Abstract

Cream is a milk derivative comparatively rich in fat, present in the form of emulsion of fat in skimmed milk, and acquired by physical extraction from raw milk with the help of centrifugal separator. The cream with variable fat content (10–40%) is commonly employed as an ingredient to traditional or modern desserts. It is also used in the production of value-added milk products such as butter and ghee apart from regular cooking applications. The pasteurisation, being an important safety requirement of milk food products, is usually materialised by heating the milk cream at a temperature of 90 °C for a period of one second. In the current work, thermodynamic and thermoeconomic derivatives in combination with all available constraints have been determined for high temperature short-time cream pasteurisation plant. The energy and exergy efficiency of cream pasteurisation plant was determined to be 86.88% and 66.11%, respectively. The cumulative value of energy destruction and exergy demolition in subunits of cream pasteurisation plant was estimated to be 93.88 kW and 11.39 kW, respectively, which mainly ascribed to complete enzymatic denaturation of fluid cream. The overall operating cost rate of complete cream pasteurisation plant was calculated as 1649.10 Rs./H, 22.02% portion of which was associated with electrical energy consumption. Further, the cost rate of exergy degradation for chilling and cooling activities was reported as 617.57 Rs./H and 357.55 Rs./H, respectively. The exergoeconomic factors of heating (14.75%) and chilling activity (0.82%) articulated that capital investment was dominant in the former while thermal degradations were enunciated most flagrant in latter.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The FAO statistics revealed that the global annual milk production was estimated to be 819 MT in the year 2016, 19.57% of which was produced by India alone. India’s share in global import and export trade of dairy products was weighed up to be 0.19% and 0.68% of its global annual counterparts [1]. India’s 4% annual growth pace propelled the engine of global milk trade from 5% in 1970 to 17.4% in 2012 despite the non-conducive environment (hot and humid) for milk production and processing along with limited automation of this industry. As far as Indian production scenario of various dairy products is concerned, the contribution of milk cream production is reported to be least (1%), whereas the second highest share of percentage production is maintained by ghee production (28%) after fluid milk production (44%) [2,3,4].

The improper demand—supply equation of energy, particularly in the developing nations—forces the processing units to install their own heavy duty thermal utility and electrical energy generation systems which would inevitably count on conventional fuel supply for execution of mechanical and non-mechanical activities of processing plants. Since the cost–quality matrix has its direct linkage with consumption and degradation, the resource quantification with the help of advanced thermodynamic and thermoeconomic tool has become highly indispensable [5,6,7]. Fadare et al. [8] evaluated exergy gauge to estimate processing capabilities of malt drink processing units. The packing house activity was reported to be least efficient, and the average process energy intensity was calculated to be 261,630 kJ hl−1. Similarly, Nasiri et al. [9] revealed the contribution of steam generator (57%) in a long-life ultra-filtrated cheese manufacturing plant. They also estimated the average specific exergy deterioration to be 2330.42 kJ kg−1. Thermodynamic evaluation of double effect tomato paste plant was carried out by Mojarab et al. [10]. The exergy deficiency of the first and second evaporative processes was computed to be 34.67% and 43.40%, respectively. The consumption of specific exergy in the said plant was calculated to be 16830 kJ kg−1 which was obtained by processing of actual operational data. Similarly, Dowlati et al. [11] portrayed variety of exergy derivatives for an ice cream manufacturing division situated in Tehran Province. The analysis diagnosed the frail and firm exergetic features of subcomponents of the plant, e.g. most deficient performance was captured in case of ice cream production line followed by steam generation and refrigeration while overall institutional exergy deficiency was figured out to be very high (97.85%) in magnitude. Furthermore, Genc et al. [12] generated some concrete outcomes by instituting exergy scale for red wine production unit located in Tehran, Iran. The subunits of the plant were ranked according to magnitude of exergy degradation, i.e. least amount of reversibility was confirmed in open fermenter (3.05%) whereas a meagre proportion of the same was assessed in case of plate and frame filter (0.53%) and crusher destemmer (0.084%). The overall exergy and energy deficiency of the plant was measured up to be 58.20% and 42.80%, respectively. In continuation of same exercise, Pandey et al. [13] chose North Indian climatic region for assessment of thermal derivatives, e.g. energy and exergy efficiency of multi-crystalline solar photovoltaic module for different months of a year. The aforementioned parameters registered the highest and lowest values in the months of February and December, respectively. Moreover, amount of availability content and efficiency thereof gauged to be comparatively on higher side in the morning time.

In another similar kind of research work, Pelvan et al. [14] assessed the sustainability characteristics of tea production process in combination with waste potential of the plant; in terms of indices such as cumulative degree of perfection (COD), cumulative carbon dioxide emission (CCO2E) and renewability indicator (RI). The study pointed towards significant improvement in exergetic behaviour of plant, given the condition when waste of subjected to valorisation. In another similar kind of research work, Basaran et al. [15] discussed the case of tomato pasteurisation by involving induction heating, wherein the system consumed 40.98 kW of high grade energy for materialising the aforementioned activity, compared to electrical energy-assisted pasteurisation in which exergy consumption was 26% higher than that of induction heating counterpart. Also, exergy efficiency of induction-based sterilisation was reported as 46.56%. Similarly, Singh et al. [16] calculated exergy and exergoeconomic aspects of ultra-high temperature milk pasteurisation. The specific exergy destruction, improvement potential and overall cost rate of exergetic degradation were identified to be 219.23 kJ kg−1, 130.60 kJ kg−1 and 8082.50 € H−1, respectively. The specific manufacturing cost of UHT processed milk was ascertained to be 1.355 € kg−1. Further, existence of some works [16,17,18,19,20,21] enumerated the significance of exergetic approach in assessment of solar energy-based applications such as heat pump operation, mobile air conditioning, food baking, water heating and sterilisation of liquid milk products. In prolongation to similar approach, Kwak et al. [22] unified exergy and cost balance equations to evolve the highest unit exergy cost rate of combustor and gas compressor. However, total cost of exergy degradation was enumerated to be 12.78 $ h−1 at 100% loading condition. On a similar note, Tsatsaronis [23] generated the circuitous information related to the exergoeconomic behaviour of thermal system which otherwise could never be dredged up by conventional gauges of economic analysis. Interconnection between exergy degradation and their monetary equivalence was studied by Lazzaretto and Tsatsaronis [24]. In this work, cost balance equations were solved in assistance with auxiliary equations to procure monetary figures of exergy demolition in a process flow structure.

