O2 in the reaction medium could decrease the degradation efficiency by acting as an HO● scavenger, by generating HO2• radical oxidizing (E0 = 1.42 V V/SHE), or by scavenging light that would otherwise be available to degrade the compounds (Boczkaj & Fernandes, 2017; de Oliveira et al., 2014; Pereira et al., 2007).

Moreover, the in situ generation of HO● from H2O2 triggered by UVC irradiation enhances the oxidation of organic compounds compared with UVC photolysis (Pereira et al., 2007). These different organic compounds can result in by-products generated at every stage of the oxidative process, as observed on the chromatogram (Fig. 2a). Lescano et al. (2021) observed that the active CP compound alone contributed with 23% of the global TOC under UV/H2O2 degradation, indicating that the remaining TOC result was related to the commercial formulation mixture, which could generate by-products. These main causes could explain the degradation rate of CP by the UV/H2O2 process in the commercial formulation.

3.2 Acute Ecotoxicity with Daphnia magna

The EC50 were 150 ng L−1 for standard CP and 0.14 ng L−1 for commercial CP. The results showed that the commercial pesticide was more toxic than the standard CP (~ 1,071 times), probably due to the contribution of adjuvants and unknown organic compounds from the formulation, such as a mixture of aromatic hydrocarbons containing naphtha solvent, heavy aromatic hydrocarbons, and other ingredients not specified on the label. Demetrio et al. (2014) evaluated the toxic effects of standard (S) and commercial (F) formulations of the active compounds of three pesticides (cypermethrin, chlorpyrifos, and glyphosate) on D. magna. All three commercial formulas were more toxic than their active ingredients, with LC50 values in the range of 9.34 mg L−1 (F) and 199 mg L−1 (S) for glyphosate, 2.81 mg L−1 (F) and 3.73 mg L−1 (S) for cypermethrin, and 0.30 mg L−1 (F) and 1.22 mg L−1 (S) for chlorpyrifos. These studies reveal the importance of performing ecotoxicological assays, as many regulatory thresholds are defined by the active ingredient EC50 and not by the commercial formula.

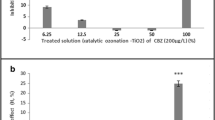

Although CP was no longer detected (< LOD = 0.02 µg L−1) after 30 min of photodegradation experiments, bioassays demonstrated that the treatments resulted in toxic effects on D. magna. The results of acute toxicity to D. magna expressed as a function of the TF are a non-dimensional number defined as the lowest sample dilution that does not cause a significant immobility effect in more than 10% of the tested organisms (ABNT NBR 12,713, 2016; Baumer et al., 2018). Wide variation was observed in acute toxicity according to the process and treatment time (Fig. 3). This behavior may be due to the different degradation rates of commercial CP for both processes, which generated CPO and unknown by-products during the treatments, as observed in Fig. 2a. Therefore, each sample represents a complex mixture of molecules that could interact with each other, both synergistically and antagonistically.

The untreated solution (0 min) resulted in the highest TF value, which corresponded to 100% immobilization of the organisms at the highest sample dilution performed in this work (sample concentration of 3.12%), resulting in a TF higher than 32. The initial TF was related to the CP concentration (200 µg L−1), which was ~ 1,428 times higher than the EC50 value for D. magna found in this work (0.14 ng L−1). The organic compounds and adjuvants in the commercial formula may also have contributed to this significant toxic effect.

The UV/H2O2 process resulted in wide variation in toxicity throughout the treatment times studied. It was observed that at 90 and 480 min, the TF decreased significantly compared with the initial time (from 32 to 2). Also, the treatment performed at 480 min decreased the percentage of immobilization from 100 (in 90 min) to 40% for non-diluted samples (TF). Compared with the initial toxic effect, the UV/H2O2 process resulted in a continuous decrease in the TF value from 30 (32 to 16) to 90 min (TF 2). However, toxicity was observed to increase from 120 (TF 4) to 360 min (TF 16) and then decrease at 480 min (TF 2) (Fig. 3a). By contrast, UVC photolysis significantly reduced the toxicity after 60 min (TF 32 to 2), and the endpoint in D. magna remained constant until 360 min of treatment. Moreover, the treatment performed at 120 min showed decrease in the percentage of immobilization in a non-diluted sample (30%). Nevertheless, the treatment performed at 480 min increased the TF from 2 to 4 (Fig. 3b).

