Abstract

TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres have been synthesized via a low-temperature hydrothermal method using SiO2 spheres as templates, combined with a light-induced reduction method and a hydrogen peroxide oxidation process. Scanning electron microscopy, energy-dispersive X-ray and X-ray diffraction analyses have demonstrated that Ag and Ag2O nanoparticles were successfully deposited on the surfaces of TiO2/SiO2 nanocomposite spheres and porous TiO2 nanospheres forming nanoheterojunctions. The photocatalytic experiment results reveal that all the as-prepared catalysts possess improved photocatalytic activities compared with P25 nanoparticles. Both TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres exhibit excellent photocatalytic performances, which can be attributed to the synergistic effects of different kinds of nanoparticles. The synergistic mechanism of these nanoparticles is also discussed in detail.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, with the constant deterioration of the global ecological environment, it is urgently required to synthesize an economical and non-polluting material that can effectively degrade a variety of harmful organic pollutants in sewage [1,2,3]. The application of semiconductor nanomaterials in the field of photocatalysis has attracted widespread concern. For example, TiO2 [4], WO3 [5], SiO2 [6], Ag2O [7] and ZnO [8] have been widely used as photocatalysts. Among them, nano-TiO2 is the most widely studied semiconductor photocatalyst because of its outstanding photo-induced activity and lack of secondary pollution [2, 9, 10]. Previous researches have proved that the photocatalytic ability of TiO2 strongly depends on its morphology and size [11,12,13]. For instance, porous nano-sized TiO2 and TiO2 nanorods generally have better photocatalytic performance than commercial P25 nanoparticles (NPs), owing to their larger surface area and more reactive sites [14, 15]. Unfortunately, there are some drawbacks that hinder the application of TiO2 catalysts due to the limitations of the material properties, such as large energy gap, high photoelectron–hole recombination rate and so on [16, 17]. Hence, researchers are seeking more effective ways to increase the surface active sites, photoelectron–hole separation rates, solar energy utilization efficiency and spectral responses for enhancing the photocatalytic properties of TiO2 [18,19,20].

Related reports demonstrate that both the noble metals (e.g., Ag, Au, Cu) and semiconductors (e.g., Ag2O, CuO, Cu2O) coupled with TiO2 photocatalysts can expand spectral responses and reduce photoelectron–hole recombination rates of TiO2 [21,22,23,24]. Ag NPs deposited on the surface of semiconductors (such as TiO2) can involve the surface plasmon resonance (SPR) effect. In particular, the Ag NPs, acting as a photoelectron catcher, have been widely applied because of their excellent performance in degrading water-borne organic pollutants compared with other noble metals [1]. Moreover, the band gap energy (1.46 eV) of p-type Ag2O semiconductors is lower than that of TiO2 [25]. A p–n nanoheterojunction consisting of p-type Ag2O and n-type TiO2 will lead to a lower photoelectron–hole recombination rate and wider spectral response; therefore, it has enhanced photocatalytic properties [26]. On the other hand, it has been reported that nano-SiO2 possesses high stability, good adsorption, large specific surface and multiple surface active sites, and are usually used as the carrier or core of various composite materials [18, 27, 28]. Consequently, TiO2/SiO2 core/shell nanostructures should have a larger specific surface area, higher thermal stability, better dispersion properties and more adsorption sites than pure TiO2 NPs. This also confirms that TiO2/SiO2 core/shell nanostructures show superior photocatalytic activity [29,30,31]. In recent years, TiO2 doped with Cu2O/Cu [32], B/N [33], Ag/Ag2O [34], SiO2/Fe3O4 [35] and Fe3O4/SiO2/Ag [36] have been synthesized and used as photocatalysts. A few studies have found that TiO2/Ag/Ag2O nanocomposites exhibit superior photocatalytic activity compared with pure TiO2 due to the combined action of Ag and Ag2O NPs [34, 37,38,39]. However, there have been very few studies on the photocatalytic ability of TiO2/SiO2/Ag/Ag2O nanocomposite structures.

In the current work, as shown in Scheme 1, TiO2/SiO2 nanocomposite spheres were first prepared by a hydrothermal method at low temperature using seeded silica spheres as templates and tetrabutyl titanate (TBOT) as the titanium source, and then TiO2/SiO2 nanocomposite spheres were etched by sodium hydroxide solution to obtain porous TiO2 nanospheres. Subsequently, Ag NPs were immobilized on the synthesized catalysts through a light-induced reduction method, and then partially oxidized by hydrogen peroxide to synthesize TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres. The photocatalytic performances of the as-prepared photocatalysts were evaluated by the photodegradation of RhB solution under simulated solar irradiation. The results show that TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres have highly efficient photocatalytic abilities.