The cost break-up of various subunits in consolidation with thermodynamic specifications of plant would induce a rational spectrum of losses for a nearly optimal mechanical system. A mathematical formulation is related to energy, exergy and exergoeconomic evaluations of large-scale cement plant and their subsequent integration with actual performance data to obtain the cost-oriented implications and repercussions in combination with thermodynamic derivatives by Atmaca and Yumrutas [25, 26]. The opportunity of heat integration and waste heat recovery apart from productivity improvement, enhancement in overall sustainability of plant, had not been comprehensively reported in previous works [27,28,29,30,31,32,33]. Moreover, the conventional approach of thermodynamic or economic evaluation of any thermal system had not been given broad coverage to explore economic or energy savings prospects, particularly for the energy system wherein aforementioned objectives are not perfectly highlighted [34,35,36,37,38,39].

Despite having a several numbers of research work related to exergy and exergoeconomic analysis for different types of food processing and production units, there still exists great scope in qualitative and quantitative judgement of exergy destruction and improvement potentials in production and processing activities of variety of traditional and modern value-added dairy products, such as whipped cream, butter milk and ghee. In view of high worth of specific thermal and electrical exergy requirements in dairy product processing divisions, the exact coverage of capital consumption or exergy destruction in consideration with thermal and monetary constraints has become a serious issue, the detailed idea of which would assist plant designer or planners to mature blueprint for accomplishment of maximum attainable thermal and thermoeconomic performances of plant. The present research work provides an exhaustive judgement of thermoeconomic and thermodynamic derivatives such as cost equivalent of exergy destruction, exergy efficiency and specific exergy destruction. In addition to above, percentage measure of cost difference in relation to exergy values of flow streams, thermoeconomic indices, comprehensive operational cost rate will provide a sound basis for genuine prediction of thermoeconomic attributes of a factory scale cream sterilisation plant of milk food industry in India.

Plant description and methodology

Plant description

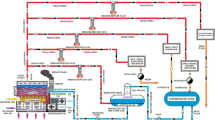

The high temperature short-time cream pasteurisation line of the dairy processing concern is represented in Fig. 1. It consists of one regeneration section, one heating section, one cooling and one chilling section. Primarily plate heat exchangers are involved for the purpose of executing above-mentioned activities of cream pasteurisation process.

The cream with 40% fat content is first passed through the regeneration section where a temperature rise of 24 °C is achieved. The pump-3 supplies the cream to heating section where another significant temperature rise is obtained. The high temperature cream is then passed again through the regeneration section where necessary heat exchange between hot and cold fluids takes place. In the last part of travel, cream flows through cooling section; the cooling activity is realised by cold water flowing in the opposite line. The temperature of hot water is brought down by condenser and fan combination which works in conjunction with cooling section of cream pasteuriser.

Finally, the chilling of cream is materialised by flowing chilled water in the chilling section of the pasteuriser. There is one separate section for hot water generation which consists of shell and coil heat exchanger, water tank and a feed water pump. There are some redundant units meant for the purpose of long- and short-time storage of the cream.

Pasteurisation

Pasteurisation is described as a process of thermal treatment administered for milk, cream or any other fluid with the goal of optimising health safety of human beings. The fluid products are prone to pathogenic disorder; therefore, it becomes highly imperative to provide suitable and sufficient heat treatment to them. In addition to the aforementioned target of pasteurisation, the secondary foremost idea behind thermal nursing is to bring reduction in any changes related to its chemical, physical and organoleptic features along with an achievement of optimum rise in the shelf life of final products by systematically phasing out the dangerous bacteria and enzymes [2].

Usually phosphatase or peroxide tests are instituted for this purpose, and in particular, they are employed for the milk food products having fat content less than 8%. But, however, in order to pasteurise the cream with different fat contents or to have strict control on enzymatic activities, the high-fat commodities are commonly pasteurised at 90 °C with different time residency requirements. Basically in order to curb the reactivation of enzymes immediately after pasteurisation, a thermal treatment of fairly strong strength is highly essential. The phosphatase and peroxide are the two main enzymes which get absolutely crushed or killed in high temperature treatment of milk and cream, respectively [4].

The pasteurisation of milk and cream is highly mandatory activity, as the stability and safety of value-added products such as butter, ghee and cheese are of utmost important. In order to secure negative results of peroxide test for the high-fat (10–48%) cream, there must be some optimum time and temperature coalitions for variety of fat compositions. Typical minimum time–temperature associations required to exhibit a negative phosphatase test are given in Table 1.

The whole milk is provided with mild heat treatment so that an environment conducive to cream separation could be created. The cream separation activity is usually performed at a temperature range of 51–55 °C. Milk is usually standardised after the fat separation, i.e. some amount of fat is added back into the milk to conform to the national or international standard of milk pasteurisation. The surplus cream is usually pasteurised in a cream pasteuriser before being processed for manufacturing of value-added products. The factors such as water activity, temperature, oxygen, osmotic pressure and pH value of cream have significant impact upon bacterial ballooning.

The magnification of pathogenic convulsion is usually accompanied by conducive thermal conditions. There exist an optimum temperature and time combination which would restrict or crush the imminent bacterial advancement. The shelf life of cream is another important requirement. Amongst the aforementioned methods of food preservations, the thermal nursing is the most viable and feasible solution of having an enhanced shelf life of food products.

Since the other specified techniques involve different kinds of mechanical arrangement, thus the product pasteurisation could be easily achieved by a food pasteuriser for variety of liquid food items. The intense exposure to fluid items creates necessary lethal effect on the micro-organisms. The HTST techniques are meant for preservation of milk or cream for the specified period of time and application. However, there are several other techniques for achievement of extended shelf life (ESL) of the milk food items. The ultra-high temperature pasteurisation of milk and its value-added products has become very common to secure its tasteful and nutritional characteristics to some extent apart from extension of its shelf life for sufficient number of days. The discussion entails the fact that in order to process any milk food item, pasteurisation is most important activity without which safety, stability and longevity of products could not be ensured [11, 27, 40]. The pasteurisation of milk cream involves successive regeneration, heating, cooling and chilling.

The fluid regeneration is accompanied by simultaneous heating and cooling by the single fluid, so that heat content of hot fluid could be utilised to heat up low temperature fluid. Before execution of cream pasteurisation, the cream separation is the integral part of HTST milk pasteurisation process. The cream is extracted out of the whole milk by the use of cream separator which purely uses centrifugal force for materialisation of this activity.

Methodology

In order to evaluate the cream pasteurisation plant on exergoeconomic and thermodynamic platforms, the necessary technical details were obtained from a nearby Verka Milk Plant, Mohali, located few hundred kilometres towards north from national capital of India, which has a cream handling capacity of 20000 kg per day. The technical information instituted for the current assessment was observed and recorded by the technical executives of the plant for one year continuously. The following assumptions are assisted in formulation of thermodynamic background of current analysis as:

-

(a)

The plant and its subdivisions remain steady under all operational conditions.

-

(b)

The magnitudes of different forms of energy, e.g. kinetic or potential, were ignored mainly due to their minimal subscription [40].

-

(c)

The reference state coordinates for thermal analysis are given as T0: 298.15 K and P0: 101.325 kPa.

