Abstract

The present study assessed the effects of antioxidants on the flash point and thermal behavior of diesel fuel blended with 3–10 vol% biodiesel made from spent coffee grounds oil (SCGO) or Jatropha seed oil (JSO) extracted using with n-hexane or acetone, with or without α-pinene and d-limonene (as volatile antioxidants) or caffeic acid (as a non-volatile antioxidant). Effects were evaluated by assessing flash points and by thermogravimetry/differential thermogravimetry and differential thermal analysis (DTA). The flash points of the JSO and SCGO biodiesels obtained from oils extracted using n-hexane were higher than those extracted using acetone, and the addition of 10 vol% JSO or SCGO biodiesel made using acetone extraction increased the flash point by up to 2 °C. The DTA results for JSO and SCGO biodiesels also changed according to the extraction solvent. The flash points of diesel/α-pinene/d-limonene mixtures decreased as the amount of α-pinene was increased up to 10 vol%. TG peaks obtained from 10% α-pinene/d-limonene (50 vol%/50 vol%) in diesel were lowered by approximately 20 °C. The addition of 100–1000 mg kg−1 caffeic acid to diesel lowered the flash point by 2 °C and shifted the TG peak to approximately 75 °C from the value of 66 °C for pure diesel. This effect was constant regardless of the caffeic acid content, while DTA results were largely unaffected by this additive. The results of this work confirm that both flash point and thermal behavior are dependent on the particular type of antioxidant employed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodiesel is currently used as an alternative to diesel fuel in some situations, due to a number of advantages. These include reduced releases of certain pollutants (such as carbon monoxide and hydrocarbons) [1], higher flash points [2] and the availability of pure biodiesel or biodiesel/diesel blends to be used in diesel engines without modifications [3]. From the perspective of engine combustion efficiency, the most common blends are B6 to B20 (meaning 6–20 vol% biodiesel in diesel), and 72.5% of such blends have been found to meet test specifications [4].

Palm oil has been employed as a raw feedstock for the production of biodiesel in southeast Asia [5] and retains up to 80% of its original antioxidants after processing, including carotene and tocopherol (vitamin E). The carotene concentrations are typically greater than 500 mg kg−1, 90% of which is alpha- and beta-carotene, while the vitamin E content is approximately 800 mg kg−1, 70% of which is in the form of tocotrienol. The oxidative stability time span of palm biodiesel has been found to be 10.3 h at 110 °C using the Rancimat method [6, 7].

In Japan, waste rapeseed oil (WRO) has also been investigated as a feedstock for biodiesel because, even though it is imported, RO is the most widely used edible oil in the country. Unfortunately, the oxidation resistance of WRO depending on the way in which it has been treated. As an example, the oxidative stability of biodiesel made from fresh RO was found to be 6.79 h at 110 °C [8], whereas in our previous study that of WRO-based biodiesel was approximately 1 h based on the Rancimat test according to EN14112 [9, 10]. According to EN14214, biodiesel is required to has at least minimum 6 h [11, 12]. Then, the oxidative stability of WRO is necessary to improve. Furthermore, the approximately 500 thousand tons of biodiesel presently produced from oils recovered from restaurants and homes represent only 2% of the current annual consumption of diesel fuel (approximately 22,000 thousand tons as of 2016) in Japan [13, 14].

In the present work, spent coffee grounds (SCG) were additionally assessed as a biodiesel feedstock, because Japan imports more than 450,000 tons of coffee each year and thus generates significant quantities of SCG [15]. The research reported herein focused on fuels derived from SCG, in which the maximum oil content is approximately 20 mass%. [16]. SCG is an attractive feedstock because it contains several phenolic compounds that act as antioxidants, such as caffeic and chlorogenic acids. The total phenolic content of SCG has been reported to range from 6.33 to 28.26 mg gallic acid equivalent per gram [17], and increasing levels of phenolic compounds have been shown to improve the antioxidant activity [18]. As a result, the oxidation stability time span of SCG oil (SCGO) was over 10 h at 110 °C in our previous study [16].

The quality of biodiesel is determined by several chemical and physical characteristics, one of which is flash point. The flash point of a liquid is the lowest temperature at which the substance is capable of generating sufficient vapors to form a flammable mixture with ambient air [19]. Biodiesels typically have high flash points (from approximately 160–170 °C) compared with petroleum diesel, which can have a flash point value as low as 38 °C. The ASTM D6751 [20] standard contains the most restrictive regulation regarding biodiesel flash point, with a lower limit of 130 °C, whereas the European EN 14214 [12] and Technical Regulation ANP N 45/2014 standards [21] require flash points of 120 and 100 °C, respectively [22].

