Abstract

This study provides insight into the mechanistic and performance features of the cyclic reduction of NOx by CO in the presence and absence of excess water on a Pt–Rh/Ba/Al2O3 NOx storage and reduction catalyst. At low temperatures (150–200 °C), CO is ineffective in reducing NOx due to self-inhibition while at temperatures exceeding 200 °C, CO effectively reduces NOx to main product N2 (selectivity >70 %) and byproduct N2O. The addition of H2O at these temperatures has a significant promoting effect on NOx conversion while leading to a slight drop in the CO conversion, indicating a more efficient and selective lean reduction process. The appearance of NH3 as a product is attributed either to isocyanate (NCO) hydrolysis and/or reduction of NOx by H2 formed by the water gas shift chemistry. After the switch from the rich to lean phase, second maxima are observed in the N2O and CO2 concentrations versus time, in addition to the maxima observed during the rich phase. These and other product evolution trends provide evidence for the involvement of NCOs as important intermediates, formed during the CO reduction of NO on the precious metal components, followed by their spillover to the storage component. The reversible storage of the NCOs on the Al2O3 and BaO and their reactivity appears to be an important pathway during cyclic operation on Pt–Rh/Ba/Al2O3 catalyst. In the absence of water the NCOs are not completely reacted away during the rich phase, which leads to their reaction with NO and O2 upon switching to the subsequent lean phase, as evidenced by the evolution of N2, N2O and CO2. In contrast, negligible product evolution is observed during the lean phase in the presence of water. This is consistent with a rapid hydrolysis of NCOs to NH3, which results in a deeper regeneration of the catalyst due in part to the reaction of the NH3 with stored NOx. The data reveal more efficient utilization of CO for reducing NOx in the presence of water which further underscores the NCO mechanism. Phenomenological pathways based on the data are proposed that describes the cyclic reduction of NOx by CO under dry and wet conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Diesel and lean burn gasoline engines are gaining increased attention lately owing to their higher fuel efficiency and lower CO2 emissions than stoichiometric engines. However, they are a major source of NOx emissions and as a result are subject to increasingly stringent emission standards worldwide, notably in Europe (emerging Euro 6 rules) and the USA. Unfortunately, the three way catalyst emission aftertreatment technology used for stoichiometric gasoline engines is ineffective in reducing NOx in the presence of excess O2. This scenario has led to an extensive research in the development of lean NOx reduction technologies, including Selective Catalytic Reduction (SCR) of NOx and NOx storage reduction (NSR).

Ammonia-based SCR is an effective lean NOx reduction technology employing Fe- and Cu-exchanged zeolite and vanadia catalysts [1, 2]. SCR is primarily suited for heavy-duty vehicles and engines since the fixed cost of the aqueous urea feed system is too high for light-duty applications [3]. In contrast, NSR, carried out in the Lean NOx trap (LNT) is suitable for light-duty diesel engines. Typical LNT catalysts consist of a high surface area support (γ-Al2O3), precious metals (Pt, Rh) and a storage component (alkali/alkaline earth metal oxides like BaO). The LNT is operated with lean-rich cycling; NOx is stored on the storage component during the longer lean phase and the trapped NOx is then reduced on the precious metals by reductants like CO, H2 and HC’s during the abbreviated rich phase. The main N-containing products are N2 (desired) and byproducts NH3 and N2O. Emerging in some applications is the combined LNT/SCR technology in which NH3 is generated in situ during the LNT regeneration and is consumed through reaction with NOx in the downstream SCR. Whether a stand-alone LNT or one combined with SCR, NH3 is a critical species whose formation, reaction mechanism and kinetics must be fully understood to develop optimal LNT design and operating strategies.

A large number of studies have investigated the mechanisms, kinetics and catalyst performance features of NOx storage [4–9] and reduction [10–13]. A review captures more recent developments [14]. The NOx reduction chemistry using H2 as the reductant is by now well established; among other features, ammonia is a major intermediate during the catalytic regeneration of stored nitrates by H2 under isothermal conditions [11, 13, 15]. A H2 front moves down the monolith length as nitrates/nitrites are regenerated by a two-step reaction mechanism, generating NH3 first, which then reacts further with stored NOx species and adsorbed oxygen to make N2. Progress has been made in understanding the behavior of other reductants like CO and hydrocarbons [16–18], but more work is needed to unravel the complex chemistry characterized by coupled reaction chemistry and transport effects. When using CO as a reductant, NH3 is formed in addition to N2 and N2O without any H other than that in H2O being fed to the catalyst [19]. In such a case two major routes to NH3 formation are possible. The first is by the water–gas shift (WGS) reaction of CO and H2O to give CO2 and H2, the latter of which then reacts with NO to give NH3. A second pathway is through reaction between NO and CO forming surface isocyanates (–N=C=O)/cyanates (N≡C–O–) [20], which are readily hydrolyzed to form NH3 in the presence of water. The contribution of both the pathways is of significance because each proceeds in the presence of high exhaust concentration of H2O (5–15 %).

