Abstract

Bacterial cellulose (BC), a nano fibrous hydrogel synthesized from non-pathogenic bacteria, is an excellent candidate scaffold for bone tissue engineering applications due to its biocompatibility, high purity and mechanical strength. However, BC is not biodegradable and possesses small pore sizes, which hinders the ingrowth of cells and thereby limits its potential as a bone tissue engineering scaffold. In this study, microporous BC (termed Porous BC) scaffolds with well-defined honeycomb pore arrays were prepared using a laser patterning technique. The BC scaffolds were modified using periodate oxidation to yield biodegradable oxidized BC scaffolds. In a unique manner, the BC scaffolds were then mineralized with nano hydroxyapatite (nano HA) to mimic the inorganic component of native bone tissue, improve bone cell compatibility, enhance mechanical properties, and control degradation. Results confirmed that sodium periodate oxidation successfully oxidized BC and Porous BC honeycomb pore arrays with 300 μm pore sizes with irregularly shaped 77 ± 15 nm nano HA and aggregated 200–500 nm nano HA were formed. BC and its composites displayed suitable mechanical properties for bone tissue engineering applications. The in vitro degradation study showed a significant 13–25 % loss of their dry mass in the oxidized BC composites thus confirming that the oxidized cellulose can biodegrade. Most importantly, the results also demonstrated that human-derived bone marrow mesenchymal stem cells (hMSCs) adhered to and were viable on the BC and its composites, thus, confirming their potential to serve as improved bone tissue engineering scaffolds. The novelty of the present study includes the precipitation of nano HA onto cellulose to promote hMSCs functions for improving orthopedic applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The design and development of synthetic bone grafts have been very popular in recent years because of the shortage of autographs and the immunological related rejections of allographs (Marolt et al. 2010). In creating bone grafts, scientists aim to develop advanced biomaterials that mimic the chemical and structural properties of native bone, permit cell adhesion and proliferation, possess suitable porous structures that permit cell ingrowth and diffusion of nutrients to cells, are biocompatible and biodegradable, and have suitable mechanical properties that can be modified to include bioactive compounds (Nguyen and Burg 2015; Pina et al. 2015). Native bone tissue is a three-dimensional (3D) hierarchical extracellular matrix (ECM) that consists of cells, non-collagenous proteins, hyaluronan, proteoglycans, nano collagen fibers and inorganic salts in the form of nano hydroxyapatite (HA) crystals (Cui et al. 2011). Hence, a viable scaffold must not only mimic the mineralized 3D structural arrangement of bone tissue but also provide mechanical support and biological function (Ma et al. 2014; Pina et al. 2015). To imitate the ECM of bone, a variety of polymeric materials with nano- and macro-structures have been prepared using techniques such as electrospinning (Bhardwaj and Kundu 2010), 3D printing (Bose et al. 2013; Liu and Webster 2011), induced phase separation of polymer solutions (Lee et al. 2000), and innovative biosynthesis methods (Harley et al. 2010; Lynn et al. 2010; Parenteau-Bareil et al. 2010). Several biocompatible materials such as hydroxyapatite (HA) (Ustundag et al. 2012), polymers filled with growth factors such as bone morphogenetic proteins (Berner et al. 2012; Wegman et al. 2014), natural polymers such as chitosan (Croisier and Jérôme 2013) and collagen copolymers (calcium phosphate mineralized collagen–glycosaminoglycans copolymers) (Harley et al. 2010; Lynn et al. 2010), and most often polymer–HA composites (Akkouch et al. 2014; Li et al. 2012; Torabinejad et al. 2014) have been studied for bone tissue engineering applications.

HA is the major bioactive inorganic ceramic in bone and is able to support bone growth and osseointegration (Bansal et al. 2014; Torabinejad et al. 2014; Tracy and Doremus 1984). HA has also been shown to permit osteoblast cell adhesion and proliferation (Akkouch et al. 2014), however, the use of pure HA as a scaffold material for tissue engineering is undesirable because of its brittleness and low strength (Kim et al. 2013). Creating polymer–HA composites can minimize the brittleness associated with the pure ceramic showing promise for biomimetic bone scaffolds (that is, materials used to regenerate bone in a 3D manner). In addition, the size of the HA particle used for biomedical applications has been shown to affect cell function. For example, Webster et al. (2000a) showed that osteoblast proliferation, synthesis of alkaline phosphatase and deposition of calcium-containing mineral was significantly greater on nano (particle sizes <100 nm) HA compared to compact (10 mm in diameter and 2 mm thick) conventional or micron grain sized HA. In addition, nano HA can be added to polymers and/or other composites to tailor degradation properties of such scaffolds to bone formation since nano HA increasingly degrades in the presence of alkaline phosphatase and other enzymes produced by osteoblasts as they form bone (Webster et al. 2000a). Nano HA has also been shown to possessed increased surface wettability properties allowing for the increased adsorption of hydrophilic proteins known to promote osteoblast adhesion, proliferation, and bone formation (Webster et al. 2000b).

Bacterial cellulose (BC) is a natural 3D nanofibril hydrogel synthesized from non-pathogenic bacteria such as Gluconacetobacter sucrofermentans or Acetobacter xylinum (Bielecki et al. 2001; Hutchens et al. 2006). BC is a desirable scaffold for tissue-engineering use because it is chemically pure, biocompatible, moldable, and possesses high mechanical strength and large accessible surface area/volume ratios (Bielecki et al. 2001; Helenius et al. 2006; Hutchens et al. 2006). BC has been used for various biomedical applications such as wound dressings for the treatment of second- or third-degree burns (Fontana et al. 1990) and chronic ulcers (Kucharzewski et al. 2003), and as a scaffold for artificial skin (Sanchavanakit et al. 2006) and artificial blood vessels (Klemm et al. 2001). BC has also been mineralized with HA to form composites for potential bone tissue engineering applications (Hutchens et al. 2006; Wan et al. 2007). BC is a non-biodegradable material and as such, it is not enzymatically degradable in vivo (Helenius et al. 2006). To make BC degradable in vivo, the scaffold can be oxidized using sodium periodate to form a biocompatible and biodegradable 2,3-dialdehyde cellulose, which degrades by a simple hydrolysis mechanism (Favi et al. 2014; Hutchens et al. 2009). Moreover, Hu et al. (2011) introduced an enzyme-incorporation strategy to degrade BC in the body.

BC is a densely packed fibrous structure with a pore size of approximately 254 nm (Favi et al. 2013). The pore structures of BC scaffolds have been shown to support the ingrowth of human chondrocytes and human smooth muscle cells in vitro (Bäckdahl et al. 2006; Svensson et al. 2005). Some studies suggest that the pore size of BC scaffolds is too small to allow the ingrowth of cells into the scaffold after in vivo implantation (Helenius et al. 2006). To increase the pore size of BC scaffolds, several methods have been employed including phase separation and sodium chloride salt leaching (Roy-Chowdhury and Kumar 2006), insertion of placeholders for pre-biosynthesis followed by removal post-biosynthesis (Backdahl et al. 2008; Rambo et al. 2008), and post-processing using laser patterning (Ahrem et al. 2014; Wang et al. 2011). These techniques introduced micron-sized pores into the network structure of the BC scaffold for potential cell ingrowth. In this study, biodegradable nano HA–BC composites with well-defined honeycomb pore arrays were prepared by using the post-processing laser patterning technique in order to make advanced biomaterials for use as biodegradable bone tissue engineering scaffolds. The microstructure, aldehyde content, chemical surface structure, mechanical properties, in vitro degradation, as well as cellular adhesion and viability properties of the composites are presented below showing much promise for orthopedic applications.

The novelty of the present study includes the precipitation of nano HA onto cellulose to promote hMSCs functions for improving orthopedic applications. This is in contrast to numerous studies which employ growth factors or cytokines to control stem cell differentiation into osteoblasts, however, during clinical use it is likely that these growth factors and cytokines would have deleterious effects on other cells, making such an approach less desirable than using nano HA as this study accomplished (Berner et al. 2012; Wegman et al. 2014).

