Abstract

In the present work the effect of storage conditions of egg on rheological properties of Liquid Whole Egg (LWE) prepared from stored eggs were evaluated using a Brookfield. Newtonian model and Ostwald-of-Waele (Power Law) model were fitted to the rheological data obtained by experiments, both represented a good adjustment to the rheological data. The Newtonian model has shown an R2value between 0.984 and 0.993 (P < 0.05) and 0.991 and 0.995 (P < 0.05) for LWE samples prepared from eggs stored at room temperatures and refrigerated temperatures. The Ostwald-of-Waele (Power Law) resulted in the best adjustment, presenting an average R2 values higher than 0.99 in all the cases and further statistical analysis showed that power law model was appropriate to explain the correct rheological behaviour of LWE prepared from stored eggs. All the LWE samples showed pseudoplastic and thixiotropic behaviour in the experimental conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Process properties of liquid egg products are not only necessary for proper design of process instruments, but also fundamental in product development, quality determination, sensory evaluation, and determination of processing method and instruments (Punidadas and McKellar 1999; Rao 1999). These properties can be categorized as the rheological, physical and optical properties of LEPs. Understanding the rheological and physical properties of LEPs with a wide range of temperature has great importance for the application of new processes in the egg products industry. The rheological data are used in engineering calculations involving a wide range of equipments such as pipelines, pumps, mixers, extruders, homogenizers, coaters, heat exchangers; in the determining ingredient functionality in the product development; shelf life testing; and in the evaluation of food texture by correlation to sensory data (Steffe 1996). Fluid foods are subjected to different temperatures during processing, storage, transportation, marketing, and consumption. For this reason, the rheological properties are studied as a function of temperature (Hamid-Samimi and Swartzel 1985).

Egg quality can be affected by the environmental conditions such as temperature and humidity of storage as well as the gaseous environment and storage time. Storage can modify some characteristics of the egg including loss of water, carbon dioxide and a subsequent increase in the pH of the albumen (Decuypere et al. 2001). The reason for these changes is that the porous shell of egg allows escape of carbon dioxide and moisture resulting in loss of weight. Storage time causes various physical, chemical and biological changes in a food product; therefore the changes in the rheological properties of a food product are also expected.

Eggs deteriorate rapidly during storage under ambient conditions but deteriorate at a decreased rate under the low temperature storage. Room temperature in the Northern region of India varies considerably throughout the year could be as high as 30°C in the dry hot season when ambient temperature reaches 40–45°C and as low as 15°C in the winter when ambient temperature reaches as low as 5–10°C. Therefore the deterioration rate may differ with respect to the seasons.

Various Studies has been carried out to study different physical, chemical, microbiological and quality parameters of shell egg, LEPs and dried egg products throughout the world (Punidadas and McKellar 1999; Hamid Samimi et al. 1984; Herald et al. 1989; Raji et al. 2009; Samli et al. 2005; Jirangrat et al. 2010), but no published work regarding the effect on the rheological characteristics of LEPs with respect to storage conditions of shell egg is available. The storage condition of shell eggs might also affect the rheological properties of LEPs is of great interest. Therefore the present study is going to be undertaken to investigate the effect of storage time and temperature of shell egg on the rheological and physical properties of LWE.

Material and methods

Materials

Fresh eggs, on the same day of laying were purchased from ShriShyam Poultries, village Lohakhera, Sangrur, Punjab, India. Eggs were stored at two different storage temperatures, room temperature (20–24°C) and refrigeration temperature (6°C) for storage studies.

Methods

Preparation and handling of Liquid Whole Egg (LWE) samples

The sample from eggs stored at room temperature was drawn out after every 7 day interval (0, 7,14,21 and 28 days) and sample from the eggs stored at refrigeration temperature was drawn out after every 14 day interval (0, 14,28,42 and 56 days) and rheological, physical and quality attributes were studied.

Fifteen Eggs from each sample were hand broken properly in 1000 ml beaker at the time of sample preparation. The membranous impurities were separated from LWE by filtering using a colander. The rheological, physical and quality measurements were carried within 2 h of sample preparation.

Measurement of physical and quality parameters

The pH and density of LWE samples was determined before its rheological measurements. Three replicates experiments were carried out for each sample. Density values of LWE were measured by using specific gravity bottle and pH of samples was measured using pH meter manufactured by Genei™, Bangalore, India. The average percentage weight loss of shell egg was determined by measuring the weight of 3 eggs after the specified time intervals for each shell egg sample. Haugh unit was also determined for the shell eggs sampled after specified time interval.

For Haugh unit calculations the following equation was used (Raji et al. 2009)

Where HU = Haugh unit, H = height of albumen (mm), W = egg weight (g).

