Abstract

We have developed a method of food sample preparation for gamma spectrometry involving the use of tetramethylammonium hydroxide (TMAH) and/or enzymes such as α-amylase or cellulase for sample homogenization. We demonstrated the effectiveness of this method using food matrices spiked with 60Co, 131I, 134,137Cs, and 241Am radionuclides, homogenized with TMAH (mixed salad, parmesan cheese, and ground beef); enzymes (α-amylase for bread, and cellulase for baked beans); or α-amylase followed by TMAH (cheeseburgers). Procedures were developed which are best compromises between the degree of homogenization, accuracy, speed, and minimizing laboratory equipment contamination. Based on calculated sample biases and z-scores, our results suggest that homogenization using TMAH and enzymes would be a useful method of sample preparation for gamma spectrometry samples during radiological emergencies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ingestion of radionuclides is a major pathway for delivery of a committed radiation dose to a population in incidents involving ionizing radiation. The radionuclides may involve fission products in severe nuclear reactor accidents, such as at Chernobyl [1] or Fukushima [2, 3], or radionuclides of concern such as actinides [4] in a radiological bomb or intentional contamination scenarios.

Laboratory-based quantification of radionuclides in food samples depends on types of radiation measured. In cases of alpha and beta radiation, total sample decomposition is necessary using chemical digestion, followed by liquid scintillation [5] or gas proportional counting [6]. Microwave digestion [7] has been used as a sample digestion method for ICP-MS of radionuclides [8] and for alpha/beta radioactivity [9]. It is not suitable for gamma spectrometry of voluminous samples, the method studied here, because it is limited to samples sizes of ~1 mL. These methods are not capable of decomposing refractory radionuclide particles formed during an explosion,which would require the use of chemical fusion techniques followed by alpha spectrometry [10]. The methods of total sample decomposition are limited by sample size ranging from a few grams in case of microwave digestion to less than 100 grams for other methods.

Owing to their penetrating nature, gamma-emitting radionuclides can be measured directly in large food samples [11]. However, sample inhomogeneity is an important factor in gamma spectrometry because it affects counting efficiency and thus measurement accuracy [12, 13]. Sample inhomogeneity is related to distribution of radionuclides in food as well as food physical form. Radionuclide(s) entering the food chain can largely be considered homogeneous within the matrix. In early stages of nuclear accidents, however, foods may be unevenly contaminated through dry deposition of hot particles or wet deposition of aerosols from the atmosphere. Hot particles may be atmospheric aerosols, fly ash particles from fires, or refractory particles from explosions that contain attached or incorporated radionuclides.

Therefore, homogenization is an important consideration when preparing samples for gamma spectrometry analysis. Methods of homogenization commonly used for food samples during a radiological emergency have a number of limitations. Although chopping and blending of food with a food processor are rapid and simple, these methods may only reposition hot particles within the sample and may not ensure complete sample homogenization. Food blending has drawbacks including difficulty of processing dry and hard food products as well as contamination of the blender and accessories, which must be decontaminated and verified before re-use. Also, storage of a large number of blenders and accessories may not be feasible if laboratory space is limited. These problems limit the number of samples that could be processed during a radiological emergency. Total decomposition of food samples using acid digestion is equally impractical because it requires prohibitive amounts of concentrated acid for larger samples, and microwave digestion of food samples is also impractical due to its small sample handling capacity.

To overcome these limitations, we have developed an alternative method for homogenization of food samples for gamma spectrometry analysis using tetramethylammonium hydroxide (TMAH) to solubilize proteins and enzymes to digest carbohydrates and cellulose in food. The proposed method provides an intermediate level of homogenization between that of the two extremes of mechanical blending and total decomposition; the limitations of both have been described above. The goal of our work is to develop a method that is relatively rapid, provides reasonable sample throughput, limits the laboratory and equipment contamination issues, suppresses loss of volatile fission products, and is able to solubilize particles resulting from release of volatile radionuclides in aerosol form during a nuclear accident, with the exception of refractory particles. This proposed method is suitable for use during a nuclear emergency with improved measurement accuracy.

The accuracy of results for contaminated foods during a nuclear emergency is important for radiation dose risk assessment by decision makers. The regulatory guidelines vary internationally and may depend on the data quality objectives for specific incidents as discussed with respect to the Chernobyl and Fukushima nuclear accidents [3]. In the U.S., the Food Emergency Response Network (FERN) [14] joined by local, state, and Federal food-testing laboratories is tasked with responding to radiological emergencies involving contamination of food. The permissible levels of radioactivity in food are defined by the Food and Drug Administration (FDA) in terms of Derived Intervention Level (DIL) [15]. For instance, the values of DILs for gamma emitters are 170 Bq kg−1 for 131I and 1200 Bq kg−1 for combined 134,137Cs. The DIL is 2 Bq kg−1 for combined alpha emitters238,239Pu and 241Am. The latter is of interest to this work since 241Am can be determined by gamma spectrometry using the 59.6 keV gamma ray [16]. In this work we report results of homogenization using 60Co, 131I, 134,137Cs, and 241Am. The combination of homogenization with gamma spectrometry described here should enable detection of these radionuclides at levels at least as low as DILs in a reasonable counting time.

Properties of TMAH and enzymes

Proteins, carbohydrates, and cellulose are major components of foods. When attempting total decomposition, the solubilization of each of these components must be approached in a different way.

