Abstract

This paper reviewed the comprehensive literature survey on the physical, chemical, and the catalytic properties and applications of iron oxide nanoparticles. In recent years, iron oxide has made a versatile progress due to its outstanding magnetic property. The average crystallite size was reported in previous literatures in the range of 10–45 nm using Scherrer’s formula. The powder morphology was found to deliberate quasi-spherical and predominantly spherical shape. The specific surface area as measured by N2 adsorption BET isotherm was reported in the range of 17.6–26.21 m2/g. Depending on the synthesis pathway there was, an inverse or normal spinel structure could be achieved. X-ray diffraction analysis revealed the crystallite size in the range between 8 and 42 nm. Fourier transform infrared spectroscopy reported the changes in functional group, stretching vibrations in the iron oxide nanoparticles. Scanning electron microscopy analysis showed most of Fe3O4 nanoparticles were in spherical morphology with the particle size range between 10 and 26 nm. Vibrating sample magnetometer reported the magnetization value for Fe3O4 nanoparticles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Iron was originated as the most common element on Earth’s outer and inner core which was found as one fourth of the elements in the Earth’s crust. Iron was the single and most important metal in human civilization and was refined and used on the scale of more than a billion tones of year, and more than 90% of refined metal was iron. Iron ore was widely distributed and reduced in a blast furnace with the support of coke and limestone. It was the most abundant transition metal and showed enormous applications in all fields. Iron has been formed with its number of oxides, and among them, Fe3O4 was a naturally occurring mineral magnetite which consisted of many impurities magnetized by lightning the strike. The permanent magnet has been known to ancient man as lodestones and used in navigational compasses for at least 800 years [1]. During the past few decades, the most active research areas in advanced materials have led to the synthesis of functional magnetic nanoparticles (MNPs) in nanoscience and nanotechnology [2, 3]. MNPs have revealed distinctive magnetic properties, and other specific properties such as electronic and optical showed a wide range of applications [4]. In recent studies, the interacting magnetic nanoparticles have revealed a very wide area in synthesis, characterization, and applications of novel composites [5, 6]. Size of the nanoparticles was the important parameter to determine the different properties of the material. The properties of nanosized materials were different from that of the corresponding bulk materials, which have been reported [7, 8]. Compared to atomic or bulky materials, nanosized materials have showed better physical and chemical properties due to their mesoscopic effect, small object effect, quantum size effect, surface effect, etc. Iron oxides were found to be familiar compounds and common in nature and could be readily synthesized in the laboratory conditions.

Eight supplementary iron oxides have been identified [9] as derivatives of iron, and mainly ferrous and ferric iron oxides existed in seven crystalline phases, such as α-Fe2O3 (hematite), γ-Fe2O3 (maghemite), Fe3O4 (magnetite), and Fe1-xO (wustite), and β and ε-Fe2O3 phases were found as the less commonly found and the low temperature rhombohedral structure of magnetite. Among these iron oxides, in addition to that, hematite (α-Fe2O3), maghemite (γ-Fe2O3), and magnetite (Fe3O4) were very promising and popular candidates due to their polymorphism involving the temperature-induced phase transition. Hematite was one of the most stable iron oxides and n-type semiconductor under ambient conditions. Due to this unique property, it was widely used as catalysts in various chemical reactions, pigments and gas sensors for its low cost and high resistance to corrosion, etc. For the synthesis of magnetite (Fe3O4) and maghemite (γ-Fe2O3), hematite was used as a starting material, which has been intensively pursued for the fundamental scientific interests and technological applications in the last few decades of iron period. Hematite was an n-type semiconductor with a band gap of 2.3 eV, where the conduction band (CB) has consisted of empty d-orbitals of Fe3+ ions and the valence band (VB) was composed of occupied 3d crystal field orbitals of Fe3+ with admixture from the oxygen, 2p non-bonding orbitals. Fe3+ ions have occupied two thirds of the octahedral sites restricted the ideal hexagonal close-packed O lattice [10, 11]. The structure of γ-Fe2O3 is found to be cubic, and each unit of maghemite contains 32 O2− ions as magnetite, 211\( \raisebox{1ex}{$1$}\!\left/ \!\raisebox{-1ex}{$3$}\right. \) are occupied by Fe3+ ions and 2\( \raisebox{1ex}{$1$}\!\left/ \!\raisebox{-1ex}{$3$}\right. \) were vacancies. Oxygen anions have been arranged to give a cubic closed packing. The ferric ions were distributed in the tetrahedral sites (eight Fe ions per unit cell) and octahedral sites (the remaining Fe ions and vacancies). So the maghemite was considered as a fully oxidized magnetite and n-type semiconductor with a band gap of 2.0 eV.

Magnetic iron oxides have served humans for centuries. The function of iron oxide nanoparticles as different agents for in vitro diagnostics has been practiced for around half a century [12, 13]. In recent times, Fe3O4 was seriously investigated because of their superparamagnetism, high coercivity, and low Curie temperature [14, 15]. Fe3O4 has a cubic inverse spinel structure and has Fd3m space group for Fe3O4. Magnetite was a black ferrimagnetic mineral containing both Fe2+ and Fe3+ ions. In Fe3O4, oxygen atom has formed a cubic structure, 1/3 of the intersites were tetrahedrally occupied and 2/3 was occupied in octahedral site. The unit cell of Fe3O4 has 32 O2− ions which were arranged in regular cubic close packing with the [100] direction. The lattice constant was found to be a = 0.839. The crystal structure of Fe3O4 consisted of two different iron sites: tetrahedral sites were occupied by Fe (III) and octahedral sites were occupied by both Fe (II) and Fe (III). In general, Fe3O4 crystals were distributed with octahedral and mixed octahedral/tetrahedral layer along in the (111) direction [16, 17]. Magnetic iron oxide nanoparticles consisted of two major parts: conserved the magnetic property of magnetic iron oxides and preserved some other properties of iron oxides with the properties of organic molecules. These three iron oxides have unique biochemical, magnetic, catalytic, and biomedical applications. Particularly, bioapplications-based magnetic nanoparticles (NPs) have received much attention due to their unique advantages over other materials. Magnetic nanoparticles were cost-effective to generate magnetite nanoparticles which showed the physical and chemical stability, biocompatibility, and environmental safety [18].

There was a higher surface energy for high-index planes. For the face-centered-cubic, the sequence was arranged to be γ(111) < γ(100) < γ(110) < γ(220) and generated the distance between the planes and the central Wulff’s point. For this reason, the Fe3O4 nanoparticles were surrounded mostly by {111}, and it has been revealed octahedral morphology. The ratio (R) of growth rate was determined by the crystal shape in the <100> direction to <111> direction. In <100> direction, faster growth has led to octahedral particles, while faster growth along the <111> direction could generate cubic particles. To get a variety of morphologies, it is necessary to control the growth rate of different surfaces of the nuclei, and hence, surfactant, templates, or other specific conditions are applied [12, 19, 20]. For the synthesize of monodispersed spherical Fe3O4 nanoparticles, both oleic acid and oleylamine were used as surfactants. Xie and co-workers have prepared Fe3O4 nanoparticles by utilizing the trichloro-s-triazine (TsT) and a linker molecule. Other routes such as solvothermal methods were also used to synthesize spherical Fe3O4 nanoparticles [21, 22].

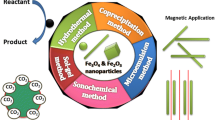

In this method, right quantities of potassium ferrocene, sodium borohydride, sodium hydroxide, polyvinylpyrrolidone, and alcohol were mixed and heated to 180 °C in an autoclave by this typical process and have been found that the growth of the (111) surface was slow down because of the absorption of hydroxyl group on the (111) facet. There was a change in the shape of the Fe3O4 from spherical particles to octahedral particles due to increase in the surfactant concentration [23]. Yang and co-workers have synthesized the monodispersed Fe3O4 nanocubes which has a controllable particle sizes of 6–30 nm. Fe (acac)3 was used as a precursor, benzyl ether as a solvent, and 1,2-hexadecanediol, oleic acid (OA), and oleylamine (OAm) as the surfactants. The carboxylic group presented in the oleic acid was bound selectively to crystal surface to control size of nanoparticles. The OAm has been possessed moderately weak, and exhibited isotropic binding to the surface affected the morphology of the Fe3O4 nanoparticles. By changing the stabilizers for the fabrication of Fe3O4 nanoparticles, they found the use of sodium oleate led to nanocubes. Potassium oleate has been generated a mixture of nanocubes with magnetite nanoparticles of different morphologies [24]. Iron oxide nanomaterial was synthesized by different methods as microwave-assisted synthesis, ultrasonication, co-precipitation, chemical reduction, hydrothermal method, bio-mediated synthesis [25,26,27,28], etc.

In Fe3O4 nanoparticles, there is a possibility of presence of impurity phases, like α-Fe2O3 in the synthesized iron nanoparticles. Liang et al. used the hydrothermal method to synthesize Fe3O4 nanoparticles and revealed the reaction time was increased, α-Fe2O3 impurities have been decreased, and simultaneously, Fe3O4 phase has been increased slowly. Alcala et al. prepared Fe3O4 nanoparticles by the mechanical alloying of iron and hematite. The result showed that continuous milling time was extended more than 3 h and there was the formation of pure phase of Fe3O4. Hu et al. studied the heat treatment effects on Fe3O4 nanoparticles at higher temperature of 650 °C showed that the synthesized particle size was reported to be 48 nm [29, 30].