Studies of biodiesels have previously considered the effects of residual alcohols on flash point [22] and also assessed the flash points of diesel/biodiesel mixtures [23]. The literature also shows that the combustion efficiency of biodiesel can be improved by adding essential oils [24], some of which contain antioxidants such as d-limonene and α-pinene [25]. Thus, it is important to understand the influence of various additives on the flash point. This is especially true in Japan, where the handling and storage of flammable liquids such as diesel and biodiesel are regulated under the Fire Service Act of the Ministry of Internal Affairs and Communications [26]. In particular, it is vital to assess the effects of essential oils on flash point because these compounds can be volatile and flammable even though they may also serve as antioxidants.

In this study, the effects of antioxidants on the flash points of diesel blends with WRO, Jatropha seed oil (JSO) and SCGO biodiesels were assessed, with and without the addition of d-limonene, α-pinene and caffeic acid. The thermal behaviors of these materials were characterized using thermogravimetry/differential thermogravimetry (TG/DTG) and differential thermal analysis (DTA). Although n-hexane is typically used for oil extraction, this study also employed acetone to assess variations in the extraction of the antioxidant components. Both α-pinene and d-limonene were used as model essential oil diesel additives because these chemicals are readily sourced from wood and citrus plants, respectively [27, 28]. Caffeic acid was used as a model antioxidant because it occurs naturally in several materials, including SCG. The physical properties of the various specimens were examined, including the density and kinetic viscosity of pure diesel and diesel mixed with the biodiesels or essential oils. Binary and ternary mixtures such as biodiesel/diesel and α-pinene/d-limonene/diesel were investigated to observe the effects of the antioxidant on flash point and thermal behavior.

Experimental

Materials

Spent coffee grounds (SCG) residue from espresso coffee processing were obtained from a coffee shop in Fukuoka and dried at 80 °C for 72 h. WRO was obtained from a cafeteria in Fukuoka University, while Jatropha shells (JS) sourced from Thailand was purchased from the IS Corporation, Ltd., Tokyo Japan.

Oils were extracted from the raw SCG and JS using n-hexane (Wako 1st Grade, Wako Pure Chemical Corporation) or acetone (Wako 1st Grade, Wako Pure Chemical Corporation). The extracted samples were designated as shown in Table 1. Extractions were performed by adding SCG or JS (500 g) to a 2-L shaking flask along with 1 L of either n-hexane or acetone, followed by agitation at 60 rpm using a shaker apparatus (SS-8, EYELA) for 1 h. The solids were subsequently removed by vacuum filtration using No. 6 filter paper (Advantec). This process was repeated three times against same sample, and the solvent fractions were combined. The solvent was then removed using a rotary evaporator (Rotavapor R-200, BUCHI) connected to a vacuum controller (V-850, BUCHI) and cooler (cool man PAL C-330, SIBATA) at 60 °C under reduced pressure to give the raw SCG and JS oils.

Methanol (Wako special grade, Wako Pure Chemical Industries, Ltd., Tokyo) and sodium hydroxide (NaOH) (Wako special grade, Wako Pure Chemical Industries, Ltd., Tokyo) were used without purification for the synthesis of biodiesel. The biodiesel was purified using 1% acetic acid (Wako special grade, Wako Pure Chemical Industries, Ltd., Tokyo) and anhydrous magnesium sulfate (MgSO4, Wako special grade, Wako Pure Chemical Industries, Ltd., Tokyo).

As noted, α-pinene (Wako 1st Grade, > 95% purity, Wako Pure Chemical Industries, Ltd., Tokyo) and d-limonene (MP biochemical, USA) were used as model essential oil diesel additives. Caffeic acid (> 98% purity, Tokyo Chemical Industry Co., Ltd., Tokyo) was applied as a model antioxidant.

