Abstract

Bacterial cellulose (BC) is believed to be a promising and cost-efficient nano-scaffold for tissue engineering. However, the pore size of BC is not big enough for cell ingrowth, which restricts its practical usage as tissue engineering scaffold. In this work, novel porous BC sponges were obtained through emulsion freeze-drying technique. Results of scanning electron microscopy (SEM) and mercury intrusion porosimeter showed that the resulted BC sponges were composed of nanofibrills with hierarchical pore structure consisting of large pores (from 20 to ~1,000 μm in diameter) and nano pores (down to ~4 nm in diameter). BC sponges possessed high surface area (92.81 ± 2.02 m2/g) and sufficient porosity (90.42 ± 0.24%). Additionally, the size and shape of BC sponges could be easily controlled by using appropriate molds. We also demonstrated that BC sponges had excellent cell compatibility as fibrous synovium-derived mesenchymal stem cells (MSCs) could proliferate well on and inside the BC sponges and the maximum ingrowth distance was 150 μm after cultured for 7 days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As an emerging multidisciplinary field, tissue engineering is revolutionizing the ways to improve the health and quality of life for people by restoring, maintaining or enhancing tissue and organ function [1, 2]. Tissue engineering approaches typically employ exogenous three-dimensional (3-D) extracellular matrices (ECMs) which act as scaffolds to bring cells together in a tissue, to control the tissue structure and to regulate the cell phenotype [3]. As the main component of ECMs, the collagen fibrous structure in connective tissue is organized into 3-D network composed of nanoscale multifibrils with spaces for nutrient and metabolite diffusion [3, 4]. The nanofibrils (~20 to 100 nm in diameter) positioned in a precise orthogonal nano-pore array pattern in the cornea are responsible of optical transparency and influence the fundamental cell behavior [5, 6]. Hence, the organization of ECMs in natural tissue is hierarchical arrangement of collagen fibrils and many properties of tissue depend on this unique hierarchical organization [6]. One obvious challenge of tissue engineering is the design and fabrication of the 3-D polymer scaffolds composed of refined nanofibrils with hierarchical pore structure including large pores and nano pores to mimic the organization of ECMs [3, 7].

Porous 3-D scaffolds fabricated from synthetic and naturally derived biodegradable polymers including poly (glycolic acid) (PGA), poly (lactic acid) (PLA), poly [lactic-co-(glycolic acid)] (PLGA) and collagen have been widely used in the tissue engineering of cartilage, bone, skin, and ligament, etc. [8]. Distinguished from these usual scaffolds, bacterial cellulose (BC) possesses natural refined 3-D nanofibrils network which has a shape similar to that of the collagen nanofibrils in natural tissue such as umbilicao cord [9] and basement membrane in cornea [5]. Meanwhile, it exhibits properties of high porosity, excellent biocompatibility, low cost [10–12] and degradation rate commensurate with new tissue formation [13], all these make BC an excellent scaffold candidate in tissue engineering applications [10, 13]. However, BC has only small pores (100–300 nm in diameter) according to the scanning electron microscopy observation by Hutchens et al. [14] and its lack of large pores restricts its application as tissue engineering scaffold [15]. In this work, BC sponges composed of refined nanofibrils with hierarchical pore structure (including large pores and nano pores) were fabricated through emulsion freeze-drying technique. Without affecting the high surface area and sufficient porosity of the resultant BC sponges, the improved pore size of BC nanofibrils will certainly increase its potential for biomedical applications. In addition, the cell compatibility of the resultant BC sponges was assessed by in vitro culturing of fibrous synovium–derived mesenchymal stem cells (MSCs).

2 Experimental

2.1 Materials

The agents used in this work for the preparation of BC fabrics were the same as previously described [10]. Polyethylene glycol 400 (PEG400) was purchased from Tianjin Tianda Tianlong Sci. & Tech. Co., Ltd., Tianjin, China. All agents were analytical grade and used as received without further purification.

2.2 Preparation of BC fabrics

The preparation and purification procedures of BC fabrics were described previously [10]. In brief, the bacterial strain, Acetobacter xylinum X-2, secreted the BC fabrics during its static growth in culture media containing 0.3 wt% green tea powder (analytical grade) and 5 wt% sucrose (analytical grade) for 7 days. The pH of the medium was adjusted to 4.5 by acetic acid. BC fabrics were purified by soaking in deionized water at 90 °C for 2 h and then boiled in a 0.5 M NaOH solution for 15 min. The fabrics were then washed with deionized water for several times and soaked in 1 wt% NaOH for 2 days. After rinsing with deionized water until neutral pH, the BC fabrics were pre-frozen in liquid nitrogen and then lyophilized at −50 °C for 2 days until further analysis.