Table 1 summarizes a few surface IR measurements that have shown the existence of isocyanate and cyanate species formation during the reduction of NO by CO on precious metals both unsupported and supported on various oxides including alumina and silica. Unland [20] first reported the formation of isocyanate species during the interaction of NO and CO on Pt/Al2O3 through infrared spectra of species adsorbed on the catalyst. Solymosi and co-workers [21–25, 29] studied the formation and stability of isocyanates during the reaction of NO and CO on various precious metals (Pt, Pd, Rh), both unsupported and supported on various oxides. They showed through infrared studies that NCO species are formed on the precious metals through the reaction of gas phase CO and adsorbed N formed in the dissociation of adsorbed NO, and that these isocyanates are highly unstable on precious metals, readily dissociating to adsorbed N and CO. On supported catalysts (Al2O3, SiO2), the migration of NCO from the precious metal onto the support is a very fast process. Moreover, these isocyanates are thermally stable on the support under dry conditions. Miners et al. [30] studied the NO + CO reaction on Pt(100) using in situ infrared absorption spectroscopy (IRAS) and observed isocyanate formation over a narrow temperature range of 380–400 K. They proposed that NCO formation becomes favorable once the concentration of N atoms on the surface is low and, more importantly, when the diffusion of these atoms becomes severely hindered by the high coverage of CO. They further suggested that the dissociation of NCO species requires vacant sites. Miyadera and co-workers [27, 28] studied the formation of NCO and its reactivity with NO, O2 and NO + O2 mixtures on Ag/Al2O3 by a pulse reaction technique and an in situ diffuse reflectance infrared Fourier transform spectroscopy. Forzatti and co-workers [31, 32] studied the reduction of previously stored NOx by CO on Pt–Ba/Al2O3 both in the presence and absence of water by means of transient response methods. They proposed a two-step reaction scheme wherein the stored nitrates are reduced to nitrites and surface isocyanate/cyanate species; these species further react with residual nitrites to give N2. In the presence of H2O the isocyanates are readily hydrolyzed to ammonia. They will also react with O2 and/or NO, NO2 to give N2, N2O and CO2 [33–37]. Burch and co-workers [38, 39] studied the reduction of NOx by CO and H2 on Ag/Al2O3 catalyst and showed that two types of isocyantes species are formed on the oxide support; an active isocyanate species close to the metal crystallite—support interface, and a spectator isocyanate species far from the interface, especially during prolonged exposure to the reductant CO. Their study suggests that while a high surface concentration of isocyanates may be measured, this does not imply that all of these species are active intermediates during the reduction of NOx by CO. Rather, the isocyanate spectators may in fact reduce the overall NOx storage capacity of the catalyst. Recently a few research groups [31, 32, 40–43] studied the reduction of stored NOx by CO over Pt–BaO/Al2O3 and Pt–K/Al2O3 catalysts and suggested that cyanate/isocyanate ad-species could act as a precursor to N2 formation as they can reduce the stored nitrates/nitrites. They also suggested that rate of isocyanate formation is faster than the rate of reaction between the isocyanates and stored nitrates/nitrites. These studies involved the pre-storage of NOx up to saturation followed by prolonged exposure to reductant (1–10 min). This procedure is not typical of conventional NSR operation and may lead to significant accumulation of isocyanates, complicating the interpretation of their reactivity.

In our recent study [19], differential steady-state kinetics experiments revealed the existence of CO inhibition for the CO + NO, CO + H2O, and CO + NO + H2O systems which was more significant in the absence of H2O. We showed that the NH3 formation in the CO + NO + H2O system was consistent with the coupled NO + CO and WGS (CO + H2O → H2 + CO2) chemistries under anaerobic conditions. The data showed that CO adsorption/inhibition was more pronounced for the NO + CO reaction (reaction order is −1) than for the WGS reaction (reaction order is −0.23). The results suggest that during the steady state anaerobic reduction of NO by CO in the presence of water, NH3 is mainly produced by the reduction of NO by surface hydrogen formed as an intermediate during the WGS reaction and CO scavenges surface O to form CO2. Contribution by the isocyanate hydrolysis pathway appeared to be secondary under steady state conditions.

Here we extend the study to transient lean storage and reduction of NOx. The transient operation simulates typical NSR operation involving the fast lean–rich cycling conditions in which the storage lasts for about a minute and the regeneration for only a few seconds. The effects of temperature and feed composition are studied through a detailed investigation of the transient NOx and reductant conversion and product distribution trends. The roles of H2O and CO2 are studied, as they are the major components of actual exhaust. The transient experiments show convincing evidence of an isocyanate route involving the support/storage phase (Al2O3/BaO). The effects of various operating conditions like catalyst temperature and feed composition on the yield of NH3 provide further insight about the cyclic operation with CO as the reductant. Finally, a phenomenological mechanism is presented that builds on the current understanding of the cyclic reduction of NOx by CO under dry and wet conditions.

2 Experimental

2.1 Catalyst

The catalyst samples used for these experiments were monolith catalysts provided by BASF (Iselin, New Jersey). Larger cylindrical cores (D = 3.8 cm and L = 7.6 cm) were cut using a dry diamond saw to a smaller, nearly cylindrical shape (88 channels; D = 1.3 cm, L = 3.0 cm). The washcoat contained 1.13 % PGM (Pt, Rh), 24.5 % BaO, and remainder γ-alumina with an overall mass loading of 4.6 g/in.3 monolith. The washcoat was supported on a cordierite structure (62 channels/cm2). The sample was wrapped in Fiberfrax® ceramic paper that had been pretreated and then placed in a quartz tube flow reactor. The catalyst was not exposed to temperatures exceeding ca. 500 °C to avoid sintering and subsequent loss in activity.

2.2 Flow Reactor Set-Up

The experimental set-up used in this study is similar to the one used in previous studies [19] and comprised four major components: a feed system, a reactor system, an analytical system, and a data acquisition system. A bank of gas cylinders (Praxair) and mass flow controllers (MKS Inc.) were utilized to simulate the feed gas mixtures. A syringe pump (Teledyne Isco model 100DX) was used for injecting water into the reactor system. In order to achieve a constant feed rate of water, a needle valve was used to reduce the pressure while at high temperature, causing flash vaporization. Stainless steel tubing of 1/16 in. diameter was used to introduce the water vapor directly into the carrier gas stream by way of a bored-through fitting. The reactor system consisted of a quartz tube flow reactor positioned inside a Thermocraft™ tube furnace. The reactor temperature was monitored with three K-type stainless steel sheathed thermocouples (OD = 0.75 mm). One thermocouple measured the catalyst temperature (Tc) which was positioned within an internal monolith channel at the approximate mid-point of the monolith (radial and axial) while the gas feed (Tf) and outlet (To) temperatures were monitored by thermocouples positioned 1 cm upstream of the catalyst and the other 0.2 cm downstream of the catalyst, respectively.

All the gas lines were heated and maintained at 140 °C to prevent water condensation and to minimize adsorption of NH3. The total gas flow rate was 3 L/min, corresponding to a gas hourly space velocity of 42,000 h−1. The outlet NO, NO2, N2O, NH3, H2O, CO and CO2 concentrations were monitored by a FTIR spectrometer (Thermo Scientific, 6700 Nicolet). Analog signals from the thermocouples, pressure gauge and mass flow controllers were sent to a National Instruments module to digitize the signals. These data were recorded on a PC using Labview® Software while the FT-IR composition data was collected on another PC using OMNIC Software. In order to synchronize the outputs from FTIR analyzer and the Labview Software, tracer studies were carried out to determine the time delays and a lag of 6 s was accounted for. An overall N material balance enabled an estimate of the N2 selectivity.