-

(d)

The contribution of crud development in exergetic degradation was negligible.

-

(e)

The variation in reference state temperature was disregarded.

-

(f)

The physical significance of fat formation exergy towards overall thermodynamic performance was disregarded [40].

Thermodynamic analysis

There are two fundamental propositions of thermal analysis which individually generate energetic and exergetic information of energy system. The exergy principle focuses upon unearthing the information related to energy degradation during product processing which could not be procured by first law of thermodynamics. Thus, it could be clearly understood that second law matures the plant planner from the view point of location and identification of domains of thermal or electrical exergy destruction or consumption along with probable improvement by simultaneous retrofitting of plant.

Energy and exergy analysis

The mass balance equation employed for current study is given as follows:

The subscripts ‘in’ and ‘out’ stand for input and output, respectively.

The thermal equilibrium equation is given by:

The first and second law performances are quantified by the following equations as:

The general exergy demolition equation is given by:

The equation concerning calculation of magnitudes of physical exergy rates at all the states of cream processing plants is given as follows:

Table 2 provides thermodynamic framework for all the subunits of the plant.

Further, Table 3 provides mathematical formulations for each of the constituents of the plant in context of aforementioned thermodynamic background.

Exergoeconomic analysis

In order to calculate basic quantities such as hourly levelised cost rate of capital investment cost, hourly levelised cost rate of operational and maintenance activities and the total levelised cost rate of constituents of cream pasteurisation plant, the purchase equipment cost of subunits and associated operational cum maintenance expenses are procured from information supplied by supplier in its quotation and maintenance section of plant, respectively. The specific exergy costing method (SPECO), being the tool required for exergoeconomic appraisement, involves estimation of cost flow rates for each of the subunits at all input and output points, thereby covering entire of the plant, to secure optimum cost matrix in relation to exergetic destruction [23, 24].

As per the said methodology, cost accounting for each of the units of exergy approaching and leaving the subunit is quantified in terms of cost which is called as fuel input and product output in general. Moreover, mathematically, cost balance expressions are evolved in coordination with exergy flow streams for all subunits of plant. The relations of exergy transmission and cost flow rates per unit exergy for thermal and electrical energy contents may be written as:

Further, overall exergoeconomic equilibrium equation for all the subunits of plant may be given as follows:

The above stated equation is the reflection of the fact that summation of cost rates of approaching exergy streams equals to sum total of cost rates of all leaving exergy streams in addition to capital and other related costs. Additionally, in exergy cost balance equation, all the terms present in the aforementioned equation are positive in nature. Moreover, SPECO methodology of exergoeconomic analysis entails that there exists n − 1 number of auxiliary set of equations for n number of exergy leaving streams involving cost flow rates which highlight the significance of F and P propositions of SPECO methodology [23, 24].

The F and P approaches impart price value to incoming and outgoing exergy streams along with establishment of cost equilibrium of exergy streams for fuel and product side. In the present section, auxiliary equations as constraints are mapped against corresponding cost flow rates of existing exergy streams for each of the constituents of cream pasteurisation plant. In an extension to same approach, capital investment as well as operational and maintenance costs are expressed as hourly levelised cost rate for flow streams at each entry and exit point of the plant. Therefore, the summation of above-mentioned levelised cost rates can be represented as follows:

The algorithm as specified in next six steps was instituted for computation of hourly levelised cost rate for each subunit of plant. For cream pasteurisation plant, the parameter present worth (PW) was determined by the following relationship as:

where TCI and S stand for total capital investment at initial stage and salvage value of plant at any stage of plant operation. The former was identified as Rs. 550,000, while the latter was calculated from the relationship as mentioned below.

Additionally, the ratio of salvage value was denoted by term J, which was taken as 8% for the purpose of current analysis. Similarly, single payment present worth factor (PWF) can be mathematically expressed as:

wherein i stands for annual interest rate value, i.e. 10%, and n indicates number of years, i.e. 10, for which the pasteurisation unit was operational. By multiplication of numerical value of present worth and capital recovery factors, annual cost of entire plant could be secured as given by the following equation.

The capital recovery factor (CRF), as discussed above, can be computed by the following mathematical relationship as:

The cream pasteurisation activity was performed continuous for 300 days in a year and 7 h on daily basis. The operational and maintenance cost dedicated for the 2100 h of annual operation of plant was estimated as Rs. 183,150. Finally, annualised cost of equipment for the plant was given by the following mathematical equation.

where τ, AC and PEC are total number of hours for which the plant is operational in a year, annual cost of subunit and cost of each subunit of plant, respectively. Thus, aforementioned algorithm assists in procurement of hourly levelised cost of capital investment \( Z_{\text{CI,k}} ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \), operational and maintenance cost \( Z_{\text{OM,k}} ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \) as 52.52 \( ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \) and 17.33 \( ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \), respectively. In addition to that, overall levelised cost rate, i.e. \( Z_{\text{T,k}} ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \), of plant is the summation of above-mentioned two levelised cost rates, i.e. 69.86 \( ({\text{Rs}}.\;{\text{H}}^{ - 1} ) \).

Exergoeconomic parameters

This section enumerates some of the main parameters related to exergoeconomic analysis, i.e. average value of cost per unit exergy for the fuel and product for any subunit k of plant, and the same are represented by the following mathematical equations as:

where \( \dot{C}_{\text{f,k}} \) and \( \dot{C}_{\text{p,k}} \) are the total cost flow rates for each of the subunits in fuel as well as product side, on the basis of which key exergoeconomic indices such as cost rate of exergetic degradation (\( \dot{D}_{\text{D,k}} \)), exergoeconomic factor (fk) and relative cost difference in terms of percentage value(rk) were ascertained by developing relationships as given in Table 4.

Basically, parameters mentioned in Table 4 collectively help in providing ranks to subunits of plant as per their order of exergoeconomic performance or characteristics. The magnitude of irreversibility or thermodynamic incompetency is quantified in terms of cost rate of exergetic degradation for any subunit of plant. Besides that, exergoeconomic factor in combination with percentage relative cost difference helps in diagnosis of level of penetration of capital investment or involvement of cost rate of exergetic degradation in overall cost composition matrix of cream pasteurisation plant; in other words, validation of exergoeconomic performance of plant could be fruitfully secured by logical outcomes of aforementioned indices.

Apart from the above discussion, percentage relative cost difference values (rk) for each of the plant constituents reflect amount of increment or decrement in cost rate of exergetic destruction received or experienced by subunit under consideration, while processing material through it. Moreover, it is established as a better index of measurement of exergoeconomic performance, i.e. with the help of which, relative estimation of performances of subunits is ascertained in relation to total operating cost rate of plant. The idea of exergoeconomic approach is to develop or strike an optimum balance between amount of capital investment to be made in a certain venture and degree of thermodynamic perfection to be procured out of it. The major goals of exergoeconomic appraisal were recognised as follows:

-

To examine the exact location and definite magnitude of exergy destruction and cost thereof in an energy system.

