Abstract

Radiation-induced grafting of acrylic acid onto alginate/chitosan beads was performed in solution at a dose rate of 20.6 Gy/min of Co-60 gamma rays. The effect of absorbed dose on grafting yield was investigated. The characterization of the grafted and un-grafted beads was performed by FTIR spectroscopy and the swelling measurements at different pHs was studied. It is found that as the pH value increases the swelling degree increases up to pH 6 but with further increase in pH value the swelling decreases. Also, it is noticed that the grafting yield increased with increase the irradiation dose. Both un-grafted and grafted alginate/chitosan beads were examined as sorbents for the removal of Pb ions from aqueous solutions. The sorption behavior of the sorbents was examined through pH, and equilibrium measurements. Grafted alginate/chitosan beads presented higher sorption capacity for Pb ions than un-grafted beads.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Trace levels of heavy metals are widely distributed in environment due to industrial and agricultural processes. Lead (Pb) is one of the most toxic heavy metal which is the main source of contamination for human being found in water and food [1]. As lead and its compounds can cause adverse effects on metabolic processes of human beings even at low concentrations, its determination is so important for scientists all over the world [2]. High levels of Pb(II) ions can affect brain development in children, resulting in learning disabilities, behavioral problems and language difficulties [3, 4]. Additionally, long-term exposure to Pb(II) ions can cause anemia, anorexia, hypertension, convulsions, coma and cancer [5, 6]. The World Health Organization (WHO) has recommended a limit of 0.05 mg/l for lead ion [7]. Many conventional techniques have been applied to remove heavy metal ions from industrial effluents, including chemical precipitation, adsorption onto activated carbon, electrochemical treatment, membrane processes, solvent extraction, ion exchange and so on [4, 8–11].

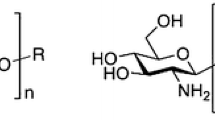

Chemical precipitation has been the practical method for treatment of wastes containing high lead concentrations, but adsorption is now widely applied in the removal of lead and other heavy metals because of its low operating cost and also because it does not produce any secondary pollutant that adds to the cost of treatment [12]. With the increase of industrial effluents containing heavy metal ions, there is a growing demand to develop novel adsorbents for efficient removal of heavy metal ions from wastewater. In recent years, insoluble polymeric hydrogels sorbents having different functional groups that can be complexed with metal ions have become well-known for the removal of metal cations from aqueous solutions [13, 14]. The main advantages of such materials are easy loading and, in most cases, stripping of cations with simple chemicals, reusability, and the possibility of semi-continuous operation. The adsorption of heavy metal ions by a polymeric sorbent depends on the macromolecular characteristics such as extent of crosslinking, the hydrophilic/hydrophobic balance of the macromolecular matrix as well as the structure of the attached ligand function and the stability constants of the resulting polymer-metal complex [15]. A vast number of polymeric sorbents having different functional groups was prepared and their complexing abilities were investigated in literature [13, 16–18]. These polymeric sorbents were prepared by post-modification of polymer matrix or by the polymerization of the monomers having functional groups that are able to complex with metal ions. These polymeric sorbents were prepared by post-modification of polymer matrix (through blending and grafting) or by the polymerization of the monomers having functional groups that are able to complex with metal ions. In the current study, different compositions of alginate and chitosan were prepared in the presence of a divalent cation as crosslinking agent and characterized by the determination of carboxylic acid group content and swelling degree and also by FT-IR spectroscopic analysis. As a comparison and increasing functionality in the prepared beads, grafting of alginate/chitosan beads with acrylic acid monomer by the effect of radiation is achieved and the effect of radiation dose and acrylic acid monomer concentration on the degree of grafting were studied. This study also, focuses on the effect of different (alginate/chitosan) gel beads formulations grafted with poly acrylic acid on the adsorption behavior of lead as an example of heavy metals. Chitosan is known for its metal adsorption properties since the 1970s [19] and is described as an excellent metal adsorbent by many investigators. It has been shown that chitosan effectively removes metals such as molybdenum, arsenic, gold, cadmium, vanadium, lead, copper, nickel, mercury, zinc, chromium, manganese and iron from aqueous solutions [20, 21]. Alginates on the other hand, are natural polysaccharides extracted from brown sea weed, composed of linear chains of the a-l-guluronic acid (G) and the b-d-mannuronic acid (M). Alginates are anionic compounds and one of their most important features is the capability to form hydrogels in the presence of divalent cations like Ca2+ [22].