After 60 min of photodegradation, the CP concentration was lower than the LOD (0.02 μg L−1) for both processes, reaching a degradation rate greater than 99.99%. Considering the EC50 for the commercial formulation of CP (0.00014 µg L−1) and standard CP (0.15 µg L−1) for D. magna, the toxicity response, in this case, may be related to the mixture of compounds present in the commercial formulation, its by-products, and the by-products generated from the CP. Moreover, studies have shown that CP in the range of ng L−1 can cause chronic toxicity. Reproduction in Daphnia carinata until the third generation was affected by prolonged exposure to 5 ng L−1 of CP (Zalizniak & Nugegoda, 2006).

Regarding the by-product CPO, Sparling and Fellers (2007) evaluated the acute toxicity of CP and CPO in the larval stage of Rana boylii (frog). They observed that 500 μg L−1 CP resulted in 100% mortality of the organisms, while 5 μg L−1 CPO was sufficient to reach the same endpoint. However, in this work, it was not possible to associate the toxic effects with the presence of a single by-product. Commercial CP is a complex mixture of molecules before and after photodegradation. Besides, the oscillation in the TF values throughout treatment for both processes, UV/H2O2 and UVC photolysis, demonstrated no relation to the presence of CPO.

In this sense, new approaches have been taken to assess the toxic effects of complex mixtures. Neale et al. (2017) proposed a battery of in vitro and in vivo ecotoxicological assays to monitor surface water. The authors selected 32 pollutants present in water, including the CP, according to environmental relevance, hazard quotients, and their mechanisms of action. The results highlight that most of the compounds are responsible for the toxic effect when they are in a mixture, even if the molecules cannot be detected by analytical methods (Mesnage & Antoniou, 2018).

3.3 Larvicidal Activity with Aedes aegypti Larvae

The EC50 values for standard and commercial CP were 0.84 and 2.24 μg L−1, respectively. The results expressed in terms of A. aegypti larvae immobility before and after UV/H2O2 and UVC photolysis are shown in Fig. 4.

For both processes, the untreated sample (0 min) showed 100% larval immobility. This was expected since the action of CP is that of an insecticide. Moreover, the initial concentration (200 µg L−1) was approximately 89 times higher than that of EC50 (2.24 µg L−1) for A. aegypti.

For the UV/H2O2 process (Fig. 2a), the residual CP concentration at 30 min of treatment was 3.51 μg L−1; this value is higher than the EC50 for A. aegypti larvae, resulting in a toxic effect. The treatments performed at 60, 90, and 120 min did not present toxic effects, and the CP values were below the LOD and EC50 of 0.02 μg L−1 and 2.24 μg L−1, respectively. Although the CPO peak was detected at 60 min of treatment, the absence of toxicity at these treatment times (60, 90, and 120 min) implies that the by-products generated were not toxic to this organism. As observed for D. magna, performing the treatment for 240 and 360 min increased the toxicity, possibly due to the sensitivity of both organisms to highly toxic by-products formed during the process.

For UVC photolysis in 30 min of treatment, the residual CP concentration of 1.65 μg L−1 resulted in a toxic effect. This endpoint could be caused, at first, by CP or by the by-products generated in the reaction medium. By contrast, the other treatment times did not result in toxicity, indicating that the by-products generated did not cause toxic effects on this organism. Taking into account the presence of CP, after 60 min of treatment, this compound was no longer analytically detected in the reaction medium, and no toxicity to A. aegypti larvae was observed (Fig. 1a). In this case, the analytical and bioanalytical tools complemented each other. However, as it is a complex mixture of molecules, the absence of toxicity observed for A. aegypti larvae in this work did not indicate any toxicity of the solution. Moreover, additional studies on the commercial formulation and its by-product are required, as the literature only presents evaluations of the sensitivity of this organism to the active CP molecule and not to the commercial formulation (Abe et al., 2014; Lopez et al., 2014; Zahrani et al., 2020).