Iron and iron-based nanoparticles have attracted considerable interest in different areas of research when compared to bulk materials. It showed exclusive properties such as catalytic, magnetic, antioxidant, anti-microbial, and optical property and attained several developments in the field of science, engineering, and technology. Expensive instruments, high energy, toxic reducing agents, maintaining the cell culture, recovery steps, etc. were found to be the list of disadvantages identified in physical-, chemical-, and microbe-mediated syntheses [31, 32]. The critical value of each particle becomes a single domain with a large spin, when the size of nanoparticles becomes smaller, it is called super spin [33]. There were two types of super spins such as superparamagnetism (SPM) which was non-interacting or weakly interacting super spins and strongly interacting spins led to super spin-glass (SSG) [34]. Figure 1 shows the phase diagram of stable iron oxide.

Iron oxide magnetic nanoparticles (Fe3O4-MNPs) have the approximate size of 20–30 nm and contained a single magnetic field with a single magnetic moment which exhibited superparamagnetism [3]. When Fe3O4 nanoparticles (MNPs) were magnetized in the presence of an external magnet, it was used to study the large surface area to volume ratios, easy functionalization, superparamagnetic property, and also used for various biological applications such as drug delivery, magnetic resonance imaging (MRI), bio-separation, biomolecular sensors, and magneto-thermal therapy, etc. [35]. It has cubic inverse spinel structure and there has a formation of FCC closed packing by oxygen atoms with interstitial tetrahedral sites and octahedral sites occupied by Fe cations. In the octahedral sites, the electrons jump between Fe2+ and Fe3+ ions at room temperature [36]. The particles attracted to an external magnetic field, but there was no magnetization when the magnetic field was removed and this was called as superparamagnetism. Using an external magnet, the suspended magnetite nanoparticles were removed without agglomeration [37].

The theory of ferrimagnetism was illustrated by Neel using Fe3O4 as an example. Before Neel’s work, Fe3O4 was classified as a ferromagnet, and magnetization of 4 μB per formula unit has been measured. Neel reported that the tetrahedral and octahedral sub-lattices were anti ferromagnetically aligned in Fe3O4 and the Fe3+ cations, and each sub-lattice has canceled each other. Hence, the magnetic moment aroused wholly from the moment of the remaining Fe2+ cation [38]. The electronic structure of Fe3O4 was studied experimentally using photoemission process. It was important to highlight the use of Fe2+ and Fe3+ ions and the presence of different cations in Fe3O4. The true point of charge disproportionation between the different cations was undoubtedly much smaller, and there aroused a question whether it existed at all. Recent work has showed the value below TV, the charge disproportionation should be “frozen in,” and the oxidation states of Fe cations have varied between 2.4+ and 2.9+. In the room temperature, all the Feoct cations were crystallographically equivalent and Mossbauer spectroscopy explained that all Feoct were equivalent, even though this was probably a time average [39, 40]. Magnetite has inverse cubic spinel structure according to [Fe3+]Td[Fe2+ Fe3+]OhO4 with a half metallic structure and exhibited semiconductive properties because of fast jumping of electrons between Fe2+ and Fe3+ in the octahedral sub-lattice evidenced by Mossbauer spectroscopy.

The optical absorption of the iron nanoparticles was studied in the wavelength of 190–900 nm. From the view of scattering theory, the shape of the spectra and wavelength of the maximum optical extinction depend only on the dielectric function of the nanoparticles. For spherical particles, a single peak of destruction spectra appeared and the absorption spectra of colloidal iron nanoparticles were determined. The observation suggested that the stability of colloidal solution and size distribution of nanoparticles depend on the nature of liquid. Due to the interaction of liquid molecules and charged nanoparticles in liquid medium, electrical double layers have been formed around the surface of the generated nanoparticles [41]. Furthermore, acetone has high dipole moment that led to the occurring of adequate electrostatic repulsive force because of the overlapping of strong electrical double layer due to the presence of nanoparticles in colloidal solution of acetone which was stable without aggregation and precipitation. And, water agglomeration occurred after 2 h due to oxidation and compared with acetone, water decreased in polarity [42]. Figure 2 shows the purification process of magnetite ore by various steps.

Magnetite nanoparticles were synthesized by two-stage continuous flow stirred reactors by aqueous co-precipitation of Fe (II) and Fe (III) salts under alkaline conditions and by heating at 70 °C [43, 44]. Iron salt solution of 0.05 mol Fe/L was continuously pumped in the first stage of the reactor (5 L/h for Fe(II) and 10 L/h for Fe(III)), when there was the addition of NaOH, the pH was adjusted to 12.0. As a result, there was a formation of black precipitate indicating the formation of magnetite. The obtained slurry was kept for 1 h and was washed in cycles of magnetic separation/re-dispersion in distilled water. Finally, the sludge was dried at 40 °C to get powder samples of Fe3O4 magnetic nanoparticles [45]. Fe3O4 nanoparticles have attracted much interest due to their potential applications in different areas, such as super capacitor electrode materials, adsorption of heavy metal processes, recyclable catalysts for catalytic oxidation of alcohols, magnetic carriers for protein separation, and wastewater treatment [46, 47].

2 Characterization

Iron oxide (Fe3O4) nanoparticles were characterized by XRD, BET surface area, SEM, TEM-EDS, TGA/DTA, and VSM analyses. The specific surface area of Fe3O4 nanoparticles was characterized by BET analysis. XRD was used to reveal the crystalline nature and crystallite size of Fe3O4 nanoparticles using Scherrer’s formula. EDS was used for the identification of the elements present in the Fe3O4 nanoparticles. SEM and TEM were used to characterize the surface morphology and particle size distribution of the iron nanoparticles. VSM was the technique used to determine the magnetization of the Fe3O4 nanoparticles. TGA/DTA analysis was used to confirm the thermal stability of the prepared Fe3O4 nanoparticles. Figure 3 shows the flow chart of properties and characterization of Fe3O4 nanoparticles.

2.1 BET Analysis of Fe3O4 Nanoparticles

BET analysis was used to determine the surface area and pore size distribution at liquid nitrogen temperature. In surface area analysis, nitrogen was used because of its availability in high purity and its strong interaction with most of the solids. Because of the interaction between gaseous and solid phases, it was usually weak and the surface was cooled using liquid N2 to obtain detectable amounts of adsorption. Cheera et al. synthesized the Fe3O4 nanoparticles by ecofriendly method using extract of Pistum sativum. The prepared Fe3O4 nanoparticles were characterized by BET surface area analysis. BET was used to study the porous nature and surface area of the PS-Fe3O4 magnetic nanoparticle materials. There were loops present in between 0.45 and 0.99 confirmed the sample has mesopores on it. The calculated surface area of the nanomaterial was found to be ∼ 17.6 m2 g−1 which was higher than other Fe nanomaterials [48]. Prasad et al. prepared the Fe3O4 nanoparticles by green synthesis using Ridge gourd as a starting material. The synthesized RG-Fe3O4 nanoparticles were characterized by BET surface area analysis. The porous nature of iron nanoparticles was studied by N2 adsorption-desorption method, and the surface area was found to be 26.21 m2 g−1. By Barrett, Joyner, and Halenda (BJH) method, the total pore volume and pore size distribution of Fe3O4 nanoparticles were identified to be about 0.134 cm3/g, and it was a mesoporous material with pore size ranged from 7 to 25 nm [49].

2.2 XRD Analysis of Fe3O4 Nanoparticles

X-ray diffraction is a very important experimental technique that has long been used to address all the information and issues related to the crystal structures of solids, including lattice constants, geometry, identification of unknown materials, orientation of single crystal, defects, stresses, average grain size, and strain defects of the Fe3O4 nanoparticles. In XRD, a collimated beam of X-rays was made incident on a specimen such as Fe3O4 nanoparticles and was diffracted by the crystalline phases according to Bragg’s law. Ting et al. synthesized the series of Fe3O4 nanoparticles by microemulsion method, and the prepared Fe3O4 was characterized by using XRD analysis. Fe3O4 consisted of cubic spinel type with single phase, and α-Fe2O3 and γ-Fe2O3 phases were not observed. And, it was compared with the standard pattern of Fe3O4 and resulted the decrement of particle size. The lattice constant of Fe3O4 nanoparticles was calculated, and the results showed that Fe3O4 nanoparticles were consistent with standard inverse spinel type Fe3O4 [50].

Yang et al. synthesized the superparamagnetic iron nanoparticles by co-precipitation method. The synthesized Fe3O4 nanoparticles diffraction pattern was nearly close to the crystalline of magnetite. The diffraction peaks were indexed to (2 2 0), (3 1 1), (4 0 0), (4 2 2), (5 1 1), and (4 4 0) planes, and the observed details have been matched with the inverse cubic spinel structure of Fe3O4 nanoparticles [51]. Yan et al. prepared the Fe3O4 nanoparticles from interior stem wall and epidermal surface of soya bean sprout. The diffraction peaks were indexed to (2 2 0), (3 1 1), (4 0 0), (5 1 1), (4 4 0), and (5 3 3) planes. Both the materials could be indexed with the inverse cubic spinel structure of Fe3O4 [52].

Aslibeiki et al. synthesized Fe3O4 nanoparticles by thermal decomposition method and calcinated in N2 atmosphere at 300° (N300) and 350° (N350) as well as air (A300 and A350). XRD pattern reported that both the samples were pure single cubic spinel. The sample of N350 that got the sharp peaks showed that calcination temperature was increased and particle size was also increased. The average particle sizes for the Fe3O4 nanoparticles were confirmed to be 8 nm and 12 nm [53]. Superparamagnetic poly (o-Toluidine) (POT)/Fe3O4 nanoparticles composite revealed the diffraction peaks indexed to (111), (220), (311) (222), (400), (422), (511), and (440) planes. It was exhibited a spinel (face-centered cubic) Fe3O4 and represented the presence of Fe3O4 nanoparticles in a prepared material [54]. Silva et al. prepared the fucan-coated and fucan-uncoated magnetites by co-precipitation method, and XRD results revealed that Fe3O4 consisted of inverse cubic spinel structure corresponded to (2 2 0), (3 1 1), (4 0 0), (4 2 2), (5 1 1), and (4 4 0) planes and the particle size was identified to be 10 nm using Scherrer’s formula. The observed peaks in the same range showed that the coating did not affect the core magnetite. And the fucan-coated in the peak height was decreased and the background becomes noisy due to its amorphous nature [55].

