Abstract

Cavitation greatly affects the safe and stable operation of hydraulic machineries and thus has been key challenge in this field. Cavity collapse caused by cavitation can form transient characteristics such as high temperature, high pressure, strong shock wave, and high-speed micro-jet, which may cause serious damage to nearby solids. Cavitation can be affected by many intercoupled factors during the collapse transition. However, existing research rarely focuses on the analysis of its influencing factors. This research aims to reveal the collapse mechanism of cavitation, the parameters of each factor, and the influencing rules of the cavity collapse process. Molecular dynamics method was employed to analyze the evolution process of cavity collapse in the computational domain of liquid argon under different conditions. The influences of relaxation time, system temperature, and cavity size on cavity collapse were investigated. These simulation results showed that when the relaxation time was within 1 ns, the longer the relaxation time, the more likely the system molecules formed a stable state, and the more easily the cavities collapsed. When the relaxation time was greater than 0.2 ns, the difference in the process of collapse was smaller. When the temperature of the system was within 80 K, as the temperature increased, the thermal motion of the molecules intensified to increase the kinetic energy and weaken the intermolecular gravitation, shortening the time for cavities to reach the collapse point. When the temperature reached 80 K, as the temperature continued to increase, the time of collapse point and the process basically unchanged. When the initial cavity size was within 15 Å, the larger the initial cavity size, the less likely the cavities tended to collapse. When the cavity size was larger than 15 Å, the cavities were further less likely to collapse as the cavity size increased. The research results can provide theoretical support for the study of cavitation characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cavity collapse widely exists in nature and energy engineering applications, in which process huge energy is released to the surrounding liquid during the collapse transition, with the order of magnitude reaching 1–1018 kW/m3, leading to the following effects:

-

(1)

Mechanical effect. A lot of shock waves are generated, with pressure of 5500 bar, average speed of 2000 m/s, and shear stress of 3.5 kPa.

-

(2)

Thermal effect. Local hot spots with extremely high temperature (2000~6000K) are formed, heated, and cooled in microseconds, with the speed higher than 1010 K/s.

-

(3)

Chemical action. Water molecules are decomposed into –H and –OH active radicals with strong oxidation. The hydroxyl free gene has a very high oxidation potential (2.80 eV), and it can have fast chain reaction with most organic pollutants and oxidize harmful substances into CO2, H2O, or mineral salts, meaning no secondary pollution.

Besides, the efficiency of oxidizing organic pollutants by cavitation is usually 20–50% (Rajoriya et al. 2017). At present, changes in the mechanical, physical, and chemical properties caused by cavitation have been employed to treat various clinical diseases (Šarc et al. 2018), process refractory sewage (Jawale and Gogate 2019), strengthen mechanical parts (Ren et al. 2018), and clean surfaces (Peng et al. 2018). Therefore, the research on the process of cavity collapse caused by cavitation has received increasingly more attention.

At present, the process of cavity collapse caused by cavitation is usually investigated using two methods, i.e., testing method and molecular dynamics (MD) simulation, where the testing method is the most effective and direct method to study cavity dynamics (Luo et al. 2016; Amarendra et al. 2018). However, cavitation is a transient process from micro level to macro level and a typical transition process of nucleation change. During this transition process, the changes in cavitation are related to not only the thermodynamic properties and limits of metastable liquids but also the surface properties, fluid dynamics, biological performance, etc. Therefore, the testing method is not repeatable, and the acquired data is not accurate (Li et al. 2015; Mahagaonkar et al. 2008).By contrast, MD simulation uses statistical methods to study the properties of molecules and atoms, as well as the factors affecting the growth and collapse of cavities. The MD simulation enables the direct observation of cavitation from a microscopic perspective, which is conducive to the in-depth understanding mechanism and essence of cavitation in a convenient and cost-saving manner (Che and Theodorakis 2017a).

This research investigated the characteristics and influencing factors of cavity collapse using MD simulation. Based on the Lennard-Jones potential energy function, LAMMPS was used to numerically examine these influencing factors including relaxation time, system temperature, and initial cavity size. The system temperature was controlled using the thermal bath coupling method to analyze the computational domain of liquid argon under cavitation and examine the influence of these factors on the transition process of cavity collapse. This research contributes to the study of cavitation erosion characteristics and the development of cavitation theory.

