Abstract

Three different water based sol–gel methods were compared in the synthesis of Bi2Sr2Co1.8Ox thermoelectric ceramics. We chose methods that can stabilize a Bi3+ ion while solution and gel are formed: chelating method using combination of ethylenediamintetraacetic acid (EDTA) and triethanolamine (TEA) chelating agents and, further, synthesis using two different water soluble polymers—polyacrylamide or polyethylenimin. In each sol–gel process, we tested two gel decomposition atmospheres. The gels were decomposed either in air or in inert atmosphere (followed by treatment in pure oxygen). Additionally, a sample synthesized by solid state reaction was used for comparison with the sol–gel prepared samples. The grain size of precursors and also their phase composition were determined for methods used and different gels decomposition atmospheres. The sintered final samples did not differ in phase composition; on the other hand, they vary in volume density and microstructure. The differences were reflected in electric transport measurement (the temperature dependence of Seebeck coefficient, resistivity and thermal conductivity). The use of EDTA/TEA or PEI methods led to the samples with improved thermoelectric parameters in comparison to the solid state sample.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the serious challenges for sustainable growth is energy generation and its storage. The use of the thermoelectric effect is one of the promising technologies—the waste heat recovery or the use of thermoelectrics as a supplement to solar cells (thermoelectrics, unlike solar cells, can convert also low frequency heat). Ceramics based on a misfit layered cobalt oxide represent a potential thermoelectric material. In contrast to intermetallic compounds (e.g. Bi2Te3), they have lower thermoelectric performance but they are non-toxic and stable up to higher temperatures.

The first reported compound from this family was the layered NaxCoO2 system with the high valence of cobalt [1]. Similar cobalt oxides (e.g. Ca3Co3.95Ox, Bi2Sr2Co1.8Ox) with general formula [MnA2On+2]x[CoO2]y have been synthetized so far [2, 3]. The structure generally consists of two crystal subsystems [4] which are mutually incommensurate with respect of at least one lattice parameter. The first one with a rock salt structure is composed of square-planar MO layers (M = Co, Bi, Pb, Tl, …) surrounded by AO planes also with square symmetry (A = Ca, Sr, Ba, …). CoO2 subsystem reveals hexagonal symmetry (CdI2 crystal type) and is built from edge sharing CoO6 octaedra. Mixed valence Co3+/Co4+ is favored for high thermoelectric performance in the misfit cobalt oxides [5].

Interestingly, the Bi2Sr2Co1.8Ox phase was first prepared with the intention to get an analogue of superconducting Bi–Sr–Ca–Cu oxide [6] with stoichiometry Bi2Sr3Co2Ox. As late as 10 years after, the crystal structure was refined [4] as a misfit layered system in contrary to the structure of the Bi–Sr–Ca–Cu oxide.

To achieve high thermoelectric efficiency, high figure of merit ZT (~S2T/ρλ) is necessary. Therefore, the thermoelectric material should meet some microstructural criteria, in particular the bulk density. Methods where bulk material is prepared from a melt (e.g. flux flow sintering, spark plasma sintering) or solid state reaction with enhanced grain growth (e.g. hot isostatic pressing) are utilized. Sol–gel methods can be successfully used for the preparation of oxide precursor powders that possess high chemical homogeneity, small grain size, and high reactivity. According to our knowledge, only a few studies describing the sol–gel preparation of Bi–Sr–Co oxide have been published. PEI (polyethyleneimine) as a water soluble polymer was used to produce Bi2Sr2Co1.8Ox material [7]. The other work describing the solution based synthesis of Bi–Sr–Co oxide is based on the chemical solution deposition (CSD) of acetates dissolved in propionic acid [8].

In this paper, we compare three different water based sol–gel methods. The choice of an appropriate procedure is difficult due to a presence of Bi3+cation as a strong hydrolyzing species (contrary to other cobaltites, e.g. Ca3Co3.95Ox). According to our previous experience with Bi-based superconducting cuprates [9], we used methods where N-donor chelating agents suitable for the bismuth cation are applied: a chelating method using the combination of ethylenediamintetraacetic acid (EDTA) and triethanolamine (TEA). Secondly, two water soluble polymer methods applying polyacrylamide (PAAM) or polyethylenimin (PEI) were used. Both polymers contain also N-donor atoms that enhance the bismuth chelation. Gels prepared by chosen sol–gel methods were decomposed either in air or in inert atmosphere (followed by treatment in pure oxygen). The phase composition and grain size of the obtained powders were compared. Further, the influence of decomposition atmosphere on the final samples microstructure was evaluated. Thermoelectric transport characteristics (the temperature dependence of Seebeck coefficient, resistivity and thermal conductivity) were also measured.