Materials and methods

Materials

Synthesis of bacterial cellulose scaffolds

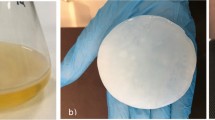

The bacterial strain Acetobacter xylinus subsp. Sucrofermentans from the American Type Culture Collection (Manassas, VA) (ATCC 700178) was a kind donation from Dr. Roberto Benson (Department of Material Science and Engineering, The University of Tennessee, Knoxville, TN). The BC was synthesized in a modified Schramm and Hestrin liquid medium (Schrarnrn and Hestrin 1954). Briefly, the medium solution was composed of mannitol (2.0 % w/v) (Fisher Scientific, Pittsburgh, PA), BD™ Difco Bacto™ peptone (0.5 % w/v) (Fisher Scientific), BD Bacto™ Difco yeast extract (0.5 % w/v) (Fisher Scientific), sodium phosphate dibasic anhydrous (0.27 % w/v) (Fisher Scientific), and citric acid monohydrate (0.115 % w/v) (Fisher Scientific). For the BC preparation, pre-cultures of the bacteria were diluted 1:10 in fresh media and were incubated in sterile 381 mm by 254 mm by 50.8 mm glassware (1500 ml of inoculated medium per glassware) for 14 days at room temperature under static conditions. Sheets of BC were produced at the air and liquid interface of the media. The size of the BC produced was dependent on the incubation container used for bacterial culture and was controlled by the dimensions of the glassware. The BC sheets produced were approximately 375 mm by 250 mm by 1.5 mm (Fig. 1, upper left column). The BC sheets were heated at 90 °C for 2 h in 1 % NaOH (w/v) (Fisher Scientific) to kill the bacteria, and were purified with repeated washes in 1 % NaOH and in ultrapure Millipore 18.2 MΩ deionized water (DI-water) as previously described (Favi et al. 2013). The purified sheets of BC scaffolds were cut into strips of approximately 375 mm by 25 mm by 1.5 mm (Fig. 1, upper center column) for easier handling and were stored in DI-water at room temperature prior to use.

Preparation of microporous bacterial cellulose scaffolds

A pulsed CO2 laser cutting system (Epilog Zing 16 Laser; Epilog Laser, Golden, CO) was used to puncture the strips of BC scaffolds with specific channel arrays. For all the laser perforations performed, the hydrated, never-dried BC scaffolds in hydrogel form were used. The strips of BC scaffolds were mounted on a polymer support inside of the laser cutting system for processing.

Circular shaped honeycomb-like channel arrays were designed in Corel Draw X4 software (Corel Corporation; Ottawa, Ontario, Canada) with a three-angle lay-down pattern (0°/60°/120°). The channel arrays were transferred to the Epilog Zing Driver 9.01 Laser Dashboard™ software (Epilog Zing 16 Laser), which controlled the cutting of the channel array patterns and the laser settings. The strips of BC scaffolds were perforated in a vertical unidirectional matter using a laser power of 15 W, speed of 65 %, and frequency of 5000 Hz to produce strips of microporous BC (Porous BC) scaffolds (Fig. 1, upper right column). The diameter of the laser beam was ~300 μm. The residues from laser processing were removed from the Porous BC scaffolds with several changes of DI-water. The cellulose scaffolds that did not undergo laser perforation (Native BC) were used as controls (Fig. 1, upper center column).

The strips of Native BC and Porous BC scaffolds were prepared as circular shaped scaffolds for oxidation, HA deposition, material characterization, in vitro degradation analysis, and as dog-bone shaped (dumbbell) specimens for mechanical analysis. The circular shaped scaffolds (Fig. 1, center and left columns) were prepared using a 6 mm Miltex Inc. disposable biopsy punches (Fisher Scientific) or a 16 mm round hole arch die (McMaster Carr, Atlanta, GA). The dog-bone shaped specimens (Fig. 1, center and left columns) were prepared using an American Society for Testing and Materials (ASTM) custom made die with dimensions described in the “Mechanical testing” section.

Oxidation of bacterial cellulose scaffolds

Sodium periodate oxidation of Native BC (OBC) and Porous BC (Porous OBC) scaffolds was completed following a previously described method (Hutchens et al. 2009). Briefly, cellulose pellicles were added to a solution of 50 mM NaIO4 (Fisher Scientific) in 5 % n-propanol (v/v) (Fisher Scientific). The container of the mixer was caped, covered with aluminum foil to simulate a dark environment, and placed on an orbital shaker for 24 h at room temperature. The oxidation reaction was stopped and excess periodate consumed by placing the vessel in an ice bath and adding 0.85 % of glycerol (v/v) (Fisher Scientific). The cellulose pellicles were then purified with several changes of DI-water to remove residual oxidation reagents.

Deposition of nano hydroxyapatite in bacterial cellulose scaffolds

Nano HA minerals were deposited within Native BC (BC–HA), OBC (OBC–HA), Porous BC (Porous BC–HA) and Porous OBC scaffolds (Porous OBC–HA). The nano HA deposition within the scaffolds were performed by incubating the samples in a calcium solution and phosphate solution, following a modification of a previous described method (Hutchens et al. 2006). Briefly, cellulose pellicles were suspended in a 1.0 mM CaCl2 (Fisher Scientific) solution under agitation on an orbital shaker (Excella E2 Platform Shaker; New Brunswick Scientific, Enfield, CT) for 24 h (23 °C), rinsed briefly in DI water, and then transferred to a 0.6 mM Na2HPO4 (Fisher Scientific) solution under agitation for another 24 h (23 °C) to obtain nano HA. The Ca/P mole ratio was maintained at 1.67. This study employed nano HA precipitation on cellulose rather than mixing nano HA with cellulose to create a more biologically-inspired scaffold compared to bone in terms of improved HA adhesion strength, better nucleation sites, and more accurate nanoscale geometries. Eight groups of scaffolds were made overall: Native BC, BC–HA, OBC, OBC–HA, Porous BC, Porous BC–HA, Porous OBC and Porous OBC–HA.

Material characterization

Scanning electron microscopy

The morphology of critically-point dried 16 mm discs of Native BC and its composites were examined using a scanning electron microscope (SEM). For critically-point drying, the scaffolds were dehydrated by incubating consecutively in 30, 50, 70, 85, 95 and 100 % ethanol (v/v) for 10 min. The BC scaffolds were then dried by critical point drying in liquid CO2. For cross-sectional imaging, the scaffolds were placed in liquid nitrogen for approximately 30 s and then were fractured in half. The critically-point dried scaffolds were mounted on carbon tape and sputter coated with platinum using a Cressington Scientific Sputter Coater 208HR (Watford, Hertfordshire, UK). The SEM images were obtained with a JOEL JEM 1010 electron microscope (Akishima, Tokyo, Japan) at a 3 kV accelerating voltage. The average pore diameter of the laser perforated cellulose scaffolds were obtained by analyzing SEM images using NIH ImageJ 1.64 software (Shareware provided by the National Institutes of Health, http://rsbweb.nih.gov/ij/). The images were opened in ImageJ and measurements were calibrated using the scale bar on the SEM images. The measure tool was used to find the average pore diameter at the top, center and bottom of the cross-sectioned pore channels of at least three randomly selected cross-sectioned pores (n = 3) from three samples (N = 3). The average fiber diameter of the Native BC scaffold was measured by analyzing SEM images using ImageJ 1.64 software. The fiber diameter of ten randomly selected fibers (n = 10) was measured. The diameter of the nano HA clusters (n = 3, N = 3) produced in non-oxidized and oxidized cellulose scaffolds were also measured by analyzing SEM images using ImageJ 1.64 software. The measurements were averaged to obtain a mean value and standard deviation of the dimensions.

Determination of dialdehyde content

The dialdehyde content present in the lyophilized 16 mm discs of OBC and Porous OBC scaffolds was determined by the Cannizzaro method as previously described (Pommerening et al. 1992; Roy-Chowdhury and Kumar 2006). For lyophilization, the cellulose scaffolds were frozen in a −80 °C freezer for 24 h and lyophilized in a Labconco FreeZone® 2.5 Freeze Dry System (Kansas City, MO) for at least 24 h at −50 °C and 60 Pa. For dialdehyde content determination, the scaffolds were reacted with 20 ml of a 0.05 M NaOH (Fisher Scientific) solution at 70 °C for 15 min. The solution was cooled to room temperature and then 10 ml of a 0.1 M HCl solution (Fisher Scientific) was added. The mixture was titrated with a 0.01 M NaOH solution to a neutral pH. The concentration of the dialdehyde group content present in the scaffolds was calculated as followed (Pommerening et al. 1992; Roy-Chowdhury and Kumar 2006): mmol of dialdehyde groups/g of scaffold = 0.01 M NaOH (mL)/(100). The percentage of oxidation was calculated between the estimated dialdehyde group content and 100 % degree of oxidation (12.5 mmol/g), as previously described (Roy-Chowdhury and Kumar 2006). Three samples were tested for each sample group (n = 3), and the mean and standard deviations were reported.