Measurement of rheological parameters

Brookfield viscometer (model RVDV-E 230), manufactured by Brookfield Engineering Laboratories, USA was used for rheological measurements. Instructions given in Brookfield manual no. M/98-350-D0902 provided by Brookfield engineering laboratories, Inc. were followed for the proper handling and operation of the viscometer and collection of rheological data (www.brookfieldengineering.com).

The rheological measurements of 500 ml LWE samples placed in a 600 ml beaker were carried out at different rotational speeds, ranging from 10–100 rpm. The temperature of sample was maintained at 25°C by using a water bath. The RV1 spindle was found suitable for viscosity measurements after following the procedure to select suitable spindle for rheological measurements (www.brookfieldengineering.com).

The time dependency or time sensitivity of the samples was measured by shearing the samples at 60 rpm and measuring the apparent viscosity readings after every 30 s up to 300 s. Further shearing was done to ensure that the viscosity readings were stabilized and shearing time sensitivity of viscosity was fully removed. After that apparent viscosity and torque data were recorded at each speed (rpm) of spindle. The torque values obtained were converted to the shear stress and the rotational speeds were converted to the shear rates according to the methodology given by Mitschka (1982); Briggs and Steffe (1997) and Windson et al. (2009).

Mathematical modelling

The shear stress and shear rate were fitted to some of the common rheological models, such as the Newtonian model (Eq. 2) and Power Law or Ostwald-of-Waele (Eq. 3) model (Steffe 1996).

Where τ is the shear stress (Pa), μ is the viscosity (Pa.s), k is the consistency index (Pas), γis the shear rate (s−1), and n is the flow behaviour index (dimensionless).

Adequacy of fit of models to the experimental data

The statistical criteria applied to discriminate goodness of the fit of the models to the experimental data were higher R2 (regression coefficient), lower Chi square (χ2) and lower the Root Mean Square Error (RMSE). For each temperature, χ2 and RMSE values were predicted by using experimental and predicted shear stress values for each shear rate values (Doymaz 2006).

where, A is number of unknown coefficients in the given model, B is number of data points. But as these parameters are not very good criterion for evaluating the non-linear mathematical models, hence the percent mean relative deviation modulus (%E) was also used to select the best equation to account for variation in the experimental and actual values calculated by experimentation. This modulus has been recommended by many scientists for drying and dehydration (Chen and Morey 1989).

The average percent difference between the experimental and predicted values, mean relative deviation modulus (%E), was defined by the following equation.

The values of %E less than 5.0 indicate an excellent fit, while values greater than 10 are indicative of a poor fit.

Statistical analysis

The data collected was analysed using Microsoft Excel and STATISTICA 7 software packages.

Results and discussions

Physical and quality measurements

The density of LWE prepared from eggs stored at room and refrigeration temperatures increased with storage time in both the cases (Fig. 1), the increase in density could be due to the loss of moisture from the porous egg shell during storage. Density (ρ) data were correlated with time and temperature and the polynomial models were derived in all the cases (Table 1). The derived models presented R2 values higher than 0.99 (P < 0.05). The pH values of LWE were found to be increasing during storage period but at different rates (Table 2).The difference between the pH of LWE prepared from eggs stored at two different temperatures could be due to their varying ability to retard carbon dioxide loss and breakdown of carbonic acid to carbon dioxide (Raji et al. 2009).

Effect of storage conditions on the Haugh unit of eggs and average percentage weight loss is shown in Fig. 1. In case of eggs stored at room temperature the Haugh unit decreased from 85.04 to 64.39 as compared to the eggs stored at refrigeration temperature, where Haugh unit changed from 86.69 to 81.25 in the same time period.

The average percentage weight loss in case of eggs stored at room temperature in 28 days was 9.44 %, while in case of eggs stored at refrigeration temperature it was only 7.91% in 56 days. The consistent decrease in egg weight with increased storage time observed in this study is consistent with the reports of ACIAR (1998) and Samli et al. (2005). Samli et al. (2005) reported significant decrease in egg weight, Haugh unit with increase in storage time. However, Scott and Silversides (2000) and Silversides et al. (1993) reported that for some unexplained reasons, egg weight did not change in the first 10 days of storage. The average temperature in their study site was 20.2°C. The same kind of effect of storage conditions on egg quality parameters was also reported by Raji et al. (2009) and Akyurek and Okur (2009).

The quality of an egg is affected by the method and length of storage. Eggs kept at high temperature deteriorated in quality at a faster rate than eggs stored under refrigeration. Refrigerated eggs were able to maintain their quality comparable to the fresh eggs. In their findings Raji et al. (2009) concluded that oiling of eggs also maintained egg quality to some extent but oiling is not a replacement for refrigeration. It may however serve for 28 days where refrigeration facilities are not available. In the hot dry climate, where ambient temperatures can reach 40–45°C, eggs should not be stored at room temperature, for more than one week before consumption (Raji et al. 2009).