-

To estimate precisely the specific manufacturing cost (Rs. kg−1) of final product.

-

To evolve technical policies and programmes with a view of upgrading thermal performance of processing plant.

-

To pinpoint or discover different approaches for achievement of maximum performance in line with reduction in overall operational cost of plant.

-

To determine the trade-off amongst techno-economic variables so as to assess suitability of different options for plant activities.

The exergetic cost rate equilibrium equations for each subunit of cream pasteurisation plant are given in Table 5.

In addition to aforementioned mathematical formulation of thermodynamics and thermoeconomic appraisals, the specific heat capacity and specific volume of milk constituents could be represented as a function of the state temperature as displayed in Table 6.

Additionally, subsequent equations were instituted for computation of specific volume and specific heat capacities of milk derivatives at all state positions of plant, respectively.

Further, the composition of milk with variable fat content employed for calculation of specific volume and heat capacity is displayed in Table 7.

Uncertainty analysis

In order to ascertain the replication and characterisation of exploratory figures, the necessary course of action related to uncertainty analysis was effectuated with the help of approach developed by Holman [41].

Results and discussions

Thermodynamic analysis

The cream pasteurisation plant mainly consists of cream pasteuriser which involved regeneration, heating, cooling and chilling activities. All of the key thermodynamic variables such as working pressure and temperature along with mass flow rates of milk flow streams at all state positions as depicted in Fig. 1 are listed out in Table 8, with the help of which, thermal performance parameters were figured out for each of the constituents of cream pasteurisation plant as shown in Tables 9 and 10.

The energy and exergy efficiency of cream pasteurisation plant was calculated to be 86.88% and 66.11%, respectively (Tables 9, 10), for complete cream pasteurisation plant. However, from the earlier research attempts [9, 27, 40], the variation in exergetic performances for milk pasteurisation line was reported to be in the range of 78.00–92.02% while energy efficiency was registered in between 68 and 72% [42]. Amongst the key processing subunits of the plant, the highest value of exergy efficiency was reported for heating section (94.14%) followed by regeneration section (84.42%) and final chilling section (59.26%) (Fig. 2). However, their corresponding energy counterparts were calculated as 94.91%, 95.88% and 74.05%, respectively. The least value of energy and exergy efficiencies was recognised for cooling tower, i.e. 27.86% and 2.41%, respectively, owing to higher level of energy loss through the unit.

The energy and exergy efficiencies of centrifugal pumps were estimated to be in the range of 88.46–97.75% and 1.78–18.18%, respectively. The second law efficiency of subunit cream pasteuriser possessed the numerical figure as 76.56%, while the variation in same in previous research approaches [9, 27, 40] was gauged to be in the range of 72.42–88.56%. Similarly, the exergy efficiency of cream storage tank and water storage tank was ascertained to be 57.87% and 96.88%, respectively. Further, exergy efficiency of four subsections, e.g. regeneration section, heating section, cooling section and chilling section, of cream pasteurisation unit was determined as 84.42%, 94.14%, 28.86% and 59.26%, respectively.

Similarly, previously recorded [9, 27, 40] variation in exergy efficiency for plate heat exchanger required for hot water generation unit was reported to be in the range of 50.53–53.32% as against 54.68%, determined in current research endeavour. Moreover, value of specific steam consumption for cream pasteurisation line was estimated to be 0.03 kg kg−1, which lies in the range of 0.02–0.05 kg kg−1 as discussed in the aforementioned literature reviews. The total value of specific energy loss for the entire plant was registered as 297.12 kJ kg−1, while exergy counterpart of the same recorded a magnitude of 56.71 kJ kg−1 (Tables 9, 10). In an extension to the same, some of the recent research ventures also identified specific degradation in exergy of milk processing units in the ambit of 25.67–77.62 kJ kg−1, wherein constituents involved in regeneration exercises maintained almost similar numerical magnitude for second law efficiency (84.42%) as specifically mentioned in previous research documentation related to milk processing or pasteurisation, i.e. 82.00–89.84% [9, 27, 40].

The total value of energy loss for the complete cream pasteuriser was enumerated to be 93.88 kW whereas its corresponding exergetic counterpart was determined as 11.39 kW (Fig. 3). The subscription of heating and cooling activities towards total exergy destruction was diagnosed as 19.91% and 40.38%, respectively. The share of pumping and storage activities towards the overall exergy demolition was reported as 46.34%, and its energy counterpart was calculated as 28.22%. It is quite important to note that electrical energy requirements of the pumping systems in dairy processing plants can be significantly reduced by employing variable speed drive (VSD) controller.

Heat exchanger, being the key constituent of the plant, was associated with gross exergy destruction of 6.63 kW, followed by final chilling or intermediate cooling; the numeric quantification of the same was expressed as 3.87 kW. A little glance over the energy and exergy derivatives of plant indicated that value of energy loss and exergy destruction for the condenser and fan combination was confirmed as 43.69 kW and 2.41 kW, respectively. Amongst the key processing units of the plant, the highest value of exergy destruction was reported for heat exchanger (6.63 kW), followed by exergetic degradation in cream storage tank (5.22 kW) and cooling or final chilling section (3.87 kW) (Fig. 3).

The demolition of cool exergy content [11] in the cream storage tank was primarily caused by higher degree of cooling, mainly needed for accomplishment of instantaneous crystallisation of milk fat or effective cream ripening, so that highest possible butter yield could be obtained. The structural strength or mechanical integrity of milk fat is essentially achieved by carrying out milk/cream chilling at higher rates in association with by non-violent agitation of milk fat in cream storage tank. The development of high grade partial coalescence amongst milk fat globules or inception of Van der Waal’s forces of attraction between the liquid and solid phases of milk fat is achieved at the cost of sufficient amount of cool exergy demolition, i.e. 7.77 kJ kg−1 of pasteurised cream.

In addition to accomplishment of complete bacteriological control over milk cream through pasteurisation, it is quite important to note that in order to secure highest possible texture quality as well as butter yield, it is highly imperative to maintain final temperature of outgoing pasteurised cream in the range of 8–12 °C, as the said temperature range also assists in control of fat loss during the churning process for butter production [43].

The specific energy improvement potential of the entire cream pasteurisation plant was computed to be 87.12 kJ kg−1, while its exergetic counterpart registered a magnitude of 35.80 kJ kg−1 (Tables 9. 10). The energy and exergy improvement potential related to cream pasteuriser was enumerated to be 19.04 kW and 4.81 kW, respectively. The maximum value of exergy improvement potential is registered in case of water tank (4.69 kW) followed by that of heat exchanger (3.00 kW), cooling section (2.75 kW) and condenser and fan combination (2.37 kW) (Fig. 4).