2.3 Lean and Rich Cycling Experiments

Several integral experiments of three reduction phase mixtures were carried out over the temperature range of 150–400 °C: (i) CO; (ii) CO + H2O; and (iii) CO + H2O + CO2. Mass flow controllers were used to control the lean and rich phase concentrations. For the cycling experiments, the storage step comprised a feed containing 500 ppm NO and 4 % O2 in Ar (60 s), while the rich pulse contained varying concentrations of the reductant in Ar (10 s). For the experiments involving H2O and CO2, 5 % H2O and 3 % CO2 was added during the entire lean-rich cycle. The cycle-averaged results were obtained over at least 9 cycles after the system had reached a transient steady state. To reach a transient steady state, it took approximately 10–30 cycles depending on the conditions but minimally 40 cycles were run at each experimental condition. The total NOx stored (mol) per lean step was calculated by

where s denotes storage, t s is the storage time (s), \(F_{\text{NO}}^{\text{o}}\) (mol/s) is the feed rate of NO and \(F_{{{\text{NO}}_{\text{x}} }}\) (mol/s) is the sum of the effluent molar flow rates of NO and NO2. The cycle-averaged NOx conversion was calculated by

where t s+R is the total cycle time (s). The corresponding product selectivities to NH3 and N2O for the entire cycle are defined as

where \(F_{{{\text{NH}}_{ 3} }}\) and \(F_{{{\text{N}}_{ 2} {\text{O}}}}\) (mol/s) are the effluent molar flow rates of NH3 and N2O respectively. Since the concentration of N2 is not measured the product selectivity to N2 is defined as

3 Results and Discussion

3.1 Cyclic Reduction of NO by CO in the Absence of Water

The baseline catalyst performance was examined by conducting NO/O2 + CO cycling studies in the absence of H2O over a wide range of feed temperatures and CO feed concentrations. Cycle-averaged conversion and selectivity data in the absence of H2O will be reviewed first followed by a closer examination of representative instantaneous transient data. The lean phase comprised a mixture of 500 ppm NO and 4 % O2 with balance Ar for 60 s. The rich phase contained CO (in Ar) with CO feed concentration varied from 0.5 % (5,000 ppm) to 2.5 % (25,000 ppm) in 0.5 % increments.

Figure 1 shows the temperature dependence of the cycle-averaged conversion of NOx (a) and CO (b) and the product selectivity to N2O (c) and N2 (d) for four CO feed concentrations. The NOx conversion increased sharply between 200 and 250 °C, from level <10 % to a constant level that increased with the CO concentration. The CO conversion was nearly complete for temperatures exceeding 300 °C and CO concentrations <1.5 %, indicating reductant-limited conditions. Complete NOx conversion was obtained for 2 % CO and T ≥ 300 °C. The N2O selectivity exhibited a local maximum at 200 °C and, with N2 being the only other product, its selectivity had a local minimum at the same temperature. The product distribution was sensitive to temperature even in the range for which the NOx conversion was constant. For example, the N2 (N2O) selectivity sharply increased (decreased) with temperature between 200 and 400 °C. The selectivity was essentially independent of the CO feed concentration at higher temperatures, while the selectivities were quite sensitive to the CO concentration at low temperatures (T < 250 °C).

Conversion of a NOx and b CO and product selectivity to c N2O and d N2 as a function of reaction temperature during the cyclic reduction of NO by CO at various feed concentrations of CO during the rich phase (Lean: 500 ppm NO + 4 % O2, 60 s; Rich 0.5–2.0 % CO, 10 s; balance: Ar); Total flowrate 3,000 sccm

To examine the CO effect in more detail, a series of cycling experiments was carried out by varying the CO feed concentration during the rich pulse while keeping the feed temperature and lean phase composition constant. Figure 2 shows the cycle-averaged conversions of NOx and CO (a, b) and product selectivities to N2O and N2 (c, d) as a function of the CO feed concentration for temperatures in the 150–300 °C range. The T ≤ 200 °C conversion data show very low NOx conversion (<10 %) but somewhat higher CO conversions. For T ≥ 250 °C the NOx and CO conversions were significantly higher. The decreasing (increasing) dependence of CO (NOx) conversion with CO concentration reflects the shift from reductant to NOx limited conditions. At 300 °C complete conversion of CO was obtained at the lower feed CO concentrations (≤10,000 ppm) whereas nearly complete conversion of NOx was obtained at 20,000 ppm of CO. The N2O and N2 selectivities moderately decreased and increased with CO concentration, respectively (Fig. 2c, d) with the highest N2 selectivity (~82 %) achieved at 300 °C over the entire CO concentration range.

The transient dependencies of the measured products CO2 and N2O help to explain the trends in the cycle-averaged conversions and selectivities. Specific features of the temporal profiles of N2O and CO2 infer a rather complex reaction system. Before analyzing the data in detail it is instructive to present the following set of adsorption, desorption, and reaction steps. (We use the numbering system of our steady-state study [19]. Stable reactants and products are shown in bold.) The main reacting species adsorb and desorb on the precious metal sites (*):

A series of surface reaction steps occur, generating N2, N2O and CO2:

The measured temporal trends of N2O and CO2 over a complete lean-rich cycle leads to some interesting observations, suggesting a more complex mechanism than one represented by steps S1–S8. For example, experiments that we describe later suggest participation by isocyanate intermediates. Based on the previous studies reported in the literature, the isocyanates form on the PGM sites and migrate over to the support/storage phase:

where S denotes a site on the support or storage function. The above sequence of steps captures the main features of the NO + CO + O2 on Pt reaction system, including the competitive NO and CO adsorption, CO oxidation, NO reduction, and isocyanate formation. It should be noted that though the catalyst employed contains both Pt and Rh, we consider the role of the total precious metal content rather than the individual effect of Pt and Rh as this is beyond the scope of the current study. Moreover, the effect of Rh has been investigated by several research groups before and is expected to increase the WGS activity and also provides excellent NO bond scission activity when added to a Pt based catalyst [51, 52]. Rh is considered to be a better NOx reduction catalyst than Pt at lower temperatures (<250 °C) [50].