State of the art

Cavitation is mainly divided into gas-liquid nucleation and cavity collapse. The gas-liquid nucleation has been extensively investigated as it is the premise of cavitation. (Sasikumar and Keblinski 2014) simulated the cavity nucleation of nonpolar Lennard-Jones fluid, which provided a basis for follow-up research. Hong et al. (2012) and Raymond et al. (2014), used Lennard-Jones fluid and MD to study the effect of cavity surface tension and the radius of curvature on gas-liquid nucleation, the mechanism of temperature affecting the surface tension and local viscosity, and the relationship between temperature and nucleation rate during the nucleation of uniform cavities. The abovementioned studies explored the main factors affecting the nucleation of Lennard-Jones fluid. However, due to the large difference between the simulation fluid model and the actual model, a clear explanation is still required for the process of variable gas-liquid nucleation.

Wang et al. (2016) used MD to study the cavitation phenomenon of water under tension by controlling the volume. They found that liquid water exhibited nonlinear elastic compressibility under hydrostatic pressure and remained stable in a finite volume until spontaneous cavitation under critical strain. For this phenomenon, an improved nucleation theory was proposed to predict the critical conditions of cavitation. Although the study clarified the effect of volume and temperature on the formation and development of cavitation, further research is needed to investigate the cavity inception, growth, and collapse under metal walls.

Sekine et al. (2008) studied the relationship between molecular potential energy parameters and macroscopic quantities as well as their influences on the nucleation rate of cavities with walls. They focused on the initial stage of cavitation under wall conditions. They confirmed that the surface nano-cavity was a stable gas phase in the liquid formed on the solid substrate. Based on the atomic force field, Che and Theodorakis (2017b) studied the effects of a system composed of water, air (N2 and O2), and highly oriented pyrolytic graphite (HOPG) on the properties of nano-cavity density, contact angle, and surface tension. However, there are few studies on the properties and changes in the evolution of cavitation.

The existing research on the properties and changes in the evolution of cavitation mainly focuses on the dynamic characteristics of cavitation bubbles which are closely related to factors like density, viscosity, contact angle, surface tension, pressure, etc. (Ma et al. 2018; Yamamoto et al. 2019; Antony et al. 2016) Among these factors, viscosity is most investigated, because it can delay the collapse of cavitation bubbles by reducing the speed of bubble shrinkage. At present, the researchers are mainly focused on the influences of these factors on the formation, growth, and nucleation rate of cavitation, while there is rare research on the evolution mechanism of cavity collapse and the factors that affect cavity collapse.

This paper mainly studied the system under the condition of controlling the temperature of liquid argon through MD simulation. The computational domain of liquid argon with cavitation was explored to find out the changing laws of relaxation time, system temperature, initial cavity size, and cavity collapse. Besides, we also researched the thermodynamic parameters related to the evolution process of cavity collapse, the system pressure, and the potential energy of the system molecules. The contents of this paper are organized as follows: “Methodology” describes the parameter setting and model selection. “Results and discussion” analyzes the effects of relaxation time, system temperature, and initial cavity size on cavity collapse. Finally, conclusions are made in “Conclusion.”

Methodology

Parameter settings for MD simulations

In this research, open-source software LAMMPS was adopted to simulate the collapse of cavities in liquid argon by MD simulation. Using a liquid argon system of 6000 atoms in contact with parallel solid surfaces, the potential energy between argon atoms is represented by the Lennard-Jones function:

where r is the distance between two argon atoms, the well depth ε = 0.238 Kcal/mol, the characteristic length σ = 3.4 Å, and the atomic mass m = 6.63 × 10−26 kg. Since this research only considered the cut-off radius between argon atoms, the cut-off radius was set to 9.5 Å. The potential energy between argon and solid wall atoms is also represented by the Lennard-Jones potential energy function and various energy parameters, where σAg-Ag = 2.64 Å, σPt-Pt = 2.54 Å, εAg-Ag = 7.95 Kcal/mol, and εPt-Pt = 15.72 Kcal/mol. The atomic cross-interaction parameters σAr-Ag and σAr-Pt are determined by the pure material parameters σAr-Ar, σAg-Ag, σPt-Pt, εAr-Ar, εAg-Ag, and εPt-Pt which can be obtained by the Lorentz-Berthelot formula:

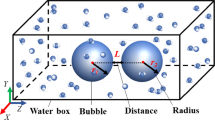

The above parameters by searching and formula calculating are applied to the operation of the entire program language, and it is the core of analog computing. All the atomic interactions in this paper were given by the Lennard-Jones potential energy in the cubic computational domain. Liquid argon was sandwiched between the top and bottom solid surfaces where periodic boundary conditions were applied in all directions, and the solid surface consisted of four layers of 1800 silver atoms in the upper layer and four layers of 1800 platinum atoms in the lower layer. We set the atomic mass mAg = 1.79 × 10−25 kg, mPt = 3.24 × 10−25 kg, and the nearest neighbor atom distance R0 = 2.77 Å. In the simulation process, the temperature of the liquid argon was controlled by the Langevin temperature control method. The total number of molecules in the simulation box was 9600 atoms. The dimensions of the simulation box were V0 = Lx × Ly × Lz = 60 Å × 60 Å × 101 Å. The time step was 1 fs, and the cavity was set in the center of the computational domain. The boundary condition of the system is that the z direction of the simulation domain moves the top wall at a constant speed of 0.003 Å/ns to compress the system volume gradually to observe the shrinkage and collapse of the cavity.

Selection of simulation model

In the simulation process, the temperature of the system was controlled by the thermal bath coupling method. The actual change rate of temperature is related to the thermal bath temperature:

where T represents the coupling degree between the thermal bath and the system, namely, relaxation time. The temperature changes between successive steps are expressed as:

The corresponding speed scale is represented by

The simulation process was divided into three parts. The first part was the relaxation process. In the second part, the cavities were set in the center of the computational domain when the system was stable, and then the top wall was moved at a constant speed of 0.003 Å/ns in the z direction to gradually compress the system volume. In the third part, the data was output.

Results and discussion

Effect of relaxation time

As is known to all, relaxation process is essentially a dynamic process in which the microscopic particles exchange energy in a system and finally reach a stable distribution, and the time that relaxation process takes is called relaxation time. In the relaxation process, the changes in temperature and pressure are important parameters measuring whether the system has reached a stable state. The system enters a stable state where the temperature and pressure fluctuate around a constant value after a period of time. Therefore, the cavity inside the computational domain is neither in tension nor in stress but actually in a state of dynamic equilibrium in the simulation process.

In the simulation process, too long relaxation time may cause long calculation time and requires the excellent performance of the computer used. A short relaxation time may affect the simulation result, and there will be some deviation from the subsequent calculation. At present, the existing research mainly focuses on the process of cavity nucleation while ignoring the possible impact of relaxation time on the process of cavity collapse. Therefore, in this research, the relaxation time (T) was divided into five parts, 0.05 ns, 0.1 ns, 0.2 ns, 0.5 ns, and 1 ns, to reveal the relationship between relaxation time and cavity collapse. Figure 1 shows the evolution of the cavity collapse process. When at the relaxation time of 0.05 ns and 0.1 ns, the volume change rate of the cavity was relatively small that was the time at which the cavity reached the collapse point was slightly delayed. At 0.2 ns, the volume change rate of the cavity was larger than that at 0.05 ns and 0.1 ns. As the relaxation time continued to increase to 0.5 ns and 1 ns, the volume change rate of the cavity was also relatively large, but with no obvious difference from that at 0.2 ns. It can be seen that when the relaxation time was too short, the time of the cavity collapse was slightly delayed, and as the relaxation time increased, the time of the cavity collapse was slightly shortened. However, as the relaxation time further increased, the time of the cavity collapse was no longer obvious.

Figure 2 is the variation curve of the molecular potential energy of the system subjected to different relaxation time during the compression process. It can be seen from the figure that different relaxation times led to a certain difference in the potential energy curve, and the potential energy of the system basically increased first and then reached the equilibrium, and the time of equilibrium state was basically the same. The molecular potential energy of the system at the relaxation of 0.05 ns and 0.1 ns was higher than that at 0.2 ns, 0.5 ns, and 1 ns. Besides, the system potential energy was still fluctuating when it reached the equilibrium, that is, in a state of dynamic equilibrium. This was because the molecules had been subjected to irregular heat movements, and the distance between molecules had constantly changed, leading to fluctuations in the potential energy between the molecules. Furthermore, because the molecular potential energy between the molecules in the nonequilibrium state was large, the relaxation time was shorter, and the instability between the molecules was greater. Therefore, the cavity with shorter relaxation time was difficult to be compressed, and the molecules with longer relaxation time tended to be more stable. As the relaxation time increased, the change in molecular potential was no longer obvious, that is, the impact on the cavity collapse was getting smaller. Therefore, it is necessary to select the appropriate relaxation time according to the system during MD simulation.