Production of biodiesel

Biodiesel was synthesized using an alkali-catalyzed method in conjunction with a methanol/oil molar ratio of 6:1 and 1 mass% NaOH (relative to the amount of oil) as a catalyst. As above procedure, sodium methoxide (CH3ONa) which is produced from mixture of 0.88g of NaOH (1 mass% on raw oil) and 19g (0.6mol) of MeOH. This CH3ONa were added to heated 88g of the raw oil (equivalent to 0.1 mol trygleceride as oleic acid) at 60 ºC. The reaction was performed at 60 °C with a stirring rate of 2000 rpm and a reaction time of 1 h, using a liquid phase organic synthesizer (Chemi Chemi-200, SIBATA). After the reaction, the mixture was transferred to a 200-mL separatory funnel, after which glycerol and unreacted methanol were removed by washing with approximately 100 mL of ion-exchanged water three separate times. Residual catalyst was removed by neutralization using 100 mL of 1% aqueous acetic acid. The sodium soap by-product was precipitated by an ion exchange reaction following the addition of 100 mL of a 1% aqueous MgSO4 solution. Finally, the biodiesel was purified by removing water using anhydrous MgSO4, followed by vacuum filtration using a Buchner funnel with no. 6 filter paper (Advantec). The biodiesels produced from the various raw oils are denoted herein as shown in Table 1.

Sample preparation

In Japan, biodiesel can be added to diesel up to a level of 5 vol%, based on the EN 590 [29] standard. In the present study, blends containing 3, 5 and 10 vol% were investigated. The flash points and thermal behaviors of binary and ternary mixtures of biodiesel, d-limonene and α-pinene with diesel at concentrations from 3 to 10 vol% were assessed, with the resulting blends referred to herein as B3 to B10. In the case that both α-pinene and d-limonene were added, the α-pinene/d-limonene ratios (vol%/vol%) were 25/75, 50/50 or 75/25. Caffeic acid was added to the diesel at 100, 500 or 1000 mg kg−1. The upper concentration was based on the limit of solubility of caffeic acid in diesel and also gave a level of antioxidant capacity equivalent to that of SCGO biodiesel, as the antioxidant capacity of caffeic acid is 6.63 μmol-Trolox equivalent (TE) μmol−1 [25].

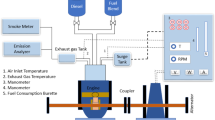

Physical properties

The effects of the various additives on the physical properties of the diesel were examined by measuring the density and kinetic viscosity values of pure diesel and of diesel mixed with the biodiesels or essential oils. These tests were performed at 40 °C according to the JIS K2249 [30] and JIS K2283 [31] standards, respectively.

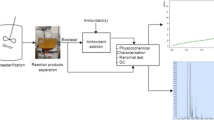

Evaluation of antioxidant activity by the ORAC method

In this study, the retention of the antioxidant capacities of the raw oil and biodiesel was considered. The antioxidant capacities of all biodiesel samples were determined using the oxygen radical absorbance capacity (ORAC) method developed by Watanabe et al. [32]. The capacities are reported herein in terms of Trolox, a radical scavenger, using Trolox equivalents (TE) as the unit [33]. In addition, a 7 w/v % solution of randomly methylated β-cyclodextrin (RMCD) in 50 v/v % acetone/water was used to solubilize the lipids.

Analysis solutions were prepared by dissolving 0.5 g of the biodiesel in 20 mL of acetone and diluting this solution with the 7% RMCD [34]. In preparation for ORAC assays, 50 μL of 2,2′-Azobis(2-methylpropionamidine) dihydrochloride (AAPH, 63.4 mmol L−1), 115 μL of an fluorescein solution (110.7 mmol L−1), 35 μL of 7% RMCD and 35 μL of the analysis solution were mixed in a clear 96-well multiple plate. The fluorescence intensity was subsequently measured at 2 min intervals using a multiple plate reader (CytoFluor Series 4000, Applied Biosystems) at 37 °C, using excitation and emission wavelengths of 485 and 530 nm, respectively.

Flash point analysis

Flash points were determined using a Setaflash Series 3 Plus apparatus (33000-0, STANHOPE-SETA) in conjunction with the ramp method according to ASTM D3828 [35]. The measurement range and heating rate were 300 °C and 2 °C min−1, respectively. Tests performed below 100 °C employed 2 mL samples and a 1-min interval, while tests above 100 °C used 4 mL samples and a 2-min interval. This ramp method was used for evaluation of various fuels [36, 37].

TG/DTA analysis

The thermal behaviors of the biodiesel/diesel blends were characterized using TG/DTA (TG/DTA 7220, Hitachi, Tokyo) under a 100 mL min−1 air flow, with heating from 30–600 °C at 10 °C min−1. In each trial, a sample of approximately 2 mg held in an alumina pan was employed. The instrumentation was calibrated using a procedure recommended by the manufacturer based on the melting point of pure indium (156.4 °C).

