Abstract

The material point method (MPM) has demonstrated itself as an effective numerical method to simulate extreme events with large deformations. However, the original MPM suffers several defects caused by the particle quadrature, including cell crossing noise, low spatial integration accuracy, and loss of spatial convergence. Our newly developed staggered grid material point method (SGMP) employs the cell center quadrature to efficiently eliminate the cell crossing noise and to recover the spatial convergence. In this paper, the SGMP is further formulated with the updated stress last, updated stress first and modified updated stress last schemes. The energy errors of the SGMP with different schemes are derived analytically to study their accuracy and stability. The performance of the SGMP is critically assessed by investigating its performance in terms of convergence, stability, dissipation and efficiency theoretically and numerically. This study shows that the SGMP performs much better than the MPM. In addition, a contact algorithm is also developed for the SGMP to model the contact-impact problems, and is verified by several numerical examples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Extreme events, such as hyper-velocity impact, blast and penetration, are usually accompanied by large deformation and strong discontinuity. Both Lagrangian methods (Zukas 1990; Wingate et al. 1993) and Eulerian methods (Hageman and Walsh 1971) show different advantages and disadvantages (Zhang et al. 2016). By combining the Lagrangian description and Eulerian description, the material point method (MPM)(Zhang et al. 2016; Sulsky et al. 1994) inherits the advantages and discards the disadvantages of the Lagrangian and Eulerian methods, thus provides a powerful tool for modeling extreme events. The MPM has been applied in modeling many extreme events, such as hyper velocity impact (Liu et al. 2016, 2013; Gong et al. 2012; Huang et al. 2008; Ma et al. 2009), penetration (Sulsky et al. 1995; Ma et al. 2010; Huang et al. 2011), explosion (Hu and Chen 2006; Wang et al. 2011), fracture evolution (Nairn 2003; Liang et al. 2017; Tan and Nairn 2002; Schreyer et al. 2002), incompressible flow (Zhang et al. 2017; Kularathna and Soga 2017; Zhang et al. 2018), fluid-structure interaction (Lian et al. 2014; Gilmanov and Acharya 2008; York et al. 2000; Li et al. 2014), multiphase flow (Zhang et al. 2008), just to name a few.

However, the original MPM suffers several defects caused by the particle quadrature, including cell crossing noise, low spatial integration accuracy, and loss of spatial convergence. To eliminate the cell crossing noise, Bardenhagen et al. proposed the generalized material point method (GIMP) (Bardenhagen and Kober 2004), using a Petrov–Galerkin discretization scheme and discretizing a continuum as a collection of particles defined by particle characteristic functions over a representative volume. The shape function has \(C^{1}\) continuity which eliminates the discontinuity of the gradient of shape function. Zhang et al. proposed a dual domain material point method (DDMP) (Zhang et al. 2011) which modifies the gradient of the shape function by introducing the information of neighbor cells without tracking the particle’s shape. The B-spline function (Steffen et al. 2008) and a mixed integration scheme (Kafaji 2013) were also employed in the MPM to reduce the cell crossing noise. Gong (2015) analyzed the convergence rate of the MPM by theory and numerical experiments, and proposed an improved material point method by employing the moving least square (MLS) reconstruction to achieve second-order accuracy. Tielen (2016) combined quadratic B-spline basis functions with a reconstruction based quadrature rule to reduce cell crossing noise, and Gan et al. (2018) studied the convergence rate of the B-spline MPM with different B-spline functions.

The staggered grid material point method (SGMP) proposed by Liang et al. (2019) eliminates the cell crossing error without increasing too much time cost by employing a novel reconstruction and mapping scheme. An auxiliary grid, which is obtained by shifting the background grid by half the side length of its cell in each direction, plays an intermediate role between particles and background grid nodes on transmitting physical quantities. Liang et al. (2019) presented the SGMP with the update stress last (USL) scheme without contact algorithm. However, the modified update stress last (MUSL) scheme, instead of the USL scheme which is unstable and energy dissipative (Zhang et al. 2016; Bardenhagen 2002), is usually used in the MPM. Therefore, the SGMP is further formulated with the USL, USF and MUSL schemes in this paper, and a further critical assessment on the SGMP is conducted by examining its energy error theoretically and numerically in the USL, USF and MUSL schemes, and by comparing the convergence rate, stability, dissipation and efficiency between the MUSL SGMP and MUSL MPM. It shows that the SGMP performs much better than the MPM.

In addition, a contact algorithm is essential for the SGMP to model penetration, explosion and fluid structure interaction problems. The contact algorithm in the MPM (Huang et al. 2011; Bardenhagen et al. 2000; Pan et al. 2008) is implemented by modifying the momentum on the background grid. However, as a new mapping relation between the particles and the background grid is established in the SGMP, the contact algorithm in the MPM cannot ensure impenetrability between particles which is essential to a contact algorithm. Therefore, a contact algorithm is proposed for the SGMP in this paper.

The paper is organized as follows. Section 2 briefly reviews the MPM and formulates the SGMP with the USL, USF and MUSL schemes. Section 3 analyzes the energy error of the SGMP in contrast with the MPM, and explains the different behaviors among the USL, USF and MUSL in the SGMP. Section 4 examines the performance of the SGMP in term of convergence rate, stability, dissipation and efficiency and compared with those of the MPM. Section 5 develops a contact algorithm for the SGMP and Sect. 6 presents the numerical examples. Section 7 draws concluding remarks.

2 Theoretical formulation

This section will briefly review the basic formulations of the MPM and formulate the SGMP with USL, USF and MUSL schemes. Please refer to the literature (Zhang et al. 2016; Liang et al. 2019) for detailed description.

The computational cycle of both the MPM and SGMP consist of four primary steps: (1) particle-to-grid projection, (2) Lagrangian mesh momentum updating, (3) particle updating and (4) resetting the background grid. The steps (2) and (4) are the same in the MPM and SGMP. In the step (4), the deformed Lagrangian grid is usually reset to its initial position.

In the step (2), the momentum equation is solved in a weak form which is given as

where \(\varGamma _{t}\) denotes the traction boundary of the material domain \({\Omega }\), \(\rho\) is the current density, the subscripts i and j indicate the components of the spatial variables following the Einstein convention, \(u_{i}\) is the displacement, \(b_{i}\) is the body force per unit mass, \({\sigma _{ij}^{s}=\sigma _{ij}/\rho }\) is the specific stress, \({\bar{t}}_{i}^{s}={\bar{t}}_{i}/\rho\) is the specific traction, \(\sigma _{ij}\) is the Cauchy stress, \({\bar{t}}_{i}\) is the traction.

The displacement filed is approximated in the background grid as

where the subscript I denotes the variables associated with the grid node I following the Einstein convention, \(N_{I}\left( {\varvec{x}}\right)\) denotes the grid nodal shape function, \(u_{iI}\) is the grid nodal displacement.

Substituting Eq. (2) into the weak form Eq. (1) and invoking the arbitrariness of the virtual displacement \(\delta u_{iI}\) lead to the grid nodal momentum equation

where \(\varGamma _{u}\) is the displacement boundary of the material domain. In Eq. (3),

is the grid nodal momentum,

is the lumped grid nodal mass,

is the internal nodal force,

is the external nodal force. In Eq. (4), the consistent grid nodal mass is replaced by the lumped grid nodal mass to significantly reduce the computational cost of the explicit integration, but it results in some numerical dissipation of kinetic energy (Burgess et al. 1992).