The cumulative value of exergy improvement potential for pumping operation in plant was calculated as 11.68 kW, while contribution rendered by cream storage units was 9.14% towards the same. The scope of exergy improvement potential for condenser and fan combination was diagnosed to be 2.37 kW. However, heat exchanger being one of the key thermodynamic entities of the pasteurisation plant scored maximum magnitude of relative exergy destruction ratio, i.e. 17.40% followed by cooling or chilling section (10.15%) and regeneration section (7.06%), respectively (Table 10). The higher rates of degradation of high grade energy potential in plate heat exchangers could be attributed to heat transfer with comparatively greater magnitudes of thermal gradients in hot and cold side.

Besides that, the exergetic deficiency of the cream pasteuriser was valued to be 23.44%, displaying its satisfactory performance characteristics in retrieving the ‘warm’ and ‘cool’ exergies of flow streams involved in regeneration or heat transfer activity [27]. However, the exergetic performances of HTST cream pasteurisation plant can be markedly improved by involving innovative perspectives such as self-heat recuperation mechanism wherein both latent heat and sensible heat of the streams can be reclaimed into a process based upon recuperation of exergy content, causing significant amount of resource saving in the activity just mentioned. Moreover, the combined exergy and pinch tools can be effectively instituted for retrofitting and designing of food pasteurisation plants [44].

The detailed investigation of Table 10 revealed that the share of cream pasteuriser towards total exergy degradation was unlocked to be 29.89% against an exergetic factor of 43.21%. The highest value of the exergetic factor was recorded for regeneration section (15.36%) followed by heating section (14.57%) and heat exchanger (13.01%).

The highest value of sustainability index was realised for heating section (SI: 17.06) followed by regeneration section (SI: 6.42) and chilling section (SI: 2.45); however, the same parameter registered a value of 4.27 for cream pasteuriser. The sustainability index for the heat exchanger was estimated to be one-third and nearly two times to that of regeneration and cooling section, respectively. In comparison with chilling section as discussed above, the heating section was expressed 2.85 times better sustainability characteristics.

As far as specific thermal and electrical exergy consumption is concerned, the literature has provided the variation in same in the range of 18.00–35.98 kJ kg−1 and 8.82–18.17 kJ kg−1, respectively [9, 27, 40], whereas the present study has reported the magnitude of aforementioned parameters as 31.86 kJ kg−1 and 22.69 kJ kg−1, respectively.

Thus, from Table 10, it could be suitably concluded that the subunit cream pasteuriser sustained good thermodynamic ranking and, in comparison with the earlier literatures [9, 27, 40], better sustainable characteristics were reflected by plate heat exchanger required for hot water generation. Moreover, 58.40% share of resources consumption had been fulfilled by thermal energy while remaining portion of exergy consumption was furnished by the electrical energy counterpart (Fig. 5).

Thermoeconomic analysis

In the current section, the exergoeconomic statuses of individual constituent as well as those of cream pasteuriser have been established. The indices of thermodynamic assessment have been quantified, and their physical significance in relation to each other was explored. The SPECO technique of exergoeconomic analysis was employed to capture the bottom line of its derivatives and predict the scope of improvement within the current architecture of the plant.

The outcomes of thermoeconomic assessments were synopsised in Table 11, which demonstrated the calibration of principal exergoeconomic indices such as cost of exergy destruction, percentage relative cost difference, levelised cost rate of components, exergoeconomic factor and comprehensive operational cost of overall plant and its constituents.

The exigency of overall operating cost rate could be described in terms of the fact that higher the dominance of comprehensive operational cost rate of entire plant, the higher will be the percussion of a constituent on the behaviour of the overall performance system. The cumulative hourly levelised cost rate of the entire plant was estimated to be 69.86 Rs. H−1, maximum contribution to which was made by cream pasteuriser (53.28%) followed by pumping and storage units (31.60%) while the rest of the contribution was made by heat exchanger and condenser and fan combination, i.e. 15.65%.

From Table 11, the percentage relative cost difference and exergoeconomic factor for the cream pasteurisation unit was calculated as 49.71% and 3.47%, respectively, which clearly indicated the majority share of total operating cost rate went into overcoming the thermal deficiencies present in the cream pasteurisation unit. The total operating cost rate for complete cream pasteurisation plant was notified to be 1649.10 Rs. H−1, 70.06% contribution to which was given by cream pasteuriser, respectively (Fig. 6). Amongst the subunits of cream pasteuriser such as regeneration section, heating section, cooling and chilling sections, cost rate of exergy destruction was enumerated to be highest for the chilling activity (617.57 Rs. H−1) followed by cooling (357.55 Rs. H−1) and regeneration activity (144.99 Rs. H−1), respectively. The subscription of heating and cooling activities towards total operating cost rate was diagnosed to be 67.43%. Similarly, pumping and storage activities consumed 23.65% portion of total operating cost rate of entire plant.

A careful observation of exergoeconomic indices of electrical energy munching subunits of the plant divulged that exergy degradation was articulated more extrusive in case of cooling water supply pump and cream supply pump, as the same consumed 21.83% portion of total operating cost rate. The water and cream supply pumps may be replaced with variable speed drive controllers and screw pumps in order to improve overall efficiency of the plant.

Amongst the key thermodynamic entities of the plant, the highest and lowest value of total operating cost rate was associated with chilling section and condenser and fan combination of the plant, i.e. 617.57 Rs. H−1 and 22.44 Rs. H−1, respectively. The cost expenditure on entities associated with chilling and cooling activities was 14.31 times higher than its heating counterpart whereas the exergetic degradation of former was more than two times to that of latter. The magnitudes of percentage relative cost differences in cooling or chilling and heating activities of the plant reflected that the fluid chilling or cooling was far more costlier than its heating counterpart. Similarly, fluid pumping was found out to be costlier than fluid storage activity.

Apart from pumping and storage units of plant, the highest value of cream processing cost was related to condenser and fan combination (97.97%) owing to higher level of exergetic degradation, followed by cooling section (67.79%) and chilling section (43.83%) of pasteuriser. However, the magnitude of percentage relative cost difference for the subunits such as regeneration section (10.92%), heat exchanger (7.17%) and heating section (17.22%) reflected comparatively low value of fluid processing cost in relation to above discussed subunits (Fig. 7). From Table 11, it was quite obvious that pumping and storage activities of plant consumed sufficient amount of cost in overcoming the irreversibilities associated with processing of cream fluid from one stage to another stage of plant.

As far as exergoeconomic factor was concerned, for the key thermodynamic entities of plant, the highest and lowest value of the exergoeconomic factor was determined for heating section (14.75%) and chilling section (0.82%), which quantified the role of capital investment and cost rate of exergy destruction (Fig. 8). The impact of exergetic degradation was quite prominent in subunits such as regeneration section; cooling section and heat exchanger as the same were obvious from the numeric quantification of aforementioned subunits, i.e. 9.81%, 7.17 and 3.55%, respectively.

