Abstract

Despite the low power conversion efficiency of solar cells n-ZnO/p-CuO and n-ZnO/p-Cu2O, they can contribute to the development of photovoltaic energy. To optimize their yields, the simulator software SCAPS-1D was used in this work to do the simulations of the two cells (Fig. 1) by varying certain parameters. Its parameters were thickness, bandgap, shallow uniform donor density (ND) for the ZnO, and shallow uniform acceptor density (NA) for the CuO and Cu2O. The values optimized of these parameters gave short-circuit currents and efficiencies of 27.7755 mA.cm−2, 31.40%, and 12.9790 mA.cm−2, 13.34% respectively for the solar cells n-ZnO/p-CuO and n-ZnO/p-Cu2O (Fig. 2). Our results reveal that the n-ZnO/p-CuO solar cell is more efficient than the n-ZnO/p-Cu2O solar cell and can be used for converting solar energy into electricity.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The world evolves with all the technology in it. Solar energy is not on the sidelines. In fact, silicon has been the subject of research for several years and is gradually giving way to other semiconductors such as oxides (Li et al. 2017; Bouich 2021; Lu et al. 2016; Shen et al. 2015; Wisz et al. 2018). Several works in the literature have been realized on the copper oxide and zinc oxide used in solar cells (Fortunato et al. 2007). Apart from solar cells made of several types of materials (Tsunomura et al. 2009; Khan et al. 2018; Ajmal Khan and Suemasu 2017), There are heterojunction solar cells made only of metal oxides. The oxides being abundant and less expensive, these cells called all-oxide photovoltaic cells are thus produced at low cost and can be an alternative to the high price of the solar cells generally used. This has prompted the scientific community to take an interest in these types of photovoltaic solar cells (Morasch et al. 2014; Wisz et al. 2018; Ruhle et al. 2012). ZnO/CuO and ZnO/Cu2O n-p junction have good properties for optoelectronic applications and can be competitive in the solar cell market (Mizuno et al. 2020).

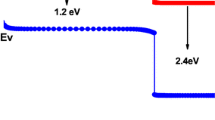

ZnO is a cheap and abundant material in nature. Its properties such as its transparency in the visible and its direct bandgap of 3.3 eV make it a good candidate for electronic and optoelectronic applications (Mizuno et al. 2020; Mahajan et al. 2020). Due to its properties, cupric oxide (CuO) is used as an active layer in solar cells. In fact, it is a p-type semiconductor stable, cheap, and non-toxic with a bandgap of 1.2 eV (Kidowaki et al. 2012). It has a monoclinic crystalline structure with an absorption coefficient of 105 cm−1 and its electrical resistivity varies from 10 to 105 cm\(\Omega\) (Shabu et al. 2015; Ooi et al. 2013; Valladares et al. 2012; Liu et al. 2011).

This work is a theoretical study that uses the SCAPS-1D simulation program to simulate solar cells n-ZnO/p-CuO and n-ZnO/p-Cu2O. The influence of certain parameters of the different layers on the performance of solar cells is studied. The goal of this work is therefore to optimize the values of these parameters to have the best efficiencies for the solar cells as well as to compare the performance of the two cells.

2 Simulator program SCAPS-1D

Several simulation software is used in the literature for thin film solar cells simulation (Decock et al. 2011) such as AMPS (Matin et al. 2010), ASPIN (Vukadinoyic et al. 2003), AFORS-HET (Froitzheim et al. 2003), and SCAPS-1D (Doumbia et al. 2022). We have used SCAPS-1D in this work. SCAPS-1D is a software simulation developed in Belgium at Gent University and was usable since 1998. Different characteristics of I-V, C-V, C-f, QE, band diagrams, electric field, carrier densities, and partial recombination currents can be used to show the results of the simulation. Before the simulation, the material parameters can be set as well as other parameters in the software such as temperature, voltage, frequency, and illumination. A stack of layers constitutes the cell. Each layer has a parameter entry. The front and the back contact are provided by two additional layers that already exist in the device (Sawicka-Chudy et al. 2018).