TMAH is a reagent known to successfully solubilize proteins [C. Palmer, private communication], and has been used to extract trace elements for analysis by inductively coupled plasma mass spectrometry (ICP-MS) from a wide range of sample types, including elements such as I, K, Mg, Mn, Na, and Zn from food samples such as milk powder, egg powder, bovine liver, and mussels [17, 18] and multiple elements from botanical samples and human hair [19, 20]. TMAH allows rapid processing of large batches of samples, with the total processing time for some tissues as short as 30 min. Homogenization using TMAH also requires less dilution than other methods, potentially allowing for larger amounts of sample to be processed, and occurs at relatively low temperatures, minimizing losses of volatile elements [7]. Although for some applications TMAH is used to extract elements by leaching [7, 19], we used TMAH to homogenize the sample matrix for accurate determination of gamma radioactivity. One drawback of TMAH is its toxicity: TMAH is highly alkaline (pH > 13) and can cause cardiac arrest, especially at higher concentrations [21].

Enzymes can effectively homogenize samples containing carbohydrates such as starch and have multiple advantages over chemical digestion [22], including safety for human health and the environment. Starch is a polymer of glucose units that comes in two forms: strands of up to 6000 glucose units joined by α-(1,4)-glycosidic bonds, and complex structures consisting of chains of 10–60 glucose units connected by α-1,4 linkages with branches attached by α-1,6 linkages [23]. α-amylases cleave both forms at α-(1,4)-glycosidic bonds, resulting in smaller oligosaccharide chains [22, 23]. Cellulose, a major component of plant tissues, is composed of tough microfibrils consisting of cellobiose, a disaccharide with two glucose units linked by β-(1,4)-glycosidic bonds. Cellulose has a crystalline structure that is highly resistant to digestion [24]. The enzymes that digest cellulose, termed cellulases, are actually a mixture of enzymes with distinct roles that include cleaving internal regions of cellulose fibers; releasing cellobiose from the termini of cellulose chains and converting intermediate-size chains to disaccharides and monosaccharides; and hydrolyzing cellobiose and other short chains to glucose units [25]. We used α-amylase to rapidly homogenize starch in samples consisting mainly of grains (white bread, bagels) and in composite meals (cheeseburger with bun, chicken pot pie) prior to addition of TMAH. We homogenized baked beans using cellulase alone.

Experimental

Food samples

All food used in these experiments was purchased at local grocery stores, and included baked beans, bananas, cheeseburgers, chicken pot pie, ground beef, hamburger, hot dogs, mixed salad, olives, Parmesan cheese, peanuts, plain bagels, potato chips, turkey sandwich with cheese and lettuce, and white whole wheat bread.

Chemicals, enzymes and conditions

TMAH (25 w/v% in aqueous solution) was obtained from Alfa Aesar (part of Thermo Fisher Scientific, Suwanee, GA, USA). For samples treated with TMAH only, TMAH was added to a final concentration of 6.25% (w/v). For samples treated with α-amylase followed by TMAH, TMAH was added to a final concentration of 2% (w/v). Enzymes used for homogenization included α-amylase from Bacillus subtilis and cellulase from Aspergillus niger (both supplied by MP Biomedicals, LLC, Solon, OH, USA; distributed by Thermo Fisher Scientific). Both enzymes were added dry to food samples and used at a final concentration of 10 g L−1. α-amylase, with a nominal pH range of 5-7 and temperature range of 60–80 °C, was used without buffer at 70 °C for 30–60 min. Cellulase has a nominal optimal pH range of 4.2–5.2. Except for samples spiked with 131I, we added sodium acetate buffer (pH 5.2; 0.021 M acetic acid and 0.079 M sodium acetate made from sodium acetate trihydrate) at 10% final concentration to samples before digestion with cellulase for ~60 min at 40 °C. To prevent volatilization of 131I in acidic conditions [26,27,28], for samples spiked with 131I we added sodium thiosulfate buffer adjusted to pH > 7.0 containing iodine carrier. The buffer composition was 0.5 M sodium thiosulfate, 1 mM sodium iodide, adjusted to pH > 7.0 with sodium carbonate at ~10% (v/v) final concentration.

Radionuclides

Reference standard solutions containing 60Co, 131I, 134,137Cs, and 241Am radionuclides traceable to the National Institute of Standards and Technology, Gaithersburg, MD, USA, were procured from Eckert and Ziegler Analytics, Atlanta, GA, USA. The standards with carriers were diluted to desirable activity concentrations and were used to spike food samples.

Gamma spectrometry and analysis

We used four high-purity p-type germanium (Ge) gamma detectors, provided by Canberra Industries, Meriden, CT, USA, to measure spiked samples and method blanks for this study. The laboratory codes for the detectors are: GE03 and GE08 (Models GC10020, 102% relative efficiency at 1332.5 keV), GE09 (Model GC13021, 134% efficiency), and GE11 (Model GC8021, 79% efficiency). GE03, GE08, and GE09 were used for all spiked samples and method blanks, while GE11 was used for counting method blanks, only, in our detectability study. All detectors were calibrated using a traceable mixed gamma standard (Eckert and Ziegler Analytics) as described elsewhere [29].

