Abstract

Herein, Cu ions surface-doped Dy2O3 photocatalyst (Cu–Dy2O3) is synthesized utilizing hydrothermal technique to degrade methyl violet under visible light irradiation. X-ray diffraction (XRD), scanning electron microscopy (SEM), and UV–Visible techniques are used to characterize the structure, morphology, and optical activities of the photocatalyst, respectively. Moreover, the radiation-attenuation ability of Dy2O3 and Cu–Dy2O3 is studied by determining the mass attenuation coefficients using Geant4 simulations. XRD measurements indicate that Cu–Dy2O3 has high crystallinity and single phase orientation which outperforms photocatalytic activity. The doped material shows 94% degradation efficiency, which is much better as compared to the undoped material under visible light. The reason for enhanced efficiency could be attributed to the synergetic effect, good morphology, small crystallite size, lattice distortion due to doping, and more charge imbalance of copper-doped Dy2O3. The excellent photocatalytic efficiency and other above mentioned characteristics of the synthesized photocatalyst may be responsible for future applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Organic dyes have been used in many industries such as paper, textile, plastic, rubber, cosmetics as well as a food coloring agent without any treatment [1,2,3]. The 10–15% of the dye remained un-used in water and the industries drop their effluents to the rivers, leaks etc. When colored waste water are introduced into the ecosystem, they produce non-aesthetic pollution, eutrophication, and aquatic life disruption [4, 5]. Toxicity of contaminated water could be evaluated using factors like biological oxygen demand (BOD), suspended solids (SS), total organic carbon (TOC) and chemical oxygen demand (COD) [6,7,8]. Among various azo dyes, methyl violet is mostly used in industrial products and uncontrolled release of methyl violet causing allergic, mutation and cancer [9,10,11].

The demand of a new technology for removing organic dyes from wastewater has become a serious issue worldwide due to increase in number of industries. Many techniques can be used to remove the color from waste water such as coagulation, adsorption, reverse osmosis, ultrafiltration, flocculation, biological process, electrocatalytic oxidation, chemical oxidation, and photochemical processes [12,13,14,15,16,17,18,19]. Moreover, adsorption and photodegradation can be employed as an effective strategies for removing organic dyes due to their simplicity and cost effectiveness [20, 21]. Adsorption has gained much attention as alternative method for industrial wastewater treatment due to its inexpensiveness, uncomplicated setup, accessibility, simple and intact adsorbent recovery [22, 23] but the disposal of adsorbent is the major issue as it may contaminate the environment. Among all, photocatalytic technology is considered as superior method since it is eco-friendly and economically viable to get rid of organic pollutants from water due to its enhanced mineralization efficacy and ease of application using light irradiation [24, 25].

For the purpose of wastewater treatment, semiconductor photocatalysts have got attraction such as nickel oxide (NiO) is a suitable option for n–p junction generator along with another n-type semiconductor because of its high catalytic surface region, low price, and purity. Methyl violet (MV) can be removed from solution using a combination of adsorption and photocatalysis to demonstrate the effectiveness of NiO and the removal of dye will be affected by pH, nanocomposite dosage, and exposure time [26]. In recent years, TiO2 and ZnO nanoparticles have been employed for degradation of many organic pollutants and synthetic dyes as non-toxic, cost-effective, and economical semiconducting photocatalysts [27, 28]. Most of the metal oxides have wide band gap value which restrict their utilization under visible light [29, 30] and various metal oxides nanoparticles were doped with different other metals to enhance the absorption of light in the visible region such as Ce-doped ZnO [31], Mn doped CuO nanosheets [32], Ag-doped CuO nanosheets [33], Ce-doped CuO [34], Tb doped CuO [35], Yb doped ZnO [36], erbium oxide-copper oxide for the degradation of organic pollutants [37,38,39]. In recent years, the lanthanide series metal oxides and their derivatives such as La2O3/Ag3VO4 [40], Ce-doped CuO [41], La doped CeO2 [42], Sn/La co-doped TiO2 [43], Dy doped CoFe2O4 [44], Dy2O3/Bi2O3 [45], and Er doped CeO2 [46] got lot of attention because of their low band gap value which absorb the visible region of light but they low photocatalytic efficiency due to recombination of electrons/holes pair. Therefore, in the present work Dy2O3 has been selected due to its low band gap (2.3 eV) but its efficiency was 62% due to recombination of charge carriers. To enhance the efficiency and to stop the recombination process copper was used as dopant which absorb the photo-generated electron. With the highest magnetic moment and susceptibility, dysprosium a lanthanide metal and its oxide have gained interest to researchers. The use of dysprosium oxide as a photocatalyst is increasing due to its paramagnetic nature along with its high degrading activity and large surface area. Combining the properties of both copper and dysprosium oxide in a nanocomposite is expected to have low band gap energy and high photocatalytic activity. Because it is already reported that the doping of different metals, such as Cu, Cr, Co, V, Ti, Li, and Al are used for scavenging the photo-excited electrons in order to stop recombination process, leading to the increase of photocatalytic efficiency [47, 48].

