Abstract

In the fine chemicals industry the preference for heterogeneous over homogeneous catalysts is well known. However, the activity and selectivity of heterogeneous metal complexes are usually better than those of their homogeneous counterparts. There has, consequently, been an increasing demand for heterogenized metal complexes which combine the advantages of both types of catalyst. In the production of fine chemicals, selectivity is probably its most important property of a catalyst. Chemoselectivity, regioselectivity, and enantioselectivity are very important in the synthesis of fine chemicals. Several examples of hydrogenation with heterogenized metal complexes have been studied, with emphasis on selectivity. Catalytic transfer hydrogenation is also discussed, as an alternative to classical hydrogenation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last decade there have been dramatic developments in the use of selective catalysis for production of fine chemicals. Among these processes selective hydrogenation with soluble catalysts has become increasingly important in the pharmaceutical industry, and, consequently, in catalysis research also. Both the activity and the selectivity of these soluble complexes are excellent, but the difficulty of recovering and recycling limit their usefulness in real processes. Because of these limitations, there has been increasing interest in the application of heterogeneous catalysts. Heterogeneous systems can be either modified heterogeneous catalysts [1–3] or heterogenized homogeneous complexes [4].

Reduction of the carbonyl functionality of aldehydes and ketones by metal-catalyzed transfer hydrogenation (CTH) with a suitable hydrogen donor is a valuable synthetic tool which has proved to be an elegant alternative of hydrogenation with molecular hydrogen [5]. Such organic molecules as unsaturated hydrocarbons, primary and secondary alcohols, and formic acid and its salts have been used as hydrogen sources in CTH reactions [6, 7]. Transition metals, for example Rh, Ir, Ni, and Pd, and, for carbonyl reduction, Ru complexes and propan-2-ol in the presence of a base, can catalyze the reduction [8]. Most practically used homogeneous and heterogeneous catalysts are based on such precious metals as ruthenium, rhodium, iridium, and palladium [9, 10]. As a result of their restricted availability, high price, and potential toxicity, the search for more economical and environmentally benign catalysts based on nonprecious analogues (Fe, Cu, Zn, Mn) is a real and challenging objective. Clearly, a state-of-the-art hydrogenation catalyst should be based on inexpensive materials (metal, ligand, or support) and should be easy to synthesize and convenient to handle. It should also be highly active with excellent selectivity toward a broad range of functional groups.

Although reduction catalysts based on iron are highly attractive candidates meeting these criteria, there are few examples of iron-catalyzed hydrogenation of carbonyl compounds [11–14]. The first efficient iron system used for hydrogenation of carbonyl compounds was developed by Casey and Guan in 2007 [15, 16]. By use of this highly air-sensitive complex a variety of simple aldehydes and ketones were reduced under mild reaction conditions. Unfortunately, this system had poor chemoselectivity for industrially important α,β-unsaturated carbonyl compounds. Milstein et al. [17–19] also developed an iron complex based on their work on similar ruthenium complexes. Although this catalyst is still the most efficient iron-based system for reduction of ketones, benzaldehyde was reduced in only 36 % yield, even with increased catalyst loading, and α,β-unsaturated substrates gave mixtures of hydrogenated products with moderate yields.

Selective hydrogenation of α,β-unsaturated aldehydes has attracted much interest in homogeneous catalysis, because of the synthetic value of the corresponding allylic alcohols [20]. Several good examples of catalysts, for example {RuCl2(TPPMS)2}2, (TPPMS = (3-sulfonatophenyl)diphenylphosphane sodium salt) have been developed and used for hydrogenation of trans-cinnamaldehyde. With this system, depending on pH, a variety of Ru hydride complexes were established as active catalysts [21]. At pH < 6 HRuCl(TPPMS)3 was the dominant Ru(II) complex, and it catalyzed slow but selective hydrogenation of the C=C bond. Conversely, at pH > 8 H2Ru(TPPMS)4 was found to be an active and selective catalyst for C=O reduction. Consequently, changing the pH of the solution could shift the equilibrium between the two Ru species and invert the selectivity of hydrogenation of trans-cinnamaldehyde.

