Abstract

To investigate the effect of permeable pavement surface materials (PPSMs) on the influences of pollutant removal in urban storm runoff, six commonly used PPSMs (porous asphalt, porous concrete, cement brick, ceramic brick, sand base brick, and shale brick) were selected and the research was carried out by batch and column experiments. Results indicated that in batch experiments, except for the shale brick, most of the PPSM will release different pollutants continuously with the contact time increasing. Compared with other materials, porous asphalt and ceramic brick could increase the concentration of pollutants in the runoff greatly. With the contact time increased to 48 h, the concentration of NO3-N and TN increased to 13.0 and 23.1 mg/L for ceramic brick and 13.3 and 32.3 mg/L for porous asphalt, respectively. This is mainly due to the artificial activity that accelerates the wear of the PPSM. Furthermore, results showed that PPSM could eliminate pollutants and influenced the removal efficiency greatly in column experiments. Most PPSMs have a noticeable purification effect on different pollutants, among them the purification effect of porous asphalt is the best. The concentrations of COD, NH3-N, and TN are 139.6, 1.32, and 7.79 mg/L in the effluent, respectively. These results may be attributed to the relatively stable environment in column experiments which is more suitable for the removal of pollutants. This study could offer new insight into the transformation of pollutants in damaged PPSM and provide useful guidelines for the better design of permeable pavement system.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, fresh water availability has become one of the main issues humankind is facing (Vialle et al. 2012). With rapid urbanization, industrialization, and population growth, available cleaning water resources are declining in urban area. Road runoff is also known to be a potential source of non-point source pollution in which the pollutants come from the compounds in road and debris deposited on road surfaces. Results showed that road runoff contained large amount of pollutants, such as nutrient pollution (total phosphorus and nitrate nitrogen), oil, grease, heavy metals, and organic matters (Angrill et al. 2016; Brown and Borst 2015; Chow and Yusop 2017; Drake et al. 2014; Göbel et al. 2007). Wei et al. and Li et al. investigated the distributions of contaminants in early runoff samples. Results showed that the concentrations of total nitrogen (TN) and total phosphorus (TP) were higher in traffic road and parking lots (Li et al. 2014; Wei et al. 2010). Gan et al. illustrated that nutrient constituents are the dominant pollutants in runoff in urban and rural runoff of Guangzhou (Gan et al. 2008). Hou and Zhang contrasted the urban runoff quality of asphalt road in Beijing and showed that the main pollutants for the rain-harvesting surfaces were organics, nutrients, and suspended particles (Hou and Zhang 2014). Many scholars have put forward that urban road runoff pollution is an important cause of environmental degradation in urban area (Fletcher et al. 2008; Van 2007). Furthermore, surface water quality is negatively impacted by the pollutant loads in storm water runoff and threatens the supply of clean water.

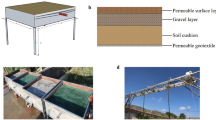

As a kind of typical rainwater facilities, the permeable pavement system (PPS) shows widespread effectiveness in reducing runoff quantity, delaying peak flow and reducing peak runoff rates due to their high surface infiltration rates (Iroumé et al. 2010; Steenbergen and Willems 2012). PPS can provide storage, treatment, and recharge of urban drainage in many countries. Furthermore, PPS could function as a multi-purpose infrastructure with the potential for clarification of urban drainage. Results showed that PPS could reduce the concentrations of storm water pollutants and improve the runoff water quality (Li et al. 2017). Jiang et al. showed that permeable asphalt could not only remove heavy metals bus also could reduce biochemical oxygen demand, chemical oxygen demand, ammonia, and total phosphorus in the runoff (Jiang et al. 2015). The ceramic permeable brick could remove effectively the total suspended solid (TSS) and TP with 79.8 and 74.2% in the runoff, while has little effect on the removal of chemical oxygen demand (COD), ammonia (NH3-N), and TN (Niu et al. 2016).

