Abstract

In adsorption-based chemical and biological refractometric sensors the dependence of the refractive index of the sensing area on the number of adsorbed particles is used for detection and quantification of analytes. We perform stochastic analysis of equilibrium fluctuations of the adsorbed particles number for monolayer adsorption using a nonlinear second-order model. We derive an analytical expression for the power spectral density (PSD) of the refractive index change fluctuations. Our theory is applicable to sensors operating in closed volume systems with spatially uniform analyte concentration. Our analysis of fluctuations in a benzene sensor shows a significant difference between the PSD according to the derived expression and the PSD obtained by the linear adsorption model, especially for very low amounts of analyte. The developed theory is valid in a wider range of pressures and temperatures. Since signal fluctuations determine the detection limit, the presented theoretical model is applicable as a tool for the design, optimization and characterization of practical adsorption-based refractometric sensors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Adsorption is a surface phenomenon, taking place at an interface between materials in different phases. It can be favorable, like in adsorption-based refractometric chemical sensors and biosensors (the prime example being nanoplasmonic devices), where it generates the output signal, or in nanostructuring of novel optical materials (Stewart et al. 2008). On the other hand, adsorption can be undesirable, e.g. when causing adsorption–desorption (AD) noise, which degrades the device performance. Therefore, a good insight into adsorption-caused phenomena and related signal fluctuations is crucial for the design and optimization of a range of different nanooptical and nanophotonic devices.

In novel ultra-sensitive adsorption-based refractometric bio/chemical sensors AD process of particles to be detected takes place at an interface between the solid surface of the sensor and a gaseous or liquid medium containing the target analyte (Dahlin 2012). The sensor output signal is determined by the number of adsorbed analyte particles. Since the AD process is inherently stochastic, the adsorbed particles number fluctuates, thus the sensor signal fluctuates too, even after the AD process equilibrium has been reached. These fluctuations contribute to the total intrinsic noise that limits the sensor performance. Fluctuations caused by various noise mechanisms in refractometric sensors have been analyzed in Jakšić et al. (2009), Zalyubovskiy et al. (2012) and Yang et al. (2014).

Fluctuations caused by monolayer AD processes in adsorption-based sensors using models assuming that the number of the analyte particles around the sensor is sufficiently high to consider the analyte pressure (or concentration) constant throughout the experiment have been analyzed in Djurić et al. (2002, 2007) and Jakšić et al. (2009). We will denote such models as the linear ones, because of the linear dependence of the instantaneous adsorption rate on the number of adsorbed particles. Models of fluctuations caused by coupling of the AD process with convection and diffusion of analyte particles, which is characteristic for the sensors operating in flow-through systems, have also been developed (Jokić et al. 2012, 2015). However, an analytical method, based on the use of the second-order nonlinear adsorption model, needed when sensor operates under the conditions of time varying analyte concentration in closed reaction chambers, has yet to be developed.

In this contribution we perform stochastic analysis of equilibrium fluctuations of the number of particles adsorbed on the surface of refractometric sensors in a monolayer. Sensors operating in closed-volume systems are considered, where the total number of analyte particles remains constant (the number, i.e. the concentration, of free particles decreases with an increase of the number of adsorbed particles). This case can be described by a nonlinear (quadratic) dependence of the adsorption rate on the number of adsorbed particles. We denote this model as the nonlinear one. We derive an analytical expression for the equilibrium power spectral density (PSD) of AD fluctuations of refractive index for the case of the nonlinear second-order adsorption model, assuming the following: (1) the effective medium theory is applicable for the calculation of refractive index, (2) the surface is homogeneous, (3) there are no interactions between gas particles on the surface, and (4) all system parameters are spatially uniform. We compare the numerical results obtained for a benzene sensor using the nonlinear model with the results obtained using the linear model and analyze when the use of a second-order model is mandatory.

