Abstract

In this study, a neutronic performance of the Laser Inertial Confinement Fusion Fission Energy (LIFE) molten salt blanket is investigated. Neutronic calculations are performed by using XSDRNPM/SCALE5 codes in S8–P3 approximation. The thorium molten salt composition considered in this calculation is 75 % LiF—25 % ThF4, 75 % LiF—24 % ThF4—1 % 233UF4, 75 % LiF—23 % ThF4—2 % 233UF4. Also, effects of the 6Li enrichment in molten salt are performed for all heavy metal salt. The radiation damage behaviors of SS-304 structural material with respect to higher fissionable fuel content and 6Li enrichment are computed. By higher fissionable fuel content in molten salt and with 6Li enrichment (20 and 50 %) in the coolant in form of 75 % LiF—23 % ThF4—2 % 233UF4, an initial TBR >1.05 can be realized. On the other hand, the 75 % LiF—25 % ThF4 or 75 % LiF—24 % ThF4—1 % 233UF4 molten salt fuel as regards maintained tritium self-sufficiency is not suitable as regards improving neutronic performance of LIFE engine. A high quality fissile fuel with a rate of ~2,850 kg/year of 233U can be produced with 75 % LiF—23 % ThF4—2 % 233UF4. The energy multiplication factor is increased with high rate fission reactions of 233U occurring in the molten salt zone. Major damage mechanisms in SS-304 first wall stell have been computed as DPA = 48 and He = 132 appm per year with 75 % LiF—23 % ThF4—2 % 233UF4. This implies a replacement of the SS-304 first wall stell of every between 3 and 4 years.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As alternative energy source, nuclear fusion could provide a cheap, environmentally benign, and inexhaustible energy. Nuclear fusion investigations are based on magnetic confinement fusion (MCF), inertial confinement fusion (ICF) technologies in the world. Magnetic fusion energy (MFE) uses strong magnetic fields to confine a low-density deuterium and tritium (DT) plasma to achieve sustainable conditions to generate fusion energy. Inertial confinement fusion (ICF) can use laser beams or heavy ion beams to compress a capsule containing a mixture of DT ice and gas, either by direct illumination or by indirect illumination [1, 2]. The DT fusion reactions yield both alpha particles and 14.1-MeV neutrons, generating significant energy gain. The National Ignition Facility (NIF) is expected to demonstrate the capability of lasers to create the conditions required for ICF ignition. Detailed information on pellet ignition and inertial confinement fusion can be found in the related literature, such as in Ref. [1]. Recently, a series of conceptual design studies on a Laser Inertial Confinement Fusion–Fission Energy (LIFE) reactor concept have been initiated at Lawrence Livermore National Laboratory (LLNL), based on the geometry of NIF [3–8]. LLNL scientists have published work on two different LIFE concepts with respect to the utilization of fissionable material:

-

The molten salt blanket: Molten salt considered is made of the eutectic mixture of 73 mol % LiF and 27 mol % UF4. The possible use of 232Th as a fuel is also mentioned [3].

-

Solid fuel concept: A depleted uranium (DU) fission fuel blanket with micro-size multi-layered TRISO particles in Flibe coolant were considered and performed [4–8].

After that, neutronic performance of LIFE engine was investigated by LLNL scientists to utilize nuclear waste [4–8]. And also, in the literature, the reactor grade (RG) plutonium and minor actinide carbide fuel in form of TRISO particles were performed by some researchers using the solid fuel concept of LIFE engine [2, 9].

In this study, the neutronic performance of LIFE engine using various thorium molten salts (75 % LiF—25 % ThF4, 75 % LiF—24 % ThF4—1 % 233UF4, 75 % LiF—23 % ThF4—2 % 233UF4) are performed. Material damage criteria displacement per atom (DPA) and He parts per million by atom (appm) after 1 years of operation, tritium breeding (TBR >1.05) and energy multiplication for the initial and fissile fuel breeding (233U/year) in the coolant are evaluated. In addition, effects of neutronic performance of the 6Li enrichment (20 and 50 %) in molten salt are investigated for all heavy metal salt.