Acquisition of gamma spectra was accomplished with the Lynx Digital Spectrum Analyzers (Canberra) using Genie 2000 software (Canberra). Gamma peak fitting was accomplished with Genie’s VMS Standard Peak Search algorithm. The energy lines used for analysis were 604.7 and 795.9 keV for 134Cs; 661.7 keV for 137Cs; 1173.2 and 1332.5 keV for 60Co; 364.5 keV for 131I; and 59.5 keV for 241Am. We used the average activity of the two energy lines for 134Cs and 60Co. For 241Am, Genie’s Interactive Peak Fit algorithm gave better results owing to the Compton distribution to the left of the 59.5 keV peak. Two counting geometries were used for the study depending on the sample size: 0.5 and 1.4 L Marinelli beakers [30] (Ga-Ma & Associates, Ocala, FL, USA). We sealed 1.4-L Marinellis with Phenoseal [31], and 0.5-L Marinellis with electrical tape. The density and coincidence (cascade) summing corrections for these geometries were calculated using the Monte Carlo simulation code GESPECOR version 4.2 [32] (CID Media GmbH, Hasselroth, Germany).

Activity reporting

To compare samples homogenized with TMAH/enzymes versus blended samples (as described below), some results are reported in units of specific activity (Bq kg−1). Otherwise, results are reported as total activity of the sample (Bq). This is straightforward for samples homogenized using mechanical means. If the original sample is aliquoted, only the aliquot mass is measured for specific activity reporting. For total activity reporting, both total mass and aliquoted mass are measured, and aliquot factor (a fraction of original sample used for analysis) is calculated. For sample homogenization with TMAH and enzymes, the situation is more complicated because addition of these agents and water usually results in a larger final sample. In this case, final sample mass is also measured for the geometry actually counted on a Ge detector, which is required for the density corrections. We report original sample masses in the text regardless of the reported activity unit.

Comparison of recovery and detection of activity using TMAH homogenization vs. blending

To evaluate the efficacy of homogenization using TMAH for recovery and detection of gamma activity, we prepared samples of identical matrices for TMAH homogenization and blending, spiked with 134,137Cs and 60Co. Figure 1 illustrates homogenization of a mixed salad sample using TMAH as well as blending. The sample (340 g) was transferred to a 1.0 L beaker with a line marked at the target volume of 0.5 L (see Fig. 1a). Containers and implements were rinsed with 0.1 M HNO3 to ensure complete transfer.

Homogenization versus blending of mixed salad samples. a Spiked sample in a beaker. b Sample after addition of TMAH solution. c Sample after heating with stirring at 90 °C for ~50 min, then heating to boiling; note that foaming occurs. d Fully homogenized sample after transfer to a 0.5 L Marinelli beaker for counting. e Equivalent sample after blending

TMAH solution (~one-fourth of sample weight) was added to the sample. For denser and less moist samples such as Parmesan cheese and ground beef, 100–200 mL water (~one-third of sample weight) was added to enable stirring. Liquid was worked into the sample using a spatula, a magnetic stir bar was added, and the sample was placed on a hot plate with magnetic stirring (Fig. 1b). The sample was heated with stirring at ~90 °C for ~50 min until mostly digested. Complete homogenization of vegetables required heating briefly to boiling, which resulted in some sample foaming (see Fig. 1c). Water was added to the hot sample to approach the desired volume to fit the calibrated counting geometry. The sample was stirred to cool down for ~30 min before transfer to a 0.5-L Marinelli beaker (Fig. 1d). A small amount of additional water was used to complete sample transfer. Total processing time for a batch of 1–3 samples homogenized using TMAH was ~1.5 h.

An identical-size portion of mixed salad was blended (Fig. 1e). Blending was performed using a 14-cup Cuisinart Elite Collection Food Processor and accessories (blender bowls and a stainless steel chopping/mixing blade; Cuisinart, East Windsor, NJ, USA). For the blended sample, the total weight of the sample was recorded, and the sample was transferred to a 0.5 L Marinelli beaker. The final sample weight was recorded. If required, an aliquot factor was calculated to determine the sample’s total activity.

Homogenization using enzymes alone or in combination with TMAH

We demonstrated the efficacy of chemical and/or enzymatic homogenization for recovery and determination of activity for gamma spectrometry using matrices spiked with 134,137Cs, 131I and/or 241Am. We used white bread for homogenization using α-amylase, only; cheeseburgers for homogenization using α-amylase followed by TMAH; and baked beans for homogenization using cellulase, only. To establish detection limits for our methods, we determined minimum detectable activities (MDAs) for method blanks consisting of the matrices described above.

Homogenization of white bread using α-amylase, only

Bread (~500 g) was torn into pieces and transferred to a tared 2 L beaker with a line marked at the target volume of 1.4 L. The bread pieces were pressed down to the 1.4 L line. Water (~0.8 L) was added to a total sample volume of ~1.3 L and worked in with a spatula. For spiked samples, previously prepared spikes were added to the bread mixture along with a stir bar. The spike containers and caps were rinsed several times with ~3 mL deionized water, and the rinses were added to the bread mixture. To minimize volatilization of 131I and enhance activity recovery, buffer containing 0.5 M sodium thiosulfate [27] and 1 mM iodine carrier were added. The beaker was warmed on a heating block before addition of 5 g of α-amylase. The enzyme was worked into the bread mixture with a spatula, and the mixture was stirred for 2–5 min. The samples were heated with magnetic stirring for 30–60 min. A small amount of additional water was added for complete transfer to a 1.4 L Marinelli beaker for counting. Total processing time for a batch of 1–3 samples was ~1.5 h.

Homogenization of cheeseburgers using α-amylase followed by TMAH

Frozen cheeseburgers were thawed and allowed to reach room temperature. A portion of ~500 g was used for each cheeseburger sample. Cheeseburgers were processed similarly to white bread, except that ~0.6 L water was added for a total sample volume of ~1.1 L. After α-amylase digestion was complete, TMAH solution was added (~10% of total sample volume). The sample was heated at 90 °C for 30–60 min, cooled, and transferred to a 1.4 L Marinelli beaker. The total processing time for a batch of 1–3 samples was ~3 h.

