Abstract

A high-frequency clonal propagation protocol was developed for Curcuma angustifolia Roxb., a high valued traditional medicinal plant. Axillary bud explants of C. angustifolia were explanted on Murashige and Skoog (MS) medium fortified with 4.4–22.2 µM 6-benzyladenine (BA), 2.9–5.7 µM indole-3-acetic acid (IAA), 2.3–23.2 µM kinetin (Kin), 2.7–5.4 µM naphthalene acetic acid (NAA) and 67.8-271.5 µM adenine sulphate (Ads) in different combinations. The maximum number of shoots per explants (14.1 ± 0.55) and roots per shoot (7.6 ± 0.47) was achieved on media containing 13.3 µM BA, 5.7 µM IAA and 135.7 µM Ads. Stability in phytomedicinal yield potential of micropropagated plants was assessed through GC–MS and HPTLC. Gas chromatogram of essential oil of conventional and micropropagated plants of C. angustifolia had similar essential oil profile. HPTLC analysis of rhizome extracts of in vitro and field grown plants revealed no significant differences in the fingerprint pattern and in curcumin content. Genetic integrity of in vitro and field grown derived plants were evaluated with inter-simple sequence repeat (ISSR) primers and flow cytometry using Glycine max as an internal standard. A total of 1260 well resolved bands were generated by 12 ISSR primers showing monomorphic banding patterns across all plants analyzed. The mean 2C DNA content of conventionally and micropropagated plant was estimated to be 2.26 pg and 2.31 pg, respectively. As no somaclonal variations were detected in tissue culture plantlets, the present micropropagation protocol could be applied for in vitro conservation and large-scale production of C. angustifolia.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Curcuma angustifolia Roxb. (East Indian Arrowroot) belonging to family Zingiberaceae is a rhizomatous perennial flowering herb found throughout Eastern India, Central and Southern India (Sharma 2012). Traditionally, East Indian Arrowroot is used as a herbal remedy for healing various ailments such as kidney disorders, thirst, fever, flattening the body, leucorrhoea, headache and remedy for joint pains (Srivastava et al. 2006; Hemadri and Rao 1984). The starch of C. angustifolia used as Tugaksheeree is an important ingredient extensively used in the preparation of Ayurvedic medicines (Rajashekhara and Sharma 2010). The essential oil extracted from this plant possess numerous pharmacological activities like antifungal, antibacterial and antioxidant activities (Jena et al. 2017).

The conventional method of vegetative propagation of C. angustifolia is not satisfactory because of slow multiplication rate (Shukla et al. 2007) and high incidence of rhizomes to pathogenic diseases in field and storage conditions. Besides this, overexploitation of the plant from natural sources has resulted in unavailability of requisite quality planting material of C. angustifolia. Thus it was felt necessary to develop a high-frequency plant regeneration system for commercial production of C. angustifolia through tissue culture. Plant tissue culture is an efficient tool for the rapid multiplication and conservation of different plant species in a controlled environment for large scale production on a commercial scale (Sliwinska and Thiem 2007; Singh et al. 2011; Al Khateeb et al. 2012). Several thousands of plantlets can be multiplied from a single explant within a limited time duration as well as limited space under the controlled environment, without seasonal changes and climate all over the year (Akin-Idowu et al. 2009; Amoo et al. 2012). Efficient micropropagation protocols have been reported in several Curcuma species, such as C. longa (De Souza Ferrari et al. 2016), C. amada (Barthakur and Bordoloi 1992), C. aromatica (Sharmin et al. 2013), C. mangga (Raihana et al. 2011) and C. zedoaria (Anisuzzaman et al. 2008). However in C. angustifolia, existing tissue culture report (Shukla et al. 2007) necessitated further work on the establishment of high-frequency plant regeneration system for the commercial purpose.

For the commercial application of micropropagation techniques, it is a requisite to maintain genetic fidelity among in vitro regenerants, because a change in the in vitro culture can result in emergence of somaclonal variations (Larkin and Scowcroft 1981; Nayak et al. 2011). Therefore it is necessary to monitor the genetic fidelity of the in vitro regenerants after acclimatization to ex vitro conditions. DNA based markers are an efficient tool to check the genetic fidelity in micropropagated plants as they are unaffected by environmental conditions (Peredo et al. 2009). Polymerase chain reaction (PCR) based techniques like inter-simple sequence repeat (ISSR), simple sequence repeat (SSR), randomly amplified polymorphic DNA (RAPD), amplified fragment length polymorphism (AFLP), retrotransposon microsatellite amplified DNA polymorphism (REMAP) are being widely used to confirm genetic fidelity (Bairu et al. 2011; Aversano et al. 2011; Nayak et al. 2011). Among these DNA markers, ISSR markers are highly polymorphic, simpler, quicker and powerful methods for the evaluation of genetic integrity of tissue culture derived plants and overcomes most of the limitation of the other techniques (Viehmannova et al. 2016; Raji et al. 2017).

Further, now-a-days, flow cytometry analysis are used to detect genome size and ploidy changes among micropropagated plants (Bairu et al. 2011; Shilpha et al. 2014; Choudhury et al. 2014; Raji et al. 2017). Through, flow cytometry, it is possible to analyze large numbers of nuclei in a shorter time period (Viehmannova et al. 2016). It is difficult to genetically control the traits that are associated with biochemical characters (Nayak et al. 2011; Singh et al. 2011). Therefore, it is crucial to carry out stability assessment of phytomedicinal yield potential of in vitro regenerants of commercial important medicinal plants.