Considering all of these results, and environmental and economic aspects, heterogenization of these catalysts was performed. NaY zeolite was chosen as support, because our previous experience has shown that this three-dimensional zeolite is suitable for heterogenization of soluble complexes [22], either by synthesis of the complex inside the zeolite or by anchoring it to the surface [23]. The complexes RuCl2(PPh3)3 and {RuCl2(TPPMS)2}2 were heterogenized, and the immobilized catalysts were used for hydrogenation of α,β-unsaturated aldehydes.

As continuation of this work we studied the CTH reaction of α,β-unsaturated aldehydes on heterogenized complexes. In this contribution we wish to emphasize the importance of selectivity, i.e. the type of selectivity in CTH reactions, and whether it is possible to change this selectivity by changing the conditions. We also wished to develop an iron-based, state-of-the-art hydrogenation catalyst prepared from inexpensive materials and easy to synthesize and convenient to handle.

Experimental

Materials: preparation of the catalysts

-

1

RuCl2(PPh3)3 was purchased from Aldrich and used as received. {RuCl2(TPPMS)2}2 was prepared from TPPMS and RuCl3·3H2O as described in the literature [24]. The purity of the TPPMS ligand was checked by NMR spectroscopy, by use of a Bruker Avance DRX 500 MHz instrument. NMR spectroscopy showed that the sulfonated triphenylphosphane has one SO3-group in position 3.

-

2

Iron phthalocyanine, Fe(Pc), was prepared under solvent-free conditions, by use of microwave irradiation [22]. Iron(II) chloride (2.5 g, 0.02 mol) and phthalonitrile (10.25 g, 0.08 mol) were used for the preparation; details are reported elsewhere [25]. The final catalyst was a deep blue fine power

Anchoring the soluble complexes

NaY zeolite (Aldrich; 1.5 g) was suspended in 30 mL 96 % ethanol. Phosphotungstic acid hydrate (PTA; 288.0 mg, 0.1 mmol) was dissolved in 25 mL ethanol and this solution was added dropwise into the zeolite suspension with efficient stirring. The stirring was continued for 2 days at room temperature, under an Ar atmosphere. The mixture was filtered and the solid residue was suspended in 30 mL ethanol. RuCl2(PPh3)3 (96 mg, 0.1 mmol) was dissolved in 40 mL deoxygenated ethanol and this solution was added slowly, with stirring, to the suspension. Stirring was continued for another 2 days. The mixture was filtered and the residues was washed with ethanol until a colorless solution was obtained. The light brown solid material, 1.6 g, was dried at 30 °C for 2 h under vacuum and for 1 day under argon, affording 1.45 g catalyst with an Ru content of 36.3 μmol/g.

Heterogenized {RuCl2(TPPMS)2}2 catalyst was prepared analogously from 90.1 mg (0.1 mmol Ru) {RuCl2(TPPMS)2}2 complex by use of 1.5 g NaY zeolite and 0.1 mmol PTA, affording 1.5 g heterogenized catalyst with an Ru content of 2.0 μmol/g.

Because the same heterogenization process was used this is a relatively large difference. Our explanation for this difference is that the neutral RuCl2(PPh3)3 is more easily anchored to PTA layers containing large polytungstate anions than the bulky {RuCl2(TPPMS)2}2 which carries negatively charged sulfonated ligands.

The immobilized Fe(Pc) complex was prepared similarly from 1.5 g Al2O3, 386.7 mg (0.15 mmol) PTA, and 56.8 mg (0.1 mmol) Fe(Pc) complex; 1.5 g light brown catalyst was obtained. The anchored catalyst was found to contain 35.8 μmol Fe/g catalyst.

Catalyst characterization

FTIR spectra of the support, the Ru complexes, and the heterogenized samples, as KBr pellets, were recorded in the range 400–4000 cm−1 by use of a Bio-Rad FTS–65 A spectrophotometer. XRD spectra were obtained by use of a Philips PW-1830 diffractometer.