The toxicity evolution of samples during AOP treatment is complex and still unclear. Therefore, the monitoring of toxicity throughout AOP treatment is crucial to assess its efficiency, and few publications provide relevant information about changes in toxicity during AOP treatment (Wang & Wang, 2021). Three different situations regarding the change in toxicity are usually found for various AOP treatments: (1) a decrease in toxicity during the AOP treatment; (2) first an increase and then a decrease during the AOP treatment; (3) an increase in toxicity during the AOP treatment. These behaviors regarding wastewater toxicity during AOPs can be due to many factors, such as the types of reactive species, structure of organic pollutants, concentration of reactive species, toxicity bioassay used, experimental parameters, residual oxidizers, and heterogeneous catalysts (Wang & Wang, 2021). Moreover, photochemical process (UVC photolysis) and photocatalysis process (such as UVC/H2O2) have different degradation mechanisms for organic pollutants, leading to variation in the toxicity of wastewater (Cedat et al., 2016). A higher concentration of reactive species (such as hydroxyl radical) is expected in the UVC/H2O than in UVC photolysis, which could explain the greater reduction in toxicity in the UVC/H2O2 process after 480 min for D. magna. Finally, the method used to assess toxicity also influences the response. Different organisms have different sensitivities and different mechanisms of action for the same compound analyzed. Thus, it is vital to investigate the toxicity changes during the treatment of AOPs using organisms of different trophic levels.

This study demonstrates the need for evaluation by combining analytical and bioanalytical assays, especially those related to AOP treatments. Recent studies have shown that partial oxidation of organic contaminants after AOPs can result in recalcitrant molecules that are more toxic than the parent compounds (Rizzo, 2011; Utzig et al., 2019). Only bioassays can assess the matrix mixture effects, including the contributions of unidentified by-products or those compounds below the detectability of analytical methods (LOD).

In this work, the toxic effects observed for both D. magna and A. aegypti after treatment by the UV/H2O2 process at 240 and 360 min probably indicate the synergy between the by-products and the organic compounds from the commercial formulation, resulting in the observed endpoint responses.

Bioassays are sized to calculate risks, which means that more potent compounds will contribute more to their response than less potent chemicals. Another advantage of bioanalytical monitoring would be the greater sensitivity to micropollutants and by-product molecules present at low concentrations in environmental matrices (Neale et al., 2012).

Besides, the organisms chosen in this work (D. magna and A. aegypti) have great representativeness and sensitivity for aquatic and terrestrial environments. D. magna is one of the main freshwater bioindicators and is used worldwide for toxic evolution evaluation. A. aegypti represent a class that can be found in high abundance in urbanized areas and at rural sites. Furthermore, this is an organism sensitive to the insecticidal action of chlorpyrifos, the active compound present in the commercial formulation.

4 Conclusion

In this study, efficient treatment with commercial CP was performed by the UV/H2O2 process and UVC photolysis, achieving 98.24% and 99.18% degradation in 30 min, respectively. Degradation rates higher than 99.99% were obtained for both processes after 60 min. Throughout the treatments, the CPO by-product was identified by chromatographic analysis. Also, unknown by-products formed during the degradation were observed, which could be from the commercial formulation, as well as the by-products generated from the CP compound itself.

Both D. magna and A. aegypti proved to be effective bioindicators since they showed sensitivity to the by-products generated, even when analytical monitoring indicated high rates of CP degradation. Moreover, the study revealed A. aegypti larvae as an alternative in terms of bioassay indicator organisms for organophosphate compounds and for commercially formulated pesticides.

The ecotoxicity tests performed before and after the treatments demonstrated that, even when high rates of target compound degradation are reached, the trace levels of the target compound should be analyzed as well as its degradation by-products, which may be responsible for the toxicity increase in the treated effluent.

However, once the presence of toxic compounds, verified by bioassay, oscillated up to 480 min for both treatments, it was difficult to determine a treatment technology for a complex sample such as the commercial pesticide CP.

Data and Materials Availability

Not applicable.

Code Availability

Not applicable.