Fourier-transform infrared spectroscopy

The chemical structure of the surface of lyophilized 16 mm discs of Native BC and its composites was determined using Fourier-transform infrared spectroscopy (FTIR). The samples were lyophilized as described above and further dried for 24 h in a Lindberg Blue M vacuum oven (Thermo Scientific, Waltham, MA) at 100 °C and 68 kPa. The FTIR spectra of the samples were collected in reflectance mode with a VERTEX 70/70v FT-IR spectrometer (Billerica, MA). The FTIR spectra were recorded over 256 scans for each sample with a resolution of 4 cm−1. The background spectra were automatically subtracted from the sample spectra. FTIR and X-ray Diffraction spectra of nano HA were previously published (Hutchens et al. 2006; Webster et al. 2000a).

Mechanical testing

The mechanical properties of the hydrated Native BC scaffolds and its composites were determined using dog-bone shaped samples cut using an ASTM custom made die (Pioneer-Dietecs, Weymouth, MA). The dog-bone shaped samples had a gauge length of 5.0 mm, a gauge width of 3.5 mm, and a total length of 19 mm. Tensile testing of the cellulose samples was conducted in accordance with ASTM D638-10 (American Society for Testing and Materials 2010) using an ADMET MTESTQuattro mechanical testing unit (ADMET, Norwood, MA) equipped with MTESTQuattro Material Testing Software (ADMET). A 44.48 N load cell was used to extend the samples at a rate of 0.5 mm/min until failure. A total of six specimens (n = 6) were tested for each sample group, and the mean and standard deviations were reported. Values for the ultimate tensile strength, strain at break and Young’s Modulus were calculated.

In vitro degradation of scaffolds

A sample from each group of the hydrated scaffolds (16 mm discs) was analyzed. Each sample was placed in 5 ml of Tris–HCl-buffered synthetic body fluid (Tris–HCl-buffered SBF, pH 7.4) (Jalota et al. 2008) and was incubated under static conditions at 37 °C to simulate physiological conditions. The Tris–HCl-buffered SBF was changed every 2 days for 14 days. After 14 days of incubation, the experiment was stopped and the samples were rinsed with several changes of DI-water to remove the salts adsorbed onto the cellulose membranes. The scaffolds were then lyophilized and weighed. A total of four specimens (n = 4) were tested for each group, and the mean and standard deviations were reported. Specimens that did not undergo degradation analysis were lyophilized and weighed for comparison.

Cellular viability and morphology

Human-derived bone marrow mesenchymal stem cells (hMSCs) were purchased from Lonza (Basel, Switzerland) and grown in cell culture media containing Dulbecco’s Modified Eagle Medium F-12 (DMEM/F-12) with 10 % fetal bovine serum (Hyclone, Logan, Utah) and a 1 % penicillin/streptomycin solution (P/S) (Invitrogen, Carlsbad, CA). For cell culture studies, BC and its composites (6 mm discs) were sterilized by autoclave (1 bar, 120 °C) for 45 min, placed in 96-well tissue cultured plates and pre-soaked in cell culture media for at least 24 h prior to cell seeding. Each scaffold was seeded with 2.0 × 104 hMSCs and incubated for 2 days at 37 °C/5 % CO2. Cellular viability was determined after 2 days by the addition of a 5 mg/mL MTS reagent (3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxy-phenyl)-2-(4-sulfophenyl)-2H-tetrazolium and phenazine methosulfate) (cell culture: MTS reagent at a 5:1 v/v ratio). The plates were incubated for an additional 3 h at 37 °C and 5 % CO2, allowing viable cells to bioreduce the MTS reagent into a colored formazan product. The absorbance values for the MTS cell product were measured on a SpectraMax M3® microplate fluorescence reader (Molecular Devices, Sunnyvale, CA) at a wavelength of 490 nm. Blanks were scaffolds cultured with media only and without the addition of cells. The recorded absorbance values at 490 nm were subtracted from the blank readings to yield the corrected absorbance. All experiments were simultaneously conducted in triplicate (n = 3) and repeated three different times (N = 3) on BC and its composites.

Phase contrast microscope images were taken of the cells on the cellulose scaffolds to access their adhesion and morphology. Images were taken after 2 days in culture using a Nikon Eclipse TS100 phase contrast microscope equipped with a PixeLINK PL-B625CU camera (Ontario, Ottawa, Canada) and µScope photo software (PixeLINK, Ontario, Ottawa, Canada).

Statistical analysis

Data are expressed as the mean ± standard deviation for at least three independent samples. Statistical comparisons between groups were performed with a two-tailed Student’s t test, p < 0.05 was considered significant.

Results and discussion

Morphology and pore diameter analysis

Qualitative assessment of the structure of the Native BC was determined by SEM and is illustrated in Fig. 2. The top view SEM image of Native BC, shown in Fig. 2a, confirmed sheet-like structures of the cellulose material and a lack of visible porous networks. A higher magnification of the scaffold as illustrated in Fig. 2b shows the small nanofibers, cellulose ribbons formed from the bundling of nanofibers, and the microscopic pores present in the Native BC. The average diameter of the BC fibers and ribbons were 33 ± 6 and 112 ± 14 nm, respectively, which confirmed the nano-scale dimensions of the BC fibers and ribbons. The average diameter of the BC nanofibers and nanoribbons were significantly different (p < 0.05). These observations are as expected and agree with previous findings (Bielecki et al. 2001; Favi et al. 2013). Morphologically, the cross-section SEM image of the Native BC (Fig. 2c) displayed a tightly packed network of cellulose nanofibers. The thickness of the cellulose scaffold was ~1.5 mm.

The top surface and cross-sectional morphologies of the unidirectional laser perforated Porous BC are shown in Fig. 3. The top view SEM image of the Porous BC scaffold confirmed the successful laser perforation of the cellulose scaffold into circular, well-defined and identical pore networks (Fig. 3a). The distance between three linear pore centers as marked by (a) in Fig. 3a, b was 1000 μm. Regular and geometrical honeycomb-like pore arrays with a 0°/60°/120° lay-down pattern were produced in the scaffold to allow for an optimum use of the existing surface area (Fig. 3a, b). Ahrem et al. (2014) compared scaffolds fabricated using a honeycomb-like array of the unidirectional laser perforated method and a rectangular array of unidirectional laser perforated method where puncturing was performed on the scaffold by means of a 0°/90° lay-down pattern (Ahrem et al. 2014). Their results showed that a greater number of pore structures could be introduced into a given surface area of a scaffold with the honeycomb-like pore array laser perforated method compared to the rectangular pore array laser perforated method.

a Top view SEM image and b a corresponding schematic view of the unidirectional laser perforated Porous BC scaffold with honeycomb-like arrangement, a 0°/60°/120° lay-down pattern and a well-defined pore network. c Cross-sectional SEM image and d a corresponding schematic view of the Porous BC scaffold revealed the trapezoid-like pore structure produced by laser perforation in the cross-section of the scaffold. The inscription in (a, b) and marked as (a) indicate the distance between the pore centers; a is approximately 1000 μm. The inscriptions in c, d and marked as b–d represent the diameter at the top, center and bottom of the cross-sectioned pore channel of Porous BC, respectively. e SEM of the well-defined round-shaped pore of the Porous BC scaffold. f SEM of the microstructure of the Porous BC scaffold consisted of nanofibrous cellulose networks

The cross-section SEM image of the Porous BC (Fig. 3c) showed that the laser perforated the compact network of cellulose nanofibers and produced a gradually decreasing pore diameter with a trapezoid-like configuration through the thickness of the scaffold (Fig. 3c, d). A close-up view of a generated pore (Fig. 3e) illustrates that the laser successfully produced a round and evenly shaped channel. The microstructure of the upper surface of the Porous BC scaffold (Fig. 3f) was comprised of randomly oriented nanofibrous cellulose networks similar to the unmodified Native BC scaffold (Fig. 2b), and did not show any indications of fiber modifications after the use of a laser. The lay-down pattern used in this study was created using Corel Draw software and the laser cutting driver software was used to directly perforate the honeycomb-like design into the synthesized Native BC scaffolds to prepare Porous BC scaffolds. More complex lay-down patterns could be designed using design software such as Corel Draw to produce other pore array patterns, or pores with varying distances between their channels (Ahrem et al. 2014).