Problem Description

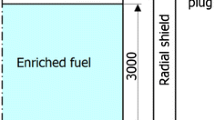

Preliminary design studies on a Laser Inertial Confinement Fusion–Fission Energy (LIFE) reactor concept have been initiated at LLNL, based on the geometry of NIF [3, 4] as shown in Fig. 1. The LLNL molten salt concept has suggested a spherical fusion chamber of 2.5 m radius, a beryllium zone (0.15 m) behind an ODS first wall, followed by a molten salt fuel zone and graphite reflector, shown in Fig. 2. In this study, beryllium zone proposed for early generation IFE reactors will be ignored. Previous studies on hybrid reactors have indicated that a beryllium multiplier, between the fusion chamber and fission blanket would cause neutron spectrum softening, and this would lead to local fission heat peaks at the immediate neighborhood of the first wall. Hence it is not recommended to use beryllium neutron multiplier for a fusion–fission (hybrid) reactor [11, 12], whereas it is strongly advisable for a pure fusion blanket. Furthermore, fissionable material 233U will cause significant neutron multiplication under fusion neutron irradiation so that an extra beryllium multiplier will not be needed. The molten salt containing heavy metal salt (ThF4 and UF4) is aggressive towards corrosion of structural materials. Therefore, a stainless steel SS-304 of LIFE engine was used. The basic structure of the molten salt blanket LIFE engine modified in this work is illustrated in Fig. 3. The spherical geometry used for neutronic calculations in modified LIFE engine is given in Fig. 4. As shown in Fig. 4 as a black zone, the (D,T) fusion fuel pellet in the center is compressed to a density of ρ = 600 gr/cm3, making an areal density of ρ = 3 gr/cm2 for a fuel shell thickness of 0.005 cm. In the present work, neutronic analysis of the molten salt blanket using various thorium molten salts (75 % LiF—25 % ThF4, 75 % LiF—24 % ThF4—1 % 233UF4, 75 % LiF—23 % ThF4—2 % 233UF4) is performed. Moreover, the effects of 6Li enrichment (20 and 50 %) on the performance of the salts 75 % LiF—25 % ThF4, 75 % LiF—24 % ThF4—1 % 233UF4 and 75 % LiF—23 % ThF4—2 % 233UF4 a are also carried out.

LIFE engine with NIF-like central hot spot (CHS) inertial confinement fusion (ICF) target features a dedicated first wall coolant with a pebble-based multiplier and fuel [10]

LIFE engine with a molten salt fuel blanket [3]

Numerical Calculations

The neutronic calculations have been performed with the help of SCALE5 system [13] solving the Boltzmann transport equation in one-dimensional geometry with the transport code XSDRNPM [14] in S8–P3 approximation by using the 238-neutron groups data library. The resonance calculations in the fissionable fuel element cell are performed with BONAMI [15] for unresolved resonances and NITAWL-III [16] for resolved resonances. The investigations are conducted for a fusion power generation of 2.857 GWth and a plant factor of 100 % to evaluate data for full power years. This gives continuous neutron source strength of 1.774 × 10+20 (14 MeV-n/s). In this study, the neutronic calculations are applicable to a static system.

Tritium Breeding Ratio

A fusion blanket must produce tritium for a self-sustainable fusion fuel supply. Tritium breeding ratio (TBR) should be higher than 1.05 to maintain tritium self-sufficiency [17–22]. Tritium can be extracted from the breeding reactions of 6Li and 7Li isotopes as given below;

where n, α and Q are the neutron, the alpha particle and the reaction energy, respectively. TBR can be calculated by the following equation:

where, \({\text{T}}_{6} = \iint {\Upphi \cdot \Upsigma_{{({\text{n}},{{\upalpha}}){\text{T}}}} }{\text{dEdV}}\) on 6Li, and \({\text{T}}_{7} = \iint {\Upphi \cdot \Upsigma_{{({\text{n}},{\text{n}}^{\prime } \alpha ){\text{T}}}} }{\text{dEdV}}\) on 7Li [17, 18].

The initial TBR values are illustrated in Fig. 5 for the investigated salts. The initial TBR value is very low for the 75 % LiF—25 % ThF4. However, the initial TBR increases due to the higher neutron multiplication rate with increasing in the fissile content of the salt. The TBR >1.05 criteria is provided with up to 75 % LiF—23 % ThF4—2 % 233UF4 in the LIFE engine as seen in Fig. 5. Also, the effects of the 6Li enrichment in molten salt are investigated. The TBR values increase with 6Li enrichment in the blanket as shown in Fig. 5. The enrichment ratio of 6Li has a great influence on the tritium production rate. Table 1 depicts the TBR in 6Li and 7Li as a function of the heavy metal fraction in the coolant. While the T7 in 7Li remains the same for both natural and enrichment Li, T6 in 6Li increases along with enrichment ratio. The production of the tritium self-sufficiency with 75 % LiF—25 % ThF4 or 75 % LiF—24 % ThF4—1 % 233UF4 molten salt aren’t provided. Therefore, 75 % LiF—25 % ThF4 or 75 % LiF—24 % ThF4—1 % 233UF4 molten salt fuel aren’t suitable to improve neutronic performance of LIFE engine. The best tritium breeding among investigated molten salts without 6Li enrichment with the 75 % LiF—23 % ThF4—2 % 233UF4 fuel is obtained.