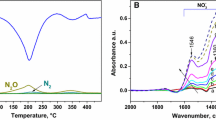

Figure 3 shows the N2O (a) and CO2 (b) temporal profiles over two lean-rich cycles for a CO feed concentration of 1 % (10,000 ppm) and temperature range of 150–300 °C. At low temperatures (150–200 °C) the cycle-averaged CO conversion is much higher than the NOx conversion; CO2 generation is significant (Fig. 3b) while that of N2O is comparatively much smaller (Fig. 3a). Two peaks were observed in the CO2 concentration at 150 and 200 °C, before and after the switch from the rich phase to the lean phase. In fact, more than half of the generated CO2 appeared during the lean phase, and most of that CO2 was formed during the first few seconds of the lean phase.

Several features of the data in Fig. 3 are consistent with a periodic process dominated by strongly bound CO on Pt and Rh. At low temperature a high fractional CO coverage of the precious metal sites inhibits the adsorption and reaction of NO, key sequential steps for NO reduction [47]. Under these conditions CO oxidation, comprising steps S2, S2′, and S8, is dominant because the high coverage of CO inhibits the adsorption of NO (S1). The resulting low coverage of NO* means that the rates of subsequent steps like NO* dissociation (S3) and reactions between NO* (S4) and N* (S5) are negligible. By the end of the rich phase the catalyst surface is occupied by CO which, upon the introduction of the lean phase containing excess O2, is oxidized to CO2. Thus, most of the CO conversion observed in this lower temperature range is due to the oxidation of adsorbed CO by O2 rather than by the reduction of NO. The difference in the extent of CO + O2 and CO + NO reactions is due in part to the much higher gas phase concentration of O2(4 %) compared to NO(500 ppm). At higher temperatures (≥250 °C) the inhibition by CO is diminished due to its increased desorption rate. The resulting lower coverage of CO enables more NO to adsorb and react. This is evidenced by the large increase in N2O production at 250 and 300 °C (Fig. 3a).

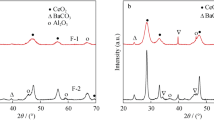

It is well established in the literature that stable isocyanates (–NCO) are formed during the reduction of NO by CO on conventional Pt catalysts supported on oxides [20, 44]. Isocyanate formation proceeds through NO* dissociation (S3), followed by reaction of N* and CO* with reversible migration to the support (S); steps S9–S11. Previous studies have shown evidence for isocyanate participation during NSR on Pt/Ba catalysts like the Pt–Rh/Al2O3 catalyst used in the current study. The presence of a NOx storage material (BaO) provides additional binding sites for the mobile isocyanates based on findings from in situ IR studies [40]. Nova and co-workers [31, 32, 40–43] suggested, based on reaction and surface IR measurements, that isocyanates are major intermediates during the reduction of NOx by CO on NOx storage catalysts and that the rate of isocyanate formation increases with CO concentration.

Other features of the temporal product data in Fig. 3, particularly those involving N2O, suggest a more complex mechanism than the one described by steps S1–S8, one that involves an intermediate isocyanate species and function of the support/storage phase. Two N2O peaks are noteworthy. The first N2O peak obtained during the rich phase is likely due to the above-mentioned Pt-catalyzed reactions; viz. reaction step S5 and associated steps. The role of CO as surface oxygen scavenger (steps S6, S8) frees-up sites for spillover of NOx species from the storage phase. It is the second N2O peak observed during the lean phase that is of more interest and relevance to isocyanate participation. By the end of the rich phase the Pt crystallites has been exposed to an anaerobic, reducing environment. Isocyanate species are likely to have formed by reaction of CO with adspecies originating from the storage phase (N* and NO*; steps S9, S10, S10′). These isocyanates either accumulate on the Pt crystallites or migrate to the adjacent Al2O3 support and/or storage material BaO. Upon the start of the subsequent lean phase containing O2, NO, and NO2, reactions are initiated between these species and surface isocyanates, producing N2, N2O, and CO2. These reactions result in a second peak in N2O and CO2. In fact, Fig. 3a also shows that at the higher temperature of 300 °C almost no N2O is formed during the rich phase while a large N2O peak is observed during the first few seconds of the lean phase. A few research groups showed through catalyst surface infrared studies that the isocyanate formation increases with temperature in this range and reported a maximum in the NCO formation at ~300 °C [32, 34]. Our reactor data are consistent with those observations; upon increasing the temperature from 250 to 300 °C, the surface –NCO concentration increases which, as described in more detail below, favors N2 formation during the rich phase. This helps to explain the drop in the N2O peak during the rich phase compared to that at 250 °C. Indeed, Fig. 4 compares the evolution trends of N2O at 250 and 300 °C for various CO feed concentrations during two consecutive lean rich cycles. It is seen that upon an increase in the CO concentration, the N2O peak increases at both temperatures. This is also attributed to an increase in the surface concentration of isocyanate/cyanate species resulting from the increase in CO concentration.