A previous report on in vitro propagation of C. angustifolia by Shukla et al. (2007) exclude any detailed analysis regarding the genetic integrity of micropropagated plants and assessment of their phytomedicinal yield potentials which is the most crucial aspect for commercial application of any micropropagated plant. For stability assessment of regenerants, a combination of several techniques should be used rather than using only one (Peredo et al. 2009; Nayak et al. 2011). Therefore, the present work was aimed to develop high-frequency plant regeneration protocol through axillary bud formation. Further evaluation of genetic stability of tissue culture derived plants of C. angustifolia was carried out by ISSR and flow cytometry analysis. GC–MS and HPTLC analysis was used to analyze the essential oil and curcumin content. The reported tissue culture technique would be of enough significance for large scale production of C. angustifolia for a stable supply of drugs of uniform quality for commercial use.

Materials and methods

Collection of plant materials

Healthy rhizomes of C. angustifolia collected from R-Udaygiri, Gajapati district, Odisha were maintained in the greenhouse of Centre for Biotechnology, Siksha ‘O’ Anusandhan (Deemed to be University, Odisha, India) until initiation of sprouting. Immature dormant rhizome axillary buds were excised with sharp blade and were washed properly with distilled water to remove dirt from the surface and then soaked in liquid detergent (Extran, Merck, Mumbai, India) for 3–5 min and subsequently rinsed with distilled water, which were used as the explants. Surface sterilization of explants were performed with 0.1% (w/v) Mercury chloride (HgCl2) solution for 8–10 min and followed by washing with autoclaved distilled water several times before inoculation.

Establishment of plant tissue culture

Surface sterilized explants were explanted aseptically on autoclaved basal medium of Murashige and Skoog (MS) (1962) containing 4.4–22.2 µM 6-benzyladenine (BA), 2.9–5.7 µM indole-3-acetic acid (IAA), 2.3–23.2 µM kinetin (Kin), 2.7–5.4 µM naphthalene acetic acid (NAA) and 67.8-271.5 µM adenine sulphate (Ads) in different combinations. The pH of all the media containing the varying combination of hormones was adjusted to 5.8. The media containing 0.8% (w/v) agar was then autoclaved at 121 °C and for 20 min. After inoculation, all the cultures were maintained at 25 ± 1 °C under a 16:8 h light/dark cycles provided by white fluorescent light with 50 µmol m2/s light intensity. After 8 weeks of culture in vitro, number of shoots per explants and number of roots per shoot were recorded. For in vitro multiplication, twenty explants were raised for each experiment and experiments were repeated three times. MS basal medium devoid of any plant growth regulators used as control.

Acclimatization

The in vitro regenerants having well-developed roots as well as shoots were taken out from the culture tube and washed properly. After washing, plantlets were further transplanted to pots containing soil, cow dung, and sand mixture in 1:1:1 ratio for acclimatization in the growth chamber at a high relative humidity (80–90%) and low temperature (24–25 °C) with 12 h photoperiod for 15 days. Finally acclimatized plantlets were later transferred to the field and grown to maturity. 2 year of field grown tissue culture derived and conventionally propagated plantlets of C. angustifolia were compared for different biochemical parameters.

Extraction of essential oil and GC–MS analysis

For GC–MS analysis of essential oil, rhizome and leaf of following plant material was selected: in vitro derived plants obtained from axillary buds and cultured on MS medium in the presence of 13.3 µM BA, 5.7 µM IAA and 135.7 µM Ads and maintaining it for 1 year by subculturing it every 8 weeks and then transferring to field for 2 years and conventionally propagated plants grown in field for 2 years was used for comparison. Essential oil was extracted using hydrodistillation according to the method of Guenther (1972) and the extracted essential oil was dehydrated over anhydrous Na2SO4. The analysis of essential oils was achieved by the Clarus 580 Gas Chromatograph (Perkin-Elmer, USA) coupled with a SQ-8 MS detector. Compounds separation was performed on Elite-5 MS capillary column (5% phenyl, 95% dimethyl polysiloxane, Perkin Elmer, USA) having 30 m length × 0.25 mm I.D. × 0.25 µm film thickness. Oven temperature was programmed at 60 °C then increased to 220 °C at 3 °C/min, and then finally kept at 220 °C for 7 min. The injector temperature was 250 °C. Helium was used as carrier gas with flow rate 1 mL/min. Transfer interface and source temperature programming was kept at 250 °C. The electron ionization source was used at 70 eV.

Gas chromatography (GC) analysis was done by Clarus 580 (Perkin Elmer, USA) gas chromatograph coupled with a Flame ionization detector (FID). Injector and detector (FID) temperatures were set at 250 °C. All programming temperatures were similar to that of the GC–MS. Further, the area percentages of the detected compounds were computed from the GC-FID peak areas. Identification of various constituents was based on by comparing the mass Spectra (MS) data obtained from each constituent with NIST library. Further identification was supported by calculating relative retention indices (RRI) using homologous n-alkane (C8–C20) series as external references and comparing its values with the published literature (Adams 2007). RI was determined according to the equation of Van den Dool and Kratz (1963).