To solve the momentum equation Eq. (3), a particle-to-grid projection scheme is required in the step (1) to construct the grid nodal mass, momentum and forces from their particle values. The particle-to-grid projection scheme used in the SGMP is different from that used in the standard MPM.

2.1 Standard MPM

In the MPM, the body is discretized into particles, so that the density can be approximated as

where \(n_{p}\) is the total number of the particles, \(m_{p}\) is the mass of particle p, \(\delta\) is the Dirac delta function with dimension of the inverse of volume, and \({\varvec{x}}_{p}\) is the spatial coordinate of particle p. Substituting Eq. (8) into Eqs. (4), (5), (6) and (7) gives the mass, momentum, internal force and external force as

where the subscript p denotes the variables associated with particle p, and \(m_{p}=\rho _{p}V_{p}\), \(V_{p}\), \(\sigma _{ijp}\) and \(b_{ip}\) are the mass, volume, stress and body force per unit mass of particle p, respectively. \(N_{Ip}=N_{I}\left( {\varvec{x}}_{p}\right)\) is the shape function of the node I evaluated at the position of particle p. In Eq .(12), \({\bar{t}}_{ip}={\bar{t}}_{i}({\varvec{x}}_{p})\) is the traction of particle p and h is the thickness of the fictitious layer used to convert the surface integral into a volume integral.

After the momentum is updated on the background grid, the particle variables are then updated from the variables on the background grid in step (3), namely

where \(n_{\mathrm {a}}\), \({\dot{\varepsilon }}_{ij}\) and \(\varOmega _{ij}\) are the total number of grid nodes, strain rate and vorticity respectively, and the superscript k denotes the variables associated with kth time step.

2.2 SGMP

In the SGMP, the integrals in Eq. (1) are evaluated by the cell center quadrature, which is similar to the one-point integration in the finite element method (FEM). The integrals are evaluated by

where the subscript c denotes the variables associated with cell center c, \(n_{\mathrm {c}}\) is the total number of background grid cells, \(m_{c}=\rho _{c}V_{c}\) is the cell mass, \(V_{c}\) is the cell quadrature weight and \(N_{Ic}=N_{I}\left( {\varvec{x}}_{c}\right)\) is the shape function of grid node I evaluated at the cell center \({\varvec{x}}_{c}\). For 3D problems, if the 8-node trilinear hexahedron cell is used, \(N_{Ic}\) equals to 1/8.

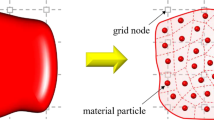

To reconstruct the cell center quantities \(m_{c}\), \(p_{ic}\), \(\sigma _{ijc}V_{c}\), \(b_{ic}\) and \({\bar{t}}_{ic}\) in Eqs. (17) – (20) from their particle values, an auxiliary grid is generated by shifting the background grid half the side length of its cells in each direction, as shown in Fig. 1. These cell center quantities can be reconstructed on the auxiliary grid as

where \(N_{cp}=N_{c}\left( {\varvec{x}}_{p}\right)\) is the shape function of the auxiliary grid node c evaluated at the position of particle \({\varvec{x}}_{p}\).

The background grid and the auxiliary grid in the SGMP (Liang et al. 2019)

In step (3), a consistent mapping scheme is applied in the SGMP to update information carried by particles. For the stress updating, the strain rate and vorticity of auxiliary grid nodes are firstly interpolated from the background grid, namely

Note that the auxiliary grid nodes are the cell centers of the background grid, so that the subscript c denotes the variables associated with the auxiliary grid nodes. The strain rate and vorticity of particles are then interpolated from the auxiliary grid by

The velocity and displacement are interpolated by the same mapping scheme, in which the particle variables are updated from those of the auxiliary grid nodes, namely

where the auxiliary grid nodal velocity \(v_{ic}^{k+1/2}\) and acceleration \(a_{ip}^{k}\) are determined by

2.3 Explicit solution scheme

The leapfrog integration (Hut et al. 1995) is a kind of central difference method which provides second-order accuracy in time integration. The velocity \(v_{iI}^{k+1/2}\) at time \(t^{k+1/2}\) can be updated as

and then the displacement \(u_{iI}^{k+1}\) at time \(t^{k+1}\) can be updated as

where \(\varDelta t^{k}=\frac{1}{2}(\varDelta t^{k-1/2}+\varDelta t^{k+1/2})\), \(a_{iI}^{k}\) is the acceleration.

Similar to the MPM, the SGMP could update the particle stress at the beginning of each time step or at the end of each time step, which are referred to the update stress first (USF) scheme, and the update stress last (USL) scheme, respectively. In addition, the modified update stress last (MUSL) scheme, which is an improvement over the USL, can also be used in the SGMP. The detailed solution scheme is illustrated in Fig. 2, where the phrases in bold italic font is the additional steps in the SGMP. The figure shows that an auxiliary grid is employed in the SGMP as an intermediate media for mapping the information between the particles and the background grid nodes.

3 Energy conservation error

In this section, the energy conservation error is analyzed. As the particles carry the whole information including constitutive information (such as stress, strain and internal energy), the energy change of particles over a time step should be zero if no external work is applied to the system (Bardenhagen 2002), which means the external force Eq. (7) equals zero. The particle energy error \(e_{\text {en}}\) over a time step equals the change of particle energy \(\varDelta E_{\text {p}}\), which can be divided into two parts, namely

where \(\varDelta E_{\text {k,p}}\) and \(\varDelta E_{\text {s,p}}\) denote the change of kinetic energy and strain energy of particles, respectively. The energy error can also be divided into the kinetic energy change due to the interpolation \(\varDelta E_{\text {int}}\) and anything else \(\varDelta E_{\text {alg}}\), namely

where

\(\varDelta E_{\text {k,g}}\) denotes the change of kinetic energy of grid. According to Eq. (38), the interpolation error \(\varDelta E_{\text {int}}\) actually indicates the error between the energy change of grid and the energy change of the particles. Using Eq. (34), \(\varDelta E_{\text {k,g}}\) and \(\varDelta E_{\text {k,p}}\) can be expanded as

Note that the superscript of \(\sum\) is omitted for simplicity, and all the summation is over the range of values of its subscript variables. The error \(\varDelta E_{\text {k,g}}\) and \(\varDelta E_{\text {k,p}}\) both have a term of \(\varDelta t\) and a term of \((\varDelta t)^{2}\). Substituting Eqs. (18), (22), (30), (33) into the first-order term of \(\varDelta E_{\text {k,g}}\) gives

Thus the first term is canceled in the subtraction, and \(\varDelta E_{\text {int}}\) then becomes

where \(m_{II'}\) is actually the full mass matrix, which is given as

It shows that the error due to interpolation has the order of \((\varDelta t)^{2}\), which can be rewritten as

where

The matrix \(M_{II'}^{p}\) is symmetric and diagonally dominant indicating that the \(M_{II'}^{p}\) is positive semi-definite (Brackbill et al. 1988). This proves that the kinetic energy error of grid \(\varDelta E_{\text {int}}\) is always positive. Because \(\varDelta E_{\text {int}}\) has opposite sign against \(\varDelta E_{\text {p}}\) which describes incremental energy error, the positive sign of \(\varDelta E_{\text {int}}\) means the interpolation energy error is dissipative.