2 Experimental procedures

2.1 Samples preparation

The thermoelectric material of stoichiometry Bi2Sr2Co1.8Ox (further called Bi-222) was prepared by three different sol–gel procedures and also by solid state reaction. In water based methods, bismuth solutions were always prepared at first with regards to the stabilization of Bi3+ in solution. Only after then, compounds containing Sr and Co were added.

2.1.1 PAAM polymer and PEI polymer methods

The procedure was similar for both used polymers. The amount of polymer was chosen as 2 monomer units per one metal cation in each process. 50 % water solutions of PAAM or PEI with average molecular weight of 1,500 or 2,000 g/mol, respectively, were used. Bi(CH3COO)3 was dissolved in diluted acetic acid; then the polymer solution was added; no pH adjustment was required. Sr(CH3COO)2·1/2H2O and Co(CH3COO)2·4H2O were added directly to the prepared Bi solution. The mixture was heated at 80 °C to evaporate water and then the temperature was increased up to 100 °C to reach gelation.

2.1.2 Chelating EDTA/TEA sol–gel route

The molar ratio of chelating agent 1:1:1 (metals:EDTA:TEA) was chosen. Bi(CH3COO)3 was dissolved in diluted acetic acid; then EDTA was added and pH was increased using ammonia solution until EDTA was fully dissolved; next, TEA was added to this solution. The second solution was prepared dissolving Sr(CH3COO)2·1/2H2O and Co(CH3COO)2·4H2O in water; EDTA was added and deprotonated using ammonia solution; TEA was inserted at the end, as well. Both prepared solutions were mixed together and heated at 80 °C. After water evaporation, the temperature was increased to 100 °C to promote the esterification process [9]. After a while, the temperature started to increase spontaneously up to 130 °C and the solution turned into gel.

The gels obtained from all sol–gel methods were further processed as follows: after the first decomposition step at 250 °C in air, the gels were heat treated either in air (500 and 800 °C/2 h) or using “N2/O2” regime (800 °C/3 h/N2 and 400 °C/2 h/O2). Prepared powders were pressed into pellets that were finally sintered at 870 °C/96 h in air. Some samples were reground and pressed again in the middle of sintering (will be described further later).

2.1.3 Solid state preparation

Bi2O3, SrCO3 and Co3O4 were homogenized in agate mortar and then the mixture was calcined at 800 °C for 12 h. After homogenization, the calcined powder was pressed into pellets that were finally sintered in air in the same way as in the sol–gel routes.

2.2 Characterization methods

Differential thermal analysis and thermogravimetric analysis (DTA/TG) were carried out simultaneously using equipment Setaram (model Setsys Evolution). The temperature range of the measurement was 20–900 °C with the heating rate 5 °C/min; the measurement was carried out in ambient atmosphere.

WTW pH meter (model Multilab 545) equipped with a glass electrode was used for pH control during the preparation of solutions and gels.

X-ray powder diffraction (XRD) data were collected at room temperature with Bruker AXS D8 θ–θ powder diffractometer with parafocusing Bragg–Brentano geometry using CoKα radiation (λ = 1.79021 Å, U = 34 kV, I = 20 mA). Data evaluation was performed in the software package HighScore Plus.

Scanning electron microscopy was carried out using TESCAN Vega3 equipped with EDS analyzator (Oxford Instruments INCA 350). All presented pictures were taken in secondary electrons regime.

Transport properties (electrical resistivity, thermal conductivity and Seebeck coefficient) were measured using four-probe method (self-designed equipment). The measurement was carried out in a vacuum cell integrated into a closed-cycle helium cryostat. The bulk density was determined by volume and weight measurement. The theoretical value of bulk density 6.81 g/cm3 was taken for Bi2Sr2Co1.8Ox phase.