Sample preparation and HPTLC analysis

In vitro regenerants obtained from axillary buds cultured on MS medium supplemented with 13.3 µM BA, 5.7 µM IAA and 135.7 µM Ads and maintaining it for 1 year by subculturing it every 8 weeks and then transferring to field for 2 years. For comparison conventionally propagated plants grown in field for 2 years was used. The rhizomes of both the plants were powdered and were subjected to extraction in methanol in soxhlet apparatus for 6 h. Then all the individual extract were combined and were concentrated under vacuum using Rotary evaporator. The extract was then stored in airtight container at 4 °C for further analysis. 1 mg of curcumin (analytical grade, purity > 98%, Sigma Aldrich, USA) was diluted in 10 ml HPLC-grade methanol. Similarly, 10 mg of extract (micropropagated and conventionally propagated plant of C. angustifolia) was reconstituted in 10 ml of methanol for HPTLC analysis. Spots of extracts and standards were applied as 6 mm wide bands positioned 10 mm from the bottom and 10 mm from the side of the plate, using Linomat V applicator (Camag, Muttenz, Switzerland). The sample was applied into the aluminium plates, precoated with silica gel 60 F254 (20 × 20 cm, 0.2 mm thick, Merck Ltd, Mumbai) at an application rate of 200 nl/s from 100 µl syringe. Standard solution volumes of 2–10 µl of curcumin (0.1 mg/ml) were applied onto the plate corresponding to a concentration of 200–1000 ng for the preparation of a calibration curve. The calibration curve showed linearity over the evaluated ranges with linear equation of y = 96 x + 34.69 and correlation coefficient of determination (R2 = 0.997). Separation was carried out in an ascending mode in a twin trough chamber pre-saturated for 15 min with mobile phase, n-hexane: ethyl acetate (85:15 v/v; 20 ml). The plate was dried in air under room temperature and scanned in absorbance/reflectance mode under TLC scanner 4 at 366 nm. Peak area data were recorded using Win CATS software. Quantification of curcumin was carried out on the basis of regression equation of the standard curve of curcumin.

ISSR analysis

Genomic DNA was isolated from fresh leaves of 20 plantlets derived from axillary buds cultured on MS medium in the presence 13.3 µM BA, 5.7 µM IAA and 135.7 µM Ads and maintaining it for 1 year by subculturing it every 8 weeks and then transferring to field for 2 years. The leaves of conventionally propagated plants were used for comparison. Total DNA was extracted following the protocol of Doyle and Doyle (1987) cetyltrimethylammonium bromide (CTAB) method with minor modification. Purification of DNA was performed with RNase A (60 µg/µl of crude DNA solution) followed by washing three times with chloroform: isoamyl alcohol (24:1). The purified DNA was quantified using a spectrophotometer by taking absorbance at 260/280 ratio and its quality checked by using 0.8% agarose gel. Then the final concentration of each sample was adjusted to 25 ng/µl for PCR with Tris–EDTA buffer (pH 8.0) and kept at − 20 °C until analysis. Amplifications were carried out in a reaction mixture of 25 µl containing 25 ng of genomic DNA as a template, 10X PCR buffer mixed with 15 mM MgCl2 (Bangalore Genei), 200 µM dNTPs (Bangalore Genei), 3 U/µl of Taq DNA polymerase (Bangalore Genei) and 5 pM of each primer. The amplification of the reaction was carried out in a thermal cycler (Applied Biosystems Veriti 96 Well Thermal Cycler) under the following program: initial denaturation for 5 min at 94 °C, followed by 40 cycles at 94 °C for 1 min (denaturation) then anneling temperature for 1 min and then 72 °C for 2 min (extension), followed by final extension at 72 °C for 7 min. The PCR products were separated using 1.5% agarose gel stained with ethidium bromide (0.5 µg/ml). The allele sizes were evaluated by comparing 100 bp plus DNA ladder (Thermo scientific) and documented using Bio-Rad gel documentation system.

Flow cytometry analysis

Nuclear DNA content was analyzed using BD FACS Calibur flow cytometer (Becton–Dickinson Immunocytometry System, San Jose, CA, USA). The genetic integrity was analyzed by comparing 2C DNA content of in vitro grown regenerants and conventionally propagated plant of C. angustifolia. Glycine max (2C DNA = 2.50 pg, Dolezel et al. 1994) was used as internal reference standard. Sample analysis was carried out following the protocol of Choudhury et al. (2014) using Otto I buffer, 50 µM propidium iodide and 100 µM RNAse. For each sample, 10,000 nuclei were measured using BD Cell Quest Pro. Analysis of measurement was carried out in FCS Express 4 software. Randomly chosen regenerants obtained from the most effective combination for in vitro multiplication was assessed to check the 2C DNA content. The nuclear DNA content of C. angustifolia was estimated by the following equation:

Statistical analysis

The data were subjected to Analysis of variance (ANOVA) followed by Tukey’s HSD test at p < 0.05. All the analysis was carried out in Minitab 17 statistical software (Minitab Inc, PA, USA).