Inspired from the above mentioned characteristics, in this article we fabricated the novel Cu-doped Dy2O3 for improving the photocatalytic properties of nanomaterial by simple and economical hydrothermal method and characterized by XRD, AFM, DLS, FTIR, and UV–Vis. Moreover, the photocatalytic efficiency of the nanoparticle was evaluated by degradation of MV dye under visible light and the results are discussed below.

2 Experimental section

2.1 Materials

All the analytical grade reagents and chemicals were used as received without further purification. Dysprosium nitrate [Dy(NO3)3], sigma Aldrich (99.5%), copper nitrate [Cu(NO3)2], sigma Aldrich (98%), sodium hydroxide (NaOH), Merck 65% and ultrapure water, methyl violet, sigma Aldrich 75%, hydrochloric acid (HCl), Analar 98% and ethylenediamine (C2H4(NH2)2) Analar 99.8% were used.

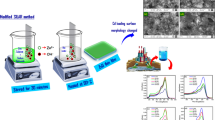

2.2 Synthesis of Cu-doped Dy2O3

Cu-doped Dy2O3 was fabricated using hydrothermal treatment. For this purpose, a solution of dysprosium nitrate (0.5 mM) was prepared and then a solution of sodium hydroxide (NaOH, 0.005 mM) which was already prepared in ultrapure water was added into the dysprosium nitrate solution dropwise to maintain the pH at 11. The precipitates were appeared after the addition of sodium hydroxide solution and the mixture was poured in the autoclave of 50 mL capacity. The autoclave was kept for heat treatment at 150 °C for 24 h and after heat treatment the autoclave was allowed to cool at room temperature. The mixture was being treated with 0.1 M HCl solution. To remove any leftover contaminants, the powder was centrifuged and washed with deionized water several times before being dried under vacuum at 60 °C. The fabrication of copper ions surface-doped Dy2O3 was conducted via following route. Firstly, ethylenediamine was added to copper nitrate [Cu(NO3)2] aqueous solution (0.05 mM) in a 2:1 stoichiometric ratio to produce Cu(en)2(NO3)2. After that the as-prepared 0.50 g of Dy2O3 was added in 50 mL of Cu(en)2(NO3)2 and the mixture was sonicated for 30 min, followed by magnetic stirring for 1 h. The resulted material was centrifuged, rinsed with deionized water repeatedly to purify the resultant product, and finally dried at 60 °C under vacuum, and then calcined at 300 °C in the presence of air for 3 h. Copper ions surface-doped Dy2O3 mechanism is shown in Scheme 1.

2.3 Physiochemical characterization

The Cu-kα radiation source on the Shimadzu Lab X-6000 X-ray Diffractometer was scanned at 4°/min in the 10–80° two theta range to confirm the crystallinity and the phase of the fabricated materials. Bragg equation nλ = 2d sinθ, was used to calculate the interlayer spacing of materials. At room temperature, UV–Visible spectra were recorded using the UV-3010 UV–Vis spectrophotometer investigate the photocatalytic activity as well as the band gap value. Using the Nova NanoSEM-450 scanning electron microscope (SEM), was used to investigate the material’s morphology.

2.4 Photocatalytic activity

For the purpose of photocatalytic studies, the dye solution of 10 ppm was taken in to the reaction chamber followed by addition 0.05 g/L of synthesized photocatalysts which was stirred in the dark for 15 min to attain the adsorption/desorption equilibrium. There was a little change in the colour of the dye solution due to adsorption as shown in Scheme 2. The starting concentration of methyl violet in the reaction solution, and the temperature of the reaction solution were maintained at 25 °C throughout the experiment. A 5 mL of sample solution was taken after every 20 min and was centrifuged. The concentration of methyl violet in each sample was determined using a spectrophotometer (UV-3010) at a wavelength of 590 nm using the Beer Lambert’s Law. Some controlled experiments were also conducted in which the dye solution was illuminated without catalyst and the other one in which the photocatalyst was added in the dye solution but without light. In both cases no change in the absorbance of the dye was observed which confirm that the degradation is due to presence of photocatalyst and light. The photocatalytic efficiency of the synthesized material was calculated using Eq. 1 [49]

where Co is the initial concentration of dye and the concentration at time t is represented by Ct.

2.5 Radiation-attenuation ability

For the purpose of radiation-attenuation studies, we determined the mass attenuation coefficient (MAC) for Dy2O3 and Cu–Dy2O3 using Geant4 simulations [50]. In this part of simulation, the MAC for the prepared samples can be obtained based on Lambert–Beer law (\(I={I}_{o}{\text{exp}}[-{\text{LAC}}\cdot x])\), herein, LAC is the linear attenuation coefficient and x is the thickness which can be adjusted to be 1 cm. More details about the simulation procedures can be found in the previous works [51, 52].