As far as thermoeconomic performance of pumping units was concerned, it was found that except for the pump-3, the value of exergoeconomic factor for other all pumping units was significantly higher, which showed that operational and maintenance expenses were on higher side compared to the former wherein exergy destruction was observed to be far more influential. Similar sort of behaviour was projected by performance of cream storage tank, wherein low value of exergoeconomic factor was primarily caused by high rate of thermodynamic irreversibilities present in it.

Further, the cost per unit exergy and exergetic cost of pasteurised cream were determined as 203.08 Rs. H−1 and 39.51 Rs. MJ−1, respectively. In view of above discussed sequences of thermodynamic and thermoeconomic outcomes, the optimisation of key derivative of exergy analysis, i.e. specific exergy demolition, is perceived to be highly indispensible as far as significant reduction in specific manufacturing cost of HTST sterilised cream is concerned, which in the present scenario was estimated to be 0.682 Rs. H−1.

In the view of current scenario of cream production and consumption in Indian Subcontinent for variety of value-added dairy products, the appropriate alterations, modifications and retrofitting in cream pasteurisation plant in combination with other production entities of dairy plant could help in procurement of higher production rates of dairy products at current level of fuel or resource requirements. Also, it is quite feasible to design and mature solar or biomass energy-assisted cream sterilisation plant, wherein temperature requirement of 100–160 °C could be easily obtained and the same would be a recognised as great breakthrough in achieving decrement in dependence upon consumption of natural resources. Overall, exergy and thermoeconomic basis of system evaluation provide an equivalent alternative to many other available methodologies in the literature in pinpointing possible exergy recovery features in dairy plant, on grounds of which exergy-related economic retrenchment up to an outstanding level could be realised. As an expansion to above stated approach, mechanism such as life cycle judgement, pinch analysis, exergy-assisted gainful optimisation and exergoenvironmental viewpoints could help in construction of feasible interpretation about operational- and maintenance-related economic expenditures as well as in estimation of impact of environmental degradation on convoluted thermal system.

Uncertainty analysis

Table 12 displays magnitude of uncertainty for the key technical variables of HTST Cream Processing Unit, the magnitude of which indicated that same were within acceptable limit, i.e. less than 5%. The uncertainty analysis is performed, firstly, to take into the consideration the variation in reading inherently present in the instrument or gauge; secondly, to display the reproducibility and representativeness of the experimental data; thirdly, from the view point of milk food biochemistry, since the variation in parameters beyond a certain range could affect the qualitative features such as yield, fat content, texture, taste and properties of product under consideration. For example, optimum temperature range of cream storage is 8–12 °C, to realise optimum butter yield as well as minimise fat loss during subsequent operation, i.e. churning. Therefore, in the current work, the variation in uncertainty in cream storage temperature (7 °C in present work) is in line with the above stated requirement, i.e. ± 1.2839.

Conclusions

The quantification of derivatives of thermodynamics is highly significant particularly when there is optimum utilisation of resource concerned or qualitative measurement of deviation from reversible behaviour is of prime importance, the exact information of which would entail better version of identification of exergy destruction and their corresponding location in an energy system. The thermal analysis generates refined picture of resource consumption in combination with all available constraints so that an approach could be developed whereby goal of optimum resource allocation as well as implementation of optimised operational parameters could be realised to fruitfully avail the corresponding monetary benefits. The said line of action remains incomplete as long as there is no involvement of economic analysis or precisely exergoeconomic analysis, wherein each unit of exergy destruction is enumerated in terms of cost.

Moreover, rational costing of thermoeconomic variable based on exergy concept assists in evolution of optimal plant architecture, i.e. specific manufacturing cost of product and cost rate of exergy demolition are ascertained in most judicious way.

Hence, collective idea of indices from both the analyses, i.e. exergy and exergoeconomic, develops resourceful picture about maximum attainable performance from entire plant. Therefore, a systematic and optimised protocol for achievement of minimum level of thermodynamic irreversibility was pertinent from the viewpoint of improvement in quantitative and qualitative indices of energy, exergy and exergoeconomic coupled with magnification in thermodynamic and thermoeconomic fertility of overall processing plant.

The overall energy and exergy efficiency of HTST Cream Pasteurisation Plant was adjudged to be 86.88% and 66.11%, respectively. The energy and exergy efficiencies of cream pasteuriser were computed to be 86.93% and 76.56%, respectively. The total value of specific energy loss for the entire plant was registered as 297.13 kJ kg−1, while exergy counterpart of the same recorded a magnitude of 56.71 kJ kg−1. Similarly, the specific energy improvement potential of the entire cream pasteurisation plant was computed to be 87.13 kJ kg−1, while its exergetic counterpart registered a magnitude of 35.80 kJ kg−1. The share of auxiliary units such as condenser and fan combination and heat exchanger towards total exergy destruction was enumerated to be 23.77%, respectively.

The total value of energetic destruction for the complete cream pasteuriser was enumerated to be 93.88 kW whereas its corresponding exergetic counterpart was determined as 11.39 kW. The subsections of cream pasteurisation units such as heating section and chilling section recorded cumulative energy and exergy improvement potentials as 19.04 kW and 4.81 kW, respectively. The highest and lowest value of percentage relative cost difference was related to condenser and fan combination (97.97%) and hot water generation unit (7.17%), respectively. The gravity of total operating cost rate could be enumerated in terms of the fact that higher the value of total operating cost rate, the higher would be the impact of constituent of overall performance of the plant.

The total operating cost rate cream pasteurisation plant was computed to be 1649.10 Rs. H−1. Amongst the key processing activities of the cream pasteurisation plant, the cost rate of exergy destruction for cooling and chilling was reported to be highest, i.e. 957.33 Rs. H−1 followed by regeneration (130.76 Rs. H−1) and heating (30.09 Rs. H−1). In the wake of thermodynamic and thermoeconomic analysis, it was quite essential to procure the balanced value of thermoeconomic factor indices for all constituents of the plant so that specific manufacturing cost of pasteurised cream could be optimised which was reported to be 0.682 Rs. kg−1 in the current analysis.

Abbreviations

- AC:

-

Annual cost of component (Rs.)