Blanket Energy Multiplication

The total energy generation in the blanket can be expressed with the help of the energy multiplication factor M. Energy of the fusion source neutrons can be amplified by the nuclear fissions in the blanket. The amount of energy released in a fission reaction is about 200 MeV. On the other hand, the amount of energy released per 6Li(n,α)T reaction is 4.784 MeV, whereas the energy absorbed per 7Li(n, nα)T is 2.467 MeV. M can be defined as below [17–22]:

The initial M change is computed for the investigated cases with molten salt fuel as shown in Fig. 6. The initial M factor increases with higher fissionable fuel content in the molten salt whereas; its decreased with 6Li enrichment. The highest M factor is obtained for the highest fissile content (75 % LiF—23 % ThF4—2 % 233UF4) as expected. M factor is around 1.5 for the 75 % LiF—25 % ThF4. On the other hand, higher fissionable fuel content in the molten salt causes higher blanket energy multiplication, namely up to M = 12 with 75 % LiF—23 % ThF4—2 % 233UF4. However, M factor with 6Li enrichment decreases for the investigated cases with molten salt fuel. M factor for 75 % LiF—24 % ThF4—1 % 233UF4 (with 20 % 6Li enrichment) molten salt obtains as ~6 whereas; the 75 % LiF—24 % ThF4—1 % 233UF4 (with 50 % 6Li enrichment) molten salt provide low M factor (~4). The more neutrons have been absorbed by increasing enrichment of 6Li. Therefore, the fewer neutrons will be involved in the fission reaction as seen in Table 1. The decrease of fission reactions will reduce the blanket energy generation. Hence, the total energy deposition will be changed depending on the material composition of the blanket (Fig. 7).

The total energy multiplication factor M in the LIFE engine (legend as in Fig. 5)

The integral fission rate in the coolant per incident fusion neutron as a function of heavy metal content in the coolant (legend as in Fig. 5)

Fissile Fuel Breeding

Heavy metal in the coolant contributes to fissile fuel breeding (FFB) and energy multiplication through neutron capture and fission, respectively. The 232Th(n,γ) 233U breeding ratio as a function of the heavy metal fraction in the coolant are given in Table 1. 233U breeding ratio is increased by higher fissionable material whereas; it’s decreased with increasing enrichment 6Li ratio due to higher neutron absorption. Figure 8 shows the total 233U/year. The highest FFB is computed for the LIFE engine using the salt of 75 % LiF—23 % ThF4—2 % 233UF4 whereas; the lowest one is obtained for that with 75 % LiF—25 % ThF4 (50 % 6Li enrichment). The FFB values is ~2,850 kg 233U/year for the 75 % LiF—23 % ThF4—2 % 233UF4 whereas, the FFB of molten salt 75 % LiF—25 % ThF4 (with 50 % 6Li enrichment) is about 450 kg 233U/year. FFB values decreases with increasing 6Li enrichment in molten salt. FFB productions are about 1,250 and 550 kg/year with 75 % LiF—24 % ThF4—2 % 233UF4 (with 20 % 6Li enrichment) and 75 % LiF—24 % ThF4—2 % 233UF4 (with 50 % 6Li enrichment), respectively.

Fissile fuel breeding (FFB) per incident fusion neutron (legend as in Fig. 5)