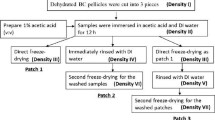

2.3 Preparation of BC sponges

BC sponges were prepared via emulsion freeze-drying technique which was considered as an important method to prepare 3-D scaffolds for tissue engineering [8, 16, 17]. BC fabrics were crushed and mixed with distilled water to prepare 0.25 wt% BC emulsion. The BC emulsion was then poured into appropriate molds (cubic and columned molds were used here) and freeze-dried at −50 °C for 1 day. In order to enhance the stability and biocompatibility of BC sponge, the samples were then immersed in PEG400 for 1 day as PEG had the unique properties including its flexibility, nontoxicity, and nonimmunogenicity and then soaked in deionized water for exchanging the excess PEG400. Water was changed several times in the following 2 days and samples were then freeze-dried at −50 °C for another 2 days. The resultant porous BC sponges were used in further analysis.

2.4 Surface property characterization

Photos were taken by digital camera (Nikon, COOLPIX P5100). The surface structures of BC sponges and BC fabrics were observed by scanning electron microscopy (SEM, Philips XL-30). The pore size distribution, porosity and surface area of BC fabrics and BC sponges were determined by mercury intrusion porosimeter (PoreMaster 60GT, Quantachrome Instruments) that could measure pore size ranging from 3.6 nm up to 950 μm.

2.5 Cell compatibility assessment

Tissues were harvested from a human donor who was an elderly patient with osteoarthritis during the knee operation following the method described by Tomoyuki Mochizuki [18] under the institutional ethical guidelines. Cells were grown as monolayer in the high-glucose Dulbecco’s modified Eagle’s medium (Invitrogen; Carlsbad, CA) containing 10% fetal bovine serum (FBS, PAA), 100 U/mL penicillin and 100 mg/L streptomycin (Invitrogen; Carlsbad, CA) and incubated in a humidified air with 5% CO2 at 37 °C. The synovium derived MSCs of passage 4 were harvested and resuspended to a cell concentration of 2 × 106 cells/mL. Then 1 × 106 cells were seeded on every BC sponge (diameter: 15 mm, height: 1 mm) and incubated in culture medium aforementioned.

The morphology of the cells during their proliferation was observed under inverted microscope (Olympus, Japan). The cell proliferation was evaluated by MTT assay as well. The cells were seeded onto scaffold and after 1, 3, 5 and 7 days of culture, the cell-scaffold constructs were rinsed with PBS to remove non-adhering cells, followed by incubation in 5 mg/mL MTT reagent in Hank’s balanced salt solution (100 μL) for 4 h under the same conditions described. After removal of the medium, the converted dye was dissolved in 500 μL/well dimethyl sulfoxide (DMSO). Solution (100 μL) from each sample was transferred to a 96-well plate. Absorbance of the converted dye was measured at a wavelength of 570 nm using an ELISA plate reader (Dynex-Mex, USA). Samples with culture medium but without cells were set as control to obtain the background absorbance. Data of the proliferation measurement were collected from triplicate samples and expressed as the mean ± standard deviation (SD).

Cells cultured for 5 days were infected with Adenovirus expressing green fluorescence protein (Ad-GFP) and kept cultured for two more days before observed by confocal laser scanning microscopy (CLSM). Ad-GFP is widely used as a fluorescent marker of gene expression for determination of protein localization and motility in living cells [19].

3 Results and discussion

3.1 Macro-morphology

The BC sponges with different shapes are shown in Fig. 1. Note that the macro shapes of BC sponges could be controlled in either the high columned shape (height: 18 mm, diameter: 20 mm, see Fig. 1a, c) or the flat cubic shape (height: 9 mm, side length: 24 mm, see Fig. 1b, d) by changing the shape and dimension of the molds. It has been reported that the macroscopic shape of scaffolds (cm to mm scale) could determine the gross size and shape of engineered tissues [3]. In this study, the macroscopic shape and dimension of BC sponges had been successfully controlled by choosing appropriate molds in order to meet the shape requirements in clinical therapies.

3.2 SEM analysis

It is well accepted that pore size of a scaffold could affect the cell adhesion, cell proliferation and directional growth [8, 20]. Figure 2 gives the SEM images of surfaces of BC sponges and BC fabrics. Note that the BC sponges (Fig. 2a) had more porous surface compared to BC fabrics (Fig. 2c). This porous structure of BC sponges was similar to that of collagen sponges reported by Mizuno et al. [21]. At 2,000× magnification, nanofibrils (Fig. 2b) same as that of BC fabrics (Fig. 2d) was observed in the pore walls of BC sponges. These nanofibrils could fabricate nano pores in the pore wall, which indicated that the BC sponges possessed hierarchical pores consisting of large pores and nano pores.