Experimental

Chemicals

All chemical reagents were of analytical grade and used without further purification. Ammonia solution (NH3·H2O, 35.05%), sodium hydroxide (NaOH, 96%), silver nitrate (AgNO3, 99.8%) and absolute ethanol were obtained from Sinopharm Chemical Reagent (China). TBOT (Ti(OC4H9)4, 99%), acetonitrile (C2H3N, 99%), silica sphere (50 nm), hydrogen peroxide (H2O2, 30%), ammonium oxalate ((NH4)2C2O4, 99.8%), sodium sulfate (NaSO4, 99%), isopropanol (C3H8O, 99.5%) and titanium tetrachloride (TiCl4, 99%) were obtained from Shanghai Aladdin Bio-Chem Technology (China). The commercial P25 was obtained from Degussa (Germany).

Preparation of seeded silica templates

In order to facilitate crystal growth, the silica templates were pretreated with titanium tetrachloride (TiCl4) solution. The detailed experimental procedures are as follows. First, the silica templates were calcined at 500 °C for 30 min. Then, 1 g of the sintered silica templates was dispersed in 8 mL of 0.3 mM TiCl4 aqueous solution and maintained in a sealed container at 70 °C for 1 h. The treated silica templates were collected by centrifugation and washed with deionized water. The dried seeded templates were calcinated at 500 °C for 30 min. The above steps were repeated three times.

Synthesis of TiO2/SiO2 nanocomposite spheres

TiO2/SiO2 nanocomposite spheres were prepared via a hydrothermal method using the pre-treated silica spheres as templates. First, 15 mL of absolute ethanol and 0.3 mL of deionized water were well mixed with 5 mL of acetonitrile, followed by adding 0.1 g of the seeded silica templates to the above mixed solution under ultrasound irradiation. Then, 60 μL of NH3·H2O was added to the suspension under magnetic stirring. After 30 min, 1.6 mL of TBOT was added and stirred for 15 min. Finally, the sealed Teflon-lined autoclave containing the mixed solution was heated at 120 °C for 3 h. The obtained TiO2/SiO2 nanocomposite spheres were washed using deionized water and absolute ethanol, dried, and calcined at 400 °C for 3 h. By controlling the hydrothermal reaction conditions, a series of TiO2/SiO2 nanocomposite spheres were obtained.

Synthesis of porous TiO2 nanospheres

First, a series of TiO2/SiO2 nanocomposite spheres were obtained by the following hydrothermal conditions: 1.3 mL TBOT for 3 h, 1.6 mL TBOT for 3 h and 1.6 mL TBOT for 8 h, which were denoted as S0, S1 and S2, respectively. Then, these catalysts were collected and thoroughly washed with deionized water. The wet samples were then immersed in 2 M NaOH aqueous solution at 80 °C for 1 h. Finally, the silica cores were removed to obtain porous TiO2 nanospheres. The obtained catalysts were washed and calcined at 400 °C for 3 h. The final porous nanospheres were denoted as PSN-0, PSN-1 and PSN-2, respectively.

Synthesis of TiO2/Ag nanocomposite spheres

The TiO2/Ag nanocomposite spheres were synthesized according to a previously reported method [1]. First, 25 mg of the obtained porous TiO2 nanospheres (PSN-1) were added into 15 mL of absolute ethanol containing 15 mg of AgNO3. The suspension was ultrasonically treated for 10 min and then stirred for 1 h under a 300-W Xenon lamp irradiation. The dark purple powder was collected and dried in a vacuum environment at 50 °C. The dried TiO2/Ag nanocomposite spheres were calcined at 400 °C for 3 h.

Synthesis of TiO2/Ag/Ag2O nanocomposite spheres

The TiO2/Ag/Ag2O nanocomposite spheres were fabricated by partially oxidization of silver nanoparticles with hydrogen peroxide on the surface of TiO2/Ag nanocomposite spheres [40]. Then, 5 mg of TiO2/Ag nanocomposite spheres were well dispersed in 20 mL of deionized water, and 2.22 mL of H2O2 was slowly dripped into the solution and then stirred for 2 h at room temperature. A light yellow powder was obtained and was washed with deionized water and absolute ethanol. The final catalysts were calcined at 400 °C for 3 h to obtain TiO2/Ag/Ag2O nanocomposite spheres. The synthesis of the TiO2/SiO2/Ag/Ag2O nanocomposite spheres can also be obtained using the same preparation process as described above.