HPLC analysis

To detect antioxidant, SCGO was assessed using high-performance liquid chromatography (HPLC), employing an LC Net-II/ADC HPLC system (JASCO Corporation, Tokyo) consisting of a UV detector (UV-2075 Plus, JASCO Corporation, Tokyo), quaternary gradient pump (PU-2089 Plus, JASCO Corporation, Tokyo), column oven (CO-965, JASCO Corporation, Tokyo), and Inertsil ODS-SP column (5 μm, 4.6 × 250 mm, GL Science Inc., Tokyo). The column and detector were set at 40 °C and 280 nm, respectively, and the mobile phase was composed of ethanol (Wako 1st grade, Wako Pure Chemical Industries, Ltd., Tokyo) and ion-exchanged water. The initial mobile phase composition of 85% ethanol/15% water was held constant for 10 min, then transitioned to 100% ethanol over the subsequent 2 min and held at this composition for 13 min, for a total analysis time of 25 min. The mobile phase flow rate was 1 mL min−1 at all times.

Results and discussion

Physical properties

Table 2 summarizes the physical properties of the original diesel fuel and of the biodiesels produced from WRO, JSO and SCGO. The kinetic viscosities of the biodiesels were found to be higher than that of the diesel. According to ASTM D6751 [12], the kinetic viscosity of a biodiesel must be in the range of 1.9–6.0 mm2 s−1, and each biodiesel met this criterion. The kinetic viscosities of the JS-2 and SCG-2 specimens were also higher than those of the samples made with oils obtained from hexane extraction. In contrast, neither the raw material nor the solvent affected the density of the product.

Table 3 summarizes the densities and kinetic viscosities of diesel blended with either the biodiesels or with d-limonene and α-pinene. In each case, the values were similar to those of pure diesel. Table 2 summarizes the antioxidant capacities of the biodiesels made from WRO, JS-1, JS-2, SCG-1 and SCG-2, which decrease in the order of SCG-2 > SCG-1 > JS-2 > JS-1 > WRO. Then, the SCG-2 biodiesel made from oil obtained via acetone extraction had the highest antioxidant activity in this study, suggesting that the antioxidant components were more readily extracted using a polar solvent. Moreover, both d-limonene and α-pinene appear to act as antioxidants, with capacities of 360 and 320 μmol-TE g−1, respectively [38]. These values are similar to the antioxidant capacity of the SCG-2 biodiesel.

Flash points of diesel blends with biodiesel, d-limonene and α-pinene

The flash points of the pure diesel and the biodiesels made from WRO, JS-1, JS-2, SCG-1 and SCG-2 are provided in Table 2, which indicates that each biodiesel had a higher flash point than the pure diesel. In addition, the flash points of the JSO and SCGO biodiesels made from oils extracted with hexane were about 10 °C higher than those obtained using acetone for extraction. On the other hand, antioxidant capacities value of JS-1 and JS-2 biodiesel were similar. It of SCG-2 was about 60 μmol-TE g−1 higher than SCG-1 biodiesel. As a result, correlation between antioxidant capacity and flash point was not observed. It was possible that polar components, not antioxidant capacity, were related to flash point.

A previous report gives the flash points of WRO, JSO and SCGO biodiesels as 170, 135 and > 160 °C, respectively [7], and our values for the WRO and SCGO biodiesels are similar. Our JS biodiesel flash point may be different because of different species of Jatropha seed. Figure 1 shows flash points of the diesel/biodiesel blends as functions of the biodiesel content. Over the range of 3–5% biodiesel, the flash points were unchanged. The data for 10 vol% biodiesel show that the flash points of blends with the WRO, JS-2 and SCG-2 biodiesels were increased by up to 2 °C compared with the samples obtained from hexane extraction oils. These results confirm that more highly flammable components were extracted when using acetone.