References

Abe, F. R., Coleone, A. C., Machado, A. A., & Machado-Neto, J. G. (2014). Ecotoxicity and environmental risk assessment of larvicides used in the control of Aedes aegypti to Daphnia magna (crustacea, cladocera). Journal of Toxicology and Environmental Health - Part a: Current Issues, 77(1–3), 37–45. https://doi.org/10.1080/15287394.2014.865581

ABNT. (2016). NBR 12713 Ecotoxicologia aquática — Toxicidade aguda — Método de ensaio com Daphnia spp (Crustacea, Cladocera) Aquatic. ABNT NBR 12713, (4), 1–23. http://revistas.ufpr.br/pesticidas/article/view/7483

Álvarez, M., Du Mortier, C., Sokolic, T., & Cirelli, A. F. (2013). Studies on the persistence of a commercial formulation of chlorpyrifos on an agricultural soil from Provincia de Buenos Aires, República Argentina. Water, Air, and Soil Pollution, 224(5). https://doi.org/10.1007/s11270-013-1571-8

Amiri, H., Nabizadeh, R., Silva Martinez, S., Jamaleddin Shahtaheri, S., Yaghmaeian, K., Badiei, A., et al. (2018). Response surface methodology modeling to improve degradation of Chlorpyrifos in agriculture runoff using TiO2 solar photocatalytic in a raceway pond reactor. Ecotoxicology and Environmental Safety, 147(August 2017), 919–925. https://doi.org/10.1016/j.ecoenv.2017.09.062

Bar, A., & Andrew, J. (2013). Morphology and morphometry of Aedes aegypti larvae. Annual Review & Research in Biology, 3(1), 1–21.

Baumer, J. D., Valério, A., de Souza, S. M. A. G. U., Erzinger, G. S., Furigo, A., & de Souza, A. A. U. (2018). Toxicity of enzymatically decolored textile dyes solution by horseradish peroxidase. Journal of Hazardous Materials, 360(May), 82–88. https://doi.org/10.1016/j.jhazmat.2018.07.102

Boczkaj, G., & Fernandes, A. (2017). Wastewater treatment by means of advanced oxidation processes at basic pH conditions: A review. Chemical Engineering Journal, 320, 608–633. https://doi.org/10.1016/j.cej.2017.03.084

Bonifacio, A. F., Ballesteros, M. L., Bonansea, R. I., Filippi, I., Amé, M. V., & Hued, A. C. (2017). Environmental relevant concentrations of a chlorpyrifos commercial formulation affect two neotropical fish species, Cheirodon interruptus and Cnesterodon decemmaculatus. Chemosphere, 188, 486–493. https://doi.org/10.1016/j.chemosphere.2017.08.156

Brandhuber, P. J., & Korshin, G. (2009). Methods for the Detection of Residual Concentrations of Hydrogen Peroxide in Advanced Oxidation Processes. Akexandria: Water Reuse Foundation.

Cáceres, T., He, W., Naidu, R., & Megharaj, M. (2007). Toxicity of chlorpyrifos and TCP alone and in combination to Daphnia carinata: The influence of microbial degradation in natural water. Water Research, 41(19), 4497–4503. https://doi.org/10.1016/j.watres.2007.06.025

Christophers, R. (1960). Aedes Aegypti: The yellow fever mosquito. Cambridge At The University Press, 10(1), 1–721.

de Oliveira, A. G., Ribeiro, J. P., De Oliveira, J. T., De Keukeleire, D., Duarte, M. S., & Do Nascimento, R. F. (2014). Degradation of the pesticide chlorpyrifos in aqueous solutions with UV/H2O2: Optimization and effect of interfering anions. Journal of Advanced Oxidation Technologies, 17(1), 133–138.