The laser beam, with a diameter of 300 μm, created a progressively decreasing, trapezoid-shaped pore arrangement (i.e., b, c and d, Fig. 3c, d) with diameters of 305 ± 6, 263 ± 6 and 202 ± 10 μm at the top, center and bottom surfaces of the cross-sectioned pore channel, respectively (Fig. 4). The diameters at the top, center and bottom surface of the cross-sectioned pore were significantly different (p < 0.05) (Fig. 4). The nominal diameters of the top, center and bottom surfaces of the cross-sectioned pore were 300, 260, and 200 μm, respectively. Pore sizes of approximately 300 μm, as produced in this study, have been reported to be optimal for pre-osteoblastic MC3T3-E1 cell migration (Murphy et al. 2010), promoting bone formation and vascularization, and directing osteogenesis (Karageorgiou and Kaplan 2005; Kuboki et al. 2001; Tsuruga et al. 1997). It is proposed that a gradually decreasing, trapezoid-shaped pore configuration was produced in the Porous BC (Fig. 3c, d) because the cellulose medium absorbed and scattered the power of the laser beam, thereby reducing its energy as it passed through the width of the scaffold. This phenomenon is known as laser beam attenuation (Kirkham and Roundy 2014). As such, the laser beam had the greatest power at the surface of the sample, removed the largest area of cellulose, and created the largest pore diameter. The opposite is true for the smaller-sized pores on the bottom surface of the scaffold.

BC is a non-biodegradable scaffold (Helenius et al. 2006). However, for tissue engineering applications, a scaffold that progressively degrades and resorbs as new tissue grows is desired because it eliminates the need for an additional surgery to remove residual materials. To assess the feasibility of Native BC and Porous BC scaffolds as tissue-engineered scaffolds, the scaffolds were modified using sodium periodate oxidation into Native OBC and Porous OBC. As illustrated in Fig. 5a, sodium periodate (NaIO4) can specifically cleave, convert the adjacent hydroxyl groups into aldehydes, and produce 2,3-dialdehyde cellulose (oxidized cellulose) (Bielecki et al. 2001; Hutchens et al. 2009). The oxidized cellulose can degrade in vivo by a simple hydrolysis mechanism into 2,4-dihydroxybutyric acid, glycolic acid and carbohydrates (Bielecki et al. 2001; Hutchens et al. 2009). The schematic diagram is shown in Fig. 5b.

Schematic diagrams of the oxidation and degradation mechanism of cellulose. a Sodium periodate oxidation of cellulose into 2,3-dialdehyde cellulose (oxidized cellulose). b Proposed degradation mechanism of oxidized cellulose into 2,4-dihydrxyxybutyric acid, glycolic acid and carbohydrates after hydrolysis

The morphological change in the scaffolds after oxidation, and the ability of the non-oxidized and oxidized cellulose scaffolds to permit the precipitation of bioactive nano HA, synthesized from the chemical precipitation of calcium and phosphate, were evaluated. The SEM images in Fig. 6 compared the morphologies of OBC, BC–HA and OBC–HA. Compared to Native BC (Fig. 2a, b), OBC (Fig. 6a, b) had a similar surface structure and fiber morphology signifying that sodium periodate oxidation did not modify the structure of the scaffold. SEM showed that similar to the Native BC (Fig. 2a), the surface morphology of the BC–HA (Fig. 6c) was still preserved. The microstructure morphology of BC–HA (Fig. 6d) confirmed that nano HA clusters had formed in the fiber of the cellulose scaffolds. Figure 6e confirmed that the OBC–HA maintained its structure in comparison to Native BC (Fig. 2a) and OBC (Fig. 6a). Microscopically, the OBC–HA (Fig. 6f) also contained irregularly shaped nano HA clusters as observed with the BC–HA (Fig. 6d). Furthermore, the pore array architecture and fiber morphologies of Porous OBC (Fig. 7a, b), Porous BC–HA (Fig. 7c, d) and Porous OBC–HA (Fig. 7e, f) were preserved, and nano HA successfully formed in the fibrous networks of the Porous BC–HA (Fig. 7d) and Porous OBC–HA (Fig. 7f) scaffolds. In the mineralized nanofibrous BC scaffolds, Figs. 6d, f, 7d, f, it was observed that irregularly shaped 77 ± 15 nm nano HA formed within the cellulose fibers (white arrows) as well as aggregated nano HA that were 200–500 nm in size (black arrows).

It has been previously reported that periodate oxidation of cellulose, without the addition of n-propanol and by not performing the reaction in the dark, resulted in a significant decrease in the volume of the scaffold due to a free radical side reaction that occurs and leads to non-specific cellulose chain breakages (Hutchens et al. 2009; Li et al. 2009). In this work, the cellulose scaffolds were oxidized in the presence of n-propanol and in the dark to eliminate these undesired side reactions, as previously reported by others (Hutchens et al. 2009; Painter 1988). Assessment of the OBC and Porous OBC after oxidation using sodium periodate in n-propanol showed no visible changes in the color and morphology of the scaffolds when compared to the non-oxidized Native BC and Porous BC.

Mass analysis

The dry weights of Native BC and its composites are shown in Fig. 8. The results in Fig. 8 indicated that the method used to mineralize Native BC and Porous BC with nano HA into BC–HA and Porous BC–HA, respectively, did not result in a significant change (p < 0.05) in the dry weight of the scaffolds. Figure 8 also confirmed that periodate oxidation of Native BC and Porous BC into OBC and Porous OBC, respectively, did not produce quantitative structural changes in the dry scaffolds as their weights were not significantly different (p < 0.05). However, a combination of periodate oxidation and nano HA mineralization of the scaffolds into OBC–HA and Porous OBC–HA did induce quantitative structural changes in the dry samples as shown by the significant decrease (p < 0.05) in the dry weight of the samples compared to the Native BC and Porous BC (Fig. 8). It is possible that the process of chemical precipitation of nano HA following the formation of aldehyde groups during periodate oxidation weakened the network structure of the cellulose and resulted in the detachment of fibers from the scaffold. This hypothesis was confirmed with the significant decrease (p < 0.05) in dry weight of the OBC and Porous OBC after the chemical precipitation of nano HA into the scaffolds to form OBC–HA and Porous OBC–HA (Fig. 8). Hutchens et al. (2009) previously reported a similar trend in the non-significant decrease in dry weight between unmodified Native BC and periodate oxidized scaffolds (Hutchens et al. 2009).

Dialdehyde content in periodate oxidized scaffolds

The concentration of dialdehyde groups introduced in the OBC and Porous OBC scaffolds due to sodium periodate oxidation is shown in Table 1. The dialdehyde contents in OBC and Porous OBC were 1.34 ± 0.03 and 1.36 ± 0.03 mmol/g, respectively. No significant difference (p < 0.05) was observed between the dialdehyde content of OBC and Porous OBC. This signified that the introduction of porosity did not influence the concentration of dialdehyde groups introduced into the cellulose scaffold. The 100 % degree of oxidation corresponds to the conversion of each C2–C3 bond in the cellulose chain into the 2,3-dialdehyde cellulose structure, and is equivalent to 12.5 mmol/g of the dialdehyde groups of the cellulose (Fig. 5a) (Roy-Chowdhury and Kumar 2006). The degrees of oxidation for OBC and Porous OBC were 10.72 ± 0.25 and 10.91 ± 0.21 %, respectively, and no significant difference (p < 0.05) was observed between the results (Table 1). The results demonstrate that the scaffolds were partially modified into oxidized cellulose with both glucopyranoside ring and 2,3-dialdehyde cellulose structures present in the oxidized scaffolds (Fig. 5a). The dialdehyde content in BC oxidized using 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) has been reported to equal 0.10 mmol/g (Okita et al. 2010), which is significantly less than the current finding using sodium periodate to oxidize BC (Table 1). The degrees of oxidation of the scaffolds can be improved by increasing the concentration of the oxidant, reaction time or temperature (Pommerening et al. 1992; Roy-Chowdhury and Kumar 2006; Varma and Kulkarni 2002), however the resulting BC may be negatively impacted and possess substantially reduced mechanical strength with increased degradation rate, which may be unsuitable for bone tissue applications.