Because, during preparation of immobilized catalyst, the uncomplexed ligand was removed by extraction, the metal content of the sample gave us the complex content. The metal content of the anchored catalysts was determined by use of a Jobin–Yvon 24 type ICP–AES instrument; 250 mg catalyst samples were dissolved in 4 mL conc. HNO3.

Hydrogenation experiments

trans-Cinnamaldehyde was hydrogenated in a 30-mL batch reactor at 65 °C and 0.4 MPa hydrogen pressure [26]. For hydrogenation of the C=C bond, acidic conditions were used. RuCl2(PPh3)3 (10 mg, 10.42 µmol) or RuCl2(PPh3)3–NaY (300 mg, 10.89 µmol Ru) was added to 3 mL 96 % ethanol, followed by 3 µL (20 µmol) Et3N and 7.8 mg (30 µmol) PPh3. The catalyst precursors were prehydrogenated overnight, then 50 µL substrate (0.396 mmol trans-cinnamaldehyde) was injected and the reactor was pressurized with H2 and the reaction was initiated by starting the stirrer. For C=O reduction we used basic conditions, with the same amount of Ru precursor, 13.5 mg (0.05 mmol) PPh3, and 6 µL (0.04 mmol) Et3N. Samples were taken every hour from the reaction mixture, and the products were analyzed by capillary gas chromatography (Hewlett Packard 5890 Series II) with a DB-5 column at 145 °C. Reactions with TPPMS-containing catalysts were conducted in the same way with 12.3 mg (0.03 mmol) or 20.5 mg (0.05 mmol) TPPMS for the two different conditions.

Catalytic transfer hydrogenation

In a 5-mL Schlenk tube 0.0038 mmol Fe(Pc) catalyst was added to 1 mL propan-2-ol and the tube was purged with Ar. Sodium hydroxide (0.19 mmol) in 0.5 mL propan-2-ol and 0.38 mmol trans-cinnamaldehyde in 0.5 mL propan-2-ol were injected into the reaction vessel. The reaction mixture was heated for 6 or 12 h at 80 °C with efficient stirring. The solution was cooled to room temperature and isolated by filtration through a plug of silica. Conversion was measured by GC without further manipulations and the products were identified by use of chromatographic standards or by GC–MS.

Catalyst recycling

The heterogenized catalysts were used in several subsequent runs. After the reactions the catalyst was recovered by filtration under Ar, washed with ethanol, dried in Ar, and then reused.

Results and discussion

With the objective of developing active, chemoselective, heterogeneous catalysts, we prepared anchored {RuCl2(TPPMS)2}2 and RuCl2(PPh3)3 catalysts and used these for hydrogenation of trans-cinnamaldehyde [26]. Fe(Pc), a new, efficient, heterogeneous catalyst for catalytic transfer hydrogenation of carbonyl functionality, was also developed [27]. The heterogenized version of this complex was prepared and used for CTH of trans-cinnamaldehyde. In this contribution we compare the performance of the two systems, with emphasis on selectivity.

Catalyst characterization

The heterogenized catalysts were characterized by use of conventional spectroscopic methods. The FTIR spectra of the support (PTA–NaY), the {RuCl2(TPPMS)2}2 and RuCl2(PPh3)3 complexes, and the heterogenized samples were all recorded. Comparison of these spectra shows convincingly that RuCl2(PPh3)3 is anchored to the NaY support. The spectrum of the heterogenized catalyst contains bands, at 1493, 1440, 1076 cm−1, which are characteristic of the RuCl2(PPh3)3 complex.

Similar spectra were obtained for {RuCl2(TPPMS)2}2 and its heterogenized analog. Comparison of the spectra leads to the same conclusion as for RuCl2(PPh3)3.

Similar characterization was performed for the Fe(Pc) complex (Fig. 1). The complex and the heterogenized catalyst were characterized by FTIR spectroscopy and the spectra contained characteristic bands (1515, 1494, 1333, 1164, 1118, and 752 cm−1) for (Pc).