Results

In vitro establishment and multiplication of plants

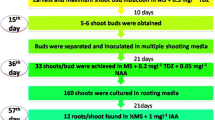

A morphologically and phenotypically healthy plant was selected as mother plant for culture establishment (Fig. 1A). The dormant axillary buds of field grown C. angustifolia were taken as explants source (Fig. 1B). Explants were inoculated vertically into MS medium fortified with different concentrations of auxins and cytokinins. MS medium supplemented with cytokinins like BA and Kin brought changes in sprouted bud explants and bud induction was visible within 30 days. BA was found to be the better as compared to Kin in terms of shoot induction and multiplication. The multiplications of axillary buds were increased, when the concentrations of BA were increased from 2.9 to 13.3 µM in the culture medium (Table 1). However, BA concentration beyond 13.3 µM did not manifest any increase in the number of shoot formation. Among all the media combinations, the maximum response of shoot initiation (90%) was observed with two media concentrations, i.e., the media containing 13.3 µM BA and 2.9 µM IAA as well as in the media with 13.3 µM BA, 2.9 µM IAA and 135.7 µM Ads. Among all tried combinations, Kin at 23.2 µM was found to be least effective. The percentage of aseptic axillary buds obtained from rhizome after the sterilization process varied from 45 to 95% for different phytohormones combination and is mentioned as % of shoot initiation in Table 1. Approximately 14 plantlets were produced from a single explants and the shoot multiplication time was 2 months. Therefore approximately 38,416 plantlets can be produced from single explants in 6 month where as multiplication rate through traditional method can be maximum 7 plants per annum. Almost 95% of rhizome buds sprouted on media supplemented with 13.3 µM BA, 2.9 µM IAA and 135.7 µM Ads giving rise to an average of 14.1 ± 0.55 shoots and 7.6 ± 0.47 of roots within 4 weeks (Fig. 1C). For rooting the same media combination was tested as that used for shoot induction. In vitro culture was maintained by sub culturing regularly at 2 month interval. After maintaining, in vitro tissue culture in the culture medium for 1 year, they were transferred to pots containing soil, cow dung, and sand mixture in 1:1:1 ratio for hardening (Fig. 1D). Plants were acclimatized in the greenhouse for 30 days and about 95% of plants survived and had normal growth after transferring them to the field during the planting season (Fig. 1E).

Assessment of phytomedicinal yield potential of regenerants

The phytomedicinal yield potential of regenerants were assessed through analysis of essential oil and curcumin content. The leaf oil yield of conventionally propagated and micropropagated plant of C. angustifolia were 0.30 and 0.32% (v/w), respectively, whereas, oil yield of rhizome of conventionally propagated and micropropagated plant of C. angustifolia were 0.40 and 0.45% (v/w), respectively. The essential oils extracted from rhizome and leaf of in vitro propagated and field grown plants of C. angustifolia were subjected to GC–MS analysis (Tables 2, 3). The rhizome essential oil in vitro propagated and field grown plants of C. angustifolia revealed the presence of 35 constituents, representing 94.21 and 92.31% of the total peak area, respectively (Fig. 2). Similarly, leaf essential oil showed the presence of 32 components, representing 94.35 and 92.57% of total volatile oil content in in vitro propagated and field grown plants, respectively (Fig. 3). Major constituents like curzerenone, camphor, germacrone, xanthorrhizol, β-eudesmol were common to both in vitro derived and field grown plants rhizome oil. Similarly, leaf oil revealed the presence of predominant components such as curzerenone, 14-hydroxy-δ-cadinene, γ-eudesmol acetate, (Z)-α-Santalol acetate, germacrone that were common to both in vitro derived and source plants. Rhizome and leaf essential oil of both conventionally propagated and micropropagated plant of C. angustifolia were dominated by curzerenone that comprises of 72.55 and 33.23% of peak area, respectively.

GC–MS chromatogram of rhizome oil of C. angustifolia (A) conventionally propagated and (B) micropropagated plant as mirror image; the numbers above the peaks correspond to the compound listed in Table 2

GC–MS chromatogram of leaf oil of C. angustifolia (A) conventionally propagated and (B) micropropagated plants as mirror image; the numbers above the peaks correspond to the compound listed in Table 3

For HPTLC analysis, different trials were made using different solvents in different proportions so as to acquire compact and precise bands. HPTLC analysis revealed that chromatogram of the conventionally propagated plant of C. angustifolia had similar fingerprint pattern to that of micropropagated plants (Fig. 4). The chromatograms obtained from field grown and in vitro derived plants of extract of C. angustifolia exhibited peaks corresponding to Rf values of 0.09, 0.14, 0.17, 0.25, 0.37, 0.44, 0.50, 0.65, 0.89 at 254 nm. Mobile phase containing n-hexane:ethyl acetate (85:15) gave a compact peak at Rf 0.17 for curcumin in both conventionally propagated and micropropagated methanol extract (Fig. 4A, B) and reference curcumin (Fig. 4C). The presence of curcumin in extract source plant and micropropagated plant was further confirmed by super impose overlay UV spectra of the corresponding peak in standard and extract (Fig. 5). The percentage of curcumin content determined using calibration curve was found to be 0.11 ± 0.01% and 0.13 ± 0.01%, in conventionally propagated and micropropagated plants of C. angustifolia, respectively.

Genetic stability of regenerants using ISSR markers and flow cytometry

ISSR marker based profiling of micropropagated and field grown plants of C. angustifolia were carried out to confirm whether the in vitro regenerants were genetically similar or not with the field grown plants. A total of twenty randomly selected in vitro derived plants and a mother plant were taken. Out of 27 ISSR primers tested, only 12 primers gave 60 well resolved and reproducible bands ranging from 350 to 2300 bp in size. A total of 1260 well resolved bands were generated by ISSR analysis were showing uniformity in banding patterns across 20 tissue culture derived plants and mother plant tested (Fig. 6). The amplicon size of each primer is given in Table 4. The no. of bands for each primer varied from 3 to 8 with an average of 5 bands per ISSR primers. The highest band of (8) was observed against ISSR 20 and the lowest band of (3) against primer ISSR 12. Monomorphic patterns were observed among micropropagated and mother plant analyzed, showing no genetic variations among them (Fig. 6A, B).

