Abstract

An additive-free, facile, efficient, and ecofriendly protocol for synthesis of (E)-nitroolefins via nitrodecarboxylation of α,β-unsaturated acids has been developed. Cu(NO3)2 was used as both nitrating agent and catalyst. Furthermore, the presented methodology offers several advantages such as easily accessible and stable substrates, inexpensive catalyst, high to excellent yield, short reaction time, and simple posttreatment procedure.

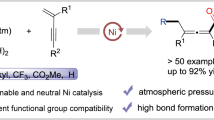

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitroolefins play important roles in organic chemistry, serving not only as a key unit in many pharmaceutical and bioactive compounds [1, 2], but also as versatile intermediates in synthetic organic chemistry for construction of carbon–carbon bonds, e.g., in the Michael reaction [3], Diels–Alder cycloaddition [4], and Morita–Baylis–Hillman reaction [5]. In addition, the nitro group can be easily transformed into other useful functional groups [6]. Hence, development of efficient methods for their preparation has been an important research direction in organic chemistry. The traditional method, namely the Henry reaction [7], relies upon base-mediated condensation of carbonyl compounds with nitroalkanes followed by dehydration. However, harsh reaction conditions and formation of undesired E/Z mixtures demand an alternative protocol. Recently, numerous useful methods have been developed for synthesis of nitroolefins, such as direct nitration of olefinic C–H bonds [8–11], nitrodecarboxylation of aromatic α,β-unsaturated carboxylic acids [12], ipso-nitration of carboxylic acids [13], and so on.

Carboxylic acids are very useful compounds, being abundant in natural products; they are commercially available with large structural variation. They are easy to store, simple to handle, and convenient to prepare by means of a large number of well-established methods. The ready availability of carboxylic acids makes them extremely promising raw materials for chemical synthesis. Recently, the decarboxylative cross-coupling reaction has attracted much attention, since it opens a new avenue for formation of carbon–carbon and carbon–heteroatom bonds [14]. Also, relevant studies have well explored research on decarboxylative nitration of α,β-unsaturated carboxylic acids. In 2002, Roy et al. [15] reported a facile nitrodecarboxylation of aromatic α,β-unsaturated carboxylic acids under the effect of nitric acid and catalytic azodiisobutyronitrile (AIBN). In 2004, Fiorentino and coworkers reported nitrodecarboxylation of cinnamic acids using cerium(IV) ammonium nitrate supported on silica as nitrating reagent [16]. However, nitration of the aromatic ring was also observed in all cases, dramatically limiting the application of this reaction. In 2011, Saiprakash et al. [17] reported a polyethylene-glycol-supported reaction for synthesis of nitroolefins from α,β-unsaturated carboxylic acids and various metal nitrates [excluding Cu(NO3)2] under mineral-acid-free and solvent-free microwave-irradiated and grinding conditions. Addition of polyethylene glycol enormously accelerated the reaction rate, and the yield was significantly increased. However, the ratio of α,β-unsaturated carboxylic acids and metal nitrates was 1:12, and the metal nitrates could not be recycled and were heavily wasted. In 2013, Maiti [18] and Prabhu [19] and their coworkers developed a decarboxylative nitration protocol for synthesis of nitroolefins from α,β-unsaturated carboxylic acids using tert-butyl nitrite as nitrating reagent, 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO), and CuCl as catalyst. Very recently, the first cellulose-supported copper-nanoparticle-catalyzed decarboxylative nitration of cinnamic and benzoic acids for synthesis of (E)-nitroolefins and substituted nitrobenzenes was reported by Baruah et al. [20]. Inspired by these results, we present herein a facile and effective method, without any additives, to prepare nitroolefins via Cu(NO3)2-catalyzed nitrodecarboxylation of α,β-unsaturated carboxylic acids.