3 Methods

The simulator program SCAPS-1D has been used to perform the simulation of photovoltaic characteristic J-V and QE of the thin films n-ZnO/p-CuO and n-ZnO/p-Cu2O solar cells. These characteristics allowed the calculation of the most important parameter such as open circuit voltage (Voc), short-circuit current (Jsc), fill factor (FF), and efficiency (eta), which were analyzed later. Simulations have been realized under standard illumination (AM 1.5 G, 100 MW.cm−2, 300 K). The values of parameters of different materials have been taken from the literature and we have played on some of them to see their influence on the performance of the solar cell. The values shown in Table 1 are unchanged. We have inserted them into the program as such. On the other hand, the parameters whose influence we want to study have values that vary. For a variation of the values of one parameter, the other `parameters have a fixed value (the ideal value if found).Table 1 below shows the parameters of different materials.

The influence of the layers’ thickness of different materials was analyzed as well as the influence of their bandgap. Additionally, the influence of the ND of ZnO and the influence of the NA of CuO and Cu2O were also evaluated. Finally, we have used the best data to do the simulation for our cells. In Table 2 below, we have put the parameters for the front and back contact of the solar cell. This parameter has been taken in the simulation program.

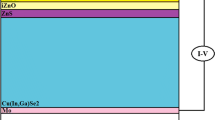

Figure 1 below shows the structure of the two solar cells n-ZnO/p-CuO and n-ZnO/p-Cu2O.

4 Results and discussions

4.1 Influence of layers thickness

To determine the best ZnO layer thickness as a window layer in the different ZnO/CuO and ZnO/Cu2O solar cells, the parameters Voc, Jsc, FF, and eta were constructed and depicted in Fig. 2 below. The smaller the thickness of the layer, the more the series resistance of the PV device is minimized (Sawicka-Chudy et al. 2019). The thickness varied from 50 to 300 nm in the step of 50 nm. The bandgap and the shallow uniform donor density were kept as constants of 3.2 eV, 1017 cm−3, respectively. Moreover, the parameters such as the thickness, the bandgap, and the shallow uniform acceptor of the CuO absorber layer were kept also as constants of 6000 nm, 1.51 eV, 1016 cm−3 respectively. The Voc depicted in a) was constant from 50 to 250 nm and decreases strongly. The other parameters decrease as increasing in the ZnO thickness. From these parameters, the optimal thickness of ZnO is 50 nm.

The influence of CuO thickness on the cell parameters is depicted in Fig. 3 below. The thickness varied from 3000 to 8000 nm in steps of 1000 nm. The bandgap and the shallow uniform acceptor density were kept as constants of 1.51 eV, 1016 cm−3, respectively. The thickness, the bandgap, and the ND of the ZnO window layer were kept also as constants of 50 nm, 3.2 eV, 1017 cm−3 respectively. The figure shows that all parameters (Voc, Jsc, FF, eta) increase as the CuO thickness increases. The curves increase slightly after 600 nm. Thus, the best-chosen thickness is 600 nm.

The influence of Cu2O thickness on the cell parameters is depicted in Fig. 4 below. The thickness varied from 500 to 4000 nm in steps of 500 nm. Here the bandgap and the shallow uniform acceptor density were kept as constants of 2.2 eV, 1018 cm−3, respectively. The same ZnO parameters previously used were used. Among the curves below, only fill factor in c) decreases with the thickness increasing. Other curves increase as increasing in the Cu2O thickness. The Jsc (Fig. 4b) and eta (Fig. 4d) increase strongly until 2000 nm and increase slightly after this. The Voc (Fig. 4a) shows that a big thickness can be used to have good results, but the fill factor (Fig. 4c) will be small. From these different curves, 2000 nm was used as the Cu2O thickness in this simulation.

4.2 Influence of bandgap

To determine the best bandgap of the ZnO layer, the bandgap varied from 2.2

to 3.3 eV and the different curves below were constructed in Fig. 5. The different parameters like the thickness of ZnO and CuO found previously were used as well as the other parameters of ZnO and CuO used previously. All curves below increase as the increase in ZnO bandgap. This increase is weak after 3.2 eV. Thus, 3.2 eV was used as the best bandgap of ZnO. It is possible to use 3.3 eV, but there won’t be a big influence.

The influence of CuO bandgap on cell parameters is illustrated in Fig. 6 below.The bandgap was varied, and the other parameters used previously or found were kept constant. Unlike the values of Voc (Fig. 6a) and fill factor (Fig. 6c), the values of the Jsc (Fig. 6b) and the ete (Fig. 6d) decrease with the CuO bandgap increasing. As 1.5 eV has good results in each case, it was used as the CuO bandgap.

