Abstract

The rheological behavior of liquid egg products (egg yolk, egg white, and whole liquid egg) was studied using a concentric cylinder viscometer. Eggs of three poultry specimens were used: hen (Isa Brown), Japanese quail (Coturnix japonica), and goose (Anser anser f. domestica). Rheological behavior was pseudoplastic and flow curves fitted by the power law model (Herschel–Bulkley and Ostwald–De Waele). The meaning of rheological parameters on friction factors and velocity profiles during flow of liquid egg products in tube has been shown.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Knowledge of the rheological properties of food products is essential for the product development, quality control, sensory evaluation and design, and evaluation of the process equipment. The flow behavior of a fluid can be varied from Newtonian to time-dependent non-Newtonian in nature depending on its origin, composition, and structure behavior and previous history [1]. The knowledge of this behavior is also very important for egg liquids owing to an increasing demand for processed egg products. The term “egg products” refers to eggs that are removed from their shells for processing and convenience, for commercial, foodservice, and home use. These products can be classified as refrigerated liquid, frozen, and dried products. Traditionally, eggs are marketed as shell eggs, but in recent years, egg consumption in the form of egg liquid products has increased [2]. Several researchers [3–10] studied the rheological characteristics of egg yolk, whites, and liquid whole egg and reported Newtonian as well as time-dependent non-Newtonian flow behavior. These works are summarized in [11]. Most of these studies have usually been carried out with only egg yolk. There is a lack of information about the rheological behavior of liquid egg white and liquid whole egg at different temperature ranges [12]. Virtually no information is available on the rheological behavior of liquid products of other eggs, such as Japanese quail eggs, which are increasingly used in the food industry.

Considering this lack of published information on fluid dynamics of liquid egg products, the main purpose of this work was to determine rheological properties of these products for eggs of three domestic fowls: hen (Isa brown), goose (Anser anser f. domestica) and Japanese quail (Coturnix japonica). The meaning of these data for the calculation of friction factors for tube flow is discussed in detail.

2 Materials and methods

2.1 Materials

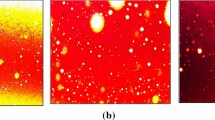

Fresh shell eggs hen (Isa brown), Japanese quails (Coturnix japonica) and goose (Anser anser f. domestica), no older than 3 days, were purchased from local farms. Egg shells were washed with deionized water and hand broken properly. Liquid whole egg was prepared by mixing approximately ten broken eggs in the same container. All liquids were filtered in order to separate impurities (chalaza, membranes). Samples, with volume 200 ml, for each liquid egg product were prepared and stored at 4 °C before measurement. From many physical parameters which have been measured, only the densities of the tested liquids are presented in Table 1.

2.2 Rheological measurement

Rheological measurements were carried out using an Anton Paar DV3-P rotary viscometer equipped with a coaxial cylinder sensor system. Rotational speed ranged between 0.3 (0.279 s−1) and 200 rpm (186 s−1). Apparent viscosity, η, is the ratio of shear stress, σ, and shear strain rate, \( \dot{\gamma} \). By [13] it has been evaluated as:

All measurements were performed at room temperature (∼20 °C).

3 Results and discussion

In Fig. 1 the flow curves, i.e., shear stress vs. shear strain rate, are shown. These curves can be fitted using the Herschel–Bulkley model [14]:

In Eq. (2), σ is the shear stress, \( \dot{\gamma} \) is the shear strain rate, K is the consistency index, n is the flow behavior index, and σo is the yield stress. For egg yolk of goose eggs, this model reduces to the Ostwald–De Waele model, given by Eq. (3), also known as the power-law model [15]:

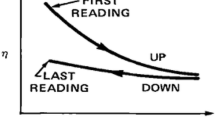

Equations (2) and (3) can be used for both Newtonian and power law fluids. For Newtonian fluids, n equals 1, and K equals η or η + σo for Newtonian and power law fluids, respectively. Equation (2) can be used for the egg white of hen and quail eggs and for liquid whole egg of all tested eggs. Parameters of Eq. (2) are given in Tables 2, 3 and 4 (R2 is the coefficient of determination). The apparent viscosity is given using the Eq. (1). The viscosity of tested egg liquids is shown in Figs. 2, 3, and 4.

The egg liquids exhibit shear thinning behavior. The main differences between liquids of different eggs can be observed for the egg yolks. The highest values of the apparent viscosity were achieved for goose eggs, followed by hen eggs, and the minimum values were exhibited by quail eggs. The differences between egg white of different eggs are not too significant. The liquid whole eggs have nearly the same value of the apparent viscosity regardless of the poultry species. The differences in rheological properties of egg liquids are caused by chemical composition of eggs from hens, geese, and quail (differences in water and lipid content).