Rheological measurements

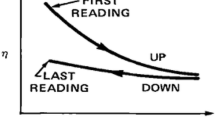

Effect of shearing time on apparent viscosity of LWE

All the LWE samples (stored at room and refrigerated temperature) showed a decrease in viscosity with respect to shearing time at a fix rpm. Results are summarized in Fig. 2. A change in the LWE viscosity with shearing time indicates time-dependent behaviour; a decrease signifies thixotropy. This decrease is an important consideration in process design. As the sample is sheared during its passage through the process system, the linkages between particles or molecules in the food are broken, resulting in reduction in the size of the structural units and offer lower resistance to flow (Rao 1995).

Rheological parameters

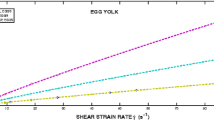

Two different rheological models (Newtonian model and Power law model) have been examined to ascertain the correct flow behaviour of LWE. The flow parameters for LWE samples are given in Table 3. Figure 3 shows the shear stress versus shear rate diagram for LWE prepared from eggs stored at room temperature and refrigeration temperature respectively. The experimental data were fitted to the Newtonian model and Ostwald-of-Waele (Power Law) model and both represented a good adjustment to the experimental data. The Newtonian model has shown an R2value between 0.984 and 0.993 (P < 0.05) for LWE samples prepared from eggs stored at room temperatures and 0.991 and 0.995 (P < 0.05) for LWE samples prepared from eggs stored at refrigerated temperatures.

The Ostwald-of-Waele (Power Law) resulted in the best adjustment, presenting an average R2 values higher than 0.99 in all the cases and further statistical analysis showed that power law model was appropriate to explain the correct rheological behaviour of LWE prepared from stored eggs, because in support of higher values of regression coefficients of power law the values of χ2, RMSE and %E were comparatively lower than Newtonian type equation for all samples studied (Table 3).

All the samples presented a non-Newtonian behaviour, with a characteristic of a pseudoplastic fluid. The LWE prepared from egg samples stored under room temperature changed to more pseudoplastic behaviour with course of storage time than egg samples stored at refrigeration temperature (Table 3), because the value of flow behaviour index (n) changed from 0.914 to 0.888 in 28 days as compared to value of flow behaviour index changed from 0.914 to 0.889 in 56 days for refrigerated samples.

By applying Power Law, the values of consistency index (k) found to be varying from 0.037 to 0.110 Pa.sn for LWE prepared from egg stored at room temperature and 0.37 and 0.130 for LWE prepared from egg stored at refrigeration temperature. Newtonian viscosity values were found to be varied from 0.029 to 0.076 Pa.s for LWE prepared from egg stored at room temperature and 0.29 to 0.091 for LWE prepared from egg stored at refrigeration temperature.

It is evident from these results that the values of apparent viscosity and consistency coefficient increased during storage at both storage temperatures. The increase in the above said flow parameters was at higher rate with respect to storage time in case of eggs stored at room temperature as compared to egg stored at refrigeration temperature, this could be due to the temperature abuse to the eggs at higher storage temperature.

Although no published data was found regarding the effect of storage conditions of shell eggs on the rheological behaviour of shell egg, but these findings were in agreement with Herald et al. (1989) who have studied rheological properties of pasteurized LWE during frozen storage and observed that the LWE samples showed increase in apparent viscosity during storage. Large differences in the viscosity of fresh and frozen LWE have been reported (Cornford et al., 1969; Palmer et al., 1969; Harrison and Cunningham, 1986). Frozen storage at −20°C for 2 months doubled the viscosity of LWE compared to controls (Torten and Eisenberg 1982). Cornford et al. (1969) and Torten and Eisenberg (1982) reported that thawed frozen whole egg was pseudoplastic. Processors have reported occasional variability in the functionality of frozen LWE used in commercially prepared baked goods. The cause of this variability is not completely understood. Preliminary experiments in the laboratories indicated that egg composition was not always the cause of variability, which suggested that temperature or conditions of frozen storage may influence the functional properties of LWE (Herald et al. 1989).

Effect of storage time and temperature of shell egg on viscosity of LWE

The effect of temperature on the Newtonian viscosity (calculated by using STATISTICA 7 software) for LWE prepared from stored eggs, is illustrated in Fig. 4, and the effect of time on the apparent viscosity at different shear rates is illustrated in Fig. 5. The figures show that the Newtonian viscosity increased during storage at both the temperatures. Newtonian viscosity values were found to be varied from 0.029 to 0.076 Pa.s for LWE prepared from egg stored at room temperature and 0.29 to 0.091 for LWE prepared from egg stored at refrigeration temperature as described in Table 3.