3 Results and discussion

3.1 Gel decomposition

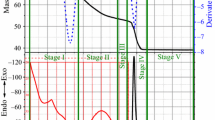

Firstly, we performed the DTA/TG analyses of gels prepared by all used sol–gel methods. Figure 1a, b show the TG and DTA curves, respectively. The gels prepared by all three sol–gel methods are presented. It is generally considered that water bound in gel is released in the temperature region up to 250 °C. It is interesting that this step exhibits the biggest mass decrease at PAAM gel decomposition. PAAM is probably able to bind a higher amount of water than other used polymers and the release of bound water is connected with a significant endothermic peak at approximately 150 °C. (Fig. 1b).

The temperature region between 250 and 400 °C represents the decomposition of acetic acid (released from acetates) and, simultaneously, the beginning of polymer resin decomposition [10–12]. The highest heat release, in each case, is located between 400 and 500 °C. This exothermic effect is attributed to the decomposition and oxidation of organic resin associated with gas evolution. On the basis of the described measurement, the prepared gels were heat treated in air at 250, 500 and 800 °C/2 h.

We also tested the decomposition of gels in inert atmosphere followed by treatment in pure oxygen (further called “N2/O2” regime). The temperatures of both steps were chosen on the basis of DTA/TG measurement in inert atmosphere; completeness of decomposition was controlled using organic elemental analysis (not presented). Such a procedure could decrease the particle size of prepared precursor [13] and, consequently, enhance the sintering process. A flow-chart of both decomposition processes is given in Fig. 2.

Figure 3 presents the SEM micrographs of precursor powders prepared by both decomposition procedures (the difference between used decomposition atmospheres was the same in all three used sol–gel methods). The photo of solid state precursor is presented, as well. For greater clarity, the same magnification is used for all three pictures. Only agglomerates of 50–100 nm grains are visible in the picture of precursor decomposed in “N2/O2” regime. On the other hand, both precursors heat-treated in air were partly sintered regardless of the method of their preparation (sol–gel or solid state).

The precursor powders from gels decomposed in air (independently of the chosen sol–gel method) contained the prepared phase Bi-222 (as a major phase) as early as after heat treatment at 500 and 800 °C/2 h. It confirms high reactivity and stoichiometric homogeneity of sol–gel precursors. Bi0.75Sr0.25Ox phase and Bi2Sr2Co1Ox phase (so called Bi-221) were detected as the most frequent secondary phases present in this system at the stage of precursor.

In contrast, the powders decomposed under “N2/O2” regime did not contain the Bi-222 final phase. These precursor powders were mainly composed of Bi2O3, SrCO3 and cobalt oxides with the presence of various binary oxides of Bi, Sr and Co. Note that the formation of carbonate is undesirable in the intermediate, yet it occurs during the heat treatment in oxygen. The carbon based matter (formed in the previous step in inert atmosphere) is oxidized and the arising CO2 is bound by SrO present.

3.2 Thermoelectric oxides preparation

With regards to the phase composition of the final samples, there were no differences between samples prepared in different gel decomposition atmosphere. None of the chosen sol–gel methods influenced the resulting phase composition. Figure 4 shows the example of XRD pattern of the final sample prepared using EDTA/TEA route with gel decomposed in “N2/O2” regime. Because of the anisotropic layered crystal structure, some diffraction peaks are intensified (and marked by # in the Figure). The reference XRD pattern of Bi-222 phase (not depicted) was calculated using JANA 2006 program for the Rietveld refinement of modulated structures. The structural data of the phase were taken from [4]. Bi0.75Sr0.25Ox phase was found as a trace phase almost in all samples.

We compared bulk density of the final samples (Table 1). Although the manner of density determination does not ensure high accuracy, we can see some trends in density changes. The sol–gel samples prepared using either EDTA/TEA or PEI (in both cases with gels decomposed in air) were denser than samples prepared by solid state reaction. Moreover, the grains of sintered samples (prepared by the mentioned procedure) were larger—see Fig. 5 where the SEM micrographs of the EDTA/TEA sample and the solid state sample are presented.

The bulk density of samples with gels decomposed in “N2/O2” regime was lower than those prepared by solid state reaction. At this point, the advantage of small high reactive grains of precursor powder is lost because of the presence of strontium carbonate. Carbonates, when decomposed at sintering, disrupt the microstructure of sintered pellets by CO2 released.