- \( \dot{C} \) :

-

Cost flow rate (Rs. H−1)

- c :

-

Exergetic cost (Rs. MJ−1)

- c f, k :

-

Unit exergetic cost of fuel (Rs. MJ−1)

- c p, k :

-

Unit exergetic cost of product (Rs. MJ−1)

- c p :

-

Specific heat (kJ kg−1 K−1)

- CRF:

-

Capital recovery factor

- D D, k :

-

Cost rate of exergy destruction (Rs. H−1)

- \( \mathop E\limits^{ \cdot } \) :

-

Energy (kJ s−1)

- \( \mathop {\text{EL}}\limits^{ \cdot } \) :

-

Energy loss rate (kW)

- E β, k :

-

Relative energy destruction ratio (%)

- Exβ, k :

-

Relative exergy destruction ratio (%)

- E F, k :

-

Energetic factor (%)

- ExF, k :

-

Exergetic factor (%)

- ex:

-

Specific exergy (kJ kg−1)

- \( \mathop {\text{Ex}}\limits^{ \cdot } \) :

-

Exergy rate (kW)

- \( \mathop {\text{Ex}}\limits^{ \cdot }_{\text{D}} \) :

-

Exergy destruction rate (kW)

- E IP :

-

Energy improvement potential (kW)

- ExIP :

-

Exergy improvement potential (kW)

- f :

-

Exergoeconomic factor of component

- h :

-

Specific enthalpy (kJ kg−1)

- H :

-

Hour

- I :

-

Interest rate (%)

- J :

-

Ratio of salvage value

- \( \mathop m\limits^{ \cdot } \) :

-

Mass flow rate (kg s−1)

- MF:

-

Milk fat

- PEC:

-

Purchase equipment cost (Rs.)

- PWF:

-

Present worth factor

- PW:

-

Present worth of component (Rs.)

- r :

-

Percentage relative cost difference (%)

- Rs. MJ−1 :

-

Rupees per mega-joule

- T :

-

Temperature (K)

- s :

-

Specific entropy (kJ kg−1 K−1)

- S :

-

Entropy (kJ K−1)

- S :

-

Salvage value (Rs.)

- SI:

-

Sustainability index

- TCI:

-

Total cost of investment (Rs.)

- TOCR:

-

Total operating cost rate (Rs. H−1)

- TPD:

-

Tons per day

- ν :

-

Specific volume (m3 kg−1)

- W :

-

Work rate (kW)

- \( \dot{Z}_{\text{T}} \) :

-

Levelised cost rate associated with capital investment and operation and maintenance cost (Rs. H−1)

- \( \dot{Z}_{\text{CI}} \) :

-

Levelised cost rate associated with capital investment (Rs. H−1)

- \( \dot{Z}_{\text{OM}} \) :

-

Levelised cost rate associated with operation and maintenance cost (Rs. H−1)

- HTST:

-

High temperature short time

- R :

-

Universal gas constant (8.314 kJ mol−1 K−1)

- ρ :

-

Density (kg m−3)

- \( \eta \) :

-

Energy efficiency (%)

- Ψ:

-

Exergy efficiency (%)

- 0:

-

Dead state

- €:

-

Euro

- Rs.:

-

Rupees (Indian currency)

- BT:

-

Balance tank

- CF:

-

Condenser and fan combination

- CHS:

-

Chilling section

- CS:

-

Cooling section

- HS:

-

Heating section

- HE:

-

Heat exchanger

- P1:

-

Pump-1

- P2:

-

Pump-2

- P3:

-

Pump-3

- P4:

-

Pump-4

- P5:

-

Pump-5

- RS:

-

Regeneration section

- ST:

-

Storage tank

- WT:

-

Water tank

- k :

-

Any component

- In:

-

Inlet

- Out:

-

Outlet

- T :

-

Total

References

Food and Agriculture Organization of the United Nations. Statistics Division. http://faostat3.fao.org/browse/Q/QP/E. Accessed 20 Oct 2017.

Bogh-Sorensen. T. Cream pasteurisation technology. In: Bulletin of the international dairy federation No. 297/1992, monograph on the pasteurisation of cream. Chapter 7. Brussels: International Dairy Federation; 1992. pp 32–9.

CII India Report: widening the scope of PAT scheme. 2013. http://shaktifoundation.in/wp-content/uploads/2017/06/widening-of-pat-sectors-dairy.pdf. Accessed 20 Oct 2017.

Dairy Processing Handbook. Sweden: Tetrapak Processing Systems. 1995. https://diaspereira.weebly.com/uploads/5/6/3/9/5639534/dairy_handbook.pdf. Accessed 20 Oct 2017.

Akinbami JFK, Ilori MO, Adeniyi AA, Sanni SA. Improving efficiency of energy use in Nigeria’s industrial sector: a case study of a beverage plant. Niger J Eng Manage. 2001;2(2):1–8.

Wall G. Exergy flows in industrial processes, Physical Resource Theory Group, Goteborg.In: Paper presented at the fourth international symposium on Second Law Analysis of Thermal Systems. Rome. 1987.

Hellstrom D. Exergy analysis of nutrient recovery processes. Water Sci Technol. 2003;48(1):27–36.

Fadare DA, Nkpubre DO, Oni AO, Falana A, Waheed MA, Bamiro OA. Energy and exergy analyses of malt drink production in Nigeria. Energy. 2010;35(12):5336–46. https://doi.org/10.1016/j.energy.2010.07.026.

Nasiri F, Aghbashlo M, Rafiee S. Exergy analysis of an industrial-scale ultrafiltrated (UF) cheese production plant: a detailed survey. Heat Mass Transf. 2017;53(2):407–24. https://doi.org/10.1007/s00231-016-1824-3.

Mojarab Soufiyan M, Dadak A, Hosseini SS, Nasiri F, Dowlati M, Tahmasebi M. Comprehensive exergy analysis of a commercial tomato paste plant with a double-effect evaporator. Energy. 2016; 111: 910–22. https://doi.org/10.1016/j.energy.2016.06.030.

Dowlati M, Mojarab Soufiyan M, Aghbashlo M. Exergetic performance analysis of an ice cream manufacturing plant: a comprehensive survey. Energy. 2017; 123:445–59. https://doi.org/10.1016/j.energy.2017.02.007.

Genc M, Genc S, Goksunger Y. Exergy analysis of wine production: red wine production process as a case study. Appl Therm Eng. 2017;17:511–21. https://doi.org/10.1016/j.applthermaleng.2017.02.009.

Pandey AK, Tyagi VV, Tyagi SK. Exergetic analysis and parametric study of multi-crystalline solar photovoltaic system at a typical climatic zone. Clean Technol Environ Policy. 2013;15:333–43. https://doi.org/10.1007/s10098-012-0528-8.

Pelvan E, Ozilgen M. Assessment of energy and exergy efficiencies and renewability of black tea, instant tea and ice tea production and waste valorization process. Sustain Prod Consump. 2017;12:59–77. https://doi.org/10.1016/j.spc.2017.05.003.

Basaran A, Yilmaz T, Civi C. Application of inductive forced heating as a new approach to food industry heat exchangers. J Therm Anal Calorim. 2018. pp. 1–18. https://doi.org/10.1007/s10973-018-7250-7.

Singh G, Singh PJ, Tyagi VV, Pandey AK. Thermal and exergoeconomic analysis of a dairy food processing plant. J Therm Anal Calorim. 2018. pp 1–18. https://doi.org/10.1007/s10973-018-7781-y.