3 Results and discussion

3.1 Congregation of Cu(en)2(OH)2 on the surface of Dy2O3

Scheme 1 depicts the complete technique for fabrication of copper-modified Dy2O3. Dy–OH was generated on the surface of hydrothermally produced Dy2O3 when it was treated with 0.1 M HCl solution before being washed with distilled water repeatedly, and shown as:

The Cu (en)2(OH2) and hydroxide radicals react with each other to form Cu ions on the surface of Dy2O3 as represented in Eq. 3.

3.2 Structural analysis

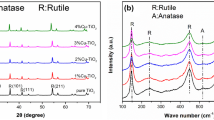

Powder X-ray diffraction analysis demonstrates the crystalline phase of synthesized catalyst and the results show that undoped Dy2O3 had 11 distinct peaks in its XRD pattern with diffraction planes (222), (321), (420), (422), (510) (521), (521), and (530), (100), (620), (620), (550) appeared at 2θ = 29.67°, 31.55°, 37.27°, 41.40°, 43.93°, 46.93°, 49.09°, 51.81°, 54.34°, 56.78° and 61.75°, respectively, as given in Fig. 1a. All the peaks adhered to the dysprosium oxide which confirmed that it crystalized into single phase. In doped Dy2O3, there is no extra peak in XRD pattern, but there is a shift in peaks which shows the presence of copper confirming the high purity of the synthesized material. Cu-doped Dy2O3 nanoparticles have broader peaks than that of un-doped indicating the smaller particle size as peak broadening in inversely proportional to the crystallite size according to the Scherer equation. The cell volume reduces when copper is introduced to Dy2O3 nanoparticles which is due the reason that Dy3+ has a greater ionic radius (1.027 Å) than Cu2+ (0.73 Å) and the reduction in cell volume indicate the copper ions also enter into the structure lattice which shrink the cell lengths.

Fourier transform infra-red spectroscopy (FTIR) was performed for the detection of functional group and molecular detection of the designed Dy2O3 and Cu-doped Dy2O3 displayed in Fig. 1b. The absorption bands demonstrated Dy–O–Dy stretching vibration is responsible for the strong peak in the IR spectrum of Dy2O3 at 620 cm−1. The FTIR spectrum of Dy2O3 has peaks at 620, 1018, 2834, 2945 and 3326 cm−1. The peaks at 1018 and 3326 cm−1 are due to H–O–H and the O–H bending vibration which appeared due to the absorption of moisture on the surface of synthesized materials. Sharp peaks at 2945 and 2834 cm−1 were observed due to stretching vibrations of Dy-O bond. Synthesized Cu-doped Dy2O3 FTIR spectrum revealed the bands at 777, 1180, 3385 and 3823 cm−1. The peak at 777 cm−1 was related to symmetric vibrational modes of Dy–O–Dy. The O–H, H–O–H, and Dy–O–Dy stretches in the Cu(en)2(NO3)2 spectrum may be recognized. Many high-frequency vibrations resulted from the incorporation of Cu(en)2–Dy2O3 into Dy2O3 nanoparticles. The peak at 3385 cm−1 was corresponding to the starching vibration of O–H bond and the bending vibration of H–O–H from water molecules on the external surface. The peak at 3823 cm−1 is caused by the bending vibration of O–Cu [50]. The obtained peaks were well-matched with the earlier reported values confirming the formation of Cu–Dy2O3.

3.3 Morphological and textural analysis

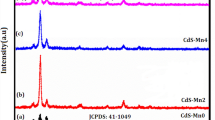

Scanning electron microscopy (SEM) was used to study the surface properties of Dy2O3 and copper-doped Dy2O3 synthesized via hydrothermal route. Figure 2a and b shows the SEM micrographs, confirming the nanoparticles with agglomeration and nanoflakes shaped morphology for Dy2O3 and copper-doped Dy2O3, respectively. The change in morphology of the copper-doped Dy2O3 may be due to the increase in rate of growth at 400 plane (as the peak intensity in the XRD pattern increase) and disappearance of 541 plane as shown in Fig. 1a. In the resultant pattern, the exterior and interior surfaces were additionally interconnected via electrostatic interactions. Figure 2c and d represent the BET isotherms of the Dy2O3 and copper-doped Dy2O3, respectively, to confirm the BET surface area of the prepared samples. The obtained BET surface area for the Dy2O3 and copper-doped Dy2O3 were 78, and 102 m2 g−1, respectively. The higher the BET surface area, higher will be the porosity, and surface-active sites of the material, which must be responsible for the improving the photocatalytic activity of the synthesized material.

3.4 XPS analysis

X-rays photoelectron spectroscopy (XPS) was used to indicate the reaction between Cu(en)2(OH)2 and OH radicals on the surface of Dy2O3 resulted to form copper ion-doped Dy2O3, and the XPS survey spectrum is depicted in Fig. 3a. According to the XPS survey spectrum, there are no other metal elements were present in the material confirming the successful synthesis of the desired material. Figure 3b shows the XPS spectra of Dy 4d with binding energy at 154.26 eV, confirming its oxidation state + 3 as reported already. While, Fig. 3c depicts the XPS spectrum of Cu 2p, having two peaks at 932 and 952 eV correspond to Cu 2p1/2 and Cu 2p3/2, respectively, indicating the typical characteristics of Cu2+ to form a bond with oxygen atoms. The XPS O 1s profile as shown in Fig. 2c, representing that O2 peak appeared at 531.8 eV was due to the adsorbed oxygen on the surface of material. On the other hand, The XPS binding energies of the obtained sample was corrected using C 1s as a reference with binding energy of 284.60 eV as shown in Fig. 2d.