Results and discussion

Initially, cinnamic acid (1a) was used as model substrate to optimize the reaction conditions, including the metal nitrate, solvent, and temperature under ambient air. As shown in Table 1, five metal nitrates, viz. Fe(NO3)3, Ni(NO3)3, AgNO3, NaNO3, and Cu(NO3)2, were investigated at 110 °C in 2 mL CH3CN; Cu(NO3)2 was found to be the most effective catalyst and nitrating reagent (86 %) (entries 1–5). Furthermore, different amounts of Cu(NO3)2 were attempted, and 1.2 equiv Cu(NO3)2 was found to be more suitable for the present reaction (compare entries 5–8). Additionally, solvents including CH3CN, 1,2-dichloroethane (DCE), tetrahydrofuran (THF), dimethylformamide (DMF), and 1,4-dioxane were tested using Cu(NO3)2 as catalyst and nitrating reagent at 110 °C; CH3CN provided the highest yield (entries 8–12). Interestingly, the yield decreased when the temperature was decreased to 100 °C (entry 13) or elevated to 120 °C (entry 14).

The scope and generality of substrates for the decarboxylative nitration of α,β-unsaturated carboxylic acids was investigated under the optimized conditions, and the results are summarized in Table 2. To our delight, cinnamic acids with electron-rich substituents (p-Me, p-OMe, 3,4,5-trimethoxy) or electron-poor substituents (p-CF3, m-NO2), as well as the para- and meta-substituted groups both gave the desired products in moderate to good yields (3b–d, 3h–j), showing no obvious electronic effect in this reaction. The para- and meta-substituted halogen atoms such as fluorine and chlorine were well tolerated, affording the corresponding products in 68, 65, and 62 % isolated yields, respectively (3e–g). Notably, 2-(2-nitrovinyl)naphthalene is also a suitable substrate for this reaction, reacting smoothly to give the expected nitrodecarboxylation products in good yield (3k, 93 %). Furthermore, application of the present protocol for nitrodecarboxylation of other aromatic heterocyclic compounds, including 3-(2-furyl)acrylic acid and 3-pyridyl acrylic acid, was explored (Scheme 1). The substrate 3-(2-furyl)acrylic acid also gave moderate yield of decarboxylated and nitrated product 3l in 41 % yield, while no nitrated product of 3-pyridyl acrylic acid was obtained under the optimized reaction conditions.

Gram-scale application of the present method was also explored. As shown in Scheme 2, the proposed reaction of 1a was investigated under the standard conditions, giving 1.33 g 3a in 89 % yield without significant loss of reactive efficiency. Thus, this simple, efficient, and practical protocol has good prospects for industrialization.

To gain further insight into the reaction mechanism, we added the radical scavenger TEMPO to the reaction system (Scheme 3); the nitrodecarboxylation reaction was suppressed, and product 3a was obtained in only 15 % isolated yield, indicating that a free-radical pathway might be involved in the present reaction. On the basis of the preliminary results above and previous related literature [15, 18], two plausible pathways for the present reaction are proposed (Scheme 4). In path I, α,β-unsaturated carboxylic acids react with Cu(NO3)2 to give compound A and HNO3. Then, NO2 radical is generated by heating of HNO3. Subsequently, the NO2 radical reacts with intermediate A to give alkyl radical intermediate B, which can be stabilized by the adjacent phenyl ring. Finally, CO2 is released from the radical intermediate B to afford the desired product 3. In a complementary mechanism, electrophile NO +2 is generated by HNO3. Subsequently, electrophile NO +2 undergoes electrophilic addition to intermediate A as shown in path II (Scheme 4). Finally, the product 3 is obtained after releasing CO2 and elimination of H+. Further investigations on the more detailed mechanism are in progress in our laboratory.

Conclusions

We present an example of additive-free, highly regioselective nitrodecarboxylation of α,β-unsaturated acids under mild conditions. The nitrodecarboxylation proceeded in good yield and tolerated a wide range of functional groups. Tentative experiments suggested that this reaction was likely to proceed via a radical pathway. The presented protocol is an environmentally benign, simple, efficient, green procedure for synthesis of (E)-nitroolefins with good prospects for industrialization.

