In order to optimize the structure of the welding process and calculate the technological mode parameters, a coupled thermomechanical approach with numerical simulation in the LS-DYNA software environment is proposed. An algorithm for modeling the process of argonarc welding with a non-consumable tungsten electrode in an inert gas environment and a model for calculating temperature fields, residual stresses, and deformations are proposed. The mathematical model of the process can be represented as a virtual experimental stand for studying the welding process, as well as for determining the composition of technical means for its implementation and technological equipment for fastening the product, which ensure the manufacture of welded constructions made of various metallic materials with the required structure and properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Although welding processes have been extensively studied, both theoretically and experimentally, the problem of improving the quality of welded structures continues to attract the attention of materials scientists. This problem can be solved by implementing state-of-the-art equipment, materials, and technologies, such as argon arc welding (AAW), which requires consideration of all external factors and inner technological parameters. To simplify the solution of such a complex problem, the phenomena under consideration are, as a rule, analyzed separately [1]. However, this approach results in a fragmented vision of the analyzed phenomenon, while the existence of any system depends on the mutual influence of its components. To create a holistic vision of a system, it is necessary to identify the main links and interdependencies that determine the specific features of its functioning and formation of integral properties. In this case, the empirical method of studying physical processes and transformations occurring in materials, while remaining reliable in the development of practical recommendations for industrial applications, becomes too labor- and time-consuming. The efficiency of research studies in the field of materials science can be increased using thermodynamic modeling methods. These methods reduce time and labor costs involved when predicting the influence of external factors on the structure, phase composition, and properties of materials during operation and, accordingly, on the service life of equipment produced on their basis.

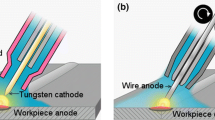

Argon arc welding is one of the most complex physical, chemical, and metallurgical processes. During AAW, the weld metal and the weld zone undergo aggregate state changes and phase transformations. These lead to the occurrence of residual stresses thus altering the structure of alloys. AAW process parameters are selected using engineering analysis tools based on numerical methods and such software packages, as Ansys CFX, LS-DYNA, etc. Simulation of the AAW process is a large-scale multidisciplinary challenge, which requires the use of concepts, laws, and methods developed in different scientific fields (Fig. 1). Creation of a methodology for simulating the AAW process for manufacturing welded structures of various complexity made of different materials with specified structures and properties represents a relevant research task.

In this article, we set out to develop an algorithm for simulating the process of argon arc welding with a non-consumable tungsten electrode in an inert gas environment and to create a model enabling the calculation of temperature fields, residual stresses, and deformations.

MODELING METHODOLOGY

The analysis of states and processes in systems requires the development of computational modeling, which represents an integrated approach to the study of physical processes and phenomena. This requires, accordingly, mathematical models reflecting the features of their functioning [2]. The technological chain of computational modeling includes the following components: phenomenon – mathematical model – algorithm – software program – calculation – model modification. Conventional modeling approaches, such as those based on unstructured meshes and finite elements, may not always be effective when modeling systems and materials with complex structures of different scales.

The study of welding processes should provide solutions to multi-physical problems by elucidating mutual relations between physical processes (melting, crystallization, elastic and plastic deformation, mass and structure variation) and physical phenomena (thermal, mechanical, chemical, electromagnetic, etc.). The complexity of the AAW process stipulates the need to design a family of mathematical models for simulating the thermomechanical weld pool and magnetogasodynamic processes in the electric arc plasma, as well as for predicting the structure and chemical composition of welded joints (Fig. 2).

Modeling of the AAW process is grounded on the theories of unsteady state heat conduction, hydrodynamics, elastic-plastic state, magnetic hydrodynamics, and electrical hydrodynamics (Fig. 3) [3].

The mathematical model of the AAW process is characterized by a set of vectors of initial (\(\overline{Z }\)), required (\(\overline{X }\)), and phase (\(\overline{Y }\)) parameters [4]. The initial parameters include the following vector parameters: Z1 (heat conductivity coefficients, heat capacity, elastic moduli, linear elongation, density of the product and filler wire materials); Z2 (parameters of the technological mode of welding); and Z3 (characteristics of equipment and fixtures).The required parameters include the elements of vectors: X1 (structure and parameters of the operation) and X2 (composition of the plant, ranges of changes in kinematic and energy parameters). For creating such a model, a coupled thermomechanical approach should be used.

Coupled thermomechanical model. The coupled thermomechanical approach consists in the coordination of thermal and mechanical calculation modules, when intermediate calculation results are exchanged after each computational cycle (Fig. 4). Thermomechanical modeling involves the calculation of a temperature field T (x, y, z ), along with the displacement and stress fields of the welded structure. The analysis of thermal and mechanical degrees of freedom in a coupled form allows calculation of complex thermal-strength interactions.