The magnetic Fe3O4, Fe3O4@SiO2, and Fe3O4@SiO2@Chol nanoparticles were synthesized by Zhihong Yan et al., and the XRD analysis showed that nanoparticles were in well accordance with one another and it was indicated that cholesterol coating did not damaged the structure of Fe3O4 nanoparticles [56]. Shete et al. synthesized the CS-OA-Fe3O4 nanoparticles by alkaline precipitation method, and the XRD results matched very well with standard iron oxide nanoparticles. The main diffraction peaks were obtained with the (hkl) values of (220), (311), (400), (422), and (511) and showed the inverse spinel structure of Fe3O4 nanoparticles with the crystallite sizes of 20 nm and 10 nm for bare and OA-CS-coated magnetic nanoparticles respectively. The particle size was decreased when capping with CS-OA, and it was confirmed by peak broadening decreased in intensity after capping [57]. Emre Cevik et al. synthesized the Fe3O4-Si (GMA-co-Vfc) nanoparticles, and the material was characterized by XRD analysis. He observed the (111), (220), (311), (400), (422), (511), (440), (620), and (533) peaks resembled the core Fe3O4. The broadening of peaks was indicated by small crystal size, and the crystal size was found to be about 9 ± 2 nm [58]. Ali Ebrahimi Fard et al. synthesized the Triethylene-glycol modified Fe3O4 nanoparticles by thermal decomposition method. XRD data showed that the Miller indices were found to be (2 2 0), (3 1 1), (2 2 2), (4 0 0), (4 2 2), (5 1 1), (4 4 0), and (5 3 3). These patterns resulted the prepared Fe3O4 nanoparticles have cubic spinel structure, and it did not consisted of nil impurities with extremely high crystalline particles. These results were in good unity with the diffraction patterns of bulk magnetite material [59]. Table 1 shows the iron oxide nanoparticles and their physical properties.

Ming et al. prepared the magnetic Fe3O4 nanoparticles and it found near to the core magnetite with face-centered cubic structure characterized by XRD [68]. Rahmatollah et al. observed the XRD pattern of magnetite bromochromate and concluded that six diffraction peaks of about (220), (311), (400), (422), (511), and (440) were in accordance with the standard magnetite nanoparticles. The intense and sharp peak revealed that the magnetite nanoparticles were crystalline in nature and the average size of reflection plane (311) was about 42 nm [69].

2.3 EDS Analysis of Fe3O4 Nanoparticles

Energy-dispersive spectrometer (EDSs) employed the pulse height analysis which was giving output pulses proportional in height to the X-ray photon energy used in conjunction with a pulse height analyzer (in this case a multichannel type). A solid state detector was used in these spectrometers because of its better energy resolution. Incident X-ray photons caused ionization in the detector and produced an electrical charge amplified by a sensitive preamplifier located close to the detector. Both the detector and pre-amplifier were cooled with liquid nitrogen to minimize the electronic noise. EDS analysis was used for the elemental analysis or chemical characterization of any material. The Fe3O4 nanoparticles were synthesized by Hongwei et al. using co-precipitation method and coated with NiS characterized by EDS. It was concluded that a small amount of Ni and S was equally distributed on the surface of synthesized Fe3O4 nanoparticles [70].

Lesbayev et al. prepared magnetite nanoparticles by liquid phase chemical condensation method. The elemental percentage composition of O as 25.70% and Fe as 74.30% and no other peaks related with any impurity have been detected in the FESEM-EDS. A sharp peak of Fe was observed at 6.7 keV, and two other peaks around 0.8 and 7.3 keV were found to be observed. A single peak was observed at 0.5 keV for oxygen atom [71]. Cheera et al. synthesized the Fe3O4 nanoparticles using extract of Pistum sativum and it was an ecofriendly method. The prepared PS-Fe3O4 nanoparticles were characterized by EDS for elemental composition analysis. The deep root observed that the elemental iron present in the Fe3O4 nanoparticles. A high intensity peak was observed for Fe at 6.2 keV with other peaks of Fe and there were no other elements observed [48].

2.4 FT-IR Analysis

The energy of most molecular vibrations corresponded to the infrared region of electromagnetic spectrum. The molecular vibrations were detected and measured by either in an infrared spectrum or indirectly Raman spectrum. FT-IR was used to study the surface groups of the assynthesized magnetic nanoparticles, and the achievement of the bonding result was illustrated by the FT-IR spectra. FT-IR was used to identify the organic, polymer and certain inorganic compounds, and the molecular components with its structure efficiency. Peng an et al. prepared the dopamine (DA)-coated Fe3O4 nanoparticles by ligand exchange of oleic acid (OA) on Fe3O4 nanoparticles and characterized. In FT-IR analysis, the characteristic band due to OA-Fe3O4 was observed in the region at 2920 cm−1 and at 2851 cm−1. The stretching frequencies such as 1524 cm−1 and 1409 cm−1 were indicated two carboxylate groups chemisorbed in Fe3O4 nanoparticles. DA-Fe3O4 showed the absorption band at 1616 cm−1 due to –NH stretching, benzene C–C stretching at 1485 cm−1, and phenolic –OH at 1264 cm−1. All the peaks assigned to OA- Fe3O4 disappeared in DA-Fe3O4 which has been showed the ligand exchange [72].

Fe3O4 magnetic nanoparticles (MNP), tannic acid–modified Fe3O4 magnetic nanoparticles (TN-MNP), and trypsin-tannic acid-Fe3O4 magnetic nanoparticles (TTA-MNP) were prepared by Keziban et al. and characterized by FT-IR studies. The peak at 1706 cm−1 confirmed the –C=O group. The characterized band for tannic acid group was confirmed by –O–H or –C–H stretching frequency observed at 2925 cm−1 and 2860 cm−1. The broad band was observed at 3600–3100 cm−1 due to the phenolic –O–H stretching and methylol group present in tannic acid. The stretching vibration at 1000–1700 cm−1 and 3600–3100 cm−1 was due to the presence of trypsin enzyme and the presence of phenolic group in TTA-magnetite nanoparticles. The range of 3600–3100 cm−1 belonged to the free hydroxyl group present in tannic acid magnetite nanoparticles which has not been participated with the trypsin enzyme [73]. Superparamagnetic magnetite nanoparticles were synthesized by Chengliang et al., and the nanoparticles were characterized by FT-IR analysis where Fe–O bonds stretching band observed at the peak at 557 cm−1. Additionally, the N–H stretching vibration and N–H bending vibration have showed two bands at 3445 cm−1 and 1640 cm−1 respectively. The peaks at 634 cm−1 and 582 cm−1 showed the characteristic absorption bands of maghemite (γ-Fe2O3), and there were Fe–O frequency deformations in the tetrahedral and the octahedral sites. Magnetite nanoparticles showed an absorption line in the range of about 572–582 cm−1 due to the presence of stretching of Fe–O in the tetrahedral sites [74].

Ali et al. prepared the iron oxide nanoparticles coated with carboxyl-functionalized PEG (polyethylene glycol) via dopamine (DPA) linker, and the prepared nanoparticles were characterized by FT-IR. Due to the stretching vibration frequency of Fe–O bonds in Fe3O4, absorption peak was observed at 567 cm−1. After the process of carboxylation of PEG, COOH group has replaced all the OH groups present in the polymeric chain. Then, the polymer was precipitated using hexane and was dried in an oven to evaluate the PEG diacid. The peak value of 1725 cm−1 was related with acidic C=O, indicating the carboxylation of PEG has been done effectively. The IR spectrum of the coated Fe3O4 nanoparticles has the peak value of 1560 cm−1 significant to the stretching vibration of acidic C=O. These results confirmed the acidic group present on the coated nanoparticles. In the IR spectrum of PEG diacid, the broadening was observed due to the presence of dopamine aromatic ring. Additionally, the C–O–C bond and asymmetric stretching of CH bond showed the absorption peaks at 1105 and 2925 cm−1 respectively. Also, the bending vibrations of CH2 group have been observed at a band of 1427 cm−1. The FT-IR spectrum confirmed the carboxylated polyethylene glycol (PEG-COOH) was successfully grafted onto the Fe3O4 nanoparticles surface [75]. Amine-functionalized Fe3O4@C nanoparticles were synthesized by solvothermal process, and the stretching vibration of the primary amine (–NH2) group was observed at 3410 cm−1 with an intense and broad absorption band of Fe3O4@C nanoparticles. The C–N stretching vibration band was at 1365 cm−1 and the C–O band observed was at 1455 and 1610 cm−1 for symmetric and anti-symmetric stretching vibrations. The –CONH2 and C–NH2 groups were present in large amount shown by the results and were covalently bonded to the carbon framework in the Fe3O4@C nanoparticles. The magnetic nanoparticles were observed and showed the characteristic absorption peak at round 580 cm−1 [76].

2.5 Raman Spectra of Fe3O4 Nanoparticles

Raman spectrum has been used as a supportive tool to differentiate the crystal phases and to identify the molecular vibrations of the Fe3O4 nanoparticles. Cheera et al. synthesized the Fe3O4 nanoparticles using extract of Pistum sativum, and it was a poor scatterrer of Raman spectra where the samples of iron oxide nanoparticles were kept under low laser powers to undergo phase transformation. The synthesized PS-Fe3O4 nanoparticles have showed the spectrum at 668 cm−1 for A1g, 538 cm−1 for T2a, 306 cm−1 for Eg, and 139 cm−1 for T2g for the FCC structure of PS-Fe3O4 nanoparticles [48]. Prasad et al. prepared the Fe3O4 nanoparticles by green synthesis using Ridge gourd as a starting material, and it showed a peak at 670 cm−1 for A1g is considered as a large peak, and 538 cm−1 for T2a, 303 cm−1 for Eg, and 138 cm−1 for T2 were the peaks observed for FCC structure of RG-Fe magnetite nanoparticles [49].