3.5 Optical properties

The diffuse reflectance spectroscopy of undoped, and copper-doped Dy2O3 are shown in Fig. 4a and b. Among them, copper-doped Dy2O3 has a slightly blue shifted absorption profile with two absorption peaks at 475 and 525 nm, respectively, as compared to undoped Dy2O3 with absorption peak at 250 nm. Red shifts are visible in the band gap transition spectra of Dy2O3. The tiny blue shift seen in this study could be linked to crystalline size which was reduced by doping as confirmed by the broadening peaks in XRD pattern. Hence, the absorbance profile of the doped material shifts toward longer wavelengths as displayed in Fig. 4a and b, which indicates that the Cu-doped material absorbs more visible light than Dy2O3. A direct charge transfer from O2 to Dy3+, or an indirect charge transfer between O2 and Dy3+, could be the cause of visible-range changes. To calculate optical band gaps, Tauc's formula was utilized to calculate the Eg band.

"A" is energy-free constant and n is the transition mode (n = 2 for a direct band gap). The Eg value was calculated using a straight-line projection to the x-axis by plotting a graph of (αhv)2 along the y-axis and hv values along the x-axis (Fig. 4c and d). The Eg values for Dy2O3 (2.3 eV), and Cu-doped Dy2O3 (1.74 eV) have been determined, and the sample with a lower Eg value has a stronger ability to catch more visible light radiation. Both energy states and deliberate defects (oxygen vacancies) boost light-capture capacities in Dy2O3 doped with Cu2+. Figure 4e represents the photoluminescence (PL) spectra for the doped and un-doped dysprosium oxide nanomaterials to confirm the photogenerated charge carriers separation. Higher the intensity of the peak in PL spectrum, higher will be the rate of recombination between the photogenerated electrons/holes pairs. The intensity of the peak for Cu-doped materials is lower as compared to the un-doped material indicating that the rate of recombination of e−/h+ pair in the doped material is lower than that of the un-doped material. The lower rate of recombination is responsible for the higher efficiency of the doped catalyst.

3.6 Photocatalytic study

In this experiment, the irradiation source was visible light, and methyl violet (MV) was used as model contaminant for testing a novel material's photocatalytic activity having λmax in the range of 584 to 590 nm. The experiment was conducted in full darkness for 15 min to allow adsorption and desorption equilibrium. The photocatalytic activities of Dy2O3, and Cu2+-doped Dy2O3 were carried out in the presence of the visible light irradiation as shown in Fig. 5a and b. The graph shows that Dy2O3 containing copper ions are more effective in photodegrading of MV than untreated Dy2O3-nanomaterial as the peak intensities are much lower in case of Cu-doped material. To promote the charge separation and avoid electron–hole pair recombination, copper ions have been doped on the surface of Dy2O3, because of their sponge shape surpass in terms of photocatalytic activity. Figure 5 shows the influence of copper concentration on Dy2O3 photocatalytic activity using the photocatalytic reaction rate constant K. The following formula was used to determine the value of rate constant (K):

Figure 6a–c illustrate the dye/catalyst solution absorption intensities as a function of time. Dy2O3, and Cu2+-doped Dy2O3 had photoreduction efficiencies of 62.0, and 94.0%, respectively, and its comparative study with the already reported results are tabulated in Table 1. The most effective photocatalytic material was found to be Cu2+-doped Dy2O3 due to its crystalline nature, good morphology, presence of oxygen vacancies which scavenge the electrons and reduced band gap. The calculated values of specific rate constant (k) for the synthesized samples were 0.01592 and 0.04036 for undoped and doped materials. The value of k for the doped material is higher as compared to the Dy2O3 indicate that the Cu–Dy2O3 is much better photocatalyst for the degradation of MV as compared to dysprosium oxide. The photocatalytic interactions between copper ions and surface-doped Dy2O3 nanoparticles mechanism was described as follows:

There is a difference in reduction potential between Cu2+/Cu+ and Cu+/Cu0. Because their positive reduction potentials are greater than the conduction band edge of Dy2O3, Cu2+ and Cu1+ can behave as electron trappers thermodynamically and to maintain the electroneutrality in the materials the oxygen vacancies are produced which are also responsible for the trapping of electron. In the way the separation of electrons/holes pair would take place. This has also been confirmed from the PL analysis (Fig. 4e) as the intensity of copper-doped dysprosium oxide is much lower with respect to Dy2O3 indicating that the recombination of electron/hole pair is lower which is responsible for the higher photocatalytic activity of the doped catalyst. The higher activity of copper-doped Dy2O3 is due to the separation of charge carriers due to entrapment of electron by the oxygen vacancies.