Then the second term \(\varDelta E_{\text {alg}}\) in Eq. (37) is also expanded. From Eq. (19), we have

where the \(\sigma _{ijp}\) without superscript denotes the different integrated stress in the USL and USF. In the USF, the stress is updated before the integral of the internal force, while in the USL, the stress used to calculate the internal force is updated in the last step. So, the value of \(\sigma _{ijp}\) is given as,

Substituting Eqs. (47) and (25) into Eq. (40) gives

The superscript of \(\varDelta \varvec{\varepsilon }_{ijp}\) denotes the node velocity used to update the strain in each step. \(\varDelta {{\varvec{\varepsilon }}}_{ijp}^{0}\) is updated by the initial nodal velocity, and \(\varDelta {{\varvec{\varepsilon }}}_{ijp}^{1}\) is updated by the updated nodal velocity, namely

As for the internal energy error, it is the same for the SGMP and the MPM. Bardenhagen (2002) shows that the \(\varDelta E_{\text {s,p}}\) is given by

In Eq. (51), the superscript of \(\varDelta \varvec{\varepsilon }_{ijp}\) follows the completely opposite rule from \(\sigma _{ijp}\), namely

Substituting Eqs. (49), (51) and (43) into \(\varDelta E_{\text {alg}}\) leads to

The error \(\varDelta E_{\text {alg}}\) and \(\varDelta E_{\text {int}}\) for the MPM was obtained by Bardenhagen (2002) as

where

Comparing the error \(\varDelta E_{\text {alg}}\) and \(\varDelta E_{\text {int}}\) for the SGMP and MPM shows that the difference only exist in the full mass matrix.

In the USF, substituting \(\sigma _{ijp}=\sigma _{ijp}^{k}\) and \(\varDelta \varvec{\varepsilon }_{ijp}=\varDelta \varvec{\varepsilon }_{ijp}^{0}\) into Eq. (53) results in

At time step k, the stress can be updated by strain increment with a stiffness tensor \({\varvec{D}}\), namely

Substituting Eq. (59) into Eq. (58), and combining Eq. (43), the \(e_{\mathrm {en}}\) in Eq. 37 is found to be

Both two terms in Eq. (60) are positive definite, so the final energy error depends on the total effect of the change of kinetic energy and internal energy. The opposite sign of two terms also trend to cancel each other, leading to energy conservation property in the USF.

In the USL, substituting \(\varvec{\sigma }_{p}=\varvec{\sigma }_{p}^{k-1}\) and \(\varvec{\varepsilon }_{p}=\varDelta \varvec{\varepsilon }_{p}^{1}\) into Eq. (53) results in

which has completely opposite sign from Eq. (58). The error \(e_{\mathrm {en}}\) then can be rewritten as

Comparing with Eq. (60), the second and third term in Eq. (62) are right the negative energy error of the USF with a negative term is added as the first term. Therefore, the USL scheme tends to be more dissipative than the USF. If any simulation is energy conservative in the USF, an energy dissipative error will definitely appear when the same simulation is conducted in the USL.

The MUSL is actually almost the same with the USF if we move the stress updating step to the next step, except for the shape function used in stress updating step. Applying this modification to the equations of USF above, only the nodal acceleration becomes,

Therefore, the \(e_{\mathrm {en}}\) can be directly written as

which indicates that the MUSL has similar energy conservation to the USF.

In conclusion, by analyzing the different performance among the MUSL, USL and USF on energy conservation, it is proved that the SGMP with USL scheme proposed by Liang et al. (2019) will cause large dissipation. Instead, the SGMP with MUSL and USF schemes are more energy-conservative. So in practical simulation with the SGMP, the MUSL or USF scheme will be the better choice.

Another important finding is that the consistent mapping and reconstruction process, in which the variables on the background grid and particles are all reconstructed or mapped through the cell centers, can make the interpolation error to be order of \(\varDelta t^{2}\). According to Eq. (42), the \(\varDelta t\) term in \(\varDelta E_{\text {k,g}}\) and \(\varDelta E_{\text {k,p}}\) in Eq. (40) is canceled in the subtraction, and this is derived from the particle velocity updating scheme Eqs. (33) and (29), in which the particle velocity is updated through the auxiliary grid. If the particle velocity is directly interpolated from the grid nodes by Eq. (15) as the MPM does, the kinetic energy error of interpolation will increase to the order of \(\varDelta t\), which will cause large energy oscillation because the sign of Eq. (42) is indefinite. Therefore, it is essential for the velocity to be updated through auxiliary grid in the SGMP as described in Eqs. (29), and (30).

4 Performance assessment of the SGMP

Compared to the MPM, three modifications have been developed in the SGMP: the reconstruction from particles to background grid, the integration points, and the mapping scheme from background grid to particles. The performance of the SGMP are critically assessed as follows.

4.1 Convergence rate

The convergence rate mentioned here is specifically referred to spatial convergence rate. According to analysis by Gong (2015), the MPM convergence rate is determined by two parts: reconstruction accuracy and integration accuracy. The momentum equation (3) is solved by the leapfrog explicit integration in Eq. (34). The accuracy of \(v_{iI}^{k+1/2}\) is determined by \(v_{iI}^{k-1/2}\), which is reconstructed from the particle velocity \(v_{ip}\), and \(a_{iI}^{k}\).

Strang and Fix (1973) showed that the one-point Gauss quadrature can maintain the second order convergence rate for the bilinear/trilinear shape functions, although the weak form is not integrated exactly. In the SGMP, the cell center quadrature, which is equivalent to the one-point Gauss quadrature, is employed to integrate the weak form Eq. (1). Thus, the SGMP can achieve the second order convergence rate. On the contrary, the conventional MPM employs the particle quadrature, which can maintain second order convergence rate only if the particles are placed at the Gauss quadrature points. However, the particles in the conventional MPM move relative to the background grid, which makes the MPM no longer achieve the second order convergence rate. The worse is the phenomenon named cell crossing noise which is caused by the change of sign of particles’ shape function gradient and will introduce enormous errors in integration (Acosta et al. 2020). In the FEM, the convergence requests that the finer the mesh size becomes, the closer to the theoretical solution the simulation results should be. However, the cell crossing noise performs oppositely. The error becomes lager when the mesh size gets finer, leading to that the scheme error decreases with the mesh size getting finer for coarse grid, but increases for fine grid. Therefore, with a fixed number of particles in each cell, the MPM method dose not converge for fine grid, as illustrated in Sect. 6.

As for the reconstruction accuracy, the grid nodal velocities \(v_{iI}^{k-1/2}\) are reconstructed in the MPM and SGMP by

respectively. The velocity reconstruction functions (65) and (66) are actually a particular case of the Shepard interpolation. It is well known that a Shepard function only can reconstruct exactly a constant function with arbitrarily distributed particles, and can reconstruct exactly a linear function only with regularly distributed particles (Gong 2015). Therefore, with regular initial particle distribution, both the MPM and SGMP have second-order reconstruction accuracy under small deformation. For large deformation, the reconstruction error will increase, making the convergence rate less than 2.

According to the aforementioned accuracy analysis, the cell center quadrature satisfies the requirement of second-order convergence rate and eliminates the cell crossing noise, but the reconstruction could only achieve second-order accuracy with regular particle distribution. So for large deformation, the SGMP will only approach second-order convergence rate. Employing a more accurate reconstruction technique like MLS can further improve the convergence rate at a higher computational cost (Gong 2015).