Synthesis of TiO2/Ag2O nanocomposite spheres

The synthesis of TiO2/Ag2O nanocomposite spheres was conducted through a modified method of that described in Ref. [41]. First, 0.1 g of porous TiO2 nanospheres (PSN-1) was uniformly dispersed in 25 mL of deionized water. Then, 0.213 g of AgNO3 was added to the suspension and 0.1 M NaOH aqueous solution was added until the pH of the mixture was around 12–13. Next, the mixture was stirring constantly for 30 min at room temperature. Finally, the TiO2/Ag2O nanocomposite spheres were obtained under UV irradiation for 10 min. The final catalysts were calcined at 400 °C for 3 h.

Catalyst characterization

The morphologies of the as-prepared catalysts were characterized by a field emission scanning electron microscope (FE-SEM; Quanta 250 FEG; FEI) and transmission electron microscopy (TEM; JEM-2100F;JEOL). Energy dispersive spectroscopy (EDS) analysis of the catalysts was carried out using an energy dispersive spectrometer (INCAX-Max 20; Oxford). The crystal structures of the catalysts were studied with an X-Ray diffractometer (XRD; D8 AVANCE; Bruker). The energy band gap of the catalysts was determined from UV–Vis DRS spectrum in the 200–600 nm range, recorded by a UV–Vis spectrophotometer (UV-3600; Shimadzu).

Photocatalytic measurement

The photocatalytic performance of the prepared catalysts was assessed via the degradation of Rhodamine B (RhB) in aqueous solution under simulated solar irradiation. During the experiment, H2O2 solution was added to enhance the separation rate of the photoelectron–hole and photocatalytic properties. In a typical experimental process, 0.0075 g of the catalyst and 0.3 mL of 30% of H2O2 were added to 30 mL of RhB aqueous solution (25 mg L−1). Prior to the photocatalytic degradation, the suspended liquid was first sonicated for 5 min, and then stirred constantly in the dark for 1 h. A Xenon lamp (300 W, PLS-SXE300C) was used as the simulated solar light source in the photocatalytic experiments. The distance between the lamp and photoreactor was 13 cm. All the catalytic experiments were carried out at a fixed light intensity. The suspension was irradiated at set intervals under simulated solar light. Several milliliter liquids were taken out and the catalysts were removed by centrifugation. The obtained supernatant concentration was finally examined between the wavelength of 400 and 700 nm by the UV–Vis spectrophotometer. The trapping experiments of the active species were carried out according to the above steps, except for adding H2O2. Ammonium oxalate (3 mg), sodium sulfate (3 mg) and isopropanol (3 μL), used as hole (h+), electron (e−) and OH radicals (OH·) scavengers, were added to above reaction solution, respectively.

Results and discussion

Characterization of TiO2/SiO2 nanocomposite spheres

The morphologies and structures of the obtained catalysts were studied by SEM analysis. Figure 1 shows the SEM images of the TiO2/SiO2 nanocomposite spheres at different magnifications prepared with silica spheres as templates. From the SEM image shown in Fig. 1a, it can be seen that the surface of the silica spheres was packed with a layer of TiO2 film after the hydrothermal reaction with 1.6 mL TBOT for 3 h. The high-magnification SEM images shown in Fig. 1b clearly demonstrate that the synthesized TiO2/SiO2 nanocomposite spheres have a peculiar and rough surface with an average diameter of about 400 nm. The reason for the formation of this peculiar morphology may be because of the exposure of a part of the silica core. The results of the energy spectrum analysis (EDS) and phase analysis (XRD) also strongly show the above results, as shown in Fig. 1c, d. The typical EDS spectrum in Fig. 1c shows that the prepared catalysts contain the following three elements: O, Ti and Si, which indicates that the presence of the Si element in the obtained TiO2/SiO2 nanocomposite spheres. The results of XRD characterization indicate that the obtained TiO2/SiO2 nanocomposite spheres are composed of anatase crystallite (JCPDS. 21-1272) [42] (Fig. 1d). The wide diffraction peak at about 25.3° may originate from the amorphous silica templates embedded in the obtained products.