3.7 Radiation-attenuation study

In this part, the values of MAC for Dy2O3 and Cu–Dy2O3 were obtained via Geant4 simulations and the results are plotted in Fig. 7. It is clear that the values of MAC decrease as the photon energy increases.

For both Dy2O3 and Cu–Dy2O3, the values are very close and there is a peak around 0.6 MeV which reflects the absorption edge of Dy element. The highest value of MAC for both Dy2O3 and Cu–Dy2O3 was observed at the lowest energy region (around 0.015 MeV) with the value of 87.556 cm2/g for Dy2O3 and the value of 85.145 cm2/g for Cu–Dy2O3. Moreover, the simulation outcomes were compared with the theoretical calculations. Table 2 shows the values of MAC of the Dy2O3 and Cu-doped Dy2O3 obtained by Geant4 simulations and theoretical calculations along with their deviation (Dev.%). Obviously, there is a very good agreement between the simulation outcomes and the theoretical calculations.

4 Conclusion

Single phase Cu-doped Dy2O3 photocatalyst was synthesized hydrothermally which was confirmed by XRD and FTIR analyses. The copper-doped surface of the material was more porous and has higher surface area as compared to the dysprosium oxide as confirmed by BET analysis and due to doping of copper the oxygen vacancies was produced which help in trapping of electrons and stop the electrons/holes recombination as confirmed by PL analysis. The doped material showed enhanced degradation efficiency up to 94% than the simple Dy2O3 (62%). The higher photocatalytic activity of the Cu–Dy2O3 is due to nanoflakes like morphology with active pores in the surface, smaller crystallite size which is confirmed by the peak broadening in XRD, smaller band gap, higher surface area, presence of oxygen vacancies and inhibition in electrons/holes recombination. Moreover, the radiation study is achieved by evaluating the values of MAC for Dy2O3 and Cu–Dy2O3 via Geant4 simulations. The highest value of MAC for both Dy2O3 and Cu–Dy2O3 was observed at the lowest energy region (around 0.015 MeV) with the value of 87.556 cm2/g for Dy2O3 and the value of 85.145 cm2/g for Cu–Dy2O3..

Data availability

Data sharing is not applicable to this article as no data sets were generated during the present study.

References

H. Zollinger, Color Chemistry: Syntheses, Properties, and Applications of Organic Dyes and Pigments (Wiley, Hoboken, 2003)

E. Clarke, R. Anliker, Organic Dyes and Pigments, Anthropogenic Compounds (Springer, New York, 1980), pp. 181–215

C.V. Reddy, K.R. Reddy, V.A. Harish, J. Shim, M. Shankar, N.P. Shetti, T.M. Aminabhavi, Metal-organic frameworks (MOFs)-based efficient heterogeneous photocatalysts: synthesis, properties and its applications in photocatalytic hydrogen generation, CO2 reduction and photodegradation of organic dyes. Int. J. Hydrogen Energy 45, 7656–7679 (2020)

R. Rahimian, S. Zarinabadi, A review of studies on the removal of methylene blue dye from industrial wastewater using activated carbon adsorbents made from almond bark. Progr. Chem. Biochem. Res. 3, 251–268 (2020)

W. Handayani, A.I. Kristijanto, A.I.R. Hunga, Are natural dyes eco-friendly? A case study on water usage and wastewater characteristics of batik production by natural dyes application. Sustain Water Resour Manag 4, 1011–1021 (2018)

S. Samsami, M. Mohamadizaniani, M.-H. Sarrafzadeh, E.R. Rene, M. Firoozbahr, Recent advances in the treatment of dye-containing wastewater from textile industries: overview and perspectives. Process Saf. Environ. Prot. 143, 138–163 (2020)

J.W. Park, S.Y. Kim, J.H. Noh, Y.H. Bae, J.W. Lee, S.K. Maeng, A shift from chemical oxygen demand to total organic carbon for stringent industrial wastewater regulations: utilization of organic matter characteristics. J. Environ. Manage. 305, 114412 (2022)

C. Wei, H. Wu, Q. Kong, J. Wei, C. Feng, G. Qiu, C. Wei, F. Li, Residual chemical oxygen demand (COD) fractionation in bio-treated coking wastewater integrating solution property characterization. J. Environ. Manage. 246, 324–333 (2019)

D. Zamel, A.U. Khan, Bacterial immobilization on cellulose acetate based nanofibers for methylene blue removal from wastewater: Mini-review. Inorg. Chem. Commun. 131, 108766 (2021)

Y. Yusbarina, R. Roto, K. Triyana, Hydroxyl functionalized graphene as a superior anode material for electrochemical oxidation of methylene blue. Rasayan J. Chem. 14, 1140–1147 (2021)

R. Al-Tohamy, S.S. Ali, F. Li, K.M. Okasha, Y.A.-G. Mahmoud, T. Elsamahy, H. Jiao, Y. Fu, J. Sun, A critical review on the treatment of dye-containing wastewater: ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 231, 113160 (2022)