The obtained rheological parameters have great meaning in many problems of industry. For example, the design of piping and pumping systems requires knowledge of the pressure drop due to the flow in straight pipe segments and through valves and fittings. Friction losses caused by the presence of valves and fittings usually result from disturbances of the flow, which is forced to change direction abruptly to overcome path obstructions and to adapt itself to sudden or gradual changes in the cross section or shape of the duct. This problem is described for example in [16]. The pressure drop is calculated using the friction factor, f. The friction factor is defined as [17]:

where ρ is fluid density, v is the average flow velocity, and σw is the stress in the wall, given by

In Eq. (5), D is the tube diameter and ΔP is the pressure drop observed in a length L of the tube. For laminar flow, the friction factor can be obtained from a simple function of the generalized Reynolds number, which is identical to the dimensionless form of the Hagen–Poiseuille equation [18]:

in which

Equations (6) and (7) can be used for both Newtonian and power law fluids. For Newtonian fluids, n equals 1 and K equals η, so that the generalized Reynolds number (Eq. 7) is reduced to the well-known number Re = Dvρ/η.

The values of the generalized Reynolds number for egg liquids tested in this article are given in Table 5. Under turbulent flow conditions, the existing correlations to estimate the friction factor are semi-empirical. For power law fluids, probably the best-known correlation is that presented by [19]:

Let us consider a cylindrical tube of diameter D = 0.01 m and an average flow velocity v = 1 m/s. This type of tube is usually used in the pasteurization process of egg products.

The Reynolds number characterizes the transition from laminar to turbulent flow. One can see that the highest Reg of yolk and white are exhibited by quail eggs and the smallest by goose eggs. The behavior of liquid whole eggs is different. The maximum value is exhibited by hen eggs. It may be a consequence of the different volume of egg liquids (volume proportion of yolk and white).

Laminar flow of a power law fluid exists in the tube when:

The critical value of the power law Reynolds number depends on the value of the flow behavior index, n, according to [20]:

Values of critical Reynolds number vary from 2,888 at n = 0.1 to the familiar value 2,100 for Newton liquids (n = 1). In all cases, the flows of liquid egg products are laminar.

The next application of the rheological properties is connected with the continuous thermal processing system. Such a system generally involves a heat exchanger in the form of a tube. A length of this tube is known as a “hold tube”, and must be sufficient in order to achieve sufficient fluid residence time. Because the hold tube is a critical part of the system, understanding velocity profiles found in the tube flow is important for the numerical simulation of the thermal process.

For a power law fluids (under laminar flow) the flow velocity v(x) is a function of the distance x. This distance is measured from the center of the pipe:

where ΔP denotes the pressure, L is the tube length, and R is its radius. For the illustration the values of R = 0.05 m, L = 1 m, and ΔP = 300 Pa were chosen. These values are usually used in the pasteurization process of egg products. Results are shown in Figs. 5, 6, and 7.

The highest values of flow velocities are observed for the flow of egg white. The lowest one was achieved for the flow of egg yolk. Velocities are different for different eggs. Liquids of the goose eggs exhibited the lowest values. The highest values of egg white and liquid whole eggs were observed for the hen eggs and the maximum of the flow velocity of the egg yolk was observed for the quail eggs.

The flow velocity equation (11) is valid for fully undisturbulent flow in straight horizontal tubes. Real processing system contain many other elements such as valves, tees, elbows etc., which can cause mixing of fluid during flow [21–24]. In addition, pipe vibration caused by energy inputs from pumps may contribute to mixing. This means that the equation given above represents only general guidelines in examining velocity profiles during tube flow.

4 Conclusions

Rheological properties of liquid egg products (liquid whole egg, egg white, and egg yolk) were studied for the eggs of three poultry species: hen (Isa Brown), Japanese quail (Coturnix japonica) and goose (Anser anser f. domestica). Experimental data were successfully fitted to a Herschel-Bulkley model. The egg liquids exhibit shear thinning behavior. The main differences between liquids of different eggs can be observed for the egg yolk. The highest values of the apparent viscosity were achieved for the goose eggs followed by the hen eggs and the minimum values were exhibited by quail eggs. The differences in rheological properties of egg yolk are caused by chemical composition of yolks from hens, geese, and quail (differences in water and lipid content). In the publication [25] it is shown that goose eggs (especially yolk) contained the highest contents of saturated and monounsaturated fatty acids but the lowest content of polyunsaturated fatty acids (PUFA). The ω-3 PUFA content and the ω-6/ω-3 ratio were higher in the yolks of goose. This can cause the higher values of apparent viscosity of goose yolk. The differences between egg white of different eggs are not too significant. The liquid whole eggs have nearly the same values of the apparent viscosity regardless of the poultry species.

The practical importance of knowledge of rheological parameters was outlined. These parameters can be used in various software applications dealing with a numerical simulation of flow problems.