Figure 2 shows flash points of binary mixtures of d-limonene and α-pinene. The flash points of pure d-limonene and α-pinene were found to be 50 and 31 °C, respectively, in agreement with literature values [39]. Additive property of flash point was not observed in binary mixture of d-limonene and α-pinene. The flash point of binary mixture was decreased depending on side of low flash point. A 25 vol% concentration of α-pinene gave the highest flash point among the binary mixtures. Figure 3 summarizes the flash points of diesel/d-limonene/α-pinene ternary mixtures. In the case of a 10 vol% addition of the d-limonene/α-pinene mixture, the flash point of the blend was decreased by 10–15 °C. The flash point values were quite close to those of the binary d-limonene/α-pinene mixtures even when only 3 vol% of the (25/75) α-pinene/d-limonene was present. The flash points evidently decreased as the amount of α-pinene was increased, as expected because this component had the lowest flash point in the ternary mixture.

The flash point of diesel with 100 mg kg−1 caffeic acid was decreased by about 2 °C, and so this compound had only a minimal effect on flash point. At levels above 100 mg kg−1, there was no effect at all, suggesting that caffeic acid could be used as an antioxidant because it changes the flash point only slightly.

TG/DTA results

Figures 4 and 5 show the TG and DTA data for the diesel and the biodiesels obtained from the WRO, JS-1, JS-2, SCG-1 and SCG-2 products. In Fig. 4, the diesel exhibits a mass loss over the range of 65–200 °C that is related to volatilization, which is indicative of its combustion potential [40]. The WRO biodiesel shows decomposition in two steps over the ranges of 130–200 °C and 200–300 °C. The TG curves obtained from the SCGO and JSO biodiesels were similar to that produced by the WRO biodiesel. The initial mass loss temperature (TTG) for the pure diesel was 66.2 °C, whiles those for the various biodiesel specimens are given in Table 4. The TTG values of the SCGO and JSO biodiesels obtained from acetone extraction were approximately 10–20 °C lower than those of the samples made using hexane-extracted oils. Therefore, the antioxidants affected the thermal decomposition of these samples.

The DTA results in Fig. 5 demonstrate that the diesel generated a minor exothermic peak in the range of 150–200 °C, related to combustion processes [41]. The WRO biodiesel produced sharp exotherms in the ranges 150–220 °C, 260–420 °C, and 430–470 °C. The SCGO and JSO biodiesels obtained from hexane and acetone extraction also produced different curves. The JS-1 biodiesel provided an exothermic peak in the range of 240–260 °C with minor exotherms in the ranges 260–350 °C, 410–450 °C, and 450–500 °C. In case of the JS-2 biodiesel, two broad exothermic peaks were produced in the ranges 100–180 °C and 410–510 °C and two sharp exothermic peaks in the ranges 180–260 °C and 260–410 °C, as shown in Fig. 6a. Similar results were observed for the SCGO biodiesels. The SCG-1 biodiesel produced two sharp exothermic peaks in the ranges 170–240 and 470–520 °C along with minor exothermic peaks in the range of 350–400 °C. In the case of the SCG-2 biodiesel, a minor peak appeared in the range of 190–240 °C and two sharp exothermic peaks in the ranges 240–400 °C and 480–540 °C, as shown in Fig. 6b. Thus, the extraction solvent also affected the thermal behavior. It was considered that acetone extraction oil has many components compared with hexane extraction oil. Figure 7 presents typical chromatograms generated by SCGO samples, from which it is apparent that the SCG-2 produced peaks at earlier retention times. The above results suggest that changes in the number and concentrations of antioxidant components affect the thermal behavior of the biodiesel, although not affected the flash point.

Figures 8 and 9 present the TG and DTA data for α-pinene, d-limonene and caffeic acid. The α-pinene and d-limonene were fully decomposed by 100 °C, while the caffeic acid degraded in three steps over the ranges 200–250 °C, 250–300 °C and 300–600 °C. The temperatures of pure d-limonene, α-pinene and caffeic acid were 30.9, 33.8 and 220 °C, respectively. In Fig. 9, both the α-pinene and d-limonene show broad endothermic peaks in the range of 30–120 °C, attributed to volatilization. The peak endotherm of the d-limonene occurred at 96 °C, while that of the α-pinene was at 93 °C.