As the integral part of PPS, the permeable pavement surface material (PPSM) is the top layer that contacts directly and firstly with the runoff. The characteristics of the PPSM will affect the runoff quality greatly in PPS. Furthermore, due to the porous structure and long-time operation, the PPSM was easily damaged by many factors. Recent researchers showed that road surface abrasion is one of the important causes of road runoff pollutants (Gnecco et al. 2005; Krein and Schorer 2000; Li et al. 2014). Hence, the damage PPS or PPSM will influence the removal of pollutants greatly in the runoff. However, until now, fewer reports focus on the removal of pollutant by PPSM, not to say the transformation of pollutants in the damaged PPSM. With the increasing types of PPSM, more attentions should be focused on this region for better investigation of long-time running efficiency and better design of PPS.

In this study, six typical PPSMs (ceramic brick, sand base brick, shale brick, cement brick, porous asphalt, and porous concrete) were selected and used for investigation of pollutant transformation in the damaged PPSM. Initial and final parameters such as pH, COD, NH3-N, nitrate nitrogen (NO3-N), TN, and TP in batch and column experiments were measured. This research could offer new insight into the transformation of pollutants in damaged PPSM and provide useful guidelines for better design of PPS.

2 Materials and Methods

2.1 Materials

According to the results showed in literatures and research in our study, six different commonly used PPSMs were selected in this study which include porous asphalt, porous concrete, cement brick, ceramic brick, sand base brick, and shale brick. According to the technical specification for permeable asphalt pavement (China 2012b) and technical specification for pervious cement concrete pavement (China 2009), the porous asphalt and porous concrete were made at the laboratory of the School of Civil and Transportation Engineering, Beijing University of Civil Engineering and Architecture. The cement brick and shale brick were bought from Ai Dao Ai He (Beijing) Technology Co., Ltd. Ceramic brick and sand base brick were supplied by Beijing million Bangpu Ruike building materials limited company. All four types of brick materials comply with the standards of water permeable brick (China 2005) and technical specification for pavement of water permeable brick (China 2012a). Other chemicals such as KI, HgI2, KNaC4H4O6·4H2O, K2S2O8, H32Mo7N6O28, ascorbic acid, H2SO4, and NaOH were all purchased from Sinopharm Chemical Reagent Co., Ltd.

2.2 Experimental Methods

Before the batch and column experiments, all six PPSMs were broken into small particles by hammer and sieved into particle size of 2–5 mm to simulate the damaged PPSM. The particles were then washed by pure water for 3–5 times and soaked into pure water for 3 days in order to remove the potential pollutants which adhere on the surface of particles. Then the particles were dried at 105 °C for 2 h and stored in polyethylene plastic bag before experiment. Typical pollutants in runoff were chosen as the target in this study, including COD, NH3-N, NO3-N, TN, and TP. The concentration of different pollution in raw water was prepared based on the traditional surface runoff from other researchers (Hou et al. 2012) (shown in Table 1).

2.2.1 Batch Experiment

In batch experiments, to investigate the effect of damaged PPSM on the runoff quality, six PPSM particles were separately added into the raw water with the dosage of 10 g L−1. The mixed solution was shaken continuously with a speed of 150 rpm at 25 °C. The samples were taken at different time intervals, filtered through a 0.45-μm membrane filter and the concentrations of pollutants in the solutions were analyzed. Before the test, the sample pH values were adjusted at the range of 1.0–2.0 and stored at 4 °C.

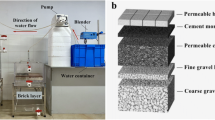

2.2.2 Column Experiment

Six columns with a diameter of 4 cm and a total height of 20 cm were used; each column has a protective layer with a height of 1 cm at the top, followed with the packing layer with a height of 18 cm, which was filled with six kinds of shattered PPSM, and another 1 cm of protective layer at the bottom of the column. The protective layer is filled with glass bead and two pieces of gauze. To avoid the side wall effect and making the operation more stable, the upstream method was used, the inlet tube is under the column, and outlet tube is on the top of column. Before the column experiment began, the columns were washed with tap water for about 3 days (the flow rate is 29.86 mL/min). During the experiment, the influent flow rate is 29.86 mL/min, which is to simulate the seepage velocity of the actual permeable pavement. The experimental conditions refer to the operation of the actual PPS.