The influence of Cu2O bandgap on the cell parameter is depicted in Fig. 7 below. ZnO and Cu2O parameters used previously or found were kept constant, and the bandgap of Cu2O varied from 2 to 2.2 eV. Results show that only the Voc increased with the bandgap from 2.1 eV. According to the results, the best bandgap is 2 eV with an efficiency of 11.8 eV.

4.3 Influence of ND and NA

Here, the influence of the ND and NA on cell parameters is studied. The parameters of different oxides used previously or found were kept constant and ND or NA varied. Results of the influence of ZnO’s ND on cell parameters are in Table 3 below. The Voc rest constant with the ND variation. The Jsc decreases slightly with the ND increasing whereas the FF increase. The efficiency (eta) increases as the increase of ZnO ND. But the efficiency is constant after 1017 cm−3. In this case, 1017 cm−3 was used as the best shallow uniform donor density of ZnO.

Table 4 below shows the results of the influence of CuO shallow uniform acceptor density on cell parameters. Results are good until the value 1022 cm−3. After this value, the fill factor is bad (28.33%). Thus, the value 1022 cm−3 has been chosen as the best value of CuO shallow uniform acceptor density with an efficiency of 31.40%.

Results of the influence of Cu2O shallow uniform acceptor density on cell parameters are in Table 5 below. The Voc and eta increase with the NA increasing which is opposite for the Jsc and FF. Contrary to previous results, the Jsc is weak at about 15 mA/cm2 of difference. Moreover, the efficiencies are weak compared to the efficiencies of the previous cell. According to the results, the fill factor is bad (FF = 39.93%) when NA is 1020 cm−3. However, the different parameters have good results with a NA equal to 1019 cm−3. Consequently, the value 1019 cm−3 has been chosen as the shallow uniform acceptor density of Cu2O with an efficiency of 13.34% (Bouich et al. 2023; Bouazizi et al. 2023; Koné et al. 2023).

Figure 8 below summarizes the results of the two solar cells and allows to compare the different values. By comparison, the results of the solar cell-based-CuO are vastly superior to those of the solar cell-based-Cu2O. For example, the efficiencies of solar cells n-ZnO/p-CuO and n-ZnO/p-Cu2O were 31.40% and 13.34% respectively.

5 Conclusion

This work investigated the solar cell n-ZnO/p-CuO and n-ZnO/p-Cu2O by using the solar cell simulator, SCAPS. The thickness, the bandgap, and the ND or NA of different layers were optimized by analyzing the results of Voc, Jsc, FF, and eta. After analyzing the ZnO film window layer, the optimized values of the thickness, the bandgap, and of the shallow uniform donor density are 50 nm, 3.2 eV, and 1017 cm−3 respectively. The values optimized for the thickness, the bandgap, and the NA of the CuO absorber layer are 6000 nm, 1.5 eV, and 1022 cm−3 respectively. The values optimized of these parameters and in this order of Cu2O are 2000 nm, 2.2 eV, and 1019 cm−3. With these different values optimized, the solar cell n-ZnO/p-CuO and n-ZnO/p-Cu2O were 31.40% and 13.34% respectively. Results of the solar cell based-CuO are vastly superior to those of the solar cell based-Cu2O. It is therefore the best solar cell for converting solar energy into electricity.

References

Ajmal Khan, M., Suemasu, T.: Donor and acceptor levels in impurity-doped semiconducting BaSi2 thin films for solar-cell application. Phys. Status Solidi A 214(9), 1700019 (2017)

Bouich, A.: Study and characterization of hybrid perovskites and copper-indium-gallium selenide thin films for tandem solar cells (Doctoral dissertation, Universitat Politècnica de València) (2021). https://doi.org/10.4995/Thesis/10251/160621

Bouazizi, S., Bouich, A., Tlili, W., Amlouk, M., Omri, A., Soucase, B. M.: Methylammonium lead triiodide perovskite-based solar cells efficiency: Insight from experimental and simulation. J Mol Graph Model 122, 108458 (2023)

Bouich, A., Torres, J. C., Chfii, H., Marí-Guaita, J., Khattak, Y. H., Baig, F., Palacios, P.: Delafossite as hole transport layer a new pathway for efficient perovskite-based solar sells: Insight from experimental DFT and numerical analysis Solar Energy 25018–250132 (2023). https://doi.org/10.1016/j.solener.2022.12.022

Doumbia, Y., Bouich, A., Soro, D., Soucase, B. M.: Mixed halide head perovskites thin films: Stability and growth investigation. Optik, 261, 169222 (2022)

