Abstract

The electron beam (EB) irradiation-induced degradation of ochratoxin A (OTA) was investigated in this study. Results showed that EB irradiation is much more effective in degrading OTA in water than that in acetonitrile and methanol–water (60:40, v/v). OTA degradation efficiency increased in an irradiation dose-dependent manner and decreased in the increasing of substrate concentration. The alkaline conditions (pH 9.99) and the addition of H2O2 (<0.1 % v/v) remarkably improved the OTA degradation efficiency. OTA degradation process agreed well with the pseudo first-order kinetic model. Furthermore, the degradation products were preliminary analyzed using liquid chromatography–mass spectrometry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ochratoxin A (OTA) is a mycotoxin produced by Aspergillus ochraceus and Penicillium verrucosum with carcinogenic, neurotoxic, immunosuppressive, and nephrotoxic properties [1]. In 1993, the International Agency for Research on Cancer (IARC) classified OTA as a possible human carcinogen [2]. OTA contamination is not only widespread in crops, but also in beverages, such as white wine, red wine, grape juice and so on [3–8]. It was found that the concentration of OTA contamination ranges from 0.028 to 3.24 µg L−1 in wine and 1.16 µg L−1 in fruit juice from Morocco in previous studies [5]. It is a pressing task to develop effective ways to remove OTA in the products or wastewater which are harmless to human and environment.

Physical, chemical, and biological methods have been developed to decontaminate mycotoxins in food commodities. Chemical methods usually change the sensory, nutritional, and functional properties of food and leave undesirable toxic residues [9]. Biological methods are usually time consuming and incomplete [10]. Physical methods are effective in degrading mycotoxins from contaminated food commodities, including heat treatment, gamma-ray irradiation, and electron beam (EB) irradiation [11–13]. Heat treatment is an economical and traditional process for the physical degradation of OTA in food. However, OTA is stable, and only up to 20 % of OTA in wheat can be degraded by dry heat at 150 °C for 32 min or 100 °C for 160 min [14]. Gamma-ray irradiation can effectively degrade OTA in liquid media and cereal seeds [15, 16], and EB irradiation is thought to offer higher dose rate capability and no nuclear waste [12, 17]. It has been widely used in degrading organic pollutants recently. Hexachlorobenzene in solutions can be removed through EB irradiation at 10 kGy [12]. Clopyralid in aqueous solutions can be completely degraded by EB irradiation at 30 kGy [18]. A high degradation efficiency of 100 μM iopromide can be achieved at 19.6 kGy by EB irradiation, and the EB/H2O2 system increases the degradation efficiency by generating OH· [19]. Degradation efficiency has a close relationship to the initial concentration and pH [18]. The kinetics and mechanisms of OH· and \( {\text{e}} _{\text{aq}}^{ - } \) reactions with dimethyl phthalate were investigated using EB irradiation [20]. Previous studies proposed that the removal scheme of degradation by irradiation relies on the oxidation and/or reduction of OH· and/or \( {\text{e}} _{\text{aq}}^{ - } \) radicals [19, 21]. Thus, reactive oxidants or reducing agents should be added before irradiation to improve degradation efficiency [19, 22].

EB irradiation is an effective method of degrading organic compounds by chemical oxidation [12]. However, the research of OTA degradation by EB irradiation has been poorly reported. The present study investigated the degradation efficiency of OTA using EB irradiation in aqueous solutions under various conditions.

Materials and methods

OTA standard was obtained from Pribolab (>98 %, purity). Acetonitrile, acetic acid, and methanol of chromatographic grade were purchased from Fisher Scientific Reagent Co., Ltd. All other reagents (H3PO4, H2O2, and NH4·H2O) of analytical grade were bought from Beijing Chemical Co. Inc. (China). All solutions were prepared using triple-distilled water, and all experiments were conducted at room temperature.

Sample preparation

OTA solutions at different concentrations (0.1, 0.2, and 20 mg L−1) were prepared in different solvents [water, acetonitrile, and methanol–water (60:40, v/v)]. HCl and NH4·H2O were added into the OTA solutions to adjust solution pH at 4–10. The additive H2O2 at concentrations of 0.01, 0.1, and 1 % (v/v) were added into 0.1 mg L−1 OTA aqueous solutions to investigate the effect of the EB/H2O2 system on degradation efficiency. All prepared solutions were stored at 4 °C until use.