3.3 Pore size distribution

Intrusion porosimeter was used to compare the porous structure of different samples. The pore size distribution curves of BC fabrics and BC sponges are shown in Fig. 3. The diameter of the dominant pores in BC fabrics was about 10 μm (Fig. 3a) and some nano pores (4–6 nm in diameter) were also observed (marked in Fig. 3a). In comparison, the dominant pores in BC sponges had a diameter of about 100 μm and the maximum diameter was about 1,000 μm (Fig. 3b). In addition, some nano pores with ~4 nm in diameter were also detected in BC sponges (marked in Fig. 3b) due to the existence of nanofibrous network structure (Fig. 2b). These findings inferred that BC sponges had hierarchical pore structure, which was consistent with SEM observations.

3.4 Surface area and porosity analysis

The large surface area of scaffold has been proven to be advantageous to cell attachment and rapid nutrient diffusion required by cell survival and growth [22, 23]. In comparison of the surface area of BC fabrics and BC sponges (Table 1), BC fabrics had a surface area of 85.72 ± 1.95 m2/g and the BC sponges exhibited a significantly bigger surface area (92.81 ± 2.02 m2/g) which was comparable with the surface area (90–110 m2/g) of reported PLLA scaffold [24]. The large surface area of BC sponges could be attributed to the nanofibrous structure [24] as the non nanofibrous scaffold had a surface area of only ~1 m2/g [23]. The existence of nanofibirls in BC sponges had been confirmed by SEM observation (Fig. 1b) and pore size distribution curve (Fig. 3b). Due to its high surface area, BC sponge might be suitable for cell survival.

High porosity is another important character of 3-D polymer scaffolds used in tissue engineering due to its essential effects on cell growth. BC sponges had a high porosity of 90.42 ± 0.25% which was similar to that of BC fabrics which exhibited a porosity of 90.21 ± 0.41%. In addition, the porosity of BC sponges was close to that of PLA and PLGA porous scaffolds (91–95%) fabricated via the same method reported by Whang et al. [17].

3.5 Fibrous synovium derived MSCs growth on BC sponges

The cell proliferation on the scaffold was determined by observing the behavior of cells cultured in close contact with the scaffold using inverted microscopy and the MTT assay. Figure 4 shows the typical phase-contrast micrographs of cells cultured on the scaffold after 1, 3, 5 and 7 days. After 1 day culture (Fig. 4a), only few cells were generated but the cells were attracted to the scaffold. The cells proliferated and differentiated and more cells were attracted towards the scaffold when culture time prolonged to 3 days. After culturing for 5 days, large amount cells have attached onto scaffold and proliferated evidently compared to day 3 (Fig. 4b). After 7 days (Fig. 4d), the population of cells still kept increasing but not so obvious as day 5 (Fig. 4c).

The result of MTT assay was presented in Fig. 5. During 7 days culture, the cell number kept increasing and the growth was more dramatic in the first 5 days after which time point, the speed of cell proliferation slowed down and this phenomenon was consistent with the observations by phase-contrast microscopy results (Fig. 4). This finding could be attributed to adherent cells’ own growth process rather than the influence of the scaffold since cells are in their multiplication period during the first 5 days and then entered the plateau phase with their proliferating rate slowing down [25]. Considering this, we think the BC sponges scaffold do not have negative effect on the cell morphology, viability and proliferation in this study.

Spreading behaviors of fibrous synovium derived MSCs on BC sponges were investigated via the CLSM observation of the surface view and side view of BC sponges when fibrous synovium derived MSCs were cultured for 7 days (see Fig. 6). Note that the MSCs could proliferate well on the surface of BC sponges (Fig. 4a). In addition, the MSCs could grow inside BC sponges and their maximum ingrowth distance was 150 μm as shown in Fig. 4b, while the maximum cell ingrowth distance was 20 μm after cultured on BC fabric for 7 days [9]. These preliminary findings indicated that the BC sponges were suitable for cell proliferation and ingrowth. More detailed investigation on cell behavior will be carried out in the further work.

4 Conclusions

BC sponges with hierarchical pore structure were prepared by emulsion freeze-drying technique. First, we demonstrated that the macroscopic dimension and shape of the resultant BC sponges could be controlled easily. Then BC sponges have been shown to possess large pores and nano pores with a high surface area of 92.81 ± 2.02 m2/g and a high porosity of 90.42 ± 0.25%. Furthermore, BC sponges exhibited excellent cell compatible as fibrous synovium derived MSCs could proliferate well and grow inside the BC sponges with the maximum ingrowth distance of 150 μm. These above results support our claim that BC sponges are one type of promising biomaterials for tissue engineering applications though further studies are still needed.