Homogenization of baked beans using cellulase, only

For baked beans, which contain sufficient liquid for homogenization, we used ~500 g of sample and added only sodium acetate buffer (see Section ‘Chemicals, enzymes and conditions’) at 10% of final volume. For samples spiked with 131I, we used sodium thiosulfate buffer as described above, having first confirmed that the cellulase enzyme worked efficiently at pH 7.5 using tris(hydroxymethyl)aminomethane (Tris) buffer (1 M Tris Hydrochloride buffer (Thermo Fisher Scientific) at 5–10% final volume). Beans were processed as described for bread with α-amylase, except that samples were heated at 40 °C for ~1 h. If any bean fragments were visible, we heated samples briefly until boiling, then cooled them by stirring. After processing, the sample was transferred to a 0.5 L Marinelli beaker for counting. Total processing time for a batch of 1–3 samples was ~1.5 h.

Amount of liquid needed for sample processing

To enable stirring of samples, which is required for homogenization using TMAH and enzymes, foods with low water content such as bread and cheeseburgers require addition of water, sometimes in a quantity equal to or greater than sample mass. Because it is preferable to add just enough liquid to rapidly and thoroughly homogenize samples, we performed a small study to determine the minimum amount of TMAH solution and/or amylase solution, with or without buffer, needed to homogenize a variety of foods (See Table 1).

Small portions of food (10–100 g) were placed in small glass beakers and dried in a drying oven for ~24 h at 60 °C. From the sample weight loss due to drying, food water contents were calculated and are given in column 2 of Table 1. When small samples are homogenized with TMAH or enzyme liquid solutions, stir bars are relatively large in comparison to sample mass and less liquid is needed than for larger samples. Therefore, the ratio of liquid required for homogenization of these samples (columns 3 and 4 of Table 1) represents a minimum amount. For small samples, all but the driest foods such as peanuts and potato chips could be homogenized with 10–25% of liquid. Addition of 75% TMAH by volume was necessary to homogenize peanuts. Addition of 70% solution by weight was necessary to homogenize potato chips with α-amylase. As samples become larger, even large stir bars are not effective without addition of larger amounts of water. For our studies with spiked samples, we used volumes appropriate for calibrated geometries that would allow ~500 g of sample, a sample size at which low levels of activities can be detected. For baked beans, liquid was added solely to allow buffering of the sample to desired pH and for stabilization of iodine. For bread and cheeseburgers, we added liquid to ~65% of sample weight. For both these matrices, ~500 g was the largest amount of sample that could be homogenized and fit into a 1.4 L Marinelli beaker. The minimum amount of liquid was ~0.6 L, and this needed to be worked in thoroughly with a spatula. Stirring with a spatula was required for ~2–5 min, until α-amylase began to work and uninterrupted magnetic stirring was possible.

Results and discussion

Method development

In preliminary experiments, we used a 25% (w/v) solution of TMAH in water to solubilize samples of meat and fish using conditions developed previously [18]. We initially used small amounts of sample (10–100 g) in glass beakers on a magnetic stirring hot plate with vigorous stirring, with a 4:1 sample:TMAH ratio for a final concentration of TMAH of 6.25% (w/v). TMAH readily homogenized meats and fish within the target time of 1 h at 90 °C. However, some food matrices such as composite meals were not readily homogenized using TMAH, which led us to attempt the use of enzymes with some types of food. For example, when we attempted homogenization of chicken pot pie (Fig. 2a), swelling of starch prevented stirring of the sample and resulted in incomplete homogenization (see Fig. 2d). The wheat crust component of chicken pot pie swelled during heating and adhered to the beaker, preventing the stir bar from turning. However, prior to adding TMAH, addition of α-amylase solution and heating with stirring at 70 °C for 30-60 min broke down the wheat crust to a smooth liquid (Fig. 2b). We found that tougher vegetables such as the peas and carrots contained in chicken pot pie were successfully homogenized by briefly heating the sample to boiling at the end of the TMAH treatment period. These steps resulted in complete homogenization of the sample (Fig. 2c). This encouraging result led us to the development of additional homogenization methods using enzymes, including the use of α-amylase only, for foods with high starch content such as bread and bagels, as well as cellulase for vegetables with high cellulose content such as beans.

Detection limits

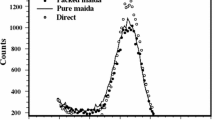

We performed a detectability study to establish the suitability of our methods for rapid analysis of emergency food samples. We determined minimum detectable activity (MDA) values for four radionuclides (131I, 134,137Cs, and 241Am) using method blanks consisting of three matrices (baked beans, white bread, and cheeseburgers) homogenized using α-amylase or cellulase alone, or in combination with TMAH. MDA is defined as the Currie’s Detection Limit [33] in this context, expressed in Bq kg−1. We measured two sets of the abovementioned matrices for 10, 100, and 1000 min using two different Ge detectors for a total of six measurements per sample. Figure 3 shows the results of the detectability study, presented as the average MDA for three matrices. Since the sample masses varied between the matrices from ~0.5 to ~1.4 kg, we normalized MDA values to a sample mass of 0.5 kg before averaging them.