Characterization of porous TiO2 nanospheres

By adjusting the hydrothermal reaction conditions, a series of TiO2/SiO2 nanocomposite spheres were obtained. The synthesis of porous TiO2 nanospheres with different morphologies (PSN-0, PSN-1 and PSN-2) was realized by etching the nanocomposites in sodium hydroxide aqueous solution, as shown in Fig. 2. From the SEM images shown in Fig. 2a, b, one can see that the surface of PSN-0 was partially etched by sodium hydroxide solution. The average diameter of the porous TiO2 nanospheres is approximately 300 nm. With increasing the amount of TBOT, the thickness of the titania layer deposited on the surface of silica is increased. Eventually, the pores in the surface of TiO2 nanospheres will be more clearly exposed after sodium hydroxide etching, as shown in Fig. 2c, d. With increasing the hydrothermal reaction time to 8 h, the average diameter of the porous TiO2 nanospheres was slightly increased. As demonstrated in Fig. 2e, f, a small agglomeration and lower porosity exposure can be found due to the increased thickness of the titania layer.

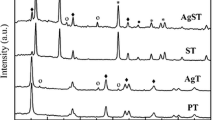

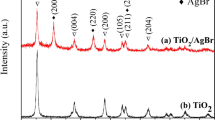

EDS and XRD analysis were used to confirm the elemental and phase compositions of porous TiO2 nanospheres formed after sodium hydroxide etching. Figure 2g shows the EDS spectrum of the as-prepared PSN-1, which indicates that the elemental compositions of the porous TiO2 nanospheres are O, Ti and Si. At the same time, it can be observed that the peak corresponding to the Si element decreases substantially compared with that demonstrated in Fig. 1c. Therefore, the above EDS results indicate that the obtained porous TiO2 nanospheres contain a small amount of residual silica. The X-ray diffraction patterns of PSN-1 are shown in Fig. 2h, from which it can be seen that the characteristic peaks at 25.4°, 48.0° and 62.6° can be indexed to the (101), (200), (211) and (204) planes of anatase TiO2 (JCPDS. 21-1272), respectively. Moreover, the characteristic peak at about 25.3° is similar to that of the TiO2/SiO2 nanocomposite spheres. This further proves that porous nanospheres are composed of anatase TiO2 and amorphous SiO2.

Characterization of TiO2/Ag, TiO2/Ag/Ag2O and TiO2/Ag2O nanocomposite spheres

Porous TiO2/Ag, TiO2/Ag/Ag2O and TiO2/Ag2O nanocomposite spheres were synthesized in order to investigate their photocatalytic properties. To systematically compare the surface morphology and further verify the composition of the obtained porous TiO2 nanocomposite spheres, SEM and EDS analyses were performed. The SEM image of TiO2/Ag nanocomposite spheres is presented in Fig. 3a. It can be distinctly seen that the diameter of nanocomposite spheres did not change very much compared to the SEM results of porous TiO2 nanospheres. The EDS spectrum shown in Fig. 3b demonstrates that the weight percents of O, Ti and Ag in the obtained catalysts are 28.85, 36.97 and 34.18%, respectively. In addition, there is a very weak characteristic peak of Si, which indicates that the obtained catalyst may contain a small amount of silica nanoparticles. In order to further clarify the crystal structure of the TiO2/Ag nanocomposite spheres, the typical XRD pattern is displayed in the inset of Fig. 3b. In addition to the characteristic peaks of anatase TiO2, a peak centered at 2θ = 44.58° appears, which corresponds to the (200) plane of Ag (JCPDS. 03-0921) [43]. The above analysis confirms the presence of Ag in the obtained nanocomposite spheres. After partially oxidizing with hydrogen peroxide solution, although the surface morphology of the catalysts shows no obvious change, its composition ratio has changed, as displayed in Fig. 3c, d. From the interpolation table in Fig. 3d, one can see that the weight percent of the O element increases from 28.85 to 32.57%, while that of the Ti and Ag elements all decrease slightly. This may be caused by the partial oxidation of Ag in the catalyst. As displayed in the inset of Fig. 3d, the overall contour of the XRD patterns of TiO2/Ag/Ag2O nanocomposite spheres is similar to anatase TiO2, except for the peak of Ag and Ag2O (JCPDS. 41-1104) [44], indicating the existence of Ag and Ag2O in the nanocomposite spheres. Therefore, it seems rational to draw a conclusion that the Ag immobilized on the porous TiO2 nanospheres was partially oxidized to form TiO2/Ag/Ag2O nanocomposite spheres. Figure 3e, f shows the SEM image and EDS spectrum of TiO2/Ag2O nanocomposite spheres. From the XRD pattern shown in the inset of Fig. 3f, in addition to the characteristic peaks of anatase TiO2, a weak diffraction peak at 46.14° can be observed [45]. This suggests that Ag2O was successfully formed on the surface of the porous TiO2 nanospheres. It is noted that the synthesized TiO2/Ag, TiO2/Ag/Ag2O and TiO2/Ag2O nanocomposite spheres contain a small amount of SiO2 due to the incomplete etching of the SiO2 embedded in the spherical structures, as demonstrated in Scheme 1.