EB irradiation treatment

The sample solutions were irradiated at absorbed doses of 2.5–25 kGy using a commercial-scale EB accelerator (FZ-10/15) at room temperature in Beijing Gaoke Jinhui Irradiation Technology Co., Ltd., China. The energy of accelerated electrons was 10 MeV, and the beam current was 1.2 mA. The total scan zone was 100 cm × 80 cm. After irradiation, the samples were stored at 4 °C and then evaluated for high-performance liquid chromatography (HPLC). Three parallel samples were set in each treatment, and non-irradiated samples were used as controls.

OTA analysis

Quantitative analysis of OTA was performed through HPLC as previously described by Ferraz [23] with minor modifications. An Agilent 1200 fluorescence detector was used (Agilent technologies, Santa Clara, USA), with excitation and emission wavelengths of 333 and 477 nm, respectively. A reversed-phase chromatographic column (C18, 150 mm × 4.6 mm, 5 µm) was used, and the column temperature was set at 35 °C. The mobile phase consisted of a mixture of acetonitrile–water–acetic acid (99:99:2, v/v/v) at a low rate of 1 mL min−1. The injection volume was 20 µL.

OTA was quantified by HPLC with an external standard. The calibration curve was established using a linear least-squares regression analysis. A good linear correlation was observed between the peak area and the OTA concentration. The linear regression equation was y = 4.2614x + 0.1998 (R 2 = 0.9999).

Liquid chromatography–mass spectrometry (LC–MS)

OTA degradation products were analyzed by LC–MS (Agilent, Palo Alto, CA) with a 20 µL solution injected to the column (C18, 150 mm × 4.6 mm, 5 µm). The mobile phase was a mixture of 0.1 % formic acid aqueous solution (component A) and acetonitrile (component B) at a flow rate of 0.3 mL min−1. MS was performed on an Agilent 6460 Q-TOF fitted with an electrospray ionization source operating in positive ionization mode. The capillary voltage was set to 3.5 kV. The nebulizer was 45 psi, and ion spraying voltage was 3800 V. Nitrogen was used as collision gas. The drying gas temperature was 350 °C at a flow rate of 10 L min−1.

Kinetic data analysis

The degradation efficiency of OTA can be described by a pseudo first-order kinetic model, which was described in Eq. (1):

In this equation, C 0 is the initial concentration, C is the residual concentration at any dose, κ (kGy−1) is the degradation rate constant, and b is the constant parameter. The constants κ and b were determined from a linear regression C/C 0 versus D dose.

From Eq. (1), the dose required for 90 % removal of OTA, D0.9, can be calculated as given by Eq. (2):

Generally, G (mol J−1) is defined as the number of molecules or species formed or destroyed per 100 eV of ionizing energy absorbed. This parameter was calculated using Eq. (3) [12, 24]:

In this equation, D is the absorbed dose (Gy), 6.24 × 1019 is the conversion constant from kGy to 100 eV L−1 (100 eV L−1 Gy−1), ΔR is the amount of reduced OTA (mol L−1) at a given dose, and N A is Avogadro’s constant (6.02 × 1023 molecules mol−1).

Statistic analysis

ANOVA was conducted using Microcal Origin 7.5 software. The treatments were performed in triplicate. All data are presented as mean ± standard deviation. Statistically significant differences were considered at P < 0.05.

Results and discussion

EB irradiation-induced degradation of OTA

During EB irradiation, water radiolysis happen within a short time. The reactive species (OH·, \( {\text{e}} _{\text{aq}}^{ - } \) and H·) are generated, which play a vital role in degrading organic compounds.

OTA was dissolved in water, acetonitrile, and methanol–water (60:40, v/v) at an initial concentration of 0.1 mg L−1. The solutions were irradiated at doses of 2.5, 5, 7.5, 10, 15, 20, and 25 kGy. As shown in Fig. 1, the OTA degradation efficiency was associated with the type of solvent. The degradation rates in the three solvents increased in a dose-dependent manner. At 2.5 kGy, the degradation rates were 92.88, 7.20, and 30.83 % in water, acetonitrile, and methanol–water (60:40, v/v), respectively. When the absorbed dose increased to 10 kGy, the corresponding degradation rates increased to 99.34, 68.76, and 66.75 %, respectively. Thereafter, no significant difference (P > 0.05) in OTA degradation efficiency was detected between the two organic solvents. At 25 kGy, over 90 % of OTA was degraded in acetonitrile and methanol − water (60:40, v/v). Dissolving OTA in organic solvents was unfavorable for OTA degradation at low-level absorbed doses (0–7.5 kGy), whereas OTA degradation efficiency was significantly enhanced at relatively high-level absorbed doses (>7.5 kGy).