Detectability study. Y-axis shows MDA averaged over three matrices (white bread, cheeseburgers, and baked beans) prepared using enzymatic and chemical homogenization. X-axis shows results for two detectors (GE09 and GE11; 134 and 79% efficiency, respectively) by radionuclide for three count times (10, 100 and 1000 min). Uncertainties are given at 1 σ. Error bars show standard error of the mean (standard deviation divided by the square root of the number of samples)

The results show that, for medium energy gamma emitters 131I and 134,137Cs, MDAs were lower for GE09, with a relative efficiency of 134% at 1332.5 keV, than for GE11, with a relative efficiency of 79%, as expected. These MDAs are well below the FDA DIL values of 170 Bq kg−1 for 131I and 1200 Bq kg−1 for combined 134,137Cs [14], even for measurements as short as 10 min.

The MDAs for 241Am are lower for GE11 than for GE09, owing to a thinner Ge dead layer (0.4 and 1.5 mm, respectively, for these p-type detectors) resulting in lower efficiency of GE09 for the 59.5 keV gamma transition from 241Am. The MDAs are 12–15 Bq kg−1 for 10 min counting, 4–5 Bq kg−1 for 100 min counting, and 1.2–1.5 Bq kg−1 for 1000 min counting. The MDAs for 1000 min counting are ten times lower than for 10 min counting, satisfying the rule of square root of the ratio of counting times √(1000/10), consistent with the previous studies [34, 35].

The FDA provides a combined DIL of 2 Bq kg−1 for 238,239Pu and 241Am, because both are alpha emitters. In this study, however, only 241Am is measured by gamma spectrometry, which would not be sensitive enough to measure 238,239Pu. Reaching an MDA of exactly 2 Bq kg−1 would require 360 min and 560 min counting on GE11 and GE09, respectively. A better approach would be to use an n-type Ge detector, which is sensitive to low gamma energies.

The MDAs determined in this work were measured from method blanks. The presence of other radionuclides of high activity in the samples would considerably worsen these MDAs owing to an increased background continuum in gamma spectra caused by Compton scattering of gamma radiation.

Comparison of homogenization versus blending

A number of factors related to the method used for sample homogenization might affect recovery and accurate determination of activity, including sample homogeneity, volatilization of radionuclides, sample loss during processing, or other effects related to the complex chemistry of food. To demonstrate that recovery and determination of activity are not adversely affected by chemical homogenization, we performed a direct comparison of homogenization versus blending using a group of samples including mixed salad spiked with 134,137Cs, as well as Parmesan cheese and ground beef spiked with 60Co. We prepared three samples by blending, one of each matrix, and five samples by chemical homogenization (three mixed salad and one each of Parmesan cheese and beef). For these samples, spikes were added before processing or addition of water or buffer. Sample masses ranged from 0.35 to ~1 kg. Table 2 compares activities and biases calculated from measured and known activities of samples prepared by blending or TMAH homogenization. z scores were computed to facilitate comparisons. Specific activities are given either for one sample or for the average of three samples of each matrix, counted on two detectors for 100 min. Bias is defined as a % deviation from known; the z-score is defined as the difference between the measured and known activity divided by the square root of the sum of variances at 95% confidence level. For each matrix, the average bias and z-score are lower for samples homogenized with TMAH than for samples prepared by blending (bias +0.40% and −3.82% for TMAH homogenization and blending, respectively; z-score: +0.14 and −1.03 for homogenization and blending, respectively). All samples for homogenization and blending were treated similarly in terms of matrices, radionuclides, measurements, calculations, density corrections, etc. Blending often results in paste-like sample consistency, whereas homogenization samples are dense liquids. Therefore, we attribute larger statistical bias for blending in this work to incomplete mixing and/or larger sample losses when transferring between containers. Losses during sample transfer can be minimized in chemical or enzymatic homogenization by rinsing containers and adding the rinse liquid to the sample.

Efficacy of homogenization using enzymes alone or in combination with TMAH for recovery and detection of gamma activity

To demonstrate the efficacy of homogenization using enzymes alone or in combination with TMAH, we processed a group of samples spiked with 134,137Cs, or 131I and 241Am. We used a variety of matrices including white whole wheat bread (homogenized using α-amylase, only), cheeseburgers (homogenized using α-amylase followed by TMAH) and baked beans (homogenized using cellulase, only). We prepared three samples of each matrix (white bread, cheeseburgers and baked beans) for each spike set (134Cs and 137Cs (set I), and 241Am and 131I (set II)) for a total of 18 samples. For these samples, spikes were added to ~500 g of sample after addition of water and buffer; total activity was used for calculations and no aliquot factor was needed. Total activities given in Table 3 are averages for three samples of each matrix, counted on two or three detectors for 50–100 min. Bias and z-scores calculated from measured and known activities are also given in Table 3.

Matrix effects on recovery and detection of activity were not significant (P > 0.37 for bread vs. cheeseburgers, bread vs. baked beans, and baked beans vs. cheeseburgers using Student’s T test). The average bias and z-score for samples processed using homogenization methods for the three matrices combined are −1.58% and −0.55, respectively. They are comparable to our previous results for homogenization with TMAH, only (see Table 2). Overall, for samples homogenized using TMAH and/or enzymes in Tables 2 and 3, the bias was −1.01 ± 2.11 and the z-score was −0.58 ± 1.25%.