4.2 Stability

Another defects generated by particle quadrature is on the scheme stability. The application of the MPM mostly concentrates on problems with extreme deformation or transient response like blast and penetration. Therefore, the explicit time integration is usually used in the MPM. As the explicit scheme is conditionally stable, the time step must be smaller than the critical time step \(\varDelta t_{\mathrm {cr}}\), which in FEM is given as

where \(l^{e}\) is the element characteristic length, c is the element sound speed, and \(T_{\text {min}}^{e}\) denotes the minimum period of element e. Eq. (67) indicates that to insure the time integration stable, the information cannot propagates further than the element characteristic length in each step. The actually time step in simulation is taken as

where \(\varDelta t\) is the current time step, and \(\alpha\) is a user specified CFL number. In FEM dynamic simulation, \(\alpha\) is often set as 0.9.

The MPM employs a similar critical time step, namely

where \(c_{p}\) and \(v_{p}\) are the sound speed and velocity of particle p, respectively, \(d_{c}\) denotes the grid cell size. Because the particle quadrature is used in the MPM, the sound speed c of an element in Eq. (67) is substituted by particle sound speed \(c_{p}\). Though Eq. (69) has been commonly used in the MPM, \(\alpha\) is usually set less than 0.6 to make simulation stable. This is because, Eq. (69) employs the stability theory in FEM without considering the errors of the MPM, which includes cell crossing noise, integration error and variable reconstruction error. Therefore, the time step criteria Eq. (69) is unable to exactly describe the scheme stability request. Ni and Zhang recently developed a more precise critical time step formula by taking the effect of particle position and neighboring cell interaction into consideration (Ni and Zhang 2020).

In the USL MPM, the small mass nodes may lead to instability. The velocity used to update stress in USL is updated by the grid nodal acceleration which is calculated as

where the denominator can be very small when the particles around the node are located near its opposite cell boundaries (i.e. \(N_{Ip}\rightarrow 0\)), but the numerator is not necessarily small due to \(N_{Ip,j}\ne 0\). Thus, the acceleration \(a_{I}\) approaches infinity which makes the USL unstable (Zhang et al. 2016). Whereas, in the SGMP, the grid nodal acceleration is given by

Because the relative positions between cell centers and nodes are fixed, the \(N_{Ic}\) and \(N_{Ic,j}\) does not change. Thus, both the numerator and the denominator have the same term \(N_{cp}\), so that the numerator and the denominator will synchronously shrink when \(N_{cp}\rightarrow 0\). Consequently, the instability caused by the small grid nodal mass is eliminated in the SGMP, so that the USL SGMP is stable (Liang et al. 2019).

Figure 3 shows the mapping scheme of the SGMP, in which the hollow dots and hollow squares denote the particles and cell centers, respectively. In the MPM, the information on grid node A will not affect the particle P, while in the SGMP, node A contributes to the information updating of particle P, indicating that the stencil of particle information updating is enlarged in the SGMP. It can be seen from Fig. 3 that the information of particle P is updated from the four cells in 2D problems, so that the characteristic length \(l^{e}\) in the SGMP is twice of that in the FEM or MPM. Therefore, the CFL number \(\alpha\) in the SGMP is theoretically twice of that in the MPM. Similarly, the GIMP (Bardenhagen and Kober 2004) also possess a larger particle support domain, which improves the scheme stability. With this better stability, the SGMP can employ a much larger CFL number. A comparative numerical analysis about stability among the MPM, SGMP and GIMP will be presented in Sect. 6.

4.3 Dissipation

The particle velocity, position, strain rate and vorticity are calculated in SGMP by

As shown in Fig. 3, the particle information is interpolated by the surrounding 4 cells in 2D simulation. Hence, the particle physical quantities are smoothed compared with the original MPM in Eq. (13)–(16).

The energy error has been analyzed in Sect. 3. The energy error in one step can be divided into \(\varDelta e_{\text {int}}\) and \(\varDelta e_{\text {alg}}\), as shown in Eqs. (43) and (53). In the MUSL which is commonly used, the difference between the SGMP and the MPM on the energy error is focused on the mass matrix, the reconstructed nodal acceleration and the nodal velocity at the previous step from which the strain increment \(\varDelta \varepsilon _{ijp}^{0}\) is calculated. Because of the mass conservation, the scheme with smoother nodal acceleration and velocity due to the reconstruction of the SGMP will show dissipation. The dissipation effect will be further studied numerically in Sect. 6.

4.4 Efficiency

As mentioned in Sect. 3, the explicit solution scheme of the SGMP can be classified into USF, MUSL and USL, as showed in Fig. 2. Among these schemes, the MUSL scheme has an extra step, so that it is more computational expensive than the USF and USL in both the MPM and the SGMP. Compared with the MPM, there exist an additional step in the SGMP to map the information. As a result, the SGMP consumes a little more CPU time in each step than the MPM. Nevertheless, because the number of cell centers is at the same scale of the grid nodes in most instances, the SGMP does not increase the computational complexity in each step.

On the other hand, according to the analysis in Sect. 4.2, the SGMP has much better stability than the MPM. Consequently, the time step size used in the SGMP is about several times of that of the MPM. As a result, the overall efficiency of the SGMP is much higher than that of the MPM, as illustrated in the numerical examples presented in Sect. 6.

5 Contact algorithm

In the MPM, all particles move in a single-valued velocity field so that the potential interpenetration among different bodies are eliminated automatically. Thus, the non-slip contact condition is inherent in the MPM without requiring any additional treatments. To allow slip and separation between different bodies, a contact algorithms (Bardenhagen et al. 2000; Pan et al. 2008; Huang et al. 2011) is required in which different bodies move with different velocity fields in the background grid.

Take the bodies shown in Fig. 4 as an example, in which the particles of different bodies are plotted in blue and green, respectively. A trial momentum and trial velocity of grid nodes are obtained as

The final grid nodal velocities \(v_{iI}^{b,k+1/2}\) must satisfy the non-interpenetration condition

where the superscript r and s denote the body r and s, respectively, and \(n_{iI}^{r}\) is the unit normal vector of body r at node I. If the trial velocity \({\bar{v}}_{iI}^{b,k+1/2}\) does not satisfy the non-interpenetration condition, a contact force \(f_{iI}^{b,c,k}\) need to be imposed between the two bodies to prevent the interpenetration. Thus, the final momentum and velocity are given by

where the contact force \(f_{iI}^{b,c,k}\) can be obtained from the non-interpenetration condition as

The normal and tangential contact force are given as

The tangential contact force is actually the static friction which is supposed to be not exceed the maximum static friction \(\mu ||f_{iI}^{b,\text {nor},k}||\), where \(\mu\) is the friction coefficient. If the tangential force calculated from Eq. (83) is larger than the maximum static friction, the contact should be revised to sliding contact, in which the contact force is given as

In the SGMP, the initial grid nodal momentum \(p_{iI}^{b,k-1/2}\) is reconstructed from the auxiliary grid nodal momentum \(p_{ic}^{b,k-1/2}\), which is reconstructed from the particle momentum, namely

Eq. (85) shows that the particle support domain in the SGMP is larger than that in the MPM. In 2D case, the support domain of a particle in the MPM is the cell in which it is located, but in the SGMP, the support domain of a particle consists of 4 cells, 2 cells in each direction, as shown in Fig. 5. Therefore, in the MPM, two bodies will contact at the node whose surrounding cells have particles in both bodies, as the node J shown in Fig. 4. While in the SGMP, the two bodies will contact at the node I shown in Fig. 4 which is farther from the body boundaries. Thus, a special contact detection method (Ma et al. 2010; Zhang et al. 2016) is required to prevent the fictitious contact which occurs much earlier than the actual contact time. Two bodies are assumed in contact only when the minimum distance \(D_{I}^{r,s}\) between them in the direction of boundary normal vector, as shown in Fig. 4, is less than a characteristic length \(\lambda d_{c}\), namely

where \(d_{c}\) is the cell size, and \(\lambda =0.5\) if 2 particles are placed initially in each direction of a cell.