Demetrio, P. M., Bonetto, C., & Ronco, A. E. (2014). The effect of cypermethrin, chlorpyrifos, and glyphosate active ingredients and formulations on Daphnia magna (straus). Bulletin of Environmental Contamination and Toxicology, 93(3), 268–273. https://doi.org/10.1007/s00128-014-1336-0

Dhiraj, S. U. D., Kumar, J., Kaur, P., & Bansal, P. (2020). Toxicity, natural and induced degradation of chlorpyrifos. Journal of the Chilean Chemical Society, 65(2), 4807–4816. https://doi.org/10.4067/S0717-97072020000204807

Dutta, A., Chakraborty, I., Sarkar, D., & Chakrabarti, S. (2015). Sunlight-assisted photo-Fenton degradation of pesticide in wastewater: Ecotoxicological impact on Nostoc sp. Algae. Water, Air, and Soil Pollution, 226(12), 1–13. https://doi.org/10.1007/s11270-015-2661-6

Fatma, F., Verma, S., Kamal, A., & Srivastava, A. (2018). Phytotoxicity of pesticides mancozeb and chlorpyrifos: Correlation with the antioxidative defence system in Allium cepa. Physiology and Molecular Biology of Plants, 24(1), 115–123. https://doi.org/10.1007/s12298-017-0490-3

Femia, J., Mariani, M., Zalazar, C., & Tiscornia, I. (2013). Photodegradation of chlorpyrifos in water by UV/H2O2 treatment: Toxicity evaluation. Water Science and Technology, 68(10), 2279–2286. https://doi.org/10.2166/wst.2013.493

Ferrario, C., Parolini, M., De Felice, B., Villa, S., & Finizio, A. (2018). Linking sub-individual and supra-individual effects in Daphnia magna exposed to sub-lethal concentration of chlorpyrifos. Environmental Pollution, 235, 411–418. https://doi.org/10.1016/j.envpol.2017.12.113

Gar Alalm, M., Tawfik, A., & Ookawara, S. (2015). Comparison of solar TiO2 photocatalysis and solar photo-Fenton for treatment of pesticides industry wastewater: Operational conditions, kinetics, and costs. Journal of Water Process Engineering, 8, 55–63. https://doi.org/10.1016/j.jwpe.2015.09.007

Kumar, U., Berliner, J., Adak, T., Rath, P. C., Dey, A., Pokhare, S. S., et al. (2017). Non-target effect of continuous application of chlorpyrifos on soil microbes, nematodes and its persistence under sub-humid tropical rice-rice cropping system. Ecotoxicology and Environmental Safety, 135(May 2016), 225–235. https://doi.org/10.1016/j.ecoenv.2016.10.003

Lescano, M. R., Lopez, A. O., Romero, R. L., & Zalazar, C. S. (2021). Degradation of chlorpyrifos formulation in water by the UV/H2O2 process: Lumped kinetic modelling of total organic carbon removal. Journal of Photochemistry and Photobiology A: Chemistry, 404(September 2020), 112924. https://doi.org/10.1016/j.jphotochem.2020.112924

Lopez, B., Ponce, G., Gonzalez, J. A., Gutierrez, S. M., Villanueva, O. K., Gonzalez, G., et al. (2014). Susceptibility to chlorpyrifos in pyrethroid-resistant populations of Aedes aegypti (Diptera: Culicidae) from Mexico. Journal of Medical Entomology, 51(3), 644–649. https://doi.org/10.1603/ME13185

Marigoudar, S. R., Nagarjuna, A., Karthikeyan, P., Mohan, D., & Sharma, K. V. (2018). Comparative toxicity of chlorpyrifos: Sublethal effects on enzyme activities and histopathology of Mugil cephalus and Chanos chanos. Chemosphere, 211, 89–101. https://doi.org/10.1016/j.chemosphere.2018.07.137

Mesnage, R., & Antoniou, M. N. (2018). Ignoring adjuvant toxicity falsifies the safety profile of commercial pesticides. Frontiers in Public Health, 5(January), 1–8. https://doi.org/10.3389/fpubh.2017.00361

Murillo, R., Sarasa, J., Lanao, M., & Ovelleiro, J. L. (2010). Degradation of chlorpyriphos in water by advanced oxidation processes. Water Science and Technology: Water Supply, 10(1), 1–6. https://doi.org/10.2166/ws.2010.777