Experimental

Unless otherwise noted, all materials were obtained from commercial suppliers and dried and purified using standard procedures. The melting point was measured on an SGW X-4 monocular microscope melting point apparatus with an unadjusted thermometer. 1H and 13C nuclear magnetic resonance (NMR) spectra were acquired on a Bruker Avance III 500, at 500 and 125 MHz, respectively, in CDCl3, with tetramethylsilane (TMS) as internal standard. Column chromatography was performed with silica gel (200–300 mesh).

General procedure for synthesis of (E)-nitroolefins 3a–l

A 25-mL Schlenk tube was charged with α,β-unsaturated acid (0.4 mmol), Cu(NO3)2 (0.48 mmol), and CH3CN (2 mL). The tube was sealed, then the mixture was stirred under air at 110 °C for 8 h. After completion of the reaction as monitored by thin-layer chromatography (TLC), H2O (5 mL) was added. The mixture was extracted with dichloromethane (3 × 4 mL). The combined organic layers were washed with saturated sodium bicarbonate solution (10 mL) and water (10 mL), dried over anhydrous Na2SO4, then concentrated by rotary evaporator. Finally, the residue was purified by column chromatography on silica gel (mobile phase: petroleum ether/ethyl acetate 6:1) to provide the desired products (3).

(E)-(2-Nitrovinyl)benzene ( 3a ) [18, 19, 21]

Yellow solid, m.p. 55–58 °C. 1H NMR (500 MHz, CDCl3) δ = 8.05 (d, J = 13.5 Hz, 1H), 7.63 (d, J = 13.5 Hz, 1H), 7.60–7.55 (m, 2H), 7.57–7.52 (m, 1H), 7.52–7.49 (m, 2H).13C NMR (125 MHz, CDCl3) δ = 139.1, 137.2, 132.2, 130.1, 129.4, 129.2.

(E)-1-Methoxy-4-(2-nitrovinyl)benzene ( 3b ) [18, 19]

Yellow solid, m.p. 82–85 °C. 1H NMR (500 MHz, CDCl3) δ = 8.02 (d, J = 13.5 Hz, 1H), 7.58–7.54 (m, 3H), 7.00 (d, J = 8.0 Hz, 2H), 3.92 (s, 3H). 13C NMR (125 MHz, CDCl3) δ = 163.0, 139.0, 135.1, 131.2, 122.6, 115.0, 55.5.

(E)-1,2,3-Trimethoxy-4-(2-nitrovinyl)benzene ( 3c ) [18]

Yellow solid, m.p. 120–122 °C. 1H NMR (500 MHz, CDCl3) δ = 7.97 (d, J = 13.5 Hz, 1H), 7.57 (d, J = 13.5 Hz, 1H), 6.80 (s, 2H), 3.95 (s, 3H), 3.94 (s, 6H). 13C NMR (125 MHz, CDCl3) δ = 153.8, 141.9, 139.3, 136.4, 125.3, 106.6, 61.1, 56.3.

(E)-1-Methoxy-3-(2-nitrovinyl)benzene ( 3d ) [21]

Yellow solid, m.p. 93–95 °C. 1H NMR (500 MHz, CDCl3) δ = 8.02 (d, J = 13.5 Hz, 1H), 7.62 (d, J = 13.5 Hz, 1H), 7.40 (d, J = 5.0 Hz, 1H), 7.31 (s, 1H), 7.18 (d, J = 5.0 Hz, 1H), 7.08 (s, 2H), 3.90 (s, 3H). 13C NMR (125 MHz, CDCl3) δ = 160.2, 139.0, 137.4, 131.4, 130.4, 121.7, 118.0, 114.0, 55.5.