Experimental

Materials

Chitosan powder with average molecular weight of 250 kDa, was burchased from Aldrish Co. The low viscosity alginic acid sodium salt was from Sigma, USA, acrylicacid (AAc), and metal salts (Lead acetate salts) of analytical grade were purchased from Fluka. All reagents and salts were used without further purification. Doubly distilled water was used for solutions preparation.

Methods and characterizations

Preparation of alginate/chitosan beads

Sodium alginate (Na–Alg) and chitosan in ultrapure water were prepared by weighting the respective solids to give (3 % wt/v) for each. Different compositions were prepared (50/50, 60/40, 80/20, and 90/10, Alg/Chit) and the solutions were prepared under magnetic stirring until became homogeneous. The formation of the hydrogel beads was based on the ionic gelation technique. Using a 10 ml syringe the Na–Alg and ALG/Chit different compositions were transferred drop wise from a distance of 10 cm into a solution of CaCl2·2H2O (3 % wt/v) which was under magnetic stirring. Hydrogel beads were formed instantly and they were left in contact with the solution for 30 min in order to complete the gelation. Finally they were rinsed gently with ultrapure water and dried at 37 °C.

Radiation grafting of acrylic acid onto alginate/chitosan beads

Crosslinked alginate/chitosan beads were immersed in different concentrations of acrylic acid (AAc) (10, 20, 30 and 40 %) at room temperature for 24 h, then irradiated using 60 Co gamma source at different radiation doses. After irradiation, the grafted chitosan/alginate beads (alginate/chitosan-AAc) were washed in boiling water to remove un-reacted monomer and homopolymer then air-dried to constant weight. The grafting yield was calculated as follows [23]:

where, W g is the weight of beads after grafting, W 0 is the weight of beads before grafting.

Equilibrium swelling measurements

The equilibrium swelling of alginate/chitosan and (alginate/chitosan)-g-AAc beads were carried out in distilled water and at different pH solutions at room temperature after 24 h. The swelling rate of the beads was calculated using the following formula [24]:

where S is the swelling rate, W s is the weight of swollen beads and W d is the initial weight of dry beads.

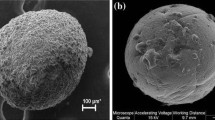

Scanning electron microscopy (SEM)

The surface morphology of different alginate/chitosan and (alginate/chitosan)-g-AAc samples were taken with a JSM-5400 instrument by JEOL-Japan. A sputter coater was used to pre-coat conductive gold onto the fracture surface before observing the microstructure at 10 kV.

Thermo-gravimetric analysis

TGA studies were carried out using a TGA-30 apparatus (Shimadzu, Kyoto, Japan), at a heating rate of 10 °C min−1 in air, over a temperature range from room temperature to 600 °C.

Batch adsorption experiments

Stock solutions (1 g/l) of Pb ions were prepared by using Pb(CH3COO)2·3H2O. The stock solutions were then diluted to give standard solutions of appropriate concentrations (50, 40, 30, and 10 mg/l).Then 20 ml aliquots of these standard solutions were poured in 100 ml beakers containing 0.1 g of alginate/chitosan or grafted alginate/chitosan beads. Batch experiments were equilibrated using a magnetic stirrer. After filtration, the concentrations of Pb ions in supernatant were analyzed at 217 nm wavelengths, respectively, using an atomic absorption spectrophotometer (Perkin-Elmer 3100 Model). The adsorbed amounts were calculated based on the difference of metal ion concentrations in the solutions before and after adsorption, the volume of the solution (20 ml) and the weight of the sorbent (0.1 g) according to the relation:

where C 0 is the initial metal ion concentration (mg/l), C e is the final equilibrium metal ion concentration (mg/l), V is the volume of the solution and W is the weight of the sorbent (g).