Characterization of TiO2/SiO2/Ag/Ag2O nanocomposite spheres

For a more systematic comparison, TiO2/SiO2/Ag/Ag2O nanocomposite spheres were fabricated via the same preparation method as the TiO2/Ag/Ag2O nanocomposite spheres. Figure 4a, b shows the SEM images of the fabricated catalysts with low and high magnifications. Compared with the TiO2/SiO2 nanocomposite spheres, no morphological changes were observed. TEM analysis of the nanocomposite spheres was also carried out and the results are shown in Fig. 4c, d. It can be seen from Fig. 4d that Ag and Ag2O NPs were effectively fabricated on TiO2 by the light-induced reduction method and the hydrogen peroxide oxidation process.

As exhibited in Fig. 4e, the EDS spectrum indicates the existence of four elements (O, Si, Ti and Ag) in the nanocomposite spheres. Moreover, the XRD analysis was performed to determine the crystal structure of the spheres. The result of the XRD analysis is shown in Fig. 4f. Compared with the XRD pattern shown in Fig. 1d, it is apparent that several weak diffraction peaks corresponding to Ag and Ag2O can be seen, which indicates the formation of TiO2/SiO2/Ag/Ag2O nanocomposite spheres.

UV–Vis DRS analysis

Figure 5a shows the UV–Vis diffuse reflectance spectra of the obtained catalysts, from which one can see that several nanocomposite catalysts exhibit higher adsorption in the visible region compared with porous TiO2 nanospheres, especially TiO2/Ag, TiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres. This indicates that the formation of various nanoparticles on TiO2 surfaces can bring about a change in the spectral response of catalysts. By using the Kubelka–Munk equation [(F(R∞) hv)1/2 vs. hv (photo energy)], the estimated energy band gap (Eg) of catalysts can be obtained. As shown in Fig. 5b, the estimated Eg value of the porous TiO2 nanospheres is 3.20 eV, which is consistent with the reported energy band gap of anatase TiO2 (Eg = 3.0–3.2 eV). With the introduction of Ag, Ag2O and SiO2 nanoparticles, the Eg values of nanocomposite catalysts decrease to values in the range of 2.19–3.01 eV.

Photocatalytic measurement

To study the effect of catalyst composition and its structure on photocatalytic performance, the photo-degradation experiments of RhB were conducted under simulated solar irradiation. During the experimental process, the photocatalytic properties of TiO2/SiO2, TiO2, TiO2/Ag, TiO2/Ag2O, TiO2/Ag/Ag2O and TiO2/SiO2/Ag/Ag2O were investigated. The photocatalytic performance of commercial TiO2 nanoparticles (P25) was also measured for comparison, and the results are displayed in Fig. 6. As can be seen from Fig. 6a, b, the absorbance of RhB solution in the presence of TiO2/SiO2 nanocomposite spheres decreased more quickly compared with porous TiO2 nanospheres, which indicates that TiO2/SiO2 nanocomposite spheres have a relatively rapid degradation rate. That is to say, the silica core can contribute to improving the photocatalytic performance of TiO2. When porous TiO2 nanospheres were modified by Ag or Ag2O, the degradation rate of RhB was improved (Fig. 6c, d), and when Ag and Ag2O NPs were deposited on the surface of porous TiO2 nanospheres and TiO2/SiO2 nanocomposite spheres, the photocatalytic efficiencies of the nanocomposite spheres were remarkably enhanced due to the synergistic effect of Ag and Ag2O. As shown in Fig. 6e–g, the degradation of RhB could be completed within 20 min, while the degradation efficiency of P25 was very low. Based on the above, it can be concluded that TiO2/Ag/Ag2O and TiO2/SiO2/Ag/Ag2O nanocomposite spheres exhibit superior photocatalytic abilities.