(E)-1-Fluoro-4-(2-nitrovinyl)benzene ( 3e ) [18, 21]

Yellow solid, m.p. 103–105 °C. 1H NMR (500 MHz, CDCl3) δ = 8.02 (d, J = 13.5 Hz, 1H), 7.62–7.56 (m, 3H), 7.21–7.18 (m, 2H). 13C NMR (125 MHz, CDCl3) δ = 166.0, 164.0, 137.8, 137.0, 131.3, 131.2, 126.4, 126.3, 116.9, 116.7.

(E)-1-Chloro-4-(2-nitrovinyl)benzene ( 3f ) [19, 21]

Yellow solid, m.p. 109–110 °C. 1H NMR (500 MHz, CDCl3) δ = 7.96 (d, J = 13.5 Hz, 1H), 7.56 (d, J = 13.5 Hz, 1H),7.50 (d, J = 5.0 Hz, 2H), 7.44 (d, J = 8.0 Hz, 2H). 13C NMR (125 MHz, CDCl3) δ = 138.4, 137.7, 137.4, 130.3, 129.8, 128.5.

(E)-1-Chloro-3-(2-nitrovinyl)benzene ( 3g ) [18, 21]

Yellow solid, m.p. 50–52 °C. 1H NMR (500 MHz, CDCl3) δ = 7.98 (d, J = 13.5 Hz, 1H), 7.62–7.58 (m, 2H), 7.53–7.49 (m, 1H), 7.47–7.43 (m, 2H). 13C NMR (125 MHz, CDCl3) δ = 138.2, 137.4, 135.5, 132.0, 131.9, 130.7, 128.8, 127.2.

(E)-1-Methyl-4-(2-nitrovinyl)benzene ( 3h ) [18, 19, 21]

Yellow solid, m.p. 106–108 °C. 1H NMR (500 MHz, CDCl3) δ = 8.03 (d, J = 13.5 Hz, 1H), 7.61 (d, J = 13.5 Hz, 1H), 7.49 (d, J = 5.0 Hz, 2H), 7.30 (d, J = 5.0 Hz, 2H), 2.45 (s, 3H). 13C NMR (125 MHz, CDCl3) δ = 143.1, 139.1, 136.4, 130.2, 129.2, 127.4, 21.7.

(E)-1-(2-Nitrovinyl)-4-(trifluoromethyl)benzene ( 3i ) [19]

Yellow solid, m.p. 93–95 °C. 1H NMR (500 MHz, CDCl3) δ = 8.02 (d, J = 13.5 Hz, 1H), 7.74–7.61 (m, 5H). 13C NMR (125 MHz, CDCl3) δ = 138.9, 137.1, 133.6, 133.5, 129.3, 126.4, 126.3, 124.8, 122.1, 30.1.

(E)-1-Nitro-3-(2-nitrovinyl)benzene ( 3j ) [18]

Yellow solid, m.p. 48–50 °C. 1H NMR (500 MHz, CDCl3) δ = 8.46 (s, 1H), 8.39 (d, J = 8.0 Hz, 1H), 8.10 (d, J = 13.5 Hz, 1H), 7.92 (d, J = 5.0 Hz, 1H), 7.75–7.71 (m, 2H).13C NMR (125 MHz, CDCl3) δ = 148.9, 139.3, 136.2 134.4, 131.9, 130.6, 126.2, 123.5.

(E)-2-(2-Nitrovinyl)naphthalene ( 3k ) [18]

Yellow solid, m.p. 89–91 °C. 1H NMR (500 MHz, CDCl3) δ = 8.90 (d, J = 13.5 Hz, 1H), 8.19 (d, J = 8.0 Hz, 1H), 8.05 (d, J = 5.0 Hz, 1H), 7.97 (d, J = 8.0 Hz, 1H), 7.81 (d, J = 8.0 Hz, 1H), 7.72 (d, J = 5.0 Hz, 1H), 7.70–7.56 (m, 3H). 13C NMR (125 MHz, CDCl3) δ = 138.6, 136.2, 133.9, 132.6, 131.6, 129.1, 127.8, 127.1, 126.8, 126.4, 125.4, 123.0.