Effect of grafting degree

The effect of grafting was studied by immersing a certain weight of ALG/Chit beads grafted to different degree in a certain volume of Pb solution at constant concentration.

Effect of pH

Pb ion adsorption was studied in (1–5) pH range. The pH of the initial solution was adjusted to the required pH value using either 0.1 M HCL and 0.1 M Na OH.

Results and discussion

Effect of alginate content on the formation of beads

Alginate content plays an important role in the formation of beads where the crosslinking relay mainly on the interaction of alginate with the divalent ions of calcium. It is noticed that as the alginate content increases the beads with spherical and definite shape is formed as shown in Fig. 1. By studying the swelling capacity of the different compositions of ALG/Chit beads it is found that the composition that gives the highest swelling ability is (50/50) ALG/Chit and as a conclusion all other factors will be studied for the beads composed of (50/50) ALG/Chit.

Effect of AAc concentration on the degree of grafting

Figure 1 below shows photograph of (ALG/Chit) before and after grafting with acrylic acid. Also, Fig. 2 shows the effect of acrylic acid concentration on the degree of grafting, where it is clearly appeared that as the concentration of acrylic acid increases the degree of grafting increases up to 20 % AAc then start to decrease with increasing the AAc concentration, this can be attributed to the dissolution effect of acrylic acid on the polymers used. Also, on the other hand, as the concentration of chitosan increased up to 10 % the degree of grafting increases, then decreases up on increasing chitosan concentration. This is clearly noticed up to 20 % AAc concentration but with increasing the AAc concentration the grafting degree decreases with increasing chitosan content in the beads composition due to dissolution effect of AAc.

Effect of radiation dose on grafting degree

Figure 3 below illustrates the relationship between radiation dose and grafting degree. The grafting degree increased with the increase in irradiation dose and peaked at (2.5–3 kGy). At the initial stage, chain initiation resulted in the slow increase of grafting rate. Thereafter, the grafting rate increased rapidly. Since there were many monomers at the vicinity of alginate and chitosan polymers, they could diffuse to the grafting sites and graft onto the ALG/Chit gel beads readily. Therefore, both copolymerization and homo-polymerization reactions proceeded simultaneously up to a total dose of 2.5 k Gy. Beyond this, the solution viscosity increased, and the monomer diffusion rate decreased correspondingly and also, the increase in radiation dose cause degradation of alginate and chitosan natural polymers.

Equilibrium swelling of (alginate/chitosan)-AAc beads

From studying the swelling behavior of (ALG/Chit) beads compared with 100 % ALG at different pHs values (Fig. 4), it is found that as the pH increase the swelling content increase, while with increasing the Chitosan content at low pH value, Chitosan has a high ionization degree in acidic media (pH2) since its pKa is 6.3 [25]; thus almost all (NH2) groups are in their protonated form (NH3+). Therefore, as the sorbent is in its ionized form, an electro-osmotic effect is produced [26] which permits the entry of water into the sorbent producing swelling of the sorbent. When the pH changes from 2 to 6, chitosan suffers from a great decrease in its ionization degree accompanied with disappearance of the electro-osmotic effect. This stops the water flow to the beads and thus the swelling process. On the other hand alginate is a pH sensitive polymer where, as the pH increases the ionization of alginate increases and so the swelling behavior of prepared beads increases.

Scanning electron microscopy

Careful examination of representative beads composition of alginate, (50/50) ALG/Chit and (50/50) ALG/Chit-g-AAc different beads using SEM microscopy revealed more detail information regarding their external and internal morphological features. As it can be seen from the SEM surface and cross-sectional images (Fig. 5) the beads of 100 % alginate presented a less rough (a, d) surface beads, by blending of chitosan with alginate the surface became more rough and pores and hills increased as appeared in images (b, e) besides a small amount of wrinkles and micropores are noticed. After grafting with acrylic acid (c, f) the roughness and wrinkles clearly appeared on the surface of beads besides a large cracks are noticed and also, the surface of beads after grafting became more compact than the un-grafted ones.