N.R.J. Hynes, J.S. Kumar, H. Kamyab, J.A.J. Sujana, O.A. Al-Khashman, Y. Kuslu, A. Ene, B.S. Kumar, Modern enabling techniques and adsorbents based dye removal with sustainability concerns in textile industrial sector-a comprehensive review. J. Clean. Prod. 272, 122636 (2020)

S. Varjani, P. Rakholiya, H.Y. Ng, S. You, J.A. Teixeira, Microbial degradation of dyes: an overview. Biores. Technol. 314, 123728 (2020)

P.S. Kumar, G.J. Joshiba, C.C. Femina, P. Varshini, S. Priyadharshini, M.A. Karthick, R. Jothirani, A critical review on recent developments in the low-cost adsorption of dyes from wastewater. Desalin. Water Treat. 172, 395–416 (2019)

K.P. Gopinath, N.V. Madhav, A. Krishnan, R. Malolan, G. Rangarajan, Present applications of titanium dioxide for the photocatalytic removal of pollutants from water: a review. J. Environ. Manage. 270, 110906 (2020)

G. Hodaifa, P.A.R. Gallardo, C.A. García, M. Kowalska, M. Seyedsalehi, Chemical oxidation methods for treatment of real industrial olive oil mill wastewater. J. Taiwan Inst. Chem. Eng. 97, 247–254 (2019)

D. Ramutshatsha-Makhwedzha, P.N. Nomngongo, Application of ultrafiltration membrane technology for removal of dyes from wastewater. Membr. Based Methods Dye Contain. Wastewater 207, 37–47 (2022)

Y. ShivaShankar, K. Ankur, P. Bhushan, D. Mohan, Utilization of water treatment plant (WTP) sludge for pretreatment of dye wastewater using coagulation/flocculation. Advances in Waste Management (Springer, New York, 2019), pp. 107–121

S. Nazia, S.C. Sekhar, V. Jegatheesan, S.K. Bhargava, S. Sridhar, Performance of chemically resistant polyurea reverse osmosis membrane in the treatment of highly alkaline industrial wastewater containing sodium aluminate. Water Sci. Technol. 82, 2259–2270 (2020)

A.A. Oyekanmi, A. Ahmad, K. Hossain, M. Rafatullah, Statistical optimization for adsorption of Rhodamine B dye from aqueous solutions. J. Mol. Liq. 281, 48–58 (2019)

Y. Wang, Z. Liu, X. Wei, K. Liu, J. Wang, J. Hu, J. Lin, An integrated strategy for achieving oil-in-water separation, removal, and anti-oil/dye/bacteria-fouling. Chem. Eng. J. 413, 127493 (2021)

R. Rashid, I. Shafiq, P. Akhter, M.J. Iqbal, M. Hussain, A state-of-the-art review on wastewater treatment techniques: the effectiveness of adsorption method. Environ. Sci. Pollut. Res. 28, 9050–9066 (2021)

W.S. Chai, J.Y. Cheun, P.S. Kumar, M. Mubashir, Z. Majeed, F. Banat, S.-H. Ho, P.L. Show, A review on conventional and novel materials towards heavy metal adsorption in wastewater treatment application. J. Clean. Prod. 296, 126589 (2021)

P.P.A. Jose, M. Kala, N. Kalarikkal, S. Thomas, Silver-attached reduced graphene oxide nanocomposite as an eco-friendly photocatalyst for organic dye degradation. Res. Chem. Intermed. 44, 5597–5621 (2018)

F. Guo, Z. Chen, X. Huang, L. Cao, X. Cheng, W. Shi, L. Chen, Cu3P nanoparticles decorated hollow tubular carbon nitride as a superior photocatalyst for photodegradation of tetracycline under visible light. Sep. Purif. Technol. 275, 119223 (2021)

A. Akbari, Z. Sabouri, H.A. Hosseini, A. Hashemzadeh, M. Khatami, M. Darroudi, Effect of nickel oxide nanoparticles as a photocatalyst in dyes degradation and evaluation of effective parameters in their removal from aqueous environments. Inorg. Chem. Commun. 115, 107867 (2020)

R. Ghosh, R.P. Sahu, R. Ganguly, I. Zhitomirsky, I.K. Puri, Photocatalytic activity of electrophoretically deposited TiO2 and ZnO nanoparticles on fog harvesting meshes. Ceram. Int. 46, 3777–3785 (2020)

X. Zhu, R. Zhu, L. Pei, H. Liu, L. Xu, J. Wang, W. Feng, Y. Jiao, W. Zhang, Fabrication, characterization, and photocatalytic activity of anatase/rutile/SnO2 nanocomposites. J. Mater. Sci. 30, 21210–21218 (2019)

J. Singh, R. Soni, Controlled synthesis of CuO decorated defect enriched ZnO nanoflakes for improved sunlight-induced photocatalytic degradation of organic pollutants. Appl. Surf. Sci. 521, 146420 (2020)