Evolution of N2O as a function of time during the reduction of NO by CO at a 250 °C and b 300 °C over two consecutive lean-rich cycles for different feed concentrations of CO during the rich phase (Lean 500 ppm NO + 4 % O2, 60 s; Rich: 0.5, 1, 1.5 % CO, 10 s; balance: Ar); Total flowrate: 3,000 sccm

With the data now described and sets of various chemical reactions presented in the context of steps S1–S13, the overall mechanism on the PGM/Ba/Al catalyst is explained as follows. The reader is referred to Fig. 5. NOx is stored in the form of nitrites [Ba(NO2)2] and nitrates [Ba(NO3)2] on the storage component during the lean phase [4, 8, 35, 41, 45, 46]. Additional reactions occur during this phase between gas phase species NO, O2, and NO2 and surface isocyanates formed during the previous regeneration phase. Some of the global reactions may include the following:

The reactions are represented as gas-solid reactions, but it is likely that the NO and O2 adsorb and react on the Pt crystallites. Kameoka et al. [27] studied the reaction of surface isocyanates with NO, O2 and NO2 on Ag/Al2O3 and Al2O3 catalyst and observed that while some N2 formation was observed on just the Al2O3 support in the absence of Ag metal, the reactions appeared to be mostly Ag-catalyzed. Upon the switch to the rich phase, CO reduces the stored nitrates to surface intermediates like nitrites and isocyanate/cyanate species in addition to N2 and N2O [18, 34]. The reduction is thought to proceed catalytically through the reaction of CO* with NOx species that spill over from the storage phase to the precious metal crystallites. It is convenient to represent the complex spillover and catalytic process by global reactions between CO and barium nitrate:

The barium isocyanate species so formed can further react with the other surface species like nitrates and nitrites to give N2 and N2O, as represented by the following reactions:

These global reactions lump together a myriad of surface steps, including nitrite/nitrate decomposition, NO/NO2 spillover from the storage material to the Pt crystallites, and Pt-catalyzed reactions. An inspection of the stoichiometries for reactions R9 and R10 indicates that the ratio of surface isocyanates/barium nitrate for N2O formation is 1 while for N2 formation is 1.67. Thus, a higher surface concentration of isocyanate favors N2 formation. A similar observation can be made for the formation of N2 and N2O from reaction between isocyanates and nitrites; i.e., a higher surface isocyanate concentration favors N2 formation over N2O formation [stoichiometric ratio of isocyanates/nitrites is 1 for N2 (R12) and 0.5 for N2O (R11)].

An alternative, non-isocyanate mechanism leading to the evolution of second peak in N2O during the lean phase involving the direct catalytic reduction of NOx by adsorbed CO can be ruled out with targeted experiments. We carried out a steady-state experiment in which a mixture containing CO, NO, and O2 with respective concentrations of 10,000, 500 ppm, and 5 % was fed over the same Pt–Rh/Al2O3 catalyst at 250 °C. Negligible conversion of NO (<5 %) was observed although complete conversion of CO was observed. This suggested that conventional Pt-catalyzed chemistry involving adsorbed NO and CO is negligible under lean conditions. This result gives more credence to reactions involving adsorbed isocyanates during the lean storage step when N2O and CO2 are evolved.

A revealing experiment that helps to confirm a role of isocyanates is to set up the conditions that synthesize surface NCO species, following procedures similar to the aforementioned spectroscopic studies [31, 32], and then to follow with different types of reacting species. This was done by subjecting the catalyst to sustained lean-rich switching at 250 °C involving a lean feed [NO(500 ppm)/O2(5.0 %)/Ar] and a rich feed [CO(1.5 %)/Ar] until a transient steady state is reached. Then, at the end of the final rich phase, the catalyst was exposed to several different feeds: Pure Ar; NO(500 ppm) in Ar; O2(4 %) in Ar; and NO(500 ppm) + O2(4 %) in Ar. Fig. 6 compares the evolution of CO2 (6a) and N2O (6b) immediately upon the switch to the different feed gases. When exposed only to the inert carrier Ar, the catalyst released CO2. A much smaller amount of N2O was released after a 5 s delay. Similar evolution profiles were obtained with the three other feed gases, the one difference being the yields of CO2 and N2O were higher. These data are consistent with two reaction pathways. The release of CO2 in an inert atmosphere is evidence for the thermal decomposition of BaCO3:

The delayed evolution of N2O may suggest the decomposition of surface isocyanates by a decomposition and spillover process. The addition of O2, NO, or NO/O2 leads to a larger but nearly identical amount of CO2 evolved with some differences in the evolution of N2O. These data suggest the accumulation of NCO* and NCO–S species which decompose and/or react at elevated temperatures. The magnitude of CO2 evolved cannot be explained by the accumulation of NCO on the Pt crystallites alone and could be a combination of BaCO3 decomposition, NCO reaction with lean phase gases and also the oxidation of CO adsorbed on the catalyst surface at the end of the rich phase. Differences in the evolved N2O concentration indicate some involvement of NO, NO2 reacting with NCO species. Nevertheless, it is clear that N2O and CO2 generation during the lean phase, which is sustained throughout the lean phase if the CO pulse concentration and temperature are sufficiently high (Figs. 4, 6), is evidence for an isocyanate pathway.

3.2 Cyclic Reduction of NOx by CO in the Presence of Excess H2O

The cyclic reduction of NOx by CO experiments were repeated in the presence of 5 % water over the entire lean and rich cycle. Figure 7a reports the cycle-averaged NOx conversion as a function of temperature for lean-rich switching using three different reductants; H2, CO, and CO + H2O. These experiments are intended to check if H2O has a promotional effect, such as through the aforementioned WGS reaction or the hydrolysis of isocyanate pathway. The data show that the H2/Ar reductant mixture gave the highest NOx conversion over the entire temperature range (Fig. 7a) and that the generated NH3 is a monotonic decreasing function of the temperature (Fig. 7c). These results agree with previous reports [34]. The lower bound NOx conversion was obtained when the 1.5 % H2 was replaced by 1.5 % CO. The light-off temperature of CO oxidation on Pt is about 200 °C at these concentrations, so it is not surprising that the sharp jump in the CO conversion occurs in this range. When 5 % H2O was added to the 1.5 % CO/Ar feed a notable increase in the cycle average NOx conversion was observed, especially at temperatures ≥250 °C.