Basing on the data of OTA degradation rate and absorbed dose in Fig. 1, we found that OTA degradation followed the pseudo first-order kinetic model [Eq. (1)]. The kinetic values (rate constant κ, b, and G D) of OTA in the three solvents are presented in Table 1. The rate constants were 1.0507, 0.0973, and 0.0972 kGy−1 in water, acetonitrile, and methanol–water (60:40, v/v). The rate constant of OTA in water was 9.8-fold higher than those of OTA in acetonitrile and methanol–water (60:40, v/v). The G D value of OTA in water, calculated from the absorbed dose D0.9, was tenfold higher than those of OTA in acetonitrile and methanol–water (60:40, v/v). These results demonstrate that OTA degradation is more efficient in water than in organic solvents.

OTA degradation efficiency increases in water because of the presence of enough reactive radicals for OTA [12]. The amount of free radicals produced by EB irradiation was relatively small in organic solvents [acetonitrile and methanol–water (60:40, v/v)] [25]; hence, OTA degradation efficiency declined. At low-level absorbed doses, the decrease in OTA degradation efficiency in the presence of acetonitrile can be ascribed to the few radicals produced. At high-level absorbed doses, the increase in OTA degradation efficiency in the presence of acetonitrile can be related to the facilitation for the degradation of OTA molecules [13]. In methanol–water (60:40, v/v), OH· and \( {\text{e}} _{\text{aq}}^{ - } \) would be scavenged by methanol promptly [Eqs. (4) and (5)] [13],

thereby decreasing the reaction between OH· and OTA compared with that between \( {\text{e}} _{\text{aq}}^{ - } \) and OTA. Hence, OTA degradation efficiency declined as expected. Guo et al. [13] reported a similar explanation with sulfadiazine degradation by gamma-ray irradiation in aqueous solutions.

Effects of initial concentrations on OTA degradation

This study investigated the effects of OTA initial concentrations (0.1, 0.2, and 20 mg L−1) on degradation efficiency at absorbed doses of 2.5, 5, 7.5, 10, 15, 20, and 25 kGy. Figure 2 shows that the OTA concentration exponentially decayed with increasing absorbed dose. OTA degradation efficiency decreased with increasing initial concentrations. At initial OTA concentrations of 0.1, 0.2, and 20 mg L−1, the required irradiation doses to 90 % degradation of OTA were approximately 2.19, 3.93, and 6.66 kGy, respectively.

OTA degradation at different initial concentrations also fitted well to the pseudo first-order kinetic model. As presented in Table 2, the rate constants and G D values decreased with increasing initial concentrations. The rate constant for 0.1 mg L−1 OTA was 1.0507 kGy−1, with a corresponding G D value of 0.0983 mol J−1, which was 1.79 and 2.81 times higher of 0.2 mg L−1 OTA and 20 mg L−1 OTA, respectively.

It’s apparent that low initial concentration facilitated the degradation of OTA. This is mainly ascribed to weak collision between OTA and active radicals at low initial concentration [12]. This finding agrees with previous reports on the radiolysis of trimethylamine, chlorophenols, and methyl orange in aqueous solutions [21, 26, 27].

Effects of initial pH on OTA degradation

OTA aqueous solutions (0.1 mg L−1) with initial pH of 3.76, 7.01, and 9.99 were irradiated at absorbed doses of 1, 2, 3, 4, 5, 7.5, and 10 kGy. As shown in Fig. 3, the normalized OTA concentration (C/C0) rapidly reduced with increasing absorbed dose. The OTA degradation efficiency in neutral and alkaline conditions was significantly higher than that in acidic conditions. At 1 kGy, the OTA degradation rates were 98.07 % and 100 % at pH 7.01 and 9.99, respectively. However, the required irradiation dose to degrade 98 % of OTA was approximately 5 kGy at pH 3.76. These results indicate that the OTA degradation efficiency increases with increasing pH.

Figure 3 and Table 3 show that OTA degradation at different pH can be fitted with the modified pseudo first-order kinetic model. At pH 3.72, 7.01, and 9.99, the rate constants for OTA degradation increased from 1.1431 to 4.3143 kGy−1. A corresponding increase in G D values, from 0.1070 to 0.4038 mol J−1, respectively, was observed. Similar to the OTA degradation rate, the rate constant and G D increased with increasing pH.