A.K.L. Sajjad, S. Sajjad, A. Iqbal, ZnO/WO3 nanostructure as an efficient visible light catalyst. Ceram. Int. 44, 9364–9371 (2018)

J. Jiang, K. Zhang, X. Chen, F. Zhao, T. Xie, D. Wang, Compounds, porous Ce-doped ZnO hollow sphere with enhanced photodegradation activity for artificial waste water. J. Alloys Compd. 699, 907–913 (2017)

T. Jiang, J. Kong, Y. Wang, D. Meng, D. Wang, M.J.C.R. Yu, Technology, optical and photocatalytic properties of Mn-doped CuO nanosheets prepared by hydrothermal method. Cryst. Res. Technol. 51, 58–64 (2016)

M. Aadil, S. Zulfiqar, M.F. Warsi, P.O. Agboola, I. Shakir, M. Shahid, N. Al-Khalli, Mesoporous and macroporous Ag-doped Co3O4 nanosheets and their superior photo-catalytic properties under solar light irradiation. Ceram. Int. 47, 9806–9817 (2021)

S.J. Singh, P.J.C. Chinnamuthu, S.A. Physicochemical, E. Aspects, Highly efficient natural-sunlight-driven photodegradation of organic dyes with combustion derived Ce-doped CuO nanoparticles. Colloids Surf. A 625, 126864 (2021)

L.V. Devi, S. Sellaiyan, T. Selvalakshmi, H. Zhang, A. Uedono, K. Sivaji, Synthesis, defect characterization and photocatalytic degradation efficiency of Tb doped CuO nanoparticles. Adv. Powder Technol. 28, 3026–3038 (2017)

D. Laokae, A. Phuruangrat, T. Thongtem, Preparation of Yb-doped ZnO nanoparticles by combustion method combined with high temperature calcination for photodegradation of methylene blue under visible light irradiation. Mater. Res. Innov. 8, 1–13 (2021)

M. Ikram, M. Rashid, A. Haider, S. Naz, J. Haider, A. Raza, M. Ansar, M.K. Uddin, N.M. Ali, S.S. Ahmed, A review of photocatalytic characterization, and environmental cleaning, of metal oxide nanostructured materials. Sustain. Mater. Technol. 30, e00343 (2021)

Z. Shaghaghi, A.R. Amani-Ghadim, M. Seraji, Structural properties and photocatalytic degradation efficiency of CuO and erbium doped CuO nanostructures prepared by thermal decomposition of some Cu-salophen type complexes as precursors. Mater. Chem. Phys. 243, 122635 (2020)

S. Mavengere, S.-C. Jung, J.S. Kim, Visible light photocatalytic activity of NaYF4:(Yb, Er)-CuO/TiO2 composite. Catalysts 8, 521 (2018)

H. Xu, H. Li, G. Sun, J. Xia, C. Wu, Z. Ye, Q. Zhang, Photocatalytic activity of La2O3-modified silver vanadates catalyst for Rhodamine B dye degradation under visible light irradiation. Chem. Eng. J. 160, 33–41 (2010)

S.J. Singh, P. Chinnamuthu, Highly efficient natural-sunlight-driven photodegradation of organic dyes with combustion derived Ce-doped CuO nanoparticles. Colloids Surf. A 625, 126864 (2021)

S. Chahal, S. Singh, A. Kumar, P. Kumar, Oxygen-deficient lanthanum doped cerium oxide nanoparticles for potential applications in spintronics and photocatalysis. Vacuum 177, 109395 (2020)

X. Zhu, L. Pei, R. Zhu, Y. Jiao, R. Tang, W. Feng, Preparation and characterization of Sn/La co-doped TiO2 nanomaterials and their phase transformation and photocatalytic activity. Sci. Rep. 8, 12387 (2018)

S. Chen, D. Jiang, G. Zeng, H. Chi, L. Li, Y. He, F. Ke, J.-D. Xiao, S. Ye, Dysprosium doped CoFe2O4 with enhanced magnetic property and photodegradation activity of methyl orange. Mater. Lett. 284, 128966 (2021)

K. Kumar, V. Samynaathan, S. Kumar, B. Neeraja, Photocatalytic degradation of methylene blue dye using dysprosium oxide/bismuth oxide nanocomposite. J. Environ. Biol. 40, 825–831 (2019)

C.M. Magdalane, K. Kaviyarasu, A. Raja, M. Arularasu, G.T. Mola, A.B. Isaev, N.A. Al-Dhabi, M.V. Arasu, B. Jeyaraj, J. Kennedy, Photocatalytic decomposition effect of erbium doped cerium oxide nanostructures driven by visible light irradiation: investigation of cytotoxicity, antibacterial growth inhibition using catalyst. J. Photochem. Photobiol. B 185, 275–282 (2018)

H.Q. Huynh, K.N. Pham, B.T. Phan, C.K. Tran, H. Lee, V.Q. Dang, Enhancing visible-light-driven water splitting of ZnO nanorods by dual synergistic effects of plasmonic Au nanoparticles and Cu dopants. J. Photochem. Photobiol. A 399, 112639 (2020)