Decock, K., Khelifi, S., Burgelman, M.: Modelling multivalent defects in thin film solar cells. Thin Solid Films 519(21), 7481–7484 (2011)

Fortunato, E., Ginley, D., Hosono, H., Paine, D.C.: Transparent conducting oxides for photovoltaics. MRS Bull. 32(3), 242–247 (2007)

Froitzheim, A., Stangl, R., Elstner, L., Kriegel, M., Fuhs, W.: AFORS-HET: a computer-program for the simulation of heterojunction solar cells to be distributed for public use. In: 3rd World Conference on Photovoltaic Energy Conversion, 2003. Proceedings of, vol. 1, pp. 279–282 (2003) IEEE

Gou, L., Murphy, C.J.: Solution-phase synthesis of Cu2O nanocubes. Nano Lett. 3(2), 231–234 (2003)

Khan, M.A., Sato, R., Sawano, K., Sichanugrist, P., Lukianov, A., Ishikawa, Y.: Growth and characterization of low composition Ge, x in epi-Si1− xGex (x⩽10%) active layer for fabrication of hydrogenated bottom solar cell. J. Phys. D Appl. Phys. 51(18), 185107 (2018)

Kidowaki, H., Oku, T., Akiyama, T.: Fabrication and characterization of CuO/ZnO solar cells. In: Journal of Physics: Conference Series, vol. 352, 1st edn, pp. 012022. IOP Publishing (2012)

Koné, K.E., Bouich, A., Soucase, B.M., Soro, D.: Manufacture of different oxides with high uniformity for copper zinc tin sulfide (CZTS) based solar cells. J. Mol. Graphics Model. 121108448 (2023). https://doi.org/10.1016/j.jmgm.2023.108448

Lam, N.D.: Modelling and numerical analysis of ZnO/CuO/Cu2O heterojunction solar cell using SCAPS. Eng. Res. Express 2(2), 025033 (2020)

Li, Z., Tong, K., Shi, R., Shen, Y., Zhang, Y., Yao, Z., Shao, G.: Reactive plasma deposition of high quality single phase CuO thin films suitable for metal oxide solar cells. J. Alloys Compounds 695, 3116–3123 (2017)

Liu, M., Lin, M.C., Wang, C.: Enhancements of thermal conductivities with Cu, CuO, and carbon nanotube nanofluids and application of MWNT/water nanofluid on a water chiller system. Nanoscale Res. Lett. 6(1), 1–13 (2011)

Lu, L., Guo, M., Thornley, S., Han, X., Hu, J., Thwaites, M.J., Shao, G.: Remote plasma sputtering deposited Nb-doped TiO2 with remarkable transparent conductivity. Sol. Energy Mater. Sol. Cells 149, 310–319 (2016)

Mahajan, P., Singh, A., Arya, S.: Improved performance of solution processed organic solar cells with an additive layer of sol-gel synthesized ZnO/CuO core/shell nanoparticles. J. Alloy. Compd. 814, 152292 (2020)

Matin, M.A., Aliyu, M.M., Quadery, A.H., Amin, N.: Prospects of novel front and back contacts for high efficiency cadmium telluride thin film solar cells from numerical analysis. Sol. Energy Mater. Sol. Cells 94(9), 1496–1500 (2010)

Mizuno, J., Jeem, M., Takahashi, Y., Kawamoto, M., Asakura, K., Watanabe, S.: Light and shadow effects in the submerged photolytic synthesis of micropatterned CuO nanoflowers and ZnO nanorods as optoelectronic surfaces. ACS Appl. Nano Mater. 3(2), 1783–1791 (2020)

Morasch, J., Li, S., Brötz, J., Jaegermann, W., Klein, A.: Reactively magnetron sputtered Bi2 O 3 thin films: analysis of structure, optoelectronic, interface, and photovoltaic properties. Phys. Status Solidi A 211(1), 93–100 (2014)

Ooi, P.K., Ng, S.S., Abdullah, M.J., Hassan, H.A., Hassan, Z.: Effects of oxygen percentage on the growth of copper oxide thin films by reactive radio frequency sputtering. Mater. Chem. Phys. 140(1), 243–248 (2013)

Ruhle, S., Anderson, A.Y., Barad, H.N., Kupfer, B., Bouhadana, Y., Rosh-Hodesh, E., Zaban, A.: All-oxide photovoltaics. J. Phys. Chem. Lett. 3(24), 3755–3764 (2012)