The results in this section indicate that when the relaxation time was too short, the time of cavity collapse was slightly delayed. When the relaxation time was longer, the time of cavity collapse was slightly shorter, but as the relaxation time further increased, the change in the time cavity collapse was no longer obvious.

Effect of system temperature

It is known that within a certain temperature range, liquid argon is in a stable liquid phase at atmospheric pressure. In this research, the same amount of argon atoms was in the simulation (N = 6000). The change of volume in the cavity collapse process can be more accurately measured by the lattice method. Figure 3 shows the volume change of the cavity at different temperatures. It can be clearly seen from the figure that the cavity collapse rates at different temperatures were quite different. At the temperature of 59 K, the cavity volume shrinks more slowly, and the collapse time was longer, being about 120,000 fs. At 66 K, the change of cavity volume was slightly larger than that at 59 K, and the collapse point time was about 100,000 fs. At 73 K, the change of cavity volume was larger than that at 66 K, and the collapse time was about 80,000 fs. At 80 K, the change of cavity volume was larger than that at 73 K, and the collapse time was shorter, being only about 60,000 fs. At 87 K, the change of cavity volume was basically the same as that at 80 K, and the collapse time was also about 60,000 fs.

Another example is that Van der Walls’ force improved the relationship between surface tension and temperature (9):

where T is the absolute temperature, γ0 is the surface tension at absolute zero, T0 is the critical temperature, and n is a constant close to 1.

Therefore, this phenomenon can be explained in two ways through Eq. (9). One is the effect of temperature on the interaction forces between liquid molecules. As the temperature increased, the thermal motion of the molecule increased, the kinetic energy increased, and the intermolecular attraction decreased, thereby reducing the energy required for the liquid molecules from the interior to the surface. The second is the effect of temperature on the bulk density on both sides of the surface. As the temperature increased, the density difference between the two bulk phases adjacent to the surface layer became smaller, resulting in a decrease in the surface tension. It can be seen that within a certain temperature range, when the temperature was lower, the cavity was difficult to be compressed, meaning longer time of cavity collapse. As the temperature continued to increase, the cavity was more likely to be compressed, but when the temperature reached a certain value, the change of the cavity volume remained basically unchanged.

Effect of cavity size

Figure 4 shows the evolution of cavity collapse at different initial radii:

It can be seen from the figure that with the change of the initial radius of the cavity, the collapse process of the cavity also showed obvious difference. When the initial radius of the cavity was R = 5 Å, 7.5 Å, and 10 Å, the cavity existed in liquid argon for a period of time and then disappeared before 25,000 fs. At 12.5 Å, the cavity volume decreased and eventually collapsed at around 50,000 fs. At 15 Å, the cavity volume also decreased, and it collapsed at around 75,000 fs. It can be seen that the cavity size of 5 Å, 7.5 Å, and 10 Å and the time of cavity collapse was short. With the increase of the initial radius of the cavity, to more than 10 Å, the collapse of the cavity took longer time. A critical value of the initial radius between 10 Å and 12.5 Å could be clearly observed. At R < 10 Å, the cavity was more likely to collapse, and at R > 12.5 Å, the cavity was not easy to collapse. This was because before the system was compressed, the cavity was under neither pressure nor tensile force, and when the system volume was compressed to a certain value, the argon atoms in the computational domain were affected by the pressure, and the cavity was compressed. As a result, the cavity size had a tendency to decrease, and the cavities with relatively small volume had a large surface tension and could resist a certain external pressure, with the cavity volume not changing or even disappearing. Larger cavities had small surface tension and could not fully resist the applied external pressure, so the cavity volume became smaller. Besides, due to the surface tension of the cavity, there was an intermolecular force between the argon atoms. The intermolecular force tended to agglomerate the argon atoms together, thus causing the cavity to evolve into an irregular shape. Therefore, under the same degree of compression, the cavity with large initial size did not change easily.