M. Goswami, Enhancement of photocatalytic activity of synthesized cobalt doped Zinc Oxide nanoparticles under visible light irradiation. Opt. Mater. 109, 110400 (2020)

T. Munawar, S. Yasmeen, F. Mukhtar, M.S. Nadeem, K. Mahmood, M.S. Saif, M. Hasan, A. Ali, F. Hussain, F. Iqbal, Zn0.9Ce0.05M0.05O (M= Er, Y, V) nanocrystals: structural and energy bandgap engineering of ZnO for enhancing photocatalytic and antibacterial activity. Ceram. Int. 46, 14369–14383 (2020)

S. Agostinelli, J. Allison, K.A. Amako, J. Apostolakis, H. Araujo, P. Arce, M. Asai, D. Axen, S. Banerjee, G.J. Barrand, F. Behner, GEANT4—a simulation toolkit. Nucl. Instrum. Methods Phys. Res. Sect. A 506, 250–303 (2003)

I. Boukhris, I. Kebaili, M.S. Al-Buriahi, A. Alalawi, A.S. Abouhaswa, B. Tonguc, Photon and electron attenuation parameters of phosphate and borate bioactive glasses by using Geant4 simulations. Ceram. Int. 46, 24435–24442 (2020)

M.S. Al-Buriahi, B.T. Tonguc, Mass attenuation coefficients, effective atomic numbers and electron densities of some contrast agents for computed tomography. Radiat. Phys. Chem. 166, 108507 (2020)

X. Li, S. Ouyang, N. Kikugawa, J. Ye, Novel Ag2ZnGeO4 photocatalyst for dye degradation under visible light irradiation. Appl. Catal. A 334, 51–58 (2008)

W. Xiong, Q. Zhao, X. Li, L. Wang, Multifunctional plasmonic co-doped Fe2O3@ polydopamine-Au for adsorption, photocatalysis, and SERS-based sensing. Part. Part. Syst. Charact. 33, 602–609 (2016)

R.B. Anjaneyulu, B.S. Mohan, G.P. Naidu, R. Muralikrishna, ZrO2/Fe2O3/RGO nanocomposite: good photocatalyst for dyes degradation. Physica E 108, 105–111 (2019)

K. Karthik, A. Raghu, K.R. Reddy, R. Ravishankar, M. Sangeeta, N.P. Shetti, C.V. Reddy, Green synthesis of Cu-doped ZnO nanoparticles and its application for the photocatalytic degradation of hazardous organic pollutants. Chemosphere 287, 132081 (2022)

G.K. Pradhan, K. Parida, Fabrication of iron-cerium mixed oxide: an efficient photocatalyst for dye degradation. Int. J. Eng. Sci. Technol. 2, 1–8 (2010)

M. Baladi, M. Hajizadeh-Oghaz, O. Amiri, M. Valian, M. Salavati-Niasari, Enhanced photocatalytic activity of Sr7Mn7O19.62-Dy2O3 nanocomposite synthesized via a green method. Int. J. Hydrogen Energy 46, 3763–3779 (2021)

Y. Ghaffari, N.K. Gupta, J. Bae, K.S. Kim, One-step fabrication of Fe2O3/Mn2O3 nanocomposite for rapid photodegradation of organic dyes at neutral pH. J. Mol. Liq. 315, 113691 (2020)

S. Chandra, P. Das, S. Bag, R. Bhar, P. Pramanik, Mn2O3 decorated graphene nanosheet: an advanced material for the photocatalytic degradation of organic dyes. Mater. Sci. Eng. B 177, 855–861 (2012)

M. Goudarzi, M. Salavati-Niasari, Controllable synthesis of new Tl2S2O3 nanostructures via hydrothermal process; characterization and investigation photocatalytic activity for degradation of some anionic dyes. J. Mol. Liq. 219, 851–857 (2016)

S. Mortazavi-Derazkola, M. Salavati-Niasari, O. Amiri, A. Abbasi, Fabrication and characterization of Fe3O4@ SiO2@ TiO2@ Ho nanostructures as a novel and highly efficient photocatalyst for degradation of organic pollution. J. Energy Chem. 26, 17–23 (2017)

Acknowledgements

The authors express their gratitude to Princess Nourah bint Abdulrahman University Researchers Supporting Project (Grant No. PNURSP2022R48), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia. Moreover, the authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through Research Groups Program under grant number R.G.P2/171/43.

Author information

Authors and Affiliations

Contributions

SA, SM: Worked in the laboratory i.e. experimental work done and also wrote the manuscript. HMTF, AGA: development or design of methodology; creation of models. JSA, SBA, MSA-B, ZAA: Review writing and editing. NA: Visualization. ZA: Supervision.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alzahrani, J.S., Aman, S., Ahmad, N. et al. Photocatalytic activity and radiation-attenuation ability of copper ions surface-doped dysprosium oxide. J Mater Sci: Mater Electron 33, 15433–15447 (2022). https://doi.org/10.1007/s10854-022-08450-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08450-z