2.6 SEM Analysis

SEM is one of the most widely used techniques used for the characterization of nanomaterials, nanostructures, and the resolution of SEM approaches in a few nanometers. SEM is used to confirm the crystal shape, surface morphology, dispersed and agglomerated nanoparticles, surface functionalizations, and absolute particle size. It also provides the chemical composition information near the surface. Yong et al. synthesized the magnetic Fe3O4 nanoparticles via co-precipitation method, and SEM analysis showed the Fe3O4 nanoparticles have the crystalline nature with rod-like structure, when prepared in the presence of magnetic field. Fe3O4 nanoparticles were prepared in the absence of magnetic field by co-precipitation method and showed the spherical structure observed by SEM [77]. Aldahir et al. prepared the Fe3O4-TMSPT-ATM by magnetite nanoparticles coated with 3- (trimethoxysilyl)-1-propanethiol (TMSPT) and modified with 2-amino-5-mercapto-1, 3, 4-thiadiazole (AMT) as a modifier. SEM analysis determined the particle size for about 114 and 149 nm with homogeneous distribution with the cubic shape of the Fe3O4 nanoparticles [78].

The iron oxide nanoparticles were synthesized using co-precipitation method by Keziban et al. The nanoparticles obtained by this method were black in color and magnetic powder in nature. SEM image of iron oxide nanoparticles revealed the heterogeneous morphology without porosity of tannic acid (TA)-MNPs and (tannic acid-trypsin) TTA-MNPs which has the particle size approximately less than 5 μm. The prepared MNPs, TA-MNPs, and TTA-MNPs were having the sizes less than 100 nm, and the SEM images were not obtained obviously in lower size. The alteration of magnetite nanoparticles produced the changes in the particle size [73]. Covalent immobilization of trypsin to modify magnetite nanoparticles by solvothermal method and the morphologies of the Fe3O4, Fe3O4-TA and Fe3O4-TA-TR were characterized. SEM images showed a characteristic low magnification of the Fe3O4. It has a cauliflower-like magnetite with agglomerate structures with the particle size approximately less than 500 nm due to the magnetic interaction between the particles. After the TA modification, the size of the agglomerate nanoparticles was found to be decreased owing to the fact that TA was coated on nanoparticles by reducing the magnetic interaction that inhibited the agglomeration. Also, trypsin was binded because enzyme immobilization made the Fe3O4-TA as a slightly bigger material [79].

Fe3O4 nanoparticles were prepared by co-precipitation method. While using the ultrasound waves, the nanoparticles were functionalized by three types of PEG, and the morphology of these nanoparticles was characterized by SEM. SEM images of Fe3O4 nanoparticles showed the uniform size of Fe3O4@Cs-sPEG and Fe3O4@Cs-PEG2 nanoparticles and spherical in shape. When it was modified with chitosan, there was spherical morphology with no aggregation found. The nanoparticles were found to be the average diameter around 45 nm suitable size for the drug delivery systems [80]. The fiber composite magnetite nanoparticles were synthesized by liquid phase chemical condensation method. The obtained nanomaterials were found to be porous in structure, and the pores were distributed evenly with the diameter of about 5 to 10 μm [71]. Magnetite nanoparticles were prepared by Aldahir et al. using the microwave-solvothermal method. In this method, the magnetite nanoparticles were coated with 3- (trimethoxysilyl)-1-propanethiol (TMSPT) and modified with 2-amino-5-mercapto-1, 3, 4-thiadiazole (AMT). The particle size was around 25 μm with agglomeration connected to a high magnetic saturation. The distribution of particles was identified to be homogeneous with an obvious particle size between 114 and 149 nm. The magnetic nanomaterial showed the cubic shape determined by SEM [78].

2.7 TEM Analysis of Fe3O4 Nanoparticles

TEM was used as a tool to determine the grain size, particle morphology, second-phase particles, size distribution, dislocations, density variations, etc. One of the specific advantages of TEM showed the high magnification range of functional materials. Yang et al. reported the pure Fe3O4 was aggregated due to its nanosize, and poly (GMA-MATAC) grafted to Fe3O4 nanoparticles showed the change in particle size of Fe3O4 nanoparticles for about 200–400 nm with well dispersion. This fact has been explained by electrostatic repulsion force and steric hindrance present in the surface of Fe3O4 nanoparticles [51]. Citric acid–coated Fe3O4 nanoparticles and Fe3O4/Au composite nanoparticles were synthesized by Yan et al. using co-precipitation method. The TEM results showed the average particle size of 10 nm for Fe3O4/Au composite nanoparticles, and it was darker than citric acid–modified Fe3O4 with the diameter of about 10–30 nm [81]. Jie Zhu et al. synthesized the Fe3O4 magnetic nanoparticles, and cyclodextrin (CD) magnetic nanoparticles by electrochemical method showed the spherical or ellipsoidal shape for Fe3O4 magnetic nanoparticles and for cyclodextrin (CD) magnetic nanoparticles also. Fe3O4 magnetic nanoparticles have been dispersed uniformly, and somehow, it has been agglomerated due to the lack of surfactants. The average size for Fe3O4 nanoparticles and cyclodextrin (CD) magnetic nanoparticles was confirmed to be 10 nm and 16 nm respectively [82]. Highly water-dispersible surfactant-stabilized magnetic Fe3O4 nanocarriers (SMNCs) were prepared by Bijaideep et al. and were found to be 10 nm with roughly spherical in shape when characterized [65].

Mustafa et al. synthesized the electro-synthesized coated and uncoated magnetite nanoparticles showing the uncoated nanoparticles were agglomerated with the average size identified to be 10 nm. EDTA capped magnetite nanoparticle confirmed to be spherical in shape with the diameter found to be about 15 nm. It showed the less agglomeration due to EDTA capped with core magnetite nanoparticle for better dispersion [60]. Superparamagnetic magnetite nanoparticles were synthesized by Chengliang et al., and the Fe3O4 nanoparticles showed irregular shape with the diameter of about 10 nm [74]. Shete et al. synthesized the CS-OA-Fe3O4 nanoparticles by alkaline precipitation and showed the bare Fe3O4 nanoparticles were extremely agglomerated with the particle size of about 22.87 nm, while CS-OA-coated nanoparticles were finely dispersed with the particle size of about 16.574 nm. Bare Fe3O4 nanoparticles have showed the strong dipole-dipole interaction which led to the high particle size of the magnetite nanoparticles. After coating, non-magnetic layer was formed so that the particle size was decreased for the coated Fe3O4 nanoparticles [57]. Ali Ebrahimi Fard et al. synthesized the triethylene-glycol modified Fe3O4 nanoparticles by thermal decomposition method. The prepared nanoparticles revealed the spherical morphology with average diameter nanoparticles of 11 ± 3 nm and the particle size distribution exposed a narrow distribution for synthesized nanoparticles [59].

2.8 Mossbauer Spectra of Fe3O4 Nanoparticles

Mossbauer technique was helpful to identify the iron state in the functional materials and widely employed to study the fine magnetic particles to find information about the electronic, structural, and magnetic properties of magnetic particles. Fe3O4 magnetic nanoparticles were coated with oleic acid (Fe3O4-OA-MN), and polyethylene glycol (Fe3O4-PEG-MN) was synthesized using co-precipitation method by Runa et al. Mossbauer spectra of Fe3O4 nanoparticles revealed in hyperfine splitting, two sextets with doublet peaks of 47 and 43 Tesla for Fe3O4 magnetic nanoparticles was observed. For Fe3O4-OA-MN, hyperfine splitting has been decreased when compared with Fe3O4, and isomeric shift was about 0.31 to 0.45 mm s−1. For Fe3O4-OA-MN, the quadrapole splitting confirmed to be zero and the quadrapole splitting was found to be 0.20 mm s−1 and the spectra of Fe3O4-OA-MN and Fe3O4-PEG-MN were comparable [83].

2.9 VSM Analysis of Fe3O4 Nanoparticles

The magnetic moment of the Fe3O4 nanoparticles with high precision was determined using vibration sample magnetometer. Dopamine (DA)-coated Fe3O4 nanoparticles were synthesized by ligand exchange of oleic acid (OA) on Fe3O4 nanoparticles. Dopamine was found to have high magnetization of 72.87 emu/g due to lower weight, and the paramagnetic property was detected for both nanoparticles by remanent value. DA-Fe3O4 showed the good dispersity confirmed by introducing the external magnetic field [73].

Using the modifiers such as 3-(trimethoxysilyl) propyl methacrylate (MPTMS), 3-(triethoxysilyl) propyl methacrylate (MPTES), and triethoxyvinylsilane (VS), Fe3O4 nanoparticles were synthesized by Ceren et al. using co-precipitation method. The magnetic properties of Fe3O4 and modified Fe3O4-MPTMS were measured by VSM at room temperature. The saturation magnetization values were identified to be 58.87 emu/g and 58.49 emu/g for Fe3O4 and modified Fe3O4-MPTMS respectively. There was no coercivity present in curve showed the superparamagnetic behavior present in the Fe3O4 nanoparticles. The VSM results of Fe3O4 nanoparticles showed the surface modification which did not changed the magnetic properties [84].