Fourier-transform infrared spectroscopy (FTIR)

The FTIR spectra of Native BC and its composites are shown in Fig. 9. The spectral curve of Native BC is a typical spectrum of cellulose with the characteristic chemical functional groups ascribed to a BC structure (Hutchens et al. 2006). For Native BC, the absorption bands at 3350 and 3270 cm−1 correspond to the cellulose hydroxyl groups (Kondo 1998; Salmen et al. 2005). The spectra of Native BC and Porous BC were indistinguishable, confirming that the samples were of the same chemistry and that thermally decomposed residues produced from the laser processing had been successfully removed from the Porous BC (Fig. 9).

Phosphate, a component of HA, had been identified in the spectra of the produced BC–HA and Porous BC–HA (Fig. 9) at 1036, 962 and 567 cm−1 (Hutchens et al. 2006), confirming that the mineral clusters present in the BC–HA and Porous BC–HA scaffolds were positively nano HA (Figs. 6d, 7d). The spectra of the OBC and Porous OBC have an absorption band at 1740 cm−1 that represents the stretching vibration in the aldehyde carbonyl group formed in the cellulose during periodate oxidation (Fig. 9). This absorption peak is absent in the Native BC and Porous BC spectra (Fig. 9), further proving that periodate oxidation successfully formed oxidized cellulose in the OBC and Porous OBC scaffolds. In the spectra of the Porous OBC–HA and OBC–HA, the aldehyde carbonyl peak (1740 cm−1) and phosphate peaks (1036, 962 and 567 cm−1) were observed, signifying that the periodate oxidation successfully formed oxidized cellulose in the scaffolds and that the oxidized cellulose scaffolds were effectively mineralized with nano HA (Fig. 9). All of the characters described above indicated that the Porous BC was chemically identical to the Native BC, the 2,3-dialdehyde formed in the sodium periodate oxidized cellulose, and the nano HA produced chemical bonds within the matrix of the biomimetic BC composites.

The Ca2+ and PO4 of HA have been previously reported to form a firm chemical bond with the hydroxyl groups of native (Hutchens et al. 2006) and oxidized cellulose (Li et al. 2009). The Ca2+ of HA have also been proposed to form bonds with the aldehyde groups of oxidized cellulose (Hutchens et al. 2009). The establishment of chemical bonds between the nano HA and the non-oxidized and oxidized BC scaffolds has the potential to improve the stability of the nanoparticles in the scaffolds, and increase the possibility that the nanoparticles will not readily release from the composite following implantation and instigate dystrophic calcification (Kubota et al. 1984). However, in vivo studies would be needed to verify this.

Mechanical testing

The mechanical characteristics of Native BC and its composites were determined by analyzing the tensile properties of the scaffolds following the ASTM D638-10 standard test method. The ultimate tensile strength, strain at break, and elastic modulus values of the Native BC and its composites were calculated from the engineering stress–strain curves of the samples and are compared in Fig. 10. The Native BC scaffold showed an ultimate tensile strength of 1.41 ± 0.20 MPa, a strain at break of 23.38 ± 2.99 % and an elastic modulus of 5.46 ± 0.42 MPa. The introduction of micron-sized pore structures to produce Porous BC weakened the cellulose by decreasing its ultimate tensile strength by approximately 50 % (Fig. 10a), increased its strain at break by approximately 30 % (Fig. 10b), and decreased its elastic modulus by approximately 30 % (Fig. 10c). The Porous BC scaffold showed an ultimate tensile strength of 0.77 ± 0.09 MPa, a strain at break of 30.89 ± 2.05 % and an elastic modulus of 3.91 ± 0.43 MPa. Mineralizing the scaffolds with nano HA did increase the ultimate tensile strength of Porous BC by approximately 40 % (Fig. 10a). There were no significant differences between the mechanical properties of BC–HA (ultimate tensile strength 1.39 ± 0.28 MPa, strain at break of 23.44 ± 2.52 %, elastic modulus 6.73 ± 0.70 MPa) and Porous BC–HA (ultimate tensile strength 1.09 ± 0.23 MPa, strain at break of 21.41 ± 2.59 %, elastic modulus 4.71 ± 0.75 MPa) (Fig. 10). The measured ultimate tensile strengths and elastic moduli of these scaffolds were significantly lower than that of compact human bone (e.g., ultimate tensile strength of 67–100 MPa and elastic modulus of 13–3 GPa for an adult human femur) but are suitable for cancellous or porous bone (Evans 1976). Moreover, the mechanical properties of these cellulose scaffolds were still comparable to the 3.4 MPa hydrogel used to form new bone matrix in an ex vivo chick femur defect model (Smith et al. 2014) and are suitable for numerous orthopedic soft tissue applications (such as cartilage, tendons, etc.).

Oxidation of the scaffolds into OBC and Porous OBC affected the cellulose scaffolds by significantly reducing their ultimate tensile strength (Fig. 10a) and elastic modulus (Fig. 10c). The mechanical properties of OBC (ultimate tensile strength 0.55 ± 0.13 MPa, strain at break of 34.39 ± 4.48 %, elastic modulus 2.84 ± 0.88 MPa) were also significantly greater than Porous OBC (ultimate tensile strength 0.33 ± 0.07 MPa, strain at break of 22.92 ± 4.43 %, elastic modulus 1.08 ± 0.33 MPa). This further implies that the introduction of micron-sized pore structures into the cellulose scaffolds decreases its mechanical properties. Compared to the previous BC composites, the combination of oxidation and nano HA mineralization of the scaffolds into OBC–HA (ultimate tensile strength 0.16 ± 0.07 MPa, strain at break of 27.73 ± 6.68 %, and elastic modulus 1.05 ± 0.37 MPa) and Porous OBC–HA (ultimate tensile strength 0.11 ± 0.02 MPa, strain at break of 24.29 ± 2.18 %, and elastic modulus 0.70 ± 0.08 MPa) significantly reduced the mechanical properties of the cellulose scaffolds (Fig. 10). The range of moduli for these biomimetic BC scaffolds remain robust enough for use as nano HA-fibrous biopolymer composites for bone tissue engineering applications when compared to the tensile strength of the 25–40 kPa crosslinked-collagen and stem cell seeded gel used for collagenous bone tissue engineering scaffolds (Engler et al. 2006). Although the observed moduli of the biomimetic BC scaffolds are lower than that of cortical human bone, the scaffolds may be best suited for bone repair under non-load conditions, such as selected cancellous plate bones of the face and skull. The BC scaffolds may also be used as a non-load bearing scaffolds to fill tissue cancellous voids resulting from tissue damage, and serve as a matrix for new tissue to attach to during tissue regeneration.

In vitro degradation

The susceptibility of the BC composite scaffolds to degradation was tested in this study by measuring the weight loss of the samples in a simulated physiological environment. The mass differences of the BC composites before and after static incubation in a Tris–HCl-buffered SBF at 37 °C for 14 days are summarized and compared in Fig. 11. As expected, non-degradable scaffolds (e.g., Native BC, Porous BC, BC–HA, and Porous BC–HA) did not show mass changes of statistical significance after incubation in the Tris–HCl-buffered SBF. The OBC, Porous OBC and Porous OBC–HA showed a statistically significant loss of mass after incubation because of the breakage of the cellulose chain caused by the reaction of the simulated physiological buffer on the degradable scaffolds. It appears that the OBC–HA lost approximately 12 % of its mass after incubation, however, the mass change was not statistically significant. This was possibly because the amount of nano HA and nano fibers that had detached from the cellulose at the time of measurement were not sufficient to show statistical significance. The dry mass of OBC, Porous OBC and Porous OBC–HA were reduced by approximately 13, 16 and 25 %, respectively. In accordance with the degradation chemistry that was previously discussed (Fig. 5b), these oxidized BC composite scaffolds will ultimately degrade after hydrolysis into organic micro-molecules such as 2,4-dihydroxybutyric acid, glycolic acid and carbohydrates. As mentioned in the “Introduction” section, there are other ways to modify the degradation of BC, each with their own pros and cons. However, we would like to introduce another method in this study which involves the use of nano HA which will degrade as bone formation occurs due to the acidic enzymes (including alkaline phosphatase) produced by osteoblasts as they differentiate.