2 Nonlinear (second-order) model of monolayer adsorption in refractometric sensors: Theory of equilibrium fluctuations

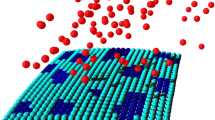

Figure 1 shows the principle of operation of an adsorption-based (nano)plasmonic sensor. The spectrum of light reflected from the bare sensor surface has a dip at the wavelength λ1, which indicates the coupling between the free carrier oscillations in the metal film and the oscillations of an in-plane electromagnetic wave. This coupling is denoted as the surface plasmon polariton (SPP). Its propagation strongly depends on the changes of refractive index at the interface between the sensing surface and the surrounding medium. Since AD process of analyte particles is taking place at that interface and causes an effective refractive index change, it influences the SPP propagation, which results in the shift of the reflection dip from λ1 to λ2. The shift is proportional to the number of adsorbed particles, thus defining the output signal. The key role belongs to the dependence of the effective refractive index change, n eff,A , on the adsorbed particles number, N a , as given by Jakšić et al. (2009)

n a is the refractive index of the analyte, n e is the refractive index of the environment, w is the proportionality factor and M is the total number of adsorption centres on the surface.

The adsorption process can be described by the following reaction rate equation

v a is the adsorption rate, v d is the desorption rate, k a and k d represent the rate constants of adsorption and desorption, respectively, N g is the number of free particles in gaseous or liquid phase and N f is the number of free adsorption centres. In a closed system there are N 0 particles in total (free and adsorbed). Thus, the resulting adsorption rate is a quadratic function of N a . The particular values of the system parameters in specific practical situations may allow simplification of (2), yielding a linear adsorption rate (Dahlin 2012; Homola 2006). In Jakšić et al. (2013, 2014a, b) a comparative analysis of these two models is given along with the criteria for their applicability for the analysis of AD kinetics. In equilibrium, which is reached when v a = v d (dN a /dt = 0), the number of adsorbed particles for the nonlinear model is Jakšić et al. (2013) and Kolar-Anić et al. (2011)

Adsorption generates both the output signal and intrinsic AD noise. Fluctuations of the number of adsorbed particles, ΔN a , result in refractive index fluctuations, Δn eff,A . We perform here stochastic analysis of AD fluctuations, based on the nonlinear model (2). In order to determine the PSD of equilibrium fluctuations of the number of adsorbed particles and the refractive index change by applying the Langevin method, we use an adaptation of the noise theory refering to quasi linear behaviour of a single variable gain-loss processes (van Vliet and Fasset 1965). The theory assumes small fluctuations of the number of adsorbed particles around the equilibrium expected value, 〈N ae 〉, and linearization of Eq. (2) around 〈N ae 〉, which becomes the Langevin equation after adding an intrinsic noise source function ξ(t) to the right side

(here v i ′(〈N ae 〉) denotes the first derivative of v i (N a ) with respect to N a at N a = 〈N ae 〉, where index ‘i’ can be ‘a’ or ‘d’). The previous equation yields the Lorentz power spectrum of fluctuations of the adsorbed particles number (van Vliet and Fasset 1965)

Here σ 2 e = 〈(ΔN a )2〉 = 〈(N a – 〈N ae 〉)2〉 is the equilibrium variance of the stochastic adsorbed particles number. Equations (4) and (5) show that it is necessary to obtain the parameters 〈N ae 〉 and σ 2 e , which are determined by the equations

as it is derived for the same class of nonlinear stochastic gain-loss processes in (van Vliet and Fasset 1965). Equation (6) gives the same result for 〈N ae 〉 as given by (3), 〈N ae 〉 = N e , thus

[the parameter τ is introduced in (4)]. Now, the variance is also determined using (7).

From (1) the PSD of the refractive index fluctuations for the nonlinear model is

Let us remember that the linear adsorption model gave a result for PSD Δn (f) in the same form as Eq. (9), but with N eL = k a N 0 M/(k d + k a N 0) and τ L = 1/(k d + k a N 0) instead of N e and τ, respectively (Jakšić et al. 2009).

3 Results of the numerical experiment

This section shows the results of the analysis of PSD of the AD refractive index noise, based on (9). A benzene sensor is considered, with a sensing area A s = 100 mm2, a volume V = 1 ml of the closed reaction chamber, and a number of adsorption centres M = 6.25 × 1014. The refractive indexes of the analyte and the environment are n a = 1.5 and n e = 1.