The magnetic properties of prepared Fe3O4 and Fe3O4 @ SiO2@PPh3@[CrO3F]− were measured at room temperature. Fe3O4 nanoparticles had the 53.35 emu/g value for saturation magnetization, and Fe3O4 @ SiO2@PPh3@[CrO3F]− was found to have 41.4 emu/g of saturation magnetization with superparamagnetic property [85]. A series of Fe3O4 nanoparticles were synthesized using various surfactants by microemulsion method. The VSM results showed the saturation magnetization (MS) values of nanoparticles were around equal to the vacancy numbers and any increase in vacancy number MS value has started to decrease which led to the crystal perfection of Fe3O4 nanoparticles with the influence of MS. Defect in any crystal led to the decrease in the MS value. The presence of coercivity and remanence showed the non-superparamagnetic behavior of reported Fe3O4 nanoparticles [50]. Citric acid–coated Fe3O4 nanoparticles and Fe3O4/Au composite particles were synthesized by Yan et al. using co-precipitation method. The magnetic properties of both the iron nanomaterials were measured by VSM. At 300 K, there was no coercivity or remanence showing the superparamagnetic properties. Citric acid–coated Fe3O4 and Fe3O4/Au composite nanoparticles showed the saturation magnetization value for about 67 and 30.2 emu/g respectively [81]. Figures 4 and 5 show the iron oxide nanoparticles and their magnetic property and optical property.

2.10 TGA/DTA Analysis

TGA/DTA analysis was used to determine the thermal stability of fabricated iron nanocomposite. This technique provided the valuable data about the thermal stability of the prepared iron oxide nanoparticles, the bonding strength of the coatings with their surface, and quantitative proof on the structure of the coating agents. The forceful proof of layer-by-layer assembly process was provided by TGA/DTGA results, assigned to the Fe3O4-NP, Fe3O4-NS (nanoreserviors), and pure NE (nettle extract). At the temperature region from 25 to 150 °C, there was a weight loss due to water adsorption of Fe3O4 nanoparticles surface and there was a loss of 2.81%. A weight loss due to the presence of water molecules bounds with Fe3O4 nanoparticles surface at the temperature region of about 1.87%. Fe3O4 nanoparticles showed the total mass loss was found to be 6.45%. The remaining weight loss at the temperature of 600 °C was due to the conversion of phase transition of Fe3O4 to stable FeO. There were three main weight loss steps shown by TGA/DTGA plots of nanoparticles. The temperature ranged from 25 to 150 °C, and a weight loss of about 9.22% was due to the loss of water present in the Nettle structure. In a temperature region of 150–400 °C, there was a weight loss of 36.8% in the decomposition of oxygen-containing groups. The DTGA plot of nanoparticles showed a broad peak consisting of four peaks, and there was intensive and sharp peak at 250 °C and three less intensive peaks at 195, 320, and 370 °C. At temperature higher than 500 °C, there was a weight loss due to the decomposition of aromatic rings. There was a weight loss peak for Fe3O4 nanoreserviors observed at 150–300 °C due to the decomposition of NE showing the well loading of inhibitor into the Fe3O4-NS. There was another sharp loss peak at 475–525 °C which led to the thermal decomposition of PANI (polyaniline) molecules adsorbed on the Fe3O4-NP. The above results validated the precipitation of PANI and NE effectively on the Fe3O4-NP surface [86].

The surface property of magnetic nanoparticles was grafted by mono-6-deoxy-6-(p-tolylsulfonyl)-cyclodextrin (6-TsO-CD) and the TGA curves of Fe3O4-MNPs, APTES-MNPs (γ-Aminopropyltriethoxysilane), and CDMNPs (cyclodextrins). At 130 °C, there was a weight loss curve of Fe3O4-magnetic nanoparticles due to the evaporation of absorbed water and there was a slight weight gain from 130 to 253 °C due to the oxidation of Fe3O4 with the total weight loss of Fe3O4-MNPs of about 4.2%. The weight loss of about 10.5% at wide temperature range of 230–600 °C due to the role of APTES modified Fe3O4-MNPs with the thermal decomposition of the 3-aminopropyl groups. Upon heating in Ar atmosphere, there were two major weight loss steps. Below 200 °C, there was a loss of residual water adhering to the Fe3O4 nanoparticles surface and was adsorbed in the CDs cavities so the weight loss was quite slow. From 200 to 760 °C, a drastic drop loss occurred owing to the thermal decomposition of CDs moieties and other organic structure for the procedure. The better thermal stability of CDs immobilized magnetic nanoparticles because of its cross-linked nature [82].

PEG diacid–grafted Fe3O4 nanoparticles were prepared by co-precipitation method and characterized by thermogravimetric analysis. At 100–200 °C, the weight loss of about 5% owing to desorption of water molecules from the surface due to the water withdrawal was hold back. There was a weight loss due to the removal and desorption of immobilized polymeric matrix along with dopamine in the time frame of 200–600 °C. The total weight loss of PEG diacid–grafted Fe3O4 nanoparticle was about 22% [75]. Fe3O4 nanoparticles modified with gallic acid (MNPs-GA), trypsin immobilization, and protein assay (MNPs-GA-TR) were synthesized and estimated by TG analysis. The TG analysis confirmed the weight loss for magnetic nanoparticles was about 3.57% owing to the loss of water residue. At the temperature range of 40 °C to 900 °C, there was a partial break down of the intermolecular bonds with the successive releasing of volatile fractions led to 5.6% of weight loss occurred for MNPs-GA. In a wide temperature range between 40 and 900 °C, the degradation of gallic acid and trypsin molecules has occurred with the weight loss of about 8.6% [87]. Figure 6 shows the TGA curve of PEG diacid–grafted Fe3O4 nanoparticles.

Magnetite Fe3O4 nanoparticle was prepared by Teena et al. using co-precipitation method and characterized by TGA. The weight loss of ferric oxide nanoparticles in the temperature test range on the surface was due to the process of physically adsorbed water or chemically attached hydroxyl groups. Other absorbed species like alkaline counter ions coming from the ammonium hydroxide solution used for the co-precipitation method undergone the weight loss beyond 200 °C [88].

3 Applications

3.1 Removal of Toxic Metal Ions from Aqueous Solutions

Figure 7 shows the application of iron oxide nanoparticles. Domestic and industrial wastewaters discharged into the environment contained various toxic metal ions. These metal ions were not eco-friendly and could not be metabolized by the environment and have the tendency to accumulate in living organisms causing several diseases and disorders. The toxic metals were not destroyed, but they only have been diluted or transformed [89]. Lead and cadmium were the most toxic metals among the various heavy metal ions in the environmental surroundings. The allowable limits of lead and cadmium in wastewater were confirmed to be 0.015 mg/L and 0.01 mg/L respectively [90]. These heavy toxic metal ions have created severe health problems to human beings and animals when the intake was above depicted threshold concentrations. When the consume level has been raised, there was a encephalopathy due to lead, cognitive impairment, behavioral disturbances, kidney damage, anemia, toxicity to the reproductive system, and due to cadmium, nephrotoxic effects, and bone damage–related problems. Hence, there was a need for appropriate method to remove toxic metal ions in the environment [91]. In advanced nanotechnology, magnetic nanomaterials have been combined with magnetic separation, and nanotechnology showed the fine recital in the removal of heavy metal ions from various effluents of the industries [92]. Magnetite (Fe3O4) was a ferromagnetic compound with maximum magnetic properties among derivatives of metallic compounds [93]. ID-g-PGMA-MAn composite was functionalized and first cross-linked with modified magnetic Fe3O4 with amine groups. It was second cross-linked using propylenediamine to enhance the resistance of adsorbent against acid, alkali, and chemicals. The ability of this nanocomposite was studied for removing the Pb (II) and Cd (II) and phenol pollutants from water and wastewater at different conditions. The effect of metal ion concentration on the adsorption process by the magnetic nanocomposite was studied at different concentrations such as 1–40 mg/L. It was reported that the metal ion concentration has increased the removal percentage of metal ions up to 10 mg/L for Pb (II) and Cd (II) ions. When the concentration of metal ions was increased, there was a fall in the removal percentage and could be owed to the saturation of the functional groups in adsorption sites of the adsorbent with the Pb (II) and Cd (II) ions at higher concentrations. There was a need to determine the ions’ adsorption process by magnetic adsorbent or not for the Langmuir type adsorption process. From this process, RL value was calculated and favored the adsorption of heavy metal ions, i.e., Pb (II) and Cd (II). After the removal of toxic metal, a useful metal chelated nanocomposite was obtained. It was a square planar complex which adsorbed the phenoxide ions [94]. Figure 8 illustrates the removal of toxic metal ions and phenol by metal chelated nanocomposite.

3.2 Degradation of Methylene Blue

The most important interest of researchers from chemistry, industry, medicine, physics, biology, and material science towards nanotechnology was to promote the synthesis methods to be easier and cleaner. At present, iron oxide nanoparticles were highly inspiring in research point of view and were considering the dependence of the magnetic properties such as shape, size, composition, surface, and interaction [95]. The green synthesis of iron oxide nanoparticles exhibited the ferromagnetic nature and one of the properties such as catalytic performance of RG-Fe magnetic nanoparticles was studied by UV-vis spectroscopy. The reduction of methylene blue by sodium borohydride in aqueous medium reacted very slowly without the presence of any catalyst. When the reduction reaction was carried out very rapidly in the presence of RG-FeMNPs as a catalyst using Ridge gourd, the UV-visible spectrum was used to fix on the catalytic reduction of the methylene blue molecular structure before and after the removal process of toxic metal ions.

The characteristic absorption band was observed at 650 nm for methylene blue used to study the efficiency of adsorption on RG-FeM nanoparticles. After 30 min, RG-FeM nanoparticles in the presence of NaBH4 have removed the ~ 96% of the whole methylene blue from the solution better than without the usage of catalyst, and it removed only 13% of methylene blue from the effluent solution. A peak at 650 nm gave the fact that it disappeared within 30 min after adding the RG-FeM nanoparticles as a catalyst. This was due to the presence of double bond cleavage in methylene blue. The observation revealed that comparing with NaBH4 spectrum, the intensity of methylene blue was decreased slowly [49]. Figure 9 reveals the adsorptive property of various types of iron oxides based on its synthesis.