Comparison of the masses of Native BC and its composites before and after static incubation in Tris–HCl-buffered SBF (pH 7.4) at 37 °C for 14 days. Data are expressed as the mean ± standard deviation; (n = 4); asterisks indicates significant differences at p < 0.05 between ‘before incubation’ and ‘after incubation’ samples

Cell compatibility

MTS assay analysis was performed to determine the viability of hMSCs seeded on the Native BC and its composite scaffolds. The MTS assay results of the hMSCs seeded on the scaffolds are shown in Fig. 12. After 2 days in culture, MTS assays showed that the hMSCs seeded on the Native BC and its composite scaffolds were metabolically active, thus confirming their viability. The various forms of BC scaffolds exhibited distinct differences in their metabolic activity. Compared to Native BC, scaffold modification with nano HA (BC–HA) and by oxidation (OBC) resulted in approximately a 19 and 16 % significant increase in cell viability, respectively. The observed increase in cell viability following the introduction of nano HA on the BC scaffold is in agreement with previous studies using stem cells and nano HA (Hu et al. 2014), and osteoblasts and nano HA (Webster et al. 2000a, b). A previous in vitro study using mesenchymal stem cells and nano HA provided evidence of the mechanism, specifically that the stem cells would favorably adhere to the nano HA crystals via cytoplasmic processes, which mediates enhanced stem cell adhesion (Hu et al. 2014). Enhanced cell adhesion onto the scaffold surface is an early but crucial function for the survival of anchorage-dependent cells, such as stem cells, because it is followed by subsequent functions such as viability, proliferation and deposition of ECM proteins by the cell (Webster et al. 2000a). Therefore, in the current study, the observed increase in cell viability on the BC–HA is likely due to enhanced stem cell adhesion via cytoplasmic processes on the nano HA ceramics on this BC composite. The increased cell viability on the OBC compared to the Native BC suggests that the dialdehyde cellulose scaffold possesses chemical properties that can produce an improved and desirable surface chemistry for cell adhesion (Wu et al. 2014) and subsequent viability. The significant increase in stem cell viability on the OBC–HA compared to the Native BC, BC–HA and OBC scaffolds, was 54, 30 and 33 %, respectively. This implies that by combining the scaffold modification methods, the advantages of both oxidation and nano HA mineralization were used to further enhance the viability of the stem cells cultured on the OBC–HA.

Compared to the Native BC, the Porous BC, Porous BC–HA and Porous OBC, results showed a significant 73, 37 and 27 % decrease in cell viability, respectively. Cell viability decreased by approximately 16 % on the Porous OBC–HA compared to the Native BC, however, the change in viability was not statistically significant. The results imply that the Porous BC produced resulted in decreased cell adhesion and subsequent cell viability, which could be attributed to the decreased cell–cell interaction brought on by the introduction of micron-sized pore structures into the cellulose scaffold (El-Ayoubi et al. 2011); however, cell adhesion and viability was improved by modifying the scaffold via oxidation (Porous OBC), nano HA mineralization (Porous BC–HA), and by combining both methods (Porous OBC–HA), as observed with the non-laser perforated BC composites.

The morphology of the hMSCs seeded on the Native BC and its composite scaffolds were assessed using a phase contrast microscope. The phase contrast images of the scaffold composites are illustrated in Fig. 13. After 2 days in culture, the results showed greater cell adhesion on the BC–HA, OBC and OBC–HA compared to the Native BC, which concurs with the viability results and further indicates that the composite scaffolds offer a more biocompatible surface environment for the hMSC adhesion. Seeding of the hMSCs on the porous composite scaffolds for 2 days resulted in the colonization of cells with mostly a round phenotype and less elongated shapes that adhered on the top surface and inner pore surface of the porous scaffolds. The round morphology of the seeded cells is attributed to a reduced cell–cell interaction on the porous scaffolds (El-Ayoubi et al. 2011), and to the soft hydrogel-like BC surface properties, which causes the cells to generate less traction force and develop a narrower and round morphology after 2 days in culture (Favi et al. 2013). Stem cells have been shown to ultimately gain traction and acquire a full spread-out fibroblastic morphology by 7 and 14 days in culture on soft hydrogel-like BC scaffolds (Favi et al. 2013). Thus, an important discovery and contribution of this experiment is that the developed Porous OBC–HA composite, which possessed a number of desirable advanced biomaterial properties including biodegradability, nano HA mineralization and adequate micropores, maintained a similar viability and cytocompatibility as Native BC. This is because of the combined scaffold modification methods, where the advantages of both oxidation and nano HA mineralization further enhanced the viability of the stem cells cultured on the Porous OBC–HA, and maintained it to that of Native BC. Moreover, the porous BC composite scaffolds do contain micropores compared to the non-laser perforated composites, which could promote plasma protein adsorption, greater cell proliferation, and permit cell ingrowth and diffusion of nutrients to the cells. The BC composite scaffolds, and more specifically the Porous OBC–HA composites have the potential to be used as a bone tissue engineering scaffold because of its advanced biomaterial properties. Further investigation including cellular proliferation and differentiation are ongoing.

This study conducted with Native BC and its biomimetic composites showed that Native BC could be engineered to possess micropores, can be chemically modified to degrade, and can be easily mineralized with nano HA to mimic bone tissue. Although these biomimetic BC composite scaffolds seems to hold great promise for future bone tissue engineering therapies, further studies into their ability to deliver growth factors such as the cell attachment mediator arginine–glycine–aspartic acid (RGD), osteoinductive bone morphogenetic protein 2 (BMP-2), and vasculogenesis promoter vascular endothelial growth factor (VEGF) (Hersel et al. 2003; Suárez-González et al. 2013) is desirable. Delivering growth factors from the BC scaffolds may enhance cell attachment and growth, stimulate stem cell differentiation, and facilitate regeneration of the damaged bone tissue. Additionally, in vivo tissue graft studies using these biomimetic BC composite scaffolds in animal models is recommended in order to fully understand their in vivo biocompatibility, degradability, and potential to enable the healing of damaged bone tissues.

Conclusions

Well-defined microporous BC scaffolds with a 300 μm pore diameter and honeycomb pore arrays were successfully prepared. The scaffold was chemically modified to degrade using sodium periodate, and mineralized with precipitated nano HA to mimic bone tissue. SEM images showed that irregularly shaped 77 ± 15 nm nano HA and aggregated nano HA that were 200–500 nm in size formed within the nano fibrous cellulose fibers of the cellulose scaffolds. The Cannizzaro method to determine dialdehyde content, FTIR analysis and an in vitro degradation study showed that sodium periodate oxidation successfully generated oxidized BC composites that can biodegrade. The materials fabricated in the current study showed mechanical properties suitable for cancellous bone tissue engineering applications when compared to the tensile strength of the 25–40 kPa crosslinked-collagen currently used in such applications (ultimate tensile strength 0.16 ± 0.07 MPa, strain at break of 27.73 ± 6.68 %, and elastic modulus 1.05 ± 0.37 MPa for the present combination of oxidation and nano HA mineralization of the scaffolds into non-porous OBC–HA and for the porous OBC–HA, an ultimate tensile strength of 0.11 ± 0.02 MPa, strain at break of 24.29 ± 2.18 %, and elastic modulus 0.70 ± 0.08 MPa). Although the observed moduli of the present biomimetic BC scaffolds are lower than that of cortical human bone, the scaffolds may be best suited for bone repair under non-load conditions, such as selected cancellous plate bones of the face and skull. It is also important to mention that these are degradable scaffolds in which initial mechanical properties are less important due to eventual full bone replacement. Most importantly, MTS assay analysis and phase contrast images showed that the Native BC and its composites were biocompatible, and allowed hMSCs to adhere and maintain their viability on the scaffolds. This study showed that biodegradable nano HA–BC composites with well-defined pore sizes are attractive as future scaffolds for bone tissue applications.