In the MPM, the unit normal to the surface of body b is determined by

However, Eq. (87) is inappropriate in the SGMP, because the nodal mass is reconstructed from cell centers instead of particles. In the extreme circumstance showed in Fig. 4, two bodies contact at node I, but no particles is located in its neighboring elements. Thus, Eq. (87) gives NAN. Therefore, the normal vector should be calculated by the gradient of mass of cell centers, namely

6 Numerical examples

In this section, five numerical examples, including free vibration of an Euler-Bernoulli beam, free vibration of a 1D bar with fixed ends, 1D TNT slab detonation, Taylor bar impact and sphere rolling, are presented to investigate the performance of the SGMP.

6.1 Free vibration of an Euler–Bernoulli Beam

Firstly, the free vibration of an Euler-Bernoulli beam is studied to investigate the performance of the MUSL, USF and USL schemes in the SGMP. The beam has a length of \(L=0.06\)m and a height of \(H=0.01\)m. Its initial velocity is prescribed by

which corresponds to the first flexural mode of the Euler–Bernoulli beam. The parameter in Eq. (89) are given as

where \(y_{\mathrm {max}}\) is the maximum deflection which is set to \(5\times 10^{-4}\)m, and the parameter \(\beta\) can be obtained from

The elastic material model is used with a density of \(\rho =1845\,\mathrm {kg/m^{3}}\), Young modulus of \(E=318\mathrm {GPa}\) and Poisson ratio of \(\nu =0.054\). The simulation ends at \(t=50\mu \text {s}\) containing about 3 periods.

According to the Bernoulli’s law, the normal stress on the cross section should linearly distributed, and the total energy should be conservative for the elastic material. The distribution of \(\sigma _{xx}\) obtained for different cases is shown in Fig. 6, which shows that the stress of the MPM (USL) scheme increases rapidly and all the particles run out of the domain after \(t=14\mu \text {s}\), which indicates that the MPM (USL) scheme is unstable. As for the other two scheme, the USF and the MUSL, though the simulation is still running, they both obtained inaccurate results because of the cell-crossing errors. As for the SGMP, the result of SGMP (USL) was proved to be correct by the comparison with LS-DYNA by Liang et al. (2019). And the stress distribution of MUSL and the USF agrees well with that obtained with the USL scheme, so that all the three schemes in the SGMP can produce correct results. And examining the three stress profiles obtained by the SGMP carefully, the result of the USL is the smoothest, and the MUSL and the USF have quite similar results. The smooth stress profile of the USL is due to its larger dissipation.

Figure 7 shows the time history of the kinetic energy \(E_{\text {k}}\), the internal energy \(E_{\text {i}}\) and the total energy, in which the energy is normalized by the initial total energy \(E_{0}\). It shows that the USF MPM whose energy keeps increasing is unstable. Although the MUSL MPM is stable, there exist large errors in both \(E_{\text {k}}\) and \(E_{\text {i}}\). In contrast, the SGMP gives stable and much more accurate results than the MPM in all three schemes. The USL SGMP scheme shows higher dissipation, while the USF SGMP and USL SGMP give almost identical results. This example illustrates that the SGMP gives far superior results than the MPM, and the USL SGMP is too dissipative. In conclusion, the USF and MUSL schemes are recommended for the SGMP.

6.2 Free vibration of a 1D bar with fixed ends

The free vibration of a 1D linear-elastic bar (Tielen 2016; Liang et al. 2019), as shown in Fig. 8, is studied to investigate the convergence rate and the stability of the SGMP. The bar has length of \(L=1\mathrm {m}\) and is fixed at both ends. The initial velocity field is chosen as \(v(x,0)=v_{0}\mathrm {sin\left( {\pi x/L}\right) }\) with \(v_{0}\mathrm {=0.1m/s}\). The elastic material model is employed with a density of \(\rho =25\mathrm {k\mathrm {g/m^{3}}}\), Young modulus of \(E=50\mathrm {Pa}\) and Poisson ratio of \(\nu =0\). The zero Poisson ratio makes the problem a 1D simulation.

The analytical displacement for small deformation case is given as

where

In this case, the vibration period is 1.414s, and the maximum displacement of the bar is 0.0225m. The convergence rate is firstly studied with the \(L^{2}\) error norm that measures the simulation error against the theoretical solution, which is defined as

where \(u_{p}^{s}\) denotes the simulation displacement while \(u^{a}\) denotes the theoretical result. The scheme error contains space discretization error and time discretization error. The SGMP only improves spatial accuracy and uses the same central difference method as the MPM. So in the following test, a fixed time step is employed which satisfies the stability requirement in the case of the finest background grid. The cell sizes in this simulation are set from 1/8m to 1/8192m.

6.2.1 Convergence rate

In the MPM, the error will accumulate with time steps, and the cell-crossing error may also appear during the simulation. To focus on the space discretization error only, the one-step convergence whose error is calculated at the end of the first time step is studied first, as showed in Fig. 9a. In this case, the time step is \(\varDelta t=10^{-5}\)s and the simulation satisfies small deformation requirement. Four cases with different number of particles per cell (PPC) are investigated, in which 1PPC means the particles are initially placed at the centers of each cell, and 2PPC means the particles are placed at the positions of 2-point Gauss points. The result shows that both the MPM and the SGMP can achieve second-order convergence rate and the PPC only affects the absolute value of error instead of the convergence rate. For the 1PPC cases, the SGMP degrades into the MPM, resulting in the same results as the MPM. For the 2PPC case, the integration accuracy with 2-point quadrature is higher than 1-point quadrature, so the error of MPM (2PPC) is a little lower than that of MPM (1PPC). However, the SGMP(2PPC) has a conversely higher error than the SGMP(1PPC) case because that in the reconstruction step, there exists boundary reconstruction error while in the SGMP(1PPC) the reconstruction error is zero due to that the particles are directly at cell centers.

To further examine the effects of the accumulate error and cell-crossing error, the short time convergence rate is investigated next, whose results are plotted in Fig. 9b. In all simulations, the ending time is set to 0.02s when the maximum strain is only 0.628%, and only 2PPC is employed for simplicity. Three different time step sizes, \(\varDelta t=1\times 10^{-5}\mathrm {s}\), \(\varDelta t=2\times 10^{-5}\mathrm {s}\) and \(\varDelta t=4\times 10^{-5}\mathrm {s}\) are employed to studied the effect of time integration error on the convergence rate. At the ending time 0.02s, the maximum displacement of the bar is about 0.002m, so the particles may move across cells when the background grid is refined.

Figure 9b shows that the error of the MPM decreases as the cell size decreases for cases with lager cell size, and the slope is close to 2. But with further grid refinement, the cell crossing error exceeds the discretization error, causing the error increases as the cell size decreases. The SGMP also achieves second-order accuracy if the cell size is not too small. When the grid is sufficiently refined, the accumulated time integration error exceeds the space discretization error, so that the simulation error approaches a constant value determined by the time step size, as shown in Fig. 9b. The smaller the time step size, the smaller the final constant error. Comparing the SGMP and MPM, both of them have second order rate for a coarse grid, but the convergence rate breaks down with the effect of cell crossing noise in the MPM for refined grid. On the contrary, the SGMP maintains the convergence rate until the accumulated time integration error becomes dominated. Therefore, the SGMP has much better convergence than the MPM.