3.3 Polymer-Grafted Magnetic Nanoparticles for Lipase Immobilization

Nowadays, superparamagnetic iron oxide nanoparticles have proved great potential applications in many biological fields like bioseparation, tumor hyperthermia, magnetic resonance imaging (MRI), diagnostic contrast agents, magnetically guided site-specific drug delivery agents, and biomolecules immobilization. The purpose for biomolecules immobilization based on the solid-phase magnetic feature has the ability to achieve a fast and easy separation and to recover the reaction medium in an external magnetic field [13, 96]. The most attractive method in recent days was polymers grafting of magnetic nanoparticles used to analyze the polymer chains that offered flexibility and diversity to control the chemical composition and functional groups on the surface of nanoparticles [97]. Graft polymerization of glycidyl methacrylate (GMA) and methacryloxyethyl trimethyl ammonium chloride (MATAC) onto the surface of modified Fe3O4 nanoparticles led to functionalized superparamagnetic particles, and the prepared nanoparticles were used to immobilize the lipase. The surface of vinyl triethoxy silane (VTES) modified-Fe3O4 nanoparticles was grafted by GMA and MATAC and induced the large amount of positive electrical charges and reactive epoxy groups on the surface. VTES modified-Fe3O4 nanoparticles have immobilized the lipase, and the activity recovery was assayed by hydrolysis of olive oil, and the maximum activity recovery was up to 70.4% [98]. The nanoparticle was added to definite pH containing the lipase solution. The lipase molecule was first adsorbed and immobilized onto the nanoparticles and the reaction between epoxy groups of the particles and the amino groups. For free lipase and immobilized lipase, thermal stability was determined under some conditions using olive oil. When the temperature was above 40 °C, the immobilized lipase was not inactivated. Also, the temperature was increased, and the activity of free enzyme was decreased. The immobilized lipases at a higher reaction temperature showed the catalytic activities and called as reusability in applications. After a catalysis run, the immobilized lipase was washed with phosphate buffer (0.1 M, pH 7.0) and reintroduced into a fresh olive oil solution for another hydrolysis at 37 °C. It was experimented that the immobilized lipase has still retained its 70% of activity for after five reuses [51].

3.4 Detection of Zn2+ in Soil Samples

For heavy transition metal (HTM) ions and their detections, particular concentration has been focused. Exposure to HTM through different pathways led to the accumulation in human body caused severe illness [99]. In particular, zinc is an essential element and it plays an important role in biological processes (e.g., protein synthesis, neuro transmission, and signal transduction) [100]. The accumulation of zinc in the human body led to the fatal organ failure, copper deficiency, stomach cramps, skin irritations, vomiting, nausea, and anemia [101]. Thus, the detection and removal of Zn2+ in contaminated samples were of major interest. Fluorescent sensors were reported as a powerful tool for detecting the metal ions in water and biological samples. The fluorescent sensors for Zn2+ have large attention, due to the biological importance of Zn2+ ions. Mostly, the sensors were exhibited a poor selectivity for Zn2+ ions than the other metal ions. There was difficulty in differentiating Cd2+ and Zn2+ ions, due to their similar binding properties. Generally, fluorescent molecules were linked to Zn2+ chelators such as dipicolylamine (DPA), bipyridine, and cyclic polyamines. [102, 103]. Dopamine-naphthalimide-dipicolylamine was immobilized onto the surface of iron oxide nanoparticle to prepare a hybrid nanomagnet 1- Fe3O4 which has the ability to detect Zn2+ in soil. The soil was treated with zinc nitrate and incubated for 30 days for the testing of Zn2+. Then, the incubated soil was treated with concentrated nitric acid and extracted. The quantitative analysis of Zn2+ was tested by the extract from the contaminated soil and evaluated by fluorescence change of 1-Fe3O4. The concentration of Zn2+ was found to be 6.3 μM. The value was nearly comparable to the obtained value from ICP-MS (5.9 μM). Thus, 1-Fe3O4 showed the potential for the qualitative and quantitate detection of Zn2+ present in contaminated soil. Nanomagnet 1-Fe3O4 was used for the selective detection and removal of Zn2+ from a soil sample and utilized as a capable medium for detecting the Zn2+ in various environmental samples [104].

3.5 Removal of Heavy Metal Ions

Magnetite (Fe3O4)-mesoporous silica (mSiO2) core-shell nanoparticles were effective and attractive heavy metal ion adsorbents. The results of copper ion adsorption indicated the removal percentage of samples having different pore sizes such as S1-S3 after 50 min was found to be 98.6%, 96.6%, and 89.4%. The removal capacity of S1-S3 was about 84.4, 80.5, and 72.7 mgg−1 respectively. All reported studies analyzed the removal of heavy metals using magnetic nanoadsorbents, and the removal capacity was superior to the other materials [105, 106]. Amino-functionalized ferrimagnetic Fe3O4-mSiO2 nanoparticles having higher Ms and susceptibility values than superparamagnetic nanoadsorbents have the tendency to capture larger amounts of heavy metal ions in a shorter time. The larger specific surface area and pore size of Fe3O4-mSiO2 nanoparticles were found to be major contributions of removal of heavy metal ions [107]. The reusability of the nanoparticles has been established in the view of their valuable use. By measuring the removal efficiency of copper ions after acid treatment, the reusability of Fe3O4-mSiO2 nanoparticles was evaluated. Considering sample S1 as a delegate example, the primary removal efficiency was found to be 98.7%, and after acid treatment, the value was decreased to 85%. Finally, it was decreased to 77.2% which confirmed the reusability of Fe3O4-mSiO2 nanoparticles. The decrease in efficiency was due to the strong interaction between the amine groups, and the chelating Cu2+ ions have not been desorbed enough. The amine groups present in the particles weakly bonded to the SiO2 surface could be weak to the acid treatment. It showed the removal of cadmium and zinc ions using S1-S3 [108]. The removal efficiency of three metal ions was given in the following order such as Cu2+ > Cd2+ > Zn2+. In general, the −SH group was used to adsorb metal ions such as Hg2+, Ag2+, and Pb2+, through Lewis acid-base interactions, and –COO– groups were used to support the adsorption of ions such as Cu2+, Pb2+, and Cd2+ by weak metal-carboxylate interactions. On the other hand, −NH2 groups were well known to bind selectively to Cu2+, Co2+, Ni2+, Pb2+, Cr2+, and Cd2+ due to their strong metal complexing capability. Hence, S1 has showed high removal efficiency for Cu2+, Cd2+, and Zn2+ [92, 109]. Figure 10 shows the reusability of Fe3O4-mSiO2 nanoparticles.

3.6 Removal of Dyes by Ultrasound Assisted Adsorption

Dyes are the pollutants having the resistant against physical, chemical, and biological treatment processes, and accordingly, their presence in water caused some difficultly and hazardous which root for the researchers to safe treatment of such pollutants [110, 111]. Disulfine blue (DSB) extensively used in wool, silk, carbon paper, cosmetics, and leather activities caused several side effects to eye and skin sensitivity [112]. This inhalation led to the effects of digestion and respiratory tract irritation. Rhodamine 123(R123) was a fluorescent laser dye with high solubility in water which functioned as a tracer in water pollution and aerial pesticide spraying studies and colorant (coloring agent) in drugs, cosmetics, textiles, food stuffs, and inks. When it was swallowed by human and animals, it causes irritation to the skin, eyes, and respiratory tract [113]. Au-Fe3O4 nanoparticles-loaded on activated charcoal (AuFe3O4-NPs-AC) was synthesized and used in water treatment to remove the rhodamine123 (R123) and disulfine blue (DSB) dyes by ultrasound-assisted adsorption. The response surface methodology (RSM) surfaces of DSB and R123 were represented the dye removal percentage versus significant variables. When R123 concentration was raised, DSB removal percentage was decreased automatically. This was due to the increase in ratio of dye molecule to offer surface area for adsorption. It denoted the removal percentage and gradual increased by rising the pH. At low pH, the major event was the protonation of the AC functional groups and most likely, Fe3O4 was the adsorbent surfaces that got positive charge. There was a decrease in the DSB removal percentage due to the strong repulsive forces between the cationic dye molecules and adsorbent similar to that of R123. When increase in the initial pH led to deprotonation of the AC, adsorption sites and the OH and COOH corresponded to AC and adsorbed the DSB molecule through electrostatic interaction and/or hydrogen bonding. When there was higher initial dye concentration, the removal percentage of DSB dye was decreased. This was due to the increase in ratio of dye molecule to offer surface area for adsorption. There was a plot between the removal percentage changes versus the adsorbent dosage; dye removal percentage has been increased with increase in adsorbent led to the positive increase of mass. Considerable reduction in removal percentage at minor amount of Au-Fe3O4-nanoparticles-AC was attributed to higher ratio of dyes to the vacant sites of the adsorbent. The interaction of pH and R123 concentration with sonication time, R123 removal percentage significantly has the positive relation with sonication time. The rapid shift of dyes to the adsorbent surface admitted the fast equilibrium and confirmed the suitability and efficiency of ultrasound power as powerful tool for wastewater treatment. It has high available surface area and vacant site of adsorbent, enhancing the interface and driving force because of the rapid initial adsorption rate. Langmuir isotherm explained the formation of monolayer of adsorbate on the outer surface of the Au-Fe3O4-NPs-AC. The dyes R123 and DSB on Au-Fe3O4-NPs-AC could be well desorbed by 10 mL of acetonitrile solution. The adsorbent was recovered, and the reusability of AuFe3O4-NPs-AC was tested and examined for four adsorption-desorption cycles. There was no significant loss in the adsorption efficiency observed and the adsorption efficiency of the sixth cycle was reduced by 8.26% compared to that of the first cycle. The desorption capacities were excessive with desorption efficiency of more than 92%. It was concluded that the adsorbent was recycled for both dye adsorptions [114].