Abbreviations

- BC:

-

Bacterial cellulose

- BC–HA:

-

Bacterial cellulose–hydroxyapatite

- FTIR:

-

Fourier-transform infrared spectroscopy

- HA:

-

Hydroxyapatite

- Native BC:

-

Native bacterial cellulose

- OBC:

-

Oxidized native bacterial cellulose

- OBC–HA:

-

Oxidized native bacterial cellulose–hydroxyapatite

- Porous BC:

-

Microporous bacterial cellulose

- Porous BC–HA:

-

Microporous bacterial cellulose–hydroxyapatite

- Porous OBC:

-

Oxidized microporous bacterial cellulose

- Porous OBC–HA:

-

Oxidized microporous bacterial cellulose–hydroxyapatite

- SEM:

-

Scanning electron microscope

References

Ahrem H et al (2014) Laser-structured bacterial nanocellulose hydrogels support ingrowth and differentiation of chondrocytes and show potential as cartilage implants. Acta Biomater 10:1341–1353. doi:10.1016/j.actbio.2013.12.004

Akkouch A, Zhang Z, Rouabhia M (2014) Engineering bone tissue using human dental pulp stem cells and an osteogenic collagen–hydroxyapatite-poly(L-lactide-co-ε-caprolactone) scaffold. J Biomater Appl 28(6):922–936. doi:10.1177/0885328213486705

American Society for Testing and Materials (2010) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA

Backdahl H, Esguerra M, Delbro D, Risberg B, Gatenholm P (2008) Engineering microporosity in bacterial cellulose scaffolds. J Tissue Eng Regen Med 2:320–330. doi:10.1002/term.97

Bäckdahl H, Helenius G, Bodin A, Nannmark U, Johansson BR, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27:2141–2149. doi:10.1016/j.biomaterials.2005.10.026

Bansal M, Kaushik M, Khattak BBP, Sharma A (2014) Comparison of nanocrystalline hydroxyapatite and synthetic resorbable hydroxyapatite graft in the treatment of intrabony defects: a clinical and radiographic study. J Indian Soc Periodontol 18:213–219. doi:10.4103/0972-124X.131329

Berner A et al (2012) Biomimetic tubular nanofiber mesh and platelet rich plasma-mediated delivery of BMP-7 for large bone defect regeneration. Cell Tissue Res 347:603–612. doi:10.1007/s00441-011-1298-z

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28:325–347. doi:10.1016/j.biotechadv.2010.01.004

Bielecki S, Krystoynowicz A, Turkiewicz M, Kalinowska H (2001) Bacterial cellulose. In: Vandamme EJ, De Baets S, Steinb A (eds) Biopolymers. Polysaccharides I, polysaccharides from prokaryotes, vol 5. Wiley, Weinham, pp 37–46

Bose S, Vahabzadeh S, Bandyopadhyay A (2013) Bone tissue engineering using 3D printing. Mater Today 16:496–504. doi:10.1016/j.mattod.2013.11.017

Croisier F, Jérôme C (2013) Chitosan-based biomaterials for tissue engineering. Eur Polym J 49:780–792. doi:10.1016/j.eurpolymj.2012.12.009

Cui D, Daley W, Naftel JP, Lynch JC, Haines DE, Yang G, Fratkin JD (2011) Atlas of histology: with functional and clinical correlations, 1st edn. Wolters Kluwer Health/Lippincott Williams & Wilkins, Philadelphia

El-Ayoubi R, Degrandpre C, DiRaddo R, Yousefi A-M, Lavigne P (2011) Design and dynamic culture of 3D-scaffolds for cartilage tissue engineering. J Biomater Appl 25:429–444. doi:10.1177/0885328209355332

Engler AJ, Sen S, Sweeney HL, Discher DE (2006) Matrix elasticity directs stem cell lineage specification. Cell 126:677–689. doi:10.1016/j.cell.2006.06.044

Evans FG (1976) Mechanical properties and histology of cortical bone from younger and older men. Anat Rec 185:1–11. doi:10.1002/ar.1091850102

Favi PM, Benson RS, Neilsen NR, Hammonds RL, Bates CC, Stephens CP, Dhar MS (2013) Cell proliferation, viability, and in vitro differentiation of equine mesenchymal stem cells seeded on bacterial cellulose hydrogel scaffolds. Mater Sci Eng C 33:1935–1944. doi:10.1016/j.msec.2012.12.100

Favi PM, Dhar MS, Neilsen NR, Benson RS (2014) Proliferation and osteogenic differentiation of mesenchymal stem cells on biodegradable calcium-deficient hydroxyapatite tubular bacterial cellulose composites. MRS Proc. doi:10.1557/opl.2014.287

Fontana J et al (1990) Acetobacter cellulose pellicle as a temporary skin substitute. Appl Biochem Biotechnol 24–25:253–264. doi:10.1007/bf02920250

Harley BA, Lynn AK, Wissner-Gross Z, Bonfield W, Yannas IV, Gibson LJ (2010) Design of a multiphase osteochondral scaffold. II. Fabrication of a mineralized collagen–glycosaminoglycan scaffold. J Biomed Mater Res A 92A:1066–1077. doi:10.1002/jbm.a.32361

Helenius G, Bäckdahl H, Bodin A, Nannmark U, Gatenholm P, Risberg B (2006) In vivo biocompatibility of bacterial cellulose. J Biomed Mater Res A 76A:431–438. doi:10.1002/jbm.a.30570

Hersel U, Dahmen C, Kessler H (2003) RGD modified polymers: biomaterials for stimulated cell adhesion and beyond. Biomaterials 24:4385–4415. doi:10.1016/S0142-9612(03)00343-0

Hu J, Zhou Y, Huang L, Liu J, Lu H (2014) Effect of nano-hydroxyapatite coating on the osteoinductivity of porous biphasic calcium phosphate ceramics. BMC Musculoskelet Disord 15:114. doi:10.1186/1471-2474-15-114

Hu J et al (2011) J Biomed Mater Res B, 2011, 97B and US Patent No. 20100172889

Hutchens SA, Benson RS, Evans BR, O’Neill HM, Rawn CJ (2006) Biomimetic synthesis of calcium-deficient hydroxyapatite in a natural hydrogel. Biomaterials 27:4661–4670. doi:10.1016/j.biomaterials.2006.04.032

Hutchens S, Benson R, Evans B, Rawn C, O’Neill H (2009) A resorbable calcium-deficient hydroxyapatite hydrogel composite for osseous regeneration. Cellulose 16:887–898. doi:10.1007/s10570-009-9300-6

Jalota S, Bhaduri SB, Tas AC (2008) Using a synthetic body fluid (SBF) solution of 27 mM HCO3− to make bone substitutes more osteointegrative. Mater Sci Eng C 28:129–140. doi:10.1016/j.msec.2007.10.058

Karageorgiou V, Kaplan D (2005) Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 26:5474–5491. doi:10.1016/j.biomaterials.2005.02.002

Kim B-S, Kang HJ, Lee J (2013) Improvement of the compressive strength of a cuttlefish bone-derived porous hydroxyapatite scaffold via polycaprolactone coating. J Biomed Mater Res B 101:1302–1309. doi:10.1002/jbm.b.32943

Kirkham KD, Roundy CB (2014) Current technology of beam profile measurement. In: Dickey FM (ed) Laser beam shaping: theory and techniques, 2nd edn. CRC Press, Taylor & Francis Group, Boca Raton, FL, pp 463–524

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog Polym Sci 26:1561–1603. doi:10.1016/s0079-6700(01)00021-1

Kondo T (1998) Hydrogen bonds in cellulose and cellulose derivatives. In: Dumitriu S (ed) Polysaccharides: structural diversity and functional versatility. vol Dumitriu S. Marcel Dekker Inc, New York, NY, pp 131–172

Kuboki Y, Jin Q, Takita H (2001) Geometry of carriers controlling phenotypic expression in BMP-induced osteogenesis and chondrogenesis. J Bone Joint Surg Am 83-A(Suppl 1 (Pt 2)):S105–S115

Kubota T, Sato K, Yamamoto S, Hirano A (1984) Ultrastructural study of the formation of psammoma bodies in fibroblastic meningioma. J Neurosurg 60:512–517. doi:10.3171/jns.1984.60.3.0512

Kucharzewski M, Slezak A, Franek A (2003) Topical treatment of non-healing venous leg ulcers by cellulose membrane. Phlebologie 32:138–169