Table 1 shows that when the initial size of the cavity was different, the average pressure of the system was also different. The average pressure of the system with smaller initial cavity size was smaller and that with larger initial cavity size was larger. As the initial size of the cavity increased, the average pressure of the system also gradually increased.

Figure 5 shows the change in the potential energy of the system when the cavities with different initial sizes collapsed. It can be seen from the figure that in the cavity collapse process, although the initial size was different, the potential energy of the system always increased first, and the time of equilibrium state was basically the same. The energy curves of the cavities with different initial sizes also have some differences. With the increase of the initial size of the cavity, the corresponding potential energy of the system also increased. This was because the molecular potential energy of the cavity influenced the stability of the internal structure of the molecules, and it appeared as a continuous increase of the molecular potential energy in terms of energy. The changing rules of the molecular potential energy determined that the larger the cavity was, the less likely it was to collapse, and the average molecular potentials of R = 5 Å, 7.5 Å, 10 Å, 12.5 Å, and 15 Å at equilibrium state were − 296,115.88 Kcal/mol, − 296,084.44 Kcal/mol, − 296,600.83 Kcal/mol, − 295,858.66 Kcal/mol, and − 295,628.51 Kcal /mol, respectively. This indicates that the average molecular potential energy of the system was proportional to the initial size of the cavity, and the smaller the initial size, the lower the molecular potential energy. From the perspective of molecular potential energy, it can be concluded that under the same external conditions, when the degree of compression was certain, the larger the initial size of the cavity was, the more stable the system was and the less likely the cavity was to collapse.

Conclusion

This research investigated the collapse characteristics and influencing factors of cavity collapse. Based on the Lennard-Jones potential energy function, LAMMPS was used to perform MD simulation on the factors of relaxation time, system temperature, and initial cavity size. The system temperature was controlled through the thermal bath coupling method. We also analyzed the computational domain of liquid argon in the presence of cavitation and the influence of these factors on the transition process of cavity collapse. The conclusions are summarized as follows.

-

1.

In the relaxation process, different relaxation time corresponded to different potential energy curves. When the relaxation time was within the critical range (0.2 ns), it was linearly related to the time of cavity collapse. When the relaxation time exceeded the critical point, the increase of the relaxation time had no significant effect on the time of cavity collapse.

-

2.

Different temperatures corresponded to the different collapse rates of cavitation. When the temperature was within the critical range (80 K), as the temperature increased, the thermal motion of the molecules increased, the kinetic energy increased, and the intermolecular gravitation decreased. Therefore, the energy required for liquid molecules from interior to surface was reduced, and temperature was inversely proportional to the time of cavity collapse. When the temperature was the critical point, it had no obvious effect on the time of cavity collapse.

-

3.

When the initial radius of the cavity was within the critical range (10 Å), the average molecular potential energy of the system was positively correlated with the initial size of the cavity, and the smaller the initial radius of the cavity, the greater the impact on the collapse point of the cavity. When the initial radius of cavity exceeded the critical point, the evolution area of the cavity tended to be irregular, and the cavity was not likely to collapse.

This study comprehensively considers the influence of relaxation time, temperature, and initial radius of cavity on the characteristic cavity collapse in Lennard-Jones fluid. However, at present, the advantages and disadvantages and associated impact of whether the initial micro cavity is vacuum cavity still remain unclear. In addition, the existing research only conducts the qualitative analysis of the characteristics that affect the cavity collapse, and the quantitative research on the influencing factors of cavity collapse still faces many challenges. This research provides theoretical guidance for revealing the cavitation damage mechanism and cavitation test.