Further genetic fidelity of the micropropagated plants with that of conventionally propagated plants of C. angustifolia was assessed by measuring their mean 2C DNA content. Nuclear suspension of small pieces of young leaves from the conventionally propagated plant and plants regenerated from in vitro auxiliary bud was employed for this technique, and it exhibited clearly resolute linear histograms (Fig. 7). The linear histograms of relative nuclear content illustrated two peaks: the first showing nuclei in the G0/G1 phase of the cell cycle of Glycine max cv. Polanka and the second showing nuclei of the conventionally propagated C. angustifolia plants in the G0/G1 phase (Fig. 7A) and micropropagated plants in the G0/G1 phase (Fig. 7B). The mean 2C DNA content of micropropagated and conventionally propagated plant was estimated to be 2.31 pg and 2.26 pg, respectively, confirming similarity in genome size.

Discussion

Standardization of culture medium is an important factor for optimum growth response of the explants. BA, synthetic cytokinin triggers breaking the bud, induce auxiliary shoot formation and influence in vitro multiplication (Sadeghi et al. 2015). Earlier studies on C. angustifolia by Shukla et al. (2007), have showed 6.9 ± 0.69 micro shoots per explants within 6 week on MS medium supplemented with 3 mg/l BAP and 25 mg/l Ads whereas the present study exhibited a high frequency of shoot induction of 14.1 ± 0.55 shoots per explants with MS medium fortified with BA (13.3 µM), IAA (5.7 µM) and Ads (135.7 µM) within 60 days of inoculation. But the Ads concentration beyond 135.7 µM did not show any increase in the shoot bud proliferation. However, BA concentration beyond 13.3 µM did not manifest any increase in the micro shoot induction. In comparison to only cytokinins (BA or Kin) supplementing medium, shoot multiplications were enhanced on culture medium containing various concentrations of cytokinins (BA and Ads) and auxin (IAA). The culture medium when additionally supplemented with IAA (5.7 µM) displayed synergistic effect by inducing shoot number. Addition of Ads at optimum concentration of (135.7 µM) showed better growth and multiplication. According to Ahmad et al. (2018), Adenine in the form of Ads can promote cell growth as well as shoot bud formation. However, further increase in Ads concentration of medium had adverse effects. The role of Ads in enhancing proliferation was also reported in several medicinal plants such as Carissa caranda (Imran et al. 2012), Syzygium cumini (Naaz et al. 2014) and Decalepis salicifolia (Ahmad et al. 2018).

Essential oils of C. angustifolia are rich source of terpenic compounds having plethora of biological activities (Afzal et al. 2013; Sun et al. 2017). Our study is an agreement with Purkayastha et al. (2006) where curzerenone has been identified as the predominant compound in the rhizome oil of C. zedoaria. Curzerenone has been reported to show various biological activities, such as antimicrobial, anti-inflammatory, irritant, antioxidant and anticancer activities (Hsu 1980; Makabe et al. 2006; Xiang et al. 2011; Joshi and Mathela 2012). Our report is in contrary to the report of Srivastava et al. (2006) who reported xanthorrhizol isomer, methyl eugenol and palmitic acid as the major constituents in the rhizome oil from Central India plants, while the oil from Travancore plants was rich in germacrone, camphor and isoborneol. The remarkable differences in the constituents are likely due to geographical variation, edaphic or environmental factors (Djouahri et al. 2015; Jena et al. 2017; Ray et al. 2018). Further our results showed similarity in essential oil yield and constituents between micropropagated and conventionally propagated plants. Previous report by Mohanty et al. (2011a, b) in Kaempferia galanga rhizome oil has shown similarity in chemical constituents in somaclones and the source plant. Similarly, the higher uniformity of chemical components was found in leaf and rhizome essential oil in tissue culture derived plants of Curcuma longa to the conventional field grown plants (Nayak et al. 2011; Singh et al. 2011). No remarkable changes in the percentage of essential oil yield, curzerenone content and other identified constituents in leaf and rhizome oil between micropropagated and conventionally propagated plants of C. angustifolia were found, thus indicating the stability in phytomedicinal yield potential of regenerants.

Qualitative chemical uniformity between the in vitro regenerants and conventionally propagated plants of C. angustifolia was confirmed using HPTLC profiling. The HPTLC fingerprint pattern of chromatogram at λ = 254 nm was similar in in vitro and field grown plants. HPTLC analysis of rhizome extract revealing similar fingerprint profile and also confirmed chemical uniformity between tissue culture derived plantlets and conventionally propagated plant. This confirms that the in vitro plants were all true-to-type. The developed HPTLC fingerprint profile can be used as a reference fingerprint for the standardisation of C. angustifolia rhizome extract. HPTLC analysis also revealed the presence of curcumin. Curcumin is a biologically active component extracted from rhizomes of several Curcuma species, having potent biological activities (Lin and Lin-Shiau 2001; Woo et al. 2003; Anand et al. 2008; Cikrikci et al. 2008). Previously, the similarity in HPTLC fingerprinting profile in tissue culture and field grown plants have been reported by several researchers in several plants such as Piper nigrum (Ahmad et al. 2013), Celastrus paniculatus (Martin et al. 2006), Asparagus adscendens (Mehta and Subramanian 2005) and Nothapodytes nimmoniana (Prakash et al. 2016). Similarly, biochemical characterization of tissue cultured plants has also been documented by many researchers revealing stability in phytomedicinal yield potential (Nayak et al. 2011; Mohanty et al. 2011b; Singh et al. 2011).