An important aspect of analysis during a possible emergency response is to retain volatile fission products such as Cs and in particular I isotopes. There is no evidence of significant loss of 131I to volatilization during processing of our samples, because biases are −0.49, −0.48, and −2.0% and |z-score| < 1 for the three matrices in Table 3. Similarly, the data from Tables 2 and 3 indicate that no significant loss of 137Cs occurred. In contrast, the biases for 134Cs are larger and z-scores <−1 in Table 3. Since both Cs isotopes behave chemically the same, within the scope of the experiments performed, we attribute larger biases and z-scores for 134Cs to incomplete correction for coincidence summing effects. However, it is possible that errors in diluting or pipetting the 134Cs standard may have contributed to the bias.

The biases and z-scores for 241Am in Table 3 reveal no significant losses of this radionuclide during sample processing. However, we observed biases of 25.2, 22.1, and 21.9% for three individual samples, despite use of Interactive Peak Fit. Owing to a low gamma energy of 59.5 keV, this radionuclide appears to be extremely sensitive to effects of geometry and positioning [12]. Settling of 241Am from solution in samples of orange juice was observed during the FERN Menu2010 radiological exercise [36]. It is, therefore, possible that these high biases were due to settling of Am and depositing on the internal section of Marinelli beaker close to the Ge detector, thereby increasing the efficiency of gamma detection. Nevertheless, these effects were not observed for most of the samples. Consequently, the three results were considered outliers and were not included in the averages in Table 3.

Summary and conclusions

We have demonstrated that homogenization using TMAH and enzymes can provide a useful alternative to commonly applied methods of food sample preparation for gamma spectrometry during a radiological emergency, enabling recovery and accurate determination of gamma activity. The method retains fission products such as Cs and I isotopes that are volatile in some circumstances, making it useful in emergencies involving nuclear reactor accidents.

The TMAH/enzymatic digestion described here fills the void between two extremes: mechanical homogenization and total sample decomposition, therefore avoiding some deficiencies of both.

TMAH/enzymatic digestion provides better homogenization than mechanical mixing, chopping or blending, and can accommodate dry samples. It cannot provide total sample decomposition like that achievable with acidic/peroxide digestion or fusion. The main advantage of TMAH/enzymes is that they can homogenize large samples. In this work we used samples up to about 0.5 kg; however, larger samples can be handled as well which would require larger counting containers. This constitutes an essential advantage over total sample decomposition methods, which can handle samples up to 100 g (and usually less). Use of larger samples increases sensitivity of radioactivity detection and, therefore, affords the opportunity to decrease counting time for better sample throughput in an emergency, as well as allowing for a better averaging of radioactivity over sample size for accurate risk assessment.

The TMAH/enzymatic homogenization method also enables good control of sample volume because the final volume can be increased by adding more liquids, or decreased by evaporation. Ability to arrive at a desired target volume is important for gamma spectrometry in order to use the largest amount of sample that will fit calibrated geometries. The total processing time per sample, excluding counting, ranges from about 1.5 h for TMAH, only, to about 3 h for enzymes plus TMAH combined. This is longer than mechanical homogenization and shorter than total sample decomposition. Several samples can be processed simultaneously by a skillful analyst. The methods developed in this work allow for efficient contamination control during a radiological emergency. The contamination is confined to beakers used to process individual samples, which can be put aside and cleaned at a later time. Conversely, blenders require decontamination after every sample which limits the throughput.

We did not directly investigate how TMAH/enzymatic digestion attacks aerosol particles. However, since these agents are aggressive enough to have successfully leached and extracted several elements from food and biological materials in analytical chemistry [17,18,19,20, 22], one can infer that radionuclides could be dissolved from fresh aerosols. Thus TMAH/enzymatic digestion is expected to provide better homogenization of fresh aerosols than purely mechanical procedures. However, the methods developed here would not be useful for decomposing refractory particles, which would require treatments that are not suitable for gamma spectrometry analysis of food.

Homogenization using enzymes and TMAH under the conditions described in this paper does not create a clear solution, as depicted in Figs. 1d and 2c. Instead, a semi-colloidal suspension of digested organic polymers is formed. Some settling of digested bread occurred after preparation, with a small layer of water appearing at the top of the container. However, measurements can be usually completed before this settling occurs so it does not affect the results. We observed that bread samples began to spoil and evolve gases within a few days after processing, presenting a danger that the Marinelli container might burst, and leading to contamination. Heating the sample to boiling delayed spoilage for a week or longer. It is, therefore, imperative to count the samples as soon as practical after filling the counting container.

In our experimental conditions, with final concentrations of stable cobalt carrier in the range of 3–5E−7 M, 60Co might be expected to precipitate as Co(OH)2 even in the absence of TMAH at a pH of ~6. Other investigators have shown that TMAH can stabilize emulsions and suspensions by adsorbing to and complexing with particles [37,38,39,40]. Successful stabilization of experimental thermodynamically stable oil/water emulsions requires quaternary ammonium salts such as TMAH which can hydrolyze oil, which then becomes amphiphilic, resulting in lowered surface tension of the oil/water interface [37]. Adsorbed TMAH can stabilize oil/water emulsions by contributing electric charges to particles such as magnetite and cobalt ferrite, preventing their transfer to the oil phase [38]. This mechanism may have special relevance to food samples such as Parmesan cheese and ground beef, which contain large amounts of fat. In the production of ceramics such as barium zirconate and silicon nitride, the nitrogen in TMAH may enhance the stability of suspensions by adsorbing to the surface of particles and forming a complex that helps to keep the ions in solution [39, 40]. These mechanisms may help to explain why our 60Co spiked samples showed no evidence of precipitation in TMAH-treated samples. The tendency of TMAH to stabilize ions in suspension may be advantageous in preparing samples for gamma spectrometry.