2.3 Test Methods

According to the Chinese National Standard Methods (SEPA of China 2002), COD was determined by fast digestion-spectrophotometric method (HJ/T 399-2007); concentrations of NH3-N, NO3-N, TN, and TP were determined by spectrophotometric method; pH value was determined by glass electrode method.

The main experimental equipment were as follows: UV spectrophotometer (UV-3200D, MAPADA, China), high-pressure steam sterilization pot (SQ810C, Yamato, China), pH detector (ORION STAR A211, Thermo Scientific, USA), peristaltic pump (BT100-1L, China), and magnetic stirrer (Chijiu84-1, China). All the water used in the experiment was ultra-pure water made by ultra-pure water machine (SIM-30UV, Service-fly, China).

3 Results and Discussion

3.1 The Changes of pH Value

The value of pH is an important parameter that represents the quality of the water environment, and abnormal changes of pH values will cause significant environmental problems. As shown in Fig. 1, with the contact time increased, the pH values in the samples showed the great differences. The six PPSMs can be roughly divided into two categories, compared with pH values of raw water (7.40), and the pH values could be increased or nearly unchanged. For cement brick, sand base brick, and porous concrete, with the contact time increased, the pH values increased greatly first and followed by a relatively slow and stabilized at about 10.77, 9.05, and 10.44, respectively. These results may be attributed to the large number of CaO in the three PPSMs (Table S1). As the PPSMs were broken, with the contact time increasing, some of CaO in the sample could be dissolved into the aqueous solution and increased the solutions’ pH values. The reason for the upward trend in the pH value is mainly due to the fact that the three PPSMs contain a large amount of CaO, which react with the water. The process can be illustrated as follows:

The new generated Ca(OH)2 is a hydroxide, when contacted with water, that causes the pH of the water to rise. For porous asphalt, shale brick, and ceramic brick, the pH values increased firstly and nearly unchanged with the contact time increased. According to the requirements of the standard in surface water environment quality, the pH values of damaged porous asphalt, shale brick, and ceramic brick are still in the range of 6~9 and may not affect the runoff quality (China 2002). However, the pH values of damaged cement brick, sand base brick, and porous concrete are higher than the standard range, indicating the potential risk for the urban rainwater environment.

3.2 The Changes of COD Value

The concentration of COD is an important index which measures the level of organic matter in water environment. As shown in Fig. 2, the different PPSMs influence the concentration of COD greatly. Six PPSMs can be roughly divided into two categories. Compared with the initial concentration of raw water (419.0 mg/L), the concentration of COD in the final sample could be increased or decreased greatly. Except for shale brick, the concentration of COD in other five PPSMs increased with the contact time increased. The final COD concentration of each material is maintained at 633.1, 627.0, 560.1, 593.5, and 609.4 mg/L for ceramic brick, sand base brick, cement brick, porous asphalt, and porous concrete, respectively. These results may be attributed to the release of organic matter coated in PPSM. Only the shale brick can decrease the concentration of COD greatly which may be caused by the amount of iron oxides in the PPSM and little release of organic matter (Table S1). The decreases of COD can be attributed to the adsorption of shale brick. The surface of shale brick has a certain number of adsorption sites for COD removal. With the contact time increasing, the useful adsorption sites are gradually saturated, which leads to purification trend that has gradually stabilized. In addition to the pore sites, Fe2O3 is also one of the important conditions for purifying COD pollutants. Related research shows that Fe2O3 can effectively adsorb COD pollutants (Koupai et al. 2016), thus purifying the purpose. The shale bricks contain a large amount of iron oxide in their constituent elements (Table S1) and thus have a high COD removal efficiency. This result is consistent with other reports that the content of iron species will directly affect the purification of COD pollutants in aqueous solution (Koupai et al. 2016).