Table 4 summarizes the TTG values of diesel blends with the biodiesels from WRO, JS-1, JS-2, SCG-1 and SCG-2, as well as d-limonene and α-pinene. The TG and DTA curves are not provided for these specimens because the peak shapes obtained from binary mixtures containing 3–10% additives were shifted without change. In the case of those compounds have a higher TTG than diesel, such as the biodiesels from WRO, JS-1, JS-2 and SCG-2, the TTG value of the blend increased up to approximately 75 °C from the value of 66.2 °C for pure diesel with increases in the additive proportion. Moreover, adding the antioxidants to samples having from 3–5% of the JSO and SCGO made from oils obtained via acetone extraction reduced the TTG values by up to 10 °C. It is likely that the antioxidants affected the TTG of the binary mixtures. However, the TTG values of specimens made with 10% SCG-2 or JS-2 in diesel were increased to as high as 78 °C. Therefore, the high TTG values of the SCGO and JSO biodiesels (about 134–144 °C, and 138–157 °C, respectively) appear to have affected the thermal behavior, rather than the presence of the antioxidants. The α-pinene and d-limonene both had TTG values lower than that of the pure diesel, and so the TTG was decreased by 15 °C as the mixture ratio increased. It can be concluded that the thermal behaviors of the binary mixture were modified by changing the proportions of both the biodiesels and the antioxidants.

Figures 10 and 11 provide the TG and DTA data for d-limonene/α-pinene binary mixtures at 25/75, 50/50 and 75/25 blending ratios. Figure 10 demonstrates that the pure d-limonene and α-pinene begin to lose mass right from the onset of heating, as a result of their low vapor pressures, and are decomposed by 100 °C. The thermal behaviors of the mixtures were essentially equivalent to those of the pure materials, although the TG curves of the mixtures were shifted to lower temperatures by approximately 5 °C. These data suggest that the binary mixtures were less stable under air flow. The DTA curve for the pure and binary samples all exhibit a single endothermic peak around 85–100 °C, the peak values of which are not correlated with the mixture ratio. Thus, although the mixtures of d-limonene with α-pinene were thermally unstable, essential oils are high volatility.

Figures 12 and 13 show the TG and DTA curves for ternary blends of d-limonene/α-pinene (50 vol%/50 vol%) as antioxidant components in diesel at 3, 5 and 10 vol%. These mixtures were decomposed by 200 °C, as compared with the binary d-limonene/α-pinene mixtures that were degraded by 100 °C. The TG data obtained from the 3 and 5 vol% mixtures were unchanged relative to that of pure diesel, while the 10 vol% mixture data were shifted to lower temperatures by approximately 20 °C. The concentrations of the α-pinene and d-limonene evidently had an effect because these components had low TTG values (Table 4). In Fig. 13, the DTA results for these ternary mixtures show no particular correlation with the mixture proportions. However, an early endothermic peak around 50–100 °C produced by the d-limonene/α-pinene binary mixture disappears along with the gradual appearance of an endothermic peak in the case of the ternary samples. Therefore, the thermal behavior of ternary mixtures was dependent on the properties of the diesel.

Figures 14 and 15 present the TG and DTA curves generated by diesel mixed with caffeic acid. In Fig. 14, the mass loss range of the diesel with caffeic acid is seen to be 100–200 °C. Moreover, the TG curves were shifted to approximately 75 °C from the value of 66.2 °C for pure diesel, and this behavior is unchanged over the concentration range of 100–1000 mg kg−1. In addition, the caffeic acid concentration had no effect on the DTA results. The thermal behavior of caffeic acid is quite different from those of α-pinene and d-limonene, and further study may be required to fully understand these results.

Conclusions

In the present work, the effects of antioxidants on the flash points of diesel mixtures with WRO, JSO and SCGO biodiesels were studied, using d-limonene, α-pinene and caffeic acid, and the thermal behaviors of these samples were characterized using TG/DTA. Binary and ternary mixture such as biodiesel/diesel and α-pinene/d-limonene/diesel were investigated to observe the changes induced by antioxidants.

The flash points of the JSO and SCGO biodiesels made from oils extracted with n-hexane were higher than those synthesized using acetone extraction. The addition of approximately 10 vol% JSO or SCGO biodiesel made from acetone extraction to diesel increased the flash point by up to 2 °C (from 75 °C for pure diesel). The TG and DTA results for the JSO and SCGO biodiesels were also observed to vary depending on the extraction solvent employed. TTG of biodiesel from hexane extraction was about 10–18 °C higher than biodiesel from acetone extraction. DTA curves of biodiesel from n-hexane extraction and acetone extraction were difference. Thus, the extraction solvent affected the thermal behaviors.

The flash points of diesel/α-pinene/d-limonene binary and ternary mixtures decreased by 75 to 60 °C as the amount of α-pinene was increased up to 10 vol%. TG data obtained following the addition of 3 and 5 vol% α-pinene/d-limonene (50 vol%/50 vol%) to diesel were unchanged relative to the results obtained from pure diesel, while the TG peak generated by a 10 vol% mixture was shifted to a lower temperature by approx. 20 °C. DTA data for these ternary mixtures exhibited no particular correlation with the mixture proportions.