To determine the metal complex concentration of the heterogenized catalysts, samples were dissolved in conc. HNO3 and the metal content of these solutions was determined by ICP–AES. The anchored RuCl2(PPh3)3 and {RuCl2(TPPMS)2}2 solid catalysts were found to contain 36.3 μmol/g and 2.0 μmol/g Ru, respectively. The metal content of the anchored Fe(Pc) was 35.8 μmol Fe/g catalyst.

Hydrogenation of trans-cinnamaldehyde

The properties of the heterogenized catalysts, {RuCl2(TPPMS)2}2–PTA–NaY and RuCl2(PPh3)3–PTA–NaY, were investigated in the hydrogenation of trans-cinnamaldehyde. When the homogeneous complexes were used under H2 a pH-dependent equilibrium was observed between the monohydrido HRuCl(TPPMS)3 and dihydrido H2Ru(TPPMS)4 derivatives. These two Ru-hydrides have different selectivity in the hydrogenation of α,β-unsaturated aldehydes. The monohydrido derivative hydrogenates the C=C double bond whereas the dihydrido species is a selective catalyst for hydrogenation of the C=O double bond [15, 16]. Consequently, simply adjusting the pH of the aqueous phase can change the selectivity of the hydrogenation of trans-cinnamaldehyde.

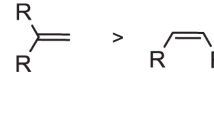

Selective hydrogenation of C=O bonds

For the hydrogenation reaction we used two slightly different conditions, on the basis of the results obtained under homogeneous conditions [21]. The pH of our ethanolic solutions was adjusted by addition of Et3N. For the C=O reduction, basic conditions were used (discussed in the “Experimental” section). The catalyst mixture was prehydrogenated for sufficient time to ensure the formation of the catalytically active Ru hydrides. The products of the reaction are shown in Scheme 1 (no other products were obtained during the hydrogenation reaction); the results are listed in Table 1.

It is apparent that the heterogenized catalysts—both sulfonated and nonsulfonated—were active in the hydrogenation of trans-cinnamaldehyde in alcoholic solution. Comparison of the TOF of the heterogenized and homogeneous catalysts revealed the former had approximately the same or higher activity than the latter. The higher activity of 2a–NaY is in a good agreement with our previous findings [28], i.e. that use of heterogenized catalysts resulted in approximately the same or higher rate of reaction than their homogeneous counterparts, leading to higher specific activity than that of the homogeneous analogs.

There are important requirements when heterogenizing soluble complexes. The immobilized complex should be as active and selective as its homogeneous counterpart, which is not always observed. Sometimes, however, the performance of the immobilized complexes is much better than that of the homogeneous analogs. Several explanations of these phenomena are available in the literature. One example is site-isolation theory, which explains the greater activity on the basis of separation of molecules of the complex, because some complexes form dimers which are not catalytically active [29]. If the heterogenized complex is a “ship-in-a-bottle” type catalyst, the usual explanation is to suppose the entactic state theory, which asserts that distorted geometry causes the higher activity [30]. Thomas et al. [31] established the confinement concept theory, which postulates more interaction between the complex and the reactants if the complex is immobilized.

Because our immobilized complexes are anchored, either the “site isolation” or “confinement concept” could be a good explanation.

Under the conditions described above, all the catalysts have fairly good selectivity for C=O hydrogenation. In other words, the synthetically important product, the unsaturated alcohol, is formed in high yield.

Selective hydrogenation of C=C bonds

Under acidic conditions, selective hydrogenation of C=C was expected. Table 2 shows the results obtained.

Table 2 shows that all the catalysts were active in the hydrogenation reaction under these conditions also. Similar to C=O hydrogenation, the specific activity of the heterogenized catalysts was approximately the same or higher than that of the homogeneous catalysts. Both sulfonated catalysts and the heterogenized nonsulfonated catalyst had some selectivity in favor of hydrogenation of C=C bond, with 3-phenylpropanal (the saturated aldehyde) as the major product. With 1b, however, C=O hydrogenation remained predominant, even under acidic conditions.