The radiation yield (G value) of water radiolysis is pH-depending, where in the range of pH 6–8.5, is given in brackets [Eq. (6)] [28].

In acidic conditions, \( {\text{e}} _{\text{aq}}^{ - } \) easily reacted with H+ [Eq. (7)] [24],

thereby decreasing the concentration of \( {\text{e}} _{\text{aq}}^{ - } \). In alkaline conditions, OH− was likely to react with H· to generate \( {\text{e}} _{\text{aq}}^{ - } \) [Eq. (8)] [18],

thereby increasing the concentration of \( {\text{e}} _{\text{aq}}^{ - } \). The decrease or increase in OTA degradation efficiency at low or high pH, respectively, suggests that \( {\text{e}} _{\text{aq}}^{ - } \) is crucial in OTA degradation. Similar results were obtained in previous studies on the EB radiolysis of clopyralid and hexachlorobenzene in aqueous solutions [12, 18]. During EB irradiation, clopyralid or hexachlorobenzene was degrade by the loss of chlorine atoms on the pyridine ring or on the benzene ring [12, 18]. We hypothesized that the degradation efficiency increases in alkaline conditions by attacking the chlorine on the benzene ring of OTA by high-concentration \( {\text{e}} _{\text{aq}}^{ - } \) radicals.

Effects of H2O2 on OTA degradation efficiency

As shown in Fig. 4, adding H2O2 to aqueous solutions affected OTA degradation during EB irradiation. The addition of 0.01 % and 0.1 % H2O2 (v/v) promoted OTA degradation, whereas the addition of 1 % H2O2 (v/v) restrained this process. At 2 kGy, the OTA degradation rates were 85.28, 95.19, 94.72, and 32.16 % when 0, 0.01, 0.1, and 1 % H2O2 (v/v) were added, respectively.

During EB irradiation, OTA degradation efficiency was improved in the presence of 0.01 % and 0.1 % H2O2 (v/v). Similar results showed that low-concentration H2O2 (<0.005 %, v/v) can enhance the degradation efficiency of chlorophenols and sulfadiazine in aqueous solutions [13, 27]. An increase in OH· concentration promotes OTA degradation during EB irradiation because H2O2 can invert \( {\text{e}} _{\text{aq}}^{ - } \) and H· into OH· [Eqs. (9, 10)] [13, 18].

However, the OTA degradation efficiency in the presence of 1 % H2O2 was lower than that in the absence of H2O2. This finding supports the result of Zhang et al. [12] that high-concentration H2O2 (>1 %, v/v) reduces hexachlorobenzene degradation. This result may be attributed to the scavenging of OH· by superfluous H2O2 [Eq. (11)] [12].

The radiolytic degradation of OTA at different initial H2O2 concentrations fitted with the modified pseudo first-order kinetic model. As shown in Table 4, two trends were observed for these G values and rate constants at different initial H2O2 concentrations. The G values and rate constants increased when the additive H2O2 concentration ranged from 0 % to 0.1 % (v/v). When this concentration was increased to 1 % H2O2, the rate constant and G value significantly decreased. At the proper dose range, H2O2 can significantly enhance OTA degradation efficiency by EB irradiation.