Therefore we decided to incorporate an intermediate grinding and pressing step into the sintering procedure. Afterwards, the prepared samples reached a similar bulk density as sol–gel samples with gels decomposed in air. The described problem is expected in all systems containing cations with high affinity to CO2 that is formed in situ during oxygen treatment of amorphous organic powder.

The samples prepared using PAAM as a gelation agent reached lower bulk densities than all the other samples; moreover, the density values did not even reach the values of the solid state prepared material. This fact could be explained by the different thermal behavior on gel decomposition visible in DTA measurement (Fig. 1). The PAAM gel when being decomposed releases more heat that causes the precocious sintering of precursor grains. Such effect can further influence the reactivity of grains and the final volume density.

The comparison of microstructures of chosen samples is visible in Fig. 5. There is a noticeable difference between the samples prepared using the EDTA/TEA sol–gel process, the solid state reaction and the PAAM method.

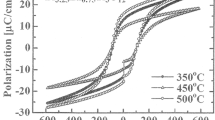

The described differences were confirmed by electric transport measurements. Generally, the samples prepared using the PAAM sol–gel method showed poor transport properties. It is in accordance with bulk density and microstructure. This method could be more successful if the heat treatment of gel is modified. The results of PAAM samples are not depicted in the following figures—data are only presented in Table 2. The values of Seebeck coefficient are not generally influenced by microstructure; however, they determine the values of both thermoelectric parameters—the power factor PF (~S2/ρ) and the figure of merit ZT (~S2T/ρλ). The temperature dependence of the Seebeck coefficient is shown in Fig. 6. It is visible that decomposition atmosphere can influence the oxygen stoichiometry of sintered material—the samples prepared using gels decomposed in inert atmosphere reveal lower S values.

Regarding the temperature dependence of electrical resistivity (not presented), the sample prepared by the solid state reaction had the higher value of ρ (~23.5 mΩ cm at room temperature) in comparison to the sol–gel prepared samples. The samples prepared using gels decomposed either in “N2/O2” regime or in air differed only slightly (e.g. ρ ~ 15.1 and 16.5 mΩ cm at room temperature for the EDTA/TEA samples with gels decomposed in “N2/O2” regime and in air, respectively). It is probably caused by well grown, larger grains of sol–gel samples (compare Fig. 5a, b) that can improve electrical conductivity. However, the temperature dependence of the power factor was more influenced by the values of Seebeck coefficient—Fig. 7. The sol–gel samples prepared using gels decomposed in air possessed the following values of PF at room temperature: 0.12 mW/K2 m (EDTA/TEA sample) and 0.14 mW/K2·m (PEI sample). These values are higher than those presented in the only article describing sol–gel preparation of Bi–Sr–Co oxide [7]. All measured transport properties are also comparable to or higher than those cited in this article for single crystals or textured materials.

Taking into account the thermal conductivity data (not presented) we will obtain the temperature dependence of the figure of merit—Fig. 8. The sol–gel samples (except samples prepared by the PAAM method) revealed more favorable values of thermoelectric efficiency than the solid state sample. The main reason is the increased electrical resistivity and higher thermal conductivity of the solid state sample. Table 2 summarizes the values of both measured and calculated electrical properties.

The most promising progress in the figure of merit showed the EDTA/TEA sample with gel decomposed in air (ZT ~ 0.017 at room temperature). Naturally, the figure of merit at higher temperatures is important for oxide materials. Therefore we will be further studying the behavior of the sol–gel prepared samples at higher temperatures.

4 Conclusions

We compared three different water based sol–gel methods for Bi–Sr–Co thermoelectric oxide preparation. Two different gel decomposition atmospheres were tested for each wet method. The solid state reaction was also used to compare with the sol–gel samples.

Independently on the chosen sol–gel method, the powder precursors prepared from gels decomposed in air were mainly composed of the desired phase as early as after the treatment at 800 °C (2 h). On the other hand, the powders prepared using gels decomposed at 800 °C (3 h) in N2 followed by treatment in O2 at 400 °C (2 h) contained three constituent oxides and strontium carbonate. These powders had much smaller grain size; however, the presence of carbonates compelled intermediate grinding during the sintering process.