Neale, P. A., Altenburger, R., Aït-Aïssa, S., Brion, F., Busch, W., de Aragão Umbuzeiro, G., et al. (2017). Development of a bioanalytical test battery for water quality monitoring: Fingerprinting identified micropollutants and their contribution to effects in surface water. Water Research, 123, 734–750. https://doi.org/10.1016/j.watres.2017.07.016

Neale, P. A., Antony, A., Bartkow, M. E., Farré, M. J., Heitz, A., Kristiana, I., et al. (2012). Bioanalytical assessment of the formation of disinfection byproducts in a drinking water treatment plant. Environmental Science and Technology, 46(18), 10317–10325. https://doi.org/10.1021/es302126t

Palma, P., Palma, V. L., Fernandes, R. M., Soares, A. M. V. M., & Barbosa, I. R. (2008). Acute toxicity of atrazine, endosulfan sulphate and chlorpyrifos to Vibrio fischeri, Thamnocephalus platyurus and Daphnia magna, relative to their concentrations in surface waters from the Alentejo Region of Portugal. Bulletin Environmental Contamination and Toxicology, 81, 485–489. https://doi.org/10.1007/s00128-008-9517-3

Pelit, F. O., Pelit, L., Ertaş, H., & Nil Ertaş, F. (2012). Development of a gas chromatographic method for the determination of chlorpyrifos and its metabolite chlorpyrifos-oxon in wine matrix. Journal of Chromatography b: Analytical Technologies in the Biomedical and Life Sciences, 904, 35–41. https://doi.org/10.1016/j.jchromb.2012.07.006

Pereira, V. J., Linden, K. G., & Weinberg, H. S. (2007). Evaluation of UV irradiation for photolytic and oxidative degradation of pharmaceutical compounds in water. Water Research, 41(19), 4413–4423. https://doi.org/10.1016/j.watres.2007.05.056

Rebechi, D., Richardi, V. S., Vicentini, M., Guiloski, I. C., Silva de Assis, H. C., & Navarro-Silva, M. A. (2014). Low malathion concentrations influence metabolism in Chironomus sancticaroli (Diptera, Chironomidae) in acute and chronic toxicity tests. Revista Brasileira De Entomologia, 58(3), 296–301. https://doi.org/10.1590/S0085-56262014000300012

Rigueira, L. M. B., De L. Ribeiro, K., De Queiroz, M. E. L. R., Neves, A. A., Zambolim, L., & Oliveira, R. M. (2013). Determination of chlorpyrifos and thiamethoxam in potato tuber (Solanum tuberosum L.) and soil of Brazil using solid-liquid extraction with low temperature partitioning (SLE/LTP). Journal of the Brazilian Chemical Society, 24(12), 2042–2049. https://doi.org/10.5935/0103-5053.20130256

Rizzo, L. (2011). Bioassays as a tool for evaluating advanced oxidation processes in water and wastewater treatment. Water Research, 45(15), 4311–4340. https://doi.org/10.1016/j.watres.2011.05.035

Rizzo, L., Malato, S., Antakyali, D., Beretsou, V. G., Đolić, M. B., Gernjak, W., et al. (2019). Consolidated vs new advanced treatment methods for the removal of contaminants of emerging concern from urban wastewater. Science of the Total Environment, 655(August 2018), 986–1008. https://doi.org/10.1016/j.scitotenv.2018.11.265

Slotkin, T. A., Seidler, F. J., Wu, C., MacKillop, E. A., & Linden, K. G. (2009). Ultraviolet photolysis of chlorpyrifos: Developmental neurotoxicity modeled in PC12 cells. Environmental Health Perspectives, 117(3), 338–343. https://doi.org/10.1289/ehp.11592

Solomon, K. R., Williams, W. M., Mackay, D., Purdy, J., Giddings, J. M., & Giesy, J. P. (2014). Properties and Uses of Chlorpyrifos in the United States In: Giesy J., Solomon K. (eds) Ecological risk assessment for chlorpyrifos in terrestrial and aquatic systems in the United States. Reviews of Environmental Contamination and Toxicology (Continuation (Vol. 231, pp. 119–162). Springer, Cham. https://doi.org/10.1007/978-3-319-03865-0_2