Catalytic transfer hydrogenation of aldehydes

With the final objective of developing a new, efficient, heterogeneous catalyst for catalytic transfer hydrogenation of carbonyl groups we prepared the Fe(phthalocyanine) complex, Fe(Pc), and the heterogenized version of it. Iron complexes under homogeneous conditions usually used in oxidation reactions; their applicability in reductions has been rather neglected in the past. We also wished to examine the possibility of replacing the generally applied rare transition metal catalysts with the Fe(Pc) complex.

In this work we also wished to optimize the reaction conditions for the CTH reaction, using benzaldehyde as starting material. When the optimum conditions had been determine, differently substituted aldehydes were then studied; the results are listed in Table 3.

As Table 3 clearly shows, all the substituted benzaldehyde derivatives were active in this reaction. Excellent conversion was achieved for benzaldehydes substituted with electron-donating groups, for example MeO and diMeO (Table 3, entries 2 and 7); almost total conversion was even obtained for 4-Cl-benzaldehyde. Substitution with electron-withdrawing substituents, for example NO2, reduced the conversion. The smallest decrease was observed for substitution at the p position and the highest for substitution at the o position (Table 3, entries 3–5). We explain this phenomenon on the basis of an ionic type of hydrogenation mechanism. The positively charged carbon atom of the formyl group and the positively charged nitrogen atom of the nitro group are repelled by each other, so the activation energy is highest if the NO2 group is in the o position and the lowest if it is in the p position.

With the heterogenized catalyst we used the same conditions as for the CTH reaction under homogeneous conditions. This study, also, started with optimization of the reaction conditions; results for selected aldehydes under the optimized conditions are listed in Table 4.

As is apparent from Table 4, under the optimized conditions with the heterogenized complex all the aldehydes studied were reduced to the corresponding alcohols with good to excellent yields, i.e., the immobilized Fe(Pc) complex was a good catalyst for CTH reaction of different aldehydes. The most important advantages of the immobilized complexes are easy separation and the possibility of recycling.

Catalytic transfer hydrogenation of trans-cinnamaldehyde

With the developed catalytic system we examined the CTH reaction of trans-cinnamaldehyde. This study was performed to answer the questions:

-

Does the CTH reaction work for α,β-unsaturated aldehydes?

-

Is there any selectivity in this reaction?

-

Is it possible to change the selectivity by changing the conditions?

The CTH reaction of α,β-unsaturated aldehydes was studied under the conditions found to be optimum for simple aldehydes; the results obtained are listed in Table 5.

The data in Table 5 show that the CTH reaction works for α,β-unsaturated aldehydes also. Some chemoselectivity was observed, because the major product was the unsaturated alcohol when the original conditions were used for the catalytic transfer hydrogenation. In this reaction the cinnamyl alcohol is the most valuable product, so the CTH reaction is more than 40 % selective for the most valuable product. The heterogenized catalyst was also active, but its activity was less than that of the free complex. Selectivity, also, was different—no C=C hydrogenation was observed and the proportion of the unsaturated alcohol was smaller. Consequently on the heterogenized catalyst the saturated alcohol became the major product. Because we were also interested in changing the selectivity, we performed the CTH reaction of trans-cinnamaldehyde under more basic conditions, i.e. with twice the amount of NaOH (Table 6).

Table 6 shows that when the conditions were changed the selectivity also changed, in favor of the most valuable product, the unsaturated alcohol. Another important observation is that we achieved full conversion on both types of catalyst. With the heterogenized complex the trend was similar to that observed for the homogeneous catalyst, i.e. the saturated aldehyde has not formed and, consequently, selectivity for the most valuable product increased to approximately 80 %.

Comparison of hydrogenation and the CTH reaction of trans-cinnamaldehyde

By studying the hydrogenation of trans-cinnamaldehyde we were able to shift the selectivity from C=O hydrogenation to C=C hydrogenation by changing the basicity. This study was performed on homogeneous and heterogenized Ru(phosphane) catalysts, and in ethanolic solution the basicity was changed by varying the amount of Et3N. Because of the industrial importance of the unsaturated alcohol, this finding seems very interesting and useful, especially because heterogenized complexes have been proved to be recyclable through several runs without any significant change in selectivity and activity whereas traditional hydrogenation, as is well known, always has the risk of high pressure and the complexes used are expensive.