Figure 6h indicates the degradation kinetics of RhB fitted by using the equation kt = ln (C0/C), in which k, C0 and C represent the slope of the straight line, and the concentration of RhB after illumination for 0 min and t min, respectively [46]. The photocatalytic activities of the catalysts can be clearly observed by comparing the slope of the lines shown in Fig. 6h. The order of the photocatalytic activity of the obtained sphere structures is as follows, TiO2/SiO2/Ag/Ag2O (k = 0.145) > TiO2/Ag/Ag2O (k = 0.138) > TiO2/SiO2 (k = 0.102) > TiO2/Ag (k = 0.039) > TiO2/Ag2O (k = 0.020) > TiO2 (k = 0.019) > P25 (k = 0.015). These results reveal that all the TiO2 nanocomposite spheres show better photocatalytic efficiencies than porous TiO2 nanospheres and P25, and TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres exhibit excellent photocatalytic performances.

The recycling efficiency of catalysts has a great influence on its further application. Therefore, it is necessary to carry out the cyclic experiment of the photocatalytic degradation of RhB solution. As illustrated in Fig. 7a, after three cycles of degradation of the RhB solution, TiO2/SiO2/Ag/Ag2O nanocomposite spheres still possess good photocatalytic activity, revealing that the prepared catalysts have excellent stability and ideal catalytic longevity.

As a commonly used co-catalyst, H2O2 can improve the degradation performance of the catalysts and shorten the catalytic reaction time. The intrinsic effect of H2O2 on the photocatalytic performance has also been investigated. Figure 7b shows the degradation kinetics of RhB over TiO2/SiO2/Ag/Ag2O nanocomposite spheres and porous TiO2 nanospheres without H2O2. As shown in Fig. 7b, the degradation properties of TiO2/SiO2/Ag/Ag2O nanocomposite spheres and porous TiO2 nanospheres are significantly improved after adding H2O2. This may be due to an inhibition of photoelectron–hole recombination and the generation of OH radicals caused by adding H2O2 under simulated solar irradiation. In addition, the photocatalytic activity of TiO2/SiO2/Ag/Ag2O nanocomposite spheres is superior to porous TiO2 nanospheres regardless of whether or not H2O2 was added to the solution.

Mechanism of photocatalytic activity

In order to explore the internal reasons for the excellent photocatalytic performance of TiO2/SiO2/Ag/Ag2O nanocomposite spheres, the illustration of the RhB degradation mechanism over the prepared catalysts under simulated solar irradiation is depicted in Fig. 8a. Since the silica core can provide a larger specific surface and more surface active sites for TiO2, this kind of structure has excellent adsorption properties for positively charged RhB in solution. Under simulated solar irradiation, Ag is first activated by the visible light and produces photoelectron–hole pairs because of the SPR effect [47]. And then, the photoelectrons (e−) on the surface of Ag shift rapidly to the conduction band (CB) of TiO2 and Ag2O. Moreover, the excited electrons at the CB of Ag2O transfer to the CB of TiO2 while the holes (h+) at the valence band (VB) of TiO2 move to the VB of Ag2O, achieving the separation of photoelectron–hole pairs. The photo-generated electrons and holes can react with O2 and H2O adsorbed on the surface of the catalysts to form O ·−2 and OH·, respectively [48]. In addition, a portion of the photoelectrons of TiO2 and Ag2O are also quickly captured by the dissolved O2 on the surface of Ag and generate O ·−2 and OH·. All of the above active radical species (O ·−2 , OH·) can efficiently decompose the RhB adsorbed on the surface of TiO2/SiO2/Ag/Ag2O nanocomposite spheres. Various scavengers were used to determine the main active species in the process of photocatalytic degradation. Figure 8b presents the effect of different scavengers on the degradation efficiency of TiO2/SiO2/Ag/Ag2O nanocomposite spheres. The sequence of their degradation activities is as follows: no scavenger (k = 0.021) > OH radicals (k = 0.0177) > electron (k = 0.0167) > hole (k = 0.008). Obviously, the presence of scavengers inhibits the degradation of RhB. This indicates that holes, electrons and OH radicals play an important role in the degradation process. The trapping of holes (h+) leads to an inferior degradation performance, i.e., the holes are the main active species in the photocatalytic degradation of RhB. Therefore, the TiO2/SiO2/Ag/Ag2O nanocomposite spheres have an excellent photocatalytic degradation performance owing to the synergistic effects of different kinds of nanoparticles.