Safe handling of TMAH is a cause of concern due to its toxicity and high pH. Neutralization of TMAH after sample homogenization with hydrochloric acid might improve safety by preventing burns that could promote contact of TMAH with the bloodstream. However, a preferred option is to boil samples containing TMAH at high temperature in a fume hood, as TMAH is stable only to 125 °C and is completely denatured at 200 °C. When samples are heated to high temperatures to decompose TMAH, strong-smelling toxic fumes of nitrogen oxides and ammonia are generated [41]. A strong fishy odor remains in the sample after being subjected to high heat. Heating above boiling (the solution temperature reaches ~105 °C) causes foaming of samples similar to that seen with nitric acid digestion.

References

Baratta EJ (2003) Determination of radionuclides in foods from Minsk, Belarus, from Chernobyl to the present. Czech J Phys 53:A31–A37

Parache V, Pourcelot L, Roussel-Debet S, Orjollet D, Leblanc F, Soria C, Gurriaran R, Renaud P, Masson O (2011) Transfer of 131I from Fukushima to the vegetation and milk in France. Environ Sci Technol 45:9998–10003

Merz S, Steinhauser G, Hamada N (2013) Anthropogenic radionuclides in Japanese food: environmental and legal implications. Environ Sci Technol 47:1248–1256

Radiological Laboratory Sample Analysis Guide for Incidents of National Significance—Radionuclides in Water (2008) Report EPA402-R-07-007, U.S. Environmental Protection Agency, National Air and Radiation Environmental Laboratory, Montgomery, AL, USA

Lin Z, Healey S, Wu Z (2016) Rapid and simultaneous detection of alpha/beta radioactivity in food by solid phase extraction liquid scintillation counting. J Radioanal Nucl Chem 307:1987–1994

Bari A, Khan AJ, Semkow TM, Syed UF, Roselan A, Haines DK, Roth G, West L, Arndt M (2011) Rapid screening of radioactivity in food for emergency response. Appl Radiat Isot 69:834–843

Nóbrega JA, Santos MC, de Sousa RA, Cadore S, Barnes RM, Tatro M (2006) Sample preparation in alkaline media. Spectrochim Acta B 61:465–495

Becker S (2005) Inductively coupled plasma mass spectrometry (ICP-MS) and laser ablation ICP-MS for isotope analysis of long-lived radionuclides. Int J Mass Spec 242:183–195

Elston HJ, Caspary M, Khayyat A, Chu L-C (2013) Microwave assisted sample preparation of organic materials for gross alpha activity analysis. In: Proceedings of the 245th American Chemical Society National Meeting, New Orleans, LA, USA, 7–11 April

Maxwell SL, Culligan BK, Kelsey-Wall A, Shaw PJ (2012) Rapid determination of actinides in emergency food samples. J Radioanal Nucl Chem 292:339–347

Khan AJ, Semkow TM, Beach SE, Haines DK, Bradt CJ, Bari A, Syed U-F, Torres M, Marrantino J, Kitto ME, Menia T, Fielman E (2014) Application of low-background gamma-ray spectrometry to monitor radioactivity in the environment and food. Appl Radiat Isot 90:251–257

Biagini R, Dersch R, de Felice P, Jerome SM, Perkin EME, Pona C, de Sanoit J, Woods MJ (1995) Homogeneity testing of spiked reference materials. Sci Total Environ 173–174:267–274

Gharbi F (2011) Inhomogeneity effects on HPGe gamma spectrometry detection efficiency using Monte Carlo technique. Nucl Instrum Meth Phys Res A 654:266–271

Food Emergency Response Network, (2017) U.S. Department of Health and Human Services, Food and Drug Administration, and U.S. Department of Agriculture, Food Safety Inspection Service. www.fernlab.org, Accessed July 2017

Supporting Document for Guidance Levels for Radionuclides in Domestic and Imported Foods (2004) U.S. Department of Health and Human Services, Food and Drug Administration, Silver Spring, MD, USA. www.fda.gov/Food/FoodborneIllnessContaminants/ChemicalContaminants/ucm078341.htm, Accessed Dec 2016

National Nuclear Data Center (2016) Brookhaven National Laboratory, Upton, NY, USA, www.nndc.bnl.gov Accessed Dec 2016

Zhou CY, Wong MK, Koh LL, Wee YC (1996) Microwave digestion of biological samples with tetramethylammonium hydroxide and ethylenediamine tetraacetic acid for element determination. Talanta 43:1061–1068

Fecher PA, Goldmann I, Nagengast A (1998) Determination of iodine in food samples by inductively coupled plasma mass spectrometry after alkaline extraction. J Anal At Spectrom 13:977–982

Uchida T, Isoyama H, Yamada K, Oguchi K, Nakagawa G, Sugie H, Chuzo I (1992) Determination of twelve elements in botanical samples with inductively coupled plasma atomic emission spectrometry after leaching with tetramethylammonium hydroxide and ethylenediaminetetraacetic acid. Anal Chim Acta 256:277–284

Rodrigues JL, Nunes JA, Batista BL, de Souza SS, Barbosa F Jr (2008) A fast method for the determination of 16 elements in hair samples by inductively coupled plasma mass spectrometry (ICP-MS) with tetramethylammonium hydroxide solubilization at room temperature. J Anal At Spectrom 23:992–996

Lin CC, Yang CC, Ger J, Deng JF, Hung DZ (2010) Tetramethylammonium hydroxide poisoning. Clin Toxicol 48:213–217