References

R.M. Nerem, A. Sambanis, Tissue Eng. 1, 3 (1995)

R. Langer, J.P. Vacanti, Science 260, 920 (1993)

B.-S. Kim, D.J. Mooney, Trends Biotechnol. 16, 224 (1998)

T. Kreis, R. Vale, Extracelluar matrix, anchor, and adhesion proteins, 2nd edn. (Oxford University Press, New York, 1999)

S.A. Fraser, Y.-H. Ting, K.S. Mallon, A.E. Wendt, C.J. Murphy, P.F. Nealey, J. Biomed. Mater. Res. A 86A, 725 (2008)

K.E. Kadler, D.F. Holmes, J.A. Trotter, J.A. Chapman, Biochem. J. 316, 1 (1996)

P.S. Eggli, W. Müller, R.K. Schenk, Clin. Orthop. Relat. R 232, 127 (1988)

G.P. Chen, T. Ushida, T. Tateishi, Macromol. Biosci. 2, 67 (2002)

H. Bäckdahl, G. Helenius, A. Bodin, U. Nannmark, B.R. Johansson, B. Risberg, P. Gatenholm, Biomaterials 27, 2141 (2006)

L. Hong, Y.L. Wang, S.R. Jia, Y. Huang, C. Gao, Y.Z. Wan, Mater. Lett. 60, 1710 (2006)

Y.Z. Wan, L. Hong, S.R. Jia, Y. Huang, Y. Zhu, Y.L. Wang, H.J. Jiang, Compos. Sci. Tech. 66, 1825 (2006)

Y.Z. Wan, Y. Huang, C.D. Yuan, S. Raman, Y. Zhu, H.J. Jiang, F. He, C. Gao, Mater. Sci. Eng. C. 27, 855 (2007)

A. Svensson, E. Nicklasson, T. Harrah, B. Panilaitis, D.L. Kaplan, M. Brittberg, P. Gatenholm, Biomaterials 26, 419 (2005)

S.A. Hutchens, R.S. Benson, B.R. Evans, H.M. O’Neill, C.J. Rawn, Biomaterials 27, 4661 (2006)

B. Fang, Y.Z. Wan, T.T. Tang, C. Gao, K.R. Dai, Tissue Eng. 15, 1091 (2009)

Y.K. Ko, S.H. Kim, J.S. Jeong, J.S. Park, J.Y. Lim, M.S. Kim, H.B. Lee, G. Khang, Polymer-Korea 31, 505 (2007)

K. Whang, C.H. Thomas, K.E. Healy, G. Nuber, Polymer 36, 837 (1995)

T. Mochizuki, T. Muneta, Y. Sakaguchi, A. Nimura, A. Yokoyama, H. Koga, I. Sekiya, Arth. Rheum. 54, 843 (2006)

A. Crameri, E.A. Whitehorn, E. Tate, W.P. Stemmer, Nat. Biotechnol. 14, 315 (1996)

H. Bakdahl, M. Esguerra, D. Delbro, B. Risberg, P. Gatenholm, J. Tissue Eng. Regen. Med. 2, 320 (2008)

S. Mizuno, J. Glowacki, Biomaterials 17, 1819 (1996)

P.X. Ma, Adv. Drug Deliver Rev. 60, 184 (2008)

V.J. Chen, P.X. Ma, Biomaterials 27, 3708 (2006)

P.X.M. Guobao Wei, J. Biomed. Mater. Res. A 78A, 306 (2006)

Z.Q. Situ, J.Z. Wu, Cell Culture, 2nd edn. (Xi’an World Publishing Corporation, 2007), pp. 13–14

Acknowledgments

This work was supported by the National Natural Science Foundation of China (50872088, 50673076 and 50539060), the Tianjin Municipal Science and Technology Committee (07ZCKFSF01100 and 07JCZDJC07200) and the Foundation of Tianjin Key Laboratory of Industrial Microbiology (Tianjin University of Science & Technology) (No. Wsw-01). Financial support was also from the National Hi-Tech Research Development (863) Program (2009AA03Z311) and the State Key Basic Research (973) Program (Grant 2007CB936100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, C., Wan, Y., Yang, C. et al. Preparation and characterization of bacterial cellulose sponge with hierarchical pore structure as tissue engineering scaffold. J Porous Mater 18, 139–145 (2011). https://doi.org/10.1007/s10934-010-9364-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9364-6