ISSR marker based genetic integrity of in vitro regenerants have been documented in several plants such as Kaempferia galanga (Mohanty et al. 2011b), Zingiber rubens (Mohanty et al. 2011a), Gerbera jamesonii (Bhatia et al. 2009) and Swertia chirayita (Joshi and Dhawan 2007). ISSR analysis of in vitro regenerated plants of C. angustifolia showed similar profile to that of the mother plant showing that no genetic variation had occurred in vitro. Genetic stability of micropropagated C. angustifolia has also been confirmed by flow cytometry. Flow cytometry technique, has been used in plant sciences, mainly focused on nuclear DNA content, ploidy and genome size stability of micropropagated plants (Dolezel and Bartos 2005; Viehmannova et al. 2016). Analysis of the DNA content of conventionally propagated and plant regenerated from axillary bud by using flow cytometry analysis confirmed unalteration in nuclear DNA content of C. angustifolia. From the earlier report, it has been documented that the 2C DNA content of the C. angustifolia collected from Bangladesh were found to be 2.121–2.141 pg (Islam 2004). Similarly, genome size stability has been documented in several in vitro regenerants as well as medicinal plants like Hydrastis Canadensis (Obae and West 2010), Solanum trilobatum (Shilpha et al. 2014), Puya berteroniana (Viehmannova et al. 2016) and Solanum lycopersicum (Alatar et al. 2017). The present findings confirmed that the established protocol guarantees in vitro regeneration of plants with stable genome size.

In conclusion, the present protocol of rapid plant regeneration using axillary bud explants with genetically uniform plantlets and stable phytomedicinal yield potential can be recommended for effective mass propagation of true-to-type C. angustifolia (East Indian Arrowroot) for commercial utilization.

References

Adams RP (2007) Identification of essential oil components by gas chromatography/mass spectroscopy. Allured Publishing Corporation, Carol Stream

Afzal A, Oriqat G, Akram Khan M, Jose J, Afzal M (2013) Chemistry and biochemistry of terpenoids from Curcuma and related species. J Biol Act Prod Nat 3:1–55

Ahmad N, Abbasi BH, ur Rahman I, Fazal H (2013) Piper nigrum: micropropagation, antioxidative enzyme activities, and chromatographic fingerprint analysis for quality control. Appl Biochem Biotechnol 169:2004–2015

Ahmad Z, Shahzad A, Sharma S, Parveen S (2018) Ex vitro rescue, physiochemical evaluation, secondary metabolite production and assessment of genetic stability using DNA based molecular markers in regenerated plants of Decalepis salicifolia (Bedd. ex Hook. f.) Venter. Plant Cell Tissue Organ Cult 132:497–510

Akin-Idowu PE, Ibitoye DO, Ademoyegun OT (2009) Tissue culture as a plant production technique for horticultural crops. Afr J Biotechnol 8:3782–3788

Al Khateeb W, Hussein E, Qouta L, Alu’datt M, Al-Shara B, Abuzaiton A (2012) In vitro propagation and characterization of phenolic content along with antioxidant and antimicrobial activities of Cichorium pumilum Jacq. Plant Cell Tissue Organ Cult 110:103–110

Alatar AA, Faisal M, Abdel-Salam EM, Canto T, Saquib Q, Javed SB, El-Sheikh MA, Al-Khedhairy AA (2017) Efficient and reproducible in vitro regeneration of Solanum lycopersicum and assessment genetic uniformity using flow cytometry and SPAR methods. Saudi J Biol Sci 24:1430–1436

Amoo SO, Aremu AO, Van Staden J (2012) In vitro plant regeneration, secondary metabolite production and antioxidant activity of micropropagated Aloe arborescens Mill. Plant Cell Tissue Organ Cult 111:345–358

Anand P, Thomas SG, Kunnumakkara AB, Sundaram C, Harikumar KB, Sung B, Tharakan ST, Misra K, Priyadarsini IK, Rajasekharan KN, Aggarwal BB (2008) Biological activities of curcumin and its analogues (Congeners) made by man and mother nature. Biochem Pharmacol 76:1590–1611

Anisuzzaman M, Sharmin SA, Mondal SC, Sultana R, Khalekuzzaman M, Alam I, Alam MF (2008) In vitro microrhizome induction in Curcuma zedoaria (Christm.) Roscoe—a conservation prioritized medicinal plant. J Biol Sci 8:1216–1220

Aversano R, Di Dato F, Di Matteo A, Frusciante L, Carputo D (2011) AFLP analysis to assess genomic stability in Solanum regenerants derived from wild and cultivated species. Plant Biotechnol Rep 5:265–271

Bairu MW, Aremu AO, Van Staden J (2011) Somaclonal variation in plants: causes and detection methods. Plant Growth Regul 63:147–173

Barthakur MP, Bordoloi DN (1992) Micropropagation of Curcuma amada (Roxb.). J Spices Aromat. Crop 1:154–156