Thermo-gravimetric analysis

TGA was employed to characterize the thermal stability of the un-grafted and grafted beads. TGA curves of un-grafted and grafted beads are shown in Fig. 6. From this figure, it was found that the thermal degradation of both grafted and un-grafted beads pass through nearly the same thermal stages but it is observed that thermal stability of grafted Alg/Chit beads is higher than that without grafting where the residual weight of grafted beads is equal 25.5 % while for un-grafted beads is equal 2.8 %.

Effect of grafting degree

The effect of grafting degree on the sorbent capacity to absorb metal ions at the same initial concentration (50 mg/l) is represented in Fig. 7. The general trend is that, with the increase in grafting degree, the adsorption capacity of the sorbent increased up to 132 % then starts to be constant this is due to that the grafting is limited with increasing the radiation dose, which cause degradation of the polymers used and formation of AAc homopolymer.

Effect of pH on the metal ions removal

The effect of pH (2, 3, 4, and 5) on metal ions removal by ALG/Chit-AAc grafted beads is shown in Fig. 8. It was observed that the adsorption capacity of metal ions by ALG/Chit-AAc grafted beads was lesser at pH 2. The amino groups of chitosan are protonated in acidic pH values, which render the sorbtion of positively charged Pb ions. Due to the positive charge of Pb ions, strong Coulombic repulsions are developed between them. At higher pH of the solution, the amino and carboxylic groups of the sorbent are de-protonated, the repulsive forces weaken and the metal uptake increases. ALG/Chit beads become strongly anionic after grafting with acrylic acid so on increasing the pH of the solution, de-protonation of ALG/Chit-AAc derivative is realized and strong attractive forces, between the positive charged metal and the negatively charged beads, result in high metal ions uptake.

Conclusion

In this study, natural alginate and chitosan beads grafted with acrylic acid were studied as sorbents for the removal of lead ions from aqueous solutions. Modified ALG/Chit beads were synthesized by a graft copolymerization reaction of ALG/Chitosan with acrylic acid by gamma radiation. The grafting degree increased with the increase in radiation dose. The grafted ALG/Chit beads have shown a higher degree of swelling than the un-grafted ones. The adsorption capacities of Pb ions from aqueous solution using grafted and un-grafted ALG/Chit beads were measured. The graft copolymer showed greater ability to absorb Pb ions compared to un-grafted beads. The optimum pH for Pb uptake is between 4 and 5 for both metal ions and synthesized sorbents.

References

Stevens JB (1991) Environ Sci Technol 25:1289

Zaijun L, Jian T, Jiaomai P (2004) Food Control 15:565

Burke DM, Morris MA, Holmes JD (2013) Chemical oxidation of mesoporous carbon foams for lead ion adsorption. Sep Purif Technol 104:150–159

Wang Y, Wang X, Wang X, Liu M, Wu Z, Yang L et al (2013) Adsorption of Pb(II) from aqueous solution to Ni-doped bamboo charcoal. J Ind Eng Chem 19:353–359

Idris A, Ismail NSM, Hassan N, Misran E, Ngomsik A-F (2012) Synthesis of magnetic alginate beads based on maghemite nanoparticles for Pb(II) removal in aqueous solution. J Ind Eng Chem 18:1582–1589

Fan L, Luo C, Sun M, Li X, Qiu H (2013) Highly selective adsorption of lead ions by water-dispersible magnetic chitosan/graphene oxide composites. Colloids Surf B 103:523–529

Rahmani A, Zavvar Mousavi H, Fazli M (2010) Effect of nanostructure alumina on adsorption of heavy metals. Desalination 253:94–100