3.3 The Changes of NH3-N Value

In water environment, NH3-N is a kind of nutrient which can consume oxygen and induce the eutrophication in aqueous solution. As shown in Fig. 3, with the contact time increased, the NH3-N concentration of all PPSM increased. Compared with the initial concentration of raw water (4.90 mg/L), the samples of six PPSMs can be roughly divided into two categories. For sand base brick, shale brick, cement brick, and porous concrete, the NH3-N concentration increased with the contact time increased and maintained at about 9 h, which the final concentrations were 5.71, 6.07, 6.34, and 6.95 mg/L, respectively. Due to the damaged structure of PPSM, the pollutants in the PPSM would be released to the aqueous solution and will increase the concentration of NH3-N. For porous asphalt and ceramic brick, the NH3-N concentration increased with the contact time increased and was not stable until 48 h with the final concentrations of 6.44 and 6.18 mg/L, respectively. These results may be attributed to the higher concentration of organic compounds in porous asphalt and ceramic brick. After the destruction of structure, the organic compounds may dissolve into the water and degrease into an inorganic ammonium continuously.

3.4 The Changes of NO3-N Value

NO3-N is another material which plays an important role in the nitrogen transformation and retention process in aqueous solutions. As shown in Fig. 4, with the contact time increasing, six PPSMs show different effects on the concentration of NO3-N in the runoff. Compared with the initial concentration (6.1 mg/L), the influences can be roughly divided into three categories. For ceramic brick and porous asphalt, the concentration of NO3-N increased greatly and finally obtained at about 13.0 and 13.3 mg/L when the contact time is 24 h. This result may be caused by the organic nitrogen dissolved in the water and gradually converted to stable nitrates, which is consistent with the effect of NH3-N. For shale brick, sand base brick, and cement brick, the concentration of NO3-N decreased with the contact time increased and the final concentrations are about 2.9, 4.2, and 5.1 mg/L, which may be caused by amounts of adsorption sites in these materials. Shale brick showed the best removal efficiency with the NO3-N concentration of 2.9 mg/L when experimental duration was 48 h. The mechanism of NO3-N removal was mainly caused by interception and redox adsorption. In this study, due to the high concentration of iron in shale brick, the higher removal efficiency of NO3-N was observed which is consistent with the previous research (Zhang et al. 2010). The process can be mainly written as follows:

Due to a large amount of iron (Table S1), shale brick has a good purification effect on NO3-N. The other two types of PPSM including sand base brick and cement brick have a less effect on the removal of NO3-N. This is probably due to the rough surfaces and more pore volume, which gives a slightly more efficient removal of NO3-N than other types of PPSM. For porous concrete, the concentration of NO3-N is nearly unchanged with the contact time increased.

3.5 The Changes of TN Value

As one of the most important indicators to measure water quality, Fig. 5 shows the influences of different PPSMs on the concentration of TN in runoff. Compared with the initial concentration in raw water (11.0 mg/L), the TN concentrations finally increased to 32.3, 23.1, 17.6, 17.4, and 15.9 mg/L for porous asphalt, ceramic brick, porous concrete, shale brick, and cement brick, respectively. This study simulated runoff preparation of raw water, and TN is composed of two parts of NH3-N and NO3-N. So the removal mechanism of TN can be summarized together with NH3-N and NO3-N. Due to the PPSM characteristics, each material released NH3-N as the experiment progressed. The removal mechanism of NO3-N by PPSM has been described above. The results were consistent with the conclusion in Figs. 3 and 4. For sand base brick, the TN concentration is nearly unchanged with the contact time increased (maintained at about 11.1 mg/L).