Bhatia R, Singh KP, Jhang T, Sharma TR (2009) Assessment of clonal fidelity of micropropagated gerbera plants by ISSR markers. Sci Hort 119:208–211

Choudhury RR, Basak S, Ramesh AM, Rangan L (2014) Nuclear DNA content of Pongamia pinnata L. and genome size stability of in vitro-regenerated plantlets. Protoplasma 251:703–709

Cikrikci S, Mozioglu E, Yilmaz H (2008) Biological activity of curcuminoids isolated from Curcuma longa. Rec Nat Prod 2:19

De Souza Ferrari MP, Antoniazzi D, Nascimento AB, Franz LF, Bezerra CS, Magalhães HEM (2016) Evaluation of new protocols to Curcuma longa micropropagation: a medicinal and ornamental specie. J Med Plant Res 10:367–376

Djouahri A, Boualem S, Boudarene L, Baaliouamer A (2015) Geographic’s variation impact on chemical composition, antioxidant and anti-inflammatory activities of essential oils from wood and leaves of Tetraclinis articulata (Vahl) Masters. Ind Crops Prod 63:138–146

Dolezel J, Bartos JAN (2005) Plant DNA flow cytometry and estimation of nuclear genome size. Ann Bot 95:99–110

Dolezel J, Dolezelova´ M, Nova´k F (1994) Flow cytometric estimation of nuclear DNA amount in diploid bananas (Musa acuminate and M. balbisiana). Biol Plant 36:351–357

Doyle JJ, Doyle JL (1987) A rapid DNA isolation procedure for small quantities of fresh leaf tissue. Phytochem Bull 19:11–15

Guenther E (1972) The production of essential oils. In: Robert E (ed) The essential oils, vol I. Krieger, New York, pp 361–391

Hemadri K, Rao SS (1984) Jaundice: tribal medicine. Anc Sci Life 3:209–212

Hsu B (1980) The use of herbs as anticancer agents. Am J Chin Med 8:301–306

Imran MA, Begum GOUSIA, Sujatha K, Mallaiah B (2012) Effect of adenine sulphate (ads) with cytokinins on multiple shoot production in Carissa carandas (l.). Int J Pharma Bio Sci 3:473–480

Islam MA (2004) Genetic diversity of the genus Curcuma in Bangladesh and further biotechnological approaches for in vitro regeneration and long-term conservation of C. longa germplasm. Univ. of Hannover 1-137

Jena S, Ray A, Banerjee A, Sahoo A, Nasim N, Sahoo S, Kar B, Patnaik J, Panda PC, Nayak S (2017) Chemical composition and antioxidant activity of essential oil from leaves and rhizomes of Curcuma angustifolia Roxb. Nat Prod Res 31:2188–2191

Joshi P, Dhawan V (2007) Assessment of genetic fidelity of micropropagated Swertia chirayita plantlets by ISSR marker assay. Biol Plant 51:22–26

Joshi SC, Mathela CS (2012) Antioxidant and antibacterial activities of the leaf essential oil and its constituents furanodienone and curzerenone from Lindera pulcherrima (Nees.) Benth. ex hook. f. Pharmacogn Res 4:80

Larkin PJ, Scowcroft WR (1981) Somaclonal variation—a novel source of variability from cell cultures for plant improvement. Theor Appl Genet 60:197–214

Lin JK, Lin-Shiau SY (2001) Mechanisms of cancer chemoprevention by Curcumin. Proc Natl Sci Counc Repub China B 25:59–66

Makabe H, Maru N, Kuwabara A, Kamo T, Hirota M (2006) Anti-inflammatory sesquiterpenes from Curcuma zedoaria. Nat Prod Res 20:680–685

Martin G, Geetha SP, Raja SS, Raghu AV, Balachandran I, Ravindran PN (2006) An efficient micropropagation system for Celastrus paniculatus Willd.: a vulnerable medicinal plant. J For Res 11:461–465

Mehta SR, Subramanian RB (2005) Direct in vitro propagation of Asparagus adscendens Roxb. Plant Tissue Cult 15:25–32

Mohanty S, Panda MK, Sahoo S, Nayak S (2011a) Micropropagation of Zingiber rubens and assessment of genetic stability through RAPD and ISSR markers. Biol Plant 55:16–20

Mohanty S, Parida R, Singh S, Joshi RK, Subudhi E, Nayak S (2011b) Biochemical and molecular profiling of micropropagated and conventionally grown Kaempferia galanga. Plant Cell Tissue Organ Cult 106:39–46

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassay with tobacco tissue cultures. Physiol Plant 15:473–497

Naaz A, Shahzad A, Anis M (2014) Effect of adenine sulphate interaction on growth and development of shoot regeneration and inhibition of shoot tip necrosis under in vitro condition in adult Syzygium cumini L.—a multipurpose tree. Appl Biochem Biotechnol 173:90–102

Nayak S, Kaur T, Mohanty S, Ghosh G, Choudhury R, Acharya L, Subudhi E (2011) In vitro and ex vitro evaluation of long-term micropropagated turmeric as analyzed through cytophotometry, phytoconstituents, biochemical and molecular markers. Plant Growth Regul 64:91–98

Obae SG, West TP (2010) Nuclear DNA content of Hydrastis canadensis L. and genome size stability of in vitro regenerated plantlets. Plant Cell Tissue Organ Cult 102:259–263

Peredo EL, Arroyo-Garcia R, Revilla MA (2009) Epigenetic changes detected in micropropagated hop plants. J Plant Physiol 166:1101–1111