Dong L, Zhu Z, Ma H, Qiu Y, Zhao J (2010) Simultaneous adsorption of lead and cadmium on MnO2-loaded resin. J Environ Sci 22:225–229

Heidari A, Younesi H, Mehraban Z (2009) Removal of Ni(II), Cd(II), and Pb(II) from a ternary aqueous solution by amino functionalized mesoporous and nano mesoporous silica. Chem Eng J 153:70–79

Lawal OS, Sanni AR, Ajayi IA, Rabiu OO (2010) Equilibrium, thermodynamic and kinetic studies for the biosorption of aqueous lead (II) ions onto the seed husk of Calophyllum inophyllum. J Hazard Mater 177:829–835

O¨nal S, Baysal SH, Ozdemir G, Adebowale Kayode O (2007) Studies on the applicability of alginate-entrapped Chryseomonas luteola TEM 05 for heavy metal biosorption. J Hazard Mater 146:417–420

Unuabonah EI, El-Khaiary MI, Olu-Owolabid BI, Adebowale KO (2012) Chem Eng Res Des 90:1105–1115

Wan Ngah WS, Endud CS, Mayanar R (2002) Removal of copper (II) ions from aqueous solution onto chitosan and crosslinked chitosan beads. React Funct Polym 50:181–190

George B, Pillai VNR, Mathew B (1999) Effect of the nature of the crosslinking agent on the metal-ion complexation characteristics of 4 mol% DVB and NMBA crosslinked polyacrylamide-supported glycines. J Appl Polym Sci 74:3432–3444

Mathew B, Pillai VNR (1993) Polymer-metal complexes of amino functionalized divinylbenzene-crosslinked polyacrylamides. J Polym 34:2650–2658

Kas¸go¨ z H, O¨ zgu¨mu¨ s¸ S, Orbay M (2001) Preparation of modified polyacrylamide hydrogels and application in removal of Cu (II) ion. J Polym 42:7497–7502

Kaşgöz H, Özgümüş S, Orbay M (2003) Modified polyacrylamide hydrogels and their application in removal of heavy metal ions. Polymer 44:1785–1793

Rivas BL, Seguel GV, Geckeler KE (2002) Synthesis, characterization and properties of polychelates of poly (styrene sulfonic acid-co-maleic acid) with Co (II), Cu (II), Ni (II) and Zn (II). J Appl Polym Sci 85:2546–2551

Masri MS, Reuter FW, Friedman M (1974) Binding of metal cations by natural substances. J Appl Polym Sci 18:675–681

Kaminski W, Modrzejewsk Z (1997) Application of chitosan membranes in separation of heavy metal ions. Sep Sci Technol 32(16):2659–2688

Mckay G, Blair HS, Chem AFIJO (1989) Equilibrium studies for the sorption of metal ions onto chitosan. Ind J Chem 28A:356–360

Bajpai SK, Sharma S (2004) Investigation of swelling/degradation behavior of alginate beads crosslinked with Ca2+ and Ba2+ ions. React Funct Polym 59:129–140

Singh V, Sharma AK, Tripathi DN, Sanghi R (2009) Poly (methylmethacrylate) grafted chitosan: an efficient adsorbent for anionic azo dyes. J Hazard Mater 161:955–966

Long Z, Hiroshi M (2009) Hydrogels of dihydroxy propyl chitosan crosslinked with irradiation at paste-like condition. Carbohydr Polym 76(2):314–319

Udayabhaskar P, Iyengar L, Rao AVSP (1990) Hexavalent chromium interaction with chitosan. J Appl Polym Sci 39:739–749

Ng JCY, Cheung WH, Mckay G (2002) Equilibrium studies of the sorption of Cu (II) ions onto chitosan. J. Colloid Interface Sci 255:64–74

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abou El Fadl, F.I. Radiation grafting of ionically crosslinked alginate/chitosan beads with acrylic acid for lead sorption. J Radioanal Nucl Chem 301, 529–535 (2014). https://doi.org/10.1007/s10967-014-3149-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3149-3