Conclusions

Rheological and selected physical properties of LWE were studied as a function of storage time and temperature. The results describing the rheological parameters of eggs stored at room and refrigeration temperatures indicated that liquid whole egg (LWE) exhibited pseudoplastic and time dependent behaviour. The experimental data were successfully fitted to the Newtonian model and Ostwald-of-Waele (Power Law) model and both represented a good adjustment to the experimental data. The Ostwald-of-Waele (Power Law) was found best between the two models to describe the flow behaviour of LWE in all the condition. All the samples showed thixotropic behaviour, which continued to increase as the storage time increased. The effect of storage time and temperature on physical and quality attributes was also studied, which showed an increase in pH and density and decrease in Haugh unit with increasing storage time at both temperatures. The shell egg samples also showed a decrease in average weight in both cases, whereas the sample stored at refrigeration temperature has showed less change in physical and quality parameters during the same period of time as compared to samples stored at room temperature.

References

ACIAR (1998) Measurements and maintenance of duck and hen egg quality in Vietnam. Australian Centre for International Agricultural Research, Research note RN 23 12/99

Akyurek H, Okur AA (2009) Effect of storage time, temperature and hen age on egg quality in free range layer hen. J Anim Vet Adv 8(10):1953–1958

Briggs JL, Steffe JF (1997) Using Brookfield data and the Mitschka method to evaluate power law foods. J Text Stud 28:517–522

Chen C, Morey RV (1989) Comparison of four ERH/EMC equations. Trans ASAE 32:983–990

Cornford SJ, Parkinson TC, Robb J (1969) Rheological characteristics of processed whole egg. J Food Technol 4:353

Decuypere E, Tona K, Bruggeman V, Bamelis F (2001) The day-old chick: acrucial hinge between breeders and broilers. World’s Poult Sci J 57:127–137

Doymaz I (2006) Thin-layer drying behaviour of mint leaves. J Food Eng 74(3):370–375

Hamid-Samimi MH, Swartzel KR (1985) Maximum change in physical and quality parameters of fluid foods during continuous flow heating: application to liquid whole egg. J Food Process Preserv 8:225–239

Hamid Samimi M, Swartzel KR, Ball HR Jr (1984) Flow behavior of liquid whole egg during Thermal treatments. J Food Sci 49:132–136

Harrison LJ, Cunningham FE (1986) Influence of frozen storage time on properties of salted yolk and its functionality in mayonnaise. J Food Qual 9:167

Herald TJ, Osorio FA, Smith DM (1989) Rheological properties of pasteurized liquid whole egg during frozen storage. J Food Sci 54(1):35–38

Jirangrat W, Torrico D, No J, No HK, Prinyawiwatkul W (2010) Effects of mineral oil coating on internal quality of chicken eggs under refrigerated storage. Int J Food Sci Technol 45(3):490–495

Mitschka P (1982) Simple conversion of Brookfield R.V.T readings into viscosity functions. Rheol Acta 21:207–209

Palmer HH, Ijichi K, Cimio SL, Roff H (1969) Salted egg yolks. 1. Viscosity and performance of pasteurized and frozen samples. Food Technol 23:1480

Punidadas P, McKellar RC (1999) Selected physical properties of liquid egg products at pasteurization temperatures. J Food Process Preserv 23:153–168

Raji AO, Aliyu J, Igwebuike JU, Chiroma S (2009) Effect of storage methods and time on egg quality traits of laying hens in a hot dry climate. ARPN J Agr Biol Sci 4(4):1–7

Rao MA (1995) Engineering properties of foods, rheological properties of fluid foods. Marcel Dekker, New York, pp 1–53

Rao MA (1999) Rheology of fluid and semisolid foods. Aspen Publishers, Inc., Gaithersburg

Samli HE, Agma A, Senkoylu N (2005) Effect of storage time and temperature on egg quality in old laying hens. J Appl Poult Res 14:548–553

Scott TA, Silversides FG (2000) The effect of storage and strain of hen on egg quality. Poult Sci 79:1725–1729

Silversides FG, Twizeyimana F, Villeneuve P (1993) Research note: a study relating to the validity of the Haugh unit correction for egg weight in fresh eggs. Poult Sci 72:760–764

Steffe JF (1996) Rheological methods in food process engineering. Freeman, Michigan

Torten J, Eisenberg H (1982) Studies on colloidal properties of whole egg magma. J Food Sci 47:1423

Windson C, Haminiuk I, Maciel GM, Plata-Oviedo MS, Quenehenn A, Scheer AP (2009) Study of the rheological parameters of honey using the Mitschka method. Int J Food Eng 5(3):1–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, J., Sharma, H.K., Premi, M. et al. Effect of storage conditions of egg on rheological properties of liquid whole egg. J Food Sci Technol 51, 543–550 (2014). https://doi.org/10.1007/s13197-011-0509-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0509-7