Figure 2a shows PSD Δn (f) for different temperatures, T (270, 280, 290, 310 K). The initial pressure in the system is p = 0.01 Pa. The curves obtained by the use of the nonlinear adsorption model are denoted by solid lines, while those corresponding to the linear model are denoted by dashed lines. There is a significant difference between the spectra obtained by these two models (both in magnitudes and the cut-off frequencies, f co = 1/(2πτ)). This lorentzian fluctuations spectrum is typical for all processes with thermally activated kinetics. The temperature dependence of the low frequency noise magnitude (LFNM) of their PSDs has a clear maximum (Verleg and Dijkhuis 1998; Djurić et al. 2002). The kinetics determines the slope of the temperature dependence of the LFNM before and after the maximum. One can find out that for a given set of parameters, the maximum is at T < 270 K for the linear model and slightly higher than 310 K for the nonlinear model. Thus, in the range 270–310 K the nonlinear model predicts the slight increase of the LFNM, while the decrease of the LFNM obtained by the use of the linear model is more pronounced. For a given pressure p = 0.01 Pa, the lower the temperature, the greater the difference, while for each T the linear model predicts a higher LFNM and a lower f co than the nonlinear model. Also, in the considered temperature range, the linear model predicts higher AD noise, defined as σ ΔneL = wσ e , of approximately 2 × 10−9 − 1 × 10−8 RIU, and the nonlinear model results in σ Δne = 1 × 10−10 − 5 × 10−10 RIU. These values are close to the minimal detectable refractive index change of refractometric sensors (Dahlin 2012). Depending on the operating conditions, sensor and analyte parameters, AD noise can be higher, and then it may determine the detection limit.

a PSDs of the refractive index fluctuations for a benzene refractometric sensor at different temperatures, obtained using the linear and the nonlinear second-order adsorption model; b–d Pressure dependence of the PSDs obtained according to two adsorption models for the same sensor operating at: b 270 K, c 290 K, and d 310 K

Figure 2b–d show PSD Δn (f) depending on the initial pressure in the range of 10−3–103 Pa for different operating temperatures. In all three diagrams an area is visible where the nonlinear model predicts a higher noise than the linear one. This area only slightly varies with temperature. The pressure dependences of the LFNMs have their maxima for a given temperature. When increasing temperature, the pressures corresponding to the maxima for the two models become nearer to each other. One also notes a decrease of the difference between the complete spectra calculated using the linear and nonlinear model with increasing temperature. At elevated temperatures, in AD process the desorption prevails. Thus the results obtained by these two models (which differ in the adsorption rate only) become closer to each other. At high pressures the number of gas phase molecules becomes much greater than the number of adsorbed molecules, at any instant it remains close to the initial number of molecules in the (closed) system so the quadratic adsorption rate approximates to linear and the spectra calculated using the two models overlap. It can be seen that the linear model is especially inaccurate at lower pressures and at lower temperatures. By equating (9) and the corresponding PSD for the linear model (Jakšić et al. 2009) one can find the conditions which determine the proper use of these models in situations of practical interest (optimization of sensor design, estimation of the minimal detectable signal, selection of operating point in frequency selective measurements etc.).

4 Conclusions

An analytical expression is derived for the equilibrium spectral density of refractive index fluctuations caused by the stochastic nature of adsorption–desorption processes. The expression is obtained using the nonlinear second-order adsorption model. The presented theory is valid for chemical and biological adsorption-based refractometric sensors operating in closed systems, assuming spatially uniform analyte concentration. Our analysis showed that the developed model enables a more accurate estimation of sensor AD noise than the linear model, in a particular pressure and temperature range. Outside of this range the results of the two models overlap. This points out to a more general applicability of the nonlinear model.

The obtained analytical expression for PSD of the refractive index change enables the analysis of AD noise of refractometric sensors as a function of numerous other system parameters. Therefore, the presented AD noise model is applicable as a tool for the design, optimization and characterization of practical adsorption-based refractometric sensors, especially those used for detection of trace amounts of analytes.

The results could be utilized for other types of affinity-based sensors and nanostructures where the effects of monolayer adsorption cannot be neglected.