In order to assess the convergence rate for large deformation, a body force is added to make the displacement for large deformation still be Eq. (95). The force is given by Gong (2015) as

where \(\rho _{0}\) denotes the initial density, \(\nu\) denotes the Poisson ratio and \(\lambda\) is the Lame parameter in Neo-Hookean model and E is the Young modulus. The F is the deformation gradient. In this case, the strain of the bar reaches peak of 7.07% at a quarter of the period \(t=0.3536\)s. Hence, the displacement error is calculated with time step \(\varDelta t=1.0\times 10^{-5}\) at time \(t=0.3536\)s when the strain becomes the largest. The convergence rate obtained by the SGMP is compared with MPM in Fig. 10. It shows that the MPM does not converge, while the SGMP converges at a rate of 2 for large cell size, but decreases with the decreasing of the mesh size. The error in the numerical solution consist three parts: the spatial discretization error, time integration error, and round-off error. For coarse grid, the spatial discretization error is dominant, so the spatial convergence rate approaches 2. With the decrease of the cell size, the spatial error decreases, and the time integration error will become dominated. The round-off error will also be accumulated with the increase of the total number of time steps. The central difference method is a non-dissipative scheme, but still suffers the dispersion error which cause the period elongation. As a consequence, \(t=0.3536\)s does not correspond exactly to a quarter of period of the original problem. This means that the error calculated is no longer the difference between the numerical solution and the exact solution at the same time t due to the dispersion error. Nevertheless, the SGMP still converges well if the cell size is not too small in this large deformation problem, as shown in Fig. 10.

6.2.2 Rotated background grid

The background grid is aligned with the bar in Sect. 6.2.1, so that the cell-crossing only occurs on the two vertical boundaries of each cell. To further investigate the performance of the SGMP and MPM in the problems with more frequent cell-crossing, the background grid is rotated by \(45^{\circ }\) in \(x-y\) plane so that the bar makes an angle of \(45^{\circ }\) with the x-axis. Therefore, the particles will cross all boundaries of each cell. This configuration also introduces extra boundary errors due to the mismatching between the particle volume and the background grid volume. Fig. 11 compares the deformed bar obtained by the SGMP, GIMP and MPM at different time, respectively. With the accumulation of cell-crossing noise, the bar starts to have artificial twisting at \(t=0.01\mathrm {s}\) in the MPM simulation. Similar twisting also occurs at about \(t=0.10\mathrm {s}\) in the GIMP, which illustrates that the GIMP improves the MPM’s performance, but still unable to eliminate the error in this situation. On the contrary, the SGMP gives accurate results during the whole simulation. Therefore, the SGMP can better eliminate the cell-crossing error and produce the best result among these three methods.

The convergence rate is also studied for this example. Figure 12 shows the convergence curves obtained by the MPM and the SGMP at \(t=1\times 10^{-5}\text {s}\) and \(t=0.02\text {s}\), which corresponds to the one step convergence rate and short time convergence rate, respectively. Different from the aligned case in Sect. 6.2.1, the SGMP performs better even in one step convergence rate. In the MPM, the convergence rate obviously degrades with the mesh size getting finer, while the SGMP maintains the second-order convergence rate. This indicates that the mismatching between the particle volume and the background grid volume have greater side effect on the MPM accuracy. In the cases ending at \(t=0.02\text {s}\), a similar curve tendency appears as the aligned case This examples shows that the SGMP can effectively eliminate the cell crossing noise generated by particles crossing cell edges in both x and y directions.

6.2.3 Stability analysis

The stability of the SGMP is studied next with the aligned background grid. The elastic material model is used with density \(\rho =8.9\,\times\, 10^{3}\,\mathrm {k\mathrm {g/m^{3}}}\) and Young’s modulus \(E=110\,\mathrm {GPa}\), so that the period is \(5.69\times 10^{-4}\text {s}\). The ending time is set as \(0.02\text {s}\) to insure that the simulation contains adequate periods, and the critical time step is determined by Eq. (69). The initial maximum velocity \(v_{0}\) is set to 100m/s.

Figures 13 and 14 plot the time history of the total energy obtained by the MPM, GIMP and SGMP with the MUSL and USF schemes, respectively. The results of the USL scheme are not compared here because it is theoretically unstable in the MPM. Figure 13 shows that the total energy increases significantly if \(\mathrm {CFL}>0.8\) in the MUSL MPM, \(\mathrm {CFL}>1.8\) in the MUSL GIMP, and \(\mathrm {CFL}>2.5\) in the MUSL SGMP, which indicates that the methods are unstable in these cases. Similarly, Fig. 14 shows that the USF MPM, USF GIMP and USF SGMP are unstable when \(\mathrm {CFL}>0.2\), \(\mathrm {CFL}>1.8\) and \(\mathrm {CFL}>2.5\), respectively. Note that the USF version of GIMP and SGMP have almost the same stable time step size as that of their MUSL versions, but the USF MPM has much smaller stable time step size than that of the MUSL MPM. Among these methods, the SGMP possess the largest stable time step, thus achieves the best stability in this example. It also shows that MUSL scheme has better stability, especially in the MPM.

6.3 1D TNT slab detonation

The one-dimension TNT slab detonation is frequently taken as a benchmark problem for detonation simulation. The slab is fixed at \(x=0\,\text {mm}\), and set free at the other end at \(x=100\,\text {mm}\). The JWL equation of state is employed with material parameters listed in Table 1. The TNT slab is detonated at \(x=0\,\text {mm}\) and time \(t=0\,\text {s}\).

After detonation, a stress wave is generated and will propagate along x-dimension accompanied by a remarkable density change. At the wave front, the pressure and the density is very large, which indicates the local large deformation and stress concentration. And at the district behind the wave front, the large material expansion will cause cell crossing phenomenon. Therefore, this example could not only prove the superiority of SGMP to calculate the stress affected by cell crossing noise, but also assess the dissipation defect of the SGMP.

The pressure profiles obtained by the MPM, GIMP and SGMP are plotted in Fig. 15. In the MPM, severe pressure oscillation occurs in the whole computational domain especially in the district where detonation wave has passed by. And as the calculation time goes on, the pressure in this area gradually drops off, while the pressure should be maintained to an extent as the pressure obtained by the SGMP and GIMP does. Though the GIMP and SGMP both obtain better pressure distribution, pressure oscillation in the SGMP is much lower than that in the GIMP. The dissipation of SGMP is also showed in Fig. 15 that the pressure peak of the profiles in the SGMP is obviously lower than the MPM and GIMP. The peak pressure of \(t=1.0\)ms by SGMP is about 7.6% lower than that of MPM. However, the peak pressure oscillation has already reached about 12.7%. If the oscillation of the pressure in the MPM is filtered out, the peak pressure reduced in the SGMP is only 1.3%. As a result, the dissipation of SGMP will indeed reduce the peak value in problems with stress concentration, but significantly improves the numerical solution elsewhere and the dissipation is acceptable.