Prakash L, Middha SK, Mohanty SK, Swamy MK (2016) Micropropagation and validation of genetic and biochemical fidelity among regenerants of Nothapodytes nimmoniana (Graham) Mabb. employing ISSR markers and HPLC. 3 Biotech 6:171

Purkayastha J, Nath SC, Klinkby N (2006) Essential oil of the rhizome of Curcuma zedoaria (Christm.) Rose. native to Northeast India. J Essent Oil Res 18:154–155

Raihana R, Faridah QZ, Julia AA, Abdelmageed AHA, Kadir MA (2011) In vitro culture of Curcuma mangga from rhizome bud. J Med Plants Res 5:6418–6422

Rajashekhara N, Sharma PP (2010) A comparative study of efficacy of Tugaksheeree [Curcuma angustifolia Roxb. and Maranta arundinacea Linn.] in management of Amlapitta. Ayu 31:482

Raji MR, Lotfi M, Tohidfar M, Zahedi B, Carra A, Abbate L, Carimi F (2017) Somatic embryogenesis of muskmelon (Cucumis melo L.) and genetic stability assessment of regenerants using flow cytometry and ISSR markers. Protoplasma 255:873–883

Ray A, Jena S, Dash B, Kar B, Halder T, Chatterjee T, Ghosh B, Panda PC, Nayak S, Mahapatra N (2018) Chemical diversity, antioxidant and antimicrobial activities of the essential oils from Indian populations of Hedychium coronarium Koen. Ind Crops Prod 112:353–362

Sadeghi F, Yadollahi A, Kermani MJ, Eftekhari M (2015) Optimizing culture media for in vitro proliferation and rooting of Tetra (Prunus empyrean 3) rootstock. Genet Eng Biotechnol J 13:19–23

Sharma A (2012) Traditional processing of Shotti (Curcuma augustifolia Roxb.)—a rhizome based ethnic weaning food. Indian J Tradit Knowl 11:154–155

Sharmin SA, Alam MJ, Sheikh MMI, Zaman R, Khalekuzzaman M, Mondal SC, Haque MA, Alam MF, Alam I (2013) Micropropagation and antimicrobial activity of Curcuma aromatica Salisb., a threatened aromatic medicinal plant. Turkish J Biol 37:698–708

Shilpha J, Silambarasan T, Largia MJV, Ramesh M (2014) Improved in vitro propagation, solasodine accumulation and assessment of clonal fidelity in regenerants of Solanum trilobatum L. by flow cytometry and SPAR methods. Plant Cell Tissue Organ Cult 117:125–129

Shukla SK, Shukla S, Koche V, Mishra SK (2007) In vitro propagation of tikhur (Curcuma angustifolia Roxb.): a starch yielding plant. Indian J Biotechnol 6:274–276

Singh S, Kuanar A, Mohanty S, Subudhi E, Nayak S (2011) Evaluation of phytomedicinal yield potential and molecular profiling of micropropagated and conventionally grown turmeric (Curcuma longa L.). Plant Cell Tissue Organ Cult 104:263–269

Sliwinska E, Thiem B (2007) Genome size stability in six medicinal plant species propagated in vitro. Biol Plant 51:556–558

Srivastava AK, Srivastava SK, Syamsundar KV (2006) Volatile composition of Curcuma angustifolia Roxb. rhizome from central and southern India. Flavour Frag J 21:423–426

Sun W, Wang S, Zhao W, Wu C, Guo S, Gao H, Tao H, Lu J, Wang Y, Chen X (2017) Chemical constituents and biological research on plants in the genus Curcuma. Crit Rev Food Sci Nutr 57:1451–1523

Van den Dool H, Kratz PD (1963) A generalization of the retention index system including linear temperature programmed gas—liquid partition chromatography. J Chromatogr A 11:463–471

Viehmannova I, Cepkova PH, Vitamvas J, Streblova P, Kisilova J (2016) Micropropagation of a giant ornamental bromeliad Puya berteroniana through adventitious shoots and assessment of their genetic stability through ISSR primers and flow cytometry. Plant Cell Tissue Organ Cult 125:293–302

Woo JH, Kim YH, Choi YJ, Kim DG, Lee KS, Bae JH, Min DS, Chang JS, Jeong YJ, Lee YH, Park JW (2003) Molecular mechanisms of curcumin-induced cytotoxicity: induction of apoptosis through generation of reactive oxygen species, down-regulation of Bcl-X L and IAP, the release of cytochrome c and inhibition of Akt. Carcinogenesis 24:1199–1208

Xiang Z, Wang XQ, Cai XJ, Zeng S (2011) Metabolomics study on quality control and discrimination of three Curcuma species based on gas chromatograph–mass spectrometry. Phytochem Anal 22:411–418

Acknowledgements

The authors are grateful to Dr. S.C. Si, Dean, Centre of Biotechnology and Dr. M.R. Nayak, President, Siksha ‘O’ Anusandhan University for providing facilities and encouragement throughout.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Nokwanda Pearl Makunga.

Rights and permissions

About this article

Cite this article

Jena, S., Ray, A., Sahoo, A. et al. High-frequency clonal propagation of Curcuma angustifolia ensuring genetic fidelity of micropropagated plants. Plant Cell Tiss Organ Cult 135, 473–486 (2018). https://doi.org/10.1007/s11240-018-1480-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-018-1480-z