Bermejo P, Capelo JL, Mota A, Madrid Y, Cámara C (2004) Enzymatic digestion and ultrasonication: a powerful combination in analytical chemistry. Trends Anal Chem 23:654–663

Miguel ASM, Martins-Meyer TS, da Costa Figueiredo ÉV, Paulo Lobo BW, Dellamora-Ortiz, GM (2013) Enzymes in Bakery: Current and Future Trends. In: Muzzalupo I (ed) Food Industry, InTech, Rijeka, Croatia, www.intechopen.com/books/food-industry/enzymes-in-bakery-current-and-future-trends. Accessed Dec 2016

Lima MA, Oliveira-Neto M, Kadowaki MA, Rosseto FR, Prates ET, Squina FM, Leme AF, Skaf MS, Polikarpov I (2013) Aspergillus niger β-glucosidase has a cellulase-like tadpole molecular shape: insights into glycoside hydrolase family 3 (GH3) β-glucosidase structure and function. J Biol Chem 288:32991–33005

Bayer EA, Chanzy H, Lamed R, Shoham Y (1998) Cellulose, cellulases and cellulosomes. Curr Opin Struct Biol 8:548–557

Rosenberg BL, Steinhauser G (2016) Preparedness for a nuclear accident: removal of radioiodine from soil by chemical processing. J Radioanal Nucl Chem 307:1765–1769

Dexter AH, Evans AG, Jones LR (1976) Iodine evaporation from irradiated aqueous solution containing thiosulfate additive. In: Proceedings of the 14th ERDA Air Cleaning Conference, Sun Valley, ID, USA, CONF-760822-26, U.S. Department of Energy Office of Scientific and Technical Information, Oak Ridge, TN, USA. www.osti.gov/scitech/servlets/purl/7239037/. Accessed Dec 2016

Howard BY (1976) Safe handling of radioiodinated solutions. J Nucl Med Technol 4:28–30

Semkow TM, Bradt CJ, Beach SE, Haines DK, Khan AJ, Bari A, Torres MA, Marrantino JC, Syed U-F, Kitto ME, Hoffman TJ, Curtis P (2015) Calibration of Ge gamma-ray spectrometers for complex sample geometries and matrices. Nucl Instr Meth Phys Res A 799:105–113

ANSI/IEEE Standard (1978) IEEE Standard Techniques for Determination of Germanium Semiconductor Detector Gamma-Ray Efficiency Using a Standard Marinelli (Reentrant) Beaker Geometry. The Institute of Electrical and Electronics Engineers, New York

Parekh PP, Bari A, Semkow TM, Torres MA (2002) A new method for sealing containers with liquid samples for radioactivity measurements. J Radioanal Nucl Chem 253:321–325

Sima O, Arnold D, Dovlete C (2001) GESPECOR: a versatile tool in gamma-ray spectrometry. J Radioanal Nucl Chem 248:359–364

Currie LA (1968) Limits for qualitative detection and quantitative determination. Application to radiochemistry. Anal Chem 40:586–593

Nisti MB, Santos AJG, Pecequilo BRS, Máduar MF, Alencar MM, Moreira SRD (2009) Fast methodology for time counting optimization in gamma-ray spectrometry based on preset minimum detectable amounts. J Radioanal Nucl Chem 281:283–286

Shweikani R, Hasan M (2015) Determination of the optimal measurement counting time and detection limit for gamma-ray spectrometry analysis. Accred Qual Assur 20:501–504

Menu2010—A Radiological Capability and Capacity Inter-Laboratory Comparison Exercise. After Action Report, FERN, WSDOH, NYSDOH, WSLOH, TDSHS, MDHMH, October 2010. (Available from the Laboratory of Inorganic and Nuclear Chemistry, Department of Environmental Health Sciences, Wadsworth Center, New York State Department of Health, Empire State Plaza, Albany, NY 12201-0509, USA)

Kraft DJ, de Folter JWJ, Luigjes B, Castillo SIR, Sacanna S, Philipse AP, Kegel WK (2010) Conditions for equilibrium solid-stabilized emulsions. J Phys Chem B 114:10347–10356

Sacanna S, Rossi L, Philipse AP (2007) Oil-in-water emulsification induced by ellipsoidal hematite colloids: evidence for hydrolysis-mediated self-assembly. Langmuir 23:9974–9982

Moreno R, Salomoni A, Mello Castanho S (1998) Colloidal filtration of silicon nitride aqueous slips. Part I: optimization of the slip parameters. J Eur Ceram Soc 18:405–416

Boschini F, Rulmont A, Cloots R, Moreno R (2005) Colloidal stability of aqueous suspensions of barium zirconate. J Eur Ceram Soc 25:3195–3201

Tetramethylammonium hydroxide. PubChem Open Chemistry Database, National Center for Biotechnology Information, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/tetramethylammonium_hydroxide. Accessed Aug 2017

Acknowledgements

K. Nishikawa acknowledges support by the U.S. Food and Drug Administration/Food Emergency Response Network’s Cooperative Agreement Continuation Program 5U18FD003485-08. We highly benefited from the discussions with C. Palmer (Wadsworth Center, New York State Department of Health) on the use of TMAH to homogenize protein samples. We are grateful to E. Fielman for discussion on sample aliquot factors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nishikawa, K., Bari, A., Khan, A.J. et al. Homogenization of food samples for gamma spectrometry using tetramethylammonium hydroxide and enzymatic digestion. J Radioanal Nucl Chem 314, 859–870 (2017). https://doi.org/10.1007/s10967-017-5434-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-017-5434-4