Conclusions

In summary, a novel synthetic method was used to prepare TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres. Both Ag and Ag2O NPs were formed on TiO2/SiO2 nanocomposite spheres or porous TiO2 nanospheres. The formed nanoheterojunctions can possess large specific surface areas, wide spectral responses and low photoelectron–hole recombination rates. The photocatalytic experiments indicate that all the prepared TiO2 nanocomposite spheres, especially TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O, exhibit superior photocatalytic efficiencies in comparison with porous TiO2 nanospheres and P25. Therefore, the obtained catalysts should have a potential application in sewage treatment. This study also strongly confirmed that the synergistic effects between different kinds of nanoparticles (Ag, Ag2O, TiO2 and SiO2) play a decisive role in affecting the photocatalytic performances of the synthesized nanocomposites.

References

Y.C. Yao, X.R. Dai, X.Y. Hu, S.Z. Huang, Z. Jin, Appl. Surf. Sci. 387, 469 (2016)

S.B. Bai, K.Z. Zhang, J.H. Sun, R.X. Luo, D.Q. Li, A.F. Chen, CrystEngComm 16, 3289 (2014)

X.H. Huang, M. Leal, Q.L. Li, Water Res. 42, 1142 (2008)

H.J. Zhang, G.D. Du, W.Q. Lu, L.L. Cheng, X.D. Zhu, Z. Jiao, CrystEngComm 14, 3793 (2012)

Z.F. Wang, D.Q. Chu, L.M. Wang, L.P. Wang, W.H. Hu, Appl. Surf. Sci. 396, 492 (2017)

A.P. Batista, H.W.P. Carvalho, G.H. Luz, P.F. Martins, M. Gonçalves, L.C. Oliveira, Environ. Chem. Lett. 8, 63 (2010)

X.F. Wang, S.F. Li, H.G. Yu, J.G. Yu, S.W. Liu, Chem. Eur. J. 17, 7777 (2011)

S. Chakrabarti, B.K. Dutta, J. Hazard. Mater. 112, 269 (2004)

Y.N. Tan, C.L. Wong, A.R. Mohamed, ISRN Mater. Sci. 2011, 1 (2011)

Z.H. Zhang, Y. Xu, X.P. Ma, F.Y. Li, D.N. Liu, Z.L. Chen, F.Q. Zhang, D.D. Dionysiou, J. Hazard. Mater. 209, 271 (2012)

H.G. Yang, G. Liu, S.Z. Qiao, C.H. Sun, Y.G. Jin, S.C. Smith, J. Am. Chem. Soc. 13, 4078 (2009)

Z.Q. Li, Y. Ding, L.E. Mo, L.H. Hu, J.H. Wu, S.Y. Dai, ACS. Appl. Mater. Interfaces 7, 22277 (2015)

X. Chen, S.S. Mao, Chem. Rev. 107, 2891 (2007)

J.R. Huang, H.B. Ren, X.S. Liu, X.X. Li, J.J. Shim, Superlattices Microstruct. 81, 16 (2015)

T.V. Gerasimova, O.L. Evdokimova, A.S. Kraev, V.K. Lvanov, A.V. Agafonov, Microporous Mesoporous Mater. 235, 185 (2016)

K.C. Christoforidis, A. Sengele, V. Keller, N. Keller, ACS. Appl. Mater. Interfaces 7, 19324 (2015)

Y. Qiu, L.P. Wu, J. Li, X.J. Li, Catal. Lett. 145, 647 (2015)

L.J. Alemany, M.A. Ban, E. Pardo, F. Martin, M. Galan-Fereres, J. Blasco, Appl. Catal. B Environ. 3, 289 (1997)

W.H. Dong, F.P. Pan, L.L. Xu, M.R. Zheng, C.H. Sow, K. Wu, Appl. Surf. Sci. 349, 279 (2015)

S.Q. Liu, N.Z. Zhang, Z.R. Tang, Y.J. Xu, ACS. Appl. Mater. Interfaces 4, 6378 (2012)

X.J. Liu, L.K. Pan, T. Lv, Z. Sun, C.Q. Sun, RSC Adv. 2, 3823 (2012)

N.D. Feng, Q.W. Wang, A.M. Zheng, Z.F. Zhang, J. Fan, S.B. Liu, J. Am. Chem. Soc. 135, 1607 (2013)