The blending of caffeic acid with diesel over the range of 100–1000 mg kg−1 slightly modified the flash point, by about 2 °C. In addition, the TG curves were shifted to approximately 75 °C (as opposed to 66.2 °C for pure diesel), and this effect was unchanged with variations in the mixture proportions. DTA results were largely unaffected by the addition of caffeic acid.

This work demonstrated that volatile antioxidants can decrease the flash point and affect thermal behavior, while a non-volatile antioxidant does not. Therefore, both flash point and thermal behavior vary with the type of antioxidant.

References

Barnwal BK, Sharma MP. Prospects of biodiesel production from vegetable oils in India. Renew Sustain Energy. 2005;9(4):363–78.

Vicente G, Martínez M, Aracil J. Integrated biodiesel production: a comparison of different homogeneous catalysts system. Bioresour Technol. 2004;92:297–305.

Demirbas A. Biodiesel: a realistic fuel alternative for diesel engines. London: Springer Verlag Limited; 2008.

Alleman TL, Fouts L, McCormick RL. Quality analysis of wintertime B6-B20 biodiesel blend samples collected in the Unite States. Fuel Process Technol. 2011;92:1297–304.

Zhou A, Thomson E. The development of biofuels in Asia. Appl Energy. 2009;86:S11–20.

Nagendran B, Unnithan UR, Choo YM, Sundram K. Characteristics of red palm oil, a carotene- and vitamin E-rich refined oil for food uses. Food Nutr Bull. 2000;21(2):189–94.

Atabani AE, Silitonga AS, Badruddin IA, Mahlia TMI, Masjuki HH, Mekhilf S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew Sustain Energy Rev. 2012;16:2070–93.

Almeia ES, Portela FM, Sousa RMF, Daniel D, Terrones MGH, Richter EM, Munoz RAA. Behavior of the antioxidant tert-butylhydroquinone on the storage stability and corrosive character of biodiesel. Fuel. 2011;90:3480–4.

Todaka M, Kowhakul W, Masamoto H, Shigematsu M. Improvement of oxidation stability of biodiesel by an antioxidant component contained in spent coffee grounds. Biofuels. 2018; https://doi.org/10.1080/17597269.2018.1468977.

EN14112:2008, European Standard EN 14112: 2003 Fatty acid methyl esters (FAME) Determination of oxidation stability (accelerated oxidation test).

Melero JA, Vicente G, Morales G, Paniagua M, Bustamante J. Oxygenated compounds derived from glycerol for biodiesel formulation: influence on EN 14214 quality parameters. Fuel. 2010;89:2011–8.

EN14214:2008 Automotive fuels—fatty acid methyl esters (FAME) for diesel engines—requirements and test method.

Ministry of Land, Infrastructure, Transport and Tourism. http://www.mlit.go.jp/k-toukei/22/annual/22a0excel.html. Accessed 26 Jan 2018.

Ministry of the Environment. https://www.env.go.jp/air/report/h22-01/4.pdf. Accessed 26 Jan 2018.

All Japan Coffee Association. http://coffee.ajca.or.jp/wp-content/uploads/2011/08/data01_2014_05.pdf. Accessed 26 Jan 2018.

Todaka M, Kowhakul W, Masamoto H, Shigematsu M, Onwona-Agyeman S. Thermal decomposition of biodiesel fuels produced from rapeseed, jatropha, and coffee oils with alcohols. J Therm Anal Calorim. 2013;113:1335–61.

Panusa A, Zuorro A, Lavecchia R, Marrosu G, Petrucci R. Recovery of natural antioxidants from spent coffee grounds. Agric Food Chem. 2013;61:4162–8.

Dudonne S, Vitrac X, Coutiere P, Woillez M, Merillon JM. Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD, and ORAC assay. J Agric Food Chem. 2009;57:1768–74.

Daniel AC, Joseph FL. Chapter 6: fire and explosion. In: Chemical process safety fundamentals with applications, 3rd edn. Pearson Education, Inc, Boston, pp. 247–249 (2011).

ASTM D6751-15ce1, Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels.

Technical Regulation ANP N45/2014.