Comparison of a Reactant NOx conversion, b Reactant CO conversion and c Product selectivity to NH3 during the reduction of NOx by H2 and by CO under dry conditions as well as in the presence of H2O, as a function of the reaction temperature (Lean 500 ppm NO + 4 % O2, 60 s; Rich 1.5 % CO or 1.5 % H2 or 1.5 % CO + 5 % H2O, 10 s; balance Ar); Total flowrate 3,000 sccm

At low temperatures (150–200 °C) the addition of water had only a negligible effect, indicating that the reactions were slow and likely inhibited by CO. At these conditions the rate of the WGS reaction is quite low and therefore the production of H2 is negligible (Fig. 7b). Along the same lines, were isocyanates formed under these conditions, one would expect a notable increase in the NH3 through hydrolysis and a subsequent increase in NOx reduction, but this is not the case. Thus, strongly bound CO inhibits the formation of NCO by inhibiting NO adsorption. The main effect of water addition at these low temperatures is the reduction in the NO oxidation activity of the catalyst during the lean phase as indicated by a decrease in the amount of NO2 evolved when compared to same in the absence of water at the same temperature (not shown here). The addition of water has a detrimental effect on the oxidation activity of the catalyst and hence the drop in NO2 concentration [47]. Most of the CO converted is due to its reaction with O2 as indicated by the CO conversion being appreciably higher than the NOx conversion at low temperature. This is consistent with the earlier results without water (Fig. 2).

At higher temperatures (≥250 °C) a significant promotional effect of water was observed. Over the 250–400 °C range the NOx conversion increased by about 15 % points when H2O was added (Fig. 7a). The NOx conversion approached that of the H2-only reductant results. Fig. 8 shows the effect of the CO feed concentration on the NOx conversion (8a), CO conversion (8b), and product selectivity (8c) both in the absence and presence of H2O(5 %) in the feed at 250 and 300 °C. A promotional effect of H2O was observed for CO concentrations ≥15,000 ppm (1.5 %). Interestingly, the NOx conversion increase was accompanied by a slight decrease in CO conversion under these conditions. The product distribution trends (Fig. 8c) reveal that the addition of H2O leads to NH3 generation for CO concentrations above 1 %, with the NH3 concentration increasing with CO concentration at the expense of the N2 selectivity. We elaborate on each of these findings below.

Comparison of conversion of a NOx at 250 and 300 °C and b CO at 250 °C during the reduction of NOx by CO both in the presence and absence of excess water and also during the water gas shift reaction as a function of feed concentration of CO (Lean 500 ppm NO + 4 % O2, 60 s; Rich 0.5–2.5 % CO, 10 s; balance 5 % H2O: balance Ar). c Corresponding dependence of product selectivity to N2, N2O and NH3 (Lean 500 ppm NO + 4 % O2, 60 s; Rich 5,000–25,000 ppm of CO, 10 s; with and without 5 % H2O: balance Ar)

Interestingly, the cycle averaged NH3 selectivity exhibited a local maximum at an intermediate temperature (Fig. 7c). At low temperatures (<250 °C) the NOx conversion is quite low (Fig. 7a) as is the NH3 selectivity (Fig. 7c). For reasons discussed earlier, strong adsorption by CO inhibits NSR. Moreover, the low WGS activity means that little H is available for NH3 formation. Similarly, CO inhibits NCO formation. For temperatures above 250 °C the yield of NH3 is higher for the CO + H2O feed than the H2 feed. This counterintuitive result can be explained by differences in the spatial dependence of NH3 production being different in the two cases. Previous spatiotemporal studies with H2 as the reductant have shown that NH3 formation occurs in the upstream section of the reactor. In its role as a H carrier, the NH3 travels downstream and reacts with stored NOx. This reduces the NH3 selectivity and yield. In contrast, with CO + H2O as the reductant feed, NH3 generation is more spatially protracted because of the additional chemistry involved in generating H2 and/or isocyanates during the rich pulse. As a result, NH3 so formed encounters a shorter zone containing stored NOx species. This explanation requires experiments that probe the spatial profile of NH3 and are currently under investigation in our lab.

The enhancement in the NOx conversion as a result of the H2O addition is attributed to either of two mechanisms. As described earlier, the first mechanism is the formation of the more efficient NOx reductant H2 via the WGS reaction. The second mechanism is the hydrolysis of the intermediate isocyanate species by the excess water, leading to the enhanced regeneration of the storage sites.

The WGS mechanism is highlighted as follows (details as related to the steady state were described in [19]). Surface hydrogen produced by a combination of steps involving surface H2O and CO, through a COOH* intermediate [48], leading ultimately to NH3, as follows:

Thus, in addition to the direct reduction of NOx by CO (steps S1–S11), the WGS mechanism involves the generation of H* adatoms that participate in the reduction of NO* supplied by the stored NOx species through a spillover process.

On the other hand, the isocyanate hydrolysis involves the generation of NCO* species by reaction of CO* with N* or NO* (steps S9, S10, S10′), which migrate to the support and/or storage phase (step S11) and are hydrolyzed to NH3. Global reactions that occur are as follows:

It may also be speculated that the addition of water could eliminate the formation of spectator isocyanates observed by Burch and co-workers [38, 39] as the isocyanates are instantaneously hydrolyzed to NH3, thereby preventing their buildup on the catalyst while preserving the NOx storage capacity of the catalyst.

A comparison of the temporal product evolution trends in the presence and absence of water provides compelling evidence for the isocyanate hydrolysis mechanism. Figure 9 compares the temporal evolution of N2O during the reduction of NOx by CO both under dry and wet conditions at 250 °C. Under otherwise identical conditions, most of the N2O is generated during the rich phase in the presence of water whilst most of it is generated during the first few seconds of the lean phase in the absence of water. This trend is difficult to explain with coupled NOx reduction by WGS generated H2. One would expect that N2O, formed by step S5, or by NH3 reacting with O* downstream, would lead to N2O primarily appearing during the rich phase. That has been the reported temporal behavior with H2 as the reductant [49]. The N2O peak features can be best explained by the involvement of surface isocyanates. During the dry reduction of NO by CO, the catalyst surface accumulates NCO species, some remaining on the metal crystallites with the remainder migrating to the Al2O3 support and/or the BaO storage function. During lean-rich switching, a periodic steady state is established in which active isocyanates are formed and consumed, while spectator isocyanates reach a steady level, presumably further removed from the metal crystallites. During the lean phase the active isocyanate species react with the NOx/O2 and/or nitrates/nitrites to give N2, N2O and CO2, as we have shown earlier in the context of Fig. 6. In contrast, in the presence of water the isocyanates are readily hydrolyzed to NH3 during the rich phase and the product NH3 may react further with stored NOx and surface oxygen, forming N2 and N2O. The hydrolysis completely consumes the NCO species by the end of the rich phase. As a result, negligible N2O is detected during the first few seconds of the subsequent lean phase because of the dearth of isocyanates in the vicinity of the Pt crystallites.