Neutron Radiation Damage

In fusion blanket, the first structural wall of the fusion reaction chamber will be exposed to nuclear radiation as shown in Fig. 3. The first wall may suffer material damage under intense neutron radiation. Main source for material damage in fusion reactor structure will be ① displacement per atom and ② helium gas production. References [23, 24] suggest a DPA value of <100 and Refs. [25, 26] suggest a damage limit of He <500 appm. In the present work, a limit of DPA and He gas production are chosen as 100 and 500 appm, respectively. It remains to be validated whether such levels can be sustained. When the molten salts; 75 % LiF—23 % ThF4—2 % 233UF4 are used in the blanket, the highest DPA is obtained as ~48 in the SS-304 first wall steel structure of LIFE engine after a plant operation of 1 full power year (FPY) as illustrated in Fig. 9. On the other hand, the lowest DPA/FBY is computed as ~35 for that with 75 % LiF—25 % ThF4 (50 % 6Li enrichment). Also, DPA/FPY increases with higher fissionable fuel content in the molten salt whereas; the values decrease with increasing 6Li enrichment in coolant. The He production for three different molten salts is illustrated in Fig. 10. The He production values are calculated as 132 appm/FPY in the steel structure of LIFE engine. He generation values at first wall are very close to each other for three molten salts. When considering both DPA/FBY and helium generation limits together, SS 304 first wall stell will need to be changed between ~3 and 4 years. However, a number of steels will be considered for building the structure of the LIFE engine. These include a variety of austenitic stainless steels, ferritic steels, and refractory metal alloys. The austenitic steels are prone to extreme swelling as well as high temperature thermal creep. Ferritic steels show relatively little swelling during neutron irradiation, and can be enhanced by inclusion of a nano-dispersion of oxide particles. In general, ferritic stainless steels exhibit much less irradiation-induced swelling than type 316 austenitic stainless steels, as shown in Fig. 11 [10, 27, 28]. And also, Ref. [29] given irradiation limiting factors depends on creep and embrittlement for conventional ferritic, martensitic or austenitic steels. The SS-316 and SS-304 stainless steel is close to the same corrosion properties. Therefore, for future studies, the first wall material can be taken into consideration the other structure materials in the calculations for both void swelling and corrosion resistant.

DPA variation for an operation period of 1 year in the first wall (legend as in Fig. 5)

Helium production change for an operation period of 1 year in the first wall (legend as in Fig. 5)

Conclusions

The study has been performed to investigate fusible and fissile fuel breeding potential of the LIFE engine. Tritium self-sufficiency is provided by 75 % LiF—23 % ThF4—2 % 233UF4 among the investigated salts. Tritium breeding increases with higher 6Li enrichment and fissionable fuel content in the molten salt. Energy multiplication factor increases with higher fissionable fuel content in the molten salt whereas; its decrease with increasing 6Li enrichment. A fissionable fuel fraction of heavy metal in the molten salt will be able to produce sufficient fissile fuel. The FFB values is 2,850 kg 233U/year for the 75 % LiF—23 % ThF4—2 % 233UF4 whereas, the FFB of molten salt 75 % LiF—25 % ThF4 (with 50 % 6Li enrichment) is about 450 kg 233U/year. DPA/FPY and helium production increases with higher fissionable fuel content in the molten salt. DPA/FPY and helium production are obtained as ~48 and 132 appm/FPY, respectively, for 75 % LiF—23 % ThF4—2 % 233UF4. When considering both DPA and helium generation limits together, the first wall in LIFE engine will need to be changed between ~3 and 4 years in LIFE engine. As a result, the neutronic performance in LIFE engine increased with higher in the fissile content of the salt. And also, a benchmark calculation in LIFE engine will be performed using MCNP and KENO nuclear code as further studies.

References

J.J. Duderstadt, G.A. Moses, Inertial Confinement Fusion (Wiley, USA, 1982)

S. Şahin, M.J. Khan, R. Ahmed, Fuel breeding and actinide transmutation in the life engine. Fusion Eng. Des. 86, 227 (2011)

R.W. Moir et al., Molten salt fuel version of Laser Inertial Fusion Fission Energy (LIFE). Fusion Sci. Technol. 56, 632–640 (2009)

K.J. Kramer et al., Parameter study of the LIFE engine nuclear design. Energy Convers. Manage. 51(9), 1744–1750 (2010)

E.I. Moses, T. Diaz de la Rubia, J.F. Latkowski, J.C. Farmer, R.P. Abbott, K.J. Kramer, P.F. Peterson, H.F. Shaw, R.F. Lehman II, A sustainable nuclear fuel cycle based on Laser Inertial Fusion Energy (LIFE). Fusion Sci. Technol. 56(2), 566–572 (2009)

R.P. Abbott, M.A. Gerhard, K.J. Kramer, J.F. Latkowski, K.L. Morris, P.F. Peterson, J.E. Seifried, Thermal and mechanical design aspects of the LIFE engine. Fusion Sci. Technol. 56(2), 618–624 (2009)

K.J. Kramer, J.F. Latkowski, R.P. Abbott, J.K. Boyd, J.J. Powers, J.E. Seifried, Neutron transport and nuclear burnup analysis for the Laser Inertial Confinement Fusion–Fission Energy (LIFE) engine. Fusion Sci. Technol. 56(2), 625–631 (2009)

W.R. Meier et al., System modeling for the Laser Fusion–Fission Energy (LIFE) power plant. Fusion Sci. Technol. 56(2), 647–651 (2009)

S. Şahin, H.M. Şahin, A. Acır, LIFE hybrid reactor as reactor grade plutonium burner. Energy Convers. Manage. 63, 44–50 (2012)