6.4 Taylor bar impact

The Taylor bar impact has been studied in many researches (Zhang et al. 2016; Johnson and Holmquist 1988; Liang et al. 2019). Liang et al. (2019) compared the numerical results obtained by the USL SGMP with those obtained by the MUSL MPM, LS-DYNA and experiment, showing that the SGMP gives the best results. Liang et al. (2019) also compared the efficiency of USL SGMP and MUSL MPM, but it was unfair to MPM because the MUSL scheme computationally costs more than the USL scheme. In this example, the efficiency of the MUSL SGMP and MUSL MPM is further compared to investigate the efficiency of the SGMP because the MUSL scheme is commonly used in practice.

In this example, a cylinder with length \(L_{0}=25.4\)mm, diameter \(D_{0}=7.6\)mm impacts on a rigid wall with initial velocity of \(v_{0}=190\,\text {mm/s}\), as shown in Fig. 16. Tab.2 lists the Johnson-Cook material parameters used. The simulation ends up at \(t=80\,{\mu}\text {s}\) when the kinetic energy approaches zero.

The simulation is conducted by the MPM, GIMP and SGMP with the MUSL scheme. In order to measure the highest method efficiency, a range of CFL numbers of every method have been tested to find the maximum CFL numbers. As a result, the CFL numbers of the three methods are respectively chosen as 0.8 for the MPM, 1.8 for the GIMP, 2.5 for the SGMP which are very close to the critical CFL numbers of each method.

Tab.3 compares the numerical results obtained by different methods with the experimental results, where L, D and W denote the deformed length, the diameter of the deformed end and the diameter at the height of \(0.2L_{0}\), respectively, and the error e is defined as

in which \(\varDelta\) denotes the error between the simulation and experiment results. It shows that the SGMP gives the most accurate results with the largest CFL number of 2.5.

Tab.4 compares the efficiency of the different methods for different cell size \(d_{\text {cell}}\), in which T denotes the total CUP time taken in the simulation, and TPS denotes the CPU time per particle per time step. \(T_{\mathrm {SGMP}}^{r}\) and \(TPS_{\mathrm {SGMP}}^{r}\) denote the relative extra cost of the SGMP to the MPM, which are defined by

Tab.4 shows that the MPM has the lowest cost per particle per time step. The SGMP increases the cost per particle per time step by up to 20%, while the GIMP increases by up to 120%. Thus, in terms of per particle per time step cost, the extra cost of the SGMP is insignificant and much less than that of the GIMP. On the other hand, both the SGMP and GIMP could employ a much larger CFL number than the MPM, so they could achieve a better overall performance. In this example, the total time cost of the GIMP is very close to that of the MPM, while the total time cost of the SGMP is only about 1/3 of that of the MPM. Therefore, in practical application, the efficiency of simulation can be significantly promoted with the SGMP.

6.5 Sphere rolling

The Sphere rolling test or the cylinder rolling test shown in Fig. 17 is widely used to validate the contact algorithm (Huang et al. 2011; Pan et al. 2008). A sphere with radius \(r=1.6\)m is placed on a rigid fixed slope, which has a length of 20.0m, a width of 4.0m and a thickness of 0.8m. The friction coefficient between the sphere and slope is chosen as \(\mu\,=\,0.4\). The sphere is modeled by the elastic material with modulus \(E=1.24\,\text {MPa}\), Poisson ratio \(\nu =0.35\), and density \(\rho =8.0\,\times\,10^{3}\,\text{kg/m}^{3}\). The gravity is vertical with \(g=10\,\text {m/s}\). After releasing, the sphere will roll or slid along the slope in x direction depending on the value of the slope angle. The analytical x-coordinate of the sphere’s centroid is given as

Based on the analytical solution, the critical slope angle is \(\text {arctan}(\frac{7}{2}\mu )=54.4623^{\circ }\). Hence, the slope angle \(\theta\) is chosen as \(60^{\circ }\) and \(45^{\circ }\), respectively, in the test. When \(\theta =45^{\circ }\) the sphere will roll only, while when \(\theta =60^{\circ }\) the sphere will roll and slip. Figure 18 plots the time history of x-coordinate of the sphere’s centroid obtained by different methods. It shows that the contact algorithm implemented in the SGMP gives sufficient accuracy for the both slipping and rolling cases.

To investigate the effect of the contact distance mentioned in Eq. (86) on the numerical results, two cases, \(\lambda =1\) and \(\lambda =0.5\), are simulated with \(\theta =60^{\circ }\) using the SGMP. Figure 19 presents the obtained configurations at different time with color denoting the velocity in x-direction. While the sphere is rolling, the particles on the edge of the sphere is continuously approaching the slope surface. If the contact status was not detected based on the real contact distance, a gap will gradually appear as shown in the case \(\lambda =1\) in Fig. 19. This fictitious contact phenomenon is more severe in the SGMP than that in the MPM due to the larger particle support, and the condition Eq. (86) can effectively eliminate the fictitious contact.

7 Conclusion

In this paper, the SGMP method is formulated with the three kinds of stress updating schemes (USF, MUSL, USL), and is thoroughly investigated in terms of energy conservation. Though the USL scheme is theoretically proved to be stable in the SGMP (Liang et al. 2019), the dissipation defect makes it not the best choice for the SGMP. On the contrary, the MUSL scheme is proved to be more energy conservative than the USL by the theoretical and numerical analysis, as well as be more stable than the USF in numerical test. So the MUSL scheme is recommended in the SGMP. In addition, the energy analysis shows that it is essential to employ the consistent mapping and reconstruction process, in which the variables on the background grid and particles are all reconstructed or mapped through cell centers, to keep the interpolation error to \(\varDelta t^{2}\) order.

The MUSL SGMP is critically assessed with respect to convergence rate, dissipation, stability and efficiency theoretically and numerically. By employing the cell center quadrature, the cell crossing error and the instability caused from little grid nodal mass are all eliminated. Hence, the SGMP can maintain second-order convergence rate under small deformation no matter particles cross the cell edges or not. The better stability guarantees a larger time step, so that the scheme efficiency is significantly increased. Specifically, a much larger CFL number which is proved to be at least 2 by numerical examples can be employed in the simulation. Consequently, although the SGMP increases the cost per particle per time step by up to 20%, it is much faster and more accurate than the MPM.

In conclusion, the SGMP has superior convergence rate, stability and efficiency than the MPM, and performs well in extreme events simulation.

References

Acosta, J.L.G., Vardon, P.J., Remmerswaal, G., Hicks, M.A.: An investigation of stress inaccuracies and proposed solution in the material point method. Comput. Mech. 65(2), 555–581 (2020)

Bardenhagen, S.G.: Energy conservation error in the material point method for solid mechanics. J. Comput. Phys. 180(1), 383–403 (2002)

Bardenhagen, S.G., Brackbill, J., Sulsky, D.: The material-point method for granular materials. Comput. Methods Appl. Mech. Eng. 187(3–4), 529–541 (2000)

Bardenhagen, S.G., Kober, E.M.: The generalized interpolation material point method. CMES Comput. Model. Eng. Sci. 5(6), 477–495 (2004)

Brackbill, J.U., Kothe, D.B., Ruppel, H.M.: FLIP: a low-dissipation, particle-in-cell method for fluid flow. Comput. Phys. Commun. 48(1), 25–38 (1988)

Burgess, D., Sulsky, D., Brackbill, J.U.: Mass matrix formulation of the flip particle-in-cell method. J. Comput. Phys. 103(1), 1–15 (1992)

Gan, Y., Sun, Z., Chen, Z., Zhang, X., Liu, Y.: Enhancement of the material point method using B-spline basis functions. Int. J. Numer. Methods Eng. 113(3), 411–431 (2018)