Thermal analysis involves the calculation of temperature distribution and thermal parameters. The analysis is based on the heat balance equation obtained in accordance with the principle of energy conservation, with the finite element method used for its discretization. The distribution of stresses inside the computational domain and the displacement vector are established by carrying out integration of continuum mechanics equations (Fig. 5).

The AAW process is characterized by the presence of moving and unknown in advance phase transition boundaries (free boundary problems). A widely used approach to determining the temperature field and the phase transition boundary consists in solving the Stefan problem. This problem is based on the assumption of the existence of a clear boundary between two phases of the same substance, passing along the melting isotherm. At this front of zero thickness, the conditions of temperature continuity with simultaneous equality to its phase transition temperature, as well as the thermal balance condition (Stefan condition), are fulfilled. In a two-phase Stefan problem, the moving boundary makes the solution of the equations much more difficult than their solution in a region with fixed boundaries.

When modeling phase transformations in the pool–product system, the phase transition is assumed to occur at a given constant temperature T* at the interface S = S (t). This interface divides the computational domain Ù into the following two subareas.

The subarea Ω+(t ) corresponds to the area occupied by the liquid phase whose temperature exceeds that of the phase transition [2]:

The subarea Ω– (t ) corresponds to the area occupied by the solid phase whose temperature does not exceed that of the phase transition:

The heat conduction equations take the following form: for the solid phase, (x, y, z, t ) ∈ Q–:

for the liquid phase, (x, y, z , y) ∈ Q+:

where c– and c+ are the heat capacity of the material in solid and liquid states, respectively; λ– and λ+ are the heat transfer coefficient of the material in solid and liquid states; ρ– and ρ+ are the density values of the material in solid and liquid states; T – and T + are the temperature values of the material in solid and liquid states; f – and f + are the density values of heat sources in solid and liquid states.

The input data for the thermomechanical model include the following: description of the heat source, setting of boundary and initial conditions, setting of mechanical and thermophysical properties of the product and filler wire materials. When solving the problem of coupled thermal analysis, account should be taken of the transfer of loads between the design modules and the set boundary conditions at the interface.

SIMULATION OF ARGON ARC WELDING PROCESS IN LS-DYNA ENVIRONMENT

Modern multidisciplinary software packages offer the opportunity to study various technological modes of welding. An effective tool for obtaining a welded joint with a given structure and properties is numerical simulation of the AAW process in the LS-DYNA computing package. In this software, discretization of differential equations is carried out using special finite elements, which have, along with displacements and rotations in nodes, degrees of freedom in terms of temperature and stresses. The element type can be switched, e.g., from thermal to strength.

The finite element LS-DYNA package is designed to perform calculations in various engineering disciplines (nonlinear dynamics, thermal problems, fracture, crack development, arbitrary Eulerian–Lagrangian behavior, multidisciplinary analysis, etc.).

The sequence of the main stages of numerical simulation can be presented in the following form.

1. Development of a geometric model.

2. Setting of the thermophysical and mechanical properties of the welded product and filler wire materials.

3. Setting of boundary and initial conditions.

4. Selection of a heat source and determination of its parameters.

5. Discretization of the computational domain into finite elements.

6. Description of connections between the boundaries of the finite element nodes.

7. Setting of the technological mode of welding.

8. Carrying out calculations.

9. Processing and analysis of the obtained results.

Geometric representation of the model. The process of multi-pass argon arc welding of a specific structural element is modelled with regard to its geometric parameters and the scheme of edge cutting for welding.

Product material. When modeling the welding process in the LS-DYNA environment, three material states are distinguished: solid, liquid, and undefined. The undefined state indicates that the material has negligible thermal and mechanical properties until it is activated at a user-specified temperature [5, 6]. The state of the material is determined by the activation temperature. It is assumed that a solid material has a very low activation temperature, a liquid material has a melting temperature, and an undefined material has a very high activation temperature. It should be noted that both thermal and mechanical material models have an activation temperature and, therefore, can be used independently of each other.

The LS-DYNA package provides the option of simulating thermal expansion due to changes in the phase composition of a material. Material models in LS-DYNA, defined by *MAT CWM_#270 and *MAT UHS_#244, include the coefficient of thermal expansion, which is tabulated as a function of temperature.

The input data for the product material model are the chemical composition, mechanical and thermophysical properties of the alloy and filler wire. To model the welding process, the function of an undefined material using the activation temperature is introduced [5, 6].