3.7 Catalytic Activity

2-amino-4H-chromenes was synthesized by condensation of aldehydes with malononitrile and resorcinol under ultrasound irradiation method. Figure 11 predicts the mechanism for synthesis of 2-amino-4H-chromenes. Using Fe3O4-chitosan nanoparticles as the heterogeneous catalysts, the reaction was carried out in a short period of time with the higher yield. The Fe3O4 acted as a Lewis acid and the electrophilic character of the aldehyde was increased by the free hydroxyl groups present on the surface of chitosan and could activate the carbonyl group of aldehyde. The nucleophilic property of the malononitrile was activated by the lone pairs of amino group present on the surface of chitosan. The intermediate 2-ethylidene malononitrile may be formed due to Knoevenagel condensation. In this reaction, the intermediate 2-((2,4-dihydroxy phenyl) (phenyl) (methyl)) malononitrile could occur due to Michael addition. An intramolecular cyclization was taken place in the intermediate 2-((2,4-dihydroxy phenyl)(phenyl)(methyl)) malononitrile to give cyclized product and the final product 2-amino-4H-chromenes was obtained. Reusability is the important property for any catalyst. After the reaction completion, ethyl acetate was added and the catalyst was removed by the external magnet. Then, the catalyst Fe3O4-chitosan nanoparticles were washed with ethyl acetate. It was dried and used for next cycle reaction without further purification when there was the same substrate. The reusability was checked for the catalyst and it could be reused for four cycles without any loss in its activity [67].

4 Conclusion

In this review, iron oxide nanoparticles have been studied as an exemplary magnetic material. Among the seven phases of iron oxide nanoparticles, Fe3O4 exhibited superparamagnetism, and it has inverse cubic spinel structure. Iron oxide nanoparticle was synthesized by various cost-effective methods. The advantages of the synthesis and the properties of iron oxide showed their sustainable and secured use to address the global environmental challenges. This paper reviewed the influence of modifiers on the morphology, structure, size, and optical properties of modified Fe3O4 nanoparticles. Fe3O4 nanoparticles showed essential applications in supercapacitor electrode materials, magnetic carriers for protein separation, and biomedical applications like targeted drug delivery and catalytic oxidation of alcohols. The catalytic activity of the material was maintained after reuse in several successive cycles of treatment.

References

Atkins, P.W., Overton, T.L., Rourke, J.P., Weller, M.T., Armstrong, F. A.: Inorganic Chemistry, 6th Edition. Oxford University Press, Great Britain (2014)

Hao, R., Xing, R.J., Xu, Z.C., Hou, Y.L., Gao, S., Sun, S.H.: Synthesis, functionalization, and biomedical applications of multifunctional magnetic nanoparticles. Adv. Mater. 22, 2729–2742 (2010)

Dave, S.R., Gao, X.H.: Monodisperse magnetic nanoparticles for biodetection, imaging, and drug delivery: a versatile and evolving technology. WIREs Nanomed. Nanobiotechnol. 1, 583–609 (2009)

Krishnan, K.M., Pakhomov, A.B., Bao, Y., Blomqvist, P., Chun, Y., Gonzals, M., Giffin, K., Ji, X., Roberts, B.K.: Nanomagnetism and spin electronics: materials, microstructure and novel properties. J. Mater. Sci. 41, 793–815 (2006)

Singh, V., Banerjee, V., Sharma, M.: Dynamics of magnetic nanoparticle suspensions. J. Phys. D. Appl. Phys. 42, 245006 (2009)

Hansen, M.F., Jonsson, P.E., Nordblad, P., Svedlindh, P.: Critical dynamics of an interacting magnetic nanoparticle system. J. Phys. Condens. Matter. 14, 4901–4914 (2002)

Guo, G.Y., Wang, Y.K., Chen, Y.Y.: Ab initio studies of the electronic structure and magnetic properties of bulk and nano-particle CeCo2. J. Magn. Magn. Mater. 272, e1193–e1194 (2004)

Dutta, P., Seehra, M.S., Thota, S., Kumar, J.: A comparative study of the magnetic properties of bulk and nanocrystalline Co3O4. J. Phys. Condens. Matter. 20, 015218 (2008)

Cornell, R.M., Schwertmann, U.: The iron oxides: structures, properties, reactions, occurrences and uses. Wiley, Weinheim (2003)

Wu, W., Xiao, X.H., Zhang, S.F., Zhou, J.A., Fan, L.X., Ren, F., Jiang, C.Z.: Large-scale and controlled synthesis of iron oxide magnetic short nanotubes: shape evolution, growth mechanism, and magnetic properties. J. Phys. Chem. C. 114(39), 16092–16103 (2010)

Zhang, Z., Boxall, C., Kelsall, G.H.: Photoelectrophoresis of colloidal iron oxides: 1. Hematite (α-Fe2O3). Colloids Surf. A Physicochem. Eng. Asp. 73, 145–163 (1993)

Wu, W., He, Q.G., Jiang, C.Z.: Magnetic iron oxide nanoparticles: synthesis and surface functionalization strategies. Nanoscale Res. Lett. 3, 397–415 (2008)

Gupta, A.K., Gupta, M.: Synthesis and surface engineering of iron oxide nanoparticles for biomedical applications. Biomaterials. 26, 3995–4021 (2005)

Kim, Y.S., Kim, Y.H.: Application of ferro-cobalt magnetic fluid for oil sealing. J. Magn. Magn. Mater. 267, 105–110 (2003)

Raj, K., Moskowitz, R.: A review of damping applications of ferrofluids. Trans. Magn. 16, 358–363 (2002)

Schwertmann, U., Cornell, R.M.: The iron oxides: structure, properties, reactions, occurrences and uses, 2nd edn. WILEY-VCH, Weinheim (2003)

Schwertmann, U., Cornell, R.M.: Iron oxides in the laboratory. Wiley-VCH, Wienheim (2000)

Lu, A.H., Salabas, E.L., Schuth, F.: Magnetic nanoparticles: synthesis, protection, functionalization, and application. Angew. Chem. Int. Ed. Engl. 46, 1222–1244 (2007)

Sun, S.H., Zeng, H.: Size-controlled synthesis of magnetite nanoparticles. J. Am. Chem. Soc. 124, 8204–8205 (2002)

Wang, Z.L.: Transmission electron microscopy of shape-controlled nanocrystals and their assemblies. J. Phys. Chem. B. 104, 1153–1175 (2000)

Xie, J., Xu, C.J., Xu, Z.C., Hou, Y.L., Young, K.L., Wang, S.X., Pourmond, N., Sun, S.H.: Linking hydrophilic macromolecules to monodisperse magnetite (Fe3O4) nanoparticles via trichloro-s-triazine. Chem. Mater. 18, 5401–5403 (2006)

Hou, Y.L., Gao, S., Ohta, T., Kondoh, H.: Linking hydrophilic macromolecules to monodisperse magnetite (Fe3O4) nanoparticles via trichloro-s-triazine. Eur. J. Inorg. Chem. 2004, 1169–1173 (2004)

Qi, H.P., Chen, Q.W., Wang, M.S., Wen, M.H., Xiong, J.: Study of self-assembly of octahedral magnetite under an external magnetic field. J. Phys. Chem. C. 113, 17301–17305 (2009)

Yang, H.T., Ogawa, T., Hasegawa, D., Takahashi, M.: Synthesis and magnetic properties of monodisperse magnetite nanocubes. J. Appl. Phys. 103, 07d526–07d529 (2008)

Karthikeyan, B., Loganathan, B.: Rapid green synthetic protocol for novel trimetallic nanoparticles. J. Nanopart. 2013, 1–8 (2013)

Zhou, J., Ao, J., Xia, Y., Xiong, H.: Stable photoluminescent ZnO@Cd(OH)2 core–shell nanoparticles synthesized via ultrasonication-assisted sol–gel method. J. Colloid Interface Sci. 393, 80–86 (2013)

Lehui, L., Kelong, A., Yukihiro, O.: Environmentally friendly synthesis of highly monodisperse biocompatible gold nanoparticles with urchin-like shape. Langmuir. 24, 1058–1063 (2008)

Satyavani, K., Gurudeeban, S., Balasubramanian, T.R.: Biomedical potential of silver nanoparticles synthesized from calli cells of Citrullus colocynthis (L.) Schrad. J. Nanobiotechnol. 9(43), 1–8 (2011)

Liang, J., Li, L., Luo, M., Wang, Y.: Fabrication of Fe3O4 octahedra by a triethanolamine-assisted hydrothermal process. Cryst. Res. Technol. 46, 95–98 (2011)

Alcala, M.D., Criado, J.M., Real, C.: Synthesis of nanocrystalline magnetite by mechanical alloying of iron and hematite. J. Mater. Sci. 39, 2365–2370 (2004)

Deepika, H., Jacob, L., Rajender, N.N.: A greener synthesis of core (Fe, Cu)-Shell (Au, Pt, Pd, and Ag) nanocrystals using aqueous vitamin C. ACS Sustain. Chem. Eng. 1, 703–712 (2013)

Roy, S., Das, T.K.: Plant mediated green synthesis of silver nanoparticles-a review. Int. J. Plant Biol. Res. 3, 1044–1055 (2015)

O’Handly, R.C.: Modern magnetic materials: principles and applications. Wiley-VCH, Weinheim (2000)

Ogielski, A.T., Morgenstern, I.: Critical behavior of three-dimensional Ising spin-glass model. Phys. Rev. Lett. 54, 928–931 (1985)