Gilmanov, A., Acharya, S.: A hybrid immersed boundary and material point method for simulating 3D fluid-structure interaction problems. Int. J. Numer. Methods Fluids 56(12), 2151–2177 (2008)

Gong, M.: Improving the material point method. Ph.D. thesis, University of New Mexico (2015)

Gong, W., Liu, Y., Zhang, X., Ma, H.: Numerical investigation on dynamical response of aluminum foam subject to hypervelocity impact with material point method. CMES Comput. Model. Eng. Sci. 83(5), 527–545 (2012)

Hageman, L.J., Walsh, J.: HELP, a multi-material Eulerian program for compressible fluid and elastic-plastic flows in two space dimensions and time, vol. 2. Fortran listing of HELP. Tech. rep, Systems, Science and Software, La Jolla, California (1971)

Hu, W., Chen, Z.: Model-based simulation of the synergistic effects of blast and fragmentation on a concrete wall using the MPM. Int. J. Impact Eng. 32(12), 2066–2096 (2006)

Huang, P., Zhang, X., Ma, S., Huang, X.: Contact algorithms for the material point method in impact and penetration simulation. Int. J. Numer. Methods Eng 85(4), 498–517 (2011)

Huang, P., Zhang, X., Ma, S., Wang, H.: Shared memory openmp parallelization of explicit mpm and its application to hypervelocity impact. CMES Comput. Model. Eng. Sci. 38(2), 119–148 (2008)

Hut, P., Makino, J., Mcmillan, S.: Building a better leapfrog. Astrophys. J. 443(2), L93–L96 (1995)

Johnson, G.R., Holmquist, T.J.: Evaluation of cylinder-impact test data for constitutive model constants. J. Appl. Phys. 64(8), 3901–3910 (1988)

Kafaji, I.K.a.: Formulation of a dynamic material point method (MPM) for geomechanical problems. Ph.D. thesis, University of Stuttgart (2013)

Kularathna, S., Soga, K.: Implicit formulation of material point method for analysis of incompressible materials. Comput. Methods Appl. Mech. Eng. 313, 673–686 (2017)

Li, J.G., Hamamoto, Y., Liu, Y., Zhang, X.: Sloshing impact simulation with material point method and its experimental validations. Comput. Fluids 103, 86–99 (2014)

Lian, Y.P., Liu, Y., Zhang, X.: Coupling of membrane element with material point method for fluid membrane interaction problems. Int. J. Mech. Mater. Des. 10(2), 199–211 (2014)

Liang, Y., Benedek, T., Zhang, X., Liu, Y.: Material point method with enriched shape function for crack problems. Comput. Methods Appl. Mech. Eng. 322, 541–562 (2017)

Liang, Y., Zhang, X., Liu, Y.: An efficient staggered grid material point method. Comput. Methods Appl. Mech. Eng. 352, 85–109 (2019)

Liu, P., Liu, Y., Zhang, X.: Simulation of hyper-velocity impact on double honeycomb sandwich panel and its staggered improvement with internal-structure model. Int. J. Mech. Mater. Des. 12(2), 241–254 (2016)

Liu, Y., Wang, H.K., Zhang, X.: A multiscale framework for high-velocity impact process with combined material point method and molecular dynamics. Int. J. Mech. Mater. Des. 9(2), 127–139 (2013)

Ma, S., Zhang, X., Qiu, X.: Comparison study of MPM and SPH in modeling hypervelocity impact problems. Int. J. Impact Eng. 36(2), 272–282 (2009)

Ma, Z., Zhang, X., Huang, P.: An object-oriented MPM framework for simulation of large deformation and contact of numerous grains. CMES Comput. Model. Eng. Sci. 55(1), 61 (2010)

Nairn, J.A.: Material point method calculations with explicit cracks. CMES Comput. Model. Eng. Sci. 4(6), 649–663 (2003)

Ni, R., Zhang, X.: A precise critical time step formula for the explicit material point method. Int. J. Numer. Methods Eng. 121(22), 4989–5016 (2020)

Pan, X., Xu, A., Zhang, G., Zhang, P., Zhu, J.S., Ma, S., Zhang, X.: Three-dimensional multi-mesh material point method for solving collision problems. Commun. Theor. Phys. 49(5), 1129–1138 (2008)

Schreyer, H., Sulsky, D., Zhou, S.: Modeling delamination as a strong discontinuity with the material point method. Computer Methods Appl. Mech. Eng. 191(23–24), 2483–2507 (2002)

Steffen, M., Kirby, R.M., Berzins, M.: Analysis and reduction of quadrature errors in the material point method (MPM). Int. J. Numer. Methods Eng. 76(6), 922–948 (2008)

Strang, G., Fix, G.J.: An Analysis of the Finite Element Method. Prentice-Hall, Hoboken (1973)

Sulsky, D., Chen, Z., Schreyer, H.L.: A particle method for history-dependent materials. Comput. Methods Appl. Mech. Eng. 118, 179–186 (1994)

Sulsky, D., Zhou, S.J., Schreyer, H.L.: Application of a particle-in-cell method to solid mechanics. Comput. Phys. Commun. 87(1), 236–252 (1995)

Tan, H., Nairn, J.A.: Hierarchical, adaptive, material point method for dynamic energy release rate calculations. Comput. Methods Appl. Mech. Eng. 191(19–20), 2123–2137 (2002)

Tielen, R.: High-order material point method. Master’s thesis, Delft University of Technology (2016)

Wang, Y., Beom, H., Sun, M., Lin, S.: Numerical simulation of explosive welding using the material point method. Int. J. Impact Eng. 38(1), 51–60 (2011)

Wingate, C.A., Stellingwerf, R.F., Davidson, R.F., Burkett, M.W.: Models of high-velocity impact phenomena. Int. J. Impact Eng. 14(1–4), 819–830 (1993)

York, A.R., Sulsky, D., Schreyer, H.L.: Fluid-membrane interaction based on the material point method. Int. J. Numer. Methods Eng. 48(6), 901–924 (2000)

Zhang, D.Z., Ma, X., Giguere, P.T.: Material point method enhanced by modified gradient of shape function. J. Comput. Phys. 230(16), 6379–6398 (2011)

Zhang, D.Z., Zou, Q., VanderHeyden, W.B., Ma, X.: Material point method applied to multiphase flows. J. Comput. Phys. 227(6), 3159–3173 (2008)

Zhang, F., Zhang, X., Liu, Y.: An augmented incompressible material point method for modeling liquid sloshing problems. Int. J. Mech. Mater. Des. 14(1), 141–155 (2018)

Zhang, F., Zhang, X., Sze, K.Y., Lian, Y., Liu, Y.: Incompressible material point method for free surface flow. J. Comput. Phys. 330, 92–110 (2017)

Zhang, X., Chen, Z., Liu, Y.: The Material Point Method: A Continuum-Based Particle Method for Extreme Loading Cases. Academic Press, Cambridge (2016)

Zukas, J.A. (ed.): High Velocity Impact Dynamics. Wiley, New York (1990)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled ‘A Critical Assessment and Contact Algorithm for the Staggered Grid Material Point Method’.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supported by the National Natural Science Foundation of China (11672154).

Rights and permissions

About this article

Cite this article

Kan, L., Liang, Y. & Zhang, X. A critical assessment and contact algorithm for the staggered grid material point method. Int J Mech Mater Des 17, 743–766 (2021). https://doi.org/10.1007/s10999-021-09557-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-021-09557-7