3.6 The Changes of TP Value

Phosphorus is a key element in the growth of algae, and the excess phosphorus in the aqueous solutions will cause serious problems. Figure 6 shows the effect of different PPSMs on the concentration of TP in runoff. Compared with the initial concentration (1.52 mg/L), nearly all PPSM could decrease the concentration of TN in runoff, especially for porous concrete and cement brick (nearly 100% removal efficiency). The TP is normally removed by the adsorption and filtration of surface materials (Jiang et al. 2015). The lower efficiency of porous asphalt is probably due to the surface that is coated with a layer of modified asphalt, which may block the adsorption site for TP. Ceramic brick that showed better effect on TP than porous asphalt may be attributed to more useful adsorption site. The removal mechanism of TP in sand base brick is mainly due to the adsorption effect of sand (Alzeyadi et al. n.d.). The purification mechanism of shale brick is mainly due to the Fe2O3 on the samples (Li et al. 2013). For porous concrete and cement brick, except the useful adsorption sites caused by Fe2O3, the increase of pH values will also form precipitation of phosphate in aqueous solutions and deduce significant purification effect on TP removal.

3.7 Column Experimental Results

The column experiment results are shown in Fig. 7. For TN, the porous asphalt, shale brick, and ceramic brick have better purification effect, the removal efficiency is about 30%, and the final concentrations are 8.0 and 8.1 mg/L (raw water 11.0). These results could be attributed to the high removal efficiency of NH3-N with the final effluent concentrations of 1.3, 1.5, and 1.7 mg/L, respectively. Sand base brick and porous concrete have the lowest treatment ability, and the concentrations of NH3-N in effluent are 3.9 and 3.2 mg/L. However, all the six PPSMs had little effect on the removal of NO3-N in the runoff.

For COD, ceramic brick, shale brick, porous concrete, and porous asphalt can eliminate the COD effectively, which is followed by the order of porous asphalt, porous concrete, shale brick, and ceramic brick, with the final concentration of 139.6, 253.6, 313.7, and 355.6 mg/L (raw water 419.0 mg/L), respectively. However, cement bricks and sand base bricks still release COD pollutants, and their effluent COD concentrations are 456.9 and 474.6 mg/L. This is similar to the results of batch experiments.

For TP, six kinds of surface materials can remove a certain amount of TP in column experiment. The best effect for the removal of TP is cement brick. Compared with the raw water (1.52 mg/L), the concentration of TP in effluent of cement brick is about 0.28 mg/L. Ceramic brick has the worst treatment effect on TP, with the effluent close to 1.00 mg/L. The TP is normally removed by the adsorption and filtration of the surface materials, as well as the precipitation reactions of phosphate and calcium ions in surface materials.

For pH, six PPSMs have little influence on the pH value of the effluent—about 7.72, 7.70, 7.89, 7.72, 7.17, and 7.07 for ceramic brick, sand base brick, shale brick, cement brick, porous asphalt, and porous concrete, respectively—and have met the requirements of the standard in surface water environment quality (China 2002).

With the development of urbanization, PPS is widely used in urban construction as an effective urban hydrological management and water quality control facility. In this research, the effects of different types of PPSM on pollutants in runoff under batch experiments and column experiments are studied. In batch experiment, shale bricks are the only PPSM that can effectively purify different types of contaminants in runoff (other PPSMs showed the release of pollutants). Therefore, for the effective control of road surface runoff water quality, shale bricks should be more used as a surface layer material. In the column experiment, most PPSMs can effectively purify runoff water quality, and for different types of pollutants, purification effect is different. So as to effectively improve the infiltration of rainwater, it is possible to select the appropriate surface layer material for the pollution characteristics of runoff in different areas. For example, cement brick and sand base brick could be used as the surface materials of PPS for the regions where the concentration of TP in runoff is higher and could not be used in the area where the concentration of COD is high due to the release of COD.