The slight decrease in CO conversion that accompanies the increase in NOx conversion upon the addition of H2O provides further evidence that favors the isocyanate regeneration mechanism while diminishing the importance of the WGS route. At first glance one would expect the CO conversion to increase if the NOx conversion increases. Instead, the NOx (CO) conversion increase (decrease) suggests a more efficient reductant utilization is achieved with the addition of water. Consider the following explanation. CO may reduce NO to N2 or N2O via the overall reactions

or may be oxidized by O2 via

Now, for CO feed concentrations exceeding 3,000 ppm, CO is in stoichiometric excess: The lean feedf containing 500 ppm NO fed for 60 s requires a rich feed containing 3,000 ppm CO fed for 10 s to achieve the CO/NO = 1 required for NO reduction to N2 (reaction R18). That the addition of H2O results in an increase in NOx conversion with a nearly constant or decreasing CO conversion means that the selectivity of lean NOx reduction is more efficient. This is contrary to what would be encountered with a WGS mechanism, which requires that CO and H2O be converted to CO2 and H2, and that the H2 so generated is used to reduce NO. The NO and CO conversions in such a system should, in effect, be coupled. Figure 8b reports the CO conversion for the WGS reaction carried out periodically. There is a finite, nonzero CO conversion for all CO concentrations. Based on the above reasoning, one would expect that the CO conversion during NSR in the presence of water should increase by approximately the value of the WGS conversion when compared to the dry reduction of NOx by CO. Instead, the CO conversion decreases. On the other hand, the isocyanate generation and hydrolysis pathway utilizes CO more efficiently through the sink-source function of the support/storage materials. NCO that is generated during the regeneration with CO may migrate to the support. In the absence of water a fraction of the NCO accumulates on the storage function and becomes spectators. In the presence of water the NCO species become reacting species due to their mobility and reactivity with H2O. This enables CO to be more selectively utilized; i.e. the NCO that is formed serves as an intermediate for NH3 and N2 production, rather than a spectator in the absence of H2O.

It should also be noted that the decrease in the CO conversion upon the addition of water is more pronounced at 300 °C than it is at 250 °C. This is consistent with the findings from Nova et al. [32, 34] who reported that the surface NCO formation is at a maximum at ~300 °C. Thus, the temperature increase from 250 to 300 °C should lead to increased generation of isocyanates, which in turn result in increased generation of NH3 from the NCO hydrolysis. The NH3 so formed can then regenerate additional stored NOx. Thus, the enhanced CO utilization through isocyanate formation may be more significant at 300 °C.

The addition of water leads to a decrease in N2O in the same temperature range, which suggests another benefit of the isocyanate mechanism. Figure 10 compares the evolution of N2O and NH3 during a rich phase (60–70 s) using CO as the reductant in the presence of excess water at 250 and 300 °C. The data show that the N2O yield decreases sharply as the temperature increases. This may be explained by the enhanced formation of NH3 from the hydrolysis of isocyanates which increases the ratio of NH3/NOx during the rich phase. A higher NH3/NOx stoichiometrically favors the formation of N2 rather than N2O as given by the following reactions:

Thus, the selectivity to N2O drops and also the amount of NH3 detected towards the end of the rich phase increases with the rise in temperature.

The mechanism of NOx reduction by CO in the presence of water is shown in the schematic of Fig. 11. In the presence of water the isocyanates are readily hydrolyzed to NH3 and hence no surface species are carried over from the rich phase after switching to the lean phase. The NH3 also reduces the stored NOx giving a deeper regeneration and enhances the NOx reduction. These experimental results suggest that the surface NCO species are important reaction intermediates at moderate to higher temperatures (>200 °C) during the cyclic reduction of NOx by CO.

4 Conclusions

During NSR on Pt–Rh/BaO/Al2O3, NH3 may be generated by two major routes, the WGS route, in which NH3 is generated by the catalytic reduction of NO by H2 produced from the WGS reaction, and the isocyanate hydrolysis route, in which NH3 is generated by the hydrolysis of surface isocyanates that are formed by the catalytic reaction of NO and CO. We have carried out a systematic study of the cyclic lean storage and reduction in the presence and absence of excess water to elucidate the NOx and CO conversion and integral selectivity trends with particular focus on the NH3 formation mechanism. New insight has been gained about the role of intermediate isocyanate species during the cyclic reduction of NOx by CO. Under the transient aerobic conditions created by the lean-rich cycling, the generation, storage, supply, and reaction of isocyanates emerges as an important route guiding the NOx reduction.

The transient reactor experiments support a mechanism in which isocyanates (–NCO) are formed during the reaction of NO and CO on the precious metal (PGM) and spill over to the neighboring Ba and Al sites. The isocyanates so formed further reduce the other stored NOx to N2 and N2O depending on the surface concentration of isocyanates and nitrates/nitrites through precious metal catalyzed reactions. In the absence of water the catalyst is not completely regenerated during the rich phase and the catalyst surface still has surface isocyanates at the end of the rich phase. Moreover, spectator isocyanates may migrate from the PGM-support interface, which may poison the NOx storage capacity of the catalyst. The active isocyanates close to PGM-support interface react with NO and/or O2 upon the switch to the lean phase and form N2, N2O and CO2. As a result, NOx is reduced both during the rich phase and also during the first few seconds of the successive lean phase. Higher surface concentration of isocyanates favors N2 formation over N2O.

On the addition of water to the NO–CO transient reduction system, isocyanates are readily hydrolyzed to NH3 and CO2 during the rich phase and the NH3 further reduce the stored NOx. Water also eliminates the buildup of spectator isocyanates on the catalyst surface and leads to the more efficient utilization of the reductant CO while preserving the storage capacity of the catalyst. As a result, the catalyst is deeply regenerated during the rich phase giving an enhancement in NOx conversion with negligible net product evolution observed during the subsequent lean phase.