References

Migliori, M., Gabriele, D., Baldino, N., Lupi, F.R., de Cindio, B.: Rheological properties of batter dough: Effect of egg level. J. Food Process Eng. 34, 1266–1281 (2011)

de Jesus, M.N., Zanqui, A.B.., Valderrama, P., Tanamati, A., Maruyama, S.A., de Souza, N.E., Matsushita, M.: Sensory and physico-chemical characteristics of desserts prepared with egg products processed by freeze and spray drying. Food Sci. Technol. 33, 549–554 (2013)

Jones, D.R.: Egg functionality and quality during long-term storage. Int. J. Poult. Sci. 6, 157–162 (2007)

Atilgan, M.R., Unluturk, S.: Rheological properties of liquid egg products. Int. J. Food Prop. 11, 296–309 (2008)

Takeuchi, J., Nagashima, T.: Chemical and physical characterization of Dromaius novaehollandiae (Emu) eggs. Food Sci. Technol. Res. 16, 149–156 (2010)

Toyosaki, T.: Rheological properties, oxidative stability, and tocopherol content during storage of fried dough made with silky fowl egg: Comparison with hen egg. Poult. Sci. 89, 1009–1014 (2010)

Alamprese, C., Casiraghi, E., Rossi, M.: Mechanical and rheological properties of fresh egg pasta as affected by shell egg production factors. Int. J. Food Sci. Technol. 47, 2503–2509 (2012)

de Souza, P.M., Fernández, A.: Rheological properties and protein quality of UV-C processed liquid egg products. Food Hydrocoll. 31, 127–134 (2013)

Toyosaki, T., Sakane, Y.: Rheological properties and oxidative stability of baked sponge cake using silky fowl egg. Adv. J. Food Sci. Technol. 5, 1351–1354 (2013)

Navidghasemizad, S., Temelli, F., Wu, J.: Physicochemical properties of leftover egg yolk after livetins removal. LWT Food Sci. Technol. 55, 170–175 (2014)

Singh, J., Sharma, H.K., Premi, M., Kumari, K.: Effect of storage conditions of egg on rheological properties of liquid whole egg. J. Food Sci. Technol. 51, 543–550 (2014)

Telis-Romero, J., Thomaz, C.E.P., Bernardi, M., Telis, V.R.N., Gabas, A.L.: Rheological properties and fluid dynamics of egg yolk. J. Food Eng. 74, 191–197 (2006)

Steffe J.F.: Introduction to rheology. In Rheological Methods in Food Process Engineering, Freeman Press, East Lansing (1996)

Travnicek, P., Krcalova, E., Vitez, T.: Rheopectic behavior of rendered fat. Pol. J. Environ. Stud. 22, 1499–1504 (2013)

Antunes, S.A., Lanza, M., Hense, H.: Rheological properties of rice bran (Oryza sativa L.) oils processing and soapstock distillation residue. Ind. Crop Prod. 46, 111–116 (2013)

Cabral, R.A.F., Telis, V.R.N., Park, K.J., Telis-Romero, J.: Friction losses in valves and fittings for liquid food products. Food Bioprod. Process 89, 375–382 (2011)

Garcia, E.J., Steffe, J.F.: Comparison of friction factor equations for non-Newtonian fluids in pipe flow. J. Food Process Eng. 9, 93–120 (1987)

Tao, J., Chen, S., Su, W.: Local Reynolds number and thresholds of transition in shear flows. Science China: Physics Mech. Astron. 56, 263–269 (2013)

Bahrani, S.A., Nouar, C.: Intermittency in the transition to turbulence for a shear-thinning fluid in Hagen–Poiseuille flow. J. Appl. Fluid Mech. 7, 1–6 (2014)

Steffe, J.F., Daubert, C.R.: Bioprocessing Pipelines: Rheology and Analysis. Freeman Press, Michigan (2006)

Telis-Romero, J., Polizelli, M.A., Gabas, A.L., Telis, V.R.N.: Friction losses in valves and fittings for viscoplastic fluids. Can. J. Chem. Eng. 83, 181–187 (2005)

Girón-Palomares, B., Hernández-Guerrero, A., Romero-Méndez, R., Oviedo-Tolentino, F.: An experimental analysis of the flow pattern in heat exchangers with an egg carton configuration (parallel, convergent and divergent cases). Int. J. Heat Fluid Flow 30, 158–171 (2009)

Wu, B.: CFD simulation of mixing in egg-shaped anaerobic digesters. Water Res. 44, 1507–1519 (2010)

Courtois, P., Ettelaie, R., Chen, J.: Numerical studies of transport properties in heterogeneous food systems. Appl. Rheol. 16, 275–286 (2006)

Wang, Q., Jin, G., Jin, Y., Ma, M., Wang, N., Liu, C., He, L.: Discriminating eggs from different poultry species by fatty acids and volatiles profiling: Comparison of SPME-GC/MS, electronic nose, and principal component analysis method. Eur. J. Lipid Sci. Technol. 116, 1044–1053 (2014)

Acknowledgments

This work was supported by IP 17/2014, financed by IGA AF MENDELU.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumbár, V., Strnková, J., Nedomová, Š. et al. Fluid dynamics of liquid egg products. J Biol Phys 41, 303–311 (2015). https://doi.org/10.1007/s10867-015-9380-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10867-015-9380-5