These aspects motivated investigation of the CTH reaction with the same substrate and study of the possibility of changing the selectivity. We also wished to use a more economical and readily accessible catalyst, Fe(phthalocyanine). Fe(Pc), both homogeneous and heterogenized, has been proved to be an active catalyst of the CTH reaction of trans-cinnamaldehyde. By using a specific amount of NaOH the industrially more important product, the unsaturated alcohol, was formed as a major product. At the same time, however, C=C bond breaking occurred, producing substantial amounts of benzyl alcohol and benzaldehyde. We were unable to reduce the formation of these side products by increasing the amount of NaOH and reducing the reaction time. This finding meant that, although we could produce the unsaturated alcohol with reasonable selectivity, and application of the CTH reaction was simpler than traditional hydrogenation, and our “state-of-the-art” catalyst was working very well, more investigation was required if the CTH reaction was to become a real alternative to traditional hydrogenation.

Recycling of immobilized catalysts

The most important advantage of immobilization is the possibility of recycling, which is crucial if the complex is expensive or difficult to obtain. Because Ru–phosphane complexes are expensive, we checked the recyclability of these complexes (Fig. 2).

As Fig. 2 clearly shows, we could recycle the catalyst for three consecutive runs without significant changes of conversion and selectivity. Because Fe(Pc) is a readily available, inexpensive material we did not investigate recyclability. However, the heterogenized version of this system should be recyclable according to our previous experience.

Conclusion

With the final objective of developing a “state-of-the-art” hydrogenation catalyst which was made from inexpensive materials, was easy to synthesize, and was convenient to handle we prepared an immobilized version of Fe(Pc) and used it in CTH reactions of aldehydes. In this work we compared use of heterogenized Ru–phosphane complexes in the hydrogenation of trans-cinnamaldehyde and in catalytic transfer hydrogenation of the same substrate. For anchored Ru(phosphane) catalysts the chemoselectivity was changed by changing the basicity. Under basic conditions the unsaturated alcohol was the major product whereas under acidic conditions C=C hydrogenation occurred. The anchored Ru(phosphane) complex was recyclable without substantial change in activity. Catalytic transfer hydrogenation was performed over an inexpensive iron complex, Fe(Pc), which has been proved to be active in CTH reactions of aldehydes. In this work we extended the application of this catalyst to reduction of trans-cinnamaldehyde, with emphasis on selectivity. Our results show that catalytic transfer hydrogenation is suitable for reduction of α,β-unsaturated aldehydes also. Fe(Pc) was proved to be an inexpensive, effective catalyst for reduction of trans-cinnamaldehyde, a reaction which is easy to perform and convenient to handle. Even the selectivity is good; under suitable conditions the most valuable product, the unsaturated alcohol, is obtained in good yield.

By comparing the two hydrogenation techniques we established that CTH could be a valid option for reduction: it is effective, convenient to handle, and is suitable for α,β-unsaturated aldehydes also. Although we have not achieved chemoselectivity by use of the Ru(phospane) system, other advantages of the CTH reaction makes it applicable in practical synthesis.

References

P.B. Wells, R.P.K. Wells, in Chiral Catalysts Immobilization and Recycling, ed. by D.E. De Vos, I.F.J. Vankelecom, P.A. Jacobs, (Wiley-VCH, Weinheim, 2000) p. 123

M. Studer, H.-U. Blaser, C. Exner, Adv. Synth. Catal. 345, 45 (2003)

M. Bartók, M. Sutyinszki, K. Felföldi, Gy. Szöllősi, Chem. Commun. 1130 (2002)

Á. Zsigmond, F. Notheisz, Curr. Org. Chem. ed. (Á. Molnár) 10, 1655 (2006)