In summary, this study provides new data and insight about the cyclic storage and reduction of NOx with CO as the reductant. The data reported here support the recent literature that isocyanates are important intermediate species and that the role of water enhances the utilization of the CO. Spatiotemporal studies are currently underway in our laboratory to build on the findings here to identify the best routes to N2 by lean NOx reduction.

References

Ozkan US, Cai YP, Kumthekar MW, Zhang LP (1993) J Catal 142:182–197

Ozkan US, Cai YP, Kumthekar MW (1994) J Catal 149:390–403

Takahashi N, Shinjoh H, Lijima T, Suzuki T, Yamazaki K, Yokota K (1996) Catal Today 27:63–69

Epling WS, Campbell LE, Yezerets A, Currier NW, Parks JE (2004) Catal Rev Sci Eng 46:163–245

Hodjati S, Petit C, Pitchon V, Kiennemann A (2000) Appl Catal B 27:117–126

Schmitz PJ, Baird RJ (2002) J Phys Chem B 106:4172–4180

Cant NW, Patterson MJ (2002) Catal Today 73:271–278

Fridell E, Skoglundh M, Westerberg B, Johansson S, Smedler G (1999) J Catal 183:196–209

Nova I, Castoldi L, Lietti L, Tronconi E, Forzatti P, Prinetto F (2004) J Catal 222:377–388

Nova I, Lietti L, Castoldi L, Tronconi E, Forzatti P (2006) J Catal 239:244–254

Lietti L, Nova I, Forzatti P (2008) J Catal 257:270–282

Nova I, Lietti L, Forzatti P (2008) Catal Today 136:128–135

Cumaranatunge L, Mulla SS, Yezerets A, Currier NW, Delgass WN, Ribeiro FH (2007) J Catal 246:29–34

Harold MP (2012) Curr Opin Chem Eng 1:303–311

Mulla SS, Chaugule SS, Yezerets A, Currier NW, Delgass WN, Ribeiro FH (2008) Catal Today 136:136–145

Poulston S, Rajaram RR (2003) Catal Today 81:603–610

Liu ZQ, Anderson JA (2004) J Catal 228:243–253

Abdulhamid H, Fridell E, Skoglundh M (2004) Top Catal 30(1):161–168

Dasari PR, Muncrief R, Harold MP (2012) Catal Today 184:43–53

Unland ML (1973) J Phys Chem 77:1952–1956

Rasko J, Solymosi F (1980) J Chem Soc Farad Trans I(76):2383–2395

Rasko J, Solymosi F (1981) J Catal 71:219–222

Solymosi F, Sarkany J, Schauer A (1977) J Catal 46:297–307

Solymosi F, Volgyesi L, Sarkany J (1978) J Catal 54:336–344

Solymosi F, Rasko J (1980) J Catal 63:217–225

Hecker WC, Bell AT (1984) Appl Catal 85:389–397

Kameoka S, Chafik T, Ukisu Y, Miyadera T (1998) Catal Lett 55:211–215

Ukisu Y, Miyadera T, Abe A, Yoshida K (1996) Catal Lett 39:265–267

Solymosi F, Rasko J (1980) J Catal 10:19–25

Miners JH, Bradshaw AM, Gardner P (1999) Phys Chem Chem Phys 1:4909–4912

Forzatti P, Lietti L, Nova I, Morandi S, Prinetto F, Ghiotti G (2010) J Catal 274:163–175

Nova I, Forzatti P, Prinetto F, Ghiotti G (2010) Catal Today 151:330–337

Unland ML (1973) Science 179:567–569

Szailer T, Kwak JH, Kim DH, Hanson JC, Peden CHF, Szanyi J (2006) J Catal 239:51–64

Lesage T, Verrier C, Bazin P, Saussey J, Daturi M (2003) Phys Chem Chem Phy 5:4435–4440

Bion N, Saussey J, Haneda M, Daturi M (2003) J Catal 217:47–58

Scholz CML, Maes BHW, De Croon M, Schouten JC (2007) Appl Catal A 332:1–7

Chansai S, Burch R, Hardacre C, Breen J, Meunier F (2010) J Catal 276:49–55

Chansai S, Burch R, Hardacre C, Breen J, Meunier F (2011) J Catal 281:98–105

Nova I, Lietti L, Forzatti P, Frola F, Prinetto F, Ghiotti G (2009) Top Catal 52:1757–1761

Castoldi L, Lietti L, Forzatti P, Morandi S, Ghiotti G, Vindigni F (2010) J Catal 276:335–350

Castoldi L, Lietti L, Bonzi R, Artioli N, Forzatti P, Morandi S (2011) J Phys Chem C 115:1277–1286

Morandi S, Ghiotti G, Castoldi L, Lietti L, Nova I, Forzatti P (2011) Catal Today 176:399–403

Unland ML (1973) J Catal 31:459–465

Kabin KS, Khanna P, Muncrief RL, Medhekar V, Harold MP (2006) Catal Today 114:72–85

Muncrief RL, Khanna P, Kabin KS, Harold MP (2004) Catal Today 98:393–402

Toops TJ, Smith DB, Epling WS, Parks JE, Partridge WP (2005) Appl Catal B 58:255–264

Chen Y, Wang HF, Burch R, Hardacre C, Hu P (2011) Faraday Disc 152:121–133

Clayton RD, Harold MP, Balakotaiah V (2009) AIChE J 55:687–700

Yongjie R, Harold MP (2011) ACS Catal 1:969–988

Theis J, Ura J, McCabe RW (2007) SAE Trans 2007-01-1055

Gandhi HS, Graham GW, McCabe RW (2003) J Catal 216:433–442

Acknowledgments

This research was supported by grants from the Texas Commission on Environmental Quality (TCEQ) and the Department of Energy Office of Vehicle Technologies (DE-EE0000205). We also acknowledge the catalyst division of BASF (Iselin, NJ) for providing the catalysts used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dasari, P., Muncrief, R. & Harold, M.P. Cyclic Lean Reduction of NO by CO in Excess H2O on Pt–Rh/Ba/Al2O3: Elucidating Mechanistic Features and Catalyst Performance. Top Catal 56, 1922–1936 (2013). https://doi.org/10.1007/s11244-013-0129-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-013-0129-8