Boundary conditions. In order to simplify the mathematical model of AAW processes, the following assumptions are introduced.

1. The motion of molten metal in the weld pool is neglected.

2. The weld pool is in a state of static balance under the action of gravitational forces, surface tension, and arc pressure.

3. An ideal elastic-plastic model of the material is used.

4. The plastic flow hypothesis is used to calculate plastic deformations.

5. The transition to the plastic state is determined by the von Mises criterion.

A fixed Cartesian coordinate system (x, y, z ) is used, where the metal of the welded joint is stationary while the electrode and arc move at welding speed v in the direction of the x coordinate. The coordinates of the electrode axis xf and yf are determined by the relations

where x0 is the arc starting point; t is the time since the onset of the welding process.

The initial conditions assume that, at the initial moment of time, there is no molten pool, the temperature in all points of space is the same and equal to the ambient temperature.

Setting the boundary conditions implies determining the geometric shape of the joint and consideration of changes in the spatial position of the weld pool. Modeling of pipe welding with edge cutting is complicated by the uncertainty of the product shape, which is established in the course of modeling and varies depending on the result of solving the model equations. The initial values of enthalpy and joint temperature are assumed to be equal to their initial values before welding. In the process of solving the problem of pool formation, the location of the non-melting electrode, filler wire, and arc relative to the edges is determined. According to the obtained values of enthalpy and temperature, the boundaries and shape of the pool surface are determined.

Heat source. As a rule, finite element modeling packages for thermomechanical welding processes use a double ellipsoidal source with normal (Gaussian) distribution of specific heat power or the Goldak heat source model as a heat source simulating the molten pool. The peculiarity of this model consists in the independent estimation of specific heat power distributions qv in the frontal (index f ) and tail (index r ) parts of the ellipsoid (Fig. 6). The heat source powers are found from the relations [7]:

where x, y, z are semi-axes of the ellipsoid in the direction of the coordinate axes; ff and fr are coefficients determining the ratio of heat introduced into the frontal and tail parts of the ellipsoid; af, ar, b, c are the corresponding radii of normal distribution.

The effective heat power of the heating source is determined from the relation

where η is the efficiency of the welding arc; I is the current; U is the arc voltage. Coordinates of the point (x0, y0, z0) correspond to the center of the ellipsoid. The coordinate x00 is estimated taking the welding speed into account by the equation:

where v is welding speed; t is time.

The coefficients ff and fr are related as follows:

According to [7], the values ff = 0.4 and fr = 1.6 are recommended for general cases of arc welding. The parameters af , ar , b and c are independent and take different values, which allows flexible optimization of the model for specific welding cases, changing its shape from almost spherical to strongly elongated along the x-axis.

Calibration of the Goldak heat source model remains the most difficult issue of its application in the study of thermal welding processes [8, 9]. The linear dimensions of the actual molten pool exceed the corresponding dimensions of the given ellipsoid. The geometric parameters of the model required for calculation are related to the dispersion of the normal distribution function, which, in turn, depends on the welding mode parameters, which are also present in the above equations [10].

In order to model the heat source, the LS-DYNA package offers the function having the keyword *BOUNDARY_THERMAL_WELD_TRAJECTORY. Switching between thermal and coupled simulations are made by changing the SOLN parameter from 1 to 2 [5]. The nodes defining the trajectory of the welding torch can be part of a deformable structure.

In addition to the double ellipsoidal heat source, the LS-DYNA package enables the selection of a double ellipsoidal heat source with constant heat flux density, a double conical heat source with constant density, and a conical heat source.

Graphical user interface. The LS-PREPOST Welding graphical user interface, which can be considered as a separate module, is used to specify the sequence of process transitions, the movement trajectory of the welding torch relative to the workpiece (Fig. 7), the welding mode, mechanical and thermal boundary conditions, material states (solid, liquid, undefined). These settings are saved in a separate process file (mesh, contacts, and materials, as well as the sets of sections, nodes, and segments for boundary conditions, etc.).

When the graphical user interface is launched, a sequence folder is displayed where the sequence of passes, mechanical and thermal boundary conditions must be set.

When simulating the process of filling the weld with the material, the algorithm of appearance and disappearance of elements (structural components, mesh cells) is used, with all elements being taken into account, including those formed during welding at later calculation stages. Stresses in structural components are equated to zero from the moment when this element disappears. In a similar manner, when an element appears, it is not added to the model, but simply restored, with its properties (stiffness, weight, loads, etc.) returning to their original values. Thermal stresses are calculated for newly activated elements according to the current temperature.