Boog JHF, Silveira ELC, Caland LBD, Tubino M. Determining the residual alcohol in biodiesel through its flash point. Fuel. 2011;90:905–7.

Gulum M, Bilgin A. Density, flash point and heating value variations of corn oil biodiesel-diesel fuel blends. Fuel Process Technol. 2015;134:456–64.

Ohtani Y. Improvement of diesel engine fuel combustion by addition wood essential oils. Report of the Grant-in-Aid for Scientific Research (no. 24580478) by Ministry of Education, Culture, Sports, Science and Technology.

Davalos A, Gomez-Cordoves C, Bartolome B. Extending applicability of the oxygen radical absorbance capacity (ORAC-fluorescein) assay. J Agric Food Chem. 2004;52:48–54.

Ministry of Internal Affairs and Communication, Fire service act, law number act No. 186 of 1948.

Koukos PK, Papadopoulou KI, Patiaka DT, Papagiannopoulos AD. Chemical composition of essential oils from needles and twigs of Balkan Pine (Pinus peuce Grisebach) grown in northern Greece. J Agric Food Chem. 2000;48:1266–8.

Lopresto CG, Petrillo F, Casazza AA, Aliakbarian B, Perego P, Calabro V. A non-conventional method to extract D-limonene from waste lemon peels and comparison with traditional soxhlet extraction. Sep Purif Technol. 2014;137:13–20.

EN 590:2004, Automotive fuel, diesel, requirements and test methods.

JIS K2249:1995, Crude petroleum and petroleum products—determination of density and petroleum measurement tables based on a reference temperature (15°C).

JIS K2283:2000, Crude petroleum and petroleum products―determination of kinematic viscosity and calculation of viscosity index from kinematic viscosity.

Watanabe J, Oki T, Takebayashi J, Yamasaki K, Takano-Ishikawa Y, Hino A, Yasui A. Improvement of the lipophilic-oxygen radical absorbance capacity (L-ORAC) method and single-laboratory validation. Biosci Biotechnol Biochem. 2013;77(4):857–9.

Huang D, Wong IC, Lipid oxidation challenge in food systems, chapter 10, antioxidant evaluation and antioxodant activity mechaniss, 2015. Editors: A. Logan, U. Nienaber, X. S. Pan.

Huang D, Ou B, Hampsch-Woodill M, Flanagan JA, Deemer EK. Development and validation of oxygen radical absorbance capacity assay for lipophilic antioxidants using randomly methylated β-cyclodextrin as the solubility enhancer. J Agric Food Chem. 2002;50:1815–21.

ASTM D3828-16a, Standard test methods for flash by small scale closed cup tester.

Yang Y, Brammer JG, Samanya J, Hossain AK, Hornung A. Investigation into the performance and emissions of a stationary diesel engine fueled by sewage sludge intermediate pyrolysis oil and biodiesel blends. Energy. 2013;62:269–76.

Prak DJL, Jones MH, Trulove P, McDaniel AM, Dickerson T, Cowart JS. Physical and chemical analysis of alcohol-to-jet (ATJ) fuel and development of surrogate fuel mixtures. Energy Fuels. 2015;29:3760–9.

Bentayeb K, Vera P, Rubio C, Nerin C. The additive properties of Oxygen Radical Absorbance Capacity (ORAC) assay: the case of essential oils. Food Chem. 2014;148:204–8.

ChemicalBook, http://www.chemicalbook.com/ChemicalProductProperty_EN_CB3499047.htm, http://www.chemicalbook.com/ChemicalProductProperty_EN_CB9853935.htm. Accessed 25 Feb. 2018.

Lang X, Dalai AK, Bakhshi NN, Reaney MJ, Hertz PB. Preparation and characterization of bio-diesels from various bio-oils. Biores Technol. 2001;80:53–62.

Candeia RA, Freitas JCO, Souza MAF, Conceicao MM, Santos IMG, Soledade LEB, Souza AG. Thermal rheological behavior of diesel and methanol biodiesel blends. J Therm Anal Calorim. 2007;87(3):653–6.

Acknowledgements

We thank Michael D. Judge, MSc, from Edanz Group (www.edanzediting.com/ac) for editing a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Todaka, M., Kowhakul, W. The flash points and thermal behaviors of diesel blends with biodiesels, α-pinene, d-limonene and caffeic acid as antioxidants. J Therm Anal Calorim 135, 2665–2675 (2019). https://doi.org/10.1007/s10973-018-7798-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7798-2