After sintering, we obtained homogeneous polycrystalline samples with trace impurities of Bi0.75Sr0.25Ox phase. The use of PAAM polymer turned out to be unsuitable for thermoelectric material preparation (the samples did not even reach the bulk density of the solid state sample). The other methods (EDTA/TEA and PEI) provided samples with improved thermoelectric parameters in comparison to the solid state sample. The samples prepared using gels decomposed in air showed higher values of the power factor and the figure of merit. In comparison to the samples with gels decomposed in “N2/O2” regime, they have higher values of the Seebeck coefficient.

Generally, the precursor powders prepared by used sol–gel process could be well used in a solid state reaction with enhanced grain growth (e.g. hot isostatic pressing) due to good homogeneity and high reactivity.

References

Terasaki I, Sasago Y, Uchinokura K (1997) Large thermoelectric power in NaCo2O4 single crystals. Phys Rev B 56(20):12685–12687

Funahashi R, Matsubara I, Sodeoka S (2000) Thermoelectric properties of Bi2Sr2Co2Ox polycrystalline materials. Appl Phys Lett 76(17):2385–2387

Li S, Funahashi R, Matsubara I, Ueno K, Yamada H (1999) High temperature thermoelectric properties of oxide Ca9Co12O28. J Mater Chem 9(8):1659–1660

Leligny H, Grebille D, Perez O, Masset AC, Hervieu M, Raveau B (2000) A five-dimensional structural investigation of the misfit layer compound Bi0.87SrO2 (2) CoO2 (1.82). Acta Crystallogr Sect B-Struct Sci 56:173–182

Yamamoto T, Uchinokura K, Tsukada I (2002) Physical properties of the misfit-layered (Bi, Pb)–Sr–Co–O system: effect of hole doping into a triangular lattice formed by low-spin Co ions. Phys Rev B 65(18):184434

Tarascon JM, Ramesh R, Barboux P, Hedge MS, Hull GW, Greene LH, Giroud M, Lepage Y, McKinnon WR, Waszcak JV, Schneemeyer LF (1989) New non-superconducting layered Bi-oxide phases of formula Bi2M3Co2Oy containing Co instead of Cu. Solid State Commun 71(8):663–668

Madre MA, Rasekh S, Diez JC, Sotelo A (2010) New solution method to produce high performance thermoelectric ceramics: a case study of Bi–Sr–Co–O. Mater Lett 64(23):2566–2568

Zhu XB, Tang XW, Shi DQ, Jian HB, Lei HC, Yeoh WK, Zhao BC, Yang J, Li Q, Zheng RK, Dou SX, Sun YP (2011) Synthesis and characterization of self-assembled c-axis oriented Bi(2)Sr(3)Co(2)O(y) thin films by the sol-gel method. Dalton Trans 40(37):9544–9550

Rubešová K, Jakeš V, Hlásek T, Vašek P, Matějka P (2012) Gel stabilization in chelate sol–gel preparation of Bi-2223 superconductors. J Phys Chem Solids 73(3):448–453

Leung WM, Axelson DE, Vandyke JD (1987) Thermal-degradation of polyacrylamide and poly(acrylamide-co-acrylate). J Polym Sci Pol Chem 25(7):1825–1846

Sotelo A, Szillat H, Majewski P, Aldinger F (1997) Rapid synthesis of the Bi-2212 phase by a polymer matrix method. Supercond Sci Technol 10(9):717–720

Motta M, Deimling CV, Saeki MJ, Lisboa-Filho PN (2008) Chelating agent effects in the synthesis of mesoscopic-size superconducting particles. J Sol-Gel Sci Technol 46(2):201–207

Chen L, Sun X, Liu Y, Li Y (2004) Preparation and characterization of porous MgO and NiO/MgO nanocomposites. Appl Catal A 265(1):123–128

Acknowledgments

This work was financially supported by the Czech Science Foundation, Project No. 203/09/1036.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rubešová, K., Hlásek, T., Jakeš, V. et al. Water based sol–gel methods used for Bi-222 thermoelectrics preparation. J Sol-Gel Sci Technol 64, 93–99 (2012). https://doi.org/10.1007/s10971-012-2831-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2831-6