4 Conclusions and Prospect

Due to close contact with runoff, various factors such as the destruction of human activities have caused the surface material to have a huge impact on runoff water quality. Laboratory studies were conducted for the influence of six kinds of materials on nutrient concentration in runoff under the influence of human activities. Based on the results from the study, the following conclusions can be made:

-

(1)

In batch experiment, the effects of different materials on the concentration of each pollutant in runoff are different. Generally, most PPSMs have the effect of releasing pollutants into runoff rainwater, and the shale brick has a relative good treatment effect on nearly all runoff pollutants compared with other materials.

-

(2)

In column experiment, the effects of different materials on different pollutants in runoff and rainwater are not consistent. According to the characteristics of runoff in different areas, reasonable selection of surface layer material can effectively improve runoff and infiltration rainwater quality.

References

Alzeyadi, A., Loffill, E. & Alkhaddar, R. (n.d.) A study of the physical and chemical characteristics of Ca-rich materials for use as phosphate removal filter media: a process based on laboratory-scale tests.

Angrill, S., Petit-Boix, A., Morales-Pinzón, T., Josa, A., Rieradevall, J., & Gabarrell, X. (2016). Urban rainwater runoff quantity and quality—a potential endogenous resource in cities? Journal of Environmental Management, 189, 14.

Brown, R. A., & Borst, M. (2015). Nutrient infiltrate concentrations from three permeable pavement types. Journal of Environmental Management, 164, 74–85.

China (2002). Environmental quality standards for surface water (pp. 1–9). Beijing: Chinese Environmental Protection Industry.

China (2005). Water permeable brick (pp. 1–15). Beijing: National Development and Reform Commission.

China (2009). Technical specification for pervious cement concrete pavement (pp. 1–45). Beijing: Ministry of Housing and Urban-Rural Development of the People’s Republic of China.

China (2012a). Technical specification for pavement of water permeable brick (pp. 1–44). Beijing: Ministry of Housing and Urban-Rural Development of the People’s Republic of China.

China (2012b). Technical specification for permeable asphalt pavement (pp. 1–41). Beijing: Ministry of Housing and Urban-Rural Development of the People’s Republic of China.

Chow, M. F., & Yusop, Z. (2017). Quantifying the quality and sampling time of oil and grease in urban stormwater runoff. Ksce Journal of Civil Engineering, 21, 1–9.

Drake, J., Bradford, A., & Van Seters, T. (2014). Stormwater quality of spring-summer-fall effluent from three partial-infiltration permeable pavement systems and conventional asphalt pavement. Journal of Environmental Management, 139, 69–79.

Fletcher, T. D., Deletic, A., Mitchell, V. G., & Hatt, B. E. (2008). Reuse of urban runoff in Australia: a review of recent advances and remaining challenges. Journal of Environmental Quality, 37, S116.

Gan, H., Zhuo, M., Li, D., & Zhou, Y. (2008). Quality characterization and impact assessment of highway runoff in urban and rural area of Guangzhou, China. Environmental Monitoring and Assessment, 140, 147–159.

Gnecco, I., Berretta, C., Lanza, L. G., & Barbera, P. L. (2005). Storm water pollution in the urban environment of Genoa, Italy. Atmospheric Research, 77, 60–73.

Göbel, P., Dierkes, C., & Coldewey, W. G. (2007). Storm water runoff concentration matrix for urban areas. Journal of Contaminant Hydrology, 91, 26–42.

Hou, L., & Zhang, X. (2014). Comparing urban runoff quality of a felt roof and an asphalt road in Beijing. Hydrology Research, 45, 282.

Hou, P. Q., Ren, Y. F., Wang, X. K., Ouyang, Z. Y., & Zhou, X. P. (2012). Research on evaluation of water quality of Beijing urban stormwater runoff. Environmental Science, 33, 71.

Iroumé, A., Mayen, O., & Huber, A. (2010). Runoff and peak flow responses to timber harvest and forest age in southern Chile. Hydrological Processes, 20, 37–50.