Change history

11 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11051-021-05264-8

References

Amarendra HJ, Hallalli GB, Madhusudhana G, Mahendra HD, Athani MK (2018) Effect of cavitation inducers’ apex angle on erosion resistance of SS304 in the slurry pot test rig [J]. Materialstoday:proceeding 5:17320–17324

Antony AC, Liang T, Akhade SA, Janik MJ, Phillpot SR, Sinnott SB (2016) Effect of surface chemistry on water interaction with Cu(111)[J]. Langmuir 32(32):8061–8070

Che Z, Theodorakis PE (2017a) Formation, dissolution and properties of surface nanobubbles[J]. J Colloid Interface Sci 10(27):123–129

Che Z, Theodorakis PE (2017b) Formation, dissolution and properties of surface nanobubbles [J]. J Colloid Interface Sci 487:123–129

Hong Y, Zhu R-Z, Jiu-An W (2012) Size-dependent surface tension of a cylindrical nanobubble in liquid Ar[J]. Atomic and Molecular Physics, Chin Phys B 21(8):146–151

Jawale RH, Gogate PR (2019) Novel approaches based on hydrodynamic cavitation for treatment of wastewater containing potassium thiocyanate[J]. Ultrason Sonochem 52:214–223

Li F, Ni M, Li J (2015) Numerical study of transient bubble growth and collapse in microscale[J]. Journal of University of Chinese Academy of Sciences 32(01):31–37

Luo X, Bin J, Yoshinobu T (2016) A review of cavitation in hydraulic machinery[J]. J Hydrodyn 28(03):335-358

Ma X, Huang B, Li Y, Chang Q, Qiu S, Su Z, Fu X, Wang G (2018) Numerical simulation of single bubble dynamics under acoustic travelling waves[J]. Ultrason Sonochem 42:619–630

Mahagaonkar SB, Brahmankar PK, Seemikeri CY (2008) Effect of shot peening parameters on microhardness of AISI 1045 and 316L material: an analysis using design of experiment[J]. Int J Adv Manuf Technol 38:563–574

Peng C, Tian S, Li G (2018) Joint experiments of cavitation jet: High-speed visualization and erosion test[J]. Ocean Eng 149:1–13

Rajoriya S, Bargole S, Saharan VK (2017) Degradation of a cationic dye using hydrodynamic cavitation coupled with other oxidative agents: reaction mechanism and pathway[J]. Ultrason Sonochem 34:183–194

Raymond A, Diemand J, Tanaka KK et al (2014) Bubble evolution and properties in homogeneous nucleation simulations.[J]. Phys Rev E Stat Nonlinear Soft Matter Phys 90(6):063301

Ren XD, Wang J, Yuan SQ, Adu-Gyamfifi S, Tong YQ, Zuo CY, Zhang HF (2018) Mechanical effect of laser-induced cavitation bubble of 2A02 alloy[J]. Opt Laser Technol 105:180–184

Šarc A, Kosel J, Stopar D, Oder M, Dular M (2018) Removal of bacteria Legionella pneumophila, Escherichia coli, and Bacillus subtilis by (super)cavitation[J]. Ultrason Sonochem 42:228–236

Sasikumar K, Keblinski P (2014) Molecular dynamics investigation of nanoscale cavitation dynamics[J]. J Chem Phys 141(23):12B648_1–12B64790

Sekine M, Yasuoka K, Kinjo T, Matsumoto M (2008) Liquid–vapor nucleation simulation of Lennard-Jones fluid by molecular dynamics method[J]. Fluid Dyn Res 40:597–605

Wang P, Gao W, Wilkerson J et al (2016) Cavitation of water by volume-controlled stretching[J]. Extreme Mech Lett 11

Yamamoto T, Hatanaka S-i, Komarov SV (2019) Fragmentation of cavitation bubble in ultrasound field under small pressure amplitude[J]. Ultrason Sonochem 58:104684

Funding

This research was supported by the National Key R&D Program of China (2018YFB0606105), Key R & D programs of Jiangsu Province of China (BE2016160, BE2017140, BE2018112), Key R & D programs of Anhui Province of China (201904a05020070), Natural Science Foundation of Jiangsu Province of China (BK20171302), and Key R & D programs of Taizhou City(TG201918).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection Role of Nanotechnology and Internet of Things in Healthcare

This article has been retracted. Please see the retraction notice for more detail: https://dx.doi.org/10.1007/s11051-021-05264-8

About this article

Cite this article

Zhao, Y., Wang, X., Zhu, R. et al. RETRACTED ARTICLE: Investigation of the key factors influencing cavity collapse using molecular dynamics simulation. J Nanopart Res 22, 220 (2020). https://doi.org/10.1007/s11051-020-04956-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-020-04956-x