References

Dahlin, A.B.: Plasmonic biosensors: an integrated view of refractometric detection. IOS Press, Washington (2012)

Djurić, Z., Jakšić, O., Randjelović, D.: Adsorption–desorption noise in micromechanical resonant structures. Sensors Actuators, A Phys. 96, 244–251 (2002)

Djurić, Z., Jokić, I., Frantlović, M., Jakšić, O.: Fluctuations of the number of particles and mass adsorbed on the sensor surface surrounded by a mixture of an arbitrary number of gases. Sens Actuators B 127, 625–631 (2007)

Homola, J. (ed.): Surface plasmon resonance based sensors. Springer, Berlin (2006)

Jakšić, Z., Jakšić, O., Matović, J.: Performance limits to the operation of nanoplasmonic chemical sensors: noise-equivalent refractive index and detectivity. J Nanophotonics 3, 31770 (2009)

Jakšić, O., Čupić, Ž., Jakšić, Z., Randjelović, D., Kolar-Anić, L.: Monolayer gas adsorption in plasmonic sensors: comparative analysis of kinetic models. Russ J Phys Chem 87, 2134–2139 (2013)

Jakšić, O., Jokić, I., Jakšić, Z., Čupić, Ž., Kolar-Anić, L.: Adsorption-induced fluctuations and noise in plasmonic metamaterial devices. Phys Scr T162, 014047 (2014a)

Jakšić, O.M., Jakšić, Z.S., Čupić, Ž.D., Randjelović, D.V., Kolar-Anić, L.Z.: Fluctuations in transient response of adsorption-based plasmonic sensors. Sensors Actuators B Chem 190, 419–428 (2014b)

Jokić, I., Djurić, Z., Frantlović, M., Radulović, K., Krstajić, P., Jokić, Z.: Fluctuations of the number of adsorbed molecules in biosensors due to stochastic adsorption–desorption processes coupled with mass transfer. Sensors Actuators B Chem 166–167, 535–543 (2012)

Jokić, I., Frantlović, M., Djurić, Z., Radulović, K., Jokić, Z.: Adsorption–desorption noise in microfluidic biosensors operating in multianalyte environments. Microelectron. Eng. 144, 32–36 (2015)

Kolar-Anić, L., Čupić, Ž., Vukojević, V., Anić, S.: The dynamics of nonlinear processes. Faculty of Physical Chemistry, Belgrade (2011)

Stewart, M.E., Anderton, C.R., Thompson, L.B., Maria, J., Gray, S.K., Rogers, J., Nuzzo, R.G.: Nanostructured plasmonic sensors. Chem Rev 108, 494–521 (2008)

Van Vliet, K. M., Fasset, J. R.: Fluctuations due to electronic transitions and transport in solids. In: Burgess, R.E. (ed.) Fluctuation Phenomena in Solids, pp. 267–352. Academic Press, New York (1965)

Verleg, P., Dijkhuis, J.I.: Resistance fluctuations in hydrogenated amorphous silicon: thermal equilibrium. Phys Rev B 58, 3904–3916 (1998)

Yang, H., Lee, W., Hwang, T., Kim, D.: Probabilistic evaluation of surface-enhanced localized surface plasmon resonance biosensing. Opt. Express 22, 28412 (2014)

Zalyubovskiy, S.J., Bogdanova, M., Deinega, A., Lozovik, Y., Pris, A.D., An, K.H., Hall, W.P., Potyrailo, R.A.: Theoretical limit of localized surface plasmon resonance sensitivity to local refractive index change and its comparison to conventional surface plasmon resonance sensor. J Opt Soc Am A 29, 994 (2012)

Acknowledgments

This work was funded by the Serbian Ministry of Education, Science and Technological Development within the Project TR32008.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Advances in the Science of Light.

Guest Edited by Jelena Radovanovic, Milutin Stepic, Mikhail Sumetsky, Mauro Pereira and Dragan Indjin.

Rights and permissions

About this article

Cite this article

Jokić, I., Jakšić, O. A second-order nonlinear model of monolayer adsorption in refractometric chemical sensors and biosensors case of equilibrium fluctuations. Opt Quant Electron 48, 353 (2016). https://doi.org/10.1007/s11082-016-0620-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0620-0