Jiang, W., Sha, A., Xiao, J., Li, Y., & Huang, Y. (2015). Experimental study on filtration effect and mechanism of pavement runoff in permeable asphalt pavement. Construction and Building Materials, 100, 102–110.

Koupai, J. A., Nejad, S. S., Mostafazadeh-Fard, S., & Behfarnia, K. (2016). Reduction of urban storm-runoff pollution using porous concrete containing iron slag adsorbent. Journal of Environmental Engineering, 142(04015072), 04015071–04015077.

Krein, A., & Schorer, M. (2000). Road runoff pollution by polycyclic aromatic hydrocarbons and its contribution to river sediments. Water Research, 34, 4110–4115.

Li, T., Dong, W. Y., Wang, H. J., Lin, J. N., Ouyang, F., & Zhang, Q. (2013). Effect of operating conditions on the chemical phosphate removal using during ferrous iron oxidation. Advanced Materials Research, 807-809, 478–485.

Li, C., Liu, M., Hu, Y., Gong, J., Sun, F., & Xu, Y. (2014). Characterization and first flush analysis in road and roof runoff in Shenyang, China. Water science and technology : a journal of the International Association on Water Pollution Research, 70, 397–406.

Li, H., Li, Z., Zhang, X., Li, Z., Liu, D., Li, T., & Zhang, Z. (2017). The effect of different surface materials on runoff quality in permeable pavement systems. Environmental Science and Pollution Research International, 24, 21103–21110.

Niu, Z. G., Lv, Z. W., Zhang, Y., & Cui, Z. Z. (2016). Stormwater infiltration and surface runoff pollution reduction performance of permeable pavement layers. Environmental Science and Pollution Research International, 23, 2576–2587.

Steenbergen, N. V., & Willems, P. (2012). Method for testing the accuracy of rainfall–runoff models in predicting peak flow changes due to rainfall changes, in a climate changing context. Journal of Hydrology s, 414–415, 425–434.

Van, R. M. (2007). Water localisation and reclamation: steps towards low impact urban design and development. Journal of Environmental Management, 83, 437–447.

Vialle, C., Sablayrolles, C., Lovera, M., Huau, M. C., Jacob, S., & Montrejaud-Vignoles, M. (2012). Water quality monitoring and hydraulic evaluation of a household roof runoff harvesting system in France. Water Resources Management, 26, 2233–2241.

Wei, Q., Zhu, G., Wu, P., Cui, L., Zhang, K., Zhou, J., & Zhang, W. (2010). Distributions of typical contaminant species in urban short-term storm runoff and their fates during rain events: a case of Xiamen City. Journal of Environmental Sciences, 22, 533–539.

Zhang, J., Hao, Z., Zhang, Z., Yang, Y., & Xu, X. (2010). Kinetics of nitrate reductive denitrification by nanoscale zero-valent iron. Process Safety & Environmental Protection, 88, 439–445.

Funding

This work was supported by the Natural Science Foundation of China (Nos. 51678025 and 51708014), the Great Scholars Program (CIT&TCD20170313), the Beijing Advanced Innovation Center of Urban Design for Future Cities: Sponge City Development and Water Quantity & Quality Risk Control (UDC2016040100), and the fifth “urban and rural construction and management” production and research graduate student training base project (No. 31061017002), the Funded by Science and Technology Plans of Ministry of Housing and Urban-Rural Development of the People’s Republic of China, and Opening Projects of Beijing Advanced Innovation Center for Future Urban Design, Beijing University of Civil Engineering and Architecture (UDC2017032922).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(DOCX 1100 kb)

Rights and permissions

About this article

Cite this article

Zhang, Z., Li, Z., Zhang, X. et al. Systematically Investigated the Influences of Permeable Pavement Materials on the Water Quality of Runoff: Batch and Column Experiments. Water Air Soil Pollut 229, 155 (2018). https://doi.org/10.1007/s11270-018-3772-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-018-3772-7