Analysis of the OTA degradation products by EB irradiation

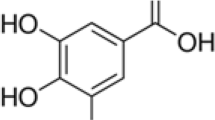

OTA solution (20 mg L−1) was irradiated at 5 kGy, and the degradation products were detected by LC–MS, which were presented in Table 5. Six new fragments at different retention time and with different m/z ratio were obtained. The [M+H]+ of six radiolytic products were of 166.0865, 285.0969, 172.1327, 468.1414, 283.0371, and 370.1282, with the corresponding formulas of C9H11NO2, C13H16O7, C9H17NO2, C22H26ClNO8, C13H11ClO5, and C20H19NO6, respectively. The DBE indicates the number of double bonds and/or the rings in the compound structure [29]. The DBE of OTA was 12, whereas that of the radiolytic products was lower (5–10) than that of OTA, except for product F (C20H19NO6) with 12 DBEs. This result implies a high possibility that the double bond and/or the ring was attacked by radicals (OH·, H· and \( {\text{e}} _{\text{aq}}^{ - } \)) or directly decomposed. The radiolytic product A (C9H11NO2) had less C11H7ClO4 molecules than OTA, thereby having the same molecular formula as that of phenylalanine. Radiolytic product C (C9H17NO2) had six more hydrogen atoms than A (C9H11NO2). Meanwhile, the DBE of C (C9H17NO2) had three less than that of A (C9H11NO2). These results indicate that the benzene ring of A (C9H11NO2) was hydrogenated by H· radicals. Radiolytic products B (C13H16O7) and D (C22H26ClNO8) had one or two more oxygen atoms than OTA, implying that OTA was oxidized by OH· radicals to generate –COOH. Radiolytic product E (C13H11ClO5) had less C11H7O molecules than OTA and had four less DBE than OTA, indicating that an addition reaction occurred. Radiolytic product F (C20H19NO6) was a result of the loss of chlorine on the benzene ring of OTA. Based on the above analysis, we can infer the main degradation pathways of OTA during EB irradiation (Fig. 5). The first way was the replacement of chlorine on the benzene ring of OTA by H· radicals and produced the intermediate “F” correspondingly. The second way was oxidized by ·OH radicals to generate D. The other way was the breaking of the NH-CO bond, and obtained “A” and another part. The “A” was further hydrogenated by H· radicals to form the product “C”. Meanwhile, another part was further oxidized by ·OH radicals to form “E”. “E” was then hydrogenated and dechlorinated by H· radicals to produce B. We can infer that the ·OH and H· radicals play a vital role in OTA degradation by EB irradiation.

Conclusions

This study is the first clear demonstration, to our knowledge, that EB irradiation could effectively induce OTA degradation in aqueous solutions and the reaction process followed a pseudo-first order kinetic model well. The OTA degradation efficiency increased in an irradiation dose-dependent manner and decreased with the increasing of substrate concentration. Water was much more conductive to the degradation of OTA than organic solvents (acetonitrile, and methanol–water (60:40, v/v)). Compared with acidic condition, the alkaline condition enhanced the OTA degradation efficiency by 29.02 % at 1 kGy. The addition of H2O2 (<0.1 % v/v) improved the OTA degradation rate by 9.91 % and higher addition concentrations (e.g., 1 % v/v) reduced the degradation rate by 53.12 % at the same dose. Six principal products were observed during OTA EB irradiation. Overall, EB is a promising method to degrade OTA in aqueous solutions.

References

Reinsch M, Töpfer A, Lehmann A, Nehls I (2005) Determination of ochratoxin A in wine by liquid chromatography tandem mass spectrometry after combined anion-exchange/reversed-phase clean-up. Anal Bioanal Chem 381:1592–1595

International Agency and for Research on Cancer—IARC (1993) Ochratoxin A. Monograph on the evaluation of carcinogenic risk to humans.v.56. Some naturally occurring substances: Food items and constituents, heterocyclic aromatic amines and mycotoxins. International Agency of Research on Cancer (IARC), Lyon

Wolff J, Bresch H, Cholmakov-Bodechtel C, Gareis M, Majerus P, Scheuer R, Engel G, Rosner H (2000) Ochratoxin A: Contamination of foods and consumer exposure-General introduction. Arch Lebensmittelhyg 51:84

Chapuis-Hugon F, du Boisbaudry A, Madru B, Pichon V (2011) New extraction sorbent based on aptamers for the determination of ochratoxin A in red wine. Anal Bioanal Chem 400:1199–1207

Filali A, Ouammi L, Betbeder AM, Baudrimont I, Soulaymani R, Benayada A, Creppy EE (2001) Ochratoxin A in beverages from Morocco: a preliminary survey. Food Addit Contam 18:565–568

Monaci L, Palmisano F (2004) Determination of ochratoxin A in foods: state-of-the-art and analytical challenges. Anal Bioanal Chem 378:96–103

Zezza F, Longobardi F, Pascale M, Eremin SA, Visconti A (2009) Fluorescence polarization immunoassay for rapid screening of ochratoxin A in red wine. Anal Bioanal Chem 395:1317–1323

Alvito PC, Sizoo EA, Almeida CMM, Van Egmond HP (2010) Occurrence of aflatoxins and ochratoxin A in baby foods in Portugal. Food Anal Methods 3:22–30

Méndez-Albores A, Del Rio-Garcia JC, Moreno-Martinez E (2007) Decontamination of aflatoxin duckling feed with aqueous citric acid treatment. Anim Feed Sci Technol 135:249–262