Saeedi, M.S., Tangestaninejad, S., Moghadam, M., Mirkhani, V., Baltork, I.M., Khosropour, A.R.: Magnetic nanoparticles supported manganese (III) tetrapyridylporphyrin catalyst via covalent interaction: a highly efficient and reusable catalyst for the oxidation of hydrocarbons. Polyhedron. 49, 158–166 (2013)

Zhang, H., Zhu, G.: One-step hydrothermal synthesis of magnetic Fe3O4 nanoparticles immobilized on polyamide fabric. Appl. Surf. Sci. 258, 4952–4959 (2012)

Farahani, M.M., Movassagh, J., Taghavi, F., Eghbali, P., Salimi, F.: Magnetite-polyoxometalate hybrid nanomaterials: synthesis and characterization. Chem. Eng. J. 184, 342–346 (2012)

Neel, L.: Magnetic properties of ferrite - ferrimagnetism and antiferromagnetism. Ann. Phys. 3, 137–198 (1948)

Joaquin, G., Gloria, S.: The Verwey transition - a new perspective. J. Phys. Condens. Matter. 16, R145–R178 (2004)

Senn, M.S., Loa, I., Wright, J.P., Attfield, J.P.: Electronic orders in the Verwey structure of magnetite. Phys. Rev. B. 85, 125119–1251123 (2012)

Tilaki, R.M., Iraji zad, A., Mahdavi, S.M.: Stability, size and optical properties of silver nanoparticles prepared by laser ablation in different carrier media. Appl. Phys. A Mater. Sci. Process. 84, 215–219 (2006)

Rao, C.N.R., Muller, A., Cheetham, A.K.: The chemistry of nanomaterials. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (2004)

Tresintsi, S., Simeonidis, K., Vourlias, G., Stavropoulos, G., Mitrakas, M.: Kilogram-scale synthesis of iron oxy-hydroxides with improved arsenic removal capacity: study of Fe(II) oxidation-precipitation parameters. Water Res. 46, 5255–5267 (2012)

Simeonidis, K., Kaprara, E., Samaras, T., Angelakeris, M., Pliatsikas, N., Vourlias, G., Mitrakas, M., Andritsos, N.: Optimizing magnetic nanoparticles for drinking water technology: the case of Cr (VI). Sci. Total Environ. 535, 61–68 (2015)

Pinakidoua, F., Katsikini, M., Simeonidis, K., Kapraraa, E., Paloura, E.C., Mitrakas, M.: On the passivation mechanism of Fe3O4 nanoparticles during Cr (VI) removal from water: a XAFS study. Appl. Surf. Sci. 360, 1080–1086 (2016)

Bhunia, P., Kim, G., Baik, C., Lee, H.: A strategically designed porous iron-iron oxide matrix on graphene for heavy metal adsorption. Chem. Commun. 48, 9888–9890 (2012)

Mi, F., Chen, X., Ma, Y., Yin, S., Yuan, F., Zhang, H.: Facile synthesis of hierarchical core-shell Fe3O4@MgAl-LDH@Au as magnetically recyclable catalysts for catalytic oxidation of alcohols. Chem. Commun. 47, 12804–12806 (2011)

Prasad, C., Yuvaraja, G., Venkateswarlu, P.: Biogenic synthesis of Fe3O4 magnetic nanoparticles using Pisum sativum peels extract and its effect on magnetic and methyl orange dye degradation studies. J. Magn. Magn. Mater. 424, 376–381 (2017)

Cheera, P., Karlapudi, S., Sellola, G., Ponneri, V.: A facile green synthesis of spherical Fe3O4 magnetic nanoparticles and their effect on degradation of methylene blue in aqueous solution. J. Mol. Liq. 221, 993–998 (2016)

Lua, T., Wanga, J., Yina, J., Wanga, A., Wanga, X., Zhanga, T.: Surfactant effects on the microstructures of Fe3O4 nanoparticles synthesized by microemulsion method. Colloids Surf. A Physicochem. Eng. Asp. 436, 675–683 (2013)

Yong, Y., Bai, Y., Li, Y., Lin, L., Cui, Y., Xia, C.: Preparation and application of polymer-grafted magnetic nanoparticles for lipase immobilization. J. Magn. Magn. Mater. 320, 2350–2355 (2008)

Cai, Y., Shen, Y., Xie, A., Li, S., Wang, X.: Green synthesis of soya bean sprouts-mediated superparamagnetic Fe3O4 nanoparticles. J. Magn. Magn. Mater. 322, 2938–2943 (2010)

Aslibeiki, B., Kameli, P., Manouchehri, I., Salamati, H.: Strongly interacting superspins in Fe3O4 nanoparticles. Curr. Appl. Phys. 12, 812–816 (2012)

Sun, J., Lin, C.: Superparamagnetic POT/ Fe3O4 nanoparticle composites with supported Au nanoparticles as recyclable high-performance nanocatalysts. Mater. Today Chem. 5(43–51), (2017)

Silva, V.A.J., Andrade, P.L., Silva, M.P.C., Bustamante, A., De Los Santos Valladares, L., Albino Aguiar, J.: Synthesis and characterization of Fe3O4 nanoparticles coated with fucan polysaccharides. J. Magn. Magn. Mater. 343, 138–143 (2013)

Yan, Z., Yuan, J., Zhu, G., Zou, Y., Chen, C., Yang, S., Yao, S.: A new strategy based on cholesterol-functionalized iron oxide magnetic nanoparticles for determination of polycyclic aromatic hydrocarbons by high-performance liquid chromatography with cholesterol column. Anal. Chim. Acta. 780, 28–35 (2013)

Shete, P.B., Patil, R.M., Tiwale, B.M., Pawar, S.H.: Water dispersible oleic acid-coated Fe3O4 nanoparticles for biomedical applications. J. Magn. Magn. Mater. 377, 406–410 (2015)

Cevik, E., Senel, M., Baykal, A., Fatih Abasiyanik, M.: Poly (glycidylmethacrylate-co-vinyl ferrocene)-grafted iron oxide nanoparticles as an electron transfer mediator for amperometric phenol detection. Curr. Appl. Phys. 13, 1611–1619 (2013)

Ebrahimi Fard, A., Zarepour, A., Zarrabi, A., Shanei, A., Salehi, H.: Synergistic effect of the combination of triethylene-glycol modified Fe3O4 nanoparticles and ultrasound wave on MCF-7 cells. J. Magn. Magn. Mater. 394, 44–49 (2015)

Aghazadeh, M., Karimzadeh, I., Ganjali, M.R.: Ethylenediaminetetraacetic acid capped superparamagnetic iron oxide (Fe3O4) nanoparticles: a novel preparation method and characterization. J. Magn. Magn. Mater. 439, 312–319 (2017)

Dhak, P., Kim, M.-K., Lee, J.H., Kim, M., Kim, S.-K.: Linear-chain assemblies of iron oxide nanoparticles. J. Magn. Magn. Mater. 433, 47–52 (2017)

Bajaj, B., Malhotra, B.D., Cho, S.: Preparation and characterization of bio-functionalized iron oxide nanoparticles for biomedical application. Thin Solid Films. 519, 1219–1223 (2010)

Zhu, J., He, J., Du, X., Lu, R., Huang, L., Ge, X.: A facile and flexible process of β-cyclodextrin grafted on Fe3O4 magnetic nanoparticles and host–guest inclusion studies. Appl. Surf. Sci. 257, 9056–9062 (2011)

Xu, Y., Zhuang, L., Lin, H., Shen, H., Li, J.W.: Preparation and characterization of polyacrylic acid coated magnetite nanoparticles functionalized with amino acids. Thin Solid Films. 544, 368–373 (2013)

Dutta, B., Shetake, N.G., Barick, B.K., Barick, K.C., Pandey, B.N., Priyadarsini, K.I., Hassan, P.A.: pH sensitive surfactant-stabilized Fe3O4 magnetic nanocarriers for dual drug delivery. Colloids Surf. B: Biointerfaces. 162, 163–171 (2018)

Dong, Y., Yang, Z., Sheng, Q., Zheng, J.: Solvothermal synthesis of Ag@Fe3O4 nanosphere and its application as hydrazine sensor. Colloids Surf. A Physicochem. Eng. Asp. 538, 371–377 (2018)

Safari, J., Javadian, L.: Ultrasound assisted the green synthesis of 2-amino-4H-chromene derivatives catalyzed by Fe3O4-functionalized nanoparticles with chitosan as a novel and reusable magnetic catalyst. Ultrason. Sonochem. 22, 341–348 (2015)

Ma, M., Zhang, Y., Guo, Z., Gu, N.: Facile synthesis of ultrathin magnetic iron oxide nanoplates by Schikorr reaction. Nanoscale Res. Lett. 8(16), 1–7 (2013)

Rahimi, R., Maleki, A., Maleki, S.: Synthesis and characterization of a new magnetic bromochromate hybrid nanomaterial with triethylamine surface modified iron oxide nanoparticles. Chin. Chem. Lett. 25, 919–922 (2014)

Tang, H., Zhang, C., Chang, K., Shangguan, E., Li, B., Chang, Z.: Synthesis of NiS coated Fe3O4 nanoparticles as high-performance positive materials for alkaline nickel-iron rechargeable batteries. Int. J. Hydrog. Energy. 42, 24939–24947 (2017)

Lesbayev, A.B., Elouadi, B., Lesbayev, B.T., Manakov, S.M., Smagulova, G.T., Prikhodko, N.G.: Obtaining of magnetic polymeric fibers with additives of magnetite nanoparticle. Procedia Manuf. 12, 28–32 (2017)

An, P., Zuo, F., Yuan Peng, W., Zhang, J.H., Zheng, Z.H., Ding, X.B., Xing Peng, Y.: Fast synthesis of dopamine-coated Fe3O4 nanoparticles through ligand-exchange method. Chin. Chem. Lett. 23, 1099–1102 (2012)