K. Lalitha, G. Sadanandam, V.D. Kumari, M. Subrahmanyam, B. Sreedhar, N.Y. Hebalkar, J. Phys. Chem. C 114, 22181 (2010)

G.H. Li, N.M. Dimitrijevic, L. Chen, T. Rajh, K.A. Gray, J. Phys. Chem. C 112, 19040 (2008)

L.M. Lyu, M.H. Huang, J. Phys. Chem. C 115, 17768 (2011)

D. Sarkar, C.K. Ghosh, S. Mukherjee, K.K. Chattopadhyay, ACS. Appl. Mater. Interfaces 5, 331 (2013)

X.K. Tang, Q.M. Feng, K. Liu, Y. Tan, Mater. Lett. 183, 175 (2016)

K. Liu, Q.M. Feng, Y.X. Yang, G.F. Zhang, L.M. Ou, Y.P. Lu, J. Non-Cryst. Solids 353, 1534 (2007)

M.M. Ye, H.H. Zhou, T.Q. Zhang, Y.P. Zhang, Y. Shao, Chem. Eng. J. 226, 209 (2013)

Y. Ren, M. Chen, Y. Zhang, L.M. Wu, Langmuir 26, 11391 (2010)

M. Bellardita, M. Addamo, A. Di Paola, G. Marcì, L. Palmisano, J. Hazard. Mater. 174, 707 (2010)

Z.H. Li, J.W. Liu, D.J. Wang, Y. Gao, J. Shen, Int. J. Hydrog. Energy 37, 6431 (2012)

N.D. Feng, A.M. Zheng, Q. Wang, P.P. Ren, X.Z. Gao, S.B. Liu, J. Phys. Chem. C 115, 2709 (2011)

C.B. Liu, C.H. Cao, X.B. Luo, S.L. Luo, J. Hazard. Mater. 285, 319 (2015)

T.A. Gad-Allah, S. Kato, S. Satokawa, T. Kojima, Desalination 244, 1 (2009)

Y. Chi, Q. Yuan, Y.J. Li, L. Zhao, N. Li, X.T. Li, W.F. Yan, J. Hazard. Mater. 262, 404 (2013)

S.A. Khan, S. Ali, M. Sohail, M.A. Morsy, Z.H. Yamani, Aust. J. Chem. 69, 41 (2016)

S.P. Prakoso, A. Taufik, R. Saleh, IOP Conf. Ser. Mater. Sci. Eng. 188, 012029 (2017)

Y.Q. Cui, Q.L. Ma, X.Y. Deng, Q. Meng, X.W. Cheng, M.Z. Xie, Appl. Catal. B: Environ. 206, 136 (2017)

D. He, S. Garg, T.D. Waite, Langmuir 28, 10266 (2012)

B. Jiang, L.L. Jiang, X.W. Shi, W.C. Wang, G.S. Li, F.X. Zhu, D.Q. Zhang, J. Sol-Gel, Sci. Technol. 73, 314 (2015)

S.Q. Liu, N. Zhang, Z.R. Tang, Y.J. Xu, ACS Appl. Mater. Interfaces 4, 6378 (2012)

Z.Q. Cheng, S.Z. Zhao, Z.L. Han, Y.Q. Zhang, X.D. Zhao, L.J. Kang, CrystEngComm 18, 8756 (2016)

W.J. Zhou, H. Liu, J.Y. Wang, D. Liu, G.J. Du, J.J. Cui, ACS Appl. Mater. Interfaces 2, 2385 (2010)

S. Liu, N. Wang, Y. Zhang, J. Hazard. Mater. 284, 171 (2015)

Z. Zhu, Y. Yan, J. Li, J. Mater. Sci. 51, 2112 (2016)

C. Liu, D. Yang, Y. Jiao, Y. Tian, Y.G. Wang, Z.Y. Jiang, ACS Appl. Mater. Interfaces 5, 3824 (2013)

S. Linic, P. Christopher, D.B. Ingram, Nat. Mater. 10, 911 (2011)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 61774070), the Natural Science Foundation of Jiangsu Province (Grant No. BK20161300), the Six Talent Peaks Project in Jiangsu Province (Grant No. XNY-008), and also sponsored by Qing Lan Project and 333 Project of Jiangsu Province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, A., Zhu, Y. Synthesis of TiO2/SiO2/Ag/Ag2O and TiO2/Ag/Ag2O nanocomposite spheres with photocatalytic performance. Res Chem Intermed 44, 4227–4243 (2018). https://doi.org/10.1007/s11164-018-3365-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-018-3365-5