Huwig A, Freimund S, Käppeli O, Dutler H (2001) Mycotoxin detoxication of animal feed by different adsorbents. Toxicol Lett 122:179–188

Jalili M, Jinap S, Noranizan A (2010) Effect of gamma radiation on reduction of mycotoxins in black pepper. Food Control 21:1388–1393

Zhang J, Zheng Z, Luan J, Yang G, Song W, Zhong Y, Xie Z (2007) Degradation of hexachlorobenzene by electron beam irradiation. J Hazard Mater 142:431–436

Guo ZB, Zhou F, Zhao Y, Zhang CZ, Liu FL, Bao CX, Lin MY (2012) Gamma irradiation-induced sulfadiazine degradation and its removal mechanisms. Chem Eng J 191:256–262

Boudra H, Le Bars P, Le Bars J (1995) Thermostability of Ochratoxin A in wheat under two moisture conditions. Appl Environ Microbiol 61:1156–1158

Kostecki M, Golinski P, Uchman W, Grabarkiewicz-Szczesna J (1991) Decomposition of ochratoxin A by heat and gamma-irradiation. IARC Sci Publ 115:109–111

Aziz NH, Moussa LAA, Far FME (2004) Reduction of fungi and mycotoxins formation in seeds by gama-radiation. J Food Saf 24:109–127

Lewis SJ, Velasquez A, Cuppett SL (2002) Effect of electron beam irradiation on poultry meat safety and quality. Poult Sci 81:896–903

Xu G, Bu T, Wu M, Zheng J, Liu N, Wang L (2011) Electron beam induced degradation of clopyralid in aqueous solutions. Radioanal Nucl Chem 288:759–764

Kwon M, Yoon Y, Cho E, Jung Y, Lee BC, Paeng KJ, Kang JW (2012) Removal of iopromide and degradation characteristics in electron beam irradiation process. J Hazard Mater 227:126–134

Wu MH, Liu N, Xu G, Ma J, Tang L, Wang L, Hu HY (2011) Kinetics and mechanisms studies on dimethyl phthalate degradation in aqueous solutions by pulse radiolysis and electron beam radiolysis. Radiat Phys Chem 80:420–425

Chen YP, Liu SY, Yu HQ, Yin H, Li Q (2008) Radiation-induced degradation of methyl orange in aqueous solutions. Chemosphere 72:532–536

Boukari SOB, Pellizzari F, Karpel Vel Leitner N (2011) Influence of persulfate ions on the removal of phenol in aqueous solution using electron beam irradiation. J Hazard Mater 185:844–851

Ferraz M, Farah A, Iamanaka BT, Perrone D, Copetti MV, Marques VX, Vitali AA, Taniwaki MH (2010) Kinetics of ochratoxin A destruction during coffee roasting. Food Control 21:872–877

Ahmed AB, Hasan MK, Ahmed AAS (2005) Trihalomethane treatment using gamma irradiation: kinetic modeling of single solute and mixtures. Radiat Phys Chem 72:555–563

Schmelling D, Poster D, Chaychian M, Neta P, Mclaughlin W, Silverman J, Al-sheikhly M (1998) Applications of ionizing radiation to the remediation of materials contaminated with heavy metals and polychlorinatedbiphenyls. Radiat Phys Chem 52:371–377

Son YS, Kim P, Park JH, Kim J, Kim JC (2013) Decomposition of trimethylamine by an electron beam. Plasma Chem Plasma Process 33:1099–1109

Hu J, Wang J (2007) Degradation of chlorophenols in aqueous solution by γ radiation. Radiat Phys Chem 76:1489–1492

Wasiewicz M, Chmielewski AG, Getoff N (2006) Radiation-induced degradation of aqueous 2, 3-dihydroxynaphthalene. Radiat Phys Chem 75:201–209

Luo X, Wang R, Wang L, Wang Y, Chen ZG (2013) Structure elucidation and toxicity analyses of the degradation products of aflatoxin B1 by aqueous ozone. Food Control 31:331–336

Acknowledgments

This work was financially supported by National Science and Technology Foundation of China (Foundation item No. 2012BAD29B03) and The Team Project of Beijing Vocational College of Agriculture.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, C., Ding, Y., An, F. et al. Degradation of ochratoxin A in aqueous solutions by electron beam irradiation. J Radioanal Nucl Chem 306, 39–46 (2015). https://doi.org/10.1007/s10967-015-4086-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-015-4086-5