(E)-2-(2-Nitrovinyl)furan ( 3l ) [19]

Yellow solid, m.p. 68–70 °C. 1H NMR (500 MHz, CDCl3) δ = 7.82 (d, J = 13.5 Hz, 3H), 7.63 (d, J = 5.0 Hz, 1H), 7.56 (d, J = 13.5 Hz, 1H), 6.93 (d, J = 3.5 Hz, 3H), 6.62 (dd, J = 3.5, 1.5 Hz, 1H).13C NMR (125 MHz, CDCl3) δ = 146.8, 146.7, 135.0, 125.4, 119.8, 113.3.

Supplementary material

1H and 13C NMR spectra for all compounds are provided.

References

M.A. Reddy, N. Jain, D. Yada, C. Kishore, V.J. Reddy, P.S. Reddy, A. Addlagatta, S.V. Kalivendi, B. Sreedhar, J. Med. Chem. 54, 6751 (2011)

L.Q. Lu, J.R. Chen, W.J. Xiao, Acc. Chem. Res. 45, 1278 (2012)

C.B. Tripathi, S. Kayal, S. Mukherjee, Org. Lett. 14, 3296 (2012)

Y.K. Liu, M. Nappi, E. Arceo, S. Vera, P. Melchiorre, J. Am. Chem. Soc. 133, 15212 (2011)

D.K. Nair, S.M. Mobin, I.N.N. Namboothiri, Org. Lett. 14, 4580 (2012)

R. Tamura, A. Kamimura, N. Ono, Synthesis 6, 423 (1991)

S. Fioravanti, L. Pellacani, P.A. Tardella, M.C. Vergari, Org. Lett. 10, 1449 (2008)

S. Maity, S. Manna, S. Rana, T. Naveen, A. Mallick, D. Maiti, J. Am. Chem. Soc. 135, 3355 (2013)

T. Naveen, S. Maity, U. Sharma, D. Maiti, J. Org. Chem. 78, 5949 (2013)

S. Maity, T. Naveen, U. Sharma, D. Maiti, Org. Lett. 15, 3384 (2013)

U. Dutta, S. Maity, R. Kancherla, D. Maiti, Org. Lett. 16, 6302 (2014)

G.B. Yan, A.J. Borah, L.G. Wang, Org. Biomol. Chem. 12, 6049 (2014)

P. Natarajan, R. Chaudhary, P. Venugopalan, J. Org. Chem. 80, 10498 (2015)

A.J. Borah, G.B. Yan, Org. Biomol. Chem. 13, 8094 (2015)

J.P. Das, P. Sinha, S. Roy, Org. Lett. 4, 3055 (2002)

A.S. Rao, P.V. Srinivas, K.S. Babu, J.M. Rao, Tetrahedron Lett. 46, 8141 (2005)

K.C. Rajanna, K. Ramesh, S. Ramgopal, S. Shylaja, P.G. Reddy, P.K. Saiprakash, Green Sustain. Chem. 1, 132 (2011)

S. Manna, S. Jana, T. Saboo, A. Maji, D. Maiti, Chem. Commun. 49, 5286 (2013)

B.V. Rokade, K.R. Prabhu, Org. Biomol. Chem. 11, 6713 (2013)

Diganta. Baruah, Pallab. Pahari, Dilip. Konwar, Tetrahedron Lett. 56, 2418 (2015)

M. Zhang, P. Hu, J. Zhou, G. Wu, W.P. Su, Org. Lett. 15, 1718 (2013)

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (21102003) and Scientific Research Foundation for the Introduction of Talent of Anhui University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Luo, ZG., Xu, F., Fang, YY. et al. Cu(NO3)2-catalyzed nitrodecarboxylation of α,β-unsaturated acids: facile synthesis of (E)-nitroolefins under additive-free conditions. Res Chem Intermed 42, 6079–6087 (2016). https://doi.org/10.1007/s11164-016-2446-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-016-2446-6