J.C. Farmer, T. Diaz de la Rubia, E. Moses, (Report Draft) The complete burning of weapons grade plutonium and highly enriched uranium with (Laser Inertial Fusion–Fission Energy) LIFE engine, LLNL-TR-410152 (2009)

S. Şahin, M. Al-Eshaikh, Fission power flattening in hybrid blankets using mixed fuel. Fusion Technol. 12, 395–408 (1987)

S. Şahin, Power flattening in a catalyzed (D, D) fusion driven hybrid blanket using nuclear waste actinides. Nucl. Technol. 92, 93–105 (1990)

L.M. Petrie, SCALE5-Scale System Driver, NUREG/CR-0200, Revision 7, Volume III, Section M1, ORNL/NUREG/CSD-2/V3/R7 (Oak Ridge National Laboratory, Oak Ridge, 2004)

N.M. Greene, L.M. Petrie, XSDRNPM, a one-dimensional discrete-ordinates code for transport analysis, NUREG/CR-0200, Revision 7, 2 , Section F3, ORNL/NUREG/CSD-2/V2/R7 (Oak Ridge National Laboratory, Oak Ridge, 2004)

N.M. Greene, BONAMI, Resonance Self-shielding by the BONDARENKO Method, NUREG/CR-0200, Revision 6, Volume 2, Section F1, ORNL/NUREG/CSD-2/V2/R7 (Oak Ridge National Laboratory, Oak Ridge, 2004)

N.M. Greene, L.M. Petrie, R.M. Westfall, NITAWL-III, Scale System Module for Performing Resonance Shielding and Working Library Production, NUREG/CR-0200, Revision 6, Volume 2, Section F2, ORNL/NUREG/CSD-2/V2/R7 (Oak Ridge National Laboratory, Oak Ridge, 2004)

A. Acır, Effect of nuclear data libraries on tritium breeding in a (D–T) fusion driven reactor. J. Fusion Energ. 27, 301–307 (2008)

M. Übeyli, A. Acır, Utilization of thorium in a high power density hybrid reactor with innovative coolants. Energy Convers. Manage. 48(2), 576–582 (2007)

M. Übeyli, A. Acır, Neutronic investigation on the ARIES-ST fusion reactor with fissionable molten salts. Energy Convers. Manage. 51(12), 2531–2534 (2010)

M. Übeyli, Neutronic performance of HYLIFE-II fusion reactor using various thorium molten salts. Ann. Nucl. Energy 33, 1417–1423 (2006)

M. Übeyli, H. Yapıcı, Utilization of heavy metal molten salts in the ARIES-RS fusion reactor. J. Fusion Energ. 27(3), 200–205 (2008)

H. Yapıcı, Study of fissile fuel breeding concept for the force-free helical reactor. Fusion Eng. Des. 65(4), 599–609 (2003)

D.L. Smith et al., Blanket comparison and selection study-final report. Argonne National Laboratory Report, ANL/FPP-84-1 (1984)

R.W. Moir et al., HYLIFE-II, a molten-salt inertial fusion energy power plant design-final report. Fusion Technol. 25(1), 5 (1994)

A. Blink et al., in High-Yield Lithium-Injection Fusion–Energy (HYLIFE) Reactor, ed. by K.L. Essary, K.E. Lewis. Lawrence Livermore National Laboratory Report, UCRL-53559 (1985)

M. Perlado, M.W. Guinan, K. Abe, Radiation Damage in Structural Materials, in Energy from Inertial Fusion, International Atomic Energy Agency, Vienna (1995), p. 272

S.J. Zinkle, Materials in extreme nuclear environments (Invited Presentation, National Ignition Facility, Lawrence Livermore National Laboratory, March 17, 2008)

S.J. Zinkle, Microstructures and mechanical properties of irradiated metals and alloys, Materials Issues for Generation IV Systems: Status, Open Questions and Challenges, Book Series: NATO Science for Peace and Security Series B—Physics and Biophysics, pp. 227–244, (2008) doi:10.1007/978-1-4020-8422-5-11

S.J. Zinkle, Fusion materials science: overview of challenges and recent progress. Phys. Plasmas 12, 058101 (2005)

Acknowledgments

The author also appreciates the constructive comments of the referees that have helped improve the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acır, A. Neutronic Analysis of the Laser Inertial Confinement Fusion–Fission Energy (LIFE) Engine Using Various Thorium Molten Salts. J Fusion Energ 32, 634–641 (2013). https://doi.org/10.1007/s10894-013-9628-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-013-9628-7