The simulation process consists of preprocessing, problem solving, solution process control, and postprocessing. Preprocessing includes constructing a geometric and finite element model of the process, defining element types and contact parameters of the process, introducing constraints and loads acting on the model, defining the calculation time and all other necessary parameters to perform the calculation. Postprocessing allows the results of the performed calculation to be visualized through graphs and an animation file of the welding process.

CONCLUSIONS

1. In this work, we have formulated the scientific and technical foundations of a methodology for simulating and optimizing the technology and modes of welding various-purpose metal structures. The methodology defines a group of interrelated tasks in the study of the welding process. These include construction of a set of mathematical models and effective computer simulation methods, as well as carrying out numerical studies to reveal the main regularities of the process.

2. The LS-DYNA software environment is shown to be an effective tool for simulating the welding process when manufacturing a welded joint with the required structure and properties. A coupled thermomechanical approach to the modeling of argon arc welding is proposed, which can be used to determine the temperature, displacement, and stress fields of the welded structure. Finite element modeling of thermal welding processes using a double ellipsoidal heating source allows the kinetics of thermal effects on the welded product to be predicted.

3. Numerical simulation of the process of argon arc welding results in optimization of its parameters, thereby ensuring the production of defect-free welded joints that meet the operational requirements. The calculated parameters of the AAW process include its structure and technological modes (arc current and voltage, current pulse and pause time, welding speed and filler wire feed, etc.). The mathematical model of AAW can be presented as a virtual experimental stand for studying the welding process and determining the composition of equipment required for its implementation, including the fastening equipment.

4. The proposed coupled thermomechanical approach to modeling of technological processes is versatile and can be used for various production applications. This approach will be used in the next part of the article to simulate the process of welding industrial pipes made of HP40NbTi alloy and to evaluate the obtained results experimentally.

References

J. O’Connor and I. McDermott, The Art of Systems Thinking: Essential Skills for Creativity and Problem Solving [In Russian], Alpina Publisher, Moscow (2018).

A. I. Rudskoy, K. N. Volkov, Yu. A. Sokolov, and S. Yu. Kondrat’ev, Digital Production Systems: Technologies, Modelling, Optimization [in Russian], Polytech Press, Saint Petersburg (2020). DOI: https://doi.org/10.18720/SPBPU/2/id20-95

V. V. Gogosov and V. A. Polyanskii, “Electrohydrodynamics,” in: Science and Technology Review. Series Mechanics of Fluid and Gas [in Russian], VINITI, Moscow (1976), Vol. 10, pp. 5 – 85.

Yu. A. Sokolov,“Designing of argon-arc welding’s industrial system in controllable atmosphere,” Metalloobrabotka, No. 1, 24 – 42 (2022). DOI: https://doi.org/10.25960/mo.2022.1.24

M. Schill and E.-L. Odenberger, “Simulation of residual deformation from a forming and welding process using LS-DYNA®,” in: Proc. of 13th Int. LS-DYNA Conf. (2014), pp. 47 – 54.

M. Schill, A. Jernberg, and T. Klöppel, “Recent developments for welding simulations in LS-DYNA® and LS-PrePost®,” in: Proc. of 14th Int. LS-DYNA Users Conf. (2016), pp. 1-1 – 1-12.

J. Goldak, A. Chakravarti, and M. Bibby, “A new finite element model for welding heat source,” Metall. Trans. B, 15B, 299 – 305 (1984).

A. Khudyakov, Yu. Korobov, P. Danilkin, and V. Kvashnin, “Finite element modeling of multiple electrode submerged arc welding of large diameter pipes,” IOP Conf. Ser.: Mater. Sci. Eng., 681, Art. 012025 (2019). DOI: https: //doi.org/https://doi.org/10.1088/1757-899X/681/1/012025

J. Wang, J. Hang, J. P. Domblesky, et al., “Development of a new combined heat source model for welding based on a polynomial curve fit of the experimental fusion line,” Int. J. Adv. Manuf. Technol., 87(5 – 8), 1985 – 1997 (2016). DOI: https://doi.org/https://doi.org/10.1007/s00170-016-8587-3

P. D. Sudersanan and U. A. Kempaiah, “The effect of heat input and travel speed on the welding residual stress by finite element method,” Int. J. Mech. Prod. Eng. Res. Dev., 2(4), 43 – 50 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 16 – 22, June, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kondrat’ev, S.Y., Slyusarenko, A.V., Sokolov, Y.A. et al. Mathematical Modeling of the Argon Arc Welding Process. Part 1. Thermomechanical Approach and Model Justification. Met Sci Heat Treat 65, 338–344 (2023). https://doi.org/10.1007/s11041-023-00936-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00936-9