Prabakaran R, Mohan Lal D. A novel exergy based charge optimisation for a mobile air conditioning system. J Therm Anal Calorim. 2018;132:1241–52. https://doi.org/10.1007/s10973-018-6998-0.

Ayub I, Munir A, Amjad W, Ghafoor A, Nasir SM. Energy and exergy based thermal analyses of a solar bakery unit. J Therm Anal Calorim. 2018;133:1001–13. https://doi.org/10.1007/s10973-018-7165-3.

Paradeshi L, Mohanraj M, Sriniwas M, Jayaraj S. Exergy analysis of direct expansion solar assisted heat pumps working with R22 and R433A. J Therm Anal Calorim. 2018;132:1241–52. https://doi.org/10.1007/s10973-018-7424-03.

Pandey AK, Tyagi VV, Rahim NA. Thermal performance evaluation of direct flow solar water heating system using exergetic approach. J Therm Anal Calorim. 2018;121:1365–73. https://doi.org/10.1007/s10973-015-4566-4.

Rashidi S, Javadi P. Esfahani J.A. Second law of thermodynamics analysis for nanofluids turbulent flow inside a solar heater with ribbed absorber plate. J Therm Anal Calorim. 2018. pp. 1–13. http://doi.org/10.1007/s10973-018-7164-4.

Kwak HY, Kwon YH, Oh S-D, Kim SM. Exergoeconomic analysis of thermal systems. Energy. 1998;23(5):393–406.

Tsatsaronis G. Recent developments in exergy analysis and exergo-economics. Int. J Exergy. 2008;5(5/6):489–99. https://doi.org/10.1504/IJEX.2008.020822.

Lazzaretto A, Tsatsaronis G. SPECO: a systematic and general methodology for calculating the efficiencies and costs of thermal system. Energy. 2006;31:1257–89.

Atmaca A, Yumrutas R. Thermodynamic and exergoeconomic analysis of a cement plant: part I—Methodology. Energy Convers Manage. 2014;79:790–8. https://doi.org/10.1016/j.enconman.2013.11.053.

Atmaca A, Yumrutas R. Thermodynamic and exergoeconomic analysis of a cement plant: part II—Methodology. Energy Convers Manage. 2014;79:799–808. https://doi.org/10.1016/j.enconman.2013.11.054.

Jafaryani JM, Aghbashlo M, Mohtasebi SS. Comprehensive exergy analysis of an industrial-scale yogurt production plant. Energy. 2015;93:1832–51.

Jekayenfa SO. Ergonomic evaluation and energy requirements of bread operations in south western Nigeria. Nutr Food Sci. 2008;38(3):239–48. https://doi.org/10.1108/00346650810871920.

Balkan F, Colak N, Hepbasli A. Performance evaluation of a triple-effect evaporator with forward feed using exergy analysis. Int J Energy Res. 2005;29(5):455–70. https://doi.org/10.1002/er.1074.

De Monte M, Padoano E, Pozzetto D. Waste heat recovery in a coffee roasting plant. Appl Therm Eng. 2003; 23: 1033–44. https://doi.org/10.1016/S1359-4311(03)00033-4.

Aghbashlo M, Kainmehr MH, Arabhosseini A. Energy and exergy analyses of thin-layer drying of potato slices in a semi-industrial continuous band dryer. Dry Technol. 2008;26(12):1501–8. https://doi.org/10.1080/07373930802412231.

Amjad W, Hensel O, Munir A, Esper A, Sturm B. Thermodynamic analysis of drying process in a diagonal-batch dryer developed for batch uniformity using potato slices. J Food Eng. 2016;169:238–49. https://doi.org/10.1016/j.jfoodeng.2015.09.004.

Park SR, Pandey AK, Tyagi VV, Tyagi SK. Energy and exergy analysis of typical renewable energy systems. Renew Sustain Energy Rev. 2014;30:105–23. https://doi.org/10.1016/j.rser.2013.09.011.

Mahmood A, Parshetti GK, Balasubramanian R. Exergy, energy and techno-economic analyses of hydrothermal oxidation of food waste to produce hydro-char and bio oil. Energy. 2016;102:187–98. https://doi.org/10.1016/j.energy.2016.02.042.

Luo X, Hu J, Zhao J, Zhang B, Chen Y, Mo S. Improved exergoeconomic analysis of retrofitted natural gas based cogeneration system. Energy. 2014; 72:459–75. https://doi.org/10.1016/j.energy.2014.05.068.

Gurturk M, Oztop HF, Hepbasli A. Comparison of exergoeconomic analysis of two different pearlitic expansion furnaces. Energy. 2015;80:589–98. https://doi.org/10.1016/j.energy.2014.12.015.

Ozdil NFT, Tantekin A. Exergy and exergoeconomic assessment of an electricity production system in a running waste water treatment plant. Renew Energy. 2016;97:390–8. https://doi.org/10.1016/j.renene.2016.05.039.

Oni AO, Fadare DA, Adeboye LA. Thermo-economic and environmental analyses of a dry process cement manufacturing in Nigeria. Energy. 2017;135:128–37. https://doi.org/10.1016/j.energy.2017.06.114.

Pandey AK. Exergy analysis and exergoeconomic evaluation of renewable energy conversion systems. Ph. D Thesis. Katra: Shri Mata Vaishno Devi University. 2013.

Mojarrab SM, Aghbashlo M, Mobli H. Exergetic performance assessment of a long-life milk processing plant: a comprehensive survey. J Clean Prod. 2017; 140(2): 590–607. http://dx.doi.org/10.1016/j.jclepro.2015.11.066.

Holman JP. Analysis of experimental data. In: Holman JP, editor. Experimental methods for engineers. Singapore: McGraw-Hill; 2001. p. 48–143.

Wojdalski J, Kaleta A, Drozdz B, Chojnacka A. Factors influencing the energy efficiency of dairy processing plant. Teka Comm Mot Energ Agric. 2012;12(1):307–13.

Walstra P. Physical Chemistry of Foods. Marcel Dekker, Inc. 2nd ed. New York (USA); 2003. Available from: http://www.flavours.asia/uploads/7/9/8/9/7989988/physical_chemistry_of_foods_www.ebookbyte.com.pdf. Accessed 20 Oct 2017.

Fushimi C, Kansha Y, Aziz M, Mochidzuki K, Kaneko S, Tsutsumi A. Novel drying process based on self-heat recuperation technology. Dry Technol. 2010;29(1):105–10. https://doi.org/10.1080/07373937.2010.482719.

Acknowledgements

The author would like to acknowledge the support provided by Verka Milk Plant, Mohali, Punjab (India), and greatly appreciate the plant management and technical staff for their cooperation throughout the evaluation phase.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, G., Singh, P.J., Tyagi, V.V. et al. Exergy and thermoeconomic analysis of cream pasteurisation plant. J Therm Anal Calorim 137, 1381–1400 (2019). https://doi.org/10.1007/s10973-019-08016-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08016-y