Sparling, D. W., & Fellers, G. (2007). Comparative toxicity of chlorpyrifos, diazinon, malathion and their oxon derivatives to larval Rana boylii. Environmental Pollution, 147(3), 535–539. https://doi.org/10.1016/j.envpol.2006.10.036

Thind, P. S., Kumari, D., & John, S. (2018). TiO2/H2O2 mediated UV photocatalysis of Chlorpyrifos: Optimization of process parameters using response surface methodology. Journal of Environmental Chemical Engineering, 6(3), 3602–3609. https://doi.org/10.1016/j.jece.2017.05.031

Utzig, L. M., Lima, R. M., Gomes, M. F., Ramsdorf, W. A., Martins, L. R. R., Liz, M. V., & Freitas, A. M. (2019). Ecotoxicity response of chlorpyrifos in Aedes aegypti larvae and Lactuca sativa seeds after UV/H 2 O 2 and UVC oxidation. Ecotoxicology and Environmental Safety, 169(October 2018), 449–456. https://doi.org/10.1016/j.ecoenv.2018.11.003

Vagi, M. C., & Petsas, A. S. (2020). Recent advances on the removal of priority organochlorine and organophosphorus biorecalcitrant pesticides defined by Directive 2013/39/EU from environmental matrices by using advanced oxidation processes: An overview (2007–2018). Journal of Environmental Chemical Engineering, 8(1), 102940. https://doi.org/10.1016/j.jece.2019.102940

Wang, J., & Wang, S. (2021). Toxicity changes of wastewater during various advanced oxidation processes treatment : An overview. Journal of Cleaner Production, 315(June), 128202. https://doi.org/10.1016/j.jclepro.2021.128202

WHO. (1981). Instruction for determining the susceptibility or resistance of mosquito larvae to insecticide (p. 1981). World Health Organization.

Zahrani, M. R. Al, Gharsan, F. N., Al-Ghamdi, K. M., Mahyoub, J. A., & Alghamdi, T. S. (2020). Toxicity of two groups of pesticides against the mosquito Aedes aegypti. GSC Biological and Pharmaceutical Sciences, 13(1), 148–155. https://doi.org/10.30574/gscbps.2020.13.1.0334

Zalizniak, L., & Nugegoda, D. (2006). Effect of sublethal concentrations of chlorpyrifos on three successive generations of Daphnia carinata. Ecotoxicology and Environmental Safety, 64(2), 207–214. https://doi.org/10.1016/j.ecoenv.2005.03.015

Acknowledgements

We are grateful to the multi-user laboratory of chemical analyses (LAMAQ) and the multi-user laboratory of equipment and environmental analyses (LAMEAA) for the chromatographic analyses and the Laboratory of Physiology and Control of Arthropod Vectors (LAFICAVE), Oswaldo Cruz Institute, RJ, in supplying the Aedes aegypti eggs.

Funding

The authors would like to thank the Federal University of Technology, Paraná (UTFPR), for financial support and the Fundação Araucária, Brazil, for the graduate scholarship. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES) (postdoctoral scholarship of PhD Liziê Prola) and National Council for Scientific and Technological (CNPq, protocol number 458362/2014–0).

Author information

Authors and Affiliations

Contributions

Suelen Angeli, Gabriella P. Masceno, Fernando R. Silva, and Liziê D. T. Prola were responsible to perform the degradation experiments and analyses of the results. Rúbia M. Lima and Suelen Angeli were responsible for the chromatographic analyses and validation methods. Eliane Adams and Larisa M. Utzig performed the ecotoxicological bioassays. Adriane M. de Freitas and Marcus V. de Liz supervised the project and revised the manuscript and responsible to funding acquisition. All authors contributed to the analysis and writing of the manuscript.

Corresponding author

Ethics declarations

Consent for Publication

The publication has been approved by all co-authors.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Angeli, S., Adams, E., Masceno, G.P. et al. Toxicity Assays of Commercial Chlorpyrifos Under UV/H2O2 and UVC Photolysis Treatments. Water Air Soil Pollut 232, 353 (2021). https://doi.org/10.1007/s11270-021-05314-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-021-05314-w