S. Gladiali, E. Alberico, Chem. Soc. Rev. 35, 226–236 (2006)

R. Noyori, M. Yamakawa, S. Hashiguchi, J. Org. Chem. 66, 7931 (2001)

F. Fache, E. Schilz, M.L. Tommasino, M. Lemaire, Chem. Rev. 100, 2159 (2000)

R. Noyori, S. Hashiguchi, Acc. Chem. Res. 30, 97–102 (1997)

F. Spindler, H.-U. Blaser, in Transition Metals for Organic Synthesis, vol. 2, ed. by M. Beller, C. Bolm (Wiley-VCH, Weinheim, 2004), p. 113

H.-U. Blaser, F. Spindler, in Handbook of Homogeneous Hydrogenation, vol. 3, ed. by J.G. de Vires, C.J. Elsevier (Wiley-VCH, Weinheim, 2007), p. 1193

S. Enthaler, G. Erre, M.K. Tse, K. Junge, M. Beller, Tetrahedron Lett. 47, 8095–8099 (2006)

S. Enthaler, B. Hagemann, G. Erre, K. Junge, M. Beller, Chem. Asian J. 1, 598–604 (2006)

S. Enthaler, B. Spilker, G. Erre, M.K. Tse, K. Junge, M. Beller, Tetrahedron 64, 3867–3876 (2008)

A. Mikhailine, A.J. Lough, R.H. Morris, J. Am. Chem. Soc. 131, 1394–1395 (2009)

C.P. Casey, H. Guan, J. Am. Chem. Soc. 129, 5816–5817 (2007)

C.P. Casey, H. Guan, J. Am. Chem. Soc. 131, 2499–2507 (2009)

R. Langer, G. Leitus, Y. Ben-David, D. Milstein, Angew. Chem. 123, 2168–2172 (2011)

R. Langer, G. Leitus, Y. Ben-David, D. Milstein, Angew. Chem. Int. Ed. 50, 2120–2124 (2011)

R. Langer, M.A. Iron, L. Konstantinowsky, Y. DiskinPosner, G. Leitus, Y. Ben-David, D. Milstein, Chem. Eur. J. 18, 7196–7209 (2012)

M. Hernandez, P. Kalck, J. Mol. Catal. 116, 131 (1997)

F. Joó, J. Kovács, A. Bényei, Á. Kathó, Catal. Today 42, 441 (1998)

Á. Zsigmond, F. Notheisz, React. Kinet. Katal. Lett. 74, 225 (2001)

Á. Zsigmond, F. Notheisz, G. Csjernyik, J.E. Bäckvall, Top. Catal. 19, 119 (2002)

F. Joó, J. Kovács, A. Bényei, Á. Kathó, Angew. Chem. Int. Ed. 37, 969 (1998)

P. Kluson, M. Drobek, S. Krejcikova, J. Krysa, A. Kalaji, T. Cajthaml, J. Rakusan, Appl. Catal. B Environ. 80, 321–326 (2008)

Á. Zsigmond, I. Balatoni, F. Notheisz, F. Joó, J. Catal. 227, 428 (2004)

P. Bata, F. Notheisz, P. Kluson, Á. Zsigmond, Appl. Organomet. Chem. 29, 45–49 (2015)

Á. Zsigmond, K. Bogár, F. Notheisz, Catal. Lett. 83, 55 (2002)

R.H. Grubbs, C. Gibbons, L.C. Kroll, W.D. Bonds Jr, C.H. Brubaker Jr, J. Am. Chem. Soc. 95, 2373 (1973)

R.J.P. Williams, Eur. J. Biochem. 234, 363 (1995)

J.M. Thomas, T. Maschmeyer, B.F.G. Johnson, D.S. Shepard, J. Mol. Catal. A Chem. 141, 139 (1999)

Acknowledgments

The authors wish to express their thanks and gratitude for research grant 103191 OTKA NN, awarded in support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bata, P., Zsigmond, Á., Gyémánt, M. et al. Use of heterogenized metal complexes in hydrogenation reactions: comparison of hydrogenation and CTH reactions. Res Chem Intermed 41, 9281–9294 (2015). https://doi.org/10.1007/s11164-015-1995-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-1995-4