Sawicka-Chudy, P., Starowicz, Z., Wisz, G., Yavorskyi, R., Zapukhlyak, Z., Bester, M., Cholewa, M.: Simulation of TiO2/CuO solar cells with SCAPS-1D software. Mater Res Express 6(8), 085918 (2019)

Sawicka-Chudy, P., Sibiński, M., Wisz, G., Rybak-Wilusz, E., Cholewa, M.: Numerical analysis and optimization of Cu2O/TiO2, CuO/TiO2, heterojunction solar cells using SCAPS. In: Journal of Physics: Conference Series, vol. 1033, pp. 012002, IOP Publishing (2018)

Scanlon, D.O., Morgan, B.J., Watson, G.W.: Modeling the polaronic nature of p-type defects in Cu 2 O: the failure of GGA and GGA+ U. J. Chem. Phys. 131(12), 124703 (2009)

Shabu, R., Raj, A.M.E., Sanjeeviraja, C., Ravidhas, C.: Assessment of CuO thin films for its suitablity as window absorbing layer in solar cell fabrications. Mater. Res. Bull. 68, 1–8 (2015)

Shen, Y., Guo, M., Xia, X., Shao, G.: Role of materials chemistry on the electrical/electronic properties of CuO thin films. Acta Mater. 85, 122–131 (2015)

Tsunomura, Y., Yoshimine, Y., Taguchi, M., Baba, T., Kinoshita, T., Kanno, H., Tanaka, M.: Twenty-two percent efficiency HIT solar cell. Solar Energy Mater Solar Cells 93(6–7), 670–673 (2009)

Valladares, L.D.L.S., Salinas, D.H., Dominguez, A.B., Najarro, D.A., Khondaker, S.I., Mitrelias, T., Majima, Y.: Crystallization and electrical resistivity of Cu2O and CuO obtained by thermal oxidation of Cu thin films on SiO2/Si substrates. Thin Solid Films 520(20), 6368–6374 (2012)

Vukadinovic, M., Krc, J., Brecl, K., Smole, F., Topic, M.: Modelling and simulation of optoelectronic devices with ASPIN. In: The IEEE Region 8 EUROCON 2003. Computer as a Tool., vol. 1, pp. 474–477, IEEE. (2003)

Wang, W.Z., Wang, G.H., Wang, X.S., Zhan, Y.J., Liu, Y.K., Zheng, C.L.: Synthesis and characterization of Cu2O nanowires by a novel reduction route. Adv. Mater. 14(1), 67–69 (2002)

Wisz, G., Nykyruy, L. I., Yakubiv, V. M., Hryhoruk, I. I., Yavorskyi, R. S.: Impact of advanced research on development of renewable energy policy: case of Ukraine (2018)

Xing, G.Z., Lu, Y.H., Tian, Y.F., Yi, J.B., Lim, C.C., Li, Y.F., Wu, T.: Defect-induced magnetism in undoped wide band gap oxides: Zinc vacancies in ZnO as an example. AIP Adv. 1(2), 022152 (2011)

Acknowledgements

Autor Klègayéré Emmanuel Koné acknowledges his grant from Erasmus + KA107. Autor Amal Bouich acknowledged the post-doctoral contract supported by the RRHH, the post-doctoral contract the Margarita Salas financed with the union European next Generation EU, The author Amal Bouich acknowledges MCIN for funding support through Margarita Salas Fellowship (MCIN/AEI/10.13039/501100011033). This research has been funded by Grant PID2019-107137RB-C22 funded by MCIN/AEI/10.13039/501100011033 and by ERDF A way of making Europe.

Funding

This research has been funded by Grant PID2019-107137RB-C22 funded by MCIN/AEI/10.13039/501100011033 and by ERDF A way of making Europe. Erasmus + (Grant No. KA107), Union European next Generation EU, (Grant No. RRHH), The author Amal Bouich acknowledges MCIN for funding support through Margarita Salas Fellowship (MCIN/AEI/10.13039/501100011033).

Author information

Authors and Affiliations

Contributions

All authors contributed to the writing of this paper. We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Conflict interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Koné, K.E., Bouich, A., Soro, D. et al. Insight of ZnO/CuO and ZnO/Cu2O solar cells efficiency with SCAPS simulator. Opt Quant Electron 55, 616 (2023). https://doi.org/10.1007/s11082-023-04892-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-023-04892-9