Lee YM et al (2000) Tissue engineered bone formation using chitosan/tricalcium phosphate sponges. J Periodontol 71:410–417. doi:10.1902/jop.2000.71.3.410

Li J, Wan Y, Li L, Liang H, Wang J (2009) Preparation and characterization of 2,3-dialdehyde bacterial cellulose for potential biodegradable tissue engineering scaffolds. Mater Sci Eng C 29:1635–1642. doi:10.1016/j.msec.2009.01.006

Li K, Wang J, Liu X, Xiong X, Liu H (2012) Biomimetic growth of hydroxyapatite on phosphorylated electrospun cellulose nanofibers. Carbohydr Polym 90:1573–1581. doi:10.1016/j.carbpol.2012.07.033

Liu H, Webster TJ (2011) Enhanced biological and mechanical properties of well-dispersed nanophase ceramics in polymer composites: from 2D to 3D printed structures. Mater Sci Eng C 31:77–89. doi:10.1016/j.msec.2010.07.013

Lynn AK, Best SM, Cameron RE, Harley BA, Yannas IV, Gibson LJ, Bonfield W (2010) Design of a multiphase osteochondral scaffold. I. Control of chemical composition. J Biomed Mater Res A 92A:1057–1065. doi:10.1002/jbm.a.32415

Ma J et al (2014) Concise review: cell-based strategies in bone tissue engineering and regenerative medicine. Stem Cells Transl Med 3:98–107. doi:10.5966/sctm.2013-0126

Marolt D, Knezevic M, Novakovic GV (2010) Bone tissue engineering with human stem cells. Stem Cell Res Ther 1:10–20

Murphy CM, Haugh MG, O’Brien FJ (2010) The effect of mean pore size on cell attachment, proliferation and migration in collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 31:461–466. doi:10.1016/j.biomaterials.2009.09.063

Nguyen DT, Burg KJL (2015) Bone tissue engineering and regenerative medicine: targeting pathological fractures. J Biomed Mater Res A 103:420–429. doi:10.1002/jbm.a.35139

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11:1696–1700. doi:10.1021/bm100214b

Painter TJ (1988) Control of depolymerisation during the preparation of reduced dialdehyde cellulose. Carbohydr Res 179:259–268. doi:10.1016/0008-6215(88)84123-5

Parenteau-Bareil R, Gauvin R, Berthod F (2010) Collagen-based biomaterials for tissue engineering applications. Materials 3:1863–1887

Pina S, Oliveira JM, Reis RL (2015) Natural-based nanocomposites for bone tissue engineering and regenerative medicine: a review. Adv Mater. doi:10.1002/adma.201403354

Pommerening K, Rein H, Betram D, Muller R (1992) Estimation of dialdehyde groups in 2,3-dialdehyde bead cellulose. Carboohydr Res 233:219–223

Rambo CR, Recouvreux DOS, Carminatti CA, Pitlovanciv AK, Antônio RV, Porto LM (2008) Template assisted synthesis of porous nanofibrous cellulose membranes for tissue engineering. Mater Sci Eng C 28:549–554. doi:10.1016/j.msec.2007.11.011

Roy-Chowdhury P, Kumar V (2006) Fabrication and evaluation of porous 2,3-dialdehydecellulose membrane as a potential biodegradable tissue-engineering scaffold. J Biomed Mater Res A 76A:300–309. doi:10.1002/jbm.a.30503

Salmen L, Akerholm M, Hinterstoisser B (2005) Two-dimensional Fourier transform infrared spectroscopy applied to cellulose and paper. In: Dumitriu S (ed) Polysaccharides: structural diversity and functional versatility, 2nd edn. CRC Press, Taylor & Francis Group, Boca Raton, FL, pp 159–187

Sanchavanakit N, Sangrungraungroj W, Kaomongkolgit R, Banaprasert T, Pavasant P, Phisalaphong M (2006) Growth of human keratinocytes and fibroblasts on bacterial cellulose film. Biotechnol Prog 22:1194–1199. doi:10.1021/bp060035o

Schrarnrn M, Hestrin S (1954) Factors affecting production of cellulose at the air/liquid interface of a culture of Acetobacter xylinum. J Gen Microbiol 11:123–129

Smith EL et al (2014) Evaluation of skeletal tissue repair, part 1: assessment of novel growth-factor-releasing hydrogels in an ex vivo chick femur defect model. Acta Biomater 10:4186–4196. doi:10.1016/j.actbio.2014.06.011

Suárez-González D et al (2013) Controlled multiple growth factor delivery from bone tissue engineering scaffolds via designed affinity. Tissue Eng A 20:2077–2087. doi:10.1089/ten.tea.2013.0358

Svensson A, Nicklasson E, Harrah T, Panilaitis B, Kaplan DL, Brittberg M, Gatenholm P (2005) Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 26:419–431. doi:10.1016/j.biomaterials.2004.02.049

Torabinejad B, Mohammadi-Rovshandeh J, Davachi SM, Zamanian A (2014) Synthesis and characterization of nanocomposite scaffolds based on triblock copolymer of l-lactide, ε-caprolactone and nano-hydroxyapatite for bone tissue engineering. Mater Sci Eng C 42:199–210. doi:10.1016/j.msec.2014.05.003

Tracy BM, Doremus RH (1984) Direct electron microscopy studies of the bone–hydroxylapatite interface. J Biomed Mater Res 18:719–726. doi:10.1002/jbm.820180702

Tsuruga E, Takita H, Itoh H, Wakisaka Y, Kuboki Y (1997) Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induced osteogenesis. J Biochem 121:317–324

Ustundag CB, Kaya F, Kamitakahara M, Kaya C, Ioku K (2012) Production of tubular porous hydroxyapatite using electrophoretic deposition. J Ceram Soc Jpn 120:569–573

Varma AJ, Kulkarni MP (2002) Oxidation of cellulose under controlled conditions. Polym Degrad Stabil 77:25–27

Wan YZ et al (2007) Biomimetic synthesis of hydroxyapatite/bacterial cellulose nanocomposites for biomedical applications. Mater Sci Eng C 27:855–864. doi:10.1016/j.msec.2006.10.002

Wang J, Chunxi Y, Yizao W, Honglin L, Fang H, Kerong D, Yuan H (2011) Laser patterning of bacterial cellulose hydrogel and its modification with gelatin and hydroxyapatite for bone tissue engineering. Soft Mater 11:173–180. doi:10.1080/1539445X.2011.611204

Webster TJ, Ergun C, Doremus RH, Siegel RW, Bizios R (2000a) Enhanced functions of osteoblasts on nanophase ceramics. Biomaterials 21:1803–1810. doi:10.1016/S0142-9612(00)00075-2

Webster TJ, Ergun C, Doremus RH, Siegel RW, Bizios R (2000b) Specific proteins mediate enhanced osteoblast adhesion on nanophase ceramics. J Biomed Mater Res 51:475–483. doi:10.1002/1097-4636(20000905)51:3<475:aid-jbm23>3.0.co;2-9

Wegman F, Geuze RE, van der Helm YJ, Cumhur Öner F, Dhert WJA, Alblas J (2014) Gene delivery of bone morphogenetic protein-2 plasmid DNA promotes bone formation in a large animal model. J Tissue Eng Regen Med 8:763–770. doi:10.1002/term.1571

Wu J, Zheng Y, Yang Z, Lin Q, Qiao K, Chen X, Peng Y (2014) Influence of dialdehyde bacterial cellulose with the nonlinear elasticity and topology structure of ECM on cell adhesion and proliferation. RSC Adv 4:3998–4009. doi:10.1039/C3RA45407J

Acknowledgments

This study was supported by Northeastern University. Dr. Pelagie Favi is grateful for Northeastern University’s ADVANCE Future Faculty Postdoctoral Fellowship Program (sponsored by National Science Foundation Grant #0811170). The authors also thank Mr. William Fowle and Dr. Wentao Liang for assistance with the TEM images and Dr. Roberto Benson for the donation of the Acetobacter xylinus subsp. Sucrofermentans cells.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Favi, P.M., Ospina, S.P., Kachole, M. et al. Preparation and characterization of biodegradable nano hydroxyapatite–bacterial cellulose composites with well-defined honeycomb pore arrays for bone tissue engineering applications. Cellulose 23, 1263–1282 (2016). https://